Abstract

Chemical modification of cellulose is challenging due to its low reactivity and poor solubility. Halogenation followed by displacement reactions has been demonstrated to be a valuable strategy for appending new functionalities to the anhydroglucose rings of cellulose and cellulose derivatives. In this paper, we report a simple and efficient pathway to modify the inexpensive, commercial cellulose ether, hydroxyethyl cellulose (HEC). First, methanesulfonyl chloride (MsCl) in N, N-dimethyl formamide (DMF) can selectively chlorinate the terminal primary hydroxyl groups from hydroxyethyl cellulose (HEC), thereby affording high terminal chloride content. Then, the resulting chlorinated HEC undergoes displacement reactions with various nucleophiles including azide (NaN3), amine (1-methylimidazole), and thiols (3-mercaptopropionic acid and 2-mercaptoethanol). All products were characterized by NMR and FT-IR spectroscopic methods. Exploiting this strategy, we prepared a library of HEC derivatives, including cationic and anionic derivatives, which are of great interest in various applications including as surfactants, in gas separation membranes, and as crystallization inhibitors in amorphous solid dispersions for oral drug bioavailability enhancement.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Cellulose is one of the most abundant natural polmers, playing an important role in structural reinforcement of plant cell walls (Klemm et al. 2005). It is also an attractive material for a number of reasons; these include the fact that its hydroxyl groups can be chemically functionalized, and that it is renewable, benign, biodegradable, and has high mechanical strength. It has been estimated that nature creates approximately 1012 tons of new cellulose annually (McNamara et al. 2015), and native cellulose is widely used in the paper, textile, and food industries. However, cellulose is insoluble in single organic and aqueous solvent systems, and it also cannot be processed thermally (cellulose decomposes before melting), preventing wider applications of cellulose as a sustainable material. Chemical functionalization of the three free hydroxyl groups per cellulose anhydroglucose unit (AGU) is a useful way to modify its physicochemical properties for various applications (Edgar et al. 2001). Despite the vast amounts of available cellulose and the practical applications of its derivatives, the commercial cellulose derivative market is dominated by only a few derivative families; cellulose esters (such as acetate, propionate, butyrate, succinate, and phthalate), cellulose ethers (containing methyl, ethyl, hydroxyethyl, hydroxypropyl, and carboxymethyl groups), and cellulose ether esters (Edgar et al. 2001; Fox et al. 2011; Arca et al. 2018). The narrow range of commercial cellulose derivatives is mainly attributed to the low reactivity of its hydroxyl groups, because of limited approach angles, slow diffusion, extensive hydrogen bonding, and poor solubility. As a result, harsh conditions are typically necessary to functionalize cellulose. For example, esterification of cellulose normally requires strong acids, and etherification methods require strongly alkaline conditions; such severe conditions limit the types of functional groups that can be appended. With the increasing demand for sustainable biomaterials, it is valuable to create efficient, selective chemical methods to modify cellulose and its derivatives.

Cellulose ethers have been used in a wide range of applications such as thickeners, binders, lubricants, and rheology modifiers in numerous products, including in foods, pharmaceuticals, personal care products, oilfield chemicals, construction, paper, and adhesives (Arca et al. 2018). Commercial cellulose ethers are typically water soluble (except for ethyl cellulose with high DS(Et)) and can be further modified by functionalizing the remaining ring hydroxyl groups or newly introduced hydroxyl groups (for example, termini of oligo(hydroxyethyl) or oligo(hydroxypropyl) groups of HEC or HPC, respectively) (Wang et al. 2019; Nichols et al. 2020). Commercially, cellulose ethers can be esterified to afford cellulose ether esters, thereby tuning the hydrophilicity of the polymer for coating applications. There are extensive reports of chemical modifications of terminal hydroxyl groups of HEC and HPC by further etherification and esterification (Abbas et al. 2017). For example, cationic HEC derivatives bearing quaternary ammonium groups can be prepared by etherification of HEC and have been demonstrated to be useful as surfactants in cosmetics (Svensson et al. 2003; Zhou et al. 2004). The Edgar group has applied various chemical methods including olefin cross-metathesis to append terminal carboxylic acid, ester, and amide groups to cellulose ethers for amorphous solid dispersion (ASD) applications (Dong and Edgar 2015; Dong et al. 2016a, b, 2017b). Through this strategy, a wide range of cellulose ether derivatives with enhanced ASD performance was prepared, and their structure-property relationships were thoroughly investigated, illustrating the potential of applying new chemistries to cellulose ether modification (Dong et al. 2017a).

One of the most common strategies for modifying cellulose is to convert the primary C-6 hydroxyl groups to good leaving groups such as tosylate, mesylate, chloride, bromide, or iodide, followed by a nucleophilic displacement reaction (Heinze and Liebert 2001; Petzold-Welcke et al. 2009). Through this strategy, a variety of cellulose derivatives containing azides, amines, thiols, and heterocycles has been prepared (Aoki et al. 1996; Berlin et al. 2000; Liu and Baumann 2002; Knaus et al. 2003; Liebert et al. 2006; Fox and Edgar 2012; Liu et al. 2016). While this strategy is well established for modifications of native cellulose, we noticed that few reports exist that describe using these strategies in cellulose ether functionalization. Eissa et al. applied Furuhata bromination (PPh3 and NBS) to HEC to successfully convert the terminal hydroxyl groups on the HEC side chain to bromide, then followed with azide displacement of the bromide and a subsequent azide-alkyne click reaction (Eissa et al. 2012). Joubert (Joubert et al. 2015) synthesized azide-substituted HEC in a similar fashion, creating a substrate that can undergo a click reaction to graft poly(ionic liquid) to the HEC backbone. In both cases, Furuhata bromination was employed and azide was the only nucleophile used in the subsequent displacement reaction (Furuhata et al. 1992). To our knowledge, tosylate and chloride, two other leaving groups frequently used in polysaccharide chemistry, have never been introduced to functionalize HEC. Each leaving group has its own advantages and disadvantages. Tosylate is a commonly used leaving group in cellulose chemistry due to its availability, hydrolytic stability, wide range of compatible solvents for tosylation (including simple organic solvents (Heinze et al. 2006), complex organic solvents (Liu and Baumann 2005), NaOH/urea aqueous solutions (Schmidt et al. 2014), and ionic liquids (Gericke et al. 2009), depending on the nature and DS of other substituents), and well-understood capability as a leaving group. However, in many cases polysaccharide alcohol tosylation is not completely regioselective, and side reactions like undesired chlorination may also complicate the product mixture (McCormick et al. 1990). Bromide can frequently be introduced with beautiful chemo- and regioselectivity by reaction with PPh3 and NBS; however, the by-product triphenylphosphine oxide (PPh3=O) can be quite challenging to remove quantitatively from the products (Fox and Edgar 2012; Zhang and Edgar 2015). Inexpensive chlorination reagents are available, but chloride is, typically, inferior (e.g. vs. bromide) as a leaving group. Thus, we wished to systematically investigate modification of HEC by introducing chloride leaving groups, then evaluate the ability to displace chloride with various nucleophiles to afford derivatives of interest.

Recently, our lab reported that methanesulfonyl chloride (MsCl) can chemo- and regioselectively react with primary hydroxyl groups on cellulose esters such as low DS cellulose acetate (DS(Ac) 1.8) (Gao et al. 2018), creating 6-chloro-6-deoxy derivatives without disturbing the ester moieties. The chlorinated cellulose esters could then undergo nucleophilic displacement reactions with a wide variety of nucleophiles, including amines, thiols, and azide. Chloride displacement is by an SN2 reaction mechanism, which aids regioselectivity, and high displacement conversion was observed. This chlorination method displayed many advantages including ease of by-product removal, low-cost reagents, and reactivity of the 6-chloro substituents that was sufficient for many purposes. This chlorination process also holds potential for functionalizing nanocellulose crystals and nanofibers. HEC contains a high content of primary hydroxyl groups, equal to the sum of the unreacted C-6 OH groups and the DS(HE), since every oligo(hydroxyethyl) chain terminates with a primary OH group. Moreover, compared even to primary 6-hydroxyl groups on the cellulose backbone of cellulose esters, the oligo(hydroxyethyl) terminal hydroxyl groups of HEC should be more reactive due to their wider approach angles. However, the balance between the competing factors of poorer chloride leaving group versus wider approach angles remains unclear and largely unexplored. We wished to investigate whether MsCl/DMF can selectively substitute chloride for the primary terminal hydroxyl groups of HEC, and whether the putative chlorinated HEC would be a useful substrate for further nucleophilic substitution reactions to afford HEC derivatives.

Thus, we hypothesize that methanesulfonyl chloride can selectively chlorinate the HEC terminal hydroxyl groups, replacing the terminal –OH with –Cl. We further hypothesize that the introduced chloride can be displaced by different nucleophiles, creating useful HEC derivatives. If reduced to practice, this two-step sequence will be a powerful strategy for hydroxyethyl polysaccharide functionalization. Herein, we report our attempts to prove or refute these hypotheses.

Experimental

Materials

2-Hydroxyethylcellulose (HEC, MS = 2.5, DS = 1.5 (data from manufacturer; it is very difficult to determine these values for HEC spectroscopically due to overlap of methylenes next to ether or hydroxyl oxygen with protons of backbone region), average Mw ~ 90,000), methanesulfonyl chloride (MsCl, 99.7+%), sodium azide, 1-methylimidazole (99+%), sodium iodide, 4-dimethylaminopyridine (99%), N, N-diisopropylethylamine (98+%), and thioacetic acid were purchased from Sigma Aldrich and used as received. Acetone and ethanol were from Fisher Scientific and used as received. Dimethylformamide (DMF, Fisher) and dimethyl sulfoxide (DMSO, Fisher) were kept over 4 Å molecular sieves and stored under dry N2 until use. Regenerated cellulose dialysis tubing (Fisher, 3500 g/mol MWCO) was used as received.

Measurements

1H and 13C NMR spectra were obtained on a Bruker Avance II 500 MHz spectrometer in DMSO-d6 or D2O at room temperature (RT) with 64 scans or 15,000 scans, respectively. Chemical shifts are reported relative to the solvent peaks. FT-IR spectra were acquired on a Nicolet 8700 instrument with 128 scans and 4 cm−1 resolution. All yields are reported on a molar basis, based on the average product repeat unit molecular weight as determined based on analytical results. Exemplary equations used to evaluate DS(Cl), DS(Mesyl) and DS(N3) are provided below; all other elemental analysis equations can be viewed in the Supplementary Information.

Regioselective chlorination of hydroxyethyl cellulose

In a 100 mL round-bottom (RB) flask, HEC (1.0 g, 3.6 mmol AGU, 5.4 mmol terminal primary OH) was dissolved in 40 mL of anhydrous DMF under mechanical stirring overnight until a homogeneous solution was obtained. MsCl (4.3 mL, 10 equiv. per terminal primary OH) was added dropwise to the solution. The reaction mixture was kept at 75 °C for 4 h under N2 as the solution turned from colorless to yellow. The solution was cooled to RT and slowly poured into 400 mL of deionized water. The crude product was isolated by filtration, extensively washed with water and ethanol, and vacuum dried overnight at 40 °C to yield ω-(2-chloroethyl)-hydroxyethylcellulose (HEC-Cl). 13C NMR (500 MHz, DMSO-d6): 43.58 (–O–CH2– CH2–Cl), 60.22 (C–6–O–), 69.69, 70.56 (–O–CH2–CH2–O–), 71.43–81.44 (C2, C3, C4 and C5), 101.89 (C1), and 161.30 (O–(C=O)–H). Elemental analysis results: %C 42.47, %H 5.73, %Cl 19.24, %S 0.4, and %N not found (below the detection limit). DS calculated by EA: DS(Cl) = 1.68. Maximum possible DS(Mesyl) calculated by EA (assuming all S comes from mesyl groups): DS(Ms) = 0.04. Yield: 921 mg (83.6%).

Synthesis of ω-(2-azidoethyl)-hydroxyethyl cellulose (HEC-N3)

HEC-Cl (0.5 g, 1.7 mmol AGU, 2.5 mmol Cl) was dissolved in anhydrous DMSO (20 mL) in a 100 mL RB flask. To the solution was added NaN3 (813 mg, 5 equiv. per Cl). The reaction mixture was heated to 75 °C and stirred 24 h under N2. The cooled solution was poured into deionized water (200 mL), filtered, and the solid product was washed with water. The product was dried in a vacuum oven overnight at 40 °C to yield HEC-N3. 13C NMR (500 MHz, DMSO-d6): 50.01 (–O–CH2– CH2–N3), 60.22 (C–6–O–), 69.30, 69.72, 69.82 (–O–CH2–CH2–O–), 70.87–82.06 (C2, C3, C4 and C5), and 100.26–103.58 (C1). Elemental analysis results: %C 41.09, %H 5.67, %N 21.03, %Cl 1.25, and %S 0.4. DS calculated by EA: DS(N3) = 1.60, DS(Cl) = 0.11. Yield: 416 mg (80.6%).

Synthesis of ω-(2-acetamidoethyl)-hydroxyethyl cellulose (HEC-NHAc)

In a 50 mL RB flask, HEC-N3 (200 mg, 0.65 mmol AGU, 0.97 mmol N3) was dissolved in anhydrous DMF (10 mL). Thioacetic acid (0.68 mL, 10 equiv. per N3) and 2,6-lutidine (1.12 mL, 10 equiv. per N3) were added separately to the solution. The solution was stirred at 65 °C for 24 h, then cooled and dialyzed against ethanol for 3 days, against water for another 3 days, then freeze-dried to yield HEC-NHAc. 1H NMR (500 MHz, DMSO-d6): 1.75–1.95 (NH–(C=O)–CH3), and 2.80–5.11 (cellulose backbone and –O–CH2–CH2–O–); 13C NMR (500 MHz, DMSO-d6): 22.58 (NH–(C=O)–CH3), 60.30 (C–6–O–), 69.17, 69.59, 69.75 (–O–CH2–CH2–O–), 70.90–81.80 (C2, C3, C4 and C5), 100.45–104.02 (C1), and 169.35 (NH–(C=O)–CH3). Yield: 124 mg (57.5%).

Synthesis of ω-(2-(1-methyl-3-imidazolio)ethyl)-hydroxyethyl cellulose (HEC-MeIM)

HEC-Cl (200 mg, 0.67 mmol AGU, 1.00 mmol Cl) was dissolved in anhydrous DMSO (10 mL) in a 50 mL RB flask. NaI (450 mg, 3 equiv. per Cl) and 1-methylimidazole (3.2 mL, 40 equiv. per Cl) were slowly added to the flask. The solution was stirred at 80 °C for 48 h under N2. The product was collected by dialysis of the cooled reaction mixture against ethanol for 3 days, then against 0.9% sodium chloride solution for 3 days, followed by freeze-drying to yield HEC-MeIM. 1H NMR (500 MHz, DMSO-d6): 3.01–4.58 (cellulose backbone, –O–CH2–CH2–O–, and N–CH3), and 7.33–7.61 (N–CH=CH–N–CH3, N–CH=CH–N–CH3, and N=CH–N–CH3); 13C NMR (500 MHz, DMSO-d6): 35.89 (N–CH3), 49.00 (–O–CH2–CH2–N), 60.34 (C–6–O–), 68.45, 69.59 (–O–CH2–CH2–O–), 70.95–81.50 (C2, C3, C4 and C5), 101.96 (C1), 122.56, 123.46 (N–CH=CH–N–CH3 and N–CH=CH–N–CH3), and 136.43 (N=CH–N–CH3). Elemental analysis results: %C 37.08, %H 5.09, %N 7.87. DS calculated by EA: DS(MeIM) ~ 1. Yield: 105 mg (42.5%).

Synthesis of ω-(2-thioethyl) hydroxyethyl cellulose (HEC-ME)

In a 50 mL RB flask, HEC-Cl (200 mg, 0.67 mmol AGU, 1.00 mmol Cl) was dissolved in anhydrous DMSO (10 mL). NaI (450 mg, 3 equiv. per Cl), N, N-diisopropylethylamine (3.5 mL, 20 equiv. per Cl), and 2-mercaptoethanol (1.4 mL, 20 equiv. per Cl) were added to the flask. The solution was stirred at 80 °C for 24 h under N2. The product was collected by dialysis of the cooled reaction mixture against ethanol for 3 days, then against water for 3 days, then freeze-dried to yield HEC-ME. 1H NMR (500 MHz, DMSO-d6): 2.58, 2.66 (S–CH2–CH2–OH), and 2.98–4.91 (cellulose backbone, –O–CH2–CH2–O–, and –S–CH2–CH2–OH); 13C NMR (500 MHz, DMSO–d6): 30.94 (–S–CH2–CH2–OH), 34.32 (–O–CH2–CH2–S–), 43.61 (–O–CH2–CH2–Cl), 60.25 (C–6–O–), 61.03 (–S–CH2–CH2–OH), 69.81, 70.35,70.58 (–O–CH2–CH2–O–), 71.77–81.65 (C2, C3, C4 and C5), and 102.32 (C1). DS calculated by 1H NMR: DS (ME) is between ~ 0.43–0.48 (see SI). Yield: 148 mg (61.4%).

Synthesis of ω-(2-carboxyethylthio) hydroxyethyl cellulose (HEC-MPA)

In a 50 mL RB flask, HEC-Cl (200 mg, 0.67 mmol AGU, 1.00 mmol Cl) was dissolved in anhydrous DMSO (10 mL). NaI (450 mg, 3 equiv. per Cl), N, N-diisopropylethylamine (3.5 mL, 20 equiv. per Cl), and 3-mercaptopropionic acid (1.8 mL, 20 equiv. per Cl) were added to the flask. The solution was stirred at 80 °C for 24 h under N2. The cooled reaction mixture was added to deionized water (100 mL) to precipitate the product, and the resulting slurry was dialyzed against water to remove impurities. The product was collected by filtration and dried under vacuum at 40 °C to yield HEC-MPA. 1H NMR (500 MHz, DMSO-d6): 2.60, 2.71, 2.87 (S–CH2–CH2–COOH and S–CH2–CH2–COOH), and 3.06–4.60 (cellulose backbone and –O–CH2–CH2–O–); 13C NMR (500 MHz, DMSO-d6): 33.15, 33.40, 33.84, 34.00 (–S–CH2–CH2–COOH, –S–CH2–CH2–COOH, –O–CH2–CH2–S–), 44.03 (–O–CH2–CH2–Cl), 64.02 (C–6–O–), 68.68, 70.23,71.01 (–O–CH2–CH2–O–), 72.73–82.26 (C2, C3, C4 and C5), 102.34 (C1), and 171.66, 173.15 (–S–CH2–CH2–COOH). Elemental analysis results: %C 40.45, %H 5.56, %Cl 3.74, and %S 11.85. DS calculated by EA: DS(MPA) ~ 1.65. Yield: 124 mg (46.0%).

Results and discussion

In this work, we selected HEC with MS = 2.5 and DS = 1.5 as the starting material because of its commercial availability, high content of terminal, primary hydroxyl groups, and adequate solubility in organic solvents (Scheme 1).

Selective chlorination of HEC by MsCl

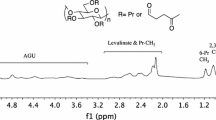

Methanesulfonyl chloride in DMF has been shown previously to successfully substitute chlorine for hydroxyl groups of polysaccharides, polysaccharide derivatives, and carbohydrates (Evans et al. 1968; Cimecioglu et al. 1994; Ren et al. 2012). Our lab has also previously employed MsCl/DMF to selectively chlorinate the remaining primary hydroxyl groups of a commercial cellulose acetate, CA320S (DS(Ac) ca. 1.8) (Gao et al. 2018). Herein we attempted to replace the terminal primary hydroxyl groups of the HEC oligo(hydroxyethyl) substituents with chlorides under similar conditions, that is using MsCl in DMF as chlorination agent (75 °C, 4 h). We obtained a product in whose 13C NMR spectrum (Fig. 1) we were delighted to observe a new C–Cl resonance at 43.6 ppm, consistent with chloride-bearing primary carbons as previously reported (Cimecioglu et al. 1994; Gao et al. 2018), indicating successful replacement of HE ω-hydroxy groups by chloride. In the 13C NMR spectrum, the HEC side chain methylene groups display higher signal-to-noise ratio than the cellulose backbone resonances, which is attributed to higher mobility of the flexible oligo(hydroxyethyl) side chains than the rigid cellulose backbone. It is worth noting that the C–Cl signal in the 13C NMR spectrum also possesses a high signal-to-noise ratio, similar to those of the HEC side chain methylene groups, suggesting that the C–Cl may have an environment similar to that of the HEC side chain. This is consistent with the hypothesis that most or all of the chlorination occurred on the oligo(hydroxyethyl) hydroxy termini. Elemental analysis for chlorine afforded a calculated DS (Cl) value of 1.68. Considering that the DS(HE) of the starting ether (and thus of ω-OH groups) is ca. 1.5, and that the DS(6-OH) of starting HEC must be quite low (reaction with ethylene oxide at C6 being favored) (Mischnick et al. 2005; Mischnick and Momcilovic 2010), this elemental analysis result suggests that essentially all of the terminal oligo(hydroxyethyl) hydroxyls have been successfully replaced by chloride. Elemental analysis results also provide useful evidence about the chemoselectivity of this chlorination reaction. Sulfur content was 0.4% and nitrogen was not found, suggesting that no more than a low DS (Mesyl) (≤ 0.04) is appended to the polymer, implying selectivity of chlorination versus mesylation ≥ 43:1 (DS chloride 1.68 vs. DS mesylate 0.038). The elemental analysis results also further confirm that the product contains no DMF by-products, either entrapped or appended (McCormick et al. 1990). No mesylate resonances were observed in the product 13C (–OSO2CH3 around 38 ppm) or 1H (–OSO2CH3 around 3–4 ppm, Figure S1) NMR spectra, confirming the low content or absence of mesylate groups. Small resonances attributed to formates were observed in the 13C (O–(C=O)–H at 163 ppm) and 1H (O–(C=O)–H at 8.1–8.4 ppm) NMR spectra. Small amounts of formates have been observed in many other MsCl chlorination examples and are consistent with the reaction mechanism (Scheme S1) (Sato et al. 1990; McCormick et al. 1990). Based on this mechanism, we propose that the regioselectivity of the HEC chlorination arises from the large difference in available approach angles between the terminal hydroxyl groups of the HEC side chains and the rigid cellulose chain hydroxy groups, particularly since the last step of the chlorination mechanism involves an SN2 displacement by chloride. While the chlorinated HEC is no longer soluble in water, it does have good solubility in polar aprotic solvents like DMF, DMSO, and DMAc.

Azide displacement of chloride and subsequent azide reduction (syntheses of HEC-N3 and HEC-NHAc)

Having successfully synthesized HEC-Cl, we explored its subsequent utilization to prepare various HEC derivatives by nucleophilic displacement reactions, simultaneously acquiring more evidence about the regioselectivity of this chlorination reaction. We began with the strong nucleophile azide. Numerous reports have indicated that for polysaccharides containing leaving groups such as bromide (Matsui et al. 2005), chloride (Cimecioglu et al. 1994), and tosylate (Liebert et al. 2006), the leaving group can be quantitatively displaced by azide at C6. Thus, azide would be an excellent nucleophile for a first test of the reactivity of the appended chloride groups. Residual chloride after reaction with azide would indicate that replacement of secondary OH groups (C2, C3) may have occurred to some extent, since SN2 displacement of these ring secondary chlorides should be very difficult. Furthermore, azide has been demonstrated to be a versatile functional group in polysaccharide chemistry; it can be reduced to amine (Zhang and Edgar 2015), amide (Zhang and Edgar 2014), or imine groups (Zhang et al. 2017; Liu et al. 2018), or can serve as a partner in Huisgen click reactions (Liebert et al. 2006; Meng and Edgar 2016; Codera et al. 2016). HEC-Cl was treated with sodium azide (DMSO, 80 °C, 24 h), affording HEC-N3, as confirmed by FT-IR, 13C NMR, and elemental analysis. In the FT-IR spectrum (Fig. 2a), a characteristic azide signal appeared at 2100 cm−1, indicating successful azide incorporation. By 13C NMR (Fig. 3), a new resonance at 50 ppm was assigned as the azide-bearing primary carbon, and the chemical shift was consistent with azide-bearing primary carbon in previous reports (Fox and Edgar 2012). Meanwhile, the former chloride-bearing primary carbon signal at 44 ppm was absent, consistent with high displacement conversion. Elemental analysis again provided useful information. DS (N3) and DS (Cl) were calculated to be 1.61 and 0.11 respectively, indicating high displacement conversion (around 95%). The high conversion suggests that chlorination is predominantly regioselective for the terminal, primary hydroxy groups, since chlorides at C2 and C3 are unlikely to be displaced by azide and, if present, should be detected by elemental analysis. The small amount of chloride observed by elemental analysis could have been the result of incomplete azide substitution, or alternatively of partial chlorination at the secondary hydroxyl groups. In our previous work with cellulose acetate chlorination by MsCl/DMF, we observed no replacement of secondary OH groups by Cl. Although azide is a strong nucleophile, high but incomplete azide displacement conversion is frequently observed when the DS of the leaving group is high (Liu and Baumann 2002). Thus, we postulate that the remaining chloride in the HEC-N3 product arises mostly from the unreacted chloride connected to the primary carbon on the HEC side chain, rather than from C2/C3 appended chlorides.

With HEC-N3 in hand, we explored useful azide transformations. Amido and amino polysaccharides (e.g. chitin, chitosan, and glycosaminoglycans (GAGs) are important natural polysaccharides, some of which have great complexity, biological activity, and are rich information carriers (Kumar 2000; Afratis et al. 2012). Recently, our lab demonstrated that thioacetic acid (AcSH) can selectively reduce azide to acetamide in polysaccharide chemistry, being of particular value for polysaccharides that have high water affinity (Gao et al. 2019; Gao and Edgar 2019). In this work, we reduced HEC-N3 to HEC-NHAc using thioacetic acid under conditions similar to those that proved effective with GAG analogs (DMF, 65 °C, 24 h, 2,6-lutidine as catalyst). In the product FT-IR spectrum (Fig. 2b), the amide carbonyl at 1650 cm−1 and N–H bend at 1560 cm−1 supported successful azide reduction to acetamide, and the disappearance of the azide absorption at 2100 cm−1 was consistent with complete conversion. The new peak around 3100 cm−1 can be attributed to N–H or C–H stretching. Increased peak intensity was observed around 1200–1500 cm−1 versus that of the starting material, which could result from C–H bending and C–N stretching due to formation of acetamide groups. Formation of the acetamide was also confirmed by the 1H and 13C NMR spectra. In the 13C NMR spectrum (Fig. 4), the previous primary carbon-bearing azide signal at 50 ppm disappeared, while the acetamide carbonyl resonance appeared at 169 ppm as well as an amide methyl at 23 ppm. A new 1H resonance (Figure S2) appeared in the range of 1.8–2.0 ppm, assigned to acetamido methyl groups. All observations are consistent with those of polysaccharide acetamide moieties described in previous publications (Zhang and Edgar 2014, 2015; Gao et al. 2019). Selective reduction to amine is of course also highly useful; thus, we also attempted to reduce the azide to amine using dithiothreitol or sodium borohydride, as has been successful for polysaccharide C6–N3 groups (Zhang and Edgar 2015; Gao et al. 2019). The product FT-IR spectrum showed the complete disappearance of the azide group. However, the obtained product was insoluble in common solvents, making NMR characterization of the amine infeasible. As a result, we do not yet have sufficient evidence to confirm or refute amine formation.

Reaction with amines (synthesis of HEC-MeIM)

After demonstrating successful displacement of chloride in HEC-Cl by the strong nucleophile azide, we then explored the reaction of HEC-Cl with a weaker, amine-based nucleophile. The aromatic amine 1-methylimidazole was chosen as a model, and to provide proof of concept for preparation of cationic HEC derivatives. We selected conditions similar to those that had previously proved useful for reacting 6-bromo-6-deoxycellulose esters with aromatic amines to prepare cationic derivatives, reacting HEC-Cl with 1-methylimidazole in DMSO (80 °C, 48 h) (Liu et al. 2016; Liu and Edgar 2017). We hypothesized that the chloride on HEC-Cl would be adequately reactive towards SN2 displacement by imidazole, even given its inferiority to bromide as a leaving group. However, to our surprise, we obtained a water insoluble product and no 1-methylimidazolium moiety was observed in the product 1H and 13C NMR spectra. This indicated that the advantage afforded by wider approach angles could not compensate for the relatively poor chloride leaving group and the inferior nucleophilicity of 1-methylimidazole relative to sodium azide. To improve reaction conversion, sodium iodide (NaI) was added to generate HEC-I in situ, since iodide is a better leaving group than chloride (Evano et al. 2018), following the Curtin-Hammett principle (Pollak and Curtin 1950; Winstein and Holness 1955). After addition of 3 equivalents of NaI per Cl, we were encouraged to obtain a water-soluble polymer. The product showed a new resonance at 7.3–7.6 ppm (1H NMR, Figure S3) from the aromatic protons of the 1-methylimidazolium moiety and a new sharp peak at 4.3 ppm from the N-methyl group, indicating successful incorporation of 1-methylimidazolium. A new 13C NMR resonance (Fig. 5) appeared at 50 ppm and was assigned to the imidazole-substituted ω-methylene group, while resonances at 122 ppm and 136 ppm were assigned to the imidazolium aromatic carbons. Due to NMR peak overlap, we had to calculate the DS (MeIM) by elemental analysis and obtained a DS value of approximately 1. The elemental analysis results suggested that a conversion of ~ 60% was observed for the chloride displacement reaction by 1-methylimidazole in the presence of iodide, significantly improving the low reactivity of 1-methylimidazole toward displacement of HEC-Cl. Cationic polysaccharide derivatives have been widely applied as surfactants (Wang and Ye 2010), in gas separation membranes (Li et al. 2019), and as vehicles for drug (DNA/RNA) and peptide delivery (Bernkop-Schnürch and Dünnhaupt 2012). Cationic HEC-MeIM also has promising potential, for example, in gas separation membranes (Nikolaeva et al. 2021).

Reaction with thiols (syntheses of HEC-ME and HEC-MPA)

Displacement reactions using reactive and nucleophilic thiols have afforded useful cellulose derivatives, including some of interest for amorphous solid dispersion (Dong et al. 2017b) and for wastewater treatment applications (Aoki et al. 1999). We chose the neutral 2-mercaptoethanol and the negatively charged 3-mercaptopropionic acid as models to study chloride displacement from HEC-Cl by thiols. HEC-Cl was first treated with 2-mercaptoethanol in the presence of N, N-diisopropylethylamine (DIPEA) to deprotonate the thiol (DMSO, 80 °C, 24 h); we employed a hindered amine to minimize competition between amine and thiolate nucleophiles. In the product 13C NMR spectrum (Fig. 6), new resonances appeared at 34 ppm, assigned to the sulfur bearing primary carbon, and at 31 ppm and 61 ppm, assigned to the two methylene groups from the thioether moiety. The C–Cl peak was still observed at 45 ppm, indicating incomplete chloride displacement. Appearance of resonances attributed to methylene groups in the range of 2.6–2.7 ppm in the 1H NMR spectrum confirmed the displacement reaction (Figure S4). Although HEC-ME has terminal ω-hydroxy groups as does HEC, HEC-ME is surprisingly insoluble in water, perhaps partly as a result of the incomplete chloride displacement.

To assess efficiency of appending a model anionic thioether substituent, HEC-Cl was then treated with 3-mercaptopropionic acid under similar conditions (DIPEA, NaI, DMSO, 80 °C, 24 h). Two new product 1H NMR resonances (Figure S5) between 2.6 and 2.9 ppm were assigned as the thioether methylene groups. In the product 13C NMR spectrum (Fig. 7), a new resonance at 33–34 ppm was assigned to overlapping S-bound HEC-terminal, primary carbon and two methylene groups, while resonances at 172 and 173 ppm were assigned to carboxyl carbonyl groups. A resonance for unreacted CH2–Cl again appeared at 43 ppm, illustrating incomplete chloride displacement by the thiol even in the presence of NaI. The DS (MPA) was calculated to be ca. 1.65 by elemental analysis, suggesting a high chloride displacement conversion by the 2-carboxyethylthio group. Cellulose ether derivatives with terminal carboxyl groups have intriguing potential for application in amorphous solid dispersions (Mosquera-Giraldo et al. 2016). This example of successfully preparing a HEC derivative with a terminal carboxyl group provides an efficient, economical synthetic strategy for preparation of HEC derivatives with potential in ASD applications and will enable systematic study of structure-property relationships, perhaps successfully competing with the olefin cross-metathesis strategy (which requires a costly ruthenium complex catalyst) (Dong et al. 2017a).

Conclusions

We have successfully developed a facile, efficient method for functionalizing hydroxyethyl cellulose by selective chlorination and explored the utility of the resulting HEC-Cl in subsequent nucleophilic displacement reactions. HEC can be selectively chlorinated by MsCl/DMF at the terminal, primary hydroxy groups with negligible side reactions (mesylation, formate group formation) and high conversion (DS (Cl) 1.68). We also illustrated the utility of the resulting chlorinated HEC for appending new functionalities, thereby synthesizing various HEC derivatives with defined structures. HEC-Cl can undergo displacement with strong nucleophiles (azide) with high conversion (95%), affording a useful precursor for click reactions or azide reduction. To demonstrate the value of HEC azides as important intermediates, HEC-N3 was reduced to HEC-NHAc using thioacetic acid (AcSH), creating intriguing amido HEC derivatives. We also demonstrated reactions of HEC-Cl with weaker nucleophiles like amines and thiols, with displacement conversions of over 60% in all such cases examined. HEC-Cl has higher DS(Cl) than the halogenated cellulose esters of the previous work; complete conversion of these higher DS halides could be expected to present a greater challenge. We discovered that adding NaI significantly improved reaction conversion by generating a (probably low) concentration of the better leaving group iodide. By partial conversion to the ω-iodide in situ, we prepared amine and thiol substituted HEC derivatives, including cationic (HEC-MeIM) and anionic (HEC-MPA) HEC derivatives. We are continuing to explore optimized reaction conditions to further improve HEC-Cl displacement conversions.

Chlorination followed by nucleophilic displacement has been demonstrated to be an efficient route to functionalized HEC derivatives. This strategy provides access to many HEC derivatives which are otherwise challenging to synthesize and are potentially useful in practical applications. For example, cationic HEC derivatives may be useful as surfactants or gas separation membranes, while HEC anionic derivatives have potential in amorphous solid dispersions for oral drug delivery. Applications of the obtained HEC derivatives, including in gas separation and amorphous solid dispersions, are currently being investigated in our laboratory. Reaction of other polysaccharides with ethylene oxide also provides hydroxyethyl derivatives (for example, hydroxyethyl starch that is an important plasma extender in traumatic injuries (Reinhart and Hartog 2012), so that broader application of this strategy should prove useful.

Data availability

Data not already included in the manuscript and supplementary material is available from the authors by request.

References

Abbas K, Amin M, Hussain MA et al (2017) Design, characterization and pharmaceutical/pharmacological applications of ibuprofen conjugates based on hydroxyethylcellulose. RSC Adv 7:50672–50679. https://doi.org/10.1039/c7ra08502h

Afratis N, Gialeli C, Nikitovic D et al (2012) Glycosaminoglycans: key players in cancer cell biology and treatment. FEBS J 279:1177–1197. https://doi.org/10.1111/j.1742-4658.2012.08529.x

Aoki N, Furuhata K-I, Saegusa Y et al (1996) Reaction of 6-bromo-6-deoxycellulose with thiols in lithium bromide-N,N-dimethylacetamide. J Appl Polym Sci 61:1173–1185. https://doi.org/10.1002/(SICI)1097-4628(19960815)61:7%3c1173::AID-APP13%3e3.0.CO;2-Z

Aoki N, Fukushima K, Kurakata H et al (1999) 6-Deoxy-6-mercaptocellulose and its S-substituted derivatives as sorbents for metal ions. React Funct Polym 42:223–233. https://doi.org/10.1016/S1381-5148(98)00076-5

Arca HC, Mosquera-Giraldo LI, Bi V et al (2018) Pharmaceutical applications of cellulose ethers and cellulose ether Esters. Biomacromol 19:2351–2376. https://doi.org/10.1021/acs.biomac.8b00517

Berlin P, Klemm D, Tiller J, Rieseler R (2000) A novel soluble aminocellulose derivative type: its transparent film-forming properties and its efficient coupling with enzyme proteins for biosensors. Macromol Chem Phys 201:2070–2082. https://doi.org/10.1002/1521-3935(20001001)201:15%3c2070. (:AID-MACP2070>3.0.CO;2-E)

Bernkop-Schnürch A, Dünnhaupt S (2012) Chitosan-based drug delivery systems. Eur J Pharm Biopharm 81:463–469. https://doi.org/10.1016/J.EJPB.2012.04.007

Cimecioglu AL, Ball DH, Kaplan DL, Huang SH (1994) Preparation of amylose derivatives selectively modified at c-6. 6-amino-6-deoxyamylose. Macromolecules 27:2917–2922. https://doi.org/10.1021/ma00089a004

Codera V, Edgar KJ, Faijes M, Planas A (2016) Functionalized celluloses with regular substitution pattern by glycosynthase-catalyzed polymerization. Biomacromol 17:1272–1279. https://doi.org/10.1021/acs.biomac.5b01453

Dong Y, Edgar KJ (2015) Imparting functional variety to cellulose ethers via olefin cross-metathesis. Polym Chem 6:3816–3827

Dong Y, Mosquera-Giraldo LI, Taylor LS, Edgar KJ (2016a) Amphiphilic cellulose ethers designed for amorphous solid dispersion via olefin cross-metathesis. Biomacromol 17:454–465. https://doi.org/10.1021/acs.biomac.5b01336

Dong Y, Mosquera-Giraldo LI, Troutman J et al (2016b) Amphiphilic hydroxyalkyl cellulose derivatives for amorphous solid dispersion prepared by olefin cross-metathesis. Polym Chem 7:4953–4963. https://doi.org/10.1039/c6py00960c

Dong Y, Matson JB, Edgar KJ (2017) Olefin cross-metathesis in polymer and polysaccharide chemistry: a review. Biomacromol 18:1661–1676. https://doi.org/10.1021/acs.biomac.7b00364

Dong Y, Mosquera-Giraldo LI, Taylor LS, Edgar KJ (2017b) Tandem modification of amphiphilic cellulose ethers for amorphous solid dispersion via olefin cross-metathesis and thiol-Michael addition. Polym Chem 8:3129–3139. https://doi.org/10.1039/C7PY00228A

Edgar KJ, Buchanan CM, Debenham JS et al (2001) Advances in cellulose ester performance and application. Prog Polym Sci 26:1605–1688. https://doi.org/10.1016/S0079-6700(01)00027-2

Eissa AM, Khosravi E, Cimecioglu AL (2012) A versatile method for functionalization and grafting of 2-hydroxyethyl cellulose (HEC) via click chemistry. Carbohydr Polym 90:859–869. https://doi.org/10.1016/j.carbpol.2012.06.012

Evano G, Nitelet A, Thilmany P, Dewez DF (2018) Metal-mediated halogen exchange in aryl and vinyl halides: a review. Front Chem 6:114

Evans ME, Long L, Parrish FW (1968) Reaction of carbohydrates with methylsulfonyl chloride in N,N-dimethylformamide. Preparation of some methyl 6-chloro-6-deoxyglycosides. J Org Chem 33:1074–1076. https://doi.org/10.1021/jo01267a028

Fox SC, Edgar KJ (2012) Staudinger reduction chemistry of cellulose: synthesis of selectively O-acylated 6-amino-6-deoxy-cellulose. Biomacromolecules 13:992–1001. https://doi.org/10.1021/bm2017004

Fox SC, Li B, Xu D, Edgar KJ (2011) Regioselective esterification and etherification of cellulose: a review. Biomacromol 12:1956–1972. https://doi.org/10.1021/bm200260d

Furuhata K, Koganei K, Chang H-S et al (1992) Dissolution of cellulose in lithium bromide-organic solvent systems and homogeneous bromination of cellulose with N-bromosuccinimide-triphenylphosphine in lithium bromide-N,N-dimethylacetamide. Carbohydr Res 230:165–177. https://doi.org/10.1016/S0008-6215(00)90519-6

Gao C, Edgar KJ (2019) Efficient synthesis of glycosaminoglycan analogs. Biomacromol 20:608–617. https://doi.org/10.1021/acs.biomac.8b01150

Gao C, Liu S, Edgar KJ (2018) Regioselective chlorination of cellulose esters by methanesulfonyl chloride. Carbohydr Polym 193:108–118. https://doi.org/10.1016/J.CARBPOL.2018.03.093

Gao C, Fisher ZB, Edgar KJ (2019) Azide reduction by DTT or thioacetic acid provides access to amino and amido polysaccharides. Cellul 26:445–462. https://doi.org/10.1007/s10570-018-2195-3

Gericke M, Liebert T, Heinze T (2009) Polyelectrolyte synthesis and in situ complex formation in ionic liquids. J Am Chem Soc 131:13220–13221

Heinze T, Liebert T (2001) Unconventional methods in cellulose functionalization. Prog Polym Sci 26:1689–1762. https://doi.org/10.1016/S0079-6700(01)00022-3

Heinze T, Liebert T, Andreas Koschella (2006) Esterification of polysaccharides. Springer, Cham

Joubert F, Yeo RP, Sharples GJ et al (2015) Preparation of an antibacterial poly(ionic liquid) graft copolymer of hydroxyethyl cellulose. Biomacromol 16:3970–3979. https://doi.org/10.1021/acs.biomac.5b01300

Klemm D, Heublein B, Fink H-PH, Bohn A (2005) Cellulose: fascinating biopolymer and sustainable raw material. Angew Chem Int Ed 44:3358–3393. https://doi.org/10.1002/anie.200460587

Knaus S, Mais U, Binder WH (2003) Synthesis, characterization and properties of methylaminocellulose. Cellulose 10:139–150. https://doi.org/10.1023/A:1024024402735

Kumar MNVR (2000) A review of chitin and chitosan applications. React Funct Polym 46:1–27

Li F, Fei P, Cheng B et al (2019) Synthesis, characterization and excellent antibacterial property of cellulose acetate reverse osmosis membrane via a two-step reaction. Carbohydr Polym 216:312–321. https://doi.org/10.1016/j.carbpol.2019.04.026

Liebert T, Hänsch C, Heinze T (2006) Click chemistry with polysaccharides. Macromol Rapid Commun 27:208–213. https://doi.org/10.1002/marc.200500686

Liu C, Baumann H (2002) Exclusive and complete introduction of amino groups and their N-sulfo and N-carboxymethyl groups into the 6-position of cellulose without the use of protecting groups. Carbohydr Res 337:1297–1307. https://doi.org/10.1016/S0008-6215(02)00132-5

Liu C, Baumann H (2005) New 6-butylamino-6-deoxycellulose and 6-deoxy-6-pyridiniumcellulose derivatives with highest regioselectivity and completeness of reaction. Carbohydr Res 340:2229–2235. https://doi.org/10.1016/J.CARRES.2005.07.018

Liu S, Edgar KJ (2017) Water-soluble co-polyelectrolytes by selective modification of cellulose esters. Carbohydr Polym 162:1–9. https://doi.org/10.1016/J.CARBPOL.2017.01.008

Liu S, Liu J, Esker AR, Edgar KJ (2016) An efficient, regioselective pathway to cationic and zwitterionic N -heterocyclic cellulose ionomers. Biomacromol 17:503–513. https://doi.org/10.1021/acs.biomac.5b01416

Liu S, Gao C, Mosquera-Giraldo LI et al (2018) Selective synthesis of curdlan ω-carboxyamides by staudinger ylide nucleophilic ring-opening. Carbohydr Polym 190:222–231. https://doi.org/10.1016/J.CARBPOL.2018.02.074

Matsui Y, Ishikawa J, Kamitakahara H et al (2005) Facile synthesis of 6-amino-6-deoxycellulose. Carbohydr Res 340:1403–1406. https://doi.org/10.1016/J.CARRES.2005.02.030

McCormick CL, Dawsey TR, Newman JK (1990) Competitive formation of cellulose p-toluenesulfonate and chlorodeoxycellulose during homogeneous reaction of p-toluenesulfonyl chloride with cellulose in N,N-dimethylacetamide-lithium chloride. Carbohydr Res 208:183–191. https://doi.org/10.1016/0008-6215(90)80098-N

McNamara JT, Morgan JLW, Zimmer J (2015) A molecular description of cellulose biosynthesis. Ann Rev Biochem 84:895–921. https://doi.org/10.1146/annurev-biochem-060614-033930

Meng X, Edgar KJ (2016) Click reactions in polysaccharide modification. Prog Polym Sci 53:52–85. https://doi.org/10.1016/J.PROGPOLYMSCI.2015.07.006

Mischnick P, Momcilovic D (2010) Chemical structure analysis of starch and cellulose derivatives. Advances in carbohydrate chemistry and biochemistry. Academic Press, Cambridge, pp 117–210

Mischnick P, Niedner W, Adden R (2005) Possibilities of mass spectrometry and tandem-mass spectrometry in the analysis of cellulose ethers. Macromol Symp 223:67–78. https://doi.org/10.1002/masy.200550505

Mosquera-Giraldo LI, Borca CH, Meng X et al (2016) Mechanistic design of chemically diverse polymers with applications in oral drug delivery. Biomacromolecules 17:3659–3671. https://doi.org/10.1021/acs.biomac.6b01156

Nichols BLB, Chen J, Mischnick P, Edgar KJ (2020) Selective oxidation of 2-hydroxypropyl ethers of cellulose and dextran: simple and efficient introduction of versatile ketone groups to polysaccharides. Biomacromolecules. https://doi.org/10.1021/acs.biomac.0c01045. (Biomacromolecules 21)

Nikolaeva D, Verachtert K, Azcune I et al (2021) Influence of ionic liquid-like cationic pendants composition in cellulose based polyelectrolytes on membrane-based CO2 separation. Carbohydr Polym 255:117375. https://doi.org/10.1016/J.CARBPOL.2020.117375

Petzold-Welcke K, Michaelis N, Heinze T et al (2009) Unconventional cellulose products through nucleophilic displacement reactions. Macromol Symp 280:72–85. https://doi.org/10.1002/masy.200950609

Pollak PI, Curtin DY (1950) Stereospecificity in the rearrangement of Amino Alcohols. J Am Chem Soc 72:961–965. https://doi.org/10.1021/JA01158A082/ASSET/JA01158A082.FP.PNG_V03

Reinhart K, Hartog CS (2012) Hydroxyethyl starch in patients with trauma. Br J Anaesth 108:321–322. https://doi.org/10.1093/bja/aer467

Ren J, Wang P, Dong F et al (2012) Synthesis and antifungal properties of 6-amino-6-deoxyinulin, a kind of precursors for facile chemical modifications of inulin. Carbohydr Polym 87:1744–1748. https://doi.org/10.1016/J.CARBPOL.2011.09.082

Sato T, Koizumi J, Ohno Y, Endo T (1990) An improved procedure for the preparation of chlorinated cellulose with methanesulfonyl chloride in a dimethylformamide–chloral–pyridine mixture. J Polym Sci A Polym Chem 28:2223–2227. https://doi.org/10.1002/pola.1990.080280817

Schmidt S, Liebert T, Heinze T (2014) Synthesis of soluble cellulose tosylates in an eco-friendly medium. Green Chem 16:1941–1946. https://doi.org/10.1039/C3GC41994K

Svensson A, Sjöström J, Scheel T, Piculell L (2003) Phases and structures of a polyion-surfactant ion complex salt in aqueous mixtures: cationic hydroxyethyl cellulose with dodecylsulfate counterions. Coll Surf A Physicochem Eng Asp 228:91–106. https://doi.org/10.1016/S0927-7757(03)00377-7

Wang X, Wu M, Zhang B et al (2019) Phase-transfer method synthesis hydroxyethyl cellulose lauryl ether. Coll Surf A Physicochem Eng Asp 562:383–391. https://doi.org/10.1016/j.colsurfa.2018.11.055

Wang K, Ye L (2010) Structure and property of cationic hydroxyethyl cellulose. Polym Plast Technol Eng 49:807–811. https://doi.org/10.1080/03602551003749619

Winstein S, Holness NJ (1955) Neighboring carbon and hydrogen. XIX. t-butylcyclohexyl derivatives. quantitative conformational analysis. J Am Chem Soc 77:5562–5578. https://doi.org/10.1021/JA01626A037/ASSET/JA01626A037.FP.PNG_V03

Zhang R, Edgar KJ (2014) Synthesis of curdlan derivatives regioselectively modified at C-6: O–(N)-Acylated 6-amino-6-deoxycurdlan. Carbohydr Polym 105:161–168. https://doi.org/10.1016/J.CARBPOL.2014.01.045

Zhang R, Edgar KJ (2015) Water-soluble aminocurdlan derivatives by chemoselective azide reduction using NaBH 4. Carbohydr Polym 122:84–92. https://doi.org/10.1016/J.CARBPOL.2014.12.020

Zhang R, Liu S, Edgar KJ (2017) Efficient synthesis of secondary amines by reductive amination of curdlan Staudinger ylides. Carbohydr Polym 171:1–8. https://doi.org/10.1016/J.CARBPOL.2017.04.093

Zhou S, Xu C, Wang J et al (2004) Phase Behavior of cationic hydroxyethyl cellulose – sodium dodecyl sulfate mixtures: effects of molecular weight and ethylene oxide side chain length of polymers. Langmuir 20:8482–8489. https://doi.org/10.1021/la049142n

Acknowledgments

We thank the Institute for Critical Technology and Applied Science (ICTAS), the Macromolecules Innovation Institute (MII), and the Virginia Tech Departments of Sustainable Biomaterials and of Chemistry for their financial, facilities, and educational support. We thank Dr. Xiuli Li for providing insights regarding NMR data interpretation.

Funding

We gratefully acknowledge partial funding support of the work from the National Science Foundation through grant IIP-1827493 (SP), and through grant DMR-2204996 (KJE). This work was partially supported by GlycoMIP, a National Science Foundation Materials Innovation Platform funded through Cooperative Agreement DMR-1933525.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Synthesis, characterization, and data interpretation and analysis, were performed by CG and SP. The first draft of the manuscript was written by CG and all authors contributed to the editing of the manuscript, including preparation of the final version. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Ethical approval

Not applicable.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gao, C., Petrova, S.P. & Edgar, K.J. Chlorination of hydroxyethyl cellulose enables selective functionalization. Cellulose 31, 1481–1495 (2024). https://doi.org/10.1007/s10570-023-05675-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-023-05675-x