Abstract

Conventional cellulosic packaging materials lack the ability to resist the penetration of water, mineral oil, and harmful chemicals. These poor barrier properties of the conventional cardboard packaging materials make them ineffectual in various industrial applications. Hence, the present work focuses on the development of hydrophobic polybenzoxazine coated cellulose paper with improved tensile strength for the replacement of existing cardboard packaging materials. The trifunctional polybenzoxazines have been synthesized and coated on cellulose paper for the hydrophobic packaging material application. A new type of series of tri-functional polybenzoxazines were synthesized using leucoaurin with paraformaldehyde and separately with five different aliphatic amines of varying chain length (i.e.) butylamine (ba), hexylamine (ha), ethylhexylamine (eha), dodecylamine (dda) and octadecylamine (oda) through Mannich condensation. In the present work, the influencing effect of aliphatic chain length present in the skeleton of polybenzoxazines has been studied and the hydrophobic behavior was exploited for water-proof packaging application by coating polybenzoxazines on normal cellulosic printable paper-75 GSM (CP) and Wattman paper (WP) through spray coatings. The hydrophobic behavior of leucoaurin based benzoxazines coated cellulose paper was tested using goniometer and the coated cellulosic paper possesses good hydrophobic behavior with value of water contact angle above 125º. Among the polybenzoxazines synthesized, the leucoaurin with octadecylamine benzoxazine coated on cellulosic WP paper shows better water repellent property (water contact angle 136 ± 2º) than that of others. In addition to that, the value of tensile strength of leucoaurin based polybenzoxazines coated papers was tested using UTM and the results obtained were compared with that of non-coated papers. The tensile strength of the coated papers was found to be 2 to 3 times higher than that of non-coated paper with the value of 21 MPa and 18 MPa for LA-PBZ coated copier paper and Wattman paper respectively. The obtained results suggest that the leucoaurin based polybenzoxazines coated papers can be considered for effective utilization for water-proof packaging applications.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Cellulose is a bio-based organic polymer, which is obtained from stem walls. Cotton and wood pulp cellulose are extensively used in various industrial applications. The commercial/consumer products manufacturing industries are showing extra interest on bio-products developed from cellulosic materials, due to the environmentally friendly, reusable, recyclable, renewable and bio-degradable. The cellulosic paper and paperboards are the major products predominantly used for the packaging application. Advancements in research for modifying cellulose-based packaging is increasing as they are bio-degradable in nature and they can be used in many industries instead of traditional fossil based polymeric materials. Primarily, cellulose-based materials are largely used as packaging materials for pharmaceuticals, electronic devices, and beverages, etc. (Tajeddin 2014; Sharma et al. 2019; Yaradoddi et al. 2020; Liu et al. 2021).

Ever since the discovery of card-board boxes in the early 1800s, the major drawback while using cellulose materials is their restricted resistivity towards water and chemicals. The moisture absorption is one of the shortcomings of paper-board materials, which leads to limit their usage, longevity and the growth of micro-organisms. This disadvantage of cellulose as poor repellant to water, has made the cellulose based materials to become unfavorable in many industrial applications. For advanced packaging applications, bio-degradable cellulose material having excellent barrier properties are needed. Conventional cellulosic packaging material possesses water penetration, permeability of oils and lubricants, and grease affinity. To improve the surface properties, the cellulose materials are often coated with various polymeric materials to prevent the permeation of water and other mineral substances. Hence, the researchers and start-up companies are focusing to address this problem through the various polymeric coatings on cellulose materials (Zhang et al. 2019; Wei et al. 2020). Many reports have been reported to enhance the surface/barrier properties of the cellulosic packaging material by coating it with a suitable polymer (Hamdani et al. 2020). Sundar et al. studied the barrier properties of the kraft paper material by coating it with biodegradable polylactic acid. They achieved the value of water contact angle of 79° for the PLA coated kraft paper material (Sundar et al. 2020b). Another interesting work was reported by coating the polylactic acid combined with polycaprolactone on the kraft material and they achieved the water contact angle value of 69° for the coated paper (Sundar et al. 2020a). Daniela Sánchez Aldana et al. used montmorillonite as a coating along with PLA for cellulose based packaging material and obtained the water contact angle value of 73o (Aldana et al. 2014). However, for a packaging material to exhibit enhanced water resistance property, the coated packaging material should possesses the value of water contact angle minimum of above 100°. Hence, the present work focuses on development of a hydrophobic coating for the cellulose paper with value of water contact angle greater than 110° and having high value of tensile strength for utilizing the coated paper as a better packaging material.

The polybenzoxazines occupy a predominant role due to their remarkable properties. They are considered as a foremost class of modified thermosetting phenolic resins, which eliminates many of the limitations experienced with conventional phenolics. No hardener or curing agent is required for benzoxazine polymerization, which is self-curing in nature. There are no by-products generated during polymerization, and form a three-dimensional cross-linked network polybenzoxazine matrix (Kim and Ishida 2001; Ishida 2011; Manuspiya and Ishida 2011). They are low out-gassing materials with very high thermal and mechanical properties. The polybenzoxazines were considered as anti-corrosive materials, weather resistance coatings, UV shielding materials, oil–water separating materials, composite materials for constructions, sound absorption panels, anti-microbial coatings, electrical insulators and energy storage devices (Zhou and Xin 2017; Gnanapragasam et al. 2018; Hariharan et al. 2020; Kumar et al. 2022; Ranganathan et al. 2022; Lawan et al. 2023). The reason for polybenzoxazines being a vital-materials for these applications is the excellent thermal stability and the hydrophobic nature. Some of the researchers focused on utilizing benzoxazines as electronic packaging materials. However, the idea of using polybenzoxazine as a replacement of traditional cellulosic packaging material is need to be studied in detail. Polybenzoxazines possess several advantages by using it as efficient coating material for anti-corrosion, anti-microbial, UV resistant and hydrophobic coatings (Aly et al. 2020; Mohamed et al. 2021; Dardeer et al. 2023; Soliman et al. 2023). However, till date, the polybenzoxazine coatings for cellulosic paper and cardboard packaging applications was used to the limited extent. The concept of using polybenzoxazine as such without any modification for packaging material would not be reliable because of its high brittle nature. Even though, long chain containing polybenzoxazines can cause flexibility and the brittleness can be decreased (Chozhan et al. 2013; Selvaraj and Raghavarshini 2019).

The present work aims to synthesize a new type of trifunctional polybenzoxazine using leucoaurin as raw material. The amines with varied length of alkyl chains have been chosen for the synthesis of benzoxazine monomers using leucoaurin and paraformaldehyde. The prepared leucoaurin benzoxazines were coated on the surface of two types of cellulose paper (i.e.) normal copier paper and Whatman filter paper. The hydrophobic behavior of the polybenzoxazines and the coated cellulose papers was assessed. The values of tensile strength and young’s modulus of the coated cellulose papers were determined and compared with those of non-coated papers. The results obtained indicated that the leucoaurin based polybenzoxazine coated cellulose papers can be effectively used as a water-proof packaging material for different purposes.

Experimental

Raw materials

The details of the raw materials that are required for the synthesis of leucoaurin and its benzoxazines mentioned in the supporting information.

Synthesis of leucoaurin (LA)

About 0.2 mol (18.82 g) of phenol was mixed with the acid mixture (2.46 ml of H2SO4 and 4.93 ml of HCl) by slow addition. To this 0.1 mol (12.2 g) of 4-hydroxybenzaldehyde was added and heated at 80˚C. The reaction was monitored for every hour by TLC and the reaction was completed after 5 h. After the completion of reaction, 1 N NaOH solution was used to neutralize the acid mixture. The light red color precipitate obtained was filtered, washed with chloroform and dried. The obtained product was named as leucoaurin (Scheme 1) and its molecular structure was analysed by spectral analysis. FTIR (cm−1): 3228 cm−1 (Ar-OH) 3011 cm−1 (= C-H) and 1596 cm-1 (aromatic C = C) (Fig. 1). 1H NMR (D6-DMSO, ppm): 5.35 (s, 1H), 6.65–6.70 (d, 6H) 6.85–6.90 (d, 6H) and 9.32 (s, 3H). HRMS (m/z): 292.11. The prepared leucoaurin (LA) was used for benzoxazine synthesis (Gnanapragasam et al. 2018)(Srinivasan and Krishnan 2023).

Synthesis of leucoaurin based benzoxazines (LA-BZ)

To synthesize LA-BZ monomer, 0.03 mol (2.19 g) of n-butylamine (ba) and 0.06 mol (1.80 g) of p-formaldehyde were mixed and stirred at room temperature for 30 min. To this mixture, 0.01 mol (2.92 g) of leucoaurin was added slowly in the presence of dioxane solvent and heated at 110 °C. The reaction mixture was allowed to condense at this temperature for another 4 h. The complete formation of benzoxazine monomer was tracked by TLC. The product obtained was washed with 2 M NaOH for two times for the removal of excess phenol and the ethylacetate solvent was removed using vaccum. The obtained product was dark brown coloured thick resin (Scheme 2). Using the same procedure the other four LA-Bz were synthesized separately with n-hexylamine (ha), 2-ethylhexylamine (eha), n-dodecylamine amine (dda) and n-octadecylamine (oda) (Nalakathu Kolanadiyil et al. 2016). The detailed preparation of polybenzoxazines was given in the supplemenatry information (Scheme S1).

Preparation of LA-PBz coated cellulose paper

For the preparation of leucoaurin benzoxazines coated hydrophobic paper, a standard copier paper (CP), (i.e.) 75 GSM cellulose paper and Whatman filter paper (WP) have been taken. The 75 GSM cellulose paper chosen for coating is having thickness of 300 µm. The grade 1 Whatman filter paper having thickness of 180 µm has been used for coating. The leucoaurin based benzoxazine resins were separately dissolved in THF solvent and taken in a spray bottle. The LA-BZ monomer solutions were sprayed over the surface of 75 GSM paper and Whatman filter paper to obtain uniform coating on both the sides. The coated papers were dried at 60 °C for 30 min for the removal of solvent. After drying, the LA-BZ coated papers were cured at 230 °C for 2 min. Light brown colored LA-PBz coated cellulose papers were obtained after curing of LA-Bz monomer coatings (Scheme 3). The LA-PBz coated cured 75 GSM cellulose papers were labeled as poly (LA-ba)-CP, poly (LA-ha)-CP, poly (LA-eha)-CP, poly (LA-dda)-CP and poly (LA-oda)-CP, where CP stands for copier paper. Similarly, the coated Whatman filter papers were named as poly(LA-ba)-WP, poly(LA-ha)-WP, poly(LA-eha)-WP, poly(LA-dda)-WP and poly(LA-oda)-WP, where WP stands for Whatman filter paper (Mohamed Mydeen et al. 2023a).

Measurements

The methods and instruments used to study the structure and properties of the synthesized leucoaurin and its polybenzoxazines were mentioned in the supplementary information.

Results and discussion

Structural characterization of leucoaurin (LA)

The leucoaurin’s structure was analysed using FTIR spectroscopic technique (Fig. 1). The presence of trifunctional phenolic group was ascertained by the –OH stretching peak appeared at 3228 cm−1. The aldehyde group present in the hydroxybenzaldehyde shows a stretching frequency of 1670 cm−1, which is not present in leucoaurin. The absence of -CHO stretching peak in leucoaurin indicates that the aldehyde group was completely involved in the formation of tris-phenol. Further, it was confirmed from the 1H-NMR spectroscopy that the leucoaurin prepared contains no impurities and unreacted components (Fig. 2). A single resonance signal was observed at 5.4 ppm, which corresponds to the proton present in the bridging –CH group. Two doublet signals identified between 6 and 7 ppm were appeared due to the Ar–H present in the leucoaurin. In addition to that, the molecular mass of the synthesized leucoaurin was predicted by HRMS analysis and compared with that of the theoretical value of molecular mass. The mass spectrum of the leucoaurin shows that there were no unreacted substances present and the calculated value of mass agreed well with that of the experimental value (Fig. 3).

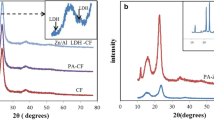

Structural characterization of the leucoaurin benzoxazines

The presence of functional groups in the LA-Bz monomers were determined using FTIR spectroscopy (Fig. 4a). From the FTIR spectra of LA-Bz monomers, the characteristic stretching band of oxazine ring has been noted at 932 cm−1 which is responsible for the out of plane bending vibration of –CH2 in oxazine ring. The alkyl aryl ether formed in benzoxazine ring has been indicated by the sharp peaks appeared at 1081 and 1244 cm−1 which are symmetric and asymmetric stretching frequencies of C–O–C respectively. A sharp peak has been noticed at 1132 cm−1 which is responsible for the C-N–C stretching vibration. The bands from 2850 to 2950 cm−1 are responsible for the methyl groups present in the aliphatic amines. The breakage of oxazine ring in the LA-Bz was ascertained from the FTIR spectra of LA-PBz (Fig. 4b). The typical oxazine stretching peak noted at 932 cm−1 was occurred to have disappeared in the FTIR spectra of LA-PBz. Further, the intensities of CH2-O-Ar and CH2-N-CH2 stretching peaks appeared at 1081, 1244 and1132 cm−1 have been reduced indicating that the oxazine ring has cleaved during the occurrence of polymerization process of LA-Bz monomers (Shah et al. 2023).

The cyclization of benzoxazine ring has been ascertained from the 1H-NMR analysis of the LA-Bz monomers (Fig. S1-S5). The 1H-NMR shows two typical resonances at around 4 ppm and 5 ppm which are responsible for the presence of Ar-CH2-N and O-CH2-N methyl protons respectively. The aliphatic methyl protons present in the amines give rise to multiple peaks around 1 ppm to 3.5 ppm. A peak appeared at 7.2 ppm in all the five LA-Bz monomers have been noticed, which is the CDCl3 solvent peak. The aromatic protons present in the LA-Bz have been identified by the multiplets appeared around 6.5 ppm to 7.5 ppm (Mohamed Mydeen et al. 2023b).

Curing behavior of the LA-Bz monomers

The curing pattern of the LA-Bz monomers was studied using the DSC traces (Mohamed et al. 2020) obtained from single heating cycle (Fig. 5). All the five LA-Bz monomers showed similar curing pattern of having a single exothermic peak. The exothermic curing peak appeared infer that the thermal ring opening polymerization process of LA-Bz accompanies with the release of heat. There is no endothermic melting peak was noticed, which shows the resinous nature of all the five LA-Bz monomers. This is because of the long alkyl chain present in the amine moieties. All the LA-Bz clearly shows an exothermic peak starting from 190 °C to 250 °C. This broad peak indicates that the slow and prolonged process of curing takes place in the LA-Bz monomers. The onset and offset temperatures of the LA-Bz monomers obtained from DSC analysis are presented in Table 1. The curing temperature of LA-Bz monomers was identified using the exothermic peak maxima (curing), which ranges from 217 °C to 233 °C. The LA-Bz monomers show comparatively lower curing temperatures than that of the conventional benzoxazines such as bisphenol-A and bisphenol-F benzoxazines (Liu and Ishida 2014; Ručigaj et al. 2015). A similar curing trend was also observed in the case of LA-Bz, ie., the longer the aliphatic chain in amine moiety, which the lowers the curing temperature. From the DSC traces of LA-Bz monomers, it is distinct that the curing pattern of all the five monomers varies according to their molecular structures. The LA-ba and LA-ha show narrow peaks with curing temperatures of 233 °C and 224 °C respectively, whereas that of LA-eha, LA-dda and LA-oda show quite broad peaks with curing temperature of 227 °C, 224 °C and 217 °C respectively. This variation in the curing peaks arises due to the presence of length of aliphatic chain present in the amine moiety. In the case butylamine and hexylamine, the alkyl chain length is very short leading to tight packing of benzoxazines, while curing, which needs more energy due to higher rigidity of the molecular system. Hence, a higher temperature is required for the polymerization of LA-ba and LA-ha. On the other hand, as the alkyl chain length increases, the molecular flexibility of the benzoxazines also increases, which eases the breakage of oxazine ring relatively at lower temperatures (Han et al. 2019). After the ring opening of benzoxazine, the methyl group present in the Mannich bridge gets crosslinked into the ortho position of the neighboring benzoxazine moiety (Patil et al. 2022). This leads to the three-dimensional crosslinked network structure (Scheme 4). According to this, among the five LA-Bz, the LA-oda shows the lowest curing temperature of 217 °C. Another reason behind this might be the influence of aliphatic chain on the basic nature of the amine. The higher the number of alkyl groups, higher is the basic nature of the amine. Because methyl groups can donate electrons, which is a positive inductive (+ I) effect, and in turn increases the basicity of the amines. The higher basic amine will initiate the cleavage of oxazine ring more effectively at relatively a lower temperature. Hence, octadecylamine having C18 alkyl chain length will have the higher basic nature and thus the LA-oda have the lowest curing temperature.

Thermal stability of the LA-PBz

The thermal behavior of the LA-PBz have been studied to ascertain their thermal stability and maximum degradation temperature (Devaraju et al. 2021). The maximum degradation temperature of all the five LA-Bz was noticed above 400 °C, which infers their thermal resistant behavior. From the TGA curves, the 5% and 10% weight loss temperatures observed are given in Table 2. The values of char yield of the LA-PBz are in the range of 20 to 40%. Among the LA-PBz, the poly(LA-ba) possess reasonably higher thermal stability with Tmax value of 476 °C and char yield of 40%. The poly(LA-oda) possesses the lowest value of char yield of 20% with Tmax value of 415 °C. The reason for higher thermal stability of poly(LA-ba) is due to the tight packing of LA-ba monomers, because of the small length of aliphatic chain in butyl amine. It takes more energy to undergo degradation of the polymer core of poly(LA-ba) when compared to that of other LA-PBz. The trifunctionality leads to the dimensional solidity across three directions by forming a cross-linked network structure, which contributes to an added stability towards degradation. Thus, the thermal stability decreases with an increase in the length of aliphatic chain in the amines (Fig. 6).

Surface morphology

The surface morphology of the leucoaurin based polybenzoxazines was analysed using FESEM images (Fig. 7). The SEM images of LA-PBz shows uniform and smooth surfaces without any voids. The LA-PBz possess homogenous morphology with no voids and cracks present in throughout the surface. In addition to that, the surface morphology of the LA-PBz coated copier (CP) and Wattman papers (WP) were also studied (Fig. 8). The LA-PBz coated papers considered as a representative sample for SEM analysis with respect to the higher water contact angle. The presence of LA-PBz coating on the surface of the cellulose paper was clearly seen in the SEM images of the coated papers when compared to the SEM images of the uncoated cellulose papers. The SEM images of the LA-PBz coated CP and WP shows evenly distributed coating on the surface of the cellulose paper. The surface roughness of the cellulose paper increases certainly after the coating of LA-PBz, which is evidently seen in the SEM images of the coated cellulose papers.

Hydrophobic behavior

The hydrophobic behavior was studied for the leucoaurin based polybenzoxazines and leucoaurin based polybenzoxazines coated CP and WP. The values of water contact angle (WCA) observed for LA-PBz are presented in Table 2. All the LA-PBz possess an excellent hydrophobic property with WCA values above 138° (Fig. 9). The highest WCA value of 144° was obtained for poly (LA-oda). This water repelling nature has been observed due the presence of long aliphatic side chain present in the leucoaurin polybenzoxazines. As the alkyl chain length increases, the hydrophobicity increases. The C18 alkyl chain present in poly (LA-oda) is one of the major reasons for obtaining the highest value of water contact angle. As polybenzoxazines are generally non-ionic molecules, the methyl groups present in the amines tends to increase their covalency and contribute to enhanced hydrophobic nature. The LA-PBz coated CP and WP cured cellulose papers also possess better hydrophobic nature than that of non-coated papers (Figs. 10 and 11). The values of WCA and the images of the LA-PBz coated CP and WP cured cellulose papers are presented in Table 3.

Tensile strength of LA-PBz coated papers

The values of tensile strength and tensile modulus of the LA-PBz coated CP and WP cellulose papers obtained from UTM were compared with those of non-coated CP and WP. The values show quite reasonable variation between the non-coated and coated cellulose papers. The leucoaurin based polybenzoxazine coatings shows a noteworthy effect on the tensile strength of the cellulose papers (Fig. 12). The LA-PBz coated CP cellulose paper shows an astounding increase in the value of tensile strength, which is twice than that of the value of non-coated CP cellulose paper. The non-coated CP has a tensile strength value of 10 ± 0.5 MPa, while that of poly (LA-BZ) coated CP has the value of 21 ± 0.5 MPa as highest value of tensile strength. Similarly, the non-coated WP shows the tensile strength value of 6 ± 0.5 MPa and that of poly (LA-BZ) coated WP possesses the value of 18 ± 0.5 MPa, which is nearly three times higher (Table 3). These observations ascertain that after coating of leucoaurin benzoxazines on the surface of cellulose papers, their value of tensile strength has been increased to an appreciable extent. The elastic nature of the material can be evaluated in terms of the young’s modulus value. Higher the tensile modulus value, lower is the elasticity. Here, the tensile modulus value of the cellulose paper increases after coating with LA-PBz, which indicates the enhanced impact nature of the coated samples. Hence, after coating with LA-PBz, both the values of tensile strength and young’s modulus of the cellulose paper are increased, which infer that benzoxazine coating contributes to improved strength and more stiffness behaviour of the coated paper samples.

Conclusion

Five leucoaurin based benzoxazines were synthesized using aliphatic amines with varying chain length such as butylamine, hexylamine, ethylhexylamine, dodecylamine and octadecylamine with paraformaldehyde through Mannich condensation. All the LA-BZ monomers showed curing temperature lower than 235 °C and among them LA-oda shows the lowest curing temperature of 217 °C. All the benzoxazine samples (LA-PBz) exhibit good thermal stability with maximum degradation temperature above 400 °C. Among them (LA-PBz), the poly(LA-ba shows the highest Tmax of 476 °C and char yield of 34%. The LA-PBz also possess the better hydrophobic behavior with water contact angle values above 138°. The two different kind of normal copier paper and Whatman filter paper were coated with benzoxazines and their hydrophobic behavior and strength properties were determined. Among the coated samples, the poly (LA-ha) coated copier paper sample possesses good tensile behavior with a value of 21 MPa. Similarly, the value of young’s modulus of the coated samples was also increased which indicates the increased impact property of the coated cellulose material. Data obtained from different studies, suggest that the leucoaurin based polybenzoxazine coated hydrophobic cellulose papers can be used as water proof packaging materials with improved performance and enhanced longevity. Further, the biodegradability of the polybenzoxazine coated cellulose paper will be taken up in near future to fully utilize the coated cellulose paper as a replacement of conventional cardboard packaging materials. The antimicrobial activity and the cytotoxicity assay can also be studied with a perspective to use the polybenzoxazine coated cellulose paper as an eco-friendly food packaging material with improved barrier properties. It is already known that the polybenzoxazines are inert and possess good antimicrobial behavior, however, the benzoxazine coated cellulose paper needs thorough analysis towards their bio-degradability along with antimicrobial character with respect to accepted standard specimens for comparison. The present work is considered as cutting-edge concept in the field of surface chemistry of benzoxazines to exploit their potential towards protection of packaging cellulose paper surfaces from moisture to improve their value addition and longevity.

Data availability

No datasets were generated or analysed during the current study.

References

Aldana DS, Villa ED, Hernández MDD et al (2014) Barrier properties of polylactic acid in cellulose based packages using montmorillonite as filler. Polymers (Basel) 6:2386–2403. https://doi.org/10.3390/polym6092386

Aly KI, Mohamed MG, Younis O et al (2020) Salicylaldehyde azine-functionalized polybenzoxazine: synthesis, characterization, and its nanocomposites as coatings for inhibiting the mild steel corrosion. Prog Org Coatings 138:105385. https://doi.org/10.1016/j.porgcoat.2019.105385

Chozhan CK, Chandramohan A, Alagar M (2013) Studies on thermal, mechanical, electrical, and morphological behavior of organoclay-reinforced polybenzoxazine-epoxy nanocomposites. High Perform Polym 25:1007–1021. https://doi.org/10.1177/0954008313493452

Dardeer HM, Abdel-Hakim M, Aly KI, Sayed MM (2023) Modification of conducting arylidene copolymers by formation of inclusion complexes: synthesis, characterization, and applications as highly corrosion inhibitors for mild steel. BMC Chem 17:1–13. https://doi.org/10.1186/s13065-023-00992-5

Devaraju S, Hariharan A, Balaji K, Alagar M (2021) Thermal and morphological analyses of polymer matrix composites. Elsevier Ltd

Gnanapragasam S, Krishnan S, Arumugam H et al (2018) Synthesis and characterization of a novel high-performance benzoxazine from benzaldehyde-based bisphenol. Adv Polym Technol 37:3056–3065. https://doi.org/10.1002/adv.21976

Hamdani SS, Li Z, Rabnawaz M et al (2020) Chitosan -graft-poly(dimethylsiloxane)/Zein coatings for the fabrication of environmentally friendly oil- and water-resistant paper. ACS Sustain Chem Eng 8:5147–5155. https://doi.org/10.1021/acssuschemeng.9b07397

Han M, You S, Wang Y et al (2019) Synthesis of highly thermally stable daidzein-based main-chain-type benzoxazine resins. Polymers (Basel) 11:1–11. https://doi.org/10.3390/polym11081341

Hariharan A, Prabunathan P, Kumaravel A et al (2020) Bio-based polybenzoxazine composites for oil-water separation, sound absorption and corrosion resistance applications. Polym Test 86:106443. https://doi.org/10.1016/j.polymertesting.2020.106443

Ishida H (2011) Handbook of benzoxazine resins, Chapter 1 -overview and historical background of polybenzoxazine research, Elsevier, 3–81. https://doi.org/10.1016/B978-0-444-53790-4.00046-1

Kim HD, Ishida H (2001) Study on the chemical stability of benzoxazine-based phenolic resins in carboxylic acids. J Appl Polym Sci 79:1207–1219. https://doi.org/10.1002/1097-4628(20010214)79:7%3c1207::AID-APP80%3e3.0.CO;2-3

Kumar S, Arumugham H, Roy D, Kannaiyan D (2022) Synthesis and characterization of fluorine functionalized graphene oxide dispersed quinoline-based polyimide composites having low-k and UV shielding properties. Polym Adv Technol 33:427–439. https://doi.org/10.1002/pat.5527

Lawan I, Arumugam H, Jantapanya N et al (2023) Development of cashew apple bagasse based bio-composites for high-performance applications with the concept of zero waste production. J Clean Prod 427:139270. https://doi.org/10.1016/j.jclepro.2023.139270

Liu J, Ishida H (2014) Anomalous isomeric effect on the properties of bisphenol f-based benzoxazines: toward the molecular design for higher performance. Macromolecules. https://doi.org/10.1021/ma501294y

Liu Y, Ahmed S, Sameen DE et al (2021) A review of cellulose and its derivatives in biopolymer-based for food packaging application. Trends Food Sci Technol 112:532–546. https://doi.org/10.1016/j.tifs.2021.04.016

Manuspiya H, Ishida H (2011) Polybenzoxazine-based composites for increased dielectric constant. Elsevier B.V.

Mohamed MG, Kuo SW, Mahdy A et al (2020) Bisbenzylidene cyclopentanone and cyclohexanone-functionalized polybenzoxazine nanocomposites: Synthesis, characterization, and use for corrosion protection on mild steel. Mater Today Commun 25:101418. https://doi.org/10.1016/j.mtcomm.2020.101418

Mohamed MG, Mahdy A, Obaid RJ et al (2021) Synthesis and characterization of polybenzoxazine/clay hybrid nanocomposites for UV light shielding and anti-corrosion coatings on mild steel. J Polym Res 28:1–15. https://doi.org/10.1007/s10965-021-02657-0

Mohamed Mydeen K, Arumugam H, Krishnasamy B et al (2023a) Nonylphenol-based polybenzoxazine composites: hydrophobic coating, ultra-low-k and anticorrosion applications. J Mater Sci 58:10340–10358. https://doi.org/10.1007/s10853-023-08671-5

Mohamed Mydeen K, Arumugam H, Krishnasamy B, Muthukaruppan A (2023b) Sesamol-based polybenzoxazines for ultra-low-k, high-k and hydrophobic coating applications. https://doi.org/10.1039/d3nj00531c

Nalakathu Kolanadiyil S, Azechi M, Endo T (2016) Synthesis of novel tri-benzoxazine and effect of phenolic nucleophiles on its ring-opening polymerization. J Polym Sci Part A Polym Chem 54:2811–2819. https://doi.org/10.1002/pola.28167

Patil DA, Naiker VE, Phalak GA et al (2022) Synthesis and characterization of vanillin derived bio-based benzoxazine resin for high temperature application. Pigment Resin Technol ahead-of-p.https://doi.org/10.1108/PRT-05-2022-0070

Ranganathan S, Arumugam H, Krishnasamy B et al (2022) Bio-based polybenzoxazines as an efficient coatings to protect mild steel surfaces from corrosion. High Perform Polym 34:593–603. https://doi.org/10.1177/09540083221085163

Ručigaj A, Alič B, Krajnc M, Šebenik U (2015) Curing of bisphenol A-aniline based benzoxazine using phenolic, amino and mercapto accelerators. Express Polym Lett 9:647–657. https://doi.org/10.3144/expresspolymlett.2015.60

Selvaraj V, Raghavarshini TR (2019) Building up of Prosopis juliflora carbon incorporated cardanol based polybenzoxazine composites with intensification of mechanical and corrosion resistance properties for adaptable applications. Polym Bull. https://doi.org/10.1007/s00289-019-03084-4

Shah M, Srinivasan H, Arumugam H et al (2023) Synthesis and characterisation of cycloaliphatic and aromatic amines based cardanol benzoxazines: a comparative study. J Mol Struct 1277:134802. https://doi.org/10.1016/j.molstruc.2022.134802

Sharma A, Thakur M, Bhattacharya M et al (2019) Commercial application of cellulose nano-composites – a review. Biotechnol Reports 21:e00316. https://doi.org/10.1016/j.btre.2019.e00316

Soliman AMM, Aly KI, Mohamed MG, et al (2023) Synthesis , characterization and protective efficiency of novel polybenzoxazine precursor as an anticorrosive coating for mild steel. Sci Rep 1–13. https://doi.org/10.1038/s41598-023-30364-x

Srinivasan H, Krishnan J (2023) Structure , thermal , hydrophobic , and dielectric properties of Bermuda grass ash bio-silica, SBA-15 , and rGO-reinforced bisphenol-BA-based polybenzoxazine composites. 1–20. https://doi.org/10.1002/app.54447

Sundar N, Keerthana P, Kumar SA et al (2020a) Dual purpose, bio-based polylactic acid (PLA)-polycaprolactone (PCL) blends for coated abrasive and packaging industrial coating applications. J Polym Res 27:1–18. https://doi.org/10.1007/s10965-020-02320-0

Sundar N, Kumar A, Pavithra A, Ghosh S (2020b) Studies on semi-crystalline poly lactic acid (PLA) as a hydrophobic coating material on kraft paper for imparting barrier properties in coated abrasive applications. Prog Org Coatings 145. https://doi.org/10.1016/j.porgcoat.2020.105682

Tajeddin B (2014) Cellulose-based polymers for packaging applications. Lignocellul Polym Compos Process Charact Prop 9781118773:477–498. https://doi.org/10.1002/9781118773949.ch21

Wei DW, Wei H, Gauthier AC et al (2020) Superhydrophobic modification of cellulose and cotton textiles: Methodologies and applications. J Bioresour Bioprod 5:1–15. https://doi.org/10.1016/j.jobab.2020.03.001

Yaradoddi JS, Banapurmath NR, Ganachari SV et al (2020) Biodegradable carboxymethyl cellulose based material for sustainable packaging application. Sci Rep 10:1–13. https://doi.org/10.1038/s41598-020-78912-z

Zhang S, Li W, Wang W et al (2019) Reactive superhydrophobic paper from one-step spray-coating of cellulose-based derivative. Appl Surf Sci 497:143816. https://doi.org/10.1016/j.apsusc.2019.143816

Zhou C, Xin Z (2017) Polybenzoxazine-based coatings for corrosion protection. Elsevier Inc

Acknowledgments

The authors thank the PSG Management, Secretary, Principal, PSG Institute of Technology and Applied Research, Coimbatore-641062, India for their moral and financial support.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

Harinei Srinivasan: Synthesis, Methodology, Characterization, Investigation, Writing – original draft. Hariharan Arumugam: Conceptualization, Methodology, Characterization, Investigation, Validation, Review & Editing, Supervision. Abdul Aleem M.I.: Resources, Alagar Muthukaruppan: Resources, Supervision.

Corresponding authors

Ethics declarations

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Srinivasan, H., Arumugam, H., M.I, A.A. et al. A novel leucoaurin based trifunctional polybenzoxazines coated hydrophobic cellulose paper for packaging application. Cellulose 31, 7713–7725 (2024). https://doi.org/10.1007/s10570-024-06049-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-024-06049-7