Abstract

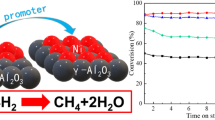

Ni-based catalysts are the most promising catalysts for CO2 methanation. The development of catalysts with low-temperature activity could bring significant energy and environmental benefits. In this work, the hydrogenation of CO2 to methane was studied on Ni-M/γ-Al2O3 (M = Fe, Co, or Mn) bimetallic catalysts. The optimum reaction was obtained using Ni-Mn/γ-Al2O3 (CO2 conversion: 85%, CH4 selectivity: 99%, 280 °C). In situ FTIR studies revealed the excellent performance of Ni-Mn/γ-Al2O3, which lowers the required reaction temperature. Based on in situ FTIR studies, CO2 methanation proceeded over three intermediates on the catalysts: bicarbonate → carbonate → formate → methane. The second metal (Co or Mn) promoted the dispersion of both Ni and itself and improved the ability of Ni to crack H2. And introduced more oxygen vacancies to strengthen the basicity of surrounding O2− on the surface of the catalysts. In effect, the number of carbonate active sites could be increased accordingly, thereby improving the adsorption capacity for CO2.

Graphic Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Global warming is one of the most important environmental issues in the twenty-first century. Limiting excessive production of CO2 is of great practical significance to delay global warming. CO2 methanation technology is considered to be one of the most effective technologies for CO2 recycling [1], and the main reaction is: CO2 (g) + 4H2 (g) → CH4 (g) + 2H2O (g); ∆H298K = − 165 kJ/mol, ΔG298K = − 114 kJ/mol, which is known as the Sabatier reaction [2]. As this reaction is exothermic, a lower temperature is conducive for the conversion of CO2. Most of the products are CH4 and H2O at 200–250 °C, but the yield and selectivity for CH4 decrease as the temperature increases [3, 4]. Moreover, CO2 is chemically stable and difficult to convert. Hence, the catalyst used for CO2 methanation needs to exhibit relatively high activity.

The active components of methanation catalysts are usually Ni, Fe, Co, Ru, and Rh [5,6,7,8,9,10,11]. Among which, Ni is widely used as a research object because of its high activity, selectivity for CH4, and low cost. However, it is difficult for Ni catalysts to achieve high CO2 conversion at low temperatures due to high thermodynamic barriers. Utilizing a second metal to form bimetallic catalysts is an effective way to lower the required reaction temperature, but the candidates for such metals are dominated by precious metals such as Pd, Ru, and Pt [7, 12, 13]. Therefore, it is necessary to investigate low-cost additives. Part of the previous research suggested that transition metals, such as Fe, Co, and Mn [14,15,16,17,18,19], may form a close interaction with Ni after annealing, thereby lowering the reduction temperature and increasing the dispersion of Ni. Density functional theory calculations have also suggested that the addition of these second metals can reduce the activation energy of CO2 methanation [20]. The chemical state of highly dispersed Ni on the surface of the support may play a key role in CO2 methanation, which means that surface species on supports must be identified for further understanding.

In situ Fourier transform infrared (in situ FTIR) spectroscopy is a powerful characterisation method that can be used to investigate CO2 adsorption, desorption, and reaction process intermediates over a catalyst surface. Although many studies have investigated CO2 methanation on Ni-, Ru- and Rh-based catalysts by in situ FTIR [21,22,23,24,25], there is no unified view among the research on the reaction mechanism. Dreyer et al. [21] suggested that the first step of CO2 methanation is the dissociation of CO2. CO2 gradually dissociates into CO, C* and O* in the presence of a catalyst and then forms hydroxymethylene (HCOH) with the assistance of H*, finally was abstracted by O to form CH4. Marwood et al. [25] proposed that CO2 is first adsorbed on the support in the form of bicarbonate and then reacts with spilled over H* cracked by an active component to form formate intermediates on the metal surface. Finally, formate reacts with H*, which then leads to methanation. However, there is minimal comprehensive research on in situ FTIR measurements for the mechanism of CO2 methanation by the addition of second metals. Moreover, it is still a challenge to develop low-cost catalysts with high activity at low temperatures (< 300 °C) [26].

In this study, we reported the effects of bimetallic catalysts Ni-M/γ-Al2O3 (M = Fe, Co, or Mn) for CO2 methanation, and the results showed that the addition of second metal Mn or Co significantly enhanced the catalytic performance of Ni/-Al2O3. Various characterization methods including XRD, SEM-EDS, XPS, H2-TPR and CO2-TPD were performed to demonstrate the changes in physicochemical properties. CO2 adsorption and methanation intermediate identification was performed via in situ FTIR, and the mechanism of CO2 adsorption and methanation was further analysed.

2 Material and Methods

2.1 Catalysts Preparation

Bimetallic catalysts were prepared via an ultrasonic assisted co-impregnation method using Ni(NO3)2·6H2O and Fe(NO3)3·9H2O, Co(NO3)2·6H2O, or Mn(NO3)2 (50%) for the addition of the second metal. First, γ-Al2O3 (40–60 mesh) was impregnated in a mixed aqueous solution of appropriate concentrations of nickel nitrate and the nitrate salt of the second metal; the solution was then sonicated for 20 min using an ultrasonic oscillator. Then, the samples were naturally dried at 25 °C for 12 h and then at 120 °C for 2 h. The prepared precursor was annealed under a N2 flow (200 mL/min) at 850 °C (the temperature was raised from room temperature to 850 °C at a rate of 10 °C/min) for 4 h and reduced under a 10% H2-N2 flow (200 mL/min) at 850 °C for 4 h. Finally, a bimetallic catalyst with a Ni load of 10wt% and a second metal load of 2.5wt% was obtained, denoted as Ni-M/ γ-Al2O3 (M = Fe, Co, or Mn).

2.2 Catalytic Tests

Catalytic tests were performed in a tubular fixed-bed flow reactor with an inner diameter of 10 mm under atmospheric pressure. First, 500 mg of the catalyst sample mixed with 2.5 g of SiC (40–60 mesh) dilution was loaded into the reactor, and a flow of H2 and CO2 (H2/CO2 = 4) mixture at 100 ml/min (12,000 mL/h·gcat) was passed through the catalyst bed. The tests were carried out at 160–380 °C in steps of 20 °C that were maintained for 30 min each to achieve a stable condition and measure three times to take the average. The effluent gases composition was monitored with a gas chromatograph (Agilent 8890). The CO2 conversion and CH4 selectivity were calculated using the equations below.

The thermodynamic equilibrium calculations were derived from the mathematical model R-Gibbs in Aspen Plus software. Only CH4 and CO were detected as carbonaceous products in the reactor outlet stream.

2.3 Characterization

The phases composition of all samples were determined by powder X-ray diffraction (XRD) on an X’Pert-ProMPD diffractometer using Cu Kα radiation (λ = 1.54 Å) at an angle of 10°–80° at 40 kV and 30 mA, and the scanning step was 0.02°/s.

The catalyst particles were ground to obtain powders needed for energy-dispersive spectroscopy (EDS) mapping using a scanning electron microscopy (SEM) instrument.

The temperature-programmed reduction (H2-TPR) test was performed using an AutoChem II 2920 instrument equipped with a TCD. A 500-mg sample was loaded and investigated under a 5% H2/N2 flow (30 mL/min) at 50–1000 °C with a temperature ramping rate of 10 °C/min.

The elemental composition and valence of all samples were determined by X-ray photoelectron spectra (XPS) on a AXI Sultra DLD Spectrometer employing a monochromatized Al-Kα X-ray source (hv = 1486.6 eV), and all binding energies were referenced to the C 1 s at 284.8 eV.

The temperature-programmed desorption (TPD) of CO2 was also performed using an AutoChem II 2920 instrument equipped with a TCD. Before TPD measurements, the catalyst was pre-treated under He flow at 450 °C for 90 min and cooled to 50 °C. A flow of 20% CO2/He mixture at 30 mL/min pass through the sample for 1 h and the weakened physical adsorption of CO2 was removed by a He flow at 30 mL/min for 1 h. Finally, the temperature is increasing to 700 °C at a rate of 10 °C /min.

2.4 In Situ FTIR Measurements

In situ FTIR measurements were performed using a Thermo Nicolet iS50 spectrometer equipped with a reaction cell with CaF2 windows. Four scans were averaged for each spectrum, which were recorded at a resolution of 4 cm−1. After the powders were pressed, 30 mg of the catalyst powder was loaded into the cell for vacuum pre-treatment at 450 °C for 90 min. For CO2 adsorption measurements, an amount of CO2 was fed into the in situ FTIR cell at 60 °C, with scanning every 30 s. For CO2 methanation intermediate measurements, a flow of H2 and CO2 (H2/CO2 = 4) mixture with a total flow rate of 50 mL/min was fed into the in situ FTIR cell. The reaction was performed at 60–300 °C (ramping rate of 10 °C/min) with scanning every 2 min.

3 Results and Discussion

3.1 Catalytic Test

Figure 1 shows the CO2 methanation performance of Ni/γ-Al2O3 and Ni-M/γ-Al2O3 catalysts. As shown in Fig. 1a, the T50 values, corresponding to the temperature at 50% conversion, are 269, 275, 220, and 232 °C for Ni/γ-Al2O3, Ni-Fe/γ-Al2O3, Ni-Mn/γ-Al2O3, and Ni-Co/γ-Al2O3 respectively. In addition, in the presence of Ni-Mn/γ-Al2O3, the highest CO2 conversion of 85% was measured at 280 °C; similarly, the corresponding value for Ni-Co/γ-Al2O3 of 84% was measured at 300 °C. This result clearly indicates a significantly enhanced low-temperature activity for CO2 methanation compared with that of Ni/γ-Al2O3, which yielded its highest conversion rate of 83% at 340 °C. Because Ni-Fe/γ-Al2O3 yielded its highest conversion rate of 84% at 340 °C, this catalyst did not exhibit a significant improvement in conversion rate and low-temperature activity compared to Ni/γ-Al2O3. For temperatures higher than 380 ℃ the reaction is close to thermodynamic equilibrium for all catalysts, and the approach to equilibrium at conversions higher than 80% slows down while the thermodynamic equilibrium of the reverse water gas reaction is very low, therefore, it is mainly that the product gas, especially H2O, inhibits the conversion of CO2 to approach thermodynamic equilibrium [27]. Figure 1b shows the CH4 selectivity as a function of reaction temperature. The Ni catalyst alone exhibited high CH4 selectivity, with CH4 selectivity of over 96% at reaction temperatures below 400 °C. The addition of the second metal did not significantly improve the CH4 selectivity at the same reaction temperatures. However, due to the reduction of the optimum reaction temperature when using Ni-Mn/γ-Al2O3 and Ni-Co/γ-Al2O3 catalysts, the corresponding CH4 selectivity was also slightly improved.

3.2 Catalyst Characterization

Figure 2 shows the results of XRD measurements. From Fig. 1a, for the annealed catalyst precursor, the diffraction peaks are assigned to NiAl2O4 (JCPDS 73-0239) phases with shoulders that are attributed to γ-Al2O3 (JCPDS 10-04025) species. No obvious diffraction peaks for NiO specie can be detected, suggesting that the NiO is highly dispersed, incorporated into the structure of γ-Al2O3 support at high annealing temperatures. After reduction, the peaks of NiAl2O4 specie could hardly be observed, suggesting that NiAl2O4 has been completely reduced, and a series diffraction peaks of Ni were observed. Figure 2b exhibit the XRD patterns of Ni-M/γ-Al2O3 after reduction. The reflections of Ni at 2θ = 44.5° (1 1 1), 51.85° (2 0 0) and 75.38° (2 2 0) that were slightly broader and weaker in intensity compared with them of Ni/γ-Al2O3, suggesting a reduction in Ni particle size upon adding Mn, Fe, or Co. Burger et al. [28,29,30] suggested that the reduction of Fe or Co interacts with metallic Ni phase, leading to Ni lattice distortion by the formation of a Ni–Fe alloy. The formation of Ni–Fe alloy would shift the peak at 44.5°, 51.85° and 75.38° of metallic Ni phase towards a low angle, although this change was not obvious. Mn species might be incorporated into the former NiO-rich matrix or that the Mn species are modified under reduction conditions, leading to a change of the lattice constant of the former mixed oxide phase, and it appears in the XRD pattern as peaks at 2θ = 36.4° and 65.0° shift to lower diffraction angles [28]. We calculated the crystal size of Ni using the Scherer formula, the average particle size of Ni in Ni/γ-Al2O3 is 14.3 nm, while in Ni-Mn/γ-Al2O3, Ni-Co/γ-Al2O3 and Ni-Fe/γ-Al2O3 are 11.3 nm, 11.8 nm, 12.0 nm, respectively. Combining with the conversions results, the introduction of Co or Mn could reduce the crystal size of Ni, which is beneficial to CO2 methanation, but Fe has little effect. Therefore, we suggest that the size and dispersion of Ni are not the main reasons that affect CO2 methanation in bimetallic catalysts. The absence of reflections assigned to Mn, Fe, and Co is likely due to they were well dispersed or the amounts of them are under the detection limit of XRD analysis.

To further verify that Mn, Fe, and Co were successfully loaded onto the surface of Ni/γ-Al2O3, we ground the catalyst samples into powders. Figure 3 shows the SEM-EDS mapping to obtain images of the elemental distribution on the surfaces of the Ni-M/γ-Al2O3 (M = Mn, Fe, or Co) catalysts. The results indicate that Mn, Fe, and Co were uniformly incorporated and well dispersed on the supports with Ni, which is consistent with the XRD results.

In order to distinguish the states of the Ni2+ species and investigate the interactions between Ni/γ-Al2O3 and Ni-M/γ-Al2O3 before reduction, H2-TPR characterisation was carried out, and the results are shown in Fig. 4. No other peaks were detected at 100–600 °C, indicating that no NiO species was generated. The strong peaks located at 800–1000 °C can be attributed to the presence of NiAl2O4 spinel. NiAl2O4 spinel was extremely difficult to reduce, but Ni was more evenly dispersed after reduction because of the strong interaction between Ni and γ-Al2O3.

The addition of Mn, Co, and Fe to Ni/γ-Al2O3 led to different hydrogen consumption features, such as the peaks corresponding to the reduction of MnO2 to Mn3O4 at 408 °C and the subsequent reduction to MnO at 480 °C; such peaks appear approximately 30 °C higher than those of bulk Mn on γ-Al2O3 [31]. The signals at 646 °C and 752 °C can be attributed to CoO and FeO, respectively, and it can be observed that the addition of different second metals lowers the reduction temperature of NiAl2O4 to different degrees. This result, in combination with the results of the XRD characterisation, indicates that the second metal oxide interacts with NiAl2O4 in ways that are beneficial to the dispersion of Ni.

To further understand the surface composition and valance state of these catalysts, X-ray photoelectron spectroscopy (XPS) were performed over Ni-M/γ-Al2O3 catalysts (Fig. 5). Peaks at 852–854 eV (Fig. 5a) can be assigned as Ni 2p3/2 XPS spectra corresponding to Ni0 and Ni2+ [32], respectively, indicating that Ni species existed as metallic Ni and nickel oxide/hydroxide [33, 34]. The ratio of Ni0 to NiT (NiT = Ni0 + Ni2+) in Ni 2p3/2 calculated by the area integrals was shown in Table 2. The ratio of Ni0 was increased with adding the second metal compared with Ni/γ-Al2O3, indicating that it could be easier for the oxidation state of the element Ni reducing to Ni due to the existence of Fe, Co or Mn, which was also consistent with the results obtained by H2-TPR. The peak of Ni0 in 2p3/2 shifted from 851.7 to 850.9 eV on Ni-Mn/γ-Al2O3 catalyst can be attributed to the electronegative of Mn (1.55) is lower than it of Ni (1.91), and the electrons can be transferred easier from Mn to Ni, and the electronegative of Fe(1.80) or Co(1.88) is similar to it of Ni, so the peak position of Ni0 in 2p3/2 on Ni-Fe/γ-Al2O3 or Ni-Co/γ-Al2O3 did not change much compared with it on Ni//γ-Al2O3.

The O 1s spectra region for Ni/γ-Al2O3 and Ni-M/γ-Al2O3 were shown at Fig. 5b. The peaks at 529.6–530.3 eV can be attributed to the lattice oxygen (OL) of the γ-Al2O3 support, while the signals at 531.0–531.2 eV can be assigned to the adsorbed oxygen surface or hydroxyl groups (OA) [35, 36]. The calculation results of the ratio of OL to OT (OT = OL + OA) was shown in Table 1. The percentage of lattice oxygen on Ni-Mn/γ-Al2O3 and Ni-Mn/γ-Al2O3 is approximately 13.4% and 7.9% decreased of that for Ni /γ-Al2O3 respectively, and the peak position of OL shifted lower binding energy from 530.2 to 529.8 eV in comparison to the Ni /γ-Al2O3. However, the peak position of OL and the ratio of OL to OT on Fe-Ni /γ-Al2O3 did not change much compared with Ni/γ-Al2O3. We suggested that the addition of the second metal of Mn and Co may have an interaction with Ni/γ-Al2O3 after annealing making it easier to deprive the OL of the supports surface during H2 reduction increase, which providing more oxygen vacancy. Because of the existence of oxygen vacancies, it will attract the surrounding lattice oxygen, resulting in a decrease in the binding energy of lattice oxygen. The addition of Fe to Ni/γ-Al2O3 did not result in more oxygen vacancies due to its high reduction temperature and strong interaction with γ-Al2O3, thus the catalytic performance of CO2 methanation did not improve.

CO2-TPD results for catalyst Ni-M/γ-Al2O3 are depicted in Fig. 6. Different basic sites correspond to different CO2 desorption temperatures, so we divide the temperature of CO2 desorption into three zones, CO2 desorption between 50 and 150 °C exhibits weak basic sites, whereas desorption between 150 and 450 °C exhibits medium basic sites, and peaks signals between 450 and 550 °C is observed, originating from CO2 desorbing from strong basic sites. In addition, we can find that Ni/γ-Al2O3 has almost no medium basic sites, but with the introduction of the second metal, the amount of medium basic sites on the catalyst increased significantly, especially the introduction of Mn, and the amount of strong basic sites also increased slightly. This indicates that with adding the second metal, weakly basic sites may form medium basic or strong basic sites. Combining the conversion results, the introduction of Mn and Co increased the amounts of strong basic sites on the catalyst surface, thereby improving the activity of the catalyst, while the introduction of Fe causing opposite effect. The amounts of intermediate basic sites seemed also to affect the activity of the catalyst, otherwise, the conversion rate of CO2 on Ni-Fe/γ-Al2O3 may be lower compared with it on /γ-Al2O3.

3.3 In Situ FTIR CO2 Adsorption Measurements

To further understand the CO2 adsorption species and reaction pathways, in situ FTIR CO2 adsorption measurements were performed, and Table 2 presents a summary of the most commonly detected intermediates during CO2 adsorption. The CO2 adsorbed on γ-Al2O3 was mainly in the forms of bicarbonate and small amounts of monodentate and bidentate carbonate (Fig. 7a). The peaks at 1648, 1440, and 1228 cm−1 were attributed to bicarbonate; the weak peaks at 1554 and 1378 cm−1 were attributed to monodentate carbonate; the weak peaks at 1634 and 1350 cm−1 were assigned to bidentate carbonates [29]. The first step of CO2 capture (Fig. 12, step 1) by –OH on γ-Al2O3 to form bicarbonate has already been described by other authors [39].

When Ni was loaded onto γ-Al2O3 for in situ FTIR CO2 adsorption measurements (Fig. 7b), we observed that the peak for C–OH stretching of bicarbonate (1228 cm−1) gradually weakened and the peak at 1648 cm−1 shifted to 1634 cm−1 with increasing adsorption time. Simultaneously, the O–C–O stretching signals of monodentate (1378 cm−1) and bidentate carbonate (1350 cm−1) slightly increased. Combined with the result of CO2-TPD, bicarbonate, bidentate carbonate and monodentate carbonate can be considered as weakly basic sites, medium basic sites, and strong basic sites as described in CO2-TPD results. It can thus be inferred that bicarbonate was transformed into carbonate. The assignment is in agreement with results of Ewald et al. [40].

Figure 7c–e display the in situ FTIR spectra of CO2 adsorption on Ni-M/γ-Al2O3 (M = Mn, Fe, or Co). The signals indicating the conversion of bicarbonate to carbonate were also observed. More interestingly, when the adsorption reached saturation (Fig. 6f), the addition of Mn, Fe or Co could provide more basic sites of monodentate and bidentate carbonate. In the case of Ni-Mn/γ-Al2O3 and Ni-Co/γ-Al2O3 in particular, the peak corresponding to O–C–O stretching of carbonate became sufficiently intense to almost completely overlap with the O–C–O stretching peak of bicarbonate and the signals of –OH of bicarbonate appear to have almost disappeared [27]. These results are almost the same as the results of CO2-TPD, which are represented by the decrease in the amount of weakly basic sites and the increased in the amount of medium or strong basic sites. The catalyst reduced by NiAl2O4 spinel contained more oxygen vacancies compared reducing by NiO [41, 42], and we suggest that the oxygen vacancy on the subsurface trapped electrons from the surrounding Ni, Co, Fe or Mn atoms in the form of electron pairs [43, 44]. The electrons at the oxygen vacancies had a pulling effect on the electrons of the surrounding O2−, which made O2− strongly basic. Hence, bicarbonate could be converted to monodentate or bidentate carbonate, and its H would be abstracted by the strongly basic O2− (Fig. 12, step 2). Combining these results with those from the H2-TPR and XPS characterisations, the addition of second metal of Mn or Co might provide more oxygen vacancies, which strengthen the surrounding surface O2− to form more strongly basic sites. When almost all of the CO2 captured by –OH was converted to monodentate and bidentate carbonate through the abundant O2− alkaline sites around –OH on the surface of the supports, the infrared signals of bicarbonate were difficult to observe. The addition Fe to Ni/γ-Al2O3 also yielded more strongly alkaline O2− sites around the –OH groups on the surface of the support, but the amount was not as much as the addition of Mn and Co.

3.4 In Situ FTIR CO2 Methanation Measurements

To further investigate the species formed on the catalyst surface during CO2 methanation, as well as the reaction mechanism, we performed in situ FTIR CO2 methanation measurements for each catalyst with temperature programming.

From 60 to 180 °C, it could be observed that the intensity of the peaks of bicarbonate and carbonate species adsorbed on the surface of Ni/γ-Al2O3 decreased as the temperature rose (Fig. 8). The peaks at 3700–3600 cm−1 could be attributed to CO2 overtones [48], and the peaks at 3740–3640 cm−1 could be assigned to –OH groups of bicarbonates [21, 49]; the intensities of such peaks also weakened with CO2 desorption. Starting at 180 °C, as the carbonate species became unstable with increasing temperature, the H cracked on the surface of Ni would be attracted by the carbon atoms on carbonates and then transferred to formate (Fig. 12, step 3). The peaks at 1590, 1370 (Δv = 220 cm−1), and 1390 cm−1, as well as the C–H peaks, could be attributed to monodentate and bridged formate (Table 3). When the temperature reached 260 °C, the appearance of C–H bands of formate at 2900 cm−1 was observed [50], and bands corresponding to C–H stretching of CH4 appeared at 3016 cm−1 upon increasing the temperature by 20 °C. We suggest that the H* cracked by Ni spilled over onto the C atom and became unstable, which allowed us to observe peaks for the stretching vibration of C–H of monodentate and bridged formate. Subsequently, the H atom bonded with the O atom to form H2O, and hydro-dehydration followed by methanation occurred over several cycles (Fig. 12, step 4). During the whole process, we did not find the peak of Nickel carbonyl hydride at 1917 cm−1 or lineart CO on Ni at 2019 cm−1 so the formate did not transfer to the surface of metal Ni and the hydrogenation step may most occurred on the surface of the support.

Figures 9, 10 and 11 show in situ FTIR CO2 methanation measurements of bimetallic catalysts Ni-M/γ-Al2O3 (M = Fe, Co, or Mn). The temperature at which point carbonate could be converted into formate was lowered to 100, 100, and 140 °C using Ni-Mn/γ-Al2O3, Ni-Co/γ-Al2O3, and Ni-Fe/γ-Al2O3, respectively. With the in situ FTIR CO2 adsorption measurements, it was also suggested that a conversion relationship between carbonate and formate, as well as the introduction of the second metal, made the active sites of carbonate more strongly basic (Fig. 12). As the temperature continued to rise, the peak corresponding to C–H stretching of formate was detected at 180 °C for Ni-Mn/γ-Al2O3 and at 220 °C for Ni-Fe/γ-Al2O3. The peaks corresponding to C–H stretching of CH4 were observed at 200, 200, and 260 °C for Ni-Mn/γ-Al2O3, Ni-Co/γ-Al2O3, and Ni-Fe/γ-Al2O3, respectively. We presumed that the second metal interacts with Ni and promotes its dispersion, which improves the ability of Ni to crack H* and cause it to overflow, thereby accelerating the process of H* spilling over from Ni to attack the C atom of formate. This process thereby improves the activity for CO2 methanation. We also determined that the introduction of metal components enhances the activity in this order: Mn ≈ Co > Fe. It is also consistent with the catalyst activity test result wherein the addition of the second metal (Fe, Co, or Mn) to Ni/γ-Al2O3 lowered the optimal reaction temperature of CO2 methanation to varying degrees.

4 Conclusion

In summary, we successfully synthesised Ni-M/γ-Al2O3 (M = Co, Mn, or Fe) catalysts by an ultrasonic-assisted co-impregnation method. According to the in situ FTIR and XPS measurements, the introduction of the second metal could increase the number of oxygen vacancies to strengthen the basicity of the O2− sites, which is more conducive to the conversion of bicarbonate to carbonate. In addition, Mn and Co could significantly strengthen the hydrogenation ability of Ni to carbonate and formate, thereby lowering the methanation reaction activity temperature. In general, the mechanism and catalyst preparation strategy provide a feasible means to develop catalysts for CO2 methanation at low temperatures.

References

Brewer PJ, Brown RJC, Miller MN, Minarro MD, Murugan A, Milton MJT, Rhoderick G (2014) Anal Chem 86:1887–1893

Vogt C, Monai M, Kramer GJ, Weckhuysen BM (2019) Nat Catal 2:188–197

Gao J-J, Wang Y-L, Ping Y, Xu D-C, Xu G-W, Gu F-N, Su F-B (2012) RSC Adv 2:2358–2368

Miguel CV, Soria MA, Mendes A, Madeira LM (2015) J Nat Gas Sci Eng 22:1–8

Wu Y-S, Lin J-H, Xu Y-F, Ma G-Y, Wang J, Ding M-Y (2020) Chem Cat Chem 12:3553–3559

Thampi KR, Lucarelli L, Kiwi J (1991) Langmuir 7:2642–2648

Karelovic A, Ruiz P (2013) ACS Catal 3:2799–2812

Ocampo F, Louis B, Roger A-C (2009) App Catal A 369:90–96

Kim HY, Lee HM, Park J-N (2010) Phys Chem C 114:7128–7131

Solymosi F, Erdohelyi A, Bansagi T (1981) J Catal 68:371–382

Huang Q-S, Lan L-Y, Wang A-J, Wang Y (2017) Petrochem Technol 46:1355–1360

Aziz MAA, Jalil AA, Triwahyono S, Ahmad A (2015) Cheminform 17:2647–2663

Shin HH, Lu L, Yang Z, Kiely CJ, Mcintosh S (2016) ACS Catal 6:2811–2818

Wang C-X, Gong J (2011) Nat Gas Chem Ind 36:4–6

Zhi G-J, Wang Y-Y, Jin G-Q (2016) Nat Gas Chem Ind 41:24–28

Vrijburg WL, Garbarino G, Chen W, Parastaev A, Hensen EJM (2020) J Catal 382:358–371

Li L-B, Wei S-Q, Xu G-L (2004) Nat Gas Chem Ind 29:27–31

Burger T, Wenng KA, Köhler TK, Hinrichsen O (2018) Catal Sci Technol 8:5920–5932

Serrer MA, Gaur A, Jelic J, Weber S, Fritsch C, Clark AH, Saraci E, Studt F, Grunwaldt JD (2020) Catal Sci Technol 10:7542–7554

Sandupatla AS, Banerjee A, Deo G (2019) App Surf Sci 485:441–449

Dreyer JAH, Li P-X, Zhang L-H, Beh GK, Zhang R-D, Sit PHL, Teoh WY (2017) App Catal B 219:715–726

Benitez JJ, Alvero R, Capitan MJ, Odriozola JA (1991) Appl Catal 71:219–231

Gupta NM, Kamble VS, Kartha VB (1994) J Catal 146:173–184

Eckle S, Denkwitz Y, Behm RJ (2010) J Catal 269:255–268

Marwood M, Doepper R, Renken A (1997) Appl Catal A 151:223–246

Lee WJ, Li C, Prajitno H, Yoo J, Patel J, Yang Y, Lim S (2020) Catal Today. https://doi.org/10.1016/j.cattod.2020.02.017

Burger T, Koschany F, Thomys O, Kohler K (2018) Appl Catal A 558:44–54

Burger T, Ewald S, Niederdrank A, Wagner FE, Kohler K, Hinrichsen O (2020) Appl Catal A 604:117778–117787

Zhao A-M, Ying W-Y, Zhang H-T, Ma H-F, Fang D-Y (2012) J Nat Gas Chem 21:17–177

Mutz B, Belimov M, Wu W, Sprenger P, Grunwaldt JD (2017) ACS Catal 7:6802–6814

Strohmeier BR, Hercules DM (1984) J Phys Chem 88:4922–4929

Lee KM, Lee WY (2002) Catal Lett 83:65–70

Hoffer BW, Langeveld ADV, Janssens JP, Bonne RLC, Lok CM, Moulijn JA (2000) Janssens Catal 192:432–440

Weidler N, Schuch J, Knaus F, Stenner P, Jaegermann W (2017) J Phys Chem C 121:6455–6463

Jian Z, Yang J, Bian ZF, Jie R, Liu YM, Yong C, Li HX, He HY, Fan KN (2007) Appl Catal B 76:82–91

He ZL, Que WX, Chen J, He CY, Wang GF (2013) J Phys Chem Solids 74:924–928

Lavalley JC (1996) Catal Today 27:377–401

Ewald S, Hinrichsen O (2019) Appl Catal A 580:71–80

Amenomiya Y, Morikawa Y, Pleizier G (1977) J Catal 46:431–433

Ewald S, Hinrichsen O (2019) Appl Catal A 580:7–80

Yu L, Song M, Williams PT, Wei Y (2019) Ind Eng Chem Res 58(27):11770–11778

Hasan M, Drazin J, Dey S, Castro RHR (2015) Am Miner 100:652–657

Matsuhashi H, Oikawa M, Arata K (2000) Langmuir 16:8201–8205

Kim HJ, Kang BS, Kim MJ, Park YM, Kim DK, Lee JS, Lee KY (2004) Catal Today 93–95:315–320

Hao E, Lian T (2000) Langmuir 16:7879–7881

Garbarino G, Bellotti D, Finocchio E, Magistri L, Busca G (2016) Catal Today 277:21–28

Lee SM, Lee YH, Moon DH, Ahn JY, Nguyen DD, Chang SW, Kim SS (2019) Ind Eng Chem Res 58:8656–8662

Baltrusaitis J, Jensen JH, Grassian VH (2006) J Phys Chem B 110:12005–12016

Bandara A, Kubota J, Wada A, Domen K, Hirose C (1996) J Phys Chem B 100:14962–14968

Collins SE, Baltanas MA, Bonivardi AL (2004) J Catal 226:410–421

Acknowledgements

The authors are grateful for the financial support provided by Sichuan Coal Industry Group Limited Liability Company for Development of Coal-coupled Methane Plasma for Synthesis of Ethylene and Acetylene (No. 2019H0449), the National Natural Science Foundation of China (No. 21878194) and the assistance in designing in-situ FTIR provided by prof Jianpin Shao of Institute of Chemical Physics, Chinese Academy of Sciences Compounds.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

qin, D., Xie, D., Zheng, H. et al. In-Situ FTIR Study of CO2 Adsorption and Methanation Mechanism Over Bimetallic Catalyst at Low Temperature. Catal Lett 151, 2894–2905 (2021). https://doi.org/10.1007/s10562-021-03539-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-021-03539-2