Abstract

Flax and hemp fibres were treated by various combinations of water/diluted alkaline solution and stirring/ultrasound, respectively. Changes in the microstructure (scanning electron microscopy) and porous structure (low-temperature nitrogen adsorption), removal of non-cellulosic materials (weight loss, FTIR), mean fibre diameter, and adhesion of the polypropylene matrix to the fibres (micro-bond test) were investigated. For both types of fibres, removal of (FTIR) was observed. The fibre diameter of hemp was decreased by several treatments, most of all by stirring in alkali and subsequent sonication in water, while the ultrasound applied in alkali solution did not change the fibre fineness. This can be attributed to the dual effect of ultra-sonication: the swelling effect of alkali combined with ultrasound energy probably served the sticking of inter-fibrillar material rather than their dissolution. Fibre diameter of flax did not change in any circumstances. The porosity of hemp in the mesopore range increased, while that of flax decreased by alkali treatment and subsequent sonication. The reason for this difference might be the dissimilar cell wall structures of the two bast fibres, the high arabinose content of the hemp, and/or the cottonisation of hemp. No treatments altered the fibre-matrix adhesion measured by pulling out the fibre from a micro-droplet of polypropylene.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Cellulose and lignocellulosic materials as renewable and biodegradable sources are being utilised for many traditional and innovative purposes. Industrial hemp and flax are very prosperous cellulose sources; they provide important cellulosic and non-cellulosic substances (fibre, sieve, seed, and oil) with relatively low agricultural investment. Their breeding and processing had already been well established in ancient times; nowadays, there is a growing interest in special cultivation methods according to the various end use destinations (Amaducci et al. 2015). Fibres gained from the stalk (phloem) of these plants (bast fibres) contain, besides cellulose (64–78 %), various other materials such as hemicelluloses (5–22 %), pectin (0,8–2,5 %), lignin (2–5 %), water-soluble materials (0.7–1.5 %) and waxes (0.7–1.5 %) (Batra 2007). These fibres are used mostly for clothing (Gouveia et al. 2010; Jinqiu and Jianchun 2010; Muzyczek 2012), insulation (Fages et al. 2013; Latif et al. 2014), agriculture (Miao et al. 2013), filtration (Anandjiwala and Boguslawsky 2008; Jianyong and Jianchun 2013), composites (Miao and Hamad 2013), adsorption of some contaminants (Kyzas et al. 2015), and biofuel (Chandra et al. 2015; Rehman et al. 2013). Due to their relatively small carbon footprint, they have an increasing role in the market of biocomposites, mainly for the automotive sector and insulation materials (Barth and Carus 2015).

These fibres need various treatments prior to particular applications. Removal of undesired materials from and delivery of special chemicals to the fibre surface are very energy- and time-consuming operations. Ultrasound is an excellent tool for improvement of mass transfer: both energy and time can be saved by its application. Ultrasound produces cavitation bubbles in the liquid; some bubbles suffer sudden expansion to an unstable size and collapse violently, which generates the energy for chemical and mechanical effects (Mason 1999). Many studies have been published on the intensification of various wet textile processes, while information on the change of fibre properties is poor.

In wet textile technologies, liquid flow passes pores by either convection (among yarns) or diffusion (through yarns). Moholkar and Warmoeskerken (2003), studying the mechanism of ultrasound-assisted mass transfer, affirmed that due to the cavitation, the permeability of the outer part of the yarn increases and the diameter of the so-called stagnant core of the yarn becomes smaller, resulting in a higher ratio of convection. The most frequently studied ultrasound-assisted textile technologies are bleaching (Hebeish et al. 2011; Davulcu et al. 2014) and dyeing (Benli and Bahtiyari 2015). The positive effect of ultrasound is generally assigned to the cavitation on the fibre surface, but the reduction of the particle size also has an important role in some dyeing (Lee and Kim 2001) and functional finishing technologies (Abramova et al. 2013; Surina and Andrassy 2013). After a long laboratory study period, nowadays industrial ultrasonic systems for wet textile processes are already available.

There are only a few papers dealing with the fibre properties changed by ultrasound, although the altered fibre characteristics might influence the final result of the process. Low-frequency (30-kHz) ultrasound pre-treatment decreased the fibre damage caused by the crosslinking reactions in crease-resistant finishing of flax fibre. Increased fibre accessibility was supposed as the reason for the results (Surina and Andrassy 2013). The role of the improved accessibility of the fibres was also emphasised in the high water retention values and easy subsequent oxidation of cellulosic fibres gained from eucalyptus (Aimin et al. 2005) and also in the enhancement of the sorption capacity of waste newspaper fibres used for methylene blue adsorption (Entezari and Al-Hoseini 2007). Low-frequency (45-kHz) ultrasound applied on ligno-cellulosic fibres as flax, hemp, and choir in water decreased the hemicellulose content of the fibres (Renouard et al. 2014). Mercerisation is a common process in the cotton industry: high-concentration aqueous sodium hydroxide solution, as an intra-crystalline swelling agent, improves some important chemical and physical properties of natural cellulosic materials. One of the main parameters characterising the effectiveness of mercerisation is the cellulose I transformation to the cellulose II lattice. This transformation in high-concentration NaOH (30 °Bé ≈ 24 w/w%), especially for a short time period, was increased by low-frequency (40 kHz) ultrasound. This was attributed to the disruption of intra-crystalline hydrogen bonds and segmental molecular motion caused by the acoustic pressure (Khajavi et al. 2013). High-frequency ultrasound (610 kHz) increased the number of non-conjugated carbonyl groups in wood fibre; the oxidation of the fibre and increase of the surface energy occurred (Gadhe et al. 2006).

Ligno-cellulosic fibres such as flax and hemp need some simple cleaning for removal of plant debris. This washing is usually carried out in water or in a diluted alkali solution facilitating the process by slight swelling of the fibres. What happens to the ligno-cellulosic fibres during this cleaning if the process is supported by ultrasound has not been investigated yet. In this work the effects of the cleaning in stirred and ultrasound-assisted systems are compared. The cleaned fibres are presented on SEM pictures, removal of non-cellulosic materials is followed by weight loss measurements and FT-IR spectroscopy, fibre diameter is measured by an optical method, and porosity is studied by nitrogen adsorption. For a composite application adhesion of the polypropylene matrix to the fibre surface is characterised by the micro-droplet method.

Materials and methods

Fibres and treatments

Flax fibres (rove) used for fine garments were kindly supplied by Flax Spinning Mill (Hungarolen Ltd., Komárom, Hungary). Hemp primary fibres produced in South Africa were mechanically refined (cottonised) at the CSIR National Centre for Fibre, Textiles and Clothing. Both types of fibres were treated in distilled water or in diluted alkali solution (10 g fibre, fibre:liquor ratio = 1:50); 20 g/l NaOH (Molar Chemicals Ltd., Hungary) solution contained 4 g/l wetting agent and 1 g/l sequestering agent. The two auxiliaries (Subitol SE and Heptol) were cordially provided by CHT/Bezema AG, Switzerland. Fibres in liquid were either stirred manually or sonicated in Elma Transsonic multifrequency unit TI-H-15, using 25 kHz, 50 W, amplitude 50 %, sweep mode, and a degassed bath. After this alkali treatment samples were neutralised by tap water, 1 % acetic acid, and distilled water. Half of each sample was sonicated in distilled water for 1 h using the same ultrasound parameters as in the alkali treatment. All treatments are presented on a flow chart (Fig. 1).

Fibres and treatments. UT untreated fibre; Alk alkaline solution: NaOH (20 g/l); wetting agent (Subitol SE) 4 g/l; sequestering agent (Heptol) 1 g/l; fibre:liquor ratio = 1:50. US ultrasound treatment (sonication): 25 kHz, 50 W, amplitude 50 %, sweep mode, and treatment after degassing of the bath. Samples without this mark were stirred

Characterisation of fibres

The scanning electron microscopic picture, removal of non-cellulosic materials (weight loss, FTIR), mean fibre diameter, porosity (nitrogen adsorption), and adhesion of the polypropylene matrix to the fibres were investigated.

Scanning electron microscopy (SEM)

The effect of treatments was followed by scanning electron microscopic pictures of fibres covered with evaporated gold in vacuum using a JEOL JSM 5600LV type microscope.

Removal of non-cellulosic materials

The weight loss was determined; the water contents of the original and treated fibres were taken into correction (the moisture percentage of the original fibres was measured on separate samples after drying at 105 °C for 24 h). Three parallel measurements were carried out.

The IR absorption was determined using a Unicam Mattson Research Series 1 FTIR instrument with diffuse reflexion detection. The accessory contained a ZnSe flat plate with a nominal incident angle of 45°. The spectra were recorded from 4000 to 500 cm−1 at a resolution of 8 cm−1, averaged from 128 scans. Characteristic bands of non-cellulosic materials were taken into consideration: 1730 cm−1 ketone/aldehyde C=O stretch for both hemicelluloses and pectins (Xu et al. 2013; Espinal-Ruiz et al. 2016), 1100 and 1017 cm−1 bands as the strongest peaks of pectic polysaccharides (Kačuráková et al. 2000), and 1507 and 1436 cm−1 C=C stretch for the aromatic rings of lignin (Sun et al. 2000; Alemdar and Sain 2008) were evaluated. Peak intensities were related to the band at around 2900 cm−1 (C–H stretching) used as internal standard since it practically does not change during various treatments (Łojewska et al. 2005).

Mean diameter of dry fibres

Diameters of equilibrated air-dried fibres were measured. An average of 4000 measurements carried out by an Optical-based Fibre Diameter Analyser (OFDA 100, BSC Electronics, Australia) were used. This is an image analysis instrument with a projection microscope and laser scan. This system provides a count of readings grouped into diameter classes. The fibre snippets are measured automatically by an optical and image processing system. The control is provided in the software with no inclusion of multiple measurements on the same fibre and false diameter readings that arise from non-fibre material. Each diameter measurement is allocated to a diameter class, and, at the completion of the slide, the class contents are statistically analysed to produce the mean, standard deviation, and coefficient of variation of the fibre diameter for the specimen.

Porosity (low-temperature nitrogen adsorption)

Samples were selected according to the fibre diameter results. Alkali-treated samples and those sonicated in water after alkali treatment were investigated. Nitrogen adsorption/desorption isotherms were measured at 77 K, using the Autosorb-1 (Quantachrome, USA) computer-controlled apparatus. Samples were dried in an oven at 105 °C for 24 h before the evacuation to a final vacuum of ca. 10−5 Hgmm at the same temperature for an additional 24 h. The sample sizes used met the recommendations of the manual. The total pore volume (V tot) was estimated from the amount of nitrogen vapour adsorbed at a relative pressure (p/p 0) close to unity on the assumption that the pores are then filled with liquid nitrogen. Due to the shape of the isotherms, this value is for orientation only.

The pore size distribution in the mesopore region was obtained from the adsorption branch of the isotherm by the method of Barrett et al. (1951). The mesopore volumes were calculated as the difference of the pore volumes filled with liquid nitrogen at pore diameters 50 and 2 nm, respectively. Calculations were performed with the Quantachrome software.

Interfacial shear strength in fibre-reinforced composite

Flax and especially hemp fibre can be used in fibre-reinforced composites, where the common matrix is polypropylene. The cleaning pre-treatments might change the fibre surface influencing the fibre-matrix interaction; it may or may not be advantageous. For clarification of the situation, fibre-matrix adhesion was measured by the micro-bond test (Miller et al. 1987; Gaur and Miller 1989; Miller et al. 1991; Schwartz 2001; Morlin and Czigány 2012). An individual fibre was fixed in a paper frame by Scotch tape, and then a polypropylene granule (Tipplen H890 homopolymer, Tisza Chemical Group, Hungary) was melted by a soldering iron and a droplet was put onto the fibre by a needle. The geometrical characteristics of the droplet (embedded length) and the fibre diameter were determined by an Olympus BX51 (Hamburg, Germany) type of optical measuring microscope. Fibre pull-out tests were made on a Zwick Z005 (Ulm, Germany) type universal tensile tester, using a special pull-off device with blades at room temperature with a speed of 2 mm/min. Twenty parallel measurements were carried out on some selected samples for studying the effects of various factors (20/60 °C, stirring/ultrasound, 1st step/2nd step). The interfacial shear strength was calculated in the following way (Gaur and Miller 1989): τ = F/(π × D × L), where τ is the interfacial shear strength (MPa), F is the pull-out force (N), D is the fibre diameter (mm), and L is the embedded fibre length (mm). The interfacial shear strength value is influenced by the size and shape of the droplet, and the scattering of the results is very high (Morlin and Czigány 2012); therefore, this measurement can be used as a rough guess for orientation.

Results and discussion

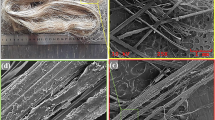

SEM pictures

Analysing the SEM pictures of ten flax and ten hemp samples, respectively, no significant differences among the results of various alkali treatments were observed. Characteristic differences were found in the sample series as ‘untreated/sonicated in distilled water/alkali treated before sonication in distilled water’ ones (Fig. 2).

Fragments that were found on the surface of the untreated fibres (a) were removed from both fibres by ultrasound; the surface of flax became mostly smooth while on the surface of hemp a slight fibrillar structure occurred (b). Fibrils on flax appeared because of the alkali treatment followed by ultrasound; this process on hemp resulted in deep grooves formed between fibrils (c). The response of hemp is more pronounced than that of flax.

Removal of non-cellulosic materials

Weight losses measured after the first step of treatment were about 5–8 % (Fig. 3).

Flax released more non-cellulosic material during the treatments than hemp did. Elevation of the temperature during alkaline treatment resulted in a moderate increase in removal. Sonication during alkali treatment did not improve the removal of non-cellulosic materials. No further weight loss occurred after the final sonication in distilled water.

In the FTIR spectra, only the intensities of the non-cellulosic carbohydrate peaks, especially the peak at 1730 cm−1 (ketone/aldehyde C=O stretch), changed significantly. These results are in agreement with those of Renouard et al. (2014) and co-workers’ findings where after a long (40 h) ultrasound (45 kHz) treatment of flax, hemp and coir in water only the degradation of hemicelluloses was found. According to the relative peak intensities (1730/2900 cm−1, Fig. 4), the extent of the non-cellulosic carbohydrate removal is practically equal for the two types of fibre.

Effects of temperature elevation and sonication are ambiguous, probably due to their dual actions as enhancement of dissolution and sticking of the inter-fibrillar material.

There is no direct correlation between weight loss and FTIR data; fragments (see SEM pictures on Fig. 2) and presumably other materials (e.g., inorganic salts, wax, and protein as in the usual scouring process of various fibres) were removed, too.

Mean fibre diameter

The mean diameter of the flax fibres (15 μm) was half of the hemp’s diameter (30 μm) (Fig. 5). Flax and hemp fibre bundles consist of several plant cells (ultimates, elementary fibres) (e.g., flax: 10–40 ultimates/fibre bundle). The diameters of these ultimates depend on the variety; hence, they are given in the literature as an interval (flax: 5–76 μm; hemp: 10–51 μm) (Batra 2007). The diameter of a fibre depends on the effectiveness of the refinement process (separation of the ultimates). The average diameter data of our untreated samples (flax: 15 μm; hemp: 32 μm) are only about threefold the minimum values of the ultimate cell diameter intervals. This suggests that in previous processes these fibres had effectively been disintegrated, even up to their individual cells.

In our experiments the mean diameter of flax was not influenced by any treatment (no further disintegration occurred) (Fig. 5), while that of the hemp fibre decreased in stirred alkaline solution (1st step), independently of the temperature. The different responses of the two types of fibre can be attributed to the different chemical constitutions of the hemicelluloses in the two species (Moriana et al. 2014). It can also be supposed that fine flax fibre had already been disintegrated up to its ultimate cells. The sonication of hemp in the same alkali systems prevented the decrease of the diameter, while sonication in water (2nd step) decreased the mean diameter of all hemp fibres. The inefficiency of alkali treatment combined with ultrasound in the disintegration of hemp fibre can be considered as the pronounced exhibition of the possible dual effect of sonication. Ultrasound energy can loosen the composite structure of the ligno-cellulosic material, resulting in partial disintegration (Pappas et al. 2002). Even micro/nano fibres were produced by sonication, but this disintegration effect was accompanied by damage of the cellulose structure (Tonoli et al. 2012). It can be supposed that at the same time ultrasound promotes the components’ aggregation, too. For the latter phenomenon there are two possible mechanisms. First, lignin becomes soft and flowing above 60–75 °C (Eriksson et al. 1991); the local thermal effect of the ultrasound can soften the lignin; hence, it can act as glue. Second, the molecular mass of lignin sonicated in the presence of 5 % NaOH increases (Wells et al. 2013). Although in our experiments only 2 % NaOH solution was used, this mechanism could also be effective. Consequently, both phenomena could act against disintegration.

For investigation of other possible effects of the treatments, porosities of hemp fibres with the largest diameter change were measured. Flax fibres treated by the same technologies were also investigated. The results are presented in Chap. 3.4.

Porosity (low-temperature nitrogen adsorption)

Untreated fibres

Figure 6 shows the adsorption/desorption isotherms of both initial fibres as well as their pore size distribution. The adsorption isotherms have a concave initial section with a local maximum at p/p 0 ≈ 0.1, which is followed by an unconventional drop. This might be caused by the distortion of the fibres. The continuous increase above p/p 0 ≈ 0.3 indicates the development of multilayer adsorption. Due to the sharp increase at high p/p 0 values, the V tot values are only rough estimations. The adsorption is not reversible. The bump at p/p 0 ≈ 0.1; the low pressure hysteresis and the shape of the adsorption/desorption braches in the higher relative pressure ranges imply that the fibres deform during the measurement. The estimated surface area of both fibres is 1 m2/g.

Comparing the primary isotherms of the two fibres (Fig. 6a), the untreated flax shows a slightly more open structure than hemp, which is more obvious from the pore size distribution curves (Fig. 6b).

Treated fibres

The character of the isotherms was not practically influenced by any of the treatments in either fibre (Figs. 7, 8): both the bump at p/p 0 ≈ 0.1 and the steep capillary condensation tail at p/p 0 → 1 persist.

Hemp (Fig. 7): Some treatments (20 Alk, 60 Alk, 60 Alk + US) did not result in any modification in the nitrogen adsorption properties of hemp. Ultrasonication in water (−+US) however resulted in a very slight opening of the porosity, i.e., the isotherms are shifted to higher uptake values in the whole relative pressure range. A real effect was obvious when hemp was treated according to the protocol 20 Alk + US. This treatment resulted in the smallest fibre diameter for hemp (Fig. 5), but it did not affect the diameter of the flax. Although the character of the isotherm is the same, a much looser fibre structure was obtained. The steeper character of the distribution curve in Fig. 7b and the pore volume data reported in Table 1 reveal these changes in the mesopore range.

Flax (Fig. 8): Ultrasonication in water (−+US) treatment compressed the flax fibre. Although the microporous region is unaffected (the isotherms overlap), the isotherm of the treated sample runs below the primary one in both directions in the higher relative pressure range. The effect of the combined 20 Alk + US treatment is also different from hemp. Again, in the p/p 0 range below the initial maximum the two curves overlap, but the treated sample shows a suppressed adsorption owing to the reduced mesoporosity (Table 1). The differences in both V tot and V meso are minor, but systematic. In HEMP the total pore volume as well as the volume of the mesopores increases with the treatments. On the other hand, in the FLAX series both pore categories show a limited decrease.

The change in porous structure may influence the adsorption of dyes or any other agents in subsequent dyeing or finishing processes. The differences between the two types of untreated fibres (Fig. 6) and the adverse change of their porous structure due to the subsequent alkali and ultrasound treatments (Figs. 7, 8) may be explained by their dissimilar cell wall and intercellular materials (middle lamella). Hemp has two cell wall layers, while in flax three layers were observed. All the layers have a spiral structure, but the slope of the spirals and the layer thickness are different in the two types of fibres (Roelofsen 1951). Furthermore, hemicelluloses have an important role in the fibre properties: hemicellulose branches of arabinose, glucuronic acid, and especially glucuronate strengthen the primary cell wall by strongly coordinating to hydrogen bond donor sites on the cellulose surface (Silveira et al. 2013). The arabinose content of hemp is about five times higher than that of flax (Moriana et al. 2014). Thus, the hemicellulose removal from flax (Figs. 3, 4) might make the fibre more flexible to a critical degree resulting in a possible collapse of the fibre structure (decrease of nitrogen adsorption). At the same time the dissolution of hemicellulose from hemp might also lead to a release of cellulose fibrils from the strong hydrogen bonds of its arabinose component, resulting in a loose and more porous structure. Last but not least, the cottonisation of hemp could also influence the relevant properties of the fibre. Cottonisation breaks down the inner middle lamella and allows the release of the individual ultimate cells from the fibre bundle (Batra 2007). In our hemp samples the inner middle lamellas, bonding the ultimate cells together, were partially degraded by the strong mechanical treatment applied during cottonisation. This treatment may contribute to the properties observed on hemp fibre. Variance of all these properties might also influence the other changes mentioned before.

Interfacial shear strength in fibre-reinforced composite

The interfacial shear strength (IFSS) values were calculated from the sizes of perfect polypropylene microbeads (Fig. 9) and the fibre diameter. The values of IFSS for flax and hemp fibres were 2–6 MPa depending on the fibre surface area covered by the actual polymer droplet. These values are significantly smaller than those measured on flax (Huang and Netravali 2007) and hemp (Kim and Netravali 2011) fibres in various soy protein matrices because of the apolar character of polypropylene in contrast to protein. The scattering for all samples was very high, around ±20–25 %. Data calculated for all samples were within this scattering zone; therefore it can be only suggested that treatments do not influence the adhesion measurable by the micro-bond method.

Conclusions

Cleaning of bast fibres (flax and hemp) by water or dilute (20 g/l) aqueous sodium hydroxide solution using stirring or ultrasound treatment modifies the properties of the fibres. These processes remove a part of the small fragments and non-cellulosic carbohydrates, simultaneously altering the hemp fibre diameter and the porous structure of both fibres. It should be taken into account that sonication of lignocellulosic fibres in the presence of alkali might have a dual effect: a concurrent dissolution of non-cellulosic components and softening/polymerisation of lignin might simultaneously go on. Although the extent of the non-cellulosic carbohydrates removal is practically equal for the two types of fibre, the diameter data show a difference for the two substrates: the fineness of flax did not change by any treatment, while sonication of hemp in water after simple alkali treatment results in a decrease of the diameter. The different responses of the two types of fibre can be attributed to either various hemicellulose constitutions or the high disintegration level of the untreated flax fibres. Alkali treatment with stirring followed by sonication in water seems to be the most effective combination considering the change in both fibre (hemp) diameters and porous structures of the fibres. Additionally, concerning the difference in the fibre diameters’ change, hemp and flax are also different in the change of porous structure according to the adsorption of low-temperature nitrogen: the porosity of hemp in the mesopore range increased while that of flax decreased by alkali treatment and subsequent sonication. The reason for these differences might be the dissimilar cell wall structures of the two bast fibres, the high arabinose content, and/or the cottonisation of hemp. As the cell wall character and arabinose content are immanent properties of flax and hemp fibre, these responses of the fibres to the ultrasound-assisted alkali cleaning seem to be unavoidable. No treatment altered the fibre-matrix adhesion measured by pulling out the fibre from a micro-droplet of polypropylene. In the future the effect of the alkali concentration and parameters of sonication might be worth studying.

References

Abramova A, Gedanken A, Popov V, Ooi E-H, Mason TJ, Joyce EM, Beddow J, Perelshtein I, Bayazitov V (2013) A sonochemical technology for coating of textiles with antibacterial nanoparticles and equipment for its implementation. Mater Lett 96:121–124. doi:10.1016/j.matlet.2013.01.041

Aimin T, Hongwei Z, Gang C, Guohui X, Wenzhi L (2005) Influence of ultrasound treatment on accessibility and regioselective oxidation reactivity of cellulose. Ultrason Sonochem 12:467–472. doi:10.1016/j.ultsonch.2004.07.003

Alemdar A, Sain M (2008) Isolation and characterization of nanofibers from agricultural residues—Wheat straw and soy hulls. Bioresour Technol 99:1664–1671. doi:10.1016/j.polymertesting.2011.10.007

Amaducci S, Scordia D, Liu FH, Zhang Q, Guo H, Testa G, Cosentino SL (2015) Key cultivation techniques for hemp in Europe and China. Ind Crop Prod 68:2–16. doi:10.1016/j.indcrop.2014.06.041

Anandjiwala RD, Bogoslavsky L (2008) Development of needle-punched nonwoven fabrics from flax fibers for air filtration applications. Text Res J 78:614–624. doi:10.1177/0040517507081837

Barrett EP, Joyner LG, Halenda PP (1951) The determination of pore volume and area distributions in porous substances. I. Computations from nitrogen isotherms. J Am Chem Soc 73:373–380. doi:10.1021/ja01145a126

Barth M, Carus M (2015) Carbon footprint and sustainability of different natural fibres for biocomposites and insulation material. Bio-based Economy, Services of Nova-Institute www.bio-based.eu/ecology. Accessed 18 Aug 2015

Batra SK (2007) Other long vegetable fibers: abaca, banana, sisal, henequen, flax, ramie, hemp, sunn, and coir. In: Lewin M (ed) Handbook of fiber chemistry, 3rd edn. CRC Press, Boca Raton, pp 464–479

Benli H, Bahtiyari MI (2015) Use of ultrasound in biopreparation and natural dyeing of cotton fabric in a single bath. Cellulose 22:867–877. doi:10.1007/s10570-014-0494-x

Chandra RP, Arantes V, Saddler J (2015) Steam pretreatment of agricultural residues facilitates hemicellulose recovery while enhancing enzyme accessibility to cellulose. Bioresour Technol 185:302–307. doi:10.1016/j.biortech.2015.02.106

Davulcu A, Eren HA, Avinc O, Erişmiş B (2014) Ultrasound assisted biobleaching of cotton. Cellulose 21:2973–2981. doi:10.1007/s10570-014-0273-8

Entezari MH, Al-Hoseini ZS (2007) Sono-sorption as a new method for the removal of methylene blue from aqueous solution. Ultrason Sonochem 14:599–604. doi:10.1016/j.ultsonch.2006.10.004

Eriksson I, Haglind I, Lidbrandt O, Salmén L (1991) Fiber swelling favoured by lignin softening. Wood Sci Technol 25:135–144. doi:10.1007/BF00226813

Espinal-Ruiz M, Restrepo-Sanchez L-P, Narvaez-Cuenca C-E, McClements DJ (2016) Impact of pectin properties on lipid digestion under simulated gastrointestinal conditions: comparison of citrus and banana passion fruit (Passiflora tripartita var. mollissima) pectins. Food Hydrocoll 52:329–342. doi:10.1016/j.foodhyd.2015.05.042

Fages E, Cano MA, Gironés S, Boronat T, Fenollar O, Balart R (2013) The use of wet-laid techniques to obtain flax nonwovens with different thermoplastic binding fibers for technical insulation applications. Text Res J 83:426–437. doi:10.1177/0040517512454183

Gadhe JB, Gupta RB, Elder T (2006) Surface modification of lignocellulosic fibers using high-frequency ultrasound. Cellulose 13:9–22. doi:10.1007/s10570-005-9018-z

Gaur U, Miller B (1989) Microbond method for determination of the shear strength of a fiber/resin interface: evaluation of experimental parameters. Compos Sci Technol 34:35–51

Gouveia IC, Dias LP, Fiadeiro JM, Queiroz JA (2010) Enzymatic treatments to improve the dyeability of linen fabrics: optimization and empirical modeling using experimental design techniques. Text Res J 80:1602–1615. doi:10.1177/0040517510363186

Hebeish A, Sharaf S, Abd El-Hady MM (2011) Ultrasound aided KMnO4-acid systems for bleaching linen fabric. Carbohydr Polym 83:1370–1376. doi:10.1016/j.carbpol.2010.09.052

Huang X, Netravali A (2007) Characterization of flax fiber reinforced soy protein resin based green composites modified with nano-clay particles. Compos Sci Technol 67:2005–2014. doi:10.1016/j.compscitech.2007.01.007

Jianyong F, Jianchun Z (2013) Oil filtration performance of a hemp/cotton spunlaced nonwoven. Text Res J 83:2191–2203. doi:10.1177/0040517513490058

Jinqiu Z, Jianchun Z (2010) Effect of refined processing on the physical and chemical properties of hemp bast fibers. Text Res J 80:744–753. doi:10.1177/0040517509342317

Kačuráková M, Capek P, Sasinková V, Wellner N, Ebringerová A (2000) FT-IR study of plant cell wall model compounds: pectic polysaccharides and hemicelluloses. Carbohydr Polym 43:195–203. doi:10.1016/S0144-8617(00)00151-X

Khajavi R, Atlasi A, Yazdanshenas M-E (2013) Alkali treatment of cotton yarns with ultrasonic bath. Text Res J 83:827–835. doi:10.1177/0040517512467077

Kim JT, Netravali AN (2011) Development of aligned-hemp yarn-reinforced green composites with soy protein resin: effect of pH on mechanical and interfacial properties. Compos Sci Technol 71:541–547. doi:10.1016/j.compscitech.2011.01.004

Kyzas GZ, Terzopoulou Z, Nikolaidis V, Alexopoulou E, Bikiaris DN (2015) Low-cost hemp biomaterials for nickel ions removal from aqueous solutions. J Mol Liq 209:209–218. doi:10.1016/j.molliq.2015.05.060

Latif E, Tucker S, Ciupala MA, Wijeyesekera DC, Newport D (2014) Hygric properties of hemp bio-insulations with differing compositions. Constr Build Mater 66:702–711. doi:10.1016/j.conbuildmat.2014.06.021

Lee KW, Kim JP (2001) Effect of ultrasound on disperse dye particle size. Text Res J 71:395–398. doi:10.1177/004051750107100505

Łojewska J, Miśkowiec P, Łojewski T, Proniewicz LM (2005) Cellulose oxidative and hydrolytic degradation: in situ FTIR approach. Polym Degrad Stab 88:512–520. doi:10.1016/j.polymdegradstab.2004.12.012

Mason TJ (1999) Sonochemistry. Oxford University Press, Oxford, p 9

Miao C, Hamad WY (2013) Cellulose reinforced polymer composites and nanocomposites: a critical review. Cellulose 20:2221–2262. doi:10.1007/s10570-013-0007-3

Miao M, Pierlot AP, Millington K, Gordon SG, Best A, Clarke M (2013) Biodegradable mulch fabric by surface fibrillation and entanglement of plant fibers. Text Res J 83:1906–1917. doi:10.1177/0040517513483861

Miller B, Muri P, Rebenfeld L (1987) A microbond method for determination of the shear strength of a fiber/resin interface. Compos Sci Technol 28:17–32

Miller B, Gaur U, Hirt DE (1991) Measurement and mechanical aspects of the microbond pull-out technique for obtaining fiber/resin interfacial shear strength. Compos Sci Technol 42:207–219

Moholkar VS, Warmoeskerken MMCG (2003) Acoustical characteristics of textile materials. Text Res J 73:827–837. doi:10.1177/004051750307300914

Moriana R, Vilaplana F, Karlsson S, Ribes A (2014) Correlation of chemical, structural and thermal properties of natural fibres for their sustainable exploitation. Carbohydr Polym 112:422–431. doi:10.1016/j.carbpol.2014.06.009

Morlin B, Czigány T (2012) Cylinder test: development of a new microbond method. Polym Test 31:164–170. doi:10.1016/j.polymertesting.2011.10.007

Muzyczek M (2012) The use of flax and hemp for textile applications. In: Kozłowski RM (ed) Handbook of natural fibres, vol 2., Processing and applicationWoodhead Publishing Ltd, Oxford, pp 312–328

Pappas C, Tarantilis PA, Daliani I, Mavromoustakos T, Polissiou M (2002) Comparison of classical and ultrasound-assisted isolation procedures of cellulose from kenaf (Hibiscus cannabinus L.) and eucalyptus (Eucalyptus rodustrus Sm.). Ultrason Sonochem 9:19–23. doi:10.1016/j.carbpol.2012.02.052

Rehman MSU, Rashid N, Saif A, Mahmood T, Han J (2013) Potential of bioenergy production from industrial hemp (Cannabis sativa): Pakistan perspective. Renew Sustain Energy Rev 18:154–164. doi:10.1016/j.rser.2012.10.019

Renouard S, Hano C, Doussot J, Blondeau J-Ph, Lainé E (2014) Characterization of ultrasonic impact on coir, flax and hemp fibers. Mater Lett 129:137–141. doi:10.1016/j.matlet.2014.05.018

Roelofsen PA (1951) Contradictory data on spiral structures in the secondary cell wall of fibers of flax, hemp, and ramie. Text Res J 21:412–418. doi:10.1177/004051755102100605

Schwartz P (2001) Measuring interface strength in composite materials. In: Pastore CM, Kiekens P (eds) Surface characteristics of fibers and textiles. Marcel Dekker, New York, pp 219–233

Silveira RL, Stoyanov SR, Gusarov S, Skaf MS, Kovalenko A (2013) Plant biomass recalcitrance: effect of hemicellulose composition on nanoscale forces that control cell wall strength. J Am Chem Soc 135:19048–19051. doi:10.1021/ja405634k

Sun RC, Tomkinson J, Wang YW, Xiao B (2000) Physico-chemical and structural characterization of hemicelluloses from wheat straw by alkaline peroxide extraction. Polymer 41:2647–2656. doi:10.1016/S0032-3861(99)00436-X

Surina R, Andrassy M (2013) Effect of preswelling and ultrasound treatment on the properties of flax fibers cross-linked with polycarboxylic acids. Text Res J 83:66–75. doi:10.1177/0040517512452928

Tonoli GHD, Teixeira EM, Corrêa AC, Marconcini JM, Caixeta LA, Pereira-da-Silva MA, Mattoso LHC (2012) Cellulose micro/nanofibres from Eucalyptus kraft pulp: preparation and properties. Carbohydr Polym 89:80–88. doi:10.1016/j.carbpol.2012.02.052

Wells T Jr, Kosa M, Ragauskas AJ (2013) Polymerization of Kraft lignin via ultrasonication for high-molecular-weight applications. Ultrason Sonochem 20:1463–1469. doi:10.1016/j.ultsonch.2013.05.001

Xu F, Yu J, Tesso T, Wang D (2013) Qualitative and quantitative analysis of lignocellulosic biomass using infrared techniques: a mini-review. Appl Energy 104:801–809. doi:10.1016/j.apenergy.2012.12.019

Acknowledgments

The authors would like to thank Ms. Kinga Simon for the valuable fibre treatments and Mr. György Bosznai for the nitrogen adsorption measurements. The authors also thank Prof. Tibor Czigány and Dr. Bálint Morlin for their valuable help in the micro-bond test and the CHT/Bezema AG (Switzerland) for kindly providing chemicals.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Borsa, J., László, K., Boguslavsky, L. et al. Effect of mild alkali/ultrasound treatment on flax and hemp fibres: the different responses of the two substrates. Cellulose 23, 2117–2128 (2016). https://doi.org/10.1007/s10570-016-0909-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-016-0909-y