Abstract

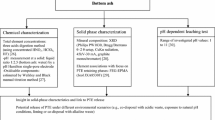

Small-scale Solid Waste Thermal Treatment (SSWTT) is prevalent in remote Chinese locations. However, the ecological threats associated with heavy metals in resultant bottom ash remain undefined. This research study scrutinized such ash from eight differing sites, assessing heavy metal content, chemical form, and leaching toxicity. Most bottom ash samples met soil contamination standards for development land (GB36600-2018). However, levels of As, Cd, Cr, Cu, Ni, Pb, and Zn in some samples exceeded agricultural land standards GB15618-2018) by 1591%, 64,478%, 1880%, 3886%, 963%, 1110%, and 2011% respectively. Additionally, the As and Cd contents surpassed the construction land control limit value by 383% and 13% respectively. The mean values of the combined oxidizable and residual fraction (F3 + F4) for each heavy metal in all samples exceeded 65%, with Cr, Cu, Ni, and Pb reaching over 95%. All sample leaching concentrations, obtained via the HJ/T 299 procedure, were less than limits set by the identification standards for hazardous wastes (GB5085.3–2007). However, only the leaching concentrations of three samples via the leaching procedure HJ/T 300 met the "Solid Waste Landfill Pollution Control Standard" (GB 16889–2008). The results indicate that the location and type of SSWTT equipment play a crucial role in determining an appropriate solution for bottom ash management.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

With China's swift economic growth, domestic waste output has surged in the last two decades. Data from China's Ministry of Health (Li et al., 2018), indicates that per capita waste output in China's villages and towns ranges between 0.5–1.0 kg and 0.4–0.9 kg per person per day, respectively. Based on the sixth census data, China's village and town populations total 266 million, with a permanent rural population of 663 million. Average garbage output across these areas hits 245 million tons per year. The Ministry of Environment's "2020 National Annual Report on the Prevention and Control of Environmental Pollution by Solid Waste in Large and Medium-sized Cities"(Association, 2021), states that domestic waste output from 196 of these cities totaled 236 million tons in 2020. Chinese cities cover 200,000 km2, a mere 5.56% of the nation's territory, yet face significant differences in domestic waste disposal compared to rural areas. National Bureau of Statistics data shows an enormous disparity in population density and waste production between urban and rural areas. In addition, the centralized transfer and treatment of urban domestic waste incurs high transportation and storage costs in villages and towns. This approach is not well-suited to current rural waste treatment conditions (Li, 2009; Li, 2015; Zhao, 2014).

At present, in China's remote villages and towns, small-scale solid waste thermal treatment (SSWTT) equipment is commonly used for on-site domestic waste treatment. This equipment includes incinerators, pyrolysis furnaces, and gasification incinerators, with incinerators being the primary treatment solution in urban areas (Yi et al., 2017). After exhaustive research, Municipal Solid Waste Incineration (MSWI) bottom ash is recognized as general solid waste due to its low risks of heavy metal leaching, environmental pollution, and biological toxicity (Chimenos et al., 1999; Gerven et al., 2007; Hu et al., 2008; Klein et al., 2001; Yao et al., 2010). Despite the disparities in performance between Small-scale Solid Waste Thermal Treatment (SSWTT) equipment and Municipal Solid Waste Incineration (MSWI), as well as the differing physical and chemical properties of domestic waste from Chinese villages and cities, limited studies have explored the bottom ash of domestic waste from these rural towns (WANG et al., 2014; YU et al., 2018; ZHANG et al., 2016). Therefore, this study examines the heavy metal properties of Small-scale Solid Waste Thermal Treatment (SSWTT) bottom ash from Chinese rural domestic waste, focusing on total amount, leaching characteristics, and heavy metal distribution. The ecological risk of bottom ash is also assessed.

Materials and methods

Sampling area

Table 1 presents eight SSWTT bottom ash samples from villages in south China, gathered between 2020–2021. The contributing SSWTT equipment included two incinerator types, a pyrolysis furnace and two gasification incinerators (Fig. 1). Type 1 incinerators utilize manual feeding and natural ventilation; Type 2, grate furnaces, operate continuously for eight hours with a feeding device. Despite its simplistic structure, the processing capacity of the latter, dictated by the furnace body size, typically varies between 2 and 10 tons/day. The two gasification incinerators differ in their first combustion chamber; in Type 1, atmospheric oxygen content variations naturally divide accumulating waste into multiple reaction layers, while in Type 2, waste is physically segregated into different reaction layers per partitions in the first combustion chamber. The first combustion chamber typically operates below 800 °C, while the second chamber reaches around 850–1000 °C, receiving feed once hourly. Pyrolysis furnaces, operating below 750 °C, break down waste into smaller organic molecules over a 24-h batch operation, converting it into gas or liquid fuel.

Bottom ash sample collection and preparation

We adhered to the "Technical Specifications on Sampling and Sample Separation from Industrial Solid Waste" (HJ/T 20–1998) (Administration, 1998). Eight bottom ash samples were collected, sealed, and transported to the lab, where larger materials and metals were removed. Following this, a 1 kg sub-sample was extracted, dried at 105 °C for 24 h, milled for 2 h, and sieved through a 0.5 mm screen.

Chemicals

In this study, analytical grade substances including deionized water (H2O), nitric acid (HNO3), sulfuric acid (H2SO4), hydrochloric acid (HCl), hydrofluoric acid (HF), perchloric acid (HClO4), glacial acetic acid (CH3COOH), hydrogen peroxide (H2O2), hydroxylamine chloride (H3NO.HCl), and ammonium acetate (CH3COONH4) were utilized (Sinopharm Chemical Reagent, China).

Analytical methods

The total heavy metals were extracted using microwave-assisted acid digestion in a HNO3-HCl-HF system, adhering to the standard "Soil and Sediment—Digestion of Total Metal Elements—Microwave Assisted Acid Digestion Method" (HJ/T 832–2017). A 0.25 g air-dried sample was subjected to microwave digestion in a mixture containing 6 ml of HNO3, 3 ml of HCl, and 2 ml of HF. Following the standard protocol, the temperature was incrementally increased until it reached 190 °C and was maintained at this level for 25 min. After digestion, the acid was removed from the solution, which was then diluted to a volume of 25 ml using a 1 mol/L nitric acid solution to obtain the sample for analysis. The digested sample was further diluted to ensure that the maximum concentration of the target elements was below 100 mg/L. Subsequently, the samples were analyzed using inductively coupled plasma optical emission spectrometry (ICP-OES; ICP-720OES, Optima 2100DV, Agilent, USA). (Administration, 2017) The detected heavy metals and their limits were As (1.2 mg/kg), Cd (0.01 mg/kg), Cr (3.6 mg/kg), Cu (2.0 mg/kg), Mn (39 mg/kg), Ni (2.4 mg/kg), Pb (4.1 mg/kg), and Zn (3.7 mg/kg). The leaching tests were performed using two methods according to the Chinese national standard "Solid Waste Toxicity Extraction—Method Sulfuric Acid and Nitric Acid Method" (HJ/T 299) (Administration, 2007b), utilizing a sulfuric and nitric acid extraction method, and HJ/T 300, utilizing an acetic acid buffer solution method (Administration, 2007a).

In leaching tests per Chinese standards HJ/T 299 and HJ/T 300, sulfuric and nitric acids (mass ratio 1:2) with pH 3.20 ± 0.05, and a 30% acetic acid solution with pH 2.64 ± 0.05 were respectively used. The extraction was carried out at a liquid–solid ratios of 10 ml:1 g and 20 ml:1 g respectively.

The contents were agitated at 30 RPM for 18 h, followed by leachate separation through filtration using a 0.7 mm glass fiber filter paper. The leachate was then acidified using nitric acid to achieve a pH lower than 2, and subsequently analyzed via ICP-OES. For HJ/T 299, the detection limits for the respective heavy metals are as follows: As, 0.030 mg/L; Cd, 0.002 mg/L; Cr, 0.003 mg/L; Cu, 0.002 mg/L; Mn, 0.001 mg/L; Ni, 0.006 mg/L; Pb, 0.030 mg/L; Zn, 0.005 mg/L.

For HJ/T 300, the respective heavy metal detection limits are: As, 0.060 mg/L; Cd, 0.002 mg/L; Cr, 0.004 mg/L; Cu, 0.005 mg/L; Mn, 0.001 mg/L; Ni, 0.006 mg/L; Pb, 0.030 mg/L; Zn, 0.005 mg/L.

The fractionation of heavy metals was carried out using a Sequential Extraction Procedure (SEP) method. This widely accepted method was utilized to assess the soluble and bioavailable forms of metals in soil, sediment, and similar matrices.

A modified four-step method from the Community Bureau of Reference (BCR) was utilized for sequential heavy metal extraction. (Du et al., 2020; Ure et al., 1995)This process yielded four distinct heavy metal fractions: acid-soluble (F1), reducible (F2), oxidizable (F3), and residual (F4). Post each step, centrifugation was conducted at 6000 rpm for a duration of 20 min to facilitate separation, followed by filtration of the resulting supernatant via 0.45-μm membranes. The filtered supernatants were subsequently analyzed using ICP-OES.

Ecological index evaluation method

The potential ecological risk index was applied to assess the potential ecological hazard risk of bottom ash. This method is fundamental in examining heavy metal pollution and ecological damage within sedimentology (Huang et al., 2019; LIU et al., 2011; Xu et al., 2008). The potential ecological risk index quantifies the combined impact of individual and multiple heavy metals in a specific environment, revealing the potential damage extent. Wastes with low toxicity levels like bottom ash and sludge residue typically fall under general solid waste. They are generally treated via landfill methods, coming into direct contact with the soil. It is widely accepted that these wastes can be evaluated for potential ecological risks using this approach (Hakanson, 1980; Huang et al., 2011; Latosińska & Czapik, 2020; Wang, 2020; ZHANG et al., 2016).

This study used the potential ecological risk index (Huang et al., 2019) to evaluate all samples, as per Eq. (1).

The potential ecological risk index, or RI, of heavy metals in bottom ash was calculated using the potential ecological hazard coefficient of heavy metal element i (Eri). This was then set against the concentration of heavy metal element i (Ci; in mg kg−1), and the evaluation background value (Cni). The heavy metal concentration limit benchmarks used were from the Chinese agricultural land pollution control standard GB15618-2018 and the Chinese construction land pollution control standard GB36600-2018, replacing natural soil background values. Developed countries often repurpose landfill land, which is challenging to restore to its natural state, for parks and other facilities (Huang & Huang, 2016; Towhata, 2008). Urbanization is also a trend in the development of Chinese villages and towns, which may gradually lead to the existing landfill sites being repurposed for urban construction. Choosing the limit value from the Chinese construction land soil pollution control standard as the assessment background value is advisable for urbanizing Chinese towns and villages. This reduces the ecological risk often escalated by using soil background value in unnatural environments.

Additionally, assessment results using the limit values in the Chinese agricultural land soil pollution control standard are presented due to the close geographical proximity between agricultural land and landfill sites in rural areas. This proximity could lead to either direct or indirect contact with soil contaminated by bottom ash. The toxicity coefficient of type i heavy metals, or Tri, is discussed as reported for 12 heavy metals in literature (Xu et al., 2008). The hazard level table of the Ecological index evaluation method can be viewed in Online Resource 1.

Quality control

Sample collection utilized uncontaminated, sealed High-Density Polyethylene (HDPE) bags or plastic buckets, ensuring no leakage. Digestion, leaching and Sequential Extraction Procedure (SEP) experiments included blank sample sets; none exhibited heavy metal elements above detection limits. All liquid samples from the study were stored in uncontaminated centrifuge tubes and underwent weak acid digestion prior to detection.

In both digestion and leaching experiments, duplicate trials were performed using two parallel samples. Should the data discrepancy between the parallel trials exceed 5%, a third trial would be conducted. Additionally, Microsoft Excel software is employed to calculate the data's error, mean, and standard deviation (SD), ensuring a comprehensive and precise analysis of the results.

Results and discussion

Total metal content of bottom ash

Table 2 compares the heavy metal content in our eight samples to that in 17 MSWI bottom ashes from China (Hu et al., 2008; Yao et al., 2010; Yi et al., 2017; Zhu et al., 2020). The mean values of As, Cd, Cu, Mn, Ni, and Pb exceeded the upper limits of samples reported in literature. Since the majority of our samples were from Yunnan Province, China, we've also included this region's soil background values (Xiao et al., 2021). Upon comparing the eight samples, it was observed that the average content of heavy metals was 7.97–35.58 times the soil background value. The concentrations of the eight heavy metals reduced in the following order: Cu > Zn > Mn > Cr > Pb > Ni > As > Cd, with Cu showing the largest standard deviation.

This indicates considerable variation in heavy metal content across samples, particularly with regards to Cr, Cu, and Zn. Bottom ash from Type 1 incinerator showed high levels of As, Cd, and Cr, while the gasification incinerator's ash contained elevated Mn, Pb, and Zn. Type 2 gasification incinerator ash had high Cu content.

The arsenic levels in most bottom ash samples are comparable to those from municipal solid waste incineration. However, Samples 1 and 5 contain substantially more arsenic. This is because Sample 1 originates from a Type 1 incinerator with natural ventilation and unstable combustion conditions, leading to incomplete combustion. Research on heavy metal migration routes during combustion shows that low-boiling elements like As and Cd, vaporize or oxidize into gaseous forms at high temperatures in both oxidizing or reducing environments. However, they become halides at lower temperatures or bond with oxygen and carbon, becoming fixed in a solid phase (Abanades et al., 2001; Rong et al., 2001). The behavior patterns of As and Cd in Sample 1 suggest that furnace combustion conditions primarily influence them. However, the migration behavior exhibited by Sample 5 does not align well with this interpretation.

The Chromium (Cr) content in most bottom ash samples is less compared to Municipal Solid Waste Incineration (MSWI). Notably, sample 1 contains Cr content 2–7 times higher than other samples. Owing to Cr's high boiling point, its migration remains relatively stable, regardless of furnace temperature (Li et al., 2012). The Chromium (Cr) levels in most bottom ash samples are lower than in Municipal Solid Waste Incineration (MSWI). Notably, Cr content in sample 1 is 2–7 times higher. Since Cr's migration remains stable due to its high boiling point, furnace temperature isn't a factor. Instead, waste materials and environmental impacts are considered. Research indicates that the thermal treatment equipment's location has high soil Cr content. Therefore, the high Cr levels in the bottom ash sample likely stems from the local soil and crops (Lu et al., 2020).

The Manganese (Mn) levels in 50% of bottom ash samples meet or exceed the maximum Mn content of Municipal Solid Waste Incineration (MSWI). Mn readily combines with oxygen and carbon in a reducing atmosphere, becoming fixed in the solid phase at lower temperatures. At higher temperatures, Mn interacts with aluminum, forming aluminosilicate (Rong et al., 2001). Additionally, samples 3, 4, and 5 are derived from gasification incinerators, while samples 6 and 7 originate from Type 2 gasification incinerators. These samples are characterized by a reducing atmosphere in the bottom ash. Sample 3 presents a markedly higher concentration of Mn, a likely outcome of the positioning of the thermal treatment equipment within an Mn-rich zone. In this area, there is considerable pollution from Mn naturally present in the soil and rocks (Luo, 2017).

The Ni content in most bottom ash samples significantly surpasses that in Chinese MSWI. The atmosphere's pH level doesn't noticeably affect Ni volatilization, but an oxidizing atmosphere greatly impacts it. This atmosphere doubles the Ni volatilization rate compared to a reducing one (Wu et al., 2019). The higher Ni content in sample 1 likely results from uneven temperatures due to the incinerator's improper combustion structure and insufficient oxygen from natural ventilation. This finding aligns with the recorded As and Cd migration in sample 1.

The Pb levels in the ash samples are similar to those in MSWI bottom ash, yet vary notably between samples. Zn levels in some samples are marginally higher than in MWI ash. Additionally, Cu levels in half of the samples exceed those in the Chinese MSWI, but remain significantly below the Australian MSWI.

Table 2 lists the heavy metal content limits found in the agricultural and development land soil contamination risk control standards (GB 15618–2018 and GB36600-2018, respectively). Grade A construction land in the latter standard consists of urban residential areas, primary/secondary schools, medical facilities, and public park locations. Grade B land encompasses industrial areas, roads, and public transportation. The heavy metal contents in bottom ash are typically compared to standard limits in soil. In Table 3, the contents of Cr, Cu, and Zn meet the Grade A construction standard. As levels, however, fluctuate widely. Samples 2, 3, 6, and 7 meet the agricultural land limit for As, while samples 4 and 8 meet the Grade A construction limit. However, samples 1 and 5 surpass the Grade B construction limit. For Ni and Pb, some samples satisfy the Grade B limit and others meet the Grade A limit.

The bottom ash from our SSWTT equipment contains high heavy metal levels, with seven target elements surpassing agricultural soil thresholds, and some even breaching Grade B construction land limits. This pollution risk warrants caution when exposing bottom ash to the environment or farmland. Such findings echo prior research on rural domestic waste incineration bottom ash's potential agricultural hazards (ZHANG et al., 2016).

Evaluation of the potential ecological risk of heavy metals

Table 3 presents the ecological risk results. According to RI values, most samples in this study fall in the "extremely strong ecological hazard" class for agricultural land, with Sample 7 in the "high ecological hazard" category. However, based on its ErCd value, Sample 7 ranks in the "strong ecological hazard" class. Notably, Sample 1 poses the most significant ecological risk, with an RI value for agricultural land that is 4.4–49.9 times higher than other samples.

For both types of construction land, most samples' RI values are beneath the light ecological hazard threshold. However, Sample 1 is an exception. Its ErAs value signifies moderate ecological hazard. Its ErCd value indicates high ecological hazards for Grade A construction land and is nearly at the light ecological hazard limit for Grade B construction land. Considering the bottom ash RI values, there is a notable variation between different furnace types. The potential ecological pollution risk associated with bottom ash can be arranged in a descending order as: Type 1 incinerator > pyrolysis furnace > Type 1 gasification incinerator > Type 2 gasification incinerator ≥ Type 2 incinerator. The ecological risks of elements lessen in this order: Cd > Cu > Zn > Cr > Pb > Ni > As, with Cd posing the highest ecological pollution risk.

Chemical forms of heavy metals

The Fig. 2 illustrates the results of the Sequential Extraction Procedure (SEP), which is used to identify the chemical forms of heavy metals. We observe three primary patterns in the chemical forms of the metals studied in our samples.

The majority of Chromium (Cr) and Nickel (Ni) are predominantly found in the residual form in bottom ash, with 86.33% and 82.55% respectively. Given their high boiling points, Cr and Ni accumulate in the bottom ash, with only a minuscule amount transferring to fly ash (Zhao et al., 2009). The oxidation of organic matter in domestic waste at high temperatures produces a residual product with minimal fluidity, thereby presenting an insignificant ecological pollution risk.

Arsenic (As), Copper (Cu), and Lead (Pb) primarily occur in bottom ash as F3 and F4 (F3 + F4[As], with percentages of 83.38%, 96.16%, and 99.63%, respectively. As contains a small acid-soluble fraction (14.16%), while Pb virtually lacks any other fractions. Research on Pb's migration during incineration indicates that low melting point Pb compounds like lead carbonate and lead acetate start to volatilize at a furnace temperature of 600 °C. Similarly, chlorides and oxides begin to volatize at 800 °C (LIU et al., 2014; Wey et al., 1996). Copper (Cu) plays a significant role in organic reactions, often acting as a catalyst, especially in reactions involving organic matter with a high component content, such as Polychlorinated Dibenzo-p-dioxins/Dibenzofurans (PCDD/DF).(Chang & Chung, 1998; Zhao et al., 2009). Two stable forms, bottom ash risks ecological pollution if deposited in landfills because of long-term weathering and rain infiltration (Tay, 1997).

The chemical compositions of Cadmium (Cd), Manganese (Mn), and Zinc (Zn) in the samples are complex and inconsistent. However, a high F1 + F2 proportion of these three elements is found in more than half of the samples. As a result, these samples may exhibit high leaching rates for Cd, Mn and Zn.

Heavy metal leaching characteristics

The HJ/T 299 and HJ/T 300 tests, utilized in this study, effectively evaluated the leaching characteristics of the samples (Table 4). The concentrations of heavy metals leached in all samples, as per the HJ/T 299 test, were significantly below the limits set by the "Identification Standard for Hazardous Wastes" (GB 5085.3–2007). Pb and Cd in sample 4, As and Pb in sample 5, Pb in samples 6 and 7, and Pb and Cd in sample 8, as per the HJ/T 300 test, surpassed the limits of the "Landfill Pollution Control Standard for Domestic Waste" (GB 16889–2008).

The heavy metal concentrations in the HJ/T 300 extraction leaching solution significantly surpass those in the HJ/T 299 extraction for all elements, barring Cr. This is due to the lower pH value of the HJ/T 300 extractant, attributable to the use of acetic acid. This weak acid maintains the acidity of the mixed solution amid the high alkalinity of the bottom ash soaking process. In the HJ/T 300 extraction, high metal concentrations result from the low pH caused by acetic acid. This maintains the solution's acidity during the process, increasing leaching concentrations (Sun & Yi, 2020). However, the leaching concentration of Cr is not significantly increased due to its formation of complexes with organic acid radicals, which lessens the acidity's effect. Thus, the leaching concentrations of both methods are generally the same (SONG et al., 2015; Sun et al., 2019). It's noteworthy that soils in Southern China are predominantly weakly acidic (ZHOU et al., 2015). This suggests a long-term risk of heavy metal migration, especially in landfills, due to the combined effect of rain and soil.

The study revealed inconsistent trends in heavy metal leaching concentrations from bottom ash samples. Furthermore, the sample from the pyrolysis furnace exhibited three instances of heavy metal leaching levels surpassing the GB 16889–2008 standard requirements. In the case of bottom ash samples from gasification incinerators, 2 out of 5 samples had two heavy metal leaching levels exceeding the standard GB 16889–2008, while another 2 out of 5 samples had one heavy metal leaching level that failed to meet the standard. On the other hand, all samples from incinerators complied with the heavy metal leaching requirements set by the standard GB 16889–2008.

Conclusions

The bottom ash from solid waste treatment technology in Chinese villages often contains more heavy metals than municipal solid waste incineration in China and elsewhere. Specifically, arsenic and chromium exceed agricultural soil limits, while nickel and lead surpass construction land limits. Using the potential ecological hazard index for construction land, all sample heavy metal contents indicate a mild ecological hazard. For agricultural soil, however, all samples show a serious ecological hazard due to their heavy metal contents.

The average values of F3 + F4 for single heavy metals surpass 65% in all samples, peaking at 95% for Cr, Cu, Ni, and Pb. These chemical forms are relatively stable with limited migration ability. From the perspective of heavy metal leaching toxicity, all bottom ash samples in this study exhibited leaching levels below the values specified by the "Identification Standard for Hazardous Waste." However, certain elements require pre-treatment before landfilling as some samples exceed landfill limits. Conclusively, the heavy metal content and forms in bottom ash greatly depend on the site and thermal treatment process, resulting in varied leaching concentrations.

References

Administration, S. E. P. (2007b). Solid Waste Toxicity Extraction Method Sulfuric Acid and Nitric Acid Method: HJ/T 299–2007[S]. In. Beijing: China Standard Press.

Abanades, S., Flamant, G., & Gauthier, D. (2001). Modelling of heavy metal vaporisation from a mineral matrix. Journal of Hazardous Materials, 88(1), 75–94.

Administration, S. E. P. (1998). Technical Specifications on Sampling and Sample Preparation from Industry Solid Wsate : HJ/T 20–1998[S]. In. Beijing: China Standard Press.

Administration, S. E. P. (2007a). Solid Waste Toxicity Extraction - Acetic Acid Buffer Solution Method: HJ/T 300–2007[S]. In. Beijing: China Standard Press.

Administration, S. E. P. (2017). Soil and sediment - Digestion of total metal elements - Microwave assisted acid digestion method: HJ/T 832–2017[S]. In. Beijing: China Standard Press.

Association, C. N. R. R. (2021). 2020 annual report on the prevention and control of environmental pollution by solid waste in large and medium cities across the country. China Resources Comprehensive Utilization, 39(1), 1.

Chang, M. B., & Chung, Y. T. (1998). Dioxin contents in fly ashes of MSW incineration in Taiwan. Chemosphere, 36(9), 1959–1968.

Chimenos, J. M., Segarra, M., Fernández, M., & Espiell, F. (1999). Characterization of the bottom ash in municipal solid waste incinerator. Journal of Hazardous Materials, 64(3), 211–222.

Du, M., Liu, H., Hu, D., Huang, J., & Fang, Y. (2020). The leaching mechanism of heavy metals (Ni, Cd, As) in a gasification slag during acidification. Waste Management, 114, 17–24.

Gerven, T. V., Cooreman, H., Imbrechts, K., Hindrix, K., & Vandecasteele, C. (2007). Extraction of heavy metals from municipal solid waste incinerator (MSWI) bottom ash with organic solutions. Journal of Hazardous Materials, 140(1/2), 376–381.

Hakanson, L. (1980). An ecological risk index for aquatic pollution control a sedimentological approach. Water Research, 14(8), 975–1001.

Hu, Y., Chen, G., & Di, M. F. (2008). Physical and chemical characterizations of MSWI bottomash. Acta Energiae Solaris Sinica, 29(10), 1187–1191.

Huang, H., Yuan, X., Zeng, G., Zhu, H., Hui, L., Liu, Z., & Bi, W. (2011). Quantitative evaluation of heavy metals’ pollution hazards in iiquefaction residues of sewage sludge. Bioresource Technology, 102(22), 10346–10351.

Huang, L., & Huang, Y. (2016). Planning remediation and regeneration for landfill sites: European and American case studies based on the perspective of slow-motion technological disasters. Shanghai Urban Planning Review, 1, 32–40.

Huang, J., Peng, S., Mao, X., Li, F., Guo, S., Shi, L., & Zeng, G.-M. (2019). Source apportionment and spatial and quantitative ecological risk assessment of heavy metals in soils from a typical Chinese agricultural county. Process Safety and Environmental Protection, 126, 339–347.

Klein, R., Baumann, T., Kahapka, E., & Niessner, R. (2001). Temperature development in a modern municipal solid waste incineration (MSWI) bottom ash landfill with regard to sustainable waste management. Journal of Hazardous Materials, 83(3), 265–280.

Latosińska, J., & Czapik, P. (2020). The ecological risk assessment and the chemical speciation of heavy metals in ash after the incineration of municipal sewage sludge. Multidisciplinary Digital Publishing Institute, 16, 13. https://doi.org/10.3390/su12166517

Li, L. (2009). Study on the Collect and Transport System of Domestic Waste in Small Towns and Villages. Master, Huazhong University of Science and Technology.

Li, H., Zhao, C., Cai, L., Duan, L., & Chen, H. (2012). Trace elements partitioning during coal combustion in fluidized bed under O2/CO2 atmosphere. Springer Berlin Heidelberg, 355-362. https://doi.org/10.1007/978-3-642-30445-3_50

Li, Z. (2015). Investigation and analysis of comprehensive costs of collection, transportation and treatment of domestic waste in villages and towns. Construction Science and Technology, 10, 125–126.

Li, D., Chen, G.-Y., Ma, W., & Duan, N. (2018). Characteristics and treatment status of rural solid waste in China. China Environmental Science, 38(11), 4187–4197. https://doi.org/10.3969/j.issn.1000-6923.2018.11.026

Liu, J.-Y., Sun, S.-Y., Chen, T., Lu, S.-Y., Wang, Y.-J., Xie, W.-M., & Li, L. (2014). Migration behavior of Pb and its vaporization control during sewage sludge incineration process. China Environmental Science, 02(2), 466–466.

Liu, Y., Yue, L., & Li, J. (2011). Evaluation of heavy metal contamination and its potential ecological risk to the soil in Taiyuan, China. Acta Scientiae Circumstantiae, 31(6), 1285–1293.

Lu, W., Tan, F., Zhang, N., & Qin, T. (2020). Chromium content and health risk assessment of soil-vegetables in high background area of Lijiang City. Humic Acid, 3, 8.

Luo, H. (2017). Study on manganese pollution in typical regions and pollution prevention and control countermeasures——taking Tongren City, Guizhou Province as an example. Intelligent City, 2, 289–291.

Rong, Y., Gauthier, D., & Flamant, G. (2001). Partitioning of trace elements in the flue gas from coal combustion. Combustion & Flame, 125(1–2), 942–954.

Song, L., Mao, L., Yang, B., Zhu, X., & Li, X. (2015). Effect of activated carbon on leaching of chromium in chromium residue. Industrial Safety and Environmental Protection, 000(002), 26–28.

Sun, X., & Yi, Y. (2020). pH evolution during water washing of incineration bottom ash and its effect on removal of heavy metals. Waste Management, 104, 213–219.

Sun, Y., Guan, F., Yang, W., & Wang, F. (2019). Removal of Chromium from a contaminated soil using oxalic acid, citric acid, and hydrochloric acid: Dynamics, mechanisms, and concomitant removal of non-targeted metals. International Journal of Environmental Research and Public Health, 16(15), 2771.

Tay, L. C. T. V. C. J. H. (1997). The influence of pH on mobility of heavy metals from municipal solid waste incinerator fly ash. Environmental Monitoring & Assessment, 44(1), 275–284.

Towhata, I. (2008). Reuse of former landfill for urban space. Japanese Geotechnical Society, 56, 24–26.

Ure, A. M., Davidson, C. M., & Thomas, R. P. (1995). Single and sequential extraction schemes for trace metal speciation in soil and sediment. Techniques and Instrumentation in Analytical Chemistry, 17(06), 505–523.

Wang, J. (2020). Morphological characteristics and ecological risk assessment of heavy metals in municipal sludge. Shanxi Science and Technology, 35(3), 62–65.

Wang, T., Shi, X.-Y., Liu, Z.-G., Li, H.-M., & Li, P. (2014). Analysis on physical characteristics of rural solid waste in Dongjiang river source area, China. Journal of Agricultural Resources and Environment, 031(003), 285–289.

Wey, M. Y., Hwang, J. H., & Chen, J. C. (1996). The behavior of heavy metal Cr, Pb and Cd during waste incineration in fluidized bed under various chlorine additives. Journal of Chemical Engineering of Japan, 29(3), 494–500.

Wu, C., Oh, K., Long, X., & Zhang, J. (2019). Effect of installed capacity size on environmental efficiency across 528 thermal power stations in North China. Environmental Science and Pollution Research, 26(2), 29822–29833.

Xiao, G., Chen, J., Bai, B., Li, Y., & Zhu, N. (2021). Content characteristics and risk assessment of heavy metals in soil of typical high geological background areas. Yunnan Province. Geology and Exploration, 57(5), 1077–1086.

Xu, Z.-Q., Ni, S.-J., Tuo, X.-G., & Zhang, C.-J. (2008). Calculation of heavy metals’ toxicity coefficient in the evaluation of potential ecological risk index. Environmental Science & Technology, 31(2), 112–115.

Yao, J., Li, W. B., Kong, Q. N., Wu, Y. Y., He, R., & Shen, D. S. (2010). Content, mobility and transfer behavior of heavy metals in MSWI bottom ash in Zhejiang Province, China. Fuel, 89(3), 616–622.

Yi, X., He, P., Shao, L., & Hua, Z. (2017). Metal distribution characteristic of MSWI bottom ash in view of metal recovery. Journal of Environmental Sciences, 52(002), 178–189.

Yu, J.-Y., Yue, B., Zhao, D., Li, Z.-L., Wu, X.-H., Huang, Q.-F., & Jin, Q. (2018). Physic-chemical properties and seasonal variation of rural living solid waste in typical agricultural villages and towns in Central China. Environmental Engineering, 36(3), 127–132.

Zhang, G., Wang, D., Yu, Y., Wang, C., & Zhuang, J. (2016). Health risk assessment of heavy metal pollution of agricultural use of municipal solid waste incineration bottom ashes. Ecology and Environmental Sciences, 25(002), 307–313.

Zhao, M. (2014). The Investigation of Rural Life Waste Collection and Transportation Mode Evaluation of WhichiIs Based on Surveys of Hubei Province Waste Disposal. Master, Huazhong University of Science and Technology.

Zhao, L., Zhang, F. S., Wang, K., & Zhu, J. (2009). Chemical properties of heavy metals in typical hospital waste incinerator ashes in China. Waste Management, 29(3), 1114–1121.

Zhou, X.-Y., Xu, M.-G., Zhou, S.-W., & Gilles, C. (2015). Soil acidification characteristics in Southern China’s croplands under long-term fertilization. Journal of Plant Nutrition and Fertilizer, 21(6), 1615–1621.

Zhu, Y., Zhao, Y., Zhao, C., & Gupta, R. (2020). Physicochemical characterization and heavy metals leaching potential of municipal solid waste incinerated bottom ash (MSWI-BA) when utilized in road construction. Environmental Science and Pollution Research, 27(12), 14184–14197.

Acknowledgements

The authors would like to express their gratitude to EditSprings (https://www.editsprings.cn/) for the expert linguistic services provided. The study was financially supported by the National Key R&D Program of China (grant number: 2018YFD1100600).

Funding

National Key Research and Development Program of China, 2018YFD1100600.

Author information

Authors and Affiliations

Contributions

Shutong Wu,Tingting Hu,Yuyan Hu and Dezhen Chen wrote the main manuscript text and Kezhen Qian prepared figures. Dong Xue completed the sample collection.Mudassir Hussain Tahir has completed the language polishing of the article.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wu, S., Hu, T., Chen, D. et al. Ecological risk assessment of heavy metals in bottom ashes generated by small-scale thermal treatment furnaces for domestic waste in villages and towns of China. Environ Geochem Health 45, 8243–8255 (2023). https://doi.org/10.1007/s10653-023-01709-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10653-023-01709-2