Abstract

The work aims to research the effect of dibutyl succinate on the water-absorbing and water-holding properties of the composite superabsorbents enriched in the sodium salt of carboxymethyl cellulose. The synthesized composite superabsorbents with a different content of dibutyl succinate were analyzed by FTIR, SEM, XRD, DSC, and rheological measurements; equilibrium swelling ratio values, Qe, in distilled water and in a saline solution were determined; and swelling kinetics, water-holding properties, and regeneration ability were researched. It was found that adding 5% w of dibutyl succinate increases Qe values in distilled water up to 51% compared to blank superabsorbents. The effect of a plasticizer is due to its selective interaction with intramolecular H-bond-forming links, which increases the flexibility of the polymeric network and the availability of sorption sites for water molecules. The non-outwashing of a plasticizer in an aqueous medium was confirmed by HPLC–MS. The presence of dibutyl succinate does not change the water absorption mechanism controlled by chemisorption and pseudo-Fickian diffusion of water molecules but accelerates the equilibrium swelling ratio achievement. Also, there is no significant impact of a plasticizer on the water-holding properties of the synthesized superabsorbents at 80 °C, as well as on their reusability, which retains during several swelling-deswelling cycles. So, dibutyl succinate may be applied as an efficient plasticizer enhancing water sorption properties of the composite superabsorbents based on carboxymethyl cellulose sodium salt.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Currently, much attention of researchers around the world is attracted to the development of superabsorbents (SAPs) which are cross-linked polymeric hydrogel materials capable of absorbing and retaining significant amounts of water, hundreds and thousands of times higher than their weight (Mignon et al. 2019). Such polymers are used in various fields of human activity, but they are especially widely used in biomedicine (Samadian et al. 2020; Amiri et al. 2021), for the controlled release of some drugs such as diclofenac sodium (Hosseinzadeh 2010; Pourjavadi et al. 2013; Haseeb et al. 2016), tetracycline (Jeong et al. 2018), doxorubicin (Khan et al. 2019), diethyl carbamazine citrate (Mehta et al. 2021), etc.; as well as in the creation of personal hygiene products (Lacoste et al. 2019) and agriculture (Li and Chen 2019; Saha et al. 2020).

Earlier research describing the creation of SAPs, also as known as hydrogels, dealt with the synthesis of cross-linked polymers based on acrylic acid derivatives (Mignon et al. 2019). However, it became clear that the use of such polymers on a commercial scale would have a negative impact on the environment. This brought about the development of eco-friendly biodegradable polymers also retaining a high water absorption capacity (Qureshi et al. 2020). Most of these studies are devoted to the incorporation of polysaccharides into polyacrylic matrices, or the creation of SAPs based on modified polysaccharides and their interpolyelectrolyte complexes (Lacoste et al. 2019; Mignon et al. 2019; Ravishankar and Dhamodharan 2020). However, fully polysaccharide SAPs, also known as natural or bioSAPs, are often inferior in water absorption capacity to synthetic polyacrylate ones (Lv et al. 2018; Ravishankar and Dhamodharan 2020). At the same time, the swelling ratio of composites containing both natural and synthetic moieties significantly depends on the content and type of polysaccharides and decreases sharply with the growth of their content (Sorokin and Lavlinskaya 2021).

The main factor determining the ability of the SAP network to swell is the crosslinking degree (Chavda and Patel 2011; Khan and Ranjha 2014; Qureshi et al. 2020). The higher it is, the more rigid the polymer structure, and the more difficult it is for water molecules to penetrate and interact with sorption centers. All this reduces the ability of the SAPs to absorb water. Therefore, in most investigations connected to the creation of composite SAPs, the best results on the swelling ratio were obtained while using a small amount of a crosslinker (less than 1% w) in the polymerization mixture. However, the viscosity of the reaction mass enriched in polysaccharides is quite high; 3D polymeric network formation is complicated with a low content of a crosslinker; and the number of side processes leading to the formation of undesirable products increases (Suo et al. 2006).

One of the possible ways to solve the problem of increasing the water absorption capacity of composite SAPs enriched in polysaccharides is the introduction of plasticizers into the polymer structure. Such additives enhance the segmental mobility of the polymeric networks (Vieira et al. 2011; Wypych 2017), which should improve the availability of sorption centers for interaction with water molecules and increase the swelling degree of the resulting composites.

Unfortunately, at the moment there is no single theory describing the mechanism of interaction of the polymers with the plasticizers (Wypych 2017); therefore, these components are selected empirically for each polymer. According to the literature data (Lin et al. 2000; Vieira et al. 2011; Wypych 2017), the plasticizers most commonly used for polyacrylates are polyols and their ethers and esters with fat and (di)carboxylic acids, including toxic diphtatalates, (di)benzoates, as well as amines and amides. For the commonly used polysaccharides, such as cellulose and its derivatives, the common plasticizers are citrates and dicarboxylic acid esters. It can be assumed that the dicarboxylic acid esters are most suitable as plasticizers for the polyacrylate-cellulose derivatives composite.

In connection with the foregoing, the current work aims to research the effect of dibutyl succinate (DiBu-Suc) on the water-absorbing and water-holding properties of the composite superabsorbents enriched in the sodium salt of carboxymethyl cellulose.

Materials and methods

Materials

Carboxymethyl cellulose sodium salt (CMC) (food grade, > 99%), with an average Mw 10 000, degree of substitution 0.72, the viscosity of 1% water solution at 25 °C 11,448 mPa × s, was purchased from Stoing, Russia, and used for the SAP synthesis without any purification. Acrylamide (AAm) (extra pure, > 98%), acrylic acid (AA) (extra pure, > 98%), N,N-methylene-bis-acrylamide (MBAAm) (> 98%), potassium persulfate (PPS) (> 98%), and potassium hydroxide (> 98%), all Acros Organic, USA, were applied in SAP synthesis. AA with Tb = 45 °C/ 15 Hgmm was previously distilled in a vacuum, AAm and MBAAm were recrystallized in ethyl acetate, and PPS was recrystallized in deionized water before the work. Succinic acid (> 98%), butanol-1(anhydrous 99.5%), and p-toulenesulfonic acid (> 98%), all Acros Organic, USA, were used for dibutyl succinate synthesis. Distilled water (21 MΩ, pH = 6.7 ± 0.2), ethanol (anhydrous 99.5%, ReaKhim, Russia), and ethyl acetate (chromatography grade, > 99%, ReaKhim, Russia) were used as solvents without any treatments.

Dibutyl succinate synthesis

Dibutyl succinate was used as a plasticizer in the work. To obtain it, 11.8 g (0.1 mol) of succinic acid, 23 ml (0.25 mol) of butanol-1 and, 1 g (0.006 mol) of p-toluenesulfonic acid as a catalyzer were placed in a one-necked round-bottom flask equipped with a Dean-Stark trap containing toluene, a condenser, and a magnetic stirrer. The mixture was vigorously stirred until full acid dissolution, and refluxed for 6 h. The resulting product was purified by vacuum distillation at 97 °C/ 10 Hgmm. HPLC–MS testing of the synthesized dibutyl succinate showed a fineness of more than 99%. The yield of the product was 78%.

Superabsorbent synthesis

For CMC-SAP synthesis, several amounts of CMC (Table 1) were placed in a thermostatically controlled reactor equipped with a condenser, a mechanical stirrer, and a nitrogen line for degassing of the reaction mixture, and dissolved under vigorous stirring in 50 mL of distilled water. Then, 10 mL of a water solution containing AAm, AA, MBAAm, and PPS (Table 1) was added to the reactor and kept at 80 °C for 2 h. The product obtained was ground with 1.63 g of KOH in 10 mL of deionized water, immersed in ethanol overnight to remove soluble compounds, milled with 2, 5, or 10% w dibutyl succinate in 5 mL of ethanol, and dried in a vacuum to a constant weight. After drying, the yield of the products was 89–95%. The resulting CMC-SAPs are insoluble in water, ethanol, propanol-2, and acetone.

Instrumental characterization

FTIR

For CMC-SAP structure characterization, FTIR ATR was used. The spectra were obtained by using a Bruker Vertex 70 instrument (Bruker Optics, Germany) with Fourier transducer in the 400–4000 cm−1 frequency range, 32 scannings during 1 cycle; the number of cycles was 4. The samples were in powder form.

SEM

For CMC-SAP surface research, the SEM method was applied. The SEM images were obtained using the scanning microscope JEOL JSM-6380LV (JEOL, Japan). The samples analyzed were sprayed with gold before conducting the scanning. The thickness of the gold film was 10 nm.

DSC

For glass transition temperature (Tg) determination, the DSC method was utilized. The research was performed on STA 449 F3 Jupiter simultaneous thermal analyzer (Netzsch, Germany) in a capped aluminum pan in a He atmosphere with a heat rate of 10 °C/min from 20 °C to 200 °C. The relaxation transition of the glass transition is accompanied by an abrupt growth in the heat capacity of the polymer and is fixed on the DSC curve as an inflexion. To obtain accurate results for this parameter on the DSC curve, it is necessary to select the point corresponding to the middle fold lines.

XRD

To investigate the influence of dibutyl succinate on the crystallinity of CMC-SAPs, the XRD method was used. The study was conducted with an Empyrean B.V. diffractometer (PANalytical B.V., Netherlands) equipped with a Cu-Kα radiation source (λ = 1.54 nm, 45 kV and 35 mA) in scattering angle range 2θ from 5° to 60° with a resolution of 0.1°, at a scanning speed of 0.2°/min.

Rheological research

To study the rheological properties and mechanical strength of the swollen particles of the synthesized CMC-SAPs, the rheological method was used. A stress-controlled Gemini HRnano rheometer (Malvern Instruments, UK) equipped with a solvent-trap and moisture controlling systems was applied for rheological measurements. The operating temperature was 210 °C controlled by a Peltier plate. The experiments were performed using acrylic parallel plate geometry (40 mm diameter, 1 mm gap). Three repetitions of measurements were carried out for each sample.

HPLC–MS

To confirm the obtaining of DiBu-Suc and its fineness, as well as outwashing of the plasticizer in aqueous media, the HPLC–MS method was applied. Agilent 1269 Infinity instrument equipped with an Agilent 6230 TOF LC/MS detector (Agilent Technologies, USA) and Poroshell 120 EC-C18 column (4.6 × 50 mm, 2.7 μm) was used for the investigation. The ionization method was double electrospray; registration was carried out in positive polarity; the registered mass range was 50–2000. Acetonitrile was utilized as eluent with a flow rate of 0.4 mL/min.

Swelling research

The equilibrium swelling ratio/swelling kinetics research in distilled water or 0.15 M NaCl aqueous solution was performed as described by Sorokin and Lavlinskaya 2021. The equilibrium swelling ratio, Qe, or swelling ratio at time t, Qt, is expressed as follows:

where m1 and m0 are the weights of swollen and dry CMC-SAP samples, respectively. The number of samples used for every synthesized SAP in the swelling ratio investigation was 3 (n = 3, P = 0.95). The results obtained were analyzed using MS Excel software and expressed as means ± SD from three independent experiments.

To study the water absorption mechanism and the effect of a plasticizer on it, swelling kinetics data were processed by common mathematical kinetic swelling models. The pseudo-first-order swelling kinetic model is expressed as (Lagergren 1898):

the pseudo-second-order swelling kinetic model is described by the following equations (Ho and McKay 1999):

and Ritger-Peppas model is characterized as (Peppas and Khare 1993):

taking the logarithm expression 4:

where Qe (g/g) and Qt (g/g) are the swelling ratios at equilibrium and time t, respectively; k2 (g∙mg−1 min−1) is the rate constant of the pseudo-second-order model; F is the fractional swelling rate at time t; k is the structural parameter, and n is the swelling exponent which exhibits the type of diffusion. The Chi-square (χ2) non-parametric test with a significance level of 0.05 and a degree of freedom = 9, χc2 = 15.5 was used to confirm the results.

Investigating water retention and regeneration

Water retention investigation and the regeneration study are performed as described by Sorokin and Lavlinskaya 2021. The water retention, R, was expressed as follows:

where m0 and m1 are the weight of the swollen CMC-SAP sample and the weight of the CMC-SAP sample after a partial water loss in each time interval, respectively.

Results and discussions

Synthesis and characterization of CMC-SAPs

The composite superabsorbents CMC-SAP were prepared in an aqueous solution at 80 °C with the use of a carboxymethyl cellulose sodium salt (CMC) as a source of the biodegradable links. The ratio of comonomers, cross-linker, initiator, as well as a concentration of the polymerization feed, was chosen based on our earlier research (Sorokin and Lavlinskaya 2021). The synthesis of the CMC-SAPs was performed in conditions providing the highest values of the equilibrium swelling ratio. The polymerization mixtures contain 10 or 20% w of CMC, denoted as CMC-SAP-10 and CMC-SAP-20, respectively. A further increase in the polysaccharide concentration led to a significant increase in the viscosity of the reaction feed and the failure to polymerize.

The possible reaction mechanism (Liu et al. 2019) includes potassium persulfate (PPS) initiator termodecay following the production of sulfate ion-radicals interacting with OH-groups of CMC, resulting in reactive radicals on polyglycoside backbones (Fig. 1). Next, comonomers–acrylic acid (AA), acrylamide (AAm), and N,N-methylene-bis-acrylamide (MBAAm)–react with CMC backbone radicals in a random order, forming growing polymeric chains. Their termination occurs due to a recombination of the macrochains, providing a dimensional composite network.

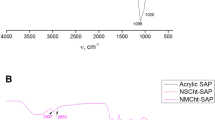

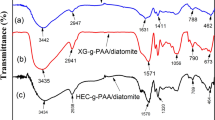

The formation of the CMC-SAPs was confirmed by FTIR (Fig. 2). The spectra of CMC-SAPs contain some characteristic bands near the following wavenumber: 1020 cm−1, 1052 cm−1, and 1120 cm−1 attributed to vibrations of the skeleton and ester bond C–O–C of the pyranose cycles, respectively (Reshma et al. 2020); 1399 cm−1 and 1448 cm−1 representing vibrations of (non)dissociated carboxylic groups (Bao et al. 2011); 1556 cm−1 and 1662 cm−1 ascribed to the stretching vibrations of the NH2-groups and C=O, respectively (Jeong et al. 2020); 2852 cm−1 characterizing secondary amino-group vibrations; 2935 cm−1 related to vibrations of the C-H bonds, and a broad band at 3200–3400 cm−1 due to the vibrations of the associated water molecules (Wang et al. 2017).

The surface of the CMC-SAPs obtained was characterized by SEM. Figure 3 represents the SEM images of the surfaces of the synthesized CMC-SAPs. As can be seen, with the increase in the CMC content in the superabsorbent polymerization feeds, the surface of the resulting SAPs is becoming more porous and developed. However, the equilibrium swelling ratio of the products obtained is decreased with CMC content growth, both in distilled water and saline solution (Table 2). This is because acrylic polymers have a higher water affinity compared to CMC (Dai et al. 2019).

The influence of the plasticizer on CMC-SAP water-absorbing and water-holding properties

The SAP ability to absorb and retain a huge amount of water is caused by the hydrogen bond formations between water molecules and SAP sorption sites (Ganji et al. 2010; Mignon et al. 2019). The more sorption sites are sterically available, the more water SAPs can absorb. To improve the availability of the sorption sites, the flexibility and mobility of the polymeric network moieties need to be enhanced. Most of the research dealing with SAP development is done by varying of comonomer ratio or cross-linker amount (Suo et al. 2006; Singh et al. 2018; Fang et al. 2018; Behrouzi et al. 2018; Fang et al. 2019; Khusbu et al. 2019; Chen et al. 2021). Polymer plasticization is a common way to tune the polymer properties related to the flexibility of the macromolecular chains or networks. Lin et al. (2000) show that plasticizer use can increase the swelling ratio and reduce glass transition temperature of Eudragit acrylic resins, confirming the enhancement of polymeric network flexibility. Additionally, a review by Vieira et al. (2011) describes plasticization additives for natural polymer films also modifying polymeric flexibility. However, the influence of plasticizers on SAP water-absorbing and water-holding properties has not been researched yet. In this work, dibutyl succinate (DiBu-Suc) was used as a plasticizer for composite SAPs based on carboxymethyl cellulose sodium salt.

Equilibrium swelling ratio, Qe, is one of the most important characteristics of SAPs, determining the efficiency of their use. Table 2 describes Qe data in distilled water and a saline solution.

As can be seen from the data obtained, the presence of varying amounts of DiBu-Suc has a different effect on the equilibrium swelling ratio. The highest Qe values are achieved for CMC-SAPs containing 5% w of plasticizer. The equilibrium swelling ratio is lower for the SAPs with 2% DiBu-Suc compared to the ones without an additive. The same is observed for samples containing 10% w of the plasticizer.

The main reason for the decrease in the SAP swelling ratio with a rise in the carbohydrate polymer content in the polymeric matrix is additional crosslinking of the three-dimensional network due to large intra- and intermolecular hydrogen bonds characterizing polysaccharide macromolecules. Therefore, when searching for a plasticizer for a composite SAP, it is necessary to select a compound that will act primarily on links prone to the formation of H-bonds. The results of studying the effect of dibutyl succinate on the equilibrium swelling ratio can be interpreted as follows: 2% w is an insufficient amount of additive to change the density of hydrogen bonds inside the polymeric network; so, the Qe values obtained for a blank sample and SAPs with 2% w of the plasticizer are practically equal, taking into account the experimental error. Next, 5% w of DiBu-Suc is the optimal amount which increases the equilibrium swelling ratio by 21% for CMC-SAP-10 and by 51% for CMC-SAP-20. A rise in the amount of the plasticizer to 10% w leads to a reduction in the values of the equilibrium swelling ratio of CMC-SAP, which is due to the partial absorption of excessive amounts of the DiBu-Suc on the acrylate moieties. A more significant increase in a Qe value for the CMC-SAP-20–5 sample confirms the assumption about a selective effect of the plasticizer on intramolecular H-bond-forming links.

FTIR data also confirm the hypothesis about the selective effect of the plasticizer on the intramolecular H-bond-forming links (Table 3). In the FTIR spectra, a decrease in the wavenumbers is observed for the bands characterizing the vibrations of the pyranose rings and primary amino groups, which indicates a weakening of the interactions between them (Shatalov et al. 2016). However, with a growth in the content of dibutyl succinate to 10% w, an increase in the wavenumber is observed for the bands corresponding to the vibrations of the carbonyl groups of the acrylate segments of the superabsorbent matrix, which suggests interactions between them and the additive.

The assumption about the action of the plasticizer which hinders the formation of hydrogen bonds within the superabsorbent network is also confirmed by the data of X-ray diffraction (Fig. 4). To prevent the influence of water on the intensity and shape of the XRD signals (Hatakeyama et al. 2004; Fang and Catchmark 2014), SAP samples were carefully dried before the research. The XRD pattern of CMC contains the peak at 2θ = 21°corresponding to the region of a higher crystallinity due to the intra- and intermolecular hydrogen bonds between hydroxyl groups of pyranose cycles (Salleh et al. 2019). The intensity of this peak decreases after CMC-SAP-20–0 formation because a part of CMC hydroxyl groups had been involved in polymerization. In the presence of a plasticizer, the intensity of a abovementioned peak, as well as total XRD signals, also decreases, confirming the reduction of the CMC-SAP-20–5 crystallinity.

Another parameter characterizing segment mobility and intersegmentation interactions is the glass transition temperature Tg. The higher the value of Tg, the stronger the aforementioned interaction, and, as a consequence, the availability of sorption centers is difficult for a reaction with water molecules. Therefore, the presence of a plasticizer has to reduce Tg, confirming the decrease of H-bond formations and other interactions. The data of Tg values obtained by DSC are presented in Table 3. As can be seen from the data obtained (Fig. 5), the DSC curves are slightly changed and become sharper with the growth of dibutyl succinate content. Moreover, the glass transition temperature is reduced in the presence of 2–5% w of DiBu-Suc, and the minimal Tg values are achieved for SAPs containing 5% w of a plasticizer; then a slight rise in glass transition temperature is observed. The results of the DSC research confirm our hypothesis.

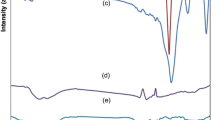

The presence of a plasticizer also affects the rheological properties of SAPs. These features of the synthesized CMC-SAPs were researched by the rheological method. The linear viscoelastic (LVE) regime was used for stress sweep tests. Storage modulus, G′, and loss modulus, G′′, are independent of the applied stress in this regime; however, the deviation of the value of both moduli from linearity is observed as the applied stress increases (Fig. 6a). The maximum stress up to which G′ remains constant is called the critical stress, σc, characterizing a transition between linear and nonlinear regimes. The critical stress can be taken as the dynamic yield stress value. This means that below the critical stress the system behaves like an elastic solid. At the externally applied stress beyond σc, the internal network structure started to break down and the material subsequently flowed like a liquid (Seetapan et al. 2011). The data represented shows that CMC-SAP-20–0 has larger critical stress and a wider LVE region than those of CMC-SAP-20–5, indicating its better resistance to the external stresses.

Moreover, the value of tan δ, which is the ratio of G′′ to G′, was calculated to measure the strength of the interaction within the polymer system and represented as a function of stress (Fig. 6b). If the value of tan δ is larger than 1 (G′′ > G′), the system behaves like a liquid, whereas if the value of tan δ is smaller than 1 (G′′ < G′), the system demonstrates solid-like (gel or network) behaviour. The results shown in this figure indicate that CMC-SAP-20–5, which has a higher water absorption capacity compared to CMC-SAP-20–0, possesses less gel strength due to its higher value of tan δ. Thus, it can be concluded that the gel strength is inversely related to its water absorption capacity, which is due to DiBu-Suc presence (Seetapan et al. 2011). The conducted rheological studies also confirm the effectiveness of the proposed plasticizer.

The swelling medium also affects the water-absorbing properties of the SAPs. The presence of electrolytes reduces the equilibrium swelling ratio due to the influence of osmotic pressure and the screening effect of metal ions (Mahon et al. 2020; Sorokin and Lavlinskaya 2021). The estimation of DiBu-Suc presence on the Qe values in a saline solution shows that there is no significant effect on those values (Table 2.). The Qe values decrease sharply in the 0.15 M NaCl aqueous solution compared to the ones in distilled water for all plasticizer contents.

Therefore, we found that dibutyl succinate enhances the equilibrium swelling ratio of composite SAPs based on carboxymethyl cellulose sodium salt due to the reduced intersegmental interaction of SAP matrixes. However, one of the most important requirements for plasticizers is non-outwashing from polymer. The water extract was analyzed by HPLC–MS after 24-h contact with CMC-SAPs. It was found that DiBu-Suc concentration in water for all samples is below the limit of detection.

An investigation of water absorption kinetics allows us to compare the rate of swelling for SAPs with different contents, as well as understand the mechanism of water sorption. Data analysis shows that the main factors characterizing swelling and water sorption of superabsorbent polymers are the chemisorption of water molecules and the diffusion of water molecules into polymeric networks (Peppas and Brannon-Peppas 1994; Ganji et al. 2010; Sorokin and Lavlinskaya 2021). The type of diffusion can be determined by Ritger-Peppas swelling kinetic model (see the Materials and Methods part) by linear logarithmic graphical processing of the research data. The n exponent shows the diffusion type:

-

(i)

If n = 0.5, this is Case I or Fickian diffusion, characterized by a water diffusion rate that is slower than the polymer relaxation rate;

-

(ii)

If n = 1.0, this is Case II diffusion or non-Fickian diffusion, in which the water diffusion rate is faster than the polymer relaxation rate;

-

(iii)

If 0.5 < n < 1, this is Case III or anomalous diffusion, non-Fickian diffusion, which occurs when the water diffusion and the polymer relaxation rate are about the same (Peppas and Brannon-Peppas 1994; Ganji et al. 2010).

Moreover, values of n > 1 and n < 0.5 have been observed, which correspond to super case II diffusion and pseudo-Fickian diffusion, respectively. As can be seen, the type of diffusion depends greatly on the nature of the polymers. For example, n < 0.5 representing pseudo-Fickian diffusion characterizes ionic dissociated polymers (Kim et al. 2003).

Figure 7 represents the swelling kinetics profiles for all synthesized CMC-SAPs. As can be seen, they are similar regardless of the presence or absence of a plasticizer. The two-stage water adsorption is observed on the curves. The first stage is fast sorption for 30 min; the next is the slow stage till 60 min; and finally, the equilibrium swelling is achieved. It should be noted that CMC-SAPs containing 5% w of DiBu-Suc swell faster compared to samples with 0% w or 2% w, and CMC-SAPs with 10% of DiBu-Suc are characterized by the lowest rate of swelling. This pattern is consistent with our hypothesis concerning the effect of the plasticizer on the superabsorbent matrix which was considered above.

To estimate the influence of DiBu-Suc on the water sorption mechanism, mathematical kinetic swelling models were utilized. Data analysis shows that the most suitable models for SAP swelling investigation are the pseudo-first-order swelling kinetic model, the pseudo-second-order swelling kinetic model, and the Ritger-Peppas model described in the Materials and Methods part (Fig. 8). The swelling data are processed by a kinetic model for SAPs without DiBu-Suc and with 5% w of additive.

The choice of the most appropriate model is carried out based on the R2 values of linear approximation of the models and the non-parametric Chi-square (χ2) test. As expected, the swelling kinetics of the CMC-SAPs without plasticizer is well-fitted to pseudo-second-order swelling kinetic model (CMC-SAP-10–0: R2 = 0.9981 and χ2 = 1 < < χc2 = 15.5; CMC-SAP-20–0: R2 = 0.9957 and χ2 = 0.9 < < χc2 = 15.5). Also, the data processed using the Ritger-Peppas model and expressed separately for fast and slow absorption stages are characterized by good R2 values (R2 = 0.9980) for the slow sorption stage. So, based on the concept of the pseudo-second-order and the Ritger-Peppas swelling kinetic models, water absorption is controlled by chemisorption at the fast stage, and pseudo-Fickian water diffusion is also important at the slow sorption stage for SAPs prepared without plasticizer. As can be seen, R2 values obtained for CMC-SAPs with 5% of plasticizer are approximately equal to the ones considered above. So, we can conclude that the presence of dibutyl succinate has no influence on the water sorption mechanism, and it is the same as the one for non-plasticized CMC-SAP.

Water-holding properties are also important for the characterization and application of superabsorbents. Water retention was researched at 80 °C with the use of an automatic moisture analyzer. The weight loss curves for CMC-SAP with 0% w and 5% w of DiBu-Suc are represented in Fig. 9. As can be seen from the data obtained, water retention for all synthesized CMC-SAPs is approximately equal, and the difference between weight loss curves is in the range of experimental errors. Therefore, we can conclude that the plasticizer has no significant influence on water loss at 80 °C.

Figure 10 represents the results of the regeneration study carried out for CMC-SAP-20–0 and CMC-SAP-20–5 expressed as a ratio of the swelling ratio after swelling-deswelling cycle to the initial swelling ratio and denoted as Qrev, %. The loss in the value of the equilibrium swelling ratio does not exceed 10 and 5% for the CMC-SAP-20–0 and CMC-SAP-20–5, respectively. In this case, the experimental error is about 4.5%. Therefore, the swelling possibility of the CMC-SAPs is almost fully retained after 4 swelling-deswelling cycles. This is due to the high stability of the three-dimensional superabsorbent networks resistant to cyclic swelling-deswelling processes. However, the presence of the plasticizer has no sufficient impact on the regeneration process, which is probably due to the significant influence of the temperature on the hydrogen bond formation and destruction (Wei et al. 2015). Consequently, synthesized SAPs are reusable regardless of the presence of dibutyl succinate plasticizer.

Conclusion

The research conducted shows that dibutyl succinate is suitable as a plasticizer for composite superabsorbents enriched in carboxymethyl cellulose sodium salt. The use of 5% w of DiBu-Suc enhances the equilibrium swelling ratio up to 51% due to selective interaction with intramolecular H-bond-forming links, increasing the segmental mobility in the polymeric network and the sterical availability of sorption sites for water molecules. The presence of DiBu-Suc does not change the water absorption mechanism controlled by chemisorption and pseudo-Fickian diffusion of water molecules, and has no significant impact on water retention properties and reusability of the composite superabsorbents.

References

Amiri M, Khazaeli P, Salehabadi A, Salavati-Niasari M (2021) Hydrogel beads-based nanocomposites in novel drug delivery platforms: recent trends and developments. Adv Colloid Interface Sci 288:102316. https://doi.org/10.1016/j.cis.2020.102316

Bao Y, Ma J, Li N (2011) Synthesis and swelling behaviors of sodium carboxymethyl cellulose-g-poly(AA-co-AM-co-AMPS)/MMT superabsorbent hydrogel. Carbohyd Polym 84:76–82. https://doi.org/10.1016/j.carbpol.2010.10.061

Behrouzi M, Moghadam PN (2018) Synthesis of a new superabsorbent copolymer based on acrylic acid grafted onto carboxymethyl tragacanth. Carbohyd Polym 202:227–235. https://doi.org/10.1016/j.carbpol.2018.08.094

Chavda HV, Patel CN (2011) Effect of crosslinker concentration on characteristics of superporous hydrogel. Int J Pharm Investig 1:17–21

Chen Y, Li W, Zhang S (2021) A multifunctional eco-friendly fertilizer used keratin-based superabsorbent as coatings for slow-release urea and remediation of contaminated soil. Prog Org Coat 154:106158. https://doi.org/10.1016/j.porgcoat.2021.106158

Dai H, Zhang Y, Ma L, Zhang H, Huang H (2019) Synthesis and response of pineapple peel carboxymethyl cellulose-g-poly (acrylic acid-co-acrylamide)/graphene oxide hydrogels. Carbohyd Polym 215:366–376. https://doi.org/10.1016/j.carbpol.2019.03.090

Fang L, Catchmark JM (2014) Structure characterization of native cellulose during dehydration and rehydration. Cellulose 21:3951–3963. https://doi.org/10.1007/s10570-014-0435-8

Fang S, Wang G, Li P, Xing R, Liu S, Qin Y, Yu H, Chen X, Li K (2018) Synthesis of chitosan derivative graft acrylic acid superabsorbent polymers and its application as water retaining agent. Int J Biol Macromol 115:754–761. https://doi.org/10.1016/j.ijbiomac.2018.04.072

Fang S, Wang G, Xing R, Chen X, Liu S, Qin Y, Li K, Wang X, Li R, Li P (2019) Synthesis of superabsorbent polymers based on chitosan derivative graft acrylic acid-co-acrylamide and its property testing. Int J Biol Macromol 132:575–584. https://doi.org/10.1016/j.ijbiomac.2019.03.176

Ganji F, Vasheghani-Farahani S, Vasheghani-Farahani E (2010) Theoretical description of hydrogel swelling. a review. Iran Polym J 19:375–398

Haseeb MT, Hussain MA, Yuk SH, Bashir S, Nauman M (2016) Polysaccharides based superabsorbent hydrogel from Linseed: Dynamic swelling, stimuli responsive on–off switching and drug release. Carbohyd Polym 136:750–756. https://doi.org/10.1016/j.carbpol.2015.09.092

Hatakeyama T, Hatakeyama H (2004) Thermal properties of green polymers and biocomposites, vol 4. Kluwer Academic Publishers, Dordeht

Ho Y, McKay G (1999) Pseudo-second order model for sorption processes. Process Biochem 34:451–465. https://doi.org/10.1016/S0032-9592(98)00112-5

Hosseinzadeh H (2010) Controlled release of diclofenac sodium from pH-responsive carrageenan-g-poly(acrylic acid) superabsorbent hydrogel. J Chem Sci 122:651–659. https://doi.org/10.1007/s12039-010-0100-1

Jeong D, Joo S-W, Hu Y, Shinde VV, Cho E, Jung S (2018) Carboxymethyl cellulose-based superabsorbent hydrogels containing carboxymehtyl β-cyclodextrin for enhanced mechanical strength and effective drug delivery. Eur Polym J 105:17–25. https://doi.org/10.1016/j.eurpolymj.2018.05.023

Jeong D, Kim C, Kim Y, Jung S (2020) Dual crosslinked carboxymethyl cellulose/polyacrylamide interpenetrating hydrogels with highly enhanced mechanical strength and superabsorbent properties. Eur Polym J 27:109586. https://doi.org/10.1016/j.eurpolymj.2020.109586

Khan S, Ranjha NM (2014) Effect of degree of cross-linking on swelling and on drug release of low viscous chitosan/poly(vinyl alcohol) hydrogels. Polym Bull 7:2133–2158. https://doi.org/10.1007/s00289-014-1178-2

Khan H, Chaudhary JP, Meena R (2019) Anionic carboxymethylagarose-based pH-responsive smart superabsorbent hydrogels for controlled release of anticancer drug. Int J Biol Macromol 124:1220–1229. https://doi.org/10.1016/j.ijbiomac.2018.12.045

Khushbu WSG, Kumar A (2019) Synthesis and assessment of carboxymethyl tamarind kernel gum based novel superabsorbent hydrogels for agricultural applications. Polymer 182:121823. https://doi.org/10.1016/j.polymer.2019.121823

Kim B, Flamme KL, Peppas NA (2003) Dynamic swelling behaviour of pH-sensitive anionic hydrogels used for protein delivery. J Appl Polym Sci 89:1606–1613. https://doi.org/10.1002/app.12337

Lacoste C, Lopez-Cuesta J-M, Bergeret A (2019) Development of a biobased superabsorbant polymer from recycled cellulose for diapers applications. Eur Polym J 116:38–44. https://doi.org/10.1016/j.eurpolymj.2019.03.013

Lagergren S (1898) Zur theorie der sogenannten adsorption gelöster stoffe. Kungliga Svenska Vetenskapsakademiens, Handlingar 24:1–39

Li S, Chen G (2019) Agricultural waste-derived superabsorbent hydrogels: preparation, performance, and socioeconomic impacts. J Clean Prod 251:119669. https://doi.org/10.1016/j.jclepro.2019.119669

Lin S-Y, Chen K-S, Run-Chu L (2000) Organic esters of plasticizers affecting the water absorption, adhesive property, glass transition temperature and plasticizer permanence of Eudragit acrylic films. J Control Release 68:343–350. https://doi.org/10.1016/S0168-3659(00)00259-5

Liu X, Luan S, Li W (2019) Utilization of waste hemicelluloses lye for superabsorbent hydrogel synthesis. Int J Biol Macromol 132:954–962. https://doi.org/10.1016/j.ijbiomac.2019.04.041

Lv X, Zhang W, Liu Y, Zhao Y, Zhang J, Hou M (2018) Hygroscopicity modulation of hydrogels based on carboxymethyl chitosan/Alginate polyelectrolyte complexes and its application as pH-sensitive delivery system. Carbohyd Polym 198:86–93. https://doi.org/10.1016/j.carbpol.2018.06.058

Mahon R, Balogun Y, Oluyemi G, Njuguna J (2020) Swelling performance of sodium polyacrylate and poly(acrylamide-co-acrylic acid) potassium salt. SN Appl Sci 2:117. https://doi.org/10.1007/s42452-019-1874-5

Mehta P, Kaith BS (2021) Green synthesis of agar/gelatin based superabsorbent (BGCP) through gamma radiation cross-linking polymerization for castoff as sustained drug delivery device and in soil treatment for improved water retention. J Polym Environ 29:647–661. https://doi.org/10.1007/s10924-020-01894-6

Mignon A, De Belie N, Dubruel P, Van Vlierberghe S (2019) Superabsorbent polymers: a review on the characteristics and applications of synthetic, polysaccharide-based, semi-synthetic and “smart” derivatives. Eur Polym J 117:165–178. https://doi.org/10.1016/j.eurpolymj.2019.04.054

Peppas NA, Brannon-Peppas L (1994) Water diffusion and sorption in amorphous macromolecular systems and foods. J Food Eng 22:189–210. https://doi.org/10.1016/B978-1-85861-037-5.50015-1

Peppas NA, Khare AR (1993) Preparation, structure and diffusional behavior of hydrogels in controlled release. Adv Drug Deliv Rev 11:1–35. https://doi.org/10.1016/0169-409X(93)90025-Y

Pourjavadi A, Ebrahimi AA, Barzegar S (2013) Preparation and evaluation of bioactive and compatible starch based superabsorbent for oral drug delivery systems. J Drug Del Sci Tech 23:511–517. https://doi.org/10.1016/S1773-2247(13)50074-8

Qureshi MA, Nishat N, Jadou S, Ansari MZ (2020) Polysaccharide based superabsorbent hydrogels and their methods of synthesis: a review. Carbohyd Polym Technol App 1:100014. https://doi.org/10.1016/j.carpta.2020.100014

Ravishankar K, Dhamodharan R (2020) Advances in chitosan-based hydrogels: evolution from covalently crosslinked systems to ionotropically crosslinked superabsorbents. React Funct Polym 149:104517. https://doi.org/10.1016/j.reactfunctpolym.2020.104517

Reshma G, Reshmi CR, Nair SV, Menon D (2020) Superabsorbent sodium carboxymethyl cellulose membranes based on a new cross-linker combination for female sanitary napkin applications. Carbohyd Polym 248:116763. https://doi.org/10.1016/j.carbpol.2020.116763

Saha A, Sekharan S, Manna U (2020) Superabsorbent hydrogel (SAH) as a soil amendment for drought management: A review. Soil till Res 204:104736. https://doi.org/10.1016/j.still.2020.104736

Salleh KM, Zakaria S, Shaiful Sajab M, Gan S, Kaco H (2019) Superabsorbent hydrogel from oil palm empty fruit bunch cellulose and sodium carboxymethylcellulose. Int J Biol Macromol 131:50–59. https://doi.org/10.1016/j.ijbiomac.2019.03.028

Samadian H, Maleki H, Allahyari Z, Jaymand M (2020) Natural polymers-based light-induced hydrogels: promising biomaterials for biomedical applications. Coord Chem Rev 420:213432. https://doi.org/10.1016/j.ccr.2020.213432

Seetapan N, Wongsawaeng J, Kiatkamjornwong S (2011) Gel strength and swelling of acrylamide-protic acid superabsorbent copolymers. Polym Adv Technol 22:1685–1695. https://doi.org/10.1002/pat.1658

Shatalov GV, Lavlinskaya MS, Pakhomova OA, Mokshina NY, Kuznetsov VA (2016) Copolymers of N-vinylcaprolactam with 1-vinyl- and 1-methacryloyl-3,5-dimethylpyrazole as sorbents of essential α-amino acids in liquid- and solid-phase extraction. Rus J Appl Chem 89:140–146. https://doi.org/10.1134/s1070427216010225

Singh J, Dhaliwal AS (2018) Synthesis, characterization and swelling behavior of silver nanoparticles containing superabsorbent based on grafted copolymer of polyacrylic acid/ Guar gum. Vacuum 157:51–60. https://doi.org/10.1016/j.vacuum.2018.08.017

Sorokin A, Lavlinskaya M (2021) Synthesis of the superabsorbents enriched in chitosan derivatives with excellent water absorption properties. Polym Bull. https://doi.org/10.1007/s00289-020-03521-9

Suo A, Qian J, Yao Y, Zhang W (2006) Synthesis and properties of carboxymethyl cellulose-graft-poly(acrylic acid-co-acrylamide) as a novel cellulose-based superabsorbent. J App Polym Sci 103:1382–1388. https://doi.org/10.1002/app.23948

Vieira MGA, da Silva MA, dos Santos LO, Beppu MM (2011) Natural-based plasticizers and biopolymer films: a review. Eur Polym J 47:254–263. https://doi.org/10.1016/j.eurpolymj.2010.12.011

Wang Z, Ning A, Xie P, Gao G, Xie L, Li X, Song A (2017) Synthesis and swelling behaviors of carboxymethyl cellulose-based superabsorbent resin hybridized with graphene oxide. Carbohyd Polym 157:48–56. https://doi.org/10.1016/j.carbpol.2016.09.070

Wei Q, Zhang Y, Wang Y, Chai W, Yang M, Zeng W, Wang M (2015) Study of the effects of water content and temperature on polyacrylamide/polyvinyl alcohol interpenetrating network hydrogel performance by a molecular dynamics method. E-Polymers 15(5):301–309. https://doi.org/10.1515/epoly-2015-0087

Wypych G (2017) Handbook of plasticizers, 3rd edn. ChemTec Publishing, Toronto

Acknowledgments

FTIR, SEM, HPLC-MS, and XRD data were obtained with the use of equipment of the Research Core Centre of Voronezh State University. DSC data were obtained with the use of equipment of the Research Core Centre of Voronezh State University of Engineering Technologies. Special thanks to Dr. Alexander Sinelnikov and Dr. Alexey Dontsov for their help with obtaining and interpretation of the XRD data.

Funding

The research was supported by the Russian Science Foundation, project number 21–74-20053 (FTIR, SEM, HPLC–MS, and XRD research), and by the Ministry of Science and Higher Education of the Russian Federation in the framework of the national project “Science” (project FZGW-2020–0001, unique number of the register of State tasks 075001X39782002).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sorokin, A., Sukhanov, P., Popov, V. et al. A new approach to increasing the equilibrium swelling ratio of the composite superabsorbents based on carboxymethyl cellulose sodium salt. Cellulose 29, 159–173 (2022). https://doi.org/10.1007/s10570-021-04326-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-021-04326-3