Synthesis and characterization of several multicyclic oxadiazoles, 3,5-bis(4-nitrofurazan-3-yl)-1,2,4-oxadiazole, 3,3'-bis(4-nitrofurazan-3-yl)-5,5'-bi(1,2,4-oxadiazole), 3-(4-nitrofurazan-3-yl)-1,2,4-oxadiazol-5-amine, and salts of 1-hydroxytetrazoles, ammonium 5,5'-(1,2,4-oxadiazole-3,5-diyl)bis(1H-tetrazol-1-olate) and hydroxylammonium 5,5'-{[3,3'-bi(1,2,4-oxadiazole)]-5,5'-diyl}bis(1H-tetrazol-1-olate), as energetic materials are reported. Two of the compounds, 3,5-bis(4-nitrofurazan-3-yl)-1,2,4-oxadiazole and 3,3'-bis(4-nitrofurazan-3-yl)-5,5'-bi(1,2,4-oxadiazole), have attractive single crystal densities of 1.91 and 1.94 g·cm–3 (at 20°C), respectively. The design of these materials has been based on the idea that these multicyclic compounds with a 1,2,4-oxadiazole core will have good thermal stability and high density because of their 3,5-substitution pattern and the possibility of achieving a planar conformation. The various synthetic approaches and interesting chemistry observed during the construction of these new heterocycles has been described.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

The design and synthesis of new energetic compounds have been of interest worldwide for many years. New heterocyclic energetic compounds play an important role, mainly because of their positive heat of formation, thermal stability, and increased oxygen balance over the respective carbocyclic analogs.1 , 2 Heterocyclic energetic compounds consisting of 1,2,5-oxadiazole (furazan) rings have received a great deal of attention because of their synthetic accessibility and improved density and thermal stability.2,3,4, – 5 Two notable examples are 3,4-bis(4-nitrofurazan-3-yl)-furazan-2-oxide (BNFF)6–11 and 3,4-bis(4-nitrofurazan-3-yl)furazan (BNFF-1),12,13 energetic compounds with increased thermal stability, low melting points, and satisfactory sensitivity properties. In comparison, there are relatively few examples of energetic materials consisting of 1,2,4-oxadiazoles and 1,3,4-oxadiazoles.2 , 14,15,16, – 17 The attractive properties of BNFF and BNFF-1 encouraged us to investigate the possibility of synthesizing analogs of these molecules in which the central oxadiazole ring is 1,2,4-oxadiazole or 1,3,4-oxadiazole.

Our approach was based on the idea that the inherent 3,5-substitution pattern for a 1,2,4-oxadiazole ring should allow for better crystal packing through the possibility of forming a coplanar arrangement of the rings, and the connectivity of the oxadiazoles via stable C–C bonds should produce materials with enhanced thermal stability. Also, the reported syntheses of a variety of 1-hydroxytetrazoles17,18,19,20,21, – 22 as energetic compounds with attractive properties led us to investigation of 1-hydroxytetrazoles appended to a central 1,2,4-oxadiazole ring system based on similar arguments to those used for the multicyclic oxadiazole ring systems. Herein, we report the synthesis of 3,5-bis(4-nitrofurazan-3-yl)-1,2,4-oxadiazole (LLM-191), 3,3'-bis(4-nitrofurazan-3-yl)-5,5'-bi(1,2,4-oxadiazole) (LLM-200), 3-(4-nitrofurazan-3-yl)-1,2,4-oxadiazol-5-amine (LLM-201), and two 1-hydroxytetrazole salts, ammonium 5,5'-(1,2,4-oxadiazole-3,5-diyl)bis(1H-tetrazol-1-olate) and hydroxylammonium 5,5'-{[3,3'-bi(1,2,4-oxadiazole)]-5,5'-diyl}bis(1H-tetrazol-1-olate), as energetic materials. In addition, a discussion of improvements to the syntheses of several intermediate compounds is presented.

Amino- and nitrofurazan compounds have been widely investigated as potential candidates in pharmaceutical drug discovery23,24, – 25 and energetic material research.25,26,27, – 28 Unlike aromatic hydrocarbons where nitro derivatives can be prepared by direct nitration of parent precursors using standard nitration methodologies, nitrofurazans are mainly prepared by oxidation of amino group-containing precursors. In this study, amidoxime 1, an easily accessible precursor29 bearing amino and amidoxime (C(NH2)=NOH) groups appended to a furazan ring, was chosen as the starting material for the construction of several of the target compounds (Scheme 1). It was envisioned that, when used in synthesis of multiple ring oxadiazole derivatives, the amino group could be oxidized to a nitro group, thus improving overall density and oxygen balance of the respective products.

There are several methods reported for chemoselective transformations of amidoxime 1 in which the amino group does not participate. When compound 1 was treated with NaNO2 in aq HCl, diazotization of the amide group of amidoxime 1, followed by nucleophilic displacement of the N2 + group by chloride anion, produced the corresponding carbohydroximidoyl chloride 2 (Scheme 1).30,31, – 32 Compound 2 is an important intermediate for the preparation of several energetic materials9 , 26 , 33 , 34 such as BNFF, a high-density and high-performance energetic material,6,7,8,9,10, – 11 , 34 and the compounds derived from BNFF,12 through the respective precursor 4,4”-diamino[3,3':4',3”-ter(furazan)] 2'-oxide (3).

Fusing amidoxime 1 with 4-amino-3-furazancarboxamide at 170°C or heating ethyl 4-amino-3-furazancarboxylate in a mixture of KOH and n-BuOH gave 1,2,4-oxadiazolelinked aminofurazan derivatives.35,36,37, – 38 Studies regarding the substitution of the amidoxime hydroxyl group with a halogen, followed by formation of C(NH2)=N–R group, where R is aliphatic or aromatic moiety, have been a part of the efforts toward pharmaceutical drug discovery.18 Chemoselective oxidation of the amidoxime group of compound 1 to a cyano group with mild oxidants, for example, MnO2,39 KMnO4,40 Pb3O4,40 Pb2O3,37 or PbO2,36 , 41 , 42 has also been reported.

As a part of our effort to synthesize large quantities of amidoxime 1, a viable starting material for energetic material research, we herein report on improved synthesis of compound 1, along with the development of new methodologies for preparation of important intermediates such as furoxan 3 and cyanofurazan 5 and exploration of new paths to aminofurazan 7. Several new aminofurazan compounds, 5-amino-3-(4-aminofurazan-3-yl)isoxazole-4-carbonitrile (4), 5-(4-amino-furazan-3-yl)[1, 2, 5]oxadiazolo[3,4-d]pyrimidin-7-amine (6), and 4,4'-{[5,5'-bi(1,2,4-oxadiazole)]-3,3'-diyl}bis(furazan-3-amine) (8), have also been discovered in the course of our studies (Scheme 1). In this paper, we also report the oxidation of 4,4'-(1,2,4-oxadiazole-3,5-diyl)bis(furazan-3-amine) (7) and 4,4'-{[5,5'-bi(1,2,4-oxadiazole)]-3,3'-diyl}bis(furazan-3-amine) (8) to the corresponding nitro compounds using common oxidation procedures.

Preparation improvement of 4-amino-3-furazancarboxamidoxime (1). The synthesis of amidoxime 1, first reported in 1965 by Ichikawa and coworkers,29 involved a series of transformations: 1) malononitrile nitrosation with NaNO2 in aq HCl to give malononitrile oxime 9, 2) reaction of compound 9 with hydroxylamine to afford amidoxime 10, and finally 3) thermal dehydration under basic conditions to give compound 1 (Scheme 2). In recent years, a modification of Ichikawa's methodology has been reported.32 The modification includes use of less HCl to initiate the nitrosation of malononitrile (step 1), employment of an excess of 50% hydroxylamine in H2O as the reagent and base to achieve full conversion of oxime 9 (step 2), and neutralization of the reaction mixture to pH 7 before collecting amidoxime 1 (step 3). We found that, using Ichikawa's procedure,29 the yield and purity of product 1 was significantly affected by the pH of the reaction mixture. To better control the pH, AcOH was employed to initiate the nitrosation of malononitrile and provide a buffer for the reaction mixture. It was found that, as a result of heating to affect the condensation to amidoxime 1 (step 3), the pH of the reaction mixture changed from 7–8 to 11–12 and at this pH the yield would drop to 40–50%, and product 1 would be of lower purity (92% by 1H NMR spectroscopy). By adjusting the acidity of the final reaction mixture to pH 9–10 via addition of AcOH, 80–85% yield of product 1 of sufficient purity (>97% by 1H NMR spectroscopy) for further transformations was obtained.

Reactions of 4-amino- N -hydroxyfurazan-3-carbimidoyl chloride (2). Carbohydroximidoyl chloride 2, easily prepared from amidoxime 1, undergoes dipolar cycloaddition reactions through a nitrile oxide intermediate to yield furoxans, dioxadiazines, 1,2,4-oxadiazole derivatives, and isoxazole derivatives, depending on the reagents and the reaction conditions.22 , 28 , 43,44,45, – 46 For the synthesis of furoxans and dioxadiazines, the choice of reaction conditions to effect the elimination of HCl and produce the intermediate nitrile N-oxide 11, has a great impact on product formation.28 , 45 , 47 The method of choice for the preparation of furoxan 3 is the use of aq Na2CO3 in a biphasic mixture with Et2O to effect the formation of intermediate 11, which subsequently dimerizes in a head-to-head cycloaddition reaction (Scheme 3).43,44, – 45 Exploitation of organic bases such as triethylamine (TEA) in organic solvents yielded dioxadiazine 12 via head-to-tail cycloaddition.28 , 47

In general, if nonpolar solvents, such as Et2O, are used, the major product is furoxan 3 (it is assumed that nitrile oxide 11, once formed, is extracted into the nonpolar Et2O solution) while in more polar media, such as Na2CO3–DMSO,28 K2CO3–H2O–THF,48 and TEA–MeCN,45 dioxadiazine 12 becomes the predominant product. This may be explained by the fact that nitrile oxides can also exist as their resonance hybrids, 1,3-dipolar canonical structures, which may be stabilized by polar solvents (Scheme 3). In another report, AgNO3 49 has been employed to effect conversion of nitrile oxide to the respective furazan 2-oxide, but AgNO3 has not been used for the preparation of furoxan 3.

This led us to investigate the use of silver salts in nonpolar solvents to affect the regioselectivity of cycloaddition. Ag2CO3 was employed as the base in nonpolar solvents, such as THF and Et2O, for the dehydrochlorination because it provides not only the driving force for elimination of HCl by formation of AgCl, but also has some solubility in organic solvents. Thus, when the mixture of carbohydroximidoyl chloride 2 and Ag2CO3 in THF was stirred at room temperature overnight, nearly 100% of starting material 2 was converted to product 3, as determined by NMR spectroscopy, and more importantly, dioxadiazine 12 was not detected. Formation of furoxan 3 was also observed when Ag2CO3 was used under acidic conditions in an excess of trifluoroacetic acid (TFA). In this case, the base that promotes the conversion of starting material even in the presence of TFA is presumably CF3CO2Ag formed in situ. When carbohydroximidoyl chloride 2 was treated with AgNO3 in THF (no base addition) at room temperature, a negligible amount of furoxan 3 was generated, as identified by thin-layer chromatography (TLC) and 1H NMR spectroscopy. These findings suggest that the use of Ag2CO3 may constitute a good general method for regioselective synthesis of furoxan derivatives from the corresponding hydroximidoyl chlorides.

Thermal elimination of HCl from hydroximidoyl chloride to form the respective nitrile oxide that undergoes cycloaddition reactions with various substrates has also been reported.50 When we attempted to synthesize 2-[3-(4-aminofurazan-3-yl)-1,2,4-oxadiazol-5-yl]acetonitrile (13) by heating carbohydroximidoyl chloride 2 with malononitrile in refluxing PhMe for 5–8 h, in a similar manner to that reported,50 we found no evidence for compound 13, but instead isolated a new compound, 5-amino-4-cyanoisoxazole derivative 4. The structure of product 4 was assigned by NMR spectroscopy and LC-MS analysis. This suggests that the reaction proceeds via nucleophilic attack of malononitrile to either nitrile oxide 11 or carbohydroximidoyl chloride 2 to give adduct 14 and salt 15. The malononitrile derivative 14 undergoes cyclization and proton exchange with compound 15 to yield product 16, a stable HCl salt of isoxazole 4, instead of the [3+2] cycloaddition reaction between starting material 2 and one of the cyano groups of malononitrile (Scheme 4).

There is a precedent for nucleophilic attack of malononitrile to hydroximidoyl chloride, more specifically, a solution of ethyl 2-chloro-2-(hydroxyimino)acetate in EtOH is added to a mixture of malononitrile and NaOEt in THF. Under these conditions, the presumptive reaction species is the malononitrile anion.52 In the synthesis described previously, no additional base is exploited, implying that compound 2 and/or product 4 may act as a general base in the formation of the anion of malononitrile (Scheme 4). Compound 16 can be converted to isoxazole 4 by treatment with aq Na2CO3 at room temperature until CO2 evolution ceases. Compound 4, with an appended cyano group, may be a viable precursor to other target oxadiazoles through functional group transformations.

Preparation improvement of 4-aminofurazan-3-carbonitrile (5). It is a well-known fact that nitriles are important starting materials for synthesis of 1,2,4-oxadiazoles via an acid-catalyzed cyclocondensation reaction.2 , 52 , 53 In our effort to synthesize the 1,2,4-oxadiazole-linked compound 7, we have explored a variety of conditions for the reaction of compounds 1 and 5. Nitrile 5 has been prepared by the oxidation of amidoxime 1 using either PbO2 in a mixture with AcOH36 , 41 , 54 or MnO2 .28,29 In our hands, these oxidants provided not only the desired product, but also amide 17 (Scheme 5). It is believed that this side product is formed by the hydrolysis (involving H2O produced during the oxidation process) of either the amidoxime group of starting material 1 or the cyano group of product 5. To reduce the amount of side product 17, lead tetraacetate (Pb(OAc)4) was selected as the oxidant with the proposition that the water generated during oxidation process would competitively react with the Pb(OAc)4 to produce AcOH and PbO2, instead of reacting with the product nitrile 5. Thus, when amidoxime 1 was treated with Pb(OAc)4 in AcOH–MeCN (1:10) (MeCN was used to improve the solubility of Pb(OAc)4 in AcOH) at room temperature, nitrile 5 was obtained in 65–70% yield after recrystallization from H2O (Scheme 5).

Preparation of 4,4'-(1,2,4-oxadiazole-3,5-diyl)bis-(furazan-3-amine) (7) from amidoxime 1 and nitrile 5 in acidic catalytic conditions. 1,2,4-Oxadiazole-linked aminofurazan 7 is the precursor to 3,5-bis(4-nitrofurazan-3-yl)-1,2,4-oxadiazole (LLM-191), a melt-castable energetic material with a melting point of 63°C (DSC peak endotherm, 10°C/min).26 The two reported syntheses of compound 7 involved either fusing amidoxime 1 and amide 17 at 170°C or heating amidoxime 1 and ethyl 4-amino-3-furazancarboxylate in a mixture of KOH and n-BuOH.35 We were interested in investigating new methodologies for preparation of aminofurazan 7 from amidoxime 1 and nitrile 5, thereby increasing both the yield and the ease of large-scale synthesis. ZnCl2-mediated coupling of amidoximes and nitriles to give 1,2,4-oxadiazoles served as a starting point for our studies.52 , 53 , 55 , 56 It was found that oxadiazole 7 could be synthesized in 23–62% yield by reacting compounds 1 and 5 under a variety of conditions using different acid catalysts and solvents (Scheme 6, Table 1).

Bolotin reported that EtOAc is the best solvent for ZnCl2-mediated synthesis of 1,2,4-oxadiazoles because the carbonyl group participates in the formation of the complex of amidoxime, nitrile, and ZnCl2 for successful nucleophilic substitution and ring closing reaction.56 However, when amidoxime 1 was refluxed with nitrile 5 and ZnCl2 in EtOAc in the presence of HCl, oxadiazole 7 was isolated in low yield, while side product 18, presumably formed by the condensation of starting material 1 and EtOAc, was obtained in 34% yield (Table 1, entry 1). Interestingly, it has been reported that compound 18 reacts with AcOH at reflux to produce oxadiazole 20 in high yields. It is, therefore, likely that under our reaction conditions the presence of ZnCl2 inhibits the cyclization reaction, presumably by complexation with amidoxime 1 36 (intermediate 19, Scheme 6). These findings initiated a study of the reaction conditions in which the identity of the solvent and the Brønsted acid cocatalyst were varied. During these attempts, n-BuOAc was tried as the solvent to both increase the reaction temperature and decrease the reactivity of the solvent toward amidoxime 1 in expectation to enhance the chemoselectivity of the condensation. Indeed, the yield of oxadiazole 7 was increased to 39%, while the yield of the side product 18 dropped to less than 10% (Table 1, entry 2).

In our examination of the role of the acid in the reaction, HCl (gas) was replaced with HBr (gas), p-toluenesulfonic acid (TsOH), and H2SO4 under a variety of conditions. When HBr was used, a higher yield of the condensation reaction product 7 was obtained (entry 3). In turn, when a more hindered solvent, i.e., n-propyl isobutyrate, was used, the yield of oxadiazole 7 dropped from 62 to 44% (entry 4). Replacing HBr with TsOH, a known cocatalyst with ZnCl2 for such condensations,53 or with H2SO4 gave similar yields of product 7 (entries 5–7). DMF, a polar aprotic solvent, was also used but provided no better yield of oxadiazole 7 (entry 6).

Preparation of 4,4'-(1,2,4-oxadiazole-3,5-diyl)bis-(furazan-3-amine) (7) from amidoxime 1 and nitrile 5 in basic catalytic conditions. In addition to ZnCl2-mediated coupling reactions, 1,2,4-oxadiazoles may also be prepared by direct heating of amidoximes and nitriles with or without a base catalyst.57 , 58 Individually, compounds 1 and 5 are stable in anisole up to 150°C, however, when a mixture of these compounds was heated at that temperature for 6 h, oxadiazole 7 was found, as well as starting material 1 and a previously unknown compound (30:64:6 based on 1H NMR integration). The 1H NMR chemical shifts of the unknown compound appear at 9.85 (1H, s), 9.68 (1H, s), and 6.83 ppm (2H, s) and in 13C NMR spectrum at 160.1, 159.2, 156.4, 155.7, 144.1, and 136.5 ppm in which chemical shifts of 155.7 and 136.5 ppm are assigned to the 4-aminofurazan unit. Together with LC-MS analysis, the molecular structure was assigned as 5-(4-amino-furazan-3-yl)[1, 2, 5]-oxadiazolo[3,4-d]pyrimidin-7-amine (6), which is a dimer of compound 5 (Scheme 7).

Interestingly, the chemical shift of two protons of the amino group on the pyrimidine ring of product 6 are nonequivalent on the NMR time scale with 1H NMR chemical shifts at 9.85 and 9.68 ppm, suggesting restricted free rotation due to significant delocalization of the lone pair of electrons on the amino group into the pyrimidine ring system. A similar NMR pattern has been reported for [1, 2, 5]oxadiazolo[3,4-d]pyrimidin-7-amine.59

In an effort to better understand this condensation reaction, nitrile 5 was heated under the same reaction conditions in the absence of amidoxime 1, but no dimer 6 was detected. However, in the presence of pyridine, dimer 6 was produced in 5% yield. Interestingly, when pyridine was used in the reaction of compounds 1 and 5, dimer 6 was isolated in 50% yield, along with oxadiazole 7 in 44% yield. However, when 2,4,6-trimethylpyridine (2,4,6-collidine, a stronger but less nucleophilic base because of the steric hindrance provided by the methyl groups) was used to replace pyridine under the same conditions, compound 6 was found in trace quantities with the major product being oxadiazole 7 in 76% yield.

Preparation of 4,4'-(1,2,4-oxadiazole-3,5-diyl)bis-(furazan-3-amine) (7) from amidoxime 1 by oxidation with metal oxides. The possibility of direct one-pot conversion of amidoxime 1 to oxadiazole 7 was considered as an interesting opportunity. We have discussed that compound 7 could be prepared in the coupling reaction of amidoxime 1 and nitrile 5 with or without acidic catalysts at elevated temperature, and that nitrile 5 could be prepared from amidoxime 1 by oxidation with PbO2 or MnO2 at room temperature or slightly above. This suggests that treatment of compound 1 with oxidants at high temperatures would ensure that the in situ formed nitrile 5 may undergo coupling with amidoxime 1 to give oxadiazole 7. Indeed, when PbO2 was added slowly to the mixture of starting material 1 and 2,4,6-collidine in anisole at 150°C, oxadiazole 7 was formed in 52% yield. Amide 17 was obtained in 22% yield (estimated by 1H NMR spectroscopy) (Scheme 7). When MnO2 was used as the oxidant, the yield of product 7 dropped to 41%, while that of amide 17 increased significantly to 48%.

Preparation of 4,4'-(1,2,4-oxadiazole-3,5-diyl)bis-(furazan-3-amine) (7) from amidoxime 1 via pyrolysis. Pyrolysis of amidoxime 1 to directly prepare oxadiazole 7 was also considered as an interesting route of exploration. According to thermal analysis, compound 1 melts at 190–191°C with thermal decomposition above 217°C, as shown by DSC.33 Thus, heating amidoxime 1 at 200°C under argon atmosphere and holding the molten mixture for a given period of time, followed by cooling to room temperature, yielded a brown cake-like solid. After trituration of the solid with hot DMF, product 7 was isolated in 25% yield (Scheme 7, Table 2, entry 1).

It should be pointed out that, under the reaction conditions (Table 2, entry 1), the starting material was not consumed completely. When the reaction was carried out in 1,3-dimethoxybenzene (1,3-DMB) for 8 h, NMR spectral analysis showed that only 10% of starting material 1 was converted to the product (entry 2). Interestingly, when the condensation was carried out in the presence of 2,4,6-collidine, the yield of oxadiazole 7 increased significantly (entry 3). Reduction of the reaction temperature to 190°C also resulted in the formation of product 7 in similar yield, but a longer reaction time was needed (entry 4). Acidic catalysis was also examined, but it was found that p-toluenesulfonic acid monohydrate (TsOH) (entry 5) promoted rapid decomposition of amidoxime 1. The mechanism of the pyrolytic preparation of oxadiazole 7 from amidoxime 1 is still unknown and requires further investigation.

Preparation of 4,4'-(1,2,4-oxadiazole-3,5-diyl)bis-(3-nitrofurazan) (LLM-191).26 Oxidation of oxadiazole 7 to compound LLM-191 was achieved by treating 4,4'-(1,2,4-oxadiazole-3,5-diyl)bis(furazan-3-amine) (7) with 70% aq H2O2 in trifluoroacetic acid (TFA) at 20°C (Scheme 8).9 , 26

The oxidation requires 20–24 h to complete at 20°C due to the poor solubility of starting material 7 in TFA. The oxidation was judged to be complete when the reaction mixture cleared to a slightly yellow solution. The product was isolated by pouring the reaction mixture into ice water and extracting with CH2Cl2. LLM-191 was purified by a short silica gel column (eluent CH2Cl2–pentane, 3:2) followed by recrystallization from a CHCl3–pentane mixture to give product in 60–70% yield. Energetic material LLM-191 has an attractive density of 1.910 g/cm3 (at 20°C) and enthalpy of formation of 687 kJ/mol (from combustion calorimetry data). It is also stable in the melt phase with a melting point of 63°C and a DSC peak exotherm of 261°C (DSC 10°C/min) (Table 3). The single crystal X-ray structure determination revealed that the molecule of LLM-191 has an essentially planar structure (Fig. 1).

Preparation of 4,4'-{[5,5'-bi(1,2,4-oxadiazole)]-3,3'-diyl}bis(furazan-3-amine) (DATO) (8) and 3,3'-bis-(4-nitrofurazan-3-yl)-5,5'-bi(1,2,4-oxadiazole) (LLM-200). Several methods have been reported in the literature regarding the synthesis of 1,2,4-oxadiazoles by condensation of amidoximes and esters under basic conditions, including KOH in n-BuOH,35 K2CO3 in PhMe–DMF,60 TEA in PhMe,61 and NaH in THF.62 Based on these reports, the condensation of amidoxime 1 and diethyl oxalate in PhMe–anisole at 150°C in the presence of the hindered base 2,4,6-collidine was chosen as the reaction conditions to prepare 4,4'-{[5,5'-bi(1,2,4-oxadiazole)]-3,3'-diyl}bis(furazan-3-amine) (8). A Dean–Stark apparatus was used to collect the produced H2O and EtOH as completely as possible. A side product, ethyl 3-(4-aminofurazan-3-yl)-1,2,4-oxadiazole-5-carboxylate (21), resulting from the condensation of only one equivalent of amidoxime 1 with diethyl oxalate was also observed (Scheme 9). To optimize the yield of compound 8, diethyl oxalate solution in PhMe–anisole was added slowly over a 3.5 h to the starting material 1 at 150°C, to continuously supply diethyl oxalate to the reaction mixture as it distills at this temperature. Compound 8 precipitated from the reaction mixture as an extremely insoluble solid that could be easily isolated, but proved difficult to characterize because of its insolubility. In hot DMSO-d 6, it was barely soluble enough for 1H NMR analysis. However, in DMF-d 7 there was enough solubility of product 8 for 13C NMR spectroscopy. Compound 8 shows only one signal at 6.60 ppm in the 1H NMR spectrum and four carbon signals at 165.1, 161.9, 157.1, and 137.6 ppm in 13C NMR spectrum.

Because of the insolubility of compound 8, initial attempts at oxidation with our standard conditions using TFA and 70% aq H2O2 were unsuccessful, resulting in a complex mixture of LLM-200 and partially oxidized products. Therefore, it was necessary to use a mixture of TFA, 90% aq H2O2, and MeNO2 at 50°C to affect the oxidation and produce LLM-200 in 73% yield (Scheme 9). Compound 8 has enough solubility in hot TFA–MeNO2 to allow the oxidation to proceed to completion. Starting material 8 slowly dissolves, and the reaction is essentially complete when a clear solution is obtained. Energetic material LLM-200 is isolated by pouring the cooled reaction mixture into a cold EtOH–H2O solution and collecting the precipitate. The addition of EtOH ensures that the quench solution and reaction mixture are completely miscible.

Usually, the product is pure enough for general applications, but it can be recrystallized from EtOAc–EtOH to give colorless plates. LLM-200 has the highest density of all the described oxadiazoles, 1.940 g/cm3 (at 20°C), and the X-ray structural analysis shows that it has an essentially planar structure (Fig. 2). Energetic material LLM-200 has a melting point of 180–182°C, a DSC peak exotherm of 295°C (DSC, 10°C/min) (Table 3), and an enthalpy of formation of 891 kJ/mol (from combustion calorimetry data).

Synthesis of 3-(4-nitrofurazan-3-yl)-1,2,4-oxadiazol-5-amine (LLM-201). During these studies on 1,2,4-oxadiazoles, there was also interest in synthesis of 5-nitro-1,2,4-oxadiazole derivatives to complement the range of 4-nitrofurazans. There are only two reports of 5-nitro- or 3-nitro-1,2,4-oxadiazoles to our knowledge and in both reports they were synthesized by the decomposition or rearrangement of a precursor molecule and not by direct oxidation of 3-amino- or 5-amino-1,2,4-oxadiazole.6 , 63 In our hands, all attempts at the oxidation of the 1,2,4-oxadiazole amino group either resulted in no reaction or decomposition of the oxadiazole ring. With this in mind, we investigated selective oxidation of 3-(4-aminofurazan-3-yl)-1,2,4-oxadiazol-5-amine (22), a precursor molecule with an amino group attached to both 1,2,4-oxadiazole and furazan, first reported by Shaposhnikov and coworkers.35 The oxidation of compound 22 with 70% aq H2O2 in TFA gave 3-(4-nitrofurazan-3-yl)-1,2,4-oxadiazol-5-amine (LLM-201) in 50% yield (Fig. 3, Scheme 10). As anticipated, the compound in which the amino group appended to the 1,2,4-oxadiazole ring has also been oxidized to a nitro group was not detected. LLM-201 is an insensitive energetic compound with a melting point of 97°C (DSC peak endotherm, 10°C/min) and is stable in the melt. It has a DSC peak decomposition temperature of 289°C (10°C/min) (Table 3), a crystal density of 1.736 g/cm3 (at 20°C), and an enthalpy of formation kof 190 kJ/mol (from combustion calorimetry data).

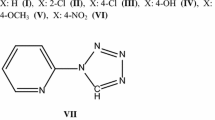

Synthesis of hydroxylammonium 5,5'-{[3,3'-bi(1,2,4-oxadiazole)]-5,5'-diyl}bis(1 H -tetrazol-1-olate) (30) and ammonium 5,5'-(1,2,4-oxadiazole-3,5-diyl)bis(1 H -tetrazol-1-olate) (40). Synthesis of hydroxylammonium salt 30 (Scheme 11) commenced with a common starting material, diaminoglyoxime (DAG), which was synthesized according to the previously published procedure by Trudell and coworkers.64 Formation of 3,3'-bi(1,2,4-oxadiazole) 23 was ensured by a one-pot procedure via the reaction of DAG and ethyl chlorooxoacetate in pyridine–CHCl3 at 0°C, followed by heating to reflux to induce cyclization. Ethyl chlorooxoacetate could also be introduced at reflux without a significant difference in yield. Upon scaling up this reaction, it was noticed that the yields typically decreased with increase in scale. Also, recrystallization of compound 23 enabled obtaining the final materials 29 and 30 with higher purity due to the moisture sensitivity, insolubility, and/or amorphous nature of the intermediate compounds. Exclusion of impurities at an early stage provided purer intermediates without the need for purification between steps.

In order to access the desired 1-hydroxytetrazole moiety, a linear and multistep approach through amide 24 was necessary.17 , 65 First, diester 23 was treated with NH3 in MeOH to provide diamide 24, which was dehydrated with trifluoroacetic anhydride (TFAA) – pyridine in 1,4-dioxane to give dicarbonitrile 25. Addition of aqueous hydroxylamine to compound 25 in i-PrOH provided diamidoxime 26, which was converted to dichloroxime 27 through diazonium salt formation in HCl.

Compound 27 was typically used right away or stored cold with desiccant prior to conversion to diazidoxime 28 using NaN3 in DMF. Compound 28 was isolated via precipitation and was dried to an amorphous powder by means of suction filtration. Attempts to further purify or dry the material were not made due to the typical sensitivities of azides. Small-scale safety testing was conducted (Table 3) on compound 28 to determine its sensitivity relative to a conventional high explosive HMX, and product 28 was found to be safe to handle under controlled conditions. Compound 28 was also used immediately, as it appeared to decompose over time upon ambient storage. This material was cyclized using saturated HCl solution in 1,4-dioxane in a closed pressure vessel at 40°C to give 1-hydroxytetrazole 29. Due to the low solubility of diazidoxime 28 in the reaction medium, the reaction was typically heterogeneous throughout. However, on occasion, the starting azide 28 slowly went entirely into solution product 29 reprecipitated as a fine white powder. This phenomenon may be explained by the presence of water in varied amounts from batch to batch due to the loosely controlled degree of drying of the diazide precursor 28. It was also observed that compound 29, isolated as a pure compound, readily absorbs two equivalents of H2O, as seen by the shifts in 1H NMR spectra of the isolated material and stored samples. Differential scanning calorimetry–thermogravimetric analysis (DSC-TGA) was used to determine the number of H2O molecules per molecule of product 29 (Fig. 4).

Hydroxylammonium salt 30 (Fig. 5) was formed by treating compound 29 with aqueous hydroxylamine and slowly recrystallizing the product from a heated solution in EtOH–H2O. Both the free diol 29 and hydroxylammonium salt 30 were off-scale with regard to friction and drop hammer and did not appear to be sensitive to electrostatic discharge (spark, Table 3).

In addition to the 3,3'-bi(1,2,4-oxadiazole) scaffold, the single 1,2,4-oxadiazole cycle was also investigated as an energetic bridge for 1-hydroxytetrazole in compounds 39 and 40 (Scheme 12). Like in the case of compounds 29 and 30, the linear synthesis of compounds 39 and 40 is quite long to exclusively install the 1-hydroxytetrazole moiety. Oxidation of tetrazole derivatives typically leads to a mixture of N-hydroxy isomers.17 Commercially available ethyl cyanoformate (31) was reacted with hydroxylamine according to a patent procedure66 to provide ethyl 2-amino-2-(hydroxyimino)acetate (32), which was then treated with ethyl chlorooxoacetate and thermally cyclized to diethyl 1,2,4-oxadiazole-3,5-dicarboxylate (33) in a one-pot sequence. Formation of diamide 34 was conducted readily using NH3 solution in MeOH.

The bottleneck of the synthetic scheme toward compounds 39 and 40 is the dehydration of diamide 34. Although the isolated dicarbonitrile 35 was obtained in satisfactory yield (70%), the scale of the reaction was limited due to the inability to efficiently mix the solid reactants – P2O5 and diamide 34. Conversion of dicarbonitrile 35 to diamidoxime 36 was conducted under anhydrous conditions, as the starting material 35 readily reverts to diamide 34 in the presence of moisture. Diazotization in the presence of HCl gave compound 37, which was used immediately in reaction with NaN3 in DMF to provide diazidoxime 38. The impact sensitivity of product 38 is still less than that of pentaerythritol tetranitrate (PETN) (control Dh50 14 cm), however, it is significantly more sensitive than compound 28 (Table 3).

Cyclization of diazidoxime 38 to 1-hydroxytetrazole 39 was conducted in the same manner as in the synthesis of compound 29. Preparation of ammonium salt 40 provided what initially appeared to be a pure product by DSC with a single exotherm peak at 270°C. However, upon storage, compound 40 tends to absorb an equivalent of H2O, as seen in the X-ray crystal structure (Fig. 6).

In conclusion, as a part of an ongoing program in the synthesis and characterization of multicyclic heterocycles as energetic compounds, the synthesis of several new compounds comprising 1,2,4-oxadiazoles bonded to other heterocycles through a stable C–C bond has been described. The various synthetic approaches and interesting chemical transformations have been discussed in detail, and new approaches to the synthesis of precursor compounds have been presented. The attractive high thermal stability and high density of the presented compounds supports further efforts in this area.

Experimental

IR spectra were collected using either Thermo Nicolet IR100 or Bruker Alpha ZnSe ATR FTIR instruments. 1H and 13C NMR spectra were acquired on either a Bruker Avance III 600 MHz spectrometer (600 and 150 MHz, respectively) with processing by Topspin 3.5 software package or an Anasazi Instruments Eft-90 MHz spectrometer with Varian magnet (90 and 22.5 MHz, respectively). 1H and 13C NMR chemical shifts were reported relative to the residual solvent protons as internal standard.67 Mass spectra (ESI) were recorded on an Agilent 6550 iFunnel Q-TOF LC/MS (high-resolution) and a Dionex UltiMate 3000/MSQ Plus instruments equipped with Zorbax Eclipse Plus C18 columns. Melting points were determined on Sigma-Aldrich Mel-Temp or SRS OptiMelt MPA100 melting point apparatus or by DSC at 10°C/min. Combustion calorimetry was performed using a Parr 6300 automatic isoperibol calorimeter. DSC was performed on a TA Instruments Q2000 DSC.

All reagents and solvents were purchased from commercial suppliers and used without further purification. Anhydrous solvents and inert gases were used as necessary and noted in procedures. Diaminoglyoxime (DAG)64 and ethyl (Z)-2-amino-2-(hydroxyimino)acetate (32)66 were synthesized according to published procedures.

Impact sensitivity test. An Explosives Research Laboratory type 12 drop-weight apparatus (Drop Hammer) was used to determine the impact sensitivity relative to the primary calibration materials pentaerythritol tetranitrate (PETN), hexogen (RDX), and Comp B-3. The apparatus was equipped with a Type 12A tool and a 2.5 kg weight. 35 ± 2 mg powder sample was impacted on a carborundum “fine” (120-grit) flint paper. A sample population of 15 was generally used. The mean height for “go” events, called the 50% impact height or Dh50, was determined using the Bruceton up-down method.

Friction sensitivity was evaluated using a BAM high-friction sensitivity tester. The tester employs a fixed porcelain pin and a moveable porcelain plate that executes a reciprocating motion. Weight affixed to a torsion arm allows for a variation in applied force between 0.5 and 36 kg.

Caution! Some of the compounds described in this paper are explosives and may be sensitive to friction, shock, heat, and spark. They should be handled with caution by qualified personnel only.

4-Amino- N'-hydroxy-1,2,5-oxadiazole-3-carboximidamide (1). H2O (960 ml), AcOH (515 ml, 540 g, 9.00 mol), and malononitrile (600 g, 9.09 mol) were placed into a 12-l, three-neck, round-bottom flask equipped with a mechanical stirrer, thermometer, and liquid addition funnel. While vigorously stirring, the reaction mixture was cooled to <10°C with an ice water bath, and a solution of NaNO2 (660 g, 9.57 mol) in H2O (1 l) was added dropwise at <10°C. After complete addition, the clear reddish solution was stirred at this temperature for 1 h and then allowed to warm to room temperature overnight.

The reaction mixture was cooled to <10°C with an ice water bath, and a solution of NaOH (360 g, 9.00 mol) in H2O (2.4 l) was added dropwise over ~2.5 h to neutralize AcOH, controlling the rate of addition to maintain the reaction temperature at <15°C. At <15°C, aqueous hydroxylamine (50 wt %, 1.32 kg, 19.4 mol) was added dropwise with vigorous stirring over a 2.5 h period. After two thirds of hydroxylamine was added, a precipitate formed. The ice water bath was replaced with a water bath, and the mixture was stirred at room temperature for 1 h. The addition funnel was replaced with a reflux condenser. With stirring, the reaction mixture was heated slowly to 50°C. Initially, the solution had a pH ~9 that increased to pH ~11 upon heating. The reaction mixture was slowly brought to reflux and heated at this temperature for 1.5 h. During heating, the pH should be monitored regularly (every 5 min) and adjusted to pH 9–10 with AcOH (total volume ~50 ml). The reaction mixture was allowed to cool down to room temperature overnight. The resulting precipitate was filtered off, washed with H2O (3×1 l), and dried by suction for 24 h to give product 1. Yield 1.08 kg (84%), pale-yellow solid, mp 190–192°C (mp 190–191°C (H2O)29). 1H NMR spectrum (90 MHz, DMSO-d 6), δ, ppm: 10.46 (1H, s, OH); 6.26 (2H, s, furazan NH2); 6.17 (2H, s, NH2). 13C NMR spectrum (22.5 MHz, DMSO-d 6), δ, ppm: 154.7; 144.4; 140.3.

4-Amino- N -hydroxy-1,2,5-oxadiazole-3-carbimidoyl chloride (2). A 12-l, three-neck, round-bottom flask equipped with a mechanical stirrer, thermometer, and solid addition funnel was charged with H2O (3.0 l), and aq HCl (37%, 2.1 l) was added in one portion while stirring. When the temperature dropped to <25°C, compound 1 (600 g, 4.20 mol) was added in one portion. Stirring was continued until a clear solution formed. The reaction mixture was cooled to 0–5°C, and NaNO2 (288 g, 4.17 mol) was added via solid addition funnel at a rate that kept the reaction temperature <10°C. After complete addition, the reaction mixture was stirred at this temperature for 1.5 h. The precipitate was filtered off, washed with cold H2O (2×2 l), and dried by suction overnight to give product 2. Yield 540 g (79%), pale-yellow solid, mp 200–201°C (mp 200–201°C32). 1H NMR spectrum (90 MHz, DMSO-d 6 ), δ, ppm: 13.26 (1H, s, OH); 6.03 (2H, s, NH2). 13C NMR spectrum (22.5 MHz, DMSO-d 6), δ, ppm: 154.2; 144.1; 127.0.

4,4”-Diamino[3,3':4',3”-ter(1,2,5-oxadiazole)] 2'-oxide (3). A 5-l round-bottom flask equipped with a magnetic stir bar and drying tube was charged with THF (2.9 l). With stirring, 4-amino-N-hydroxy-1,2,5-oxadiazole-3-carbimidoyl chloride (2) (520 g, 3.20 mol) was added in one portion. The stirring was continued until a solution was formed. The reaction mixture was cooled with a water bath (~19°C), and Ag2CO3 (450 g, 1.63 mol) was added in one portion. The reaction mixture was stirred overnight. To remove the by-product AgCl and other solids, the reaction mixture was filtered by suction through a layer of Celite® yielding a clear yellow solution. The filtrate was concentrated, and the residue was heated in i-PrOH (600 ml) to reflux. After cooling to room temperature with stirring, the precipitate was filtered off, washed with a minimal amount of i-PrOH, and dried under suction to give product 3. The mother liquor can be concentrated under reflux to 200–250 ml and cooled to yield additional product 3. Yield 343 g (85%), pale-yellow solid, mp 164–167°C (mp 167–168°C45). 1H NMR spectrum (90 MHz, DMSO-d 6), δ, ppm: 6.62 (2H, s, NH2); 6.58 (2H, s, NH2). 13C NMR spectrum (22.5 MHz, DMSO-d 6), δ, ppm: 156.2; 155.3; 146.7; 136.4; 133.5; 104.4.

5-Amino-3-(4-amino-1,2,5-oxadiazol-3-yl)isoxazole-4-carbonitrile (4). A 100-ml, three-neck, round-bottom flask equipped with a thermometer, magnetic stir bar, and solid addition funnel was charged with malononitrile (4.2 g, 64 mmol) and PhMe (40 ml). The mixture was heated to 110°C in an oil bath, and carbohydroximidoyl chloride 2 (8.0 g, 49 mmol) was added slowly over 15 min period via the solid addition funnel. After complete addition, the reaction mixture was heated at 110°C for 1.5 h and then cooled to room temperature. Pentane (50 ml) was added with stirring, and the precipitate was filtered off, washed with pentane (25 ml), and dried under suction to give hydrochloride salt 16. The obtained salt 16 (11.5 g, 50.3 mmol) was stirred with 10% aq Na2CO3 (30 ml) at room temperature for 30 min or until CO2 evolution ceased. The precipitate was filtered off, washed with H2O (30 ml), and dried under suction to give product 4. Yield 6.4 g (68%), yellow solid, mp 260–262°C (decomp.). 1H NMR spectrum (90 MHz, DMSO-d 6), δ, ppm: 8.90 (2H, s, NH2); 6.35 (2H, s, NH2). 13C NMR spectrum (22.5 MHz, DMSO-d 6), δ, ppm: 173.4; 155.0; 151.7; 137.4; 112.0; 63.7. Mass spectrum (–75 eV), m/z (I rel, %): 191 [M–H]– (100).

4-Amino-1,2,5-oxadiazole-3-carbonitrile (5). A 2-l, three-neck, round-bottom flask equipped with a mechanical stirrer, thermometer, and solid addition funnel was charged with compound 1 (121 g, 0.85 mol), anhydrous MeCN (600 ml), and AcOH (60 ml). The mixture was cooled in a water bath (10–15°C), and Pb(OAc)4 (500 g, 1.13 mol) was added in small portions at 15–25°C. After complete addition, the reaction mixture was stirred in the cooling bath and allowed to warm to room temperature over 3 h. The precipitate was removed by filtration through a layer of Celite®, and the filtrate was concentrated in vacuo to ~100 ml. The oily residue was poured onto ice (500 g), and the dark-brown mixture was treated with saturated aq Na2SO3 (~200 ml) until the color of solution changed to yellow (with formation of a significant amount of precipitate). The product was extracted with EtOAc (3×300 ml), the organic phase was washed with brine (400 ml), 10% aq Na2CO3 (2×300 ml), and brine (400 ml) and dried over anhydrous MgSO4. After removing the solvent, the crude material was recrystallized from H2O (120 ml) to give product 5. Yield 68 g (72%), colorless crystalline solid, mp 85–87°C (H2O) (mp 85–87°C39). 1H NMR spectrum (90 MHz, DMSO-d 6), δ, ppm: 7.10 (2H, s, NH2). 13C NMR spectrum (22.5 MHz, DMSO-d 6), δ, ppm: 158.3; 127.8; 109.8.

ZnCl 2 -mediated reaction of amidoxime 1 with nitrile 5 (General method for experiments listed in Table 1). Appropriate amounts of compounds 1 and 5 were suspended in the chosen solvent. With vigorous stirring, ZnCl2 was added in one portion at room temperature. HCl (gas) or HBr (gas) was introduced as a stream at <30°C, or TsOH·H2O was added. When all the solids were dissolved, the reaction mixture was heated as described below. The reaction mixture was cooled to room temperature, and the solvent was removed in vacuo. The residue was treated with H2O at room temperature, the precipitate was filtered off, washed with H2O, and dried under suction. The crude material was subjected to column chromatography (silica gel, EtOAc–CH2Cl2, 1:5).

Table 1, entry 1. Amidoxime 1 (1.25 g, 8.75 mmol), nitrile 5 (1.10 g, 10.0 mmol), ZnCl2 (7.60 g, 55.7 mmol), EtOAc (10 ml), and HCl (gas), reflux for 10 h gave compounds 7 and 18.

4,4'-(1,2,4-Oxadiazole-3,5-diyl)bis(1,2,5-oxadiazol-3-amine) (7). Yield 0.46 g (23%), white solid, mp 224–226°C (mp 238°C64). 1H NMR spectrum (90 MHz, DMSO-d 6), δ, ppm: 6.86 (2H, s, NH2); 6.68 (2H, s, NH2). 13C NMR spectrum (22.5 MHz, DMSO-d 6), δ, ppm: 166.8; 159.6; 155.9; 155.7; 136.6; 135.4.

N -[(4-Amino-1,2,5-oxadiazol-3-yl)(hydroxyimino)-methyl]acetamide (18). Yield 0.56 g (34%), pale-yellow solid, mp 253°C (decomp.). 1H NMR spectrum (90 MHz, DMSO-d 6), δ, ppm: 10.71 (1H, s) and 10.46 (1H, s, NH, OH); 6.45 (2H, s, NH2); 2.20 (3H, s, CH3). 13C NMR spectrum (22.5 MHz, DMSO-d 6), δ, ppm: 167.7; 148.2; 143.20; 141.3; 23.8. Mass spectrum (–75 eV), m/z (I rel, %): 184 [M–H]– (100).

Table 1, entry 2. Amidoxime 1 (1.67 g, 11.7 mmol), nitrile 5 (1.93 g, 17.7 mmol), ZnCl2 (5.10 g, 37.4 mmol), n-BuOAc (15 ml), and HCl (gas); heating at 120°C for 1 h gave compound 7. Yield 1.08 g (39%). Side product 20,35 yield 200 mg (9%).

Table 1, entry 3. Amidoxime 1 (13.0 g, 90.9 mmol), nitrile 5 (15.0 g, 136 mmol), ZnCl2 (20.0 g, 145 mmol), n-BuOAc (100 ml), and HBr (gas); heating at 120°C for 2 h gave product 7. Yield 13.4 g (62%) after recrystallization from H2O.

Table 1, entry 4. Amidoxime 1 (6.50 g, 45.5 mmol), nitrile 5 (7.50 g, 68.2 mmol), ZnCl2 (10.0 g, 73.4 mmol), i-PrCO2Pr (50 ml), and HBr (gas); heating at 120°C for 2 h gave product 7. Yield 4.80 g (44%) after recrystallization from H2O.

Table 1, entry 5. Amidoxime 1 (4.50 g, 31.5 mmol), nitrile 5 (10.5 g, 95.4 mmol), ZnCl2 (14.1 g 104 mmol), n-BuOAc (35 ml), and TsOH·H2O (6.00 g, 31.5 mmol); heating at 120°C for 2 h gave product 7. Yield 3.95 g (53%) after recrystallization from H2O.

Table 1, entry 7. Amidoxime 1 (17.4 g, 122 mmol), nitrile 5 (20.0 g, 182 mmol), ZnCl2 (33.4 g, 242 mmol), n-BuOAc (140 ml), and concd H2SO4 (3 ml, 5.3 g, 54 mmol); heating at 120°C for 1 h gave compound 7. Yield 16.0 g (55%) after recrystallization from H2O.

Synthesis of 4,4'-(1,2,4-oxadiazole-3,5-diyl)bis(1,2,5-oxadiazol-3-amine) (7) without added base. 4-Amino-N'-hydroxy-1,2,5-oxadiazole-3-carboximidamide (1) (1.0 g, 7.0 mmol) and nitrile 5 (0.77 g, 7.0 mmol) were heated in anisole (10 ml) at 150°C for 6 h. The reaction mixture was cooled to room temperature, and pentane (20 ml) was added. The precipitate was filtered off and washed with pentane (20 ml). The crude product was refluxed with acetone (15 ml), filtered hot, and the solid was washed with acetone (5 ml) to give 5-(4-aminofurazan-3-yl)[1, 2, 5]-oxadiazolo[3,4-d]pyrimidin-7-amine (6). Yield 30 mg (4%), white solid, mp 286°C (decomp.). 1H NMR spectrum (90 MHz, DMSO-d 6), δ, ppm: 9.85 (1H, s) and 9.68 (1H, s, pyrimidine NH2); 6.83 (2H, s, NH2). 13C NMR spectrum (22.5MHz, DMSO-d6), δ, ppm: 160.1; 159.2; 156.4; 155.7; 144.1; 136.5. Mass spectrum (–75 eV), m/z (I rel, %): 219 [M–H]– (100).

The filtrate was concentrated to 10 ml and refluxed with H2O (5 ml). After cooling to room temperature, the precipitate was filtered off and washed with H2O (5 ml) to give product 7. Yield 800 mg (48%).

Synthesis of 4,4'-(1,2,4-oxadiazole-3,5-diyl)bis(1,2,5-oxadiazol-3-amine) (7) in the presence of pyridine. 4-Amino-N'-hydroxy-1,2,5-oxadiazole-3-carboximidamide (1) (5.0 g, 35.0 mmol), 4-aminofurazan-3-carbonitrile (5) (4.2 g, 38.0 mmol), and pyridine (10 ml, 124 mmol) were heated in anisole (30 ml) at 150°C for 14 h. The reaction mixture was cooled to room temperature, the precipitate was filtered off, washed with acetone (5 ml), and dried under suction to give product 6. The filtrate was concentrated to afford additional portion of compound 6 as a precipitate. Yield 2.1 g (50%).

Product 7 was obtained by concentrating the filtrate, treating the residue with 20 ml of water, heating to reflux, allowing the mixture to cool to room temperature, filtering off the precipitate and washing it with water. Yield 3.6 g (44%).

Synthesis of 4,4'-(1,2,4-oxadiazole-3,5-diyl)bis(1,2,5-oxadiazol-3-amine) (7) in the presence of 2,4,6-collidine. A mixture of amidoxime 1 (20 g, 0.14 mol), nitrile 5 (22 g, 0.20 mol), 2,4,6-collidine (3 ml, 23 mmol), PhMe (20 ml), and anisole (300 ml) was heated in an oil bath at 150°C while collecting the resulting azeotrope. After heating for 6 h, nitrile 5 (3 g, 27 mmol) and 2,4,6-collidine (0.5 ml, 3.8 mmol) were added, and heating was continued for 5 h. The mixture was cooled to room temperature, hexane (300 ml) was added, and the precipitate was filtered off to give a pinkish-brown solid. The solid was refluxed in a mixture of AcOH (100 ml), acetone (200 ml), and MeOH (50 ml) for 5 min, then treated with charcoal (4 g). After removing the charcoal by filtration, the filtrate was concentrated to a volume of ~100 ml. H2O (200 ml) was added, and the mixture was brought to reflux. After cooling to 50–60°C, the precipitate was filtered off, washed with warm H2O (~60°C), and dried under suction to give product 7. Yield 25 g (76%) of a light-yellow solid.

Synthesis of 5-(4-amino-1,2,5-oxadiazol-3-yl)[1,2,5]-oxadiazolo[3,4- d ]pyrimidin-7-amine (6) by dimerization of nitrile 5 in the presence of pyridine. 4-Amino-1,2,5-oxadiazole-3-carbonitrile (5) (5.00 g, 45.4 mmol) and pyridine (10 ml, 124 mmol) were heated in anisole (30 ml) at 150°C for 20 h. The reaction mixture was cooled to room temperature, and the precipitate was filtered off, washed with acetone (200 ml), and dried under suction to give product 6. Yield 250 mg (5%).

Preparation of 4,4'-(1,2,4-oxidazole-3,5-diyl)bis(1,2,5-oxadiazol-3-amine) (7) from amidoxime 1 by oxidation with lead dioxide. Amidoxime 1 (7.50 g, 52.4 mmol), 2,4,6-collidine (0.3 ml, ~2.3 mmol), toluene (30 ml), and anisole (75 ml) were stirred and heated to reflux in an oil bath (160–170°C) while collecting azeotropic mixture. When the reaction temperature reached 140°C and no more azeotropic mixture was distilled, the reaction mixture was cooled to <100°C and lead dioxide (7.50 g, 31.3 mmol) was added in one portion. The reaction mixture was then reheated to reflux and kept refluxing for 5 h (monitored by 1H NMR). It was cooled to room temperature and pentane (150 ml) was added. The precipitate was filtered off, washed with pentane (2×50 ml). The solid was stirred with DMF (60 ml), and the insoluble inorganic compounds were removed by filtration through a layer of Celite®. The clear filtrate was concentrated, and the residue was refluxed with water (120 ml). The mixture was allowed to cool to room temperature, and product 7 was obtained by filtration, washed with water (3×20 ml), and dried under suction to yield 3.25 g (52%) of a white solid. The yield of amide 17 was estimated at 22% by 1H NMR spectroscopy. Amide 17: 1H NMR spectrum (90 MHz, DMSO-d 6), δ, ppm: 8.40 (1H, s) and 8.04 (1H, s, CONH2); 6.32 (2H, br. s, NH2 furazan). (Lit.: 1H NMR spectrum (DMSO-d 6), δ, ppm: 8.38 (1H, s) and 8.02 (1H, s, CONH2); 6.31 (2H, br. s, NH2 furazan)).27

Preparation of 4,4'-(1,2,4-oxidazole-3,5-diyl)bis(1,2,5-oxadiazol-3-amine) (7) from amidoxime 1 by oxidation with MnO 2 . Amidoxime 1 (5.0 g, 35.0 mmol), 2,4,6-collidine (0.2 ml, ~1.5 mmol), toluene (30 ml), and anisole (40 ml) were heated to reflux in an oil bath (160–170°C) while collecting the azeotropic mixture. When the reaction temperature reached 140°C and no more azeotropic mixture was distilled, the reaction mixture was cooled to <100°C and activated manganese dioxide (1.68 g, 19.3 mmol) was added in one portion, and refluxed for another 9 h (monitored by 1H NMR spectroscopy). The reaction mixture was cooled to room temperature and pentane (150 ml) was added with stirring. The precipitate was filtered off, and washed with pentane (2×50 ml). The solid was refluxed with acetone (100 ml) and activated charcoal (0.5 g) and filtered hot. The solvent was removed under vacuum, the residue was refluxed with water (100 ml) and filtered hot. The filtrate was allowed to cool to room temperature. The precipitate was filtered off to yield a mixture of compounds 7 and 18; yields 1.7 g (41%) and 2.1 g (32%), respectively, as estimated from 1H NMR spectrum.

Synthesis of 4,4'-(1,2,4-oxadiazole-3,5-diyl)bis(1,2,5-oxadiazol-3-amine) (7) by pyrolysis (General method, Table 2, entry 1). 4-Amino-N'-hydroxy-1,2,5-oxadiazole-3-carboximidamide (1) (20 g, 0.14 mol) was heated in an oil bath under argon atmosphere at 200°C for 12 h. The reaction mixture was cooled to room temperature, and the one-piece crude material was broken down by heating at 100°C in DMF (30 ml). After cooling to room temperature, the mixture was filtered through a layer of Celite®, and the filtrate was refluxed with H2O (200 ml). The product was collected by hot filtration and washed with hot H2O (100 ml) to afford product 7. Yield 4.2 g (25%).

Table 2, entry 2. Amidoxime 1 (250 mg, 1.75 mmol) and 1,3-dimethoxybenzene (0.5 ml) were heated at 200°C for 8 h. The formation of product 7 was confirmed by 1H NMR analysis.

Table 2, entry 3. Amidoxime 1 (2.20 g, 15.4 mmol) and 2,4,6-collidine (0.2 ml, ~1.5 mmol) were heated at 200°C for 14 h to give product 7. Yield 950 mg (52%).

Table 2, entry 4. Amidoxime 1 (23.7 g, 166 mmol) and 2,4,6-collidine (3.3 ml, ~25 mmol) were heated at 190°C for 26 h to give product 7. Yield 12.5 g (57%).

Table 2, entry 5. Amidoxime 1 (1.20 g, 8.4 mmol) and TsOH·H2O (0.12 g, 0.60 mmol) were heated at 200°C for 5 h to give product 7. Yield 0.36 g (36%).

3,5-Bis(4-nitro-1,2,5-oxadiazol-3-yl)-1,2,4-oxadiazole (LLM-191).26 Oxadiazole 7 (70.0 g, 300 mmol) was suspended in TFA (500 ml). The suspension was cooled with an ice water bath (10–15°C), and aq H2O2 (70%, 150 ml, 3.10 mol) was added dropwise maintaining the reaction temperature at 15–20°C. After complete addition, the reaction mixture was allowed to warm to room temperature and stirred overnight. The reaction mixture was poured with stirring into a blend of ice (1 kg) and H2O (1 l). After stirring for 5 min, NaCl (200 g) was added, and the sticky solid was stirred at room temperature for 4–5 h. The solidified product was filtered off, washed with H2O (300 ml), and dried under suction. The solid was stirred in a mixture of CH2Cl2 (400 ml) and H2O (200 ml) at room temperature, and the mixture was filtered to remove any insoluble material. The aqueous phase was separated, and the organic phase was washed with brine (3×200 ml) and dried over anhydrous MgSO4. The drying agent was removed by filtration, and the filtrate was purified on a short column (silica gel, 80 g; CH2Cl2–pentane, 3:2). The crude material was further purified by recrystallization from CHCl3–pentane to LLM-191. Yield 58.3 g (66%), colorless crystalline solid, mp 63°C (DSC peak endotherm). 13C NMR spectrum (90 MHz, CDCl3), δ, ppm: 164.0; 158.5 (2C); 157.9; 138.6; 136.9.

4,4'-{[5,5'-Bi(1,2,4-oxadiazole)]-3,3'-diyl}bis(furazan-3-amine) (8). A 1-l, three-neck, round-bottom flask equipped with a magnetic stir bar, Dean–Stark trap/condenser, thermometer, and liquid addition funnel, was charged with amidoxime 1 (100 g, 0.700 mol), solution A (70 ml) (total amount of solution A used in the synthesis, which consists of: diethyl oxalate (120 g, 0.820 mol), 2,4,6-collidine (18.0 g, 0.150 mol)), anisole (300 ml), and PhMe (40 ml)). The mixture was heated at 150°C while collecting the resulting azeotrope. After heating for 2 h, solution A (~30 ml) was added. After another 1.5 h, solution A (~35 ml) was added. After complete addition, the reaction mixture was heated at 150°C for 1.5 h. The reaction mixture was cooled to room temperature, and acetone (400 ml) was added with stirring. The precipitate was filtered off and washed with acetone (100 ml). The solid was stirred with H2O (800 ml) and collected by filtration, washed with H2O (100 ml) and acetone (100 ml), and dried under suction to give product 8. Yield 82.8 g (78%), colorless solid. 1H NMR spectrum: (90 MHz, DMSO-d 6), δ, ppm: 6.59 (2H, s, NH2). 1H NMR spectrum (90 MHz, DMF-d 7), δ, ppm: 6.60 (2H, s, NH2). 13C NMR spectrum (22.5 MHz, DMF-d 7), δ, ppm: 165.1; 161.9; 157.0; 137.6.

Ethyl 3-(4-amino-1,2,5-oxadiazol-3-yl)-1,2,4-oxadiazole-5-carboxylate (21). From an aliquot of the filtrate, compound 21 was isolated by column chromatography (silica gel, CH2Cl2–AcOEt, 5:1, R f 0.32). The product was obtained as a white solid, mp 116–118°C. 1H NMR spectrum (600 MHz, DMSO-d 6 ), δ, ppm (J, Hz): 6.53 (2H, s, NH2); 4.49 (2H, q, J = 7.0, CH2); 1.38 (3H, t, J = 7.0, CH3). 13C NMR spectrum (22.5 MHz, DMSO-d 6), δ, ppm: 167.5; 159.8; 155.5; 153.2; 136.8; 63.7; 13.8.

3,3'-Bis(4-nitro-1,2,5-oxadiazol-3-yl)-5,5'-bi(1,2,4-oxadiazole) (LLM-200). A 3-l, three-neck, round-bottom flask equipped with a thermometer, magnetic stir bar, and liquid addition funnel was charged with oxadiazole 8 (50 g, 164 mmol), TFA (200 ml), and MeNO2 (750 ml). The mixture was stirred at 50°C, and H2O2 (90%, 75 ml, 95 g, 2.8 mol) was added dropwise at this temperature over period of 18 h. After complete addition (if the reaction mixture was not clear, the heating should be extended until a clear solution was obtained), the reaction mixture was cooled to room temperature and poured into a mixture of ice water (400 ml) and EtOH (100 ml). The mixture was stirred at room temperature for 1 h, and the precipitate was filtered off, washed with H2O (200 ml), and dried in air. The crude material was recrystallized from EtOAc–EtOH to give LLM-200. Yield 44 g (73%), colorless crystalline solid, mp 182°C (DSC peak endotherm). 13C NMR spectrum (22.5 MHz, DMSO-d 6), δ, ppm: 164.5; 160.1;158.1; 140.5.

3-(4-Nitro-1,2,5-oxadiazol-3-yl)-1,2,4-oxadiazol-5-amine (LLM-201). A 250-ml, three-neck flask was loaded with pulverized 3-(4-amino-1,2,5-oxadiazol-3-yl)-1,2,4-oxadiazol-5-amine (22)64 (10 g, 60 mmol). The flask was submerged in a cool water bath, and TFA (25 ml) was slowly added with gentle stirring at <20°C. With stirring, H2O2 (80%, 15 ml, 20.4 g, 600 mmol) was added slowly, dropwise to the slurry at 20°C. A blue or green solution was observed. The reaction mixture was stirred until the oxidation was complete, as indicated by the loss of the blue/green color. The precipitate was filtered off and washed with H2O (50 ml). If product LLM-201 failed to precipitate upon quenching, it was extracted with EtOAc (3×100 ml) and recrystallized from EtOAc–hexanes. LLM-201 may be also purified by sublimation at 95–100°C. Yield 6.0 g (50%) of a white microcrystalline solid, mp 97–99°C. 1H NMR spectrum (600 MHz, acetone-d 6), δ, ppm: 6.60 (2H, s, NH2). 13C NMR spectrum (150 MHz, acetone-d 6), δ, ppm: 174.1; 160.3; 157.8; 141.7.

Diethyl [3,3'-bi(1,2,4-oxadiazole)]-5,5'-dicarboxylate (23). Two methods of synthesis are presented, and yields of product 23 typically decreased with increase in scale regardless of the method.

Method I. A 1-l, three-neck flask fitted with a reflux condenser, drying tube, dropping funnel, and thermometer was charged with DAG (7.90 g, 67.0 mmol) and CHCl3 (500 ml). Anhydrous pyridine (32.7 ml, 421 mmol) was added to the slurry that was cooled with an ice bath (internal temperature 5–10°C). Ethyl chlorooxoacetate (23.0 ml, 206 mmol) was added from the dropping funnel over a period of 1 h at such a rate to maintain the reaction temperature around 10°C (heavy crystalline precipitate formed). The cooling bath was removed, and the reaction mixture was stirred at room temperature for 30 min before bringing to reflux for 3 h. The precipitate dissolved during heating, while a more fine precipitate was formed during reflux. After cooling to room temperature, this fine precipitate was filtered off. The CHCl3 solution was diluted with CH2Cl2 (150 ml) and washed successively with 1 N HCl (3×300 ml), H2O (2×300 ml), and brine (2×300 ml). The organic layer was dried over anhydrous Na2SO4, which was later filtered off. The organic solution was evaporated to give the crude material as orange solid. Recrystallization from i-PrOH provided product 23. Yield 16.0 g (84%), white crystalline solid, mp 110–111°C (i-PrOH) (mp 108°C (EtOH)76). IR spectrum (thin film), ν, cm–1: 2986, 1758 (C=O), 1314 (C–O), 1234. 1H NMR spectrum (90 MHz, CDCl3), δ, ppm (J, Hz): 4.60 (4H, q, J = 7.1, CH2); 1.50 (6H, t, J = 7.1, CH3). 13C NMR spectrum (150 MHz, acetone-d 6), δ, ppm: 169.4; 161.4; 154.2; 64.7; 14.2.

Method II. DAG (63.3 g, 536 mmol) was suspended in CHCl3 (2 l) in a 5-l flask fitted with a reflux condenser, two liquid addition funnels, a thermometer, and a drying tube. With stirring, anhydrous pyridine (262 ml, 3.25 mol) was added to the slurry, which was then brought to reflux. With continuous heating and vigorous stirring, ethyl chlorooxoacetate (184 ml, 1.65 mol) was added dropwise over a period of 2 h. Additional ethyl chlorooxoacetate (50 ml, 0.45 mol) was added over 30 min. Reflux was continued for 2 h before cooling to room temperature, vacuum filtration, and rotary evaporation. The resulting residue was poured into vigorously stirred EtOAc (2.5 l), at which time pyridine hydrochloride (hygroscopic) precipitated as an orange solid. This was filtered off and washed with additional EtOAc (500 ml). The organic layer was then washed with 1 N HCl (2×250 ml), H2O (500 ml), brine (500 ml), saturated NaHCO3 (4×100 ml), H2O (500 ml), and brine (500 ml). The additional washing steps were necessary to remove pyridine hydrochloride and oxalic acid formed during decomposition of ethyl chlorooxoacetate. The organic layer was dried over anhydrous Na2SO4, filtered, and evaporated. The crude material was suspended in hexane and vacuum-filtered prior to recrystallization from i-PrOH. Yield 95.0 g (63%), white crystalline solid, mp 110–111°C (i-PrOH) (mp 108°C (EtOH)68), spectrally identical material to that obtained by Method I.

[3,3'-Bi(1,2,4-oxadiazole)]-5,5'-dicarboxamide (24). Diester 23 (52.4 g, 186 mmol) was suspended in MeOH (100 ml) and cooled with an ice bath. NH3 solution in MeOH (7 N, 120 ml, 14.3 mmol) was added, and the solution immediately started to thicken. After complete addition of the NH3 solution, the thick, white slurry was stirred at room temperature for 16–18 h before vacuum filtering. Product 24 was washed with MeOH (300 ml) and dried under vacuum suction before using in the next step. The obtained material is extremely insoluble in different solvents at room temperature. A sample for analysis was prepared by heating product 24 in DMF, filtering the slurry, then resuspending the precipitate in hot acetone, followed by filtration. Yield 38.0 g (92%), light-brown solid, mp >300°C (decomp.). IR spectrum (KBr pellet), ν, cm–1: 3450, 3239, 1694 (C=O). 1H NMR spectrum (90 MHz, DMSO-d 6), δ, ppm: 8.95 (2H, br. s, NH2); 8.54 (2H, br. s, NH2). 13C NMR spectrum (22.5 MHz, DMSO-d 6), δ, ppm: 170.6; 159.6; 153.7. Found, m/z: 225.0356 [M+H]+. C6H5N6O4. Calculated, m/z: 225.0367. Found, m/z: 247.0186 [M+Na]+. C6H4N6NaO4. Calculated, m/z: 247.0186.

[3,3'-Bi(1,2,4-oxadiazole)]-5,5'-dicarbonitrile (25). A 1-l, three-neck, round-bottom flask equipped with a magnetic stir bar, thermometer, reflux condenser, drying tube, and dropping funnel was charged with diamide 24 (38.0 g, 170 mmol). Diamide 24 was suspended in anhydrous 1,4-dioxane (500 ml), and anhydrous pyridine (136.6 ml, 1.7 mol) was added followed by cooling the suspension with an ice bath. TFAA (143 ml, 1.01 mol) was added over a period of 1 h in such a manner to keep the reaction temperature <10°C. The ice bath was then removed, and the reaction mixture was stirred at room temperature for 1 h, then at 30°C for 30 min. After dissolution of all solids, the heat was turned off, and the solution was stirred at room temperature for 19 h. The brown solution was poured carefully into ice water (1.5 l) and diluted with ice to a total volume of 2.5 l. After stirring for 30 min, the slurry was vacuum-filtered, and the precipitate was dried under suction to afford product 25. Dicarbonitrile 25 slowly reverts to diamide 24 upon absorption of moisture. Yield 23.3 g (73%), off-white amorphous powder. IR spectrum (KBr), ν, cm–1: 2270 (C≡N), 1554, 1269, 1220. 13C NMR spectrum (150 MHz, acetone-d 6), δ, ppm: 160.6; 155.0; 106.9.

N ' 5 , N ' 5' -Dihydroxy[3,3'-bi(1,2,4-oxadiazole)]-5,5'-dicarboximidamide (26). Dicarbonitrile 25 (23 g, 122 mmol) was suspended in i-PrOH (500 ml). Aqueous hydroxylamine (50%, 18.4 ml, 279 mmol) was added to the slurry, followed by refluxing for 15 h. The reaction mixture was heterogeneous throughout, and the remaining white solid was filtered off after cooling to room temperature. After washing with i-PrOH (100 ml) and vacuum-drying, product 26 was obtained. Yield 31 g (99%), white amorphous powder. IR spectrum (ATR, thin film), ν, cm–1: 3649, 3289, 3155, 1716, 1655 (C=N), 1581, 1245, 967. 1H NMR spectrum (90 MHz, DMSO-d 6), δ, ppm: 11.00 (2H, br. s, NOH); 6.36 (4H, br. s, NH2). 13C NMR spectrum (150 MHz, DMSO-d 6), δ, ppm: 171.8; 159.9; 140.9. Found, m/z: 255.0585 [M+H]+. C6H7N8O4. Calculated, m/z: 255.0585. Found, m/z: 277.0404 [M+Na]+. C6H6N8NaO4. Calculated, m/z: 277.0404.

N ' 5 , N ' 5' -Dihydroxy[3,3'-bi(1,2,4-oxadiazole)]-5,5'-dicarboximidoyl dichloride (27). A three-neck roundbottom flask equipped with a magnetic stir bar, thermometer, and dropping funnel was charged with diamidoxime 26 (19.5 g, 76.8 mmol) and aq HCl (6 M, 300 ml). The suspension was cooled with a NaCl–ice bath to keep the temperature <0°C while adding dropwise a solution of NaNO2 (12.5 g, 181 mmol) in H2O (50 ml). The reaction mixture was allowed to warm to room temperature slowly over 3 h, and it was then cooled again to add solution of NaNO2 (5.2 g, 76.8 mmol) in H2O (20 ml) in the same manner as above. The reaction mixture was allowed to warm to room temperature slowly over 18 h, and the precipitate was vacuum-filtered, washed with ice water (50 ml), and dried under suction. Product 27 was typically weighed in a closed container, as the material appears to be a mild sternutator. Yield 17.0 g (75%), white amorphous solid. IR spectrum (KBr), ν, cm–1: 3232, 2360, 1722 (C=N), 1560. 1H NMR spectrum (90 MHz, DMSOd 6), δ, ppm: 14.21 (2H, s, OH). 13C NMR spectrum (150 MHz, acetone-d 6), δ, ppm: 171.7; 161.1; 125.0.

N ' 5 , N ' 5' -Dihydroxy[3,3'-bi(1,2,4-oxadiazole)]-5,5'-dicarboximidoyl diazide (28). Caution! Although no incidents occurred during the handling of diazidoxime 28, and small-scale safety testing (drop hammer, friction, and spark) showed the crude material to be safe to handle, careful and minimal handling of compound 28 is strongly advised. All material synthesized was used in the next step as soon as possible without storing the material for future use.

The azidation procedure was adapted from a report by Klapötke.71 Bischloroxime 27 (1.3 g, 4.3 mmol) was suspended in anhydrous DMF (5 ml) and stirred at room temperature, while NaN3 (0.60 g, 9.2 mmole) was added slowly. A condenser with a drying tube was added to the flask, and the vessel was submerged in a cool water bath, while the mixture started to turn yellow and warm. The reaction mixture was stirred for 30 min before heating to 35–40°C for an additional 1 h. After cooling to room temperature, the solution was poured into ice water (60 ml), and H2O was added to a final volume of 100 ml. The suspension was stirred for ~1 h, and the solid was filtered by vacuum filtration. After washing with ice water, product 28 was dried overnight on the vacuum filter. There were always signals of DMF in the NMR spectra, and efforts to remove it were not attempted further. Yield 1.0 g (77%). IR spectrum (KBr), ν, cm–1: 3233, 2359, 2160 and 2162 (N3), 1567, 1267, 1029. 1H NMR spectrum (90 MHz, DMSO-d 6), δ, ppm: 13.28 (2H, s, OH). 13C NMR spectrum (150 MHz, DMSO-d 6), δ, ppm: 169.9; 159.9; 132.9.

5,5'-{[3,3'-Bi(1,2,4-oxadiazole)]-5,5'-diyl}bis(1 H -tetrazol-1-ol) (29). Diazidoxime 28 (1.0 g, 3.3 mmol) was placed into a 50-ml pressure vessel with a magnetic stir bar and enough 1,4-dioxane to stir the suspension. A solution of HCl in 1,4-dioxane (4 N, 10–15 ml) was added dropwise. The vessel was sealed, placed behind a safety shield, and the reaction mixture was heated at 40°C for 18–24 h. Occasionally, the suspension turned into solution and precipitated back out, while other times it remained as white, heterogeneous suspension throughout. After cooling to room temperature, a small portion of the reaction mixture was filtered for IR spectroscopy. If the reaction was judged to be complete (absence of diazidoxime 28 characteristic stretches), precipitate of the remaining mixture was filtered off and dried by vacuum suction. The filtrate was poured into vigorously stirred anhydrous Et2O (250 ml), and the stirring was continued until a free-flowing precipitate formed, which was then filtered off. The combined fractions of product 29 appeared to be hygroscopic, as shown by a drastic peak shift in 1H NMR over time. DSC-TGA showed a 10.5% weight loss (two equivalents of H2O) during the endothermic trough between 95–129°C. Yield 750 mg (77%), white powder. DSC of dihydrate 29·2H2O (10°C/min): endotherm 129°C (trough), exotherm 220°C (peak). IR spectrum (KBr), ν, cm–1: 3390 (O–H), 1672, 1234, 1254. 1H NMR spectrum (600 MHz, DMSO-d 6), δ, ppm: 5.52 (2H, br. s, OH) or 7.20 (2H, br. s, OH) after absorption of H2O. 13C NMR spectrum (150 MHz, acetone-d 6), δ, ppm: 165.9; 161.4; 137.9. Found, m/z: 307.0391 [M+H]+. C6H3N12O4. Calculated, m/z: 307.0395. Found, m/z: 324.0658 [M+NH4]+. C6H6N13O4. Calculated, m/z: 324.0660. Found, m/z: 329.0211 [M+Na]+. C6H2N12NaO4. Calculated, m/z: 329.0214.

Hydroxylammonium 5,5'-{[3,3'-bi(1,2,4-oxadiazole)]-5,5'-diyl}bis(1 H -tetrazol-1-olate) (30). Hydroxylamine hydrochloride (0.45 g, 6.5 mmol) was dissolved in minimal volume of H2O and was added to a mixture of aq KOH (85%, 0.45 g, 6.5 mmol) and EtOH (10 ml) with cooling in an ice bath. After stirring for 0.5 h, the formed KCl was filtered off. A suspension of dehydrated compound 29 (0.91 g, 2.7 mmol) in EtOH (20 ml) was stirred and cooled in an ice bath while the solution of hydroxylamine in EtOH was added dropwise to form a milky slurry. After complete addition, the mixture was heated to reflux, and H2O was added until a solution formed. Any insoluble material was removed via gravity filtration while keeping the mixture hot. The solution was allowed to cool slowly to precipitate hydroxylammonium salt 30. Yield 940 mg (93%), white needles, mp 230°C (decomp.). IR spectrum (KBr), ν, cm–1: 3409 (O–H), 3067, 2709, 1629, 1475, 1232. 1H NMR spectrum (90 MHz, DMSO-d 6), δ, ppm: 10.08 (2H, br. s, OH). 13C NMR spectrum (150 MHz, DMSO-d 6 ), δ, ppm: 167.3; 159.8; 132.5.

Diethyl 1,2,4-oxadiazole-3,5-dicarboxylate (33).69 A 1-l, three-neck flask equipped with a magnetic stir bar, reflux condenser, drying tube, dropping funnel, and thermometer was charged with ethyl 2-amino-2-(hydroxyimino)acetate (32)74 (32.0 g, 242 mmol) and CHCl3 (500 ml). Anhydrous pyridine (59.0 ml, 732 mmol) was added to the slurry, and the reaction mixture was cooled with an ice bath (internal temperature 5–10°C). Ethyl chlorooxoacetate (40.6 ml, 363 mmol) was added over a period of 1 h from the dropping funnel at such a rate to maintain the reaction temperature around 10°C. The cooling bath was removed, the reaction mixture was stirred at room temperature for 30 min and then refluxed for 3 h. A fine precipitate impurity was formed during reflux, which was filtered off after cooling to room temperature. The CHCl3 solution was diluted with CH2Cl2 and washed successively with 1 N HCl (3×300 ml), H2O (2×300 ml), and brine (2×300 ml). The organic layer was dried with anhydrous Na2SO4, and the organic solution concentrated to give product 33 that was used in the next step without any further purification. Yield 52 g (>99%), colorless oil. IR spectrum (ATR, neat), ν, cm–1: 1752 (C=O). 1H NMR spectrum (600 MHz, CDCl3), δ, ppm: 4.67–4.41 (4H, m, 2CH2); 1.54–1.37 (6H, m, 2CH3). 13C NMR spectrum (150 MHz, CDCl3), δ, ppm: 167.7; 162.6; 156.5; 153.2; 64.3; 63.4; 14.0; 13.9.

1,2,4-Oxadiazole-3,5-dicarboxamide (34). Diester 33 (51.9 g, 0.24 mol) was suspended in MeOH (100 ml) and cooled in an ice bath. NH3 solution in MeOH (7 N, 200 ml, 1.40 mol) was added, and the reaction mixture immediately started to thicken due to the formation of precipitate. After complete addition of NH3 solution, the thick slurry was stirred at room temperature for 16–18 h before vacuum filtration. The product was washed with MeOH (100 ml) and dried under vacuum before exploitation in the next step. Yield 36.0 g (96% over two steps), white amorphous solid. A sample for analytical characterization was heated in DMF. The obtained slurry was filtered, and the precipitate was washed with acetone (100 ml) and subjected to vacuum drying. IR spectrum (ATR, thin film), ν, cm–1: 3400, 3311, 3243, 3169, 1719, 1695 (C=O), 1596, 1557, 1237, 1197. 1H NMR spectrum (600 MHz, DMSO-d 6 + NH4OH), δ, ppm: 8.80 (1H, br. s) and 8.46 (1H, br. s, NH2); 8.42 (1H, br. s) and 8.20 (1H, br. s, NH2). 13C NMR spectrum (150 MHz, DMSO-d 6 + NH4OH), δ, ppm: 170.4; 164.4; 157.7; 154.5. Found, m/z: 179.0174 [M+Na]+. C4H4N4NaO3. Calculated, m/z: 179.0176.

1,2,4-Oxadiazole-3,5-dicarbonitrile (35).70 A dry 250-ml Erlenmeyer flask equipped with a ground glass joint and filled with oven-dried sand (1/6th volume) was charged with P4O10 (32.0 g, 134 mmol) under argon flow. Diamide 34 (8.0 g, 51.2 mmol) was added, and the flask was shaken to mix all of the solids well under argon. The flask was connected to a distillation setup, equipped with a double vacuum trap, and placed into a preheated oil bath at 210°C (to minimize the sublimation of P4O10). The bath temperature was then lowered to 205°C, and distillation under high vacuum (<1 bar) was performed. Each trap was cooled with liquid N2, and to avoid clogging of the tubing during distillation, 24/40 joints were used throughout the distillation apparatus. If clogging occurred, the system was purged with argon and allowed to warm enough to melt the distilled product. Distillation was then continued under vacuum and took 1.5 to 2 h to complete. The distillate can be redistilled to the second trap with gentle warming (warm water bath) under vacuum if desired. Dinitrile 35 is extremely volatile and highly susceptible to hydrolysis and was therefore used in the next step immediately. The use of sand aided in heat transfer as well as eased the clean-up of the remaining residue. Without sand, yields of product 35 were varied and reduced, and significant foaming occurred during heating. Later experiments showed that preheating under argon at 160°C followed by switching to vacuum was sufficient to distill the product, while avoiding sublimation of P4O10, and carry-over the monodehydrated material. The completion of the reaction could be judged by loss of white material in the sand mixture and no more condensation of product in the condenser. Yield 4.32 g (70%), colorless oil. 13C NMR spectrum (22.5 MHz, neat), δ, ppm: 152.6; 147.7; 105.5; 103.6. 13C NMR spectrum (150 MHz, DMSO-d 6), δ, ppm: 154.5; 148.3; 107.9; 106.3.

N ' 3 , N ' 5 -Dihydroxy-1,2,4-oxadiazole-3,5-dicarboximidamide (36). A round-bottom flask was charged with anhydrous MeOH (250 ml) and KOH (4.2 g, 75 mmol). After dissolution of KOH, hydroxylamine hydrochloride (5.2 g, 75 mmol) was added, and the reaction mixture was stirred at room temperature for 30 min. The formed KCl was filtered off, and the flask was fitted with a reflux condenser equipped with a drying tube. Dicarbonitrile 35 (4.3 g, 36 mmol) was added to the hydroxylamine solution in MeOH, and immediately a white precipitate formed. The mixture was refluxed for 3 h, and most of the precipitate dissolved. Any remaining solids were filtered off from the hot mixture, and MeOH was evaporated to give the crude material 36, which was recrystallized from i-PrOH. Yield 4.8 g (71%), white solid, mp 180–181°C (i-PrOH). IR spectrum (ATR, neat), ν, cm–1: 3468, 3271, 1722, 1660 (C=N), 1583, 1184. 1H NMR spectrum (600 MHz, DMSO-d 6), δ, ppm: 10.87 (1H, s, OH); 10.42 (1H, s, OH); 6.24 (2H, s, NH2); 6.00 (2H, s, NH2). 13C NMR spectrum (150 MHz, DMSO-d 6), δ, ppm: 170.0; 163.6; 141.9; 140.6. Found, m/z: 187.0574 [M+H]+. C4H7N6O3. Calculated, m/z: 187.0574. Found, m/z: 209.0394 [M+Na]+. C4H6N6NaO3. Calculated, m/z: 209.0394.

N ' 3 , N ' 5 -Dihydroxy-1,2,4-oxadiazole-3,5-dicarboximidoyl dichloride (37). A three-neck, round-bottom flask equipped with a magnetic stir bar, thermometer, and dropping funnel was charged with aq HCl (6 M, 15 ml), cooled with an ice bath, and diamidoxime 36 (2.0 g, 10.8 mmol) was added. The suspension was cooled in a NaCl–ice bath to keep the temperature <0°C while adding a solution of NaNO2 (1.6 g, 23.7 mmol) in H2O (10 ml). The reaction mixture was stirred at this temperature for 1 h and then warmed to room temperature over 30 min. The formed precipitate was filtered off, washed with ice-cold H2O (10 ml), and dried under vacuum. Compound 37 was typically weighed in a closed container as the material appeared to be a mild sternutator. Yield 2.1 g (87%), white amorphous solid. IR spectrum (thin film), ν, cm–1: 3512, 3232, 1607, 1572, 1524, 1442, 1119, 1044, 926. 1H NMR spectrum (90 MHz, DMSO-d 6), δ, ppm: 14.10 (1H, s, OH); 13.60 (1H, s, OH). 13C NMR (150 MHz, DMSO-d 6), δ, ppm: 170.8; 165.6; 127.0; 125.8.

N ' 3 , N ' 5 -Dihydroxy-1,2,4-oxadiazole-3,5-dicarboximidoyl diazide (38). Caution! Although no incidents occurred during handling of diazidoxime 38, and small-scale safety testing (regarding drop hammer, friction, and ESD) showed the crude material to be safe to handle, careful and minimal handling of this material is strongly advised. All of the compound 38 synthesized was used in the next step as soon as possible without storing the material for future use.

Dichloroxime 37 (1.23 g, 5.46 mmol) was suspended in anhydrous DMF (5 ml) and stirred at 0°C, while NaN3 (0.78 g, 12.0 mmol) was added slowly. A condenser with a drying tube was added to the flask, and the reaction mixture was stirred at 0°C for 15 min before warming to room temperature and finally to 40°C. The solution was stirred for 1.5 h at room temperature and then poured into ice-cold H2O (50 ml). The suspension was stirred for approximately 1 h, and the solids filtered by vacuum filtration. After washing with ice-cold H2O (50 ml), product 38 was dried by suction overnight. There were always signals of DMF in the NMR spectra and no further attempts were made to purify product 38. Yield 1.18 g (91%), off-white amorphous solid, mp 163–165°C (decomp.). IR spectrum (KBr), ν, cm–1: 2160 and 2106 (N3). 1H NMR spectrum (600 MHz, acetone-d 6), δ, ppm: 12.08 (1H, br. s, OH); 12.10 (1H, br. s, OH). 13C NMR spectrum (150 MHz, acetone-d 6), δ, ppm: 169.4; 163.8; 135.2; 134.0.