Abstract

In this study, antimicrobial packaging was prepared by mixing colloidal silver nanoparticles with cellulose nanofiber (CNF) and depositing this hybrid coating (CNF/Ag) as a layer on different paper substrates. The CNF/Ag-coated papers were then characterized by scanning electron microscopy (SEM). In addition, their antimicrobial activity, and barrier and strength properties were assessed. SEM showed deposition of Ag nanoparticles on the surface of CNF and formation of a relatively smooth, dense coating layer on the paper surface. The results also demonstrated that the CNF/Ag coating exhibited good antibacterial activity against Escherichia coli (Gram-negative) and Staphylococcus aureus (Gram-positive) bacteria. Although the coating coverage was influenced by paper surface characteristics and coat weights, almost all properties (except water absorption of greaseproof paper) including the water vapor transmission rate, oil resistance, and tensile strength of the CNF/Ag-coated papers were improved in comparison with uncoated papers.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Packaging materials play an important role in food safety and quality preservation, mainly due to increased demands in terms of product safety, shelf-life extension, cost efficiency, environmental issues, and consumer convenience. Antibacterial packaging material can help to maintain product quality and prevent microbial adhesion. To improve packaging performance, innovative modified and controlled packaging materials are being developed and optimized for potential commercial use. Antimicrobial packaging materials may be produced by introducing silver, gold, or copper nanoparticles into polymer film. Various researchers have found that silver nanoparticles are effective killers of pathogenic bacteria such as E. coli, Bacillus subtilis, and S. aureus (Kim et al. 2007; Rai et al. 2009; Li et al. 2010). Also, packaging materials must have adequate mechanical properties, and provide a sufficient barrier to oxygen, water vapor, and oil to prevent food deterioration. In recent years, there has also been increasing interest in oil-resistant papers and paperboards in new products (Kjellegren and Engstrom 2005; Kjellgren et al. 2006; Perng and Wang 2012). Different polymers, polymer blends, and composites are the most widely used barrier materials in the world today. Cellulosic fibers, such as paper and paperboard, have traditionally been used in packaging for a wide range of food categories such as dry food products, frozen or liquid foods, beverages, and even fresh foods (Spence et al. 2010). Cellulose fibers are fibrillated to obtain cellulose microfibril units (Missoum et al. 2013). Such microfibrillated cellulose (MFC) or nanofibrillated cellulose (NFC), being organized in an irreversibly fixed supermolecular cellulose network structure (Klemm et al. 2009), can form smooth, strong, transparent films, with good oxygen barrier properties (Chinga-Carrasco and Syverud 2012). Several recent publications have demonstrated applications of MFC in different fields (Eichhorn et al. 2010; Siró and Plackett 2010; Klemm et al. 2011; Lin and Dufresne 2014). However, little has been reported about NFC use in paper applications or the properties of NFC coatings (Aulin et al. 2010a; Hii et al. 2012; Sehaqui et al. 2013).

In a recent study, Gottesman et al. (2011) developed antimicrobial packaging paper based on direct coating of silver nanoparticles onto paper using ultrasonic radiation. On the other hand, application of MFC as a coating layer has been proposed to enhance the barrier properties of paper (Syverud and Stenius 2009; Aulin et al. 2010a). In this work, we attempted to combine these two approaches, i.e., functionalizing cellulose nanofiber (CNF) with silver nanoparticles and coating onto a paper surface, to develop a material with specific properties for food packaging applications. Hence, the antimicrobial activity, morphology, tensile strength, water vapor transmission rate (WVTR), oil resistance, and water absorption of such coated papers were thoroughly characterized after incorporation of silver nanoparticles into the CNF coating structure.

Experimental

Materials

A greaseproof and a kraft paper (wrapping paper) with different grammage levels were purchased from Russia and used as base papers for coating purposes. The kraft paper was unbleached and was not pigment filled. The compositions of the base papers and their grammage values are presented in Table 1. Escherichia coli (PTCC-1399) as a model Gram-negative bacterium and Staphylococcus aureus (PTCC-1431) as a model Gram-positive bacterium were provided by the Microbiological Resources Centre, Department of Sciences and Food Industry Engineering, University of Tehran. Nutrient broth was purchased from Micro Media Company based in Hungary. Nutrient agar was obtained from the German company of Merck. Anhydrous calcium chloride was obtained from AppliChem, Germany. Silver colloid solution and cellulose nanofiber were purchased from Iranian corporations Nano Novin Polymer and Nano Pooshesh Felez Co., respectively. Castor oil, as edible vegetable oil, and industrial paraffin, as mineral oil, were purchased from Iran Dine Inc., and oil-soluble red dye (Sudan III) was obtained from the Polish company MP Biomedicals to make the colorless oils easily detectable on paper samples by changing their color to red.

Impregnation of CNF with silver nanoparticles

To impregnate CNF with silver nanoparticles (CNF/Ag), the desired amount of CNF was dispersed into colloid silver solution at different concentrations of 5, 10, 15, 20, and 25 ppm. The mixtures were then stirred at 800 rpm for 30 min at room temperature.

Paper coating

Base paper sheets were cut with diameter of 11 cm and set inside a fritted glass filter (P3 with pore size of 16–40 µm). The sheets were coated by filtration and deposition of CNF/Ag layers with variable weights on the surface of the base papers. The coated papers were enclosed with blotting papers and pressed between plates at 4 bar. Then, the papers were allowed to dry at temperature of 23 °C and relative humidity (RH) of 50 % for 72 h. The coat weight of the conditioned papers was calculated using the following equation:

Characterization

Antimicrobial activity

The antimicrobial activity of the CNF/Ag-coated papers was investigated against E. coli as a model Gram-negative bacterium and S. aureus as a model Gram-positive bacterium. The antimicrobial activity of the CNF/Ag-coated papers was determined using the following methods:

The colony-forming count method: CNF/Ag-coated papers were cut into disc shape with 1.5 cm diameter. Before inoculation of bacteria, the sample pieces were sterilized by autoclaving at 120 °C for 15 min. Samples were divided into two groups, each consisting of eight pieces. The first group was seeded with 1 mL sterile nutrient broth as sterile control, whereas the second group was seeded with fresh E. coli and S. aureus culture at concentration of 107 and 109 colony-forming units per mL (CFU/mL), respectively, then incubated in a shaking incubator at 37 °C for 24 h. After incubation, 50 mL saline was added to each of the groups, then all tubes were vortexed. Afterwards, about 50 μL of suspension was drawn out of each tube and distributed on a sterile plate. Then, about 15–25 mL of nutrient agar medium, previously sterilized and whose temperature had reached 45 °C, was transported to the plate and completely mixed with the suspension using figure-8 pattern rotational movements. Finally, to count the number of colonies formed, the plates were put inside an incubator for 24 h at 37 °C.

The same procedure was performed on control samples. The percentage reduction in bacterial count was calculated using the following equation (Li et al. 2006; Maneerung et al. 2008):

Morphology (SEM)

The morphology of the CNF/Ag-coated papers was assessed using a TESCAN–WEGA scanning electron microscope (SEM). Prior to observation, the surface of the paper specimens was coated with a thin conducting layer of gold.

Tensile strength

The tensile strength of the CNF/Ag-coated papers was determined in accordance with Technical Association of the Pulp and Paper Industry (TAPPI standard T404 om-92 using a Frank tester. The results are reported as the mean of six measurements.

Water vapor transmission rate (WVTR)

The water vapor transmission rate of the CNF/Ag-coated papers was determined gravimetrically according to TAPPI standard method T448 om-98. This method describes gravimetric determination of the WVTR of sheet materials at 23 °C with atmosphere of 50 % RH on one side and desiccant on the other side.

In this method, calcium chloride (CaCl2) salt was poured into a 6-mm-high Petri dish with internal diameter of 9 cm. The coated sample (coated side upwards and exposed to fresh air) was sealed on a Petri dish using solid silicone oil to avoid air penetration. The entire set, after weighing, was placed at 23 ± 1 °C and 50 % RH for 18 h. After this period, the weight of the dish containing the sample was measured. The amount of water vapor sorption by the coated paper samples during y hours was calculated using the following equation, with the results reported in units of g/m2 day:

where x is the sample weight change in grams during y hours, and A is the area of paper under test in m2. The measurements were conducted in three replications.

Oil resistance

The oil resistance of the CNF/Ag-coated papers was measured in accordance with TAPPI T 507. In this test, the resistance of the paper against penetration of paraffin (as mineral oil) and castor oil (as edible vegetable oil) was investigated, with results reported as the average of three measurements. Initially, the colors of the liquid oils were changed to red by solving Sudan III. Then, according to the pattern given in TAPPI T 507, ten-layer arrangements including the test samples were stacked and this order repeated up to 10 times. After that, a flat panel with mass of 400 ± 20 g was placed on top of the stacks. Finally, the whole set was kept in an oven at 60 °C for 4 h. The resistance of the coated papers to oil penetration is reported as the percentage of blotter stained area as analyzed using the image processing toolbox of MATLAB 13a.

Water absorptiveness (Cobb test)

This test was carried out in accordance with TAPPI T 441 om-98, in which the quantity of water absorbed by paper is determined. In this method, the coated paper was placed in the apparatus and then 100 mL water (23 ± 1 °C) was poured into the ring and onto the sample. After 120 s, the water was evacuated and the surplus water on the paper removed using a blotting paper and moving a hand roller over the paper. The weight of water absorbed by the sample was obtained using the following equation:

Results and discussion

Antimicrobial activity

The results indicated that the antimicrobial activity was independent of the base paper composition but was dramatically influenced at each coat weight by the concentration of silver nanoparticles used to modify the CNF. It was evident that the amount of silver nanoparticles impregnated into the CNF with the same colloid solution concentration would be higher for heavy coat weights than light ones and so could influence the antibacterial activity.

Therefore, the antimicrobial activity of CNF/Ag-coated kraft paper with 1 g/m2 coat weight with different amounts of silver nanoparticles against E. coli and S. aureus is reported herein. As can be seen from Table 2, the higher the concentration, the greater the bacterial reduction; when it reached 20 ppm (and higher concentrations) no bacteria survived, neither E. coli nor S. aureus (100 % reduction). Moreover, no bacterial growth was observed from the sterile control.

It is well known that silver nanoparticles exhibit efficient antimicrobial activity due to their high surface area, which provides better contact with microbes. Some possible mechanisms of action have been proposed, including cell membrane perforation, alteration of selective permeability, interaction with thiol group compounds found in respiratory enzymes, as well as interaction with phosphorus-containing compounds such as DNA and interference with the replication process, resulting in bacteriostatic and bactericidal effects (Feng et al. 2000; Rai et al. 2009).

After 48 h of incubation, there was a 73.3 and 78.3 % decrease in viable S. aureus and E. coli, respectively, on CNF/Ag-coated paper modified with 5 ppm colloid silver solution. For uncoated paper, not only was there no reduction in viable counts, but the viable counts of E. coli and S. aureus actually increased, by 40.90 and 35.77 %, respectively. This clearly demonstrated that the CNF/Ag-coated papers with different contents of silver nanoparticles exhibited good antimicrobial activity against both E. coli (Gram negative) and S. aureus (Gram positive). The antibacterial activity against S. aureus was lower than that against E. coli, probably due to the difference in the cell wall between Gram-positive and Gram-negative bacteria. The cell wall of Gram-negative bacteria consists of lipids, proteins, and lipopolysaccharides (LPS), whereas Gram-positive bacteria (e.g., S. aureus) possess additional protection in the form of a dense peptidoglycan cell wall that provides effective protection against several biocides (Gottesman et al. 2011; Maneerung et al. 2008).

Surface microstructure

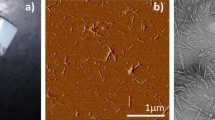

As mentioned above, the surface microstructures of the CNF/Ag-coated and uncoated kraft and greaseproof papers were studied using SEM. The results of this study are summarized in Figs. 1, 2, and 3, which present micrographs of coated papers at different magnifications. Uncoated kraft paper (Fig. 1a, c) showed a very open and porous network of randomly crossing fibers. As expected, the greaseproof paper (Fig. 2a, c) revealed a closer and less porous structure than the kraft paper.

We believe that the more open structure and surface roughness of the kraft paper may contribute more to physical interlocking of fibers and consequently to development of strong adhesion between the deposited CNF/Ag layer and the base paper; however, this requires further delamination assessment, which was not addressed in this work.

However, the network structure of the papers became less apparent when the surface was coated by CNF/Ag at coat weight of 2.5 (Fig. 1b, d) and 1.5 g/m2 (Fig. 2b, d) for kraft and greaseproof paper, respectively. These micrographs depict that the coating covered the fibers at this coat weight, forming a continuous film over the fibers (see also Fig. 3c, d). When the same coat weight of CNF/Ag was applied on both base substrates, the greaseproof paper exhibited a denser structure, which correlates well with the oil resistance measurements discussed in Sect. 3.5.

Also, SEM analysis of the specimens demonstrated deposition and distribution of silver nanoparticles particularly on the surface of CNF and inside the dense network. Moreover, aggregated morphology of nanoparticles was also observed (Fig. 3a, b). It has been proposed that loading of fibers using a simple mixing and physical adsorption method compared with in situ synthesis often leads to aggregation and relatively low distribution of silver nanoparticles (Jiang et al. 2011; Raho et al. 2015).

In addition, comparing these results with findings of other researchers (Syverud and Stenius 2009; Aulin et al. 2010a), we can say that the effect of coating technique is evident and that development of special methods for coating CNF would improve the uniformity of the coating structure.

Tensile properties

The use of CNF/Ag coating as the surface layer (with coat weight of 0.5–2.5 g/m2) on the base papers significantly increased the strength of the paper sheets. When a strip of CNF/Ag-coated paper is exposed to a tensile force, the whole combination of coating layer and base paper carries the load. Since the tensile strength of CNF-free films with strong network is much greater than for conventional papers, the enhancement of the whole material strength is evident.

The tensile strength index of the greaseproof and kraft papers coated with CNF/Ag layers of different weights is compared in Figs. 4 and 5, respectively. As can be seen from these figures, an increase in the tensile strength index of CNF/Ag-coated papers was observed for both base papers (in comparison with uncoated ones), and with increasing coating weight, the strength of the coated greaseproof and kraft papers was further enhanced. Therefore, for the samples of greaseproof and kraft paper, the maximum strength was observed for coat weight of 1.5 and 2.5 g/m2, respectively. Among the tested samples, the strength of the coated papers was the same for both 10 and 5 ppm concentrations. As a result, the use of silver nanoparticles had no effect on the tensile strength, at least in this range. However, it has been recognized that silver nanoparticles can interact with hydroxyl groups (Mbhele et al. 2003) to cause improved mechanical strength and viscoelastic properties of Ag-modified sheets (Csoka et al. 2012).

Obviously, addition of CNF helped to improve the tensile strength of the papers, as also proved in the research works of Savadekar and Mhaske (2012), Syverud and Stenius (2009), and Fernandes et al. (2010).

Water vapor transmission rate (WVTR)

Figures 6 and 7 present the WVTR results for the greaseproof and kraft papers coated by CNF/Ag, respectively. As illustrated in Fig. 6, the coated greaseproof paper, compared with the control sample, showed little resistance to water vapor penetration. Meanwhile, according to Fig. 7, the coated kraft paper exhibited higher resistance to water vapor transmission in comparison with the control sample. As the base weight of the CNF coating on the paper surface was increased, the water vapor transmission rate decreased. Hence, the coated samples with coat weight of 1.5 g/m2 for greaseproof paper and 2.5 g/m2 for kraft paper (i.e., the samples with maximum coat weight) displayed higher barrier properties compared with those with lower coat weights. Among the tested samples, the difference between the kraft papers with 10 versus 5 ppm silver nanoparticles was negligible and might be due to the use of more silver nanoparticles and filling of paper surface pores.

The strong hydrophilic nature of CNF impairs its barrier properties against water vapor, but the denser structure of the CNF/Ag coating results in penetration of less water through the coated paper thickness and prevents the increased WVTR.

The WVTR of pure CNF film with thickness of 42 μm has been measured to be about 243 g/m2 day (Rodionova et al. 2011), which is about 14 times more than most commercial polyethylene plastic film with thickness of 18.3 μm. However, it has been reported that the WVTR of CNF film was significantly lower compared with films made from bleached softwood fibers (Nair et al. 2014). Recently, heat treatment and acetylation of CNF has been proposed to enhance its hydrophobicity (Rodionova et al. 2011; Sharma et al. 2014), deserving more attention in future work.

Oil resistance

Although the oil barrier property is rarely measured, it is often an essential consideration in food and packaging industries. Figures 8, 9, 10 and 11 display the oil resistance of the coated greaseproof and kraft papers against castor oil and paraffin. The results show that the oil permeability drastically decreased as the weight of the CNF/Ag coating was increased. For the greaseproof paper with coat weight of 1.5 g/m2, the castor oil permeability was about 13.3 and 15.8 % for CNF impregnated with 10 and 5 ppm silver colloid solution, respectively, while the paraffin permeability was about 27.7 and 30.1 % for the same samples. For kraft paper with coat weight of 2.5 g/m2, the castor oil permeability was about 27.3 and 29 % for CNF impregnated with 10 and 5 ppm silver colloid solution, respectively, while the paraffin permeability was about 20.7 and 22.6 % for the same samples. The oil permeability decreased considerably for the two coated papers compared with uncoated ones, but the coated greaseproof paper was more resistant towards the oils compared with the kraft paper. These results are consistent with the works of Aulin et al. (2010a, b).

Oil resistance usually results from a relative absence of pores in the paper and is mainly determined by the largest pore size in the paper (Kjellgren 2005). This barrier property is usually achieved by extensive beating of fibers. Therefore, it is evident that deposition of a denser layer of CNF with high crystallinity on the paper surface could boost this property. In other words, the improved barrier properties were correlated with a reduction in the surface porosity.

An alternative approach to achieve this property is application of fluorochemicals as coating material on papers. Recently, the surface of cellulose nanocrystals as a biocompatible nanomaterial was fluorinated or polyfluorinated to impart hydrophobic and oleophobic properties for application in oil-resistant packaging materials (Salam et al. 2015).

Water absorption

The results of the water absorption tests are presented in Figs. 12 and 13 for both coated papers. As shown in Fig. 12, the coated greaseproof paper showed no resistance to water absorption in comparison with the control sample. As the base weight of the CNF was increased, the resistance to water absorption decreased. Therefore, the samples with base weight of 1.5 g/m2 exhibited the lowest resistance. Among the tested greaseproof samples, there was no significant difference between those containing 10 versus 5 ppm nanosilver.

According to the results presented in Fig. 13, coated kraft paper, unlike for greaseproof paper, showed higher resistance to water absorption compared with the control sample. The coat weight of CNF/Ag was directly proportional to the water absorption resistance. Hence, samples with base weight of 2.5 g/m2 showed the highest resistance. Among the tested kraft samples, CNF impregnated with 10 ppm silver colloid solution absorbed less water compared with those impregnated with 5 ppm (for given coat weight), although the difference was negligible. This slight difference was probably due to the use of more nanosilver and filling of the paper surface and network pores.

The different behavior of the two substrates, i.e., greaseproof and kraft paper, coated with the same material may be attributed to the water absorption mechanisms. In kraft paper with an open surface structure and presence of lignin, sorption of water into pores could possibly be the predominant mechanism, whereas the most important mechanism for greaseproof paper is sorption of liquid into the fibers due to the absence of large surface pores and high swelling potential of the highly beaten fibers (Kjellgren 2005). Hence, closing the surface of kraft paper with a dense layer of CNF could influence its water absorption potential more efficiently.

Conclusions

Novel antibacterial packaging papers were prepared by impregnating cellulose nanofiber with silver nanoparticles (CNF/Ag) and deposition as a coating layer on top of two substrates, i.e., kraft or greaseproof base paper. As evident from SEM analysis, impregnation and then filtration of CNF/Ag caused formation of a relatively uniform, dense layer with good distribution of Ag nanoparticles on the CNF surface. The formation of a continuous coat was less influenced by the surface characteristics of the base papers, particularly at high coat weights.

Measurements of antibacterial activity revealed that the silver nanoparticles incorporated into the coating structure had a significant effect, reducing the percentage of E. coli and S. aureus bacteria. Silver colloid solution with concentration of 5 and 10 ppm could provide optimum amounts of silver nanoparticles for preparing CNF/Ag antibacterial coating due to the great effect on the percentage reduction of both Gram-negative and Gram-positive bacteria.

According to the results, application of CNF/Ag coatings on both kraft and greaseproof base papers improved their mechanical and barrier properties. CNF/Ag-coated kraft paper with different coat weights, in comparison with greaseproof base paper, showed overall the best results for most of the barrier properties. The role of the coating was particularly more noticeable in terms of the resistance to oil penetration. In spite of the hydrophilic nature of CNF, the coating showed resistance to water vapor transmission and water absorption when deposited on the kraft surface. However, this coating on greaseproof paper could not enhance the water absorption resistance, a difference attributed to its water sorption mechanism.

The results obviously show that application of CNF/Ag hybrid coating on kraft and greaseproof paper can enhance their potential as environmentally friendly antimicrobial packaging materials, particularly for oily solid food packaging applications.

References

Aulin C, Gällstedt M, Lindström T (2010a) Oxygen and oil barrier properties of microfibrillated cellulose films and coatings. Cellulose 17(3):559–574

Aulin C, Netrval J, Wågberg L, Lindström T (2010b) Aerogels from nanofibrillated cellulose with tunable oleophobicity. Soft Matter 6(14):3298–3305

Chinga-Carrasco G, Syverud K (2012) On the structure and oxygen transmission rate of biodegradable cellulose nanobarriers. Nanoscale Res Lett 7(1):1–6

Csoka L, Bozanic DK, Nagy V, Dimitrijevic-Brankovic S, Luyt AS, Grozdits G, Djokovi V (2012) Viscoelastic properties and antimicrobial activity of cellulose fiber sheets impregnated with Ag nanoparticles. Carbohyd Polym 90:1139–1146. doi:10.1016/j.carbpol.2012.06.065

Eichhorn S, Dufresne A, Aranguren M, Marcovich N, Capadona J, Rowan S, Weder C, Thielemans W, Roman M, Renneckar S (2010) Review: current international research into cellulose nanofibres and nanocomposites. J Mater Sci 45:1–33

Feng QL, Wu J, Chen GQ, Cui FZ, Kim TN, Kim JO (2000) A mechanistic study of the antibacterial effect of silver ions on Escherichia coli and Staphylococcus aureus. J Biomed Mater Res 52(4):662–668

Fernandes S, Freire CS, Silvestre AJ, Pascoal Neto C, Gandini A, Berglund LA, Salmén L (2010) Transparent chitosan films reinforced with a high content of nanofibrillated cellulose. Carbohyd Polym 81(2):394–401

Gottesman R, Shukla S, Perkas N, Solovyov AL, Nitzan Y, Gedanken A (2011) Sonochemical coating of paper by microbiocidal silver nanoparticles. Langmuir 27(2):720–726

Hii C, Gregersen WØ, Chinga-Carrasco G, Eriksen Ø (2012) The effect of MFC on the pressability and paper properties of TMP and GCC based sheets. Nord Pulp Pap Res J 27(2):388–396

Jiang T, Liu L, Yao J (2011) In situ deposition of silver nanoparticles on the cotton fabrics. Fiber Polym 12(5):620–625. doi:10.1007/s12221-011-0620-4

Kim JS et al (2007) Antimicrobial effects of silver nanoparticles. Nanomed-Nanotechnol 3:95–101. doi:10.1016/j.nano.2006.12.001

Kjellegren H, Engstrom G (2005) The relationship between energy requirement and barrier properties in the production of grease proof paper. TAPPI J 4(8):7–11

Kjellgren H (2005) Barrier properties of greaseproof paper. Thesis, Karlstad University

Kjellgren H, Gallstedt M, Engstrom G, Jarnstrom L (2006) Barrier and surface properties of chitosan-coated greaseproof paper. Carbohyd Polym 65:453–460. doi:10.1016/j.carbpol.2006.02.005

Klemm D, Schumann D, Kramer F, Heßler N, Koth D, Sultanova B (2009) Nanocellulose materials—different cellulose, different functionality. Macromol Symp 280(1):60–71. doi:10.1002/masy.200950608

Klemm D, Kramer F, Moritz S, Lindström T, Ankerfors M, Gray D, Dorris A (2011) Nanocelluloses: a new family of nature-based materials. Angew Chem Int Ed 50:5438–5466

Li Y, Leung P, Yao L, Song QW, Newton E (2006) Antimicrobial effect of surgical masks coated with nanoparticles. J Hosp Infect 62(1):58–63

Li W-R, Xie X-B, Shi Q-S, Zeng H-Y, OU-Yang Y-Sh, Chen Y-B (2010) Antibacterial activity and mechanism of silver nanoparticles on Escherichia coli. Appl Microbiol Biotechnol 85:1115–1122. doi:10.1007/s00253-009-2159-5

Lin N, Dufresne A (2014) Nanocellulose in biomedicine: current status and future prospect. Eur Polym J 59:302–325

Maneerung T, Tokura S, Rujiravanit R (2008) Impregnation of silver nanoparticles into bacterial cellulose for antimicrobial wound dressing. Carbohyd Polym 72(1):43–51

Mbhele ZH, Salemane MG, Van Sittert CGCE, Nedeljkovic JM, Djokovic V, Luyt AS (2003) Fabrication and characterization of silver–polyvinyl alcohol nanocomposites. Chem Mater 15:5019–5024

Missoum K, Belgacem MN, Bras J (2013) Nanofibrillated cellulose surface modification: a review. Materials 6(5):1745–1766

Nair SS, Zhu JY, Deng Y, Ragauskas AJ (2014) High performance green barriers based on nanocellulose. Sustain Chem Processes 2:23 http://www.sustainablechemicalprocesses.com/content/2/1/23

Perng Y-Sh, Wang EI-Ch (2012) Optimization of handsheet greaseproof properties: the effects of furnish, refining, fillers and binders. BioResources 7(3):3895–3909

Raho R, Paladini F, Anna Lombardi F, Boccarella S, Zunino B, Pollini M (2015) In-situ photo-assisted deposition of silver particles on hydrogel fibers for antibacterial applications. Mater Sci Eng C 55:42–49. doi:10.1016/j.msec.2015.05.050

Rai M, Yadav A, Gade A (2009) Silver nanoparticles as a new generation of antimicrobials. Biotechnol Adv 27:76–83. doi:10.1016/j.biotechadv.2008.09.002

Rodionova G, Lenes M, Eriksen Ø, Gregersen Ø (2011) Surface chemical modification of microfibrillated cellulose: improvement of barrier properties for packaging applications. Cellulose 18:127–134. doi:10.1007/s10570-010-9474-y

Salam A, Lucia LA, Jameel H (2015) Fluorine-based surface decorated cellulose nanocrystals as potential hydrophobic and oleophobic materials. Cellulose 22:397–406. doi:10.1007/s10570-014-0507-9

Savadekar NR, Mhaske ST (2012) Synthesis of nano cellulose fibers and effect on thermoplastics starch based films. Carbohyd Polym 89(1):146–151

Sehaqui H, Zhou Q, Berglund AL (2013) Nanofibrillated cellulose for enhancement of strength in high-density paper structures. Nord Pulp Pap Res J 28(2):182–189. doi:10.3183/NPPRJ-2013-28-02-p182-189

Sharma S, Zhang X, Nair SS, Ragauskas A, Zhu J, Deng Y (2014) Thermally enhanced high performance cellulose nano fibril barrier membranes. RSC Adv 4:45136–45142. doi:10.1039/C4RA07469F

Siró I, Plackett D (2010) Microfibrillated cellulose and new nanocomposite materials: a review. Cellulose 17:459–494

Spence KL, Venditti RA, Rojas OJ, Habibi Y, Pawlak JJ (2010) The effect of chemical composition on microfibrillar cellulose films from wood pulps: water interactions and physical properties for packaging applications. Cellulose 17(4):835–848

Syverud K, Stenius P (2009) Strength and barrier properties of MFC films. Cellulose 16(1):75–85

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Amini, E., Azadfallah, M., Layeghi, M. et al. Silver-nanoparticle-impregnated cellulose nanofiber coating for packaging paper. Cellulose 23, 557–570 (2016). https://doi.org/10.1007/s10570-015-0846-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-015-0846-1