Abstract

The ultraviolet rays from sunlight pose a natural hazard to human health and can cause serious health problems. Some medical artificial lights also emit ultraviolet radiation. Unprotected human skin exposed to ultraviolet (UV) light can cause serious health problems, including skin aging, photosensitivity (rash), erythema (redness of the skin), and melanoma (skin cancer). To protect human skin from UV radiation, UV-blocking or protective products are used. According to medical professionals, UV protection products must be safe, chemically inert, non-irritating, non-toxic, and resistant to light, and completely block the replication of UV rays. Sunscreen cream/lotion products are used for UV protection, but these products cannot provide complete protection. According to experts, one of the most efficient strategies to avoid sun damage is to wear protective gear. Researches are going on the manufacture of smart textiles that can be deployed as a protective shield with an adornment look to wear. Therefore, researchers have paid great attention to the development of fibers with anti-ultraviolet function. This review discusses the upshot of UV radiation on textile materials in particular cotton fabrics. It also describes the correlation between ultraviolet protection factor (UPF) and the physicochemical and structural properties of cotton fabrics. This review focuses on the manufacturing of UV protective cotton fabrics by applying UV absorbers and nanoparticles, their application process, and effects.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The Sun is the largest source of ultraviolet radiation. As a result of the depletion of the ozone layer, UV rays cannot be absorbed by O3 and therefore, enter the surface of the earth. Besides the ozone layer depletion index, UV rays transmittance varies with the longevity of daytime, season, latitude, and altitude. These geological factors affect the increase in the transmittance of UV rays. For example, the transmittance of ultraviolet B (UVB) rays increases with each degree decrease in latitude. Therefore, meteorological factors such as fog, clouds, and pollution have an impact on lowering the transmittance of UV rays (Manaia et al. 2013; Frederick 2015; Bais et al. 2018). The UV rays are not strong enough to affect deep biodiversity, but they can cause mutations in species composition, and species with poor protection can get harmed at an early stage of their life. UV radiation promotes the deterioration of both natural and synthetic polymers (Kocić et al. 2019). In the case of humans, the power of penetration of UV radiation is very low. Therefore, it cannot dive deep into the organ, except for the layers of the skin. Two beneficial outcomes of ultraviolet radiation (UVR) on humans include the stimulation of vitamin D production and the treatment of skin infections such as psoriasis and eczema (Parisi and Wilson 2005). It does, however, have certain severe health consequences, like skin cancer. UV is a type of electromagnetic wave radiation with a wavelength of 100-400nm. These UV rays are classified as ultraviolet A (UVA) (320-400 nm), ultraviolet B (UVB) (280-320 nm), and ultraviolet C (UVC) (100-280 nm). UVA rays have a longer wavelength and are quite safe. UVB harms the skin and eyes of humans. Despite the fact that UVB is absorbed by the ozone layer to a degree of 95%, it can still reach the atmosphere of the Earth. UVC is the most dangerous and deadly ray, with a shorter wavelength that is utterly absorbed by the atmosphere of the Earth before reaching the surface (Kerr and Fioletov 2008; Fioletov et al. 2010; Kang et al. 2011; Barnes et al. 2019). UVB is thought to be the primary cause of sunburn, tanning, wrinkling, aging of the skin, and skin cancer. UVA is taken into account harmless, but recent research has indicated that it can be potentially harmful in the long run (Xu and Fisher 2005; Marionnet et al. 2014; Knollmann-Ritschel and Markowitz 2017).

The most efficient strategy to reduce the detrimental accomplishments of UVRs would be to avoid sun exposure altogether, which is clearly impractical or undesirable. Therefore, it is recommended to wear UV-blocking clothing, sunglasses, and sunscreen that limit exposure to sunlight at noon when maximum UV rays enter the surface of the earth (Gies et al. 2018; McKenzie and Lucas 2018). Even if the textile material itself is susceptible to limited degradation due to UVRs, the light protection of textiles can be very considerable against the harmful effects of solar UVRs (Andrady et al. 2015). Clothes are the most effective tool for protecting the skin from the harmful rays of the sun. Previously, such protective clothing was developed taking into account the thickness and therefore the absorption coefficient of certain textile materials (Wilson and Parisi 2006; Zaratti et al. 2014). Studies have shown that the sequels to sun disclosure and the depletion of the ozone layer have the highest ratings in summer. During the summer season, New Zealand, Australia, South, and Eastern Europe experience the highest level of UV radiation in the world (Laperre and Gambichler 2003). In order make these protective cloth users friendly and high comfort, studies have come up with some magnificent solutions to make these clothing as protective and cozy at the same time. Among all other natural fibers, cotton is the most popular fabric in the hot season because of its hygroscopicity, air permeability, biodegradability, lack of static electricity, and so on. It is a plentiful natural fiber made up almost entirely of cellulose (about 88–96%) (Mahbubul Bashar and Khan 2013). Cotton has the highest moisture regain properties in both slack and tight fabric dyeing, which also indicates the comfort of cotton fabric (Çil et al. 2009). Several factors are considered during the development of UV protective clothing. Factors that influence the UPF of fabrics are structures, materials, dye, and yarn morphology, UVR absorbing additives, moisture absorption, and fabric deformation. UPF values above 40 (rating 40+) and 50 (rating 50+) are entertained as the ultimate sun-blocks (Gambichler et al. 2001; Duan et al. 2011; Mishra et al. 2014). UPF is higher in fabrics with closer and tighter structures, higher GSM (weight per unit area), or thickness (Aguilera et al. 2014; Louris et al. 2018). The UPF values are also influenced by the materials used. Synthetic yarns perform better than natural fibers in terms of UV performance (Gies et al. 1998; Aguilera et al. 2014). UVR is absorbed more by darker hues, leading to greater UPFs (Hustvedt and Crews 2005; Aguilera et al. 2014). UPF is also affected by yarn morphology. Yarns with a more wavy filament structure have a structure that allows for increased UV transmission (Singh and Singh 2013). The UV protection efficacy of clothes can be improved by using fabric with UVR absorption compounds (Gies et al. 1998).

Although many studies have been conducted on the development of UV protective textiles, there is still a lack of comprehensive reviews that provide a clear conception of UV protective cotton clothing that can be worn comfortably in the summer season. In this comprehensive review, the development of UV protective cotton fabric is focused on. This review discusses the UV protection factor of cotton fabric and the factors to consider while making UV protective clothing. It also describes the use of UV absorbers and nanoparticles for UV protection. In this review, the nanoparticle synthesizing process is also discussed to apply them onto the fabric. Finally, this review presents the current situation and future directions for further developments.

UV protection of textile materials

The potency of UV blocking is evaluated by the UV protection factor of UVA and/or UVB. UV transmittance through a fabric, both direct and diffuse, is a vital component in determining UV protection of the fabric (Gambichler et al. 2002; Dubrovski and Golob 2009). The UV protective textile should have reflecting and absorbing properties that it can head off UV rays to reach the skin. The vital property of a protective textile is determined by its transmittance (Parisi et al. 2000; Gabrijelčič et al. 2009). Fabric structures for both woven and knit fabrics are essential factors for UV transmission modification. Figure 1 shows the effect of UV radiation on textile materials.

UV radiation effect on textile materials (Singh and Singh 2013). Published under a CC-BY license, Hindawi

The UV transmission factor of woven and knitted fabrics is associated with the cover and gauge of the fabric; closer and tighter structures with fewer pores result in less transmission (Wilson et al. 2008). UV rays that contact textiles are partially reflected, absorbed, and transmitted over the fibers and interstices, and the optical porosity of a fabric inhibits its probability to furnish UVR protection (Saravanan 2007; Kocić et al. 2019). According to Krste Dimitrovski et al. (Dimitrovski et al. 2010), the UV protection level of fabric can be determined by its designs and constructional parameters. The transmitted UV radiation in textiles is made up of two constituents: a diffuse component that is affected by the absorption qualities of the fabric and an unchanging component that passes directly through the gaps between the yarns. Changes in the construction parameters of textile materials can be used to reduce UV transmission. The right combination of the thickness, areal density, and weave of woven or knitted fabric, as well as the yarn type (mono or multifilament) and fineness, offers the possibility of UV-protective textiles. The chemical properties of the fiber and the construction parameters of the fabric influence the UPF (Majumdar et al. 2010, 2012; Wong et al. 2013).

Standard for measuring UV protective factors

The UV protection factor (UPF) is a significant statistical tool of the protection provided by UV ray protection products such as sunscreen or clothing, and it is considered to be an excellent representative of in vivo methods for determining the photo protection (Laperre et al. 2001). The corollary of UPF is the sun protection factor (SPF). The core difference between UPF and SPF is that SPF is measured by human tests, whereas UPF is measured by instruments (Hustvedt and Crews 2005; Grifoni et al. 2009). To measure the UPF based on transmitted radiation, the international scientific community has established Equation (1).

Where,

- Eλ:

-

is the solar UVR spectral irradiance (in W·m-2·nm-1)

- Sλ:

-

is the relative erythemal effectiveness according to the Commission Internationale de l'Elcairage (CIE) (Webb et al. 2011).

- Δλ:

-

is the bandwidth (in nm)

- Tλ:

-

is the spectral transmission through the textile is the wavelength (in nm)

Based on this UPF calculation method, UV protective excellence has specific categories of international standards. The higher the rating indicates the better the protection. For better understanding, we can give examples like if an uncovered fair skin starts showing redness or erythema under the sun exposure at 10 minutes then under the protection of UPF rating 20 will increase the time by 20 times, which means 200 minutes. UPF ratings 40+ or 50+ are considered as excellent protection. The method mentioned in Table 1 has gained widespread acceptance as a laboratory-based test procedure (Stankovic et al. 2009). The UV Protection Factor rating categories according to AS/NZS, ASTM, and European standards are shown in Table 1.

Factors considered for fabric construction for UV protection

Nature of fiber

Natural fiber has a great impact on the UPF of fabric. Due to the variations in ultraviolet transparency, the chemical nature of the fibers has an effect on UPF. Fibers with a large conjugated aromatic polymer system were found to be more effective in blocking UV radiation (Daoud and Kong 2004; Paul et al. 2010). Researchers have found that hydrophobic fibers, like polyester, have a high UV light transmittance protection ratio. The presence of a benzene circle in polyester may help it obtain a specious property of UV protection (Gorensek and Sluga 2004; Shim et al. 2009; Pan and Sun 2011). Benzene exhibits very strong light absorption properties. The minimal comfort properties made polyester the least used fabric during the summer. Natural fiber-made fabrics are more comfortable and are mostly used instead. Among all other natural fibers, cotton is the most widely used fabric in summer and hot weather. Most of the researchers and scientists who are interested in UV protection of natural fibers have their attention on cotton fabric. Natural fibers, such as cotton, silk, and linen, absorb less ultraviolet radiation than synthetic fibers. Spectroscopic studies of ‘WB Achwal’ show that cotton has relatively high UV transmission in the range of 280-400nm. Bleached cotton has a high level of permeability to ultraviolet radiation. Gray cotton shows higher UPF properties. The presence of natural pigments, pectin, and waxes in gray cotton acts as ultraviolet absorbers. Flax, hemp, ramie, and jute are examples of natural fibers that are strong UV barrier raw materials. They include colors, lignin, waxes, and pectin, all of which function as natural UV radiation absorbers (Zimniewska and Batog 2012; Subramaniyan et al. 2013). Researchers have observed a high UPF naturally-pigmented cotton fabric (Hustvedt and Crews 2005). A fabric composed of a mixture of polyester and cotton would be much more protective than one made solely of cotton. Furthermore, for warm-weather clothes, a combination of polyester and cotton would give higher absorbency and comfortability at the same time (Bajaj et al. 2000; Osterwalder et al. 2000; Stott 2010). In the case of cotton fabrics, it is obvious that greige fabrics (raw) have superior UVR protection, regardless of fabric construction (Sarkar 2007; Jansen et al. 2013). The ability of a cloth to block UV radiation is also affected by its fiber chemistry. Fibers containing a large conjugated aromatic polymer system were shown to be more effective at UV blocking (Xin et al. 2004). The chemical modification of the fiber influences the UPF. An inclusion complex was developed by the reaction of β-cyclodextrin (β-CD) with 4-hydroxy benzophenone (4-HBP), since β-CD acts as a host molecule for 4-HBP. The complex was added up to a finishing bath comprising citric acid (CA) and sodium hypophosphite (SHP) as a catalyst to provide the anti-crease and ultraviolet (UV) protection properties of the cotton fabric. The best concentration for both the UPF and anti-crease qualities was found to be 0.25 g of β-CD and 4-HBP. The UPF and the wrinkle recovery angle increase when the concentrations of CA and SHP increase. The finished fabrics show an excellent durability against 30 successive washing cycles (El Tahlawy et al. 2007; Abidi 2018). The sunscreen ingredient octyl methoxycinnamate was integrated into cyclodextrin cavities and covalently bonded to cloth fibers in another investigation. Tencel, a cellulosic fabric, was grafted with β-cyclodextrin molecules via a monochlorotriazinyl-β-cyclodextrin process (β-CDMCT). The finished fabric showed better photoprotective characteristics than the unmodified textile material even after repeated washings (Scalia et al. 2006a, 2006b).

Yarn properties

The UPF of the fabric is inversely proportional to the yarn count. Fabrics constructed from finer yarns have a finer composition (Sarkar 2004). For fabrics with finer yarns, it may also be a result of higher porosity in the fabric. However, according to another analysis, with increasing yarn fineness, the UPF increases first and then decreases (Dubrovski and Brezocnik 2009; Chattopadhyay et al. 2013; Gorjanc et al. 2014). The cross-sectional structure of the fiber can influence the UPF of textiles. According to optical theory, the cross-section of fiber has an impact on light transmittance and reflectance. Triangular configurations outperform other forms in single yarns with cube, rectangular, and rectangle cross-sections, while the round one has the least UV protection impact (yu et al. 2015; Yu et al. 2017). Yarn twist is a crucial element in determining the core and surface characteristics of the fabric, as well as the porous structure. As a result, it has a great influence on UV transmission through the fabric. Due to the increased fiber density caused by high-twist yarns, the UVR transmittance through them is reduced (Stankovic et al. 2009). The yarn hairiness may also influence the UV protection properties of the textiles. However, further studies are needed to determine the impact of yarn properties on UV shielding of cloth (Stankovic et al. 2009).

Fabric structure

Sun protective knitted and woven fabrics must have higher cover factor properties. Higher cover factors mean higher UV protection. The primarily constructional parameters of the fabric are determined by its weave/knit design, yarn count, and thread density. Yarn crimp, fabric cover factor, fabric porosity, fabric thickness, fabric mass, and fabric mass density are the secondary constructional parameters. Generally, woven fabric has a higher UV protection rate compared to knit fabric (Kathirvelu et al. 2009; Alebeid and Zhao 2017). The woven fabric has frequent interlacements with yarn. Comparatively knit fabric has more open structure, the porosity further increases due to stretching (Bajaj et al. 2000). Porosity and the cover factor are quite related, as both measure the tightness of the weave and the knitting (Stankovic et al. 2009; Behcet and Halil Rifat 2010). Tighter fabric structures with smaller pores occupied more percentage of the area and created more opaque UV radiation. The fabric cover factor is proportional to its weight per unit area; a heavier fabric allows the least UV transmission, as it has a smaller space between the yarns. This gives the advantage of blocking more radiation (Sarkar 2004). The UPFs for fabrics of various densities are mentioned in Fig. 2. The designed cotton fabric can give good UV protection (UPF > 15) when the air permeability is high, and it can give excellent UV protection (UPF > 40) when the air permeability is low (Majumdar et al. 2010)(Stankovic et al. 2009).

UPFs for fabrics of various densities. Reproduced with permission (Zimniewska and Batog 2012). Copyright © 2012, Elsevier

Satin, twill, and plain weaves among woven structures give better UV protection than sateen weave because of its higher cover factor (Gabrijelčič et al. 2009). Twill and satin materials provide an excellent UPF at 70-80% tightness (Dubrovski and Golob 2009). In addition, the UPF of the different tightness weaves varied, with satin coming out on top, followed by twill and plain weaves among the three weaves important points to consider (Dubrovski and Brezocnik 2009; Khan et al. 2020). In knit construction, the double knit fabric shows higher UV protection than the single knit structure. The interlock fabric provides the highest level of UV protection, right ahead to the 1×1 rib structure, full Milano, and full cardigan (Kan 2014). Because their UPF ratings were less than 15, the plain weave and sateen weave fabrics cannot be considered to provide any level of protection based on the previously established classification parameters. The UV protection of the undyed twill weave fabric is rated as good, with a UPF of 19.2. The UPF values of undyed fabrics can be addressed using the fiber composition and the structure of the fabric (Sarkar 2004). The structure and UPF of the undyed cotton fabrics are demonstrated in Fig. 3.

The UPF of undyed materials was greatly increased by dyeing with natural colorants, particularly for fabrics like plain weave and sateen weave, which had no protective properties in their original state. The amount of protection provided after dying was determined by the concentration of colorant in the fabric. The UPF values increased as the percentage depth of the shade increased within the same fabric type (Sarkar 2004). The UPF values, protection class, and color strength of different weave cotton fabric dyed with natural colorants at different concentrations are shown in Table 2.

Bleaching and dyeing effect

Pretreatment of the fabric is done to remove natural, applied, and obtained impurities, and coloring particles. Certain UV blocking agents are often removed or reduced in the fabric, yarn, and fiber structure. The removal of hydrophobic impurities from the fabrics is known as bleaching.

The bleached cotton significantly provides less UV protection than the unbleached cotton (Gabrijelčič et al. 2009; Ibrahim et al. 2009). Bleaching cotton textiles massively increases their transmittance and reduces their UV protection, according to studies. The presence of wax, pectin, and natural coloring particles in unbleached cotton exhibits more UPF than bleached cotton itself. Because of the bleaching agent and consequently low UV absorbance, even the most tightly woven and maximally coated samples have inadequate UPF (Gabrijelčič et al. 2009; Samant et al. 2020). Bleaching techniques, as well as the addition of optical brightening, fluorescent, and whitening agents, have an effect on transmission (Downs and Harrison 2018). Optical brightening chemicals, also known as fluorescent whitening agents, are poor chemical compounds that absorb and re-emit light at various wavelengths. They make white persons appear to be "whiter than white" (Sarkar 2007). Optical brightening compounds included in laundry detergents enhanced the effectiveness of UV radiation blocking of cotton clothing and cotton/polyester blends, according to the study (Algaba and Riva 2002; Riva and Algaba 2006; Abidi et al. 2007; Wang et al. 2010).

Ultraviolet protection capabilities of textile materials substantially depend on the type of pigment and dyestuff, the depth of the dyeing, the group of absorptives in the dyestuff, the uniformity and additive (Bajaj et al. 2000; Saravanan 2007; Riva et al. 2009; Alebeid et al. 2015; Wong et al. 2016a). When UV protection can be obtained by using dyes and pigments, it is not so wise to choose a heavy fabric for summer conditions. Darker colors of the same fabric type (black, navy, dark red) absorb UV radiation significantly more powerfully than light colors for equivalent weaves with UPF in the ranges of 18-37 and 19-34 for cotton and polyester, respectively. The UPF rating of some dyes, such as direct, reactive, and vat dyes, is greater than 50 (Bajaj et al. 2000; Grifoni et al. 2011). Several direct dyes increase the UPF of bleached fabric by a large amount, which is determined by the relative UVB absorbance of the dyes. The UPF of natural dyes varies from 15 to 45, depending on the mordant utilized (Gupta et al. 2005; Kim 2006; Kamel et al. 2007; Bonet-Aracil et al. 2016; Islam et al. 2021a, b, c; Liman et al. 2021; Rahman Liman et al. 2021). Cellulosic fabrics transmit UV-A and UV-B equally, according to the research, with a transmittance ratio (TA/TB) of 0.9. And if the same fabric is dyed with reactive dye, the UPF increases from 4.7 to 5.0-14.0, depending on the concentration, which is not enough to meet the minimum standards (Oda 2011; Emam and Bechtold 2015; Wong et al. 2016b). Cellulosic fabrics dyed with some vinyl sulphone dyes and monochlorotriazine dyes exhibit the reduction of UV ray transmission from 24.6% to 10-20% and 27.8% to 8-22% for UVA and UVB collectively. The UPF increases synergistically when these dyes are mixed together. For polyester/cotton blends, some dispersed reactive mix combinations may provide long-lasting UV defense with a UPF of 50+ (Alebeid and Zhao 2017). The structures of some dyes with good UV absorption are shown in Fig. 4.

UV radiation is absorbed by several dyes. According to studies, the darker the shade of a specific color, the greater the protection. In general, navy, black, and olive tones offer more protection than light pastels and, as a result, have a higher UPF rating. The influence of color on the UPF of cotton fabrics with identical weaves and weights is shown in Fig. 5. This should only be used as a reference, as different fabrics may have different properties.

The naturally coloured cottons demonstrated considerably higher UPF values than conventional cotton (Hustvedt and Crews 2005). The natural dye produced from henna leaves can be used to produce outstanding UV-protective cotton fabric. The dyeing temperature and time were found to be important factors in improving UV protection (Alebeid et al. 2015). Feng et al. developed ultraviolet protective cotton fabric using Rheum and Lithospermum erythrorhizon. The materials coloured with natural dyes exhibited good ultraviolet protection characteristics, according to the results of the experiments. They were able to absorb around 80% of UV radiation (Feng et al. 2007). When natural dyes are exposed to UVR, they can undergo a photochemistry reaction, as seen in Fig. 6. Salah investigated the antibacterial activity and UV protection properties of cotton fabrics treated with aqueous extract from banana peel and discovered that the mercerized cotton fabrics had excellent antibacterial activity, high dye uptake, and high UV protection properties compared to control and unmercerized cotton (Salah 2013).

Illustration of a UV-absorptive scheme for the natural dyes: a. Rheum and b. Lithospermum erythrorhizon. Reproduced with permission (Feng et al. 2007). Copyright © 2007, Elsevier

Moisture and swelling effect

The UPF of the moist garment is slightly better than that of the same garments in the dry state. The presence of water molecules in the fabric’s interstices decreases scattering and thereby increases its permeability to ultraviolet radiation. The UPF rating of the fabric decreases from 30% to 50% when it is wet. The capacity of textile fibers to protect against UV radiation varies depending on their structure and other additions (Tsuzuki and Wang 2010; Sayed et al. 2015). The UPF of textile materials is also impacted by the construction characteristics and wear circumstances of textile materials, as well as the moisture and additives used during production (Bajaj et al. 2000). Moisture has a strong impact on the form and hygroscopicity of the fibers, as well as on the conditioning time, resulting in swelling phenomena (Hearle and Morton 2008; Grishanov 2011). The UPF of a fabric is affected by the relative humidity percentage or the moisture content of the fibers in two ways. Fibers swell as a consequence of moisture absorption, reducing interstices and thus the UV penetrance. The presence of water, on the other hand, decreases scattering effects because the refractive index of water is similar to that of the textile polymer, resulting in higher ultraviolet transmission compared to a lower UPF value (Bajaj et al. 2000). When a cotton garment is wet, it can emit up to 50% more UV rays than when it is dry. For sufficient and exceptionally good protection, ultraviolet radiation transmission should be less than 6% and 2.5% (Saravanan 2007).

UV absorbers

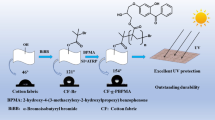

Colorless organic or inorganic compounds that absorb substantially in the UV range of 290–360 nm are termed as UV absorbers (Krizek and Gao 2004; Saravanan 2007; Das et al. 2010). UV absorbers operate as radical scavengers and quench singlet oxygen in the fibers, converting electrical excitation energy into heat energy. The high-energy, short-wave UVR stimulates the UV absorber to a higher energy state, and the energy absorbed can then be dissipated as longer-wave radiation (Das et al. 2010). Isomerization can occur, on the other hand, causing the UV absorber to fragment into non-absorbing isomers. UV absorbers, which are used in sunscreen lotions, physically block UVR (Aloui et al. 2007; Das et al. 2010). 2-hydroxybenzophenones, 2-hydroxyphenyl benzotriazoles, and 2-hydroxyphenyl-s-triazines seem to be the most important classes of ultraviolet absorbers. The most widely used UVB screens, 2-ethyl hexyl-4-methoxy cinnamate, have a high refractive index (RI) and contribute significantly to the skin RI matching (Smith et al. 2002; Shen et al. 2014). To avoid color deterioration or loss, an effective UV absorber must be able to absorb across the spectrum, remain stable against UVR, and disperse the energy absorbed (Wong et al. 2013). O-hydroxybenzophenones, O-hydroxy phenyl triazines, and O-hydroxy phenyl hydrazines are the most commonly used organic UV absorbers. The chemical structures of UV absorbers for cotton fabric are mentioned in Table 3.

The orthohydroxyl group is known to promote absorption and ensure that the chemical is soluble in alkaline solutions. UV absorbers often employed include 2-hydroxy benzophenones, 2-hydroxy phenyl benzotriazoles, 2-hydroxy phenyl-striazines, and compounds such as benzoic acid esters and hindered amines (Sekar 2000). The significant absorption of 2, 4 dihydroxybenzophenone near UV is due to conjugate chelation between the orthohydroxyl and carbonyl groups. Organic compounds, including benzotriazole, hydro benzophenone, and phenyl triazine, are commonly employed in coating and padding techniques to produce a wide UV protection (J. Rupp 2001). Synergistic effects can be achieved by using the right mixture of UV absorbers and antioxidants (Smith 2000; Hussain et al. 2012; Khan et al. 2017). Low energy levels, quick diffusibility, and low sublimation fastness characterize benzophenone derivatives. Orthohydroxyphenyl and diphenyltriazine derivatives have excellent sublimation fastness, and a self-dispersing formulation can be utilized in both pad-baths and print pastes for high-temperature dyeing (Kathirvelu et al. 2009).

UV absorbers applied to the spinning dope prior to fiber extrusion and dye bath in bath dyeing increase the light fastness and weatherability of spun-dyed fibers (Hearle and Morton 2008). UV absorbers to the extent of 0.6–2.5% are sufficient to provide UVR protection fabrics (Wong et al. 2006). Even so, recent findings have shown that these chemicals have limitations in terms of application due to toxicity, poor activity, and poor washing fastness.

The performance of two common UV absorbers, benzophenone, and its derivative 2, 4 dihydroxybenzophenone, was investigated in terms of UV protection factor (UPF), color fastness, tensile strength, handling, and other factors. The ability of two novel UV absorbers, avobenzone alone and in conjunction with octocrylene, to absorb UV radiation over a broader spectrum was also tested. Compared to benzophenone, the effect of UV finish with 2, 4 dihydroxybenzophenone was found to be more apparent; UPF ratings increased up to 200 with avobenzone alone and in conjunction with octocrylene. In the UV-A and UV-B ranges, the combination of innovative UV absorbers significantly reduced UV transmission to well below 1% (Chakraborty 2014). The influences of benzophenone, 2, 4-dihydroxy benzophenone, avobenzene, and avobenzene + octocrylene on UPF of white and reactive dyed cotton are shown in Fig. 7.

Influence of (a) benzophenone, (b) 2, 4dihydroxy benzophenone, (c) avobenzene, and (d) avobenzene + octocrylene on the UPF of white and reactive dyed cotton (Chakraborty et al. 2014). Published under a CC-BY license

Nanoparticles for UV protection

Common textile finishing methods for imparting various properties to cotton fabric do not always to produce long-term results, and their effect is impaired after laundering or usage. Nanoparticles (NPs) have a larger surface area and energy; thus they can provide a large surface area for treated fabrics, resulting in a significant affinity for the fabric and a better endurance of the intended textile functionalities (Wong et al. 2006). The use of semiconductor and metal nanostructures in textile finishes has exploded in recent years due to their unique properties (Roe and Zhang 2009). In addition to UV protection properties, researchers have found that cotton fabric treated with different nanoparticles is useful in a variety of applications, including hydrophobicity, antimicrobial, and self-cleaning (Wong et al. 2006; Gorenšek and Recelj 2007; Shateri-Khalilabad and Yazdanshenas 2013).

ZnO as UV protective nanoparticles

ZnO (zinc oxide) nanoparticle has unique photocatalytic, electrical, electronic, optical, dermatological, and antibacterial properties; due to these characteristics, ZnO is the most vastly studied material (Çakir et al. 2012; Barani 2014; Ibǎnescu et al. 2014). Many recent studies have found that cotton fabrics containing nano-ZnO provide better UV protection. The performance of ZnO nanoparticles as UV absorbers can be efficiently transferred to fabric materials by coating them with ZnO nanoparticles on the surface of cotton (Vigneshwaran et al. 2006; Becheri et al. 2008; Li et al. 2011; Abd Elhady 2012; Shateri-Khalilabad and Yazdanshenas 2013; Advances 2019). The nanoparticles must be diffused in a suitable solvent and a series of processes must be performed to enhance the stability of the ZnO nanoparticles and inhibit particle aggregation in order to manufacture UV-protective textiles (Kathirvelu et al. 2009; Lee 2009; El Shafei and Abou-Okeil 2011; Sivakumar et al. 2013). ZnO nanoparticles were produced using a solution of ZnCl2 and 2-propanol in the research conducted by S. Kathirvelu et al. As a result, samples made in an aqueous medium are larger than those produced in a more monodisperse propanol solution (see in Fig. 8). The results of the UV transmission and UPF values for the UVA and UVB ranges found that cotton samples containing ZnO nanoparticles provided greater protection than cotton samples manufactured using the synthesis 2 techniques. It should be remembered that the padding method of applying ZnO nanoparticles to fabrics will result in particle penetration into the yarn interstices. Since these nanoparticles may not remain on the surface of the fabrics, they might not quite be effective (Kathirvelu et al. 2009).

(A) water-synthesized samples (synthesis 1) and (B) samples synthesized in 1, 2-propanol solution (synthesis 2). Reproduced with permission (Kathirvelu et al. 2009). Copyright © 2009, NOPR

Electrospinning was utilized in another study to investigate the influence of ZnO nanoparticle accumulation on polypropylene nonwoven fabrics (Lee 2009). The solution of polyurethane in DMF and the addition of zinc oxide nanoparticles at various concentrations to the solution produce electrospinning solutions. Depending on the degree of ZnO content (0–2 wt%), UPF increased from 2 to 50+ (see in Fig. 9). Wang et al. used the sol-gel finishing process to create dumbbell-shaped ZnO crystallites with a size greater than 500 nm on cotton fabric. Using a dip-pad-cure technique, clear solutions of zinc acetate and triethenamine in 2-methoxyethanol, equal to 3 percent by the weight of ZnO, were added twice to cotton fabrics and then cured at up to 400°C. Curing at temperatures above 150°C resulted in a UPF value of >400. After five laundering cycles, this approach offered consistent fastness (Wang et al. 2005). Yadav et al. used zinc nitrate and sodium hydroxide as precursors and soluble starch as a stabilizing agent to make ZnO using a wet chemical process. Around 75% of the incident UV ray was blocked by 2% nano-ZnO on cotton fabric (Yadav et al. 2006). Noorian et al. employed a bi-component metal oxide to improve UV protection in textiles and polymers. Cu2O/ZnO nanoparticles were produced in situ on the cotton fabric surface to improve UV protection. According to the findings, the use of Cu2O/ZnO nanoparticles on cotton fabric provides significantly better UV protection than using ZnO and Cu2O nanoparticles alone. They claim that ZnO nanoparticles have higher UV absorption and reflectance than Cu2O nanoparticles, which protect treated cotton fabric, and that both can shield fibers together by forming a thin layer of particles on the fabric surface in situ (Noorian et al. 2015).

SEM of electrospun polyurethane nanofiber web (A), electrospun polyurethane/zinc oxide nanocomposite fiber web (B) cross-sectional view of a nanocomposite fiber (inset), and cross-sectional view of a layered fabric system (C). Reproduced with permission (Lee 2009). Copyright © 2009, Springer nature

Lu et al. recommended that cotton fabrics be treated with encapsulated ZnO in polystyrene. Although a grainy coating on the fibers provided a high UPF value, after 10 home washings, the UPF value decreased significantly from 86.6 to 15.3 (Lu et al. 2006). Fig. 10 shows a ZnO-PS based nanosphere with carboxylic surface functional groups, as well as the attachment of a ZnO-PS based hybrid nanosphere to cotton through an esterification reaction between the cotton –OH groups and the ZnO-PS based hybrid nanosphere –COOH groups. A primary hydroxyl group is found at C6 in a cellulose moiety of cotton fabric, whereas secondary hydroxyl groups are found at C3 and C2 (Seth et al. 2020).

Schematic showing a ZnO-PS based hybrid nanocoating on cotton fabrics. (a) ZnO-PS nanosphere with carboxylic surface functional groups; (b) esterification reaction of cotton –OH groups and ZnO-PS hybrid nanosphere –COOH groups to connect the ZnO-PS hybrid nanosphere to cotton. Reproduced with permission (Lu et al. 2006). Copyright © 2006, Elsevier

Becheri et al. synthesized ZnO nanoparticles from ZnCl2 and NaOH in a homogeneous phase process in H2O or C2H6O2 at high temperatures and then applied them to cotton and wool fibers. The UV transmittance of the textiles was lowered from 90% to 20% (Becheri et al. 2008). Mao et al. developed ZnO nanoparticles directly in situ on SiO2-coated cotton fibers using a hydrothermal mechanism (Mao et al. 2009). Hydrothermal techniques have been recognized as a favorable and easy control approach for the creation of crystalline nanoparticle metal oxides with a limited size distribution, excellent crystallization, few agglomerates, and phase purity (Ledwith et al. 2004). Cotton fabric was pretreated with SiO2 sol to optimize wash and light color fastness (Mahltig and Textor 2006). The cotton was coated with needle-shaped ZnO nanorods with a diameter of 24 nm after hydrothermal processing. The UV-blocking quality of the coated fabrics was excellent, with a UPF value of over 50. However, after 5 launderings, the UPF dropped to half what it was before (Fig. 11) (Mao et al. 2009). Another study discovered that cotton fabric functionalized with biosynthesised NP ZnO had a higher efficacy in blocking ultraviolet light (UV) (Asmat-campos et al. 2021).

SEM images of cotton (A) before modification, (B) after soaking in the SiO2 solution, (C) after chemical deposition of ZnO, and (D) after hot H2O treatment at 100°C for 2.5 h. Reproduced with permission (Mao et al. 2009). Copyright © 2009, Elsevier

Cotton fabrics treated with ZnO nanoparticles demonstrated significant UV protection (87.8 UPF), hydrophobicity (155), and zone of bacterial inhibition against E. coli and S. aureus (25.13, 0.05 mm and 30.17, 0.03 mm, respectively). This study used zinc acetate as a precursor to green synthesis of ZnO nanoparticles from Acalypha indica leaf extract (Karthik et al. 2017). When the cotton fabric was treated with AuNPs/ZnONPs, it demonstrated a significant increase in UV protection. Even after 15 washings, the imparted functional qualities showed outstanding preservation. The antibacterial activity of the activated fabric samples is significantly improved against both S. aureus and E. coli (Ibrahim et al. 2016). In another study, aminopropyltriethoxysilane was used as a silane cross-linker to anchor zinc oxide nanoparticles to a pristine cotton fabric surface, which was then modified using hexadecyltrimethoxysilane, a silane hydrophobe. With a water contact angle of 154°, a water shedding angle of 2°, antibacterial activity of up to 98%, and UV-blocking ability more than 200 times that of pure cotton, this dual-silanization technique produces highly functional fabrics with superhydrophobicity. The materials are extremely resistant to abrasion, ultrasonic washing, immersion in various pH solutions, and UV irradiation when used as is (Agrawal et al. 2019).

TiO2 as UV protective nanoparticles

TiO2 (titanium dioxide) is widely used in photocatalytic processes rather than any other semiconductor, including ZnO, SnO2, ZrO2, Fe2O3, and TiO3, since it is chemically and thermally stable and non-toxic (Roessler et al. 2002; Akhavan Sadr and Montazer 2014; Karimi et al. 2014). Special properties of TiO2 nanoparticles such as higher stability, long-lasting, safe, and broad-spectrum antibiosis, have paved the way for new applications as an appealing multi-functional material (Roessler et al. 2002; Bae et al. 2003; Abidi et al. 2009). All these properties make TiO2 nanoparticles useful in a variety of applications, including self-cleaning, antibacterial, UV-protection, and environmental purification (Han and Yu 2006; El-Naggar et al. 2016; Ahmad et al. 2019). Three well-known crystalline forms for TiO2 are anatase (which has a wavelength of 388 nm), rutile, and brookite (Park and Kim 2005). Anatase is metastable at lower temperatures, according to Reidy, Holmes, and Morris, and is particularly suitable for catalysis and photo-catalysis along with its greater surface area (Reidy et al. 2006). Anatase titanium dioxide has excellent catalytic activity than rutile, according to another research (Fu et al. 2005). As titanium dioxide is irradiated with light that has higher energy than that of its band gaps, electron hole pairs form at the surface, causing redox reactions. As a consequence, electrons in TiO2 jump from the valence band to the conduction band, resulting in the formation of electron (e-) and electric hole (h+) pairs on the photo-catalyst surface. Negative electrons and oxygen form O2, while positive electric holes and water form hydroxyl radicals (see in Fig. 12) (Wong et al. 2006; Dastjerdi et al. 2010).

The mechanism of photocatalytic activity of TiO2 quantum dots (QDs). Reproduced with permission (Gnanasekaran et al. 2015). Copyright © 2015, Elsevier

For the synthesis of TiO2 nanoparticles, a variety of techniques have been used. Sol–gel processing is one of the most popular processes (Keshmiri et al. 2004). The anatase form of the TiO2 nanoparticles was produced using the sol–gel technique. The pH of the solution and the rate at which isopropoxide is supplied are thought to affect particle size. Titanium dioxide nanoparticles have been used to achieve antibacterial, self-cleaning, UV protection, hydrophilic or ultrahydrophobic characteristics, and color degradation in textile effluent (Daoud et al. 2005; Mahmoodi et al. 2006).

According to a report, because of its large specific surface area and high surface energy, nanoscale TiO2 has a strong affinity for fabrics. When used as a solar UV protector, however, the blue change of the nano-absorption TiO2 edge is disadvantageous because it decreases UVA absorption (Yang et al. 2004). According to Zheng et al., treating cotton fabrics with nano-TiO2 sols can lead to improved UV resistance. For cotton fabrics treated with nano-TiO2 sols, the following finishing method is recommended: 40 % nano-TiO2 sols, two dip-two pads with 70% wet pickup, drying at 50°C for 5 minutes, and curing at 165°C for 3 minutes (Zheng et al. 2011). Abidi et al. treated the cotton fabric with TiO2 nano sol, which gave the cotton fabric excellent UVR protection, particularly in the UVB [290–315 nm] area. The establishment of covalent bonds between the (OH) groups of cellulose and the (OH) groups of the titania network resulted in excellent durability of the treatment in repeated home laundering (Abidi et al. 2007).

The cotton fabrics coated with TiO2 nanoparticles were found to be resistant to domestic washing by Roshan et al. The UPF values remained similar even though the load of nanoparticles on the fabric surface decreased after washing, indicating the performance of the technology. The linking agent strategy produced better results for both undyed and dyed samples compared to the sol–gel method. Similarly, it has been observed that the rutile crystalline phase is more useful for UV protection in existing textile mill gear, making it industrially feasible (Mukaihata et al. 2008; Paul et al. 2010). Ukaji et al. coated thin layers of aminoethyl aminopropyl trimethoxy silane on TiO2 particles in ethanol, by applying silane during the ball-milling process (Ukaji et al. 2007). Shafi et al. used ultrasonic irradiation to coat octadecyltrihydrosilane on TiO2 surfaces in heptane (Paul et al. 2010). Inert shells, usually composed of silica, were recently coated onto TiO2 cores to suppress the photocatalytic property of TiO2 while retaining their UV-protective property (Paul et al. 2010). Toni et al. used a seeded sol–gel method of tetraethyl silicate (TEOS) in ethanol to coat dense SiO2 shells with TiO2 particles (El-Toni et al. 2006). The techniques mentioned here could be utilized to effectively create TiO2–SiO2 core-shell particles, however, they do have certain limitations. TiO2 colloids or TiO2 dispersion must be developed prior to the silica coating procedure. Second, the silica layer is often formed in a non-aqueous environment, requiring a considerable volume of organic solvent. Finally, the core-shell particles manufactured using the techniques described above are relatively large due to the agglomeration of commercial TiO2 powders. As a result, these particles can not be found in transparent materials (El-Toni et al. 2006; Demirörs et al. 2010).

Zhang et al. used a simple miniemulsion-combined sol–gel approach to make the TiO2–SiO2 hybrid. The UV-blocking efficiency of this hybrid was excellent without affecting the transparency (Zhang et al. 2010). Zhang et al. used the sol–gel technique to synthesize TiO2–SiO2. Materials modified with TiO2/SiO2 had better protection compared to materials modified with silica particles or materials that were not treated. Furthermore, the coated nanoparticles had no impact on the organic materials in terms of photodecomposition. The TiO2/SiO2 has potential in UV blocking utilizations during inhibiting photodecomposition upshot on organic substrate, according to the experimental results and the technological approach (Zhang et al. 2011). Figure 13 exhibits SEM of cotton colored with CI reactive red 120 at varying concentrations of TiO2, as well as specimens colored with commercial CI reactive red. Figures 14 and 15 demonstrate XRD, and SEM images of untreated and treated cotton with TiO2 NPs based on different urea nitrate (UN) concentrations.

SEM of colored cotton with colour index (CI) reactive red 120 doped with various amounts of TiO2 nano-sol and specimens colored with commercial CI reactive red 120. Reproduced with permission (Alebeid and Zhao 2016). Copyright © 2016, Taylor & Francis

XRD of untreated and treated cotton fabrics with TiO2 NPs based on different concentrations of UN, (A) untreated, (T1) treated cotton fabric with 0.2 g, (T2) treated cotton fabric with 0.4 g, and (T3) treated cotton fabric with 0.6 g of UN. Reproduced with permission (El-Naggar et al. 2016). Copyright © 2016, American Chemical Society

SEM of (a) pristine cotton, TiO2 NPs treated cotton employing (b) 0.2 g of UN, (c) 0.4 g of UN, and (d) 0.6 g of UN, (e) EDX, and (f) elemental contents of TiO2NPs treated cotton fabrics. Reproduced with permission (El-Naggar et al. 2016). Copyright © 2016, American Chemical Society

As indicated in Fig. 14, the structural characterization of TiO2NPs with various concentrations on the cotton surface was studied using XRD with Cu radiation. The peaks at 2theta 14.8°, 16.6°, 22.7°, and 34.4° (Fig. 14) correspond to the diffraction planes of cellulose Ibeta (1-10), (110), (200) and (004), respectively (French 2014). Some reasonably strong reflection peak at 27.56°, 40.44°, 43.33°, 65.88°, and 87.42° correspond to TiO2NPs (T1). There is a small shift for the stated peak as the concentration of TiO2 NPs increases (T2 and T3). The produced TiO2NPs were found to be well correlated to the rutile phase, with significant diffraction peaks corresponding to the (110), (101), (111), (211), and (220) orientations, accordingly.

Figure 15 shows how treated cotton modifies the morphological structure (T1, T2 and T3). As a result, the surface of the cotton turns rough and uneven, suggesting that TiO2 NPs have been successfully coated on the surface. The EDX spectrum revealed elemental analyses of C, O, and Ti, indicating the existence of a Ti layer coating on the cotton surface.

Graphene as UV protective nanoparticles

Because of its remarkable mechanical, electrical, thermal, and optical properties, graphene and its derivatives have attracted a lot of attention from the semiconductor field (Bonaccorso et al. 2010; Ponraj et al. 2016; Ergoktas et al. 2020; Bhattacharjee et al. 2021). The pad-dry-cure approach was employed by Lijun et al. to functionalize cotton fabric coated with low graphene nanoplate (GNP) (0.05–0.4 wt.%). With only 0.4% weight of GNP, the modified cotton gave outstanding UV protection, with a 10-fold increase in UPF (from 32.71 to 356.74) (Qu et al. 2014). Pandiyarasan et al. proposed a new way for increasing the UPF value of cotton fabric by using a non-toxic hydrothermal technique to deposit reduced graphene oxide (rGO). Before and after laundering, the UPF values of bare cotton and rGO-deposited cotton fabric were calculated to be 7.83, 442.69, and 442.32, respectively. The manufactured material was established to have outstanding UV protection properties as well as a long lifespan (Pandiyarasan et al. 2017). In order to improve the UPF value of cotton fabric, Tian et al. developed a new electrostatic self-assembly (ESA) technology (Tian et al. 2016).

Graphene oxide (GO) is a negatively charged nanostructure in an aqueous solution that may be simply constructed on a substrate with positively charged polyelectrolyte through the ESA method to form a multilayer network. They used the layer-by-layer ESA technique to create a UV-protective cotton fabric with GO as a polyanion and chitosan (CS) as a polycation. The UPF values increased as the number of GO/CS-deposited layers on the textile increased. In comparison to cotton control fabric with a UPF of 9.37, fabric with a double layer of (GO/CS)1 had a UPF of 88.93, while fabric with ten double layers of (GO/CS)10 had a UPF of 452. The UPF values of the (GO/CS)1 and (GO/CS)10 specimens decreased from 88.93 to 80.22 and 452 to 431.39, respectively, after 10 times water washings. The UV (UVA and UVB) transmittance increased by less than 1%, showing that GO/CS-deposited textiles delivered excellent UV protection and washing endurance. Figure 16 illustrates a graphical representation of UV protection cotton fabric developed through layer by layer self-assembly of GO and chitosan technique (Tian et al. 2016).

Schematic illustration of UV protection cotton fabric developed through layer by layer self-assembly of GO and chitosan. Reproduced with permission (Tian et al. 2016). Copyright © 2016, Elsevier

Carbon nanotube (CNT) as UV protective nanoparticles

Carbon nanotubes (CNTs) are one of the important components of nanotechnology, with a length-to-diameter ratio of more than 1,000,000. They are used in a variety of sectors in material research because of their anisotropic electrical, mechanical, and thermal properties. CNT has been created through a variety of ways. They offer great promise for use in a variety of industries, including nanoelectronics, biotechnology, material science, polymer, composite, and textiles. Recent studies on the use of carbon nanotubes in UV protection for cotton fabrics are covered in this study. Fabrics treated with carbon nanotubes produce a wide range of conductive textiles with varying electrical characteristics. The fabric wear properties combined with carbon nanotubes expand the possibility of creating composite materials for both traditional and novel implementations, ranging from traditional apparel and sportswear to protective clothing, heating equipment, automotive textiles, building coverings, geotextiles, biomedical textiles, and so on. Nanotubes are classified into two types: single-walled nanotubes (SWNTs) and multi-walled nanotubes (MWNTs). To develop single-walled nanotubes, a single graphite sheet is precisely coiled into a cylindrical tube (SWNT). The majority of SWNTs are about 1 nanometer in diameter, although they can be much larger. The multi-walled carbon nanotubes (MWCNTs) were made up of tens of graphitic shells, each with a high length-to-diameter ratio (Kuzmany et al. 2004; Grobert 2007; Wu 2009; Bilotti et al. 2013; Cao et al. 2013; Mallakpour and Khadem 2016; Siqueira and Oliveira 2017; Shahidi and Moazzenchi 2018; Devi and Gill 2021).

Chemically, inorganic UV blockers are harmless and chemically stable. UV radiation is efficiently absorbed and scattered by nanoscale semiconductor oxides. Scattering is affected by the size and wavelength of the nanoparticles (Yetisen et al. 2016). The surface coating approach was used to modify the properties of cotton fibers using CNT. CNT network armor has indeed been constructed on the exterior of cotton fibers, and cotton fabrics with 0.25 percent CNT demonstrate remarkable UV protection (Liu et al. 2008). The UV-blocking characteristics of polymer materials can really be improved by carbon nanotubes. The coloring effect is a limitation of employing CNT in textiles. After the operation, the cotton fabrics will turn black. Combining CNT with additional UV-blocking chemicals is recommended to reduce the coloring influence of CNT on fabrics (Liu et al. 2008). The schematic of the structures of cotton fiber and cotton fiber with CNT network armor is shown in Fig. 17. SEM images of pristine cotton fibers and CNT-coated cotton fibers are presented in Fig. 18.

Schematic showing the structures of: (a) cotton fiber and (b) cotton fiber with CNT network armor. Reproduced with permission (Liu et al. 2008). Copyright © 2008, Royal Society of Chemistry

SEM of pristine cotton fibers (a, bar = 10 μm; b, bar = 1 μm) and CNT coated cotton (c, bar = 10 μm; d, bar = 1 μm; e, bar = 1 μm; f, bar = 1 μm). Reproduced with permission (Liu et al. 2008). Copyright © 2008, Royal Society of Chemistry

The UV absorption capabilities of single and multi-wall carbon nanotubes were investigated, and the results obtained were compared to chemical and mineral UV absorbers (Mahmoudifard and Safi 2012). CNTs, particularly SWCNTs, have the same specific absorption value as typical UV absorbers in the UV region of the electromagnetic spectrum. Moreover, the cotton cloth impregnated with the SWCNT had the highest UPF value. UV protection treatment for textiles might include SWCNT and MWCNT (Amini et al. 2014). Cotton fabrics were treated with MWCNTs using a cross-linking agent. It was found that treating cotton fabrics with MWCNTs boosts UV blocking performance significantly (Karimi et al. 2014). The effectiveness of the cured sample to block UV light is greater than that of the uncured sample. It could be due to nanomaterials' capacity to block UV light. To manufacture conductive cotton yarns, cotton yarns were dipped in SWNTs solutions and then dried at room temperature—a simple procedure that exhibits uniformity in coating cotton yarns with conductive CNTs. The impact of manufacturing conditions on the conductivity of SWNT-CY was investigated. According to the results (Zhao et al. 2018), the conductive yarns can transport weak bio-electrical impulses without significant attenuation or distortion. Figure 19 shows a schematic explanation of the manufacturing pathway for SWNT-coated conductive cotton yarns.

Graphical presentation of the fabrication process for the conductive SWNT-coated cotton yarns (Zhao et al. 2018). Published under a CC-BY license, MDPI

Boron and nitrogen co-doped carbon dots (BN-CD) were developed using one-pot hydrothermal carbonization and used as UV-absorbers for cotton textiles. The UV protection and washing resistance of treated cotton fabrics are assessed. According to the findings, as-prepared BN-CD has a substantial fluorescence and down-conversion fluorescence emission. The UV transmittance of cotton fabric finished with BN-CD and poly(vinyl alcohol) in the 280–400 nm range is less than 4%, with a UV protection factor of up to 38.6 and remarkable laundry durability, indicating that BN-CD has a promising potential as UV absorbers for finishing cotton fabrics (Zuo et al. 2019). The possible mechanism of anti-ultraviolet radiation for cotton fabrics by BN-CD is shown in Fig. 20.

Potential anti-ultraviolet radiation technique for cotton using BN-CD. Reproduced with permission (Zuo et al. 2019). Copyright © 2019, Springer nature

Nanoparticles synthesis

Multiple nanoparticle synthesis methods have been applied, since they are appropriate for the synthesis of nanoparticles of diverse formats. Synthesizing is the primary step of preparing the ultimate solution that coats the fabric and acquires a good UV protection ability. Various nanoparticles synthesis for cotton fabric, their UPF and durability are shown in Table 4.

Conclusions and outlook

The UV protection factors of cotton fabric depend on its structural parameters. The type of weave or knit, yarn fineness, weave or knit density, relative fabric tightness, cover factor, open porosity, and thickness are the most key aspects to consider. Treating cotton fabric with conventional ultraviolet absorbers is another way to achieve ultraviolet blocking properties of a fabric. Even so, recent findings have shown that these chemicals have limitations in terms of application because of toxicity, low activity, and poor washability. Due to their effectiveness against UV radiation and multifunctional properties, nanoparticles have attracted much attention from researchers. The effectiveness and durability of ZnO and TiO2 have been documented in a number of studies and investigations. Because of its exceptional mechanical, electrical, thermal, and optical properties, graphene is also gaining attention as an excellent ultraviolet protective nanoparticle. In recent studies, UV-protective substances derived from natural sources have been disregarded and very few studies are available for discussion. Different nanoparticles are more advanced solutions due to their superior fastness properties. Different semiconductor nanoparticles like silicon dioxide can be an advanced solution, as they also have self-cleaning properties. Cotton surface modification has been pioneered by textile and polymer scientists, and R&D continues to prioritize the development of functional textiles in a variety of industries, including medical, defence, garments, and sports. Despite the progress made thus far, a few research have been carried out to verify all of the statements mentioned in this review. There is not enough scientific evidence to figure out how bioactive natural colorants work once they have been applied to cotton substrates. As a result, more research on surface changes is needed to better understand how they attach to various textile substrates. The current point of view, according to the authors, will help scientists in developing novel green surface modification technologies for cotton and understanding the dye-fiber bonding mechanism for UV protection.

References

Abd Elhady MM (2012) Preparation and Characterization of Chitosan/Zinc Oxide Nanoparticles for Imparting Antimicrobial and UV Protection to Cotton Fabric. Int J Carbohydr Chem 2012:1–6. https://doi.org/10.1155/2012/840591

Abidi N (2018) Chemical Properties of Cotton Fiber and Chemical Modification. In: Fang DD (ed) Cotton Fiber: Physics, Chemistry and Biology. Springer, Cham, pp 95–115

Abidi N, Hequet E, Tarimala S, Dai LL (2007) Cotton fabric surface modification for improved UV radiation protection using sol-gel process. J Appl Polym Sci 104:111–117. https://doi.org/10.1002/app.24572

Abidi N, Cabrales L, Hequet E (2009) Functionalization of a cotton fabric surface with titania nanosols: Applications for self-cleaning and UV-protection properties. ACS Appl Mater Interfaces 1:2141–2146. https://doi.org/10.1021/am900315t

Advances R (2019) Zinc Oxide for Functional Textile Coatings. Coatings 550:17–23

Agrawal N, Si J, Tan J et al (2019) Green Synthesis of Robust Superhydrophobic Antibacterial and UV-Blocking Cotton Fabrics by a Dual-Stage Silanization Approach. Adv Mater Interfaces 6:1–10. https://doi.org/10.1002/admi.201900032

Aguilera J, De-Gálvez MV, Sánchez- Roldán C, Herrera-Ceballos E (2014) New Advances in Protection Against Solar Ultraviolet Radiation in Textiles for Summer Clothing. Photochem Photobiol 90:1199–1206. https://doi.org/10.1111/php.12292

Ahmad I, Kan CW, Yao Z (2019) Photoactive cotton fabric for UV protection and self-cleaning. RSC Adv 9:18106–18114. https://doi.org/10.1039/c9ra02023c

Akhavan Sadr F, Montazer M (2014) In situ sonosynthesis of nano TiO2 on cotton fabric. Ultrason Sonochem 21:681–691. https://doi.org/10.1016/j.ultsonch.2013.09.018

Alebeid OK, Zhao T (2016) Simultaneous dyeing and functional finishing of cotton fabric using reactive dyes doped with TiO2 nano-sol. J Text Inst 107:625–635. https://doi.org/10.1080/00405000.2015.1054209

Alebeid OK, Zhao T (2017) Review on: developing UV protection for cotton fabric. J Text Inst 108:2027–2039. https://doi.org/10.1080/00405000.2017.1311201

Alebeid OK, Tao Z, Seedahmed AI (2015) New approach for dyeing and UV protection properties of cotton fabric using natural dye extracted from henna leaves. Fibres Text East Eur 23:60–65. https://doi.org/10.5604/12303666.1161758

Algaba I, Riva A (2002) In vitro measurement of the ultraviolet protection factor of apparel textiles. Color Technol 118:52–58. https://doi.org/10.1111/j.1478-4408.2002.tb00137.x

Aloui F, Ahajji A, Irmouli Y et al (2007) Inorganic UV absorbers for the photostabilisation of wood-clearcoating systems: Comparison with organic UV absorbers. Appl Surf Sci 253:3737–3745. https://doi.org/10.1016/j.apsusc.2006.08.029

Amini A, Zohoori S, Mirjalili A et al (2014) Improvement in physical properties of paper fabric using multi-wall carbon nanotubes. J Nanostruct Chem 4:1–5. https://doi.org/10.1007/s40097-014-0103-4

Andrady AL, Torikai A, Redhwi HH et al (2015) Consequences of stratospheric ozone depletion and climate change on the use of materials. Photochem Photobiol Sci 14:170–184. https://doi.org/10.1039/c4pp90038c

Asmat-Campos D, Delf D, Ju L (2021) Textiles Functionalized with ZnO Nanoparticles Obtained by Chemical and Green Synthesis Protocols : Evaluation of the Type of Textile and Resistance to UV Radiation. Fibers 9:1–14

Bae HS, Lee MK, Kim WW, Rhee CK (2003) Dispersion properties of TiO2 nano-powder synthesized by homogeneous precipitation process at low temperatures. Colloids Surf A Physicochem Eng Asp 220:169–177. https://doi.org/10.1016/S0927-7757(03)00077-3

Bais AF, Lucas RM, Bornman JF et al (2018) Environmental effects of ozone depletion, UV radiation and interactions with climate change: UNEP Environmental Effects Assessment Panel, update 2017. Photochem Photobiol Sci 17:127–179. https://doi.org/10.1039/c7pp90043k

Bajaj P, Kothari VK, Ghosh SB (2000) Some innovations in UV protective clothing. Indian J Fibre Text Res 25:315–329

Barani H (2014) Preparation of antibacterial coating based on in situ synthesis of ZnO/SiO 2 hybrid nanocomposite on cotton fabric. Appl Surf Sci 320:429–434. https://doi.org/10.1016/j.apsusc.2014.09.102

Barnes PW, Williamson CE, Lucas RM et al (2019) Ozone depletion, ultraviolet radiation, climate change and prospects for a sustainable future. Nat Sustain 2:569–579. https://doi.org/10.1038/s41893-019-0314-2

Becheri A, Dürr M, Lo Nostro P, Baglioni P (2008) Synthesis and characterization of zinc oxide nanoparticles: Application to textiles as UV-absorbers. J Nanopart Res 10:679–689. https://doi.org/10.1007/s11051-007-9318-3

Behcet B, Halil Rifat A (2010) Ultraviolet (Uv) Protection of Textiles : a Review. Int Sci Conf Gabrovo 2010:301–311

Bhattacharjee S, Joshi R, Yasir M et al (2021) Graphene- And Nanoparticle-Embedded Antimicrobial and Biocompatible Cotton/Silk Fabrics for Protective Clothing. ACS Appl Bio Mater 4:6175–6185. https://doi.org/10.1021/acsabm.1c00508

Bilotti E, Zhang H, Deng H et al (2013) Controlling the dynamic percolation of carbon nanotube based conductive polymer composites by addition of secondary nanofillers: The effect on electrical conductivity and tuneable sensing behaviour. Compos Sci Technol 74:85–90. https://doi.org/10.1016/j.compscitech.2012.10.008

Bonaccorso F, Sun Z, Hasan T, Ferrari AC (2010) Graphene photonics and optoelectronics. Nat Photonics 4:611–622. https://doi.org/10.1038/nphoton.2010.186

Bonet-Aracil MÁ, Díaz-García P, Bou-Belda E et al (2016) UV protection from cotton fabrics dyed with different tea extracts. Dyes Pigments 134:448–452. https://doi.org/10.1016/j.dyepig.2016.07.045

Boomi P, Poorani GP, Selvam S et al (2020) Green biosynthesis of gold nanoparticles using Croton sparsiflorus leaves extract and evaluation of UV protection, antibacterial and anticancer applications. Appl Organomet Chem 34:1–13. https://doi.org/10.1002/aoc.5574

Çakir BA, Budama L, Topel Ö, Hoda N (2012) Synthesis of ZnO nanoparticles using PS-b-PAA reverse micelle cores for UV protective, self-cleaning and antibacterial textile applications. Colloids Surf A Physicochem Eng Asp 414:132–139. https://doi.org/10.1016/j.colsurfa.2012.08.015

Cao Q, Yu Q, Connell DW, Yu G (2013) Titania/carbon nanotube composite (TiO2/CNT) and its application for removal of organic pollutants. Clean Techn Environ Policy 15:871–880. https://doi.org/10.1007/s10098-013-0581-y

Chakraborty JN (ed) (2014) Fundamentals and Practices in Colouration of Textiles, 2nd edn. Woodhead Publishing India, New Delhi

Chakraborty JN, Sharma V, Gautam P (2014) Enhancing UV protection of cotton through application of novel UV absorbers. J Text Apparel, Technol Manag 9:1–17. https://ojs.cnr.ncsu.edu/index.php/JTATM/article/view/5620/3279

Chattopadhyay SN, Pan NC, Roy AK et al (2013) Development of natural dyed jute fabric with improved colour yield and UV protection characteristics. J Text Inst 104:808–818. https://doi.org/10.1080/00405000.2012.758352

Çil MG, Nergis UB, Candan C (2009) An Experimental Study of Some Comfort-related Properties of Cotton—Acrylic Knitted Fabrics. Text Res J 79:917–923. https://doi.org/10.1177/0040517508099919

Daoud WA, Kong YY (2004) A New Approach to UV-Blocking Treatment for Cotton Fabrics. Text Res J 74:97–100. https://doi.org/10.1177/004051750407400202

Daoud WA, Xin JH, Zhang YH (2005) Surface functionalization of cellulose fibers with titanium dioxide nanoparticles and their combined bactericidal activities. Surf Sci 599:69–75. https://doi.org/10.1016/j.susc.2005.09.038

Das BR, Ishtiaque SM, Rengasamy RS et al (2010) Ultraviolet Absorbers for Textiles. Res J Text Appar 14:42–52. https://doi.org/10.1108/RJTA-14-01-2010-B005

Dastjerdi R, Mojtahedi MRM, Shoshtari AM, Khosroshahi A (2010) Investigating the production and properties of Ag/TiO2/PP antibacterial nanocomposite filament yarns. J Text Inst 101:204–213. https://doi.org/10.1080/00405000802346388

Demirörs AF, Van Blaaderen A, Imhof A (2010) A general method to coat colloidal particles with titania. Langmuir 26:9297–9303. https://doi.org/10.1021/la100188w

Devi R, Gill SS (2021) A squared bossed diaphragm piezoresistive pressure sensor based on CNTs for low pressure range with enhanced sensitivity. Microsyst Technol 27:3225–3233. https://doi.org/10.1007/s00542-020-05208-7

Dimitrovski K, Sluga F, Urbas R (2010) Evaluation of the Structure of Monofilament PET Woven Fabrics and their UV Protection Properties. Text Res J 80:1027–1037. https://doi.org/10.1177/0040517509352527

Downs NJ, Harrison SL (2018) A comprehensive approach to evaluating and classifying sun-protective clothing. Br J Dermatol 178:958–964. https://doi.org/10.1111/bjd.15938

Duan W, Xie A, Shen Y et al (2011) Fabrication of superhydrophobic cotton fabrics with UV protection based on CeO2 particles. Ind Eng Chem Res 50:4441–4445. https://doi.org/10.1021/ie101924v

Dubrovski PD, Brezocnik M (2009) Prediction of the ultraviolet protection of cotton woven fabrics dyed with reactive dystuffs. Fibres Text East Eur 72:55–59

Dubrovski PD, Golob D (2009) Effects of Woven Fabric Construction and Color on Ultraviolet Protection. Text Res J 79:351–359. https://doi.org/10.1177/0040517508090490

El Shafei A, Abou-Okeil A (2011) ZnO/carboxymethyl chitosan bionano-composite to impart antibacterial and UV protection for cotton fabric. Carbohydr Polym 83:920–925. https://doi.org/10.1016/j.carbpol.2010.08.083

El Tahlawy K, El Nagar K, Elhendawy AG (2007) Cyclodextrin-4 Hydroxy benzophenone inclusion complex for UV protective cotton fabric Cyclodextrin-4 Hydroxy benzophenone inclusion complex for UV protective cotton fabric. J Text Inst 98:453–462. https://doi.org/10.1080/00405000701556327

El-Naggar ME, Shaheen TI, Zaghloul S et al (2016) Antibacterial Activities and UV Protection of the in Situ Synthesized Titanium Oxide Nanoparticles on Cotton Fabrics. Ind Eng Chem Res 55:2661–2668. https://doi.org/10.1021/acs.iecr.5b04315

El-Toni AM, Yin S, Sato T (2006) Control of silica shell thickness and microporosity of titania-silica core-shell type nanoparticles to depress the photocatalytic activity of titania. J Colloid Interface Sci 300:123–130. https://doi.org/10.1016/j.jcis.2006.03.073

Emam HE, Bechtold T (2015) Cotton fabrics with UV blocking properties through metal salts deposition. Appl Surf Sci 357:1878–1889. https://doi.org/10.1016/j.apsusc.2015.09.095

Ergoktas MS, Bakan G, Steiner P et al (2020) Graphene-Enabled Adaptive Infrared Textiles. Nano Lett 20:5346–5352. https://doi.org/10.1021/acs.nanolett.0c01694

Farouk A, Textor T, Schollmeyer E et al (2010) Sol-gel-derived inorganic-organic hybrid polymers filled with zno nanoparticles as an ultraviolet protection finish for textiles. Autex Res J 10:58–63

Feng XX, Zhang LL, Chen JY, Zhang JC (2007) New insights into solar UV-protective properties of natural dye. J Clean Prod 15:366–372. https://doi.org/10.1016/j.jclepro.2005.11.003

Fioletov V, Kerr JB, Fergusson A (2010) The UV index: Definition, distribution and factors affecting it. Can J Public Health 101:15–19. https://doi.org/10.1007/bf03405303

Frederick JE (2015) Ozone Depletion and Related Topics: Ozone as a UV Filter, 2nd edn. Elsevier, Amsterdam

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21:885–896. https://doi.org/10.1007/s10570-013-0030-4

Fu G, Vary PS, Lin CT (2005) Anatase TiO 2 nanocomposites for antimicrobial coatings. J Phys Chem B 109:8889–8898. https://doi.org/10.1021/jp0502196

Gabrijelčič H, Urbas R, Sluga F, Dimitrovski K (2009) Influence of fabric constructional parameters and thread colour on UV radiation protection. Fibres Text East Eur 72:46–54

Gambichler T, Rotterdam S, Altmeyer P, Hoffmann K (2001) Protection against ultraviolet radiation by commercial summer clothing: Need for standardised testing and labelling. BMC Dermatol 1:1–4. https://doi.org/10.1186/1471-5945-1-6

Gambichler T, Hatch KL, Avermaete A et al (2002) Ultraviolet protection factor of fabrics: Comparison of laboratory and field-based measurements. Photodermatol Photoimmunol Photomed 18:135–140. https://doi.org/10.1034/j.1600-0781.2001.00739.x

Gambichler T, Laperre J, Hoffmann K (2006) The European standard for sun-protective clothing: EN 13758. J Eur Acad Dermatol Venereol 20:125–130. https://doi.org/10.1111/j.1468-3083.2006.01401.x

Gies PH, Roy CR, Toomey S, Mclennan A (1998) Protection against solar ultraviolet radiation. Mutat Res 422:15–22. https://doi.org/10.1016/S0027-5107(98)00181-X

Gies P, Van Deventer E, Green AC et al (2018) Review of the Global Solar UV Index 2015 Workshop Report. Health Phys 114:84–90. https://doi.org/10.1097/HP.0000000000000742

Gnanasekaran L, Hemamalini R, Ravichandran K (2015) Synthesis and characterization of TiO2 quantum dots for photocatalytic application. J Saudi Chem Soc 19:589–594. https://doi.org/10.1016/j.jscs.2015.05.002

Golob V, Ojstršek A (2005) Removal of vat and disperse dyes from residual pad liquors. Dyes Pigments 64:57–61. https://doi.org/10.1016/j.dyepig.2004.04.006

Gorenšek M, Recelj P (2007) Nanosilver Functionalized Cotton Fabric. Text Res J 77:138–141. https://doi.org/10.1177/0040517507076329

Gorenšek M, Sluga F (2004) Modifying the UV blocking effect of polyester fabric. Text Res J 74:469–474. https://doi.org/10.1177/004051750407400601

Gorjanc M, Jazbec K, Mozetič M, Kert M (2014) UV protective properties of cotton fabric treated with plasma, UV absorber, and reactive dye. Fibers Polym 15:2095–2104. https://doi.org/10.1007/s12221-014-2095-6

Grifoni D, Bacci L, Zipoli G et al (2009) Laboratory and outdoor assessment of UV protection offered by flax and hemp fabrics dyed with natural dyes. Photochem Photobiol 85:313–320. https://doi.org/10.1111/j.1751-1097.2008.00439.x

Grifoni D, Bacci L, Zipoli G et al (2011) The role of natural dyes in the UV protection of fabrics made of vegetable fibres. Dyes Pigments 91:279–285. https://doi.org/10.1016/j.dyepig.2011.04.006

Grishanov S (2011) Structure and properties of textile materials. Woodhead Publishing Limited, Sawston

Grobert N (2007) Carbon nanotubes - becoming clean. Mater Today 10:28–35. https://doi.org/10.1016/S1369-7021(06)71789-8

Gupta D, Jain A, Panwar S (2005) Anti-UV and anti-microbial properties of some natural dyes on cotton. Indian J Fibre Text Res 30:190–195

Han K, Yu M (2006) Study of the preparation and properties of UV-blocking fabrics of a PET/TiO2 nanocomposite prepared by in situ polycondensation. J Appl Polym Sci 100:1588–1593. https://doi.org/10.1002/app.23312

Harrison SL, Downs N (2015) Development of a Reproducible Rating System for Sun Protective Clothing That Incorporates Body Surface Coverage. World J Eng Technol 03:208–214. https://doi.org/10.4236/wjet.2015.33c031

Hearle JWS, Morton WE (2008) Physical Properties of Textile Fibres, 4th edn. Woodhead Publishing Limited, Cambridge

Hussain M, Shamey R, Hinks D et al (2012) Synthesis of novel stilbene-alkoxysilane fluorescent brighteners, and their performance on cotton fiber as fluorescent brightening and ultraviolet absorbing agents. Dyes Pigments 92:1231–1240. https://doi.org/10.1016/j.dyepig.2011.06.034

Hustvedt G, Crews PC (2005) The ultraviolet protection factor of naturally-pigmented cotton. J Cotton Sci 9:47–55

Ibǎnescu M, Muşat V, Textor T et al (2014) Photocatalytic and antimicrobial Ag/ZnO nanocomposites for functionalization of textile fabrics. J Alloys Compd 610:244–249. https://doi.org/10.1016/j.jallcom.2014.04.138

Ibrahim NA, Gouda M, Hussefny SM et al (2009) UV-protectleg and antibacterial finishing of cotton knits. J Appl Polym Sci 112:3589–3596. https://doi.org/10.1002/app.29669

Ibrahim NA, Eid BM, Abdel-aziz MS (2016) Applied Surface Science Green synthesis of AuNPs for eco-friendly functionalization of cellulosic substrates. Appl Surf Sci 389:118–125. https://doi.org/10.1016/j.apsusc.2016.07.077

Islam MT, Liman MLR, Roy MN et al (2021a) Cotton dyeing performance enhancing mechanism of mangiferin enriched bio-waste by transition metals chelation. J Text Inst 0:1–13. https://doi.org/10.1080/00405000.2021.1892337

Islam MT, Repon MR, Liman MLR et al (2021b) Functional modification of cellulose by chitosan and gamma radiation for higher grafting of UV protective natural chromophores. Radiat Phys Chem 183:109426. https://doi.org/10.1016/j.radphyschem.2021.109426

Islam MT, Repon MR, Liman MLR et al (2021c) Plant tannin and chitosan-templated cellulose for improved absorption of UV protective natural chromophores. Sustain Chem Pharm 21:100452. https://doi.org/10.1016/j.scp.2021.100452

Jansen R, Wang SQ, Burnett M et al (2013) Photoprotection: Part I. Photoprotection by naturally occurring, physical, and systemic agents. J Am Acad Dermatol 69:853.e1–853.e12. https://doi.org/10.1016/j.jaad.2013.08.021

Kamel MM, El-Shishtawy RM, Youssef BM, Mashaly H (2007) Ultrasonic assisted dyeing. IV. Dyeing of cationised cotton with lac natural dye. Dyes Pigments 73:279–284. https://doi.org/10.1016/j.dyepig.2005.12.010

Kan CW (2014) A study on ultraviolet protection of 100% cotton knitted. Sci World J 2014:1–10

Kang SM, Polvani LM, Fyfe JC, Sigmond M (2011) Impact of polar ozone depletion on subtropical precipitation. Science (80) 332:951–954. https://doi.org/10.1126/science.1202131

Karimi L, Zohoori S, Amini A (2014) Multi-wall carbon nanotubes and nano titanium dioxide coated on cotton fabric for superior self-cleaning and UV blocking. New Carbon Mater 29:380–385. https://doi.org/10.1016/S1872-5805(14)60144-X

Karthik S, Siva P, Shanmugam K, Suriyaprabha R (2017) Acalypha indica – mediated green synthesis of ZnO nanostructures under differential thermal treatment : Effect on textile coating , hydrophobicity , UV resistance , and antibacterial activity. Adv Powder Technol 28:3184–3194. https://doi.org/10.1016/j.apt.2017.09.033

Kathirvelu S, D’Souza L, Dhurai B (2009) UV protection finishing of textiles using ZnO nanoparticles. Indian J Fibre Text Res 34:267–273

Kerr JB, Fioletov VE (2008) Surface ultraviolet radiation. Atmosphere-Ocean 46:159–184. https://doi.org/10.3137/ao.460108

Keshmiri M, Mohseni M, Troczynski T (2004) Development of novel TiO2 sol-gel-derived composite and its photocatalytic activities for trichloroethylene oxidation. Appl Catal B Environ 53:209–219. https://doi.org/10.1016/j.apcatb.2004.05.016

Khan ZA, Iqbal A, Shahzad SA (2017) Synthetic approaches toward stilbenes and their related structures. Mol Divers 21:483–509. https://doi.org/10.1007/s11030-017-9736-9

Khan A, Nazir A, Rehman A et al (2020) A review of UV radiation protection on humans by textiles and clothing. Int J Cloth Sci Technol 32:869–890. https://doi.org/10.1108/IJCST-10-2019-0153

Kim S (2006) Dyeing characteristics and UV protection property of green tea dyed cotton fabrics. Fibers Polym 7:255–261. https://doi.org/10.1007/bf02875682

Knollmann-Ritschel BEC, Markowitz M (2017) Educational Case: Lead Poisoning. Acad Pathol 4:1–3. https://doi.org/10.1177/2374289517700160

Kocić A, Bizjak M, Popović D et al (2019) UV protection afforded by textile fabrics made of natural and regenerated cellulose fibres. J Clean Prod 228:1229–1237. https://doi.org/10.1016/j.jclepro.2019.04.355