Abstract

Introducing nanomaterials in gas sensor applications has conspicuously improved the detection performance due to the unique nanostructures. Transition-metal dichalcogenides (TMDs) recently aroused widespread interest because of their ultrathin and layered two-dimensional nanosheet structures. The graphene-like MoS2 has good electrical, chemical, mechanical, and optical properties, making it of great interest for developing gas sensors and an exceptionally promising building block for designing novel semiconducting nanomaterials. The content of this mini-review aspires to summarize the current progress on mono/few-layered MoS2-based gas sensors and the influence of different components. Herein, we described the current progress on MoS2-based gas sensors, which encompasses the preparation and application of MoS2, and the potential improvement directions for future possibilities of expanding its applications.

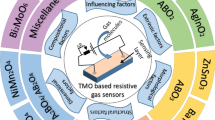

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The past decades’ research shows that in addition to the composition and arrangement of atoms in materials, dimensionality also plays a crucial role in determining their fundamental properties. Since Professor A. K. Geim and his research team obtained monolayer graphene from graphite by mechanical tape stripping method in 2004, the existence of graphene was confirmed which set off an upsurge of research on other new two-dimensional (2D) monolayer nanomaterials. As we all know, graphene and its composites are chemically inert with lower sensitivity and thus must be activated by decoration with desired molecules before use, resulting in the loss of some singular properties [1, 2]. Besides, the lack of a band gap of graphene has inspired researchers to search for other graphene-like materials with appropriate band gap. Recently, the fabrication and application of transition metal dichalcogenides (TMDs) have become fundamentally and technologically intriguing due to the ultrathin and layered two-dimensional nanosheet structures, and have been widely used in many fields, including field-effect devices, catalysis, energy storage, chemical and biological sensors, etc.

Monolayer sheet-like TMDs can be defined as MX2, where M covers the transition metals from the 4th to 10th group and X represents the chalcogen group (Fig. 1), and these versatile chemical properties offer fundamental and technological guidance for the various research fields. The performances of bulk TMDs are quite different from insulators like HfS2, semiconductors like MoS2 and WS2, semimetals like WTe2 and TiSe2, and true metals like NbS2 and VSe2. Exfoliating these bulk TMD materials into single or few layers can maximize the confinement effects, thus offers powers far beyond graphene and open up new technological fields for inorganic 2D nanomaterials.

Structure of monolayered TMDs: a The transition metals and the three chalcogen elements that predominantly crystallize in that layered structure are highlighted in the periodic table. Partial highlights for Co, Rh, Ir, and Ni indicate that only some of the dichalcogenides form layered structures. For example, NiS2 is found to have a pyrite structure but NiTe2 is a layered compound; c-Axis and section view of single-layer TMD with trigonal prismatic (b), and octahedral (c) coordinations. Images in (a)–(c) are reproduced with permission from Ref. 2

Among which, the intrinsic MoS2 (Eg = ~ 1.8 eV), known for its special 2D structure similar to graphene and stacked by van der Waals force interaction with a 0.62 nm (vs. 0.34 nm of graphene) larger spacing, and good electrical, chemical, mechanical and optical properties [3], has proved to be an exceptionally promising building block for designing novel semiconducting nanomaterials. Especially, MoS2 shows outstanding selective molecular adsorption and carrier mobility, and to some extent, it can take advantage of the performance that metal oxide semiconductors don’t have, which enables MoS2 to be a promising candidate in the field of gas sensing materials [4,5,6]. For this purpose, it’s very important to synthesize MoS2 nanosheets with large areas and high-quality sensing performances, like good selectivity, higher response, lower operating temperature even down to room temperature (RT), etc. [7,8,9].

In this short review, we highlight some interesting gas-sensing properties of mono/few-layered MoS2 and how they are influenced by the components. Some recent progress on the preparation of intrinsic and doped MoS2, including hydrothermal/solvothermal treatment, chemical vapor deposition (CVD), and chemical exfoliation of the bulk precursors is reviewed, as well as the implementation of the resulting MoS2 (pristine/hybrid) sensing materials as high performance, low temperature-working and portable gas sensor devices in detail, and indicates possible future developments in MoS2-based gas sensors.

2 Preparation of MoS2-Based Gas Sensing Nano-materials

It’s worth noting that monolayer MoS2 presents only two polymorphs: trigonal prismatic and octahedral phases, and the former can be referred to as a stable monolayer 2H (or D3h) semiconductor state whereas the latter referred to the metastable 1T (or D3d) metallic state. For simplicity, they are described as monolayer 2H and 1T MoS2, respectively. However, it is challenging to separately prepare 1T phase MoS2 layers from bulk MoS2 materials because of the two phases present (2H semiconducting and 1T metallic), and the prepared monolayer 1T phase of MoS2 is unstable and tends to form the multilayer 2H phase with low conductivity over 95 °C.

As we all know, the sensing properties of the semiconductor gas sensors have been largely affected by their structure and components, since the sensing process relies on the adsorption and reaction with a target molecule on the surface of nanomaterials to account for the change in resistance [10]. For example, the layer-by-layer accumulated nano-sheet structure of MoS2 has significant advantages in improving sensing performances because of their larger exposed area, good surface permeability, low density, and high interfacial charge-transfer efficiency [11, 12], thus will open the field of real-time and room-temperature monitoring of the toxic gas compounds [12,13,14]. Besides, the novel gas sensing properties of intrinsic MoS2 are largely dependent on the number of layers. For instance, atomic-layered MoS2 has a direct band gap (Eg) of about 1.8 eV, while multi-layered MoS2 has an indirect band gap (Eg) of about 1.2 eV, which has been regarded as an important factor that affects electronic and optical applications.

In 2012, Gordon et al. [15] from Nanyang University of Technology fabricated 1–4 layers of MoS2 nanosheets on Si/SiO2 substrate by micromachined exfoliation, and fabricated MoS2 transistor by photolithography of Ti/Au electrode to realize the detection of NO gas at room temperature, which spurred the upsurge of scientists’ research on MoS2 gas sensor. However, some defects still exist in the intrinsic MoS2, and oxygen in the air will affect its electrical properties and make it unstable. So people found that modifying MoS2 with metal oxides, precious metals, or non-metallic nano-materials can make it stable in the air and improve its gas-sensing properties. In the following content, we will discuss the synthesis methods of intrinsic and doped MoS2 gas sensing nano-materials in detail.

2.1 Intrinsic MoS2 Gas Sensing Nano-materials

Generally speaking, there are two main methods for preparing MoS2: top-down and bottom-up. The distinction and classification between the two methods are described in detail as follows.

Therefore, the top-down methods include the mechanical stripping method, liquid stripping method and electrochemical or chemical stripping method. Mechanical stripping is the earliest method used to prepare 2D nano-materials, and the operation process is to rub the lamellar material with other hard physical surfaces, so that a thin layer of nano-materials can be obtained. For example, Song et al. [16] fabricated MoS2 nanosheets successfully with the size of 72.0727 m2/g on Fe3O4 substrates by such a method. Although the mechanical stripping method is simple, the yield is low and the size of MoS2 nanocrystals is limited, so it is unsuitable for large-scale production. At the same time, the liquid-phase stripping method is different from the mechanical stripping. Specifically, the MoS2 nanosheet is floated on the surface of the solvent under ultrasonic treatment by placing the MoS2 crystal in a suitable solvent, and finally, the supernatant is extracted to obtain the pure MoS2 nanosheet. Accordingly, Coleman et al. [17] prepared 5–20 layers of MoS2 nanocrystals by such a method. The liquid stripping method is simple and easy to operate and can avoid the influence of water and air, but the number of lamellae is difficult to control. Lastly, the electrochemical stripping method is usually based on the chemical method of SO42− or Li2+ intercalation, as described in Fig. 2a, Zeng et al. [18] prepared a single-layered MoS2 nanosheet on a glass substrate using an electrochemical lithium-based method. Lithiation was carried out in a set of battery test devices using the MoS2 material and the lithium foil as the cathode and anode, respectively. The lithium process was carried out at a constant current of 0.05 mA. When the lithium-ion insertion was finished, the intercalation compounds were cleaned with acetone to remove the electrolyte, and then the MoS2 nanosheets were stripped out in water or ethanol by ultrasonication. Finally, as shown in Fig. 3, Amini et al. [19] reported different methods to intercalate the layers of MoS2 successfully, such as acid treatment, ultrasonication, oxidation, thermal shock, and so on. To summarize, this method is simple and efficient, but transferring the obtained MoS2 nanosheets to other substrates is difficult. Besides, lithium deposition will decrease the semiconductor properties of the nanosheets, and it is hard to fabricate them with large areas.

Modify and intercalate stages of MoS2 nanolayers. Image is reproduced with permission from Ref. [19]

Another method is a bottom-up approach, which includes chemical vapor deposition (CVD) and hydrothermal methods. CVD is one of the most popular methods used by researchers to prepare high-quality MoS2 nanosheets, and the process is to make the reactive substances react in the high-temperature gas state and then form solid substances deposited on the surface of a heated solid matrix. The morphology, quality and layer number of MoS2 nanosheets can be controlled by changing the precursor, matrix and reaction conditions during the preparation process. As shown in Fig. 2b, Liu et al. [20] added MoO3 nanowires and sulfur powder into the reactor and filled it with N2 gas, then heated it to 550 °C at the rate of 20 °C/min, and then heated to 850 °C at the rate of 5 °C/min and kept for 10–15 min after the sulfur powder was evaporated into steam. Finally, MoS2 nanosheets with a thickness of 10–20 μm were deposited on the SiO2/Si substrate after cooling, and high purity and good crystallinity of the MoS2 product were acquired by the CVD method. However, these preparation conditions are rigorous, also the reaction temperature and the energy consumption are both very high.

Alternatively, as shown in Fig. 4, the hydrothermal method, a universal method that people are familiar with, refers to the synthesis method of chemical reaction in a sealed pressure vessel (such as an autoclave), in which water solution is used as a reaction solvent under certain high temperature and high-pressure reaction conditions. Meanwhile, if water is substituted by an organic solvent, we call it the solvothermal method. The hydrothermal method has synthesised different morphologies and structures of MoS2 and was applied in various fields. For example, as seen in Fig. 5, Li et al. [21] prepared hierarchical and hollow MoS2 microspheres by hydrothermal method with sodium molybdate and thioacetamide as molybdenum source and sulfur source, and polystyrene as template, respectively. In addition, Wang et al. [20] reported the use of MoS2 nano petal arrays for supercapacitor electrode materials fabricated by a facile hydrothermal method, which showed a specific capacitance of 133 F/g at a discharge current density of 1 A/g. In Zhang’s report [22], the novel 3D flower-like MoS2 hemispheres assembled by ultrathin MoS2 nano-sheet petals have been successfully prepared via a facile hydrothermal method using CTAB as a surfactant. Mishra et al. [23] employed a one-pot solvothermal method to synthesize metallic 1T phase MoS2 petal-like nanostructures (MP-LNs) with large surface areas associated with densely formed petals, and so on.

A typical hydrothermal process to fabricate An-ZnO nanowires. Images are reproduced with permission from Ref. [9]

Schematic depiction of the growth mechanism of hierarchical hollow and solid MoS2 microspheres. a MoS2 nanosheets nucleate on the PS template. b MoS2 nanosheets nucleate and grow continually. c PS template was removed and the hollow sphere remain. d MoS2 nucleates on the surface of MoS2 nanosheets and grows up into little solid spheres. e Solid spheres fall off from hollow spheres. f Schematic illustration of the sensing process. Images are reproduced with permission from Ref. [21]

Compared with the CVD method, the recently reported hydrothermal method has partly resolved the batch synthesis issue hydrothermal method needs a lower temperature and lower cost, but it’s time-consuming and difficult to control the number of layers of MoS2 nanosheets [23]. Therefore, the focus of current research will still be how to fabricate MoS2 nanosheets with large size, good quality, and low cost.

2.2 Doped/Modified MoS2 Gas Sensing Nano-materials

For practical application, poor intrinsic electronic conductivity still hinders the development of MoS2. Nanocomposites formed by integration and synergetic interaction of two or three materials with different components, such as N-rich graphitic-C3N4 modified MoS2 would result in heterostructures with better electrical and mechanical properties [24]. Furthermore, the fabrication of doped/modified MoS2 nanocomposites with other dopants would be expected to effectively suppress the restacking and aggregation of MoS2 layers, and be suitable for optical, catalytical, electric or chemical applications. Herein, we summarize the synthetic methods of doping or modifying MoS2 compounds for the peers’ review.

The present paper from Zhang et al. demonstrates a simple, scalable, and economical solvent thermal method for preparing flower-shaped TiO2/C/MoS2 microspheres, which can be employed as an anode for LIBs. The flower-shaped TiO2/C microspheres with flake-shaped petals acted as a backbone to provide an efficient pathway for the fast Li+ intercalation/deintercalation of MoS2, and to accommodate the volume changes. Compared with pure MoS2 and TiO2/C, TiO2/C/MoS2 microspheres can significantly enhance electrochemical properties, which showed a high initial discharge capacity of 1219 mA h g−1 and Coulombic efficiency (CE) of 70% at 100 mA g−1. After 100 cycles, the TiO2/C/MoS2 composites discharge capacity remained at 621 mA h g−1 and had a CE of 98% [25]. Besides, the layered MoS2 was also modified with nitrogen-doped carbon to improve the capacity in Li–Na psuedocapacitors [24], and lithium-ion batteries [26]. And Shi et al. [27] the positively charged ultrathin g-C3N4/MoS2 composites are fabricated through a simple electrostatic adsorption and self-assembly process followed by a hydrothermal method. The superb photocatalytic performance benefits from the unique advantages, with an excellent synergistic effect toward photocatalytic degradation of organic pollutants. Senthil et al. [24] reported the synthesis of a 3D network of MoS2 encapsulated over g-C3N4 nanosphere forming an inter-connected and uniform g-C3N4/MoS2 scaffolds. The electrochemical properties of such scaffolds were investigated as potential anode materials for lithium-ion batteries and exhibited superior electrochemical properties, which is attributed to g-C3N4 support which favors better electronic conductivity, and affords more sites for Li+ ions. Another carbon-modified composite like reduced graphene oxide-few layer MoS2 nanocomposite for enhanced electrochemical performance in supercapacitors and water purification was also presented by Raghu et al. [28] and his group.

In addition to carbon-based MoS2 composite materials, there are also many metal oxide/MoS2 heterojunctions, for example, Benavente et al. [29] successfully prepared a series of novel heterostructured hybrid layered ZnO and MoS2 nanosheets composites with different MoS2 contents. In this work, they investigated the synergetic role of MoS2 nanosheets in enhancing the photocatalytic activity of layered hybrid ZnO (LHZnO) nanocomposites, especially in utilizing the visible light regions of the solar spectrum. Zhang et al. [30] developed a facile one-step hydrothermal method to fabricate the 3D flower-like heterostructure of MoS2/CuS nanohybrid, and this 3D flower-like heterostructure of MoS2/CuS nanohybrid catalyst exhibits great potential for renewable energy applications. Guo’s group [31] used the first-principles calculation based on density functional theory (DFT) to explore the enhanced photocatalytic mechanism of TiO2 by combining with both pristine and defective monolayer MoS2. It was demonstrated that the combination of TiO2 with MoS2 was favorable thermodynamically. Wang’s group [32] controllably synthesized the sesame ball-like CoS/MoS2 nanospheres via a facile hydrothermal and solvothermal consecutive reaction, which then was utilized as efficient counter electrode catalysts for dye-sensitized solar cells. The hybrid interactions took place between the p orbital of I and 3d states of Co, which lead to I3− was activated and dissociated easily. In addition to MoS2-based heterojunction that conforms to stoichiometric ratio, there are also some composites with non-stoichiometric ratios, and take Xie’s work [33] as an example, they firstly prepared V0.13Mo0.87O2.935/MoS2 nanocomposites via an in-situ hydrothermal approach based on the NH4VO3 and MoS2 as precursors. Furthermore, the visible-driven photocatalytic experiment results showed that the V0.13Mo0.87O2.935/MoS2 composites displayed better degradation ability in contrast to pure MoS2 and other stoichiometric ratios, which could be attributed to the suppression of charge recombination by confined space effect.

Finally, there are also some synthesis methods for TMD/TMD heterojunctions. Typically, for Said Ridene’s report [34], the optical gain in the new class of 2D-materials was calculated for MoS2/WSe2 single quantum well (QW), where a numerical solution of the k.p equation at (K+, K−) points of the Brillouin zone was done to obtain the energy levels and the corresponding wave functions of electrons and holes in QW. And the result turned out that MoS2/WSe2 QW could satisfy the lasing requirements and give interesting results about the performance of laser emitting devices.

3 Application of the MoS2-Based Gas Sensors

Generally speaking, there are not many reports on detecting gas types by MoS2-based gas sensors, mainly about NOx. Recently, researchers have tried to apply different techniques to synthesize a high-quality MoS2-based gas sensor at room temperature (RT). Cui et al. [35] also pointed out that MoS2 can be used as a promising candidate for high-performance RT sensing. However, the properties of pristine MoS2 nanosheets are strongly influenced by the significant adsorption of oxygen in an air environment, which leads to instability of the MoS2 sensing device, and all sensing results on MoS2 reported to date were exclusively obtained in an inert atmosphere. To solve the problem, their lab reported a novel nanohybrid of SnO2 nanocrystal (NC)-decorated crumpled MoS2 nanosheets (MoS2/SnO2) and its exciting air-stable property for room temperature sensing of NO2 are reported. Interestingly, the SnO2 NCs serve as strong p-type dopants for MoS2, leading to p-type channels in the MoS2 nanosheets. The SnO2 NCs also significantly enhance the stability of MoS2 nanosheets in dry air. As a result, unlike other MoS2 sensors operated in an inert gas (e.g. N2), the nanohybrids exhibit high sensitivity, excellent selectivity, and repeatability to NO2 under a practical dry air environment. This work suggests that NC decoration significantly tunes the properties of MoS2 nanosheets for various applications.

Besides, Yong Zhou and Donarellia et al. reported different exfoliation methods of MoS2 for use as a NOx gas sensor [36,37,38]. In these reports, results were obtained in the presence of N2 gas and showed a long response time accompanying incomplete recovery, which significantly decreases the practical application of the sensor in an open atmosphere. Consequently, it is much more meaningful to develop feasible strategies to enhance the gas sensing performance of MoS2 NSs for operation at low temperatures in the air. Thus, functionalization is essential to sensitize the surface or to engender selectivity. Heterojunction NMs can effectively enhance the gas-sensing ability of the sensor via the synergistic effect of the constituents. To overcome the limitations and expand the application of MoS2 NSs, research on MoS2-based composite modified with noble metals has been reported, which improved the gas sensing and overall catalytic properties of MoS2 NSs [39,40,41]. Nevertheless, more recent studies have been carried out on the decoration of MoS2 NSs with noble metals; however, the use of expensive metal is not advantageous from an economic perspective, so it is better to functionalize MoS2 NSs with another nanomaterial such as metal oxides (MOs). Studies relevant to Mos-modified MoS2 NSs (MOs-MoS2) used as a gas sensor have been seldom reported until now. Therefore, it is worth studying the gas-sensing properties of different MOS-MoS2 composites. For this purpose, bismuth oxide (Bi2O3) is one of the most important semiconducting materials, which has drawn great attention due to its narrow band gap of 2.8 eV and its highly catalytic properties [42].

Li et al. [21] also have reported that the edge sites of MoS2 are highly chemical active over the inert MoS2 basal planes, and their hierarchical hollow MoS2 microspheres show excellent sensing performance with 3.1 times enhancement compared with the contrast sample of a smooth solid structure. The rapid and sensitive response, decreased working temperature, as well as prominent selectivity, enable the material with attractive sensing performance for NO2 detection. Such a study also provides new opportunities on the surface morphology control at both the micro- and nanoscale for enhancing the sensing performance of MoS2. Ikram et al. [43] designed a facile strategy to synthesize a controllable morphology and composition for three-component heterojunctions of MoS2/Bi2O3/Bi2S3 (as can be seen in Fig. 6), which exhibited an ultra-fast response time of only 1 s at room temperature (RT) in air and the detection limit was predicted to be as low as 50 ppb.

Preparation process of three component heterojunctions of MoS2/Bi2O3/Bi2S3. Images are reproduced with permission from Ref. [43]

Besides, according to Li’s report [41], the reduced graphene oxide/MoS2 composite sensitive films were prepared by layer-by-layer self-assembly method, as can be seen in Fig. 7a. The sensitivity to the formaldehyde gas was measured at room temperature, as present in Fig. 7b, where the rGO/MoS2 composite films showed obviously higher current values than rGO when exposed to the formaldehyde, and even tens of times higher than that of the MoS2, indicating the rGO/MoS2 composite films presented improved sensitivity after doping rGO onto MoS2 films. The barrier and electron band of rGO/MoS2 composite film are shown in Fig. 7c, and the electrons released from formaldehyde are first transferred to the surface of MoS2, adsorbed by oxygen molecules on its conduction band, and then further transferred to rGO, which makes the conductivity of the mixed thin film change dramatically.

Fabrication of rGO/MoS2 film (a), the response of MoS2, rGO, and rGO/ MoS2 film to HCHO at RT (b), and potential and energy diagram (c). Images are reproduced with permission from Ref. [41]

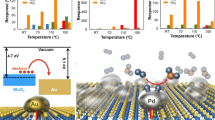

Furthermore, Zhang et al. [44] successfully prepared Pd-SnO2/MoS2 composite sensitive thin films by hydrothermal synthesis, as shown in Fig. 8a. The sensitivity of Pd-SnO2/MoS2 to H2 was studied at room temperature with the results shown in Fig. 8b and c. It was found that the gas-sensing properties of the modified MoS2 were greatly improved, and the selectivity of H2 was obviously enhanced. So the doping and modifying of the noble metal and the metal oxide can form the catalytic activity of gas adsorption, reduce the activation energy of interface reaction between the gas and the MoS2, expand the gas detection range, and enhance the response sensitivity and selectivity of the MoS2 sensor to the specific gas.

Preparation (a), H2 response (b), and selectivity (c) of Pd-SnO2/MoS2. Images are reproduced with permission from Ref. [44]

4 Conclusion

This short review enhanced our understanding of the research progress and recent development of MoS2-based gas sensors, summarized the preparations of intrinsic and modified MoS2 gas-sensing nano-materials, and summed up their application in gas sensing detection. The following summarization highlights the tangible advantages:

-

(1)

The MoS2 modified with rGO, nitrogen-doped carbon, metal oxide, or noble metal particles can significantly improve the detection sensitivity and selectivity of gas sensors, and enlarge the gas species.

-

(2)

Advanced modification methods, different fabrication processes, and various functional gas sensing nano-materials make MoS2-based nanocomposites promising candidates for high-performance, low-power micro-nano gas sensor materials.

-

(3)

The 2D layer MoS2-based heterojunction structure is a promising approach to maximize the interfacial heterojunction area and enable electronic interactions at the interface to enhance sensing response.

However, despite the significant progress made in MoS2-based sensors there are still some problems with gas sensors based on MoS2:

-

(1)

When the adsorption between MoS2-based nanomaterial and gas molecules is strong, the desorption process will be relatively slow. Presently, the common desorption methods are heating and ultraviolet irradiation, hence causing more energy consumption and indistinctive effects. Therefore, a new desorption technique needs to be developed.

-

(2)

Although modified by the functionalization, the MoS2 can be only selective for certain gases, but the selective detection of the specific gas in the complex gas environment is difficult to be realized.

-

(3)

So far, the MoS2-based gas sensor is still in the laboratory research stage. Realizing the industrialization of MoS2-based electronic devices is still facing many challenges.

The following countermeasures are proposed to improve the property of the MoS2-based sensors:

-

a.

The structural guide agents or template agents should be applied to the synthesis of MoS2 for unique shapes and morphologies, enabling discrimination of VOC gases that are typically demanding to detect due to different exposure surfaces and oxygen vacancies.

-

b.

The chemical simulation software, such as VASP, Materials Studio, and Gaussian could be employed to calculate electronic structures, energy levels of diverse molecular conformations, and other essential mechanisms to provide a deeper understanding of mechanisms for improving performance.

-

c.

Wearable electronic devices in environmental monitoring, disease diagnosis, the food industry, and other fields pose significant challenges requiring researchers' further consideration and exploration.

References

Chuanxing J, Dongzhi Z, Yan SUN, Hongyao CAO, Guanghui W (2017) Research and development of graphene-like molybdenum disulfide based gas sensor. Electron Component Mater 2:19–24. https://doi.org/10.14106/j.cnki.1001-2028.2017.08.003

Akbari E, Jahanbin K, Afroozeh A, Yupapin P, Buntat Z (2018) Brief review of monolayer molybdenum disulfide application in gas sensor. Phys B 545:510–518. https://doi.org/10.1016/j.physb.2018.06.033

Huang Y, Guo J, Kang Y, Ai Y, Li CM (2015) Two dimensional atomically thin MoS2 nanosheets and their sensing applications. Nanoscale. https://doi.org/10.1039/c5nr06144j

Niu Y, Wang R, Jiao W, Ding G, Hao L, Yang F, He X (2015) MoS2 graphene fiber based gas sensing devices. Carbon N Y 95:34–41. https://doi.org/10.1016/J.CARBON.2015.08.002

Zhao PX, Tang Y, Mao J, Chen YX, Song H, Wang JW, Song Y, Liang YQ, Zhang XM (2016) One-dimensional MoS2-decorated TiO2 nanotube gas sensors for efficient alcohol sensing. J Alloys Compd 7:252–258. https://doi.org/10.1016/j.jallcom.2016.03.029

Lee K, Gatensby R, McEvoy N, Hallam T, Duesberg GS (2013) High-performance sensors based on molybdenum disulfide thin films. Adv Mater. https://doi.org/10.1002/adma.201303230

Cho SY, Koh HJ, Yoo HW, Kim JS, Jung HT (2017) Tunable volatile-organic-compound sensor by using Au nanoparticle incorporation on MoS2. ACS Sens. https://doi.org/10.1021/acssensors.6b00801

Jlidi Z, Baachaoui S, Raouafi N, Ridene S (2021) Temperature effect on structural, morphological and optical properties of 2D-MoS2 layers: an experimental and theoretical study. Optik 228:166166. https://doi.org/10.1016/j.ijleo.2020.166166

Mastour N, Jemai M, Ridene S (2022) Calculation of ground state and Hartree energies of MoS2/WSe2 assembled type II quantum well. Micro Nanostruct 171:207417. https://doi.org/10.1016/j.micrna.2022.207417

Shokri A, Salami N (2016) Gas sensor based on MoS2 monolayer. Sens Actuators B 236:378–385. https://doi.org/10.1016/j.snb.2016.06.033

Yan H, Song P, Zhang S, Zhang J, Yang Z, Wang Q (2016) A low temperature gas sensor based on Au-loaded MoS2 hierarchical nanostructures for detecting ammonia. Ceram Int 42:9327–9331. https://doi.org/10.1016/j.ceramint.2016.02.160

Jung MW, Kang SM, Nam KH, An KS, Ku BC (2018) Highly transparent and flexible NO2 gas sensor film based on MoS2/rGO composites using soft lithographic patterning. Appl Surf Sci 456:7–12. https://doi.org/10.1016/j.apsusc.2018.06.086

Xu T, Pei Y, Liu Y, Wu D, Shi Z, Xu J, Tian Y, Li X (2017) High-response NO2 resistive gas sensor based on bilayer MoS2 grown by a new two-step chemical vapor deposition method. J Alloys Compd 725:253–259. https://doi.org/10.1016/j.jallcom.2017.06.105

Zhou Y, Liu G, Zhu X, Guo Y (2017) Ultrasensitive NO2 gas sensing based on rGO/MoS2 nanocomposite film at low temperature. Sens Actuators B 251:280–290. https://doi.org/10.1016/j.snb.2017.05.060

Gordon JM, Katz EA, Feuermann D, Albu-Yaron A, Levy M, Tenne R (2007) Singular MoS2, SiO2 and Si nanostructures—synthesis by solar ablation. J Mater Chem 18:458–462. https://doi.org/10.1039/b714108d

Song HJ, You S, Jia XH, Yang J (2015) MoS2 nanosheets decorated with magnetic Fe3O4 nanoparticles and their ultrafast adsorption for wastewater treatment. Ceram Int 41:13896–13902. https://doi.org/10.1016/j.ceramint.2015.08.023

Coleman JN, Lotya M, Neill AO, Bergin SD, King PJ, Khan U, Young K, Gaucher A, De S, Smith RJ, Shvets IV, Arora SK, Stanton G, Kim H, Lee K, Kim GT, Duesberg GS, Hallam T, Boland JJ, Wang JJ, Donegan JF, Grunlan JC, Moriarty G, Shmeliov A, Nicholls RJ, Perkins JM, Grieveson EM, Theuwissen K, Mccomb DW, Nellist PD, Nicolosi V (2011) Produced by liquid exfoliation of layered materials. Science 331:568–571

Zeng Z, Yin Z, Huang X, Li H, He Q, Lu G, Boey F, Zhang H (2011) Single-layer semiconducting nanosheets: high-yield preparation and device fabrication. Angew Chem Int Ed 50:11093–11097. https://doi.org/10.1002/anie.201106004

Amini M, Ramazani A, Faghihi M, Fattahpour S (2017) Preparation of nanostructured and nanosheets of MoS2 oxide using oxidation method. Ultrason Sonochem 39:188–196. https://doi.org/10.1016/j.ultsonch.2017.04.024

Wang X, Feng H, Wu Y, Jiao L (2013) Controlled synthesis of highly crystalline MoS2 flakes by chemical vapor deposition. J Am Chem Soc 135:5304–5307. https://doi.org/10.1021/ja4013485

Li Y, Song Z, Li Y, Chen S, Li S, Li Y, Wang H, Wang Z (2019) Hierarchical hollow MoS2 microspheres as materials for conductometric NO2 gas sensors. Sens Actuators B 282:259–267. https://doi.org/10.1016/j.snb.2018.11.069

Zhang X, Suo H, Zhang R, Niu S, qi Zhao X, Zheng J, Guo C (2018) Photocatalytic activity of 3D flower-like MoS2 hemispheres. Mater Res Bull 100:249–253. https://doi.org/10.1016/j.materresbull.2017.12.036

Mishra RK, Manivannan S, Kim K, Kwon HI, Jin SH (2018) Petal-like MoS2 nanostructures with metallic 1T phase for high performance supercapacitors. Curr Appl Phys 18:345–352. https://doi.org/10.1016/j.cap.2017.12.010

Chenrayan S, Chandra K, Manickam S (2017) Ultrathin MoS2 sheets supported on N-rich carbon nitride nanospheres with enhanced lithium storage properties. Appl Surf Sci 410:215–224. https://doi.org/10.1016/j.apsusc.2017.03.102

Zhang J, Li Y, Gao T, Sun X, Cao P, Zhou G (2018) Flower-shaped TiO2/C microspheres embedded with fish-scale-like MoS2 as anodes for lithium-ion batteries. Ceram Int 44:8550–8555. https://doi.org/10.1016/j.ceramint.2018.02.059

Abbas AN, Liu B, Chen L, Ma Y, Cong S, Aroonyadet N, Köpf M, Nilges T, Zhou C (2015) Black phosphorus gas sensors. ACS Nano 9:5618–5624. https://doi.org/10.1021/acsnano.5b01961

Shi L, Ding W, Yang S, He Z, Liu S (2018) Rationally designed MoS2/protonated g-C3N4 nanosheet composites as photocatalysts with an excellent synergistic effect toward photocatalytic degradation of organic pollutants. J Hazard Mater 347:431–441. https://doi.org/10.1016/j.jhazmat.2018.01.010

Raghu MS, Yogesh Kumar K, Rao S, Aravinda T, Sharma SC, Prashanth MK (2018) Simple fabrication of reduced graphene oxide -few layer MoS2 nanocomposite for enhanced electrochemical performance in supercapacitors and water purification. Phys B 537:336–345. https://doi.org/10.1016/j.physb.2018.02.017

Benavente E, Durán F, Sotomayor-Torres C, González G (2018) Heterostructured layered hybrid ZnO/MoS2 nanosheets with enhanced visible light photocatalytic activity. J Phys Chem Solids 113:119–124. https://doi.org/10.1016/j.jpcs.2017.10.027

Zhang L, Guo Y, Iqbal A, Li B, Gong D, Liu W, Iqbal K, Liu W, Qin W (2018) One-step synthesis of the 3D flower-like heterostructure MoS2/CuS nanohybrid for electrocatalytic hydrogen evolution. Int J Hydrog Energy 43:1251–1260. https://doi.org/10.1016/j.ijhydene.2017.09.184

Guo F, Jia J, Dai D, Gao H (2018) The electronic properties and enhanced photocatalytic mechanism of TiO2 hybridized with MoS2 sheet. Phys E 97:31–37. https://doi.org/10.1016/j.physe.2017.10.011

Wang X, Xie Y, Cai Z, Xiong N, Xu Z, Li M, Feng Q, Zhou W, Pan K (2018) The sesame ball-like CoS/MoS2 nanospheres as efficient counter electrode catalysts for dye-sensitized solar cells. J Alloys Compd 739:568–576. https://doi.org/10.1016/j.jallcom.2017.12.345

Xie J, Li H, Lu H, Tian C, Li M (2018) Nanosheet assembled flower-like V0.13Mo0.87O2.935/MoS2 heterojunction hybrid: synthesis and its visible-driven photocatalytic research. Mater Lett 218:27–31. https://doi.org/10.1016/j.matlet.2018.01.138

Ridene S (2018) Large optical gain from the 2D-transition metal dichalcogenides of MoS2/WSe2 quantum wells. Superlatt Microstruct 114:379–385. https://doi.org/10.1016/j.spmi.2017.12.060

Cui S, Wen Z, Huang X, Chang J, Chen J (2015) Stabilizing MoS2 nanosheets through SnO2 nanocrystal decoration for high-performance gas sensing in air. Small 19:2305–2313. https://doi.org/10.1002/smll.201402923

Kumar R, Goel N, Kumar M (2017) UV-activated MoS2 based fast and reversible NO2 sensor at room temperature. ACS Sens 2:1744–1752. https://doi.org/10.1021/acssensors.7b00731

Donarelli M, Prezioso S, Perrozzi F, Bisti F, Nardone M, Giancaterini L, Cantalini C, Ottaviano L (2015) Response to NO2 and other gases of resistive chemically exfoliated MoS2-based gas sensors. Sens Actuators B 207:602–613. https://doi.org/10.1016/j.snb.2014.10.099

Liao J, Li Z, Zhu Z, Zhao S, Lv S, Wang G (2018) Vertically aligned MoS2 /ZnO nanowires nanostructures with highly enhanced NO2 sensing activities. Appl Surf Sci 456:808–816. https://doi.org/10.1016/j.apsusc.2018.06.103

Kang J, Ikram M, Zhao Y, Zhang J, Ur A (2017) Fabrication, characterization and high-performance sensing properties to NOx at room temperature. N J Chem 41(20):12071–12078

Liang X, Zhang XJ, You TT, Yang N, Wang GS, Yin PG (2018) Three-dimensional MoS2-NS@Au-NPs hybrids as SERS sensor for quantitative and ultrasensitive detection of melamine in milk. J Raman Spectrosc 49:245–255. https://doi.org/10.1002/jrs.5273

Li BL, Luo HQ, Lei JL, Li NB (2014) Hemin-functionalized MoS2 nanosheets: enhanced peroxidase-like catalytic activity with a steady state in aqueous solution. RSC Adv 4:24256–24262. https://doi.org/10.1039/c4ra01746c

Zhong W, Cao Z, Qiu P, Wu D, Liu C, Li H, Zhu H (2015) Laser-marking mechanism of thermoplastic polyurethane/Bi2O3 composites. ACS Appl Mater Interfaces 7:24142–24149. https://doi.org/10.1021/acsami.5b07406

Ikram M, Liu L, Lv H, Liu Y, Ur Rehman A, Kan K, Zhang WJ, He L, Wang Y, Wang R, Shi K (2019) Intercalation of Bi2O3 /Bi2S3 nanoparticles into highly expanded MoS2 nanosheets for greatly enhanced gas sensing performance at room temperature. J Hazard Mater 363:335–345. https://doi.org/10.1016/j.jhazmat.2018.09.077

Zhang D, Sun Y, Jiang C, Zhang Y (2017) Room temperature hydrogen gas sensor based on palladium decorated tin oxide/molybdenum disulfide ternary hybrid via hydrothermal route. Sens Actuators B 242:15–24. https://doi.org/10.1016/j.snb.2016.11.005

Acknowledgements

This work was funded by the Key Projects of Guangxi Natural Science Foundation (No. 2020GXNSFDA297015), China; Natural Science Foundation of Guangxi Province (No. 2022GXNSFAA035565), China; Innovation Project of Guangxi Graduate Education (No. YCSW2022101).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, H., Zhang, S., Cheng, Q. et al. A Mini Review on the Recent Progress of MoS2-Based Gas Sensors. Catal Lett 154, 1375–1384 (2024). https://doi.org/10.1007/s10562-023-04436-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-023-04436-6