Abstract

In this work, layered double hydroxides (LDHs) including the variable valence Co2+ ions (CoAl-LDHs) is discovered to be capable of serving as the support and the reducing agent for the fabrication of well-distributed PdAu nanoparticles because of the low potential for reduction. Specifically, the active metal precursors undergo the redox process, in which Co2+ is oxidized to Co3+, while active metal ions are successfully reduced to bimetallic PdAu nanoparticles with the dispersion of 73%. Furthermore, the obtained catalysts are evaluated in the selective oxidation of benzyl alcohol as the probing reaction to explore the catalytic behavior. As for intrinsic activity, PdAu/CoAl-LDHs derived by the above in situ spontaneous reduction exhibits activation energy of 62.4 kJ mol−1, much lower than that of PdAu/CoAl-LDHs prepared by sol-immobilization. When the reaction time reaches to 4 h, the benzaldehyde selectivity over the former catalyst is up to 94%, originating from the surface electron starvation of active metals that promots the hydroxyl groups reacting with O2 to produce benzaldehyde.

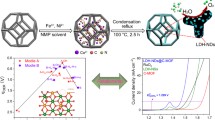

Graphic Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Supported noble metal catalysts assume enormous importance in the field of petrochemical industry and fine chemical synthesis owing to their preferable catalytic behavior and easy separation, but the scarcity of reserves limits their application [1,2,3]. Consequently, the demand for developing highly efficient and stable noble metal catalysts with small particle sizes has attracted rapidly increasing attention as the high accessible reactive sites for efficient catalysis [4]. Generally, traditional impregnation has been historically utilized to synthesize catalysts owing to the simple process and low cost, but fail to achieve highly dispersed active metal nanoparticles [5, 6]. In pace with the vigorous development of nanoscience and the deepening of nanotechnology, the researchers created some innovations such as sol immobilization [7], successfully obtaining well-distributed metal catalysts. However, the growing of surface energy as the metal particle size reducing is also apt to result in serious aggregation of metal atoms under weak metal-support interaction, leading to the deactivation [8, 9].

For this above issue, the preferred possible solution for nanometer sized metal catalysts is employing supporting substrate since the catalytic behavior depends strongly on the properties of support materials [10,11,12]. Dai and his coworker [13] covered electroless deposition of active noble metals on carbon nanotubes through spontaneous redox between metal ions and nanotubes. In this process, the loading of active component on support occurs together with their nucleation. Furthermore, Mao et al. [14] also employed the same method to fabricate Pd nanoparticles with a narrow size distribution (~ 4 nm) by spontaneous reduction of PdCl42− on graphdiyne oxides without the addition of any reducing agent or extra surfactant. The sp2-hybridized carbon of GO promoted the well and stable dispersion of Pd nanoparticles due to the low potential for reduction and strong interaction with metal atoms. It thus can be concluded that the dispersion degree of the active metal by this method is closely related with the distribution of the reductive site of support. Accordingly, if the distribution of these sites for reduction in the substrate can be effectively controlled, we can further optimize the preparation method to realize an impressive promotion of the dispersion and stability over active metals, and thus improve the efficiency.

Layered double hydroxides (LDHs) are a class of two-dimensional brucite-like inorganic layered materials with the general formula of [M1−xIIMxIII(OH)2]x+(An−) x/n·mH2O [15,16,17]. Based on the characteristics of LDHs structure, the MII and MIII ions are well-distributed in the atomic level in the laminate [18]. Owing to the flexibility in composition, some of the divalent ions could be replaced by metal ions with a radius similar to that of Mg2+ in a wide range of proportion [19]. Inspired by this advantage of LDHs, the variable valence metal ions in low valence state with the reducibility can be introduced into the laminates, and thus achieve the controllable reductive sites in quantity and distribution. This provides the wider opportunity for highly and stably dispersed catalyst derived by the spontaneous in situ reduction method. Recently, our group [20] introduced simultaneously the variable valence transition metal Co and Al into laminate to obtain CoAl-LDHs with good crystallinity, and found that the LDH material including Co2+ in the laminate can induce the reduction of active metal Pd. The obtained Pd nanoparticles exhibited the improved metal dispersion (ca. 50%) relative to that obtained by impregnation (ca. 20%) [21], but limited. Additionally, the exploration concerning the influence of different preparation methods on the structure of catalysts in bimetallic system and catalytic performance is still rarely reported.

Herein, in this work, we discover a facile and green route to fabricate CoAl-LDHs supported PdAu nanoparticles by in situ spontaneous redox of support, with the materials derived by sol immobilization as comparison. STEM, XPS and XRD results are exhibited to demonstrate how the precursor of active metal evolves and reduces with the CoAl-LDHs support without the extra reducing agent to yield a highly active and selective catalyst for the oxidation of benzyl alcohol. Detailed characterizations by STEM-mapping, ICP, EDX and XPS give an understanding of how the dispersion and structure of catalysts obtained by different synthesis strategy impacts on catalytic behavior. This work not only offers a novel route to prepare stable and well-dispersed bimetallic catalysts, but also gives an insight into the dependence between the nature of support and active metal.

2 Experimental Section

2.1 Synthesis of CoAl-LDHs

The support was synthesized by a typical co-precipitation method [22, 23]. 5.8210 g of Co(NO3)2·6H2O and 3.7513 g of Al(NO3)3·9H2O were dissolved in 100 mL of deionized water with the molar ratio of Co:Al = 2:1 to obtain solution A. 2.1200 g of NaCO3 and 1.9200 g of NaOH were dissolved in 100 mL of deionized water, named solution B. Furthermore, the solution A and B were simultaneously dropped into the flask reactor with the rate of 200 mL h−1 at room temperature under vigorous stirring for 6 h. The resulting blue–violet suspension was aged at 90 °C for 4 h, followed by washing with distilled water until pH = 7. The precipitate was then dried at 90 °C overnight and identified as CoAl-LDHs.

2.2 Preparation of Supported PdAu Catalyst by In Situ Reduction Method

0.5 g of CoAl-LDHs was added to 100 mL of deionized water under vigorous stirring. 165 μL of K2PdCl4 solution (50 mM) and 340 μL of HAuCl4 solution (24.3 mM) were then added, and stirred with the speed of 700 rpm for another 6 h at room temperature. The obtained suspension was centrifuged, washed with deionized water until neutral, followed by vacuum freeze-drying for 8 h. The product was denoted as Situ-PdAu/CoAl-LDHs. Similarly, the corresponding monometallic catalysts with same metal loading were also prepared using the above method and named as Situ-Pd/CoAl-LDHs and Situ-Au/CoAl-LDHs, respectively.

2.3 Preparation of Supported PdAu Catalysts by Sol-Immobilization [7]

165 μL of 50 mM K2PdCl4 solution and 340 μL of 24.3 mM HAuCl4 solution together with 3.12 mg of NaBH4 and 3.00 mg of PVA were mixed together under vigorous stirring, in which polyvinylpyrrolidone (PVP) was used as a stabilizer, and sodium borohydride (NaBH4) as a reducing agent. After stirring for 1 h, grey PdAu colloidal solution was obtained. 0.50 g of CoAl-LDHs was then poured into above colloidal solution and stirred at room temperature for another 2 h. The resulting suspension was centrifuged, washed with deionized water, and dried in the vacuum at − 50 °C freeze-drying for 8 h. The product was denoted as Sol-PdAu/CoAl-LDHs.

2.4 Characterization

The crystal structures of CoAl-LDHs and catalysts were characterized by X-ray diffraction (XRD) using Shimadzu XRD-600 with Cu Kα (λ = 0.154 nm) as a radiation source with a rate of 10° min−1 from 3° to 70°. The morphology of support was characterized by scanning electron microscopy (SEM, JEM-ARM 200F) equipped with an energy dispersive spectrometer (EDS). JEOL JEM-2100F high-resolution transmission electron microscopy (HRTEM) and a high-angle annular dark-fifield scanning transmission electron microscopy (HAADF-STEM) were employed to collect the particle size and structure of catalysts. The electronic structure was obtained by X-ray photoelectron spectroscopy (XPS) using Thermo VG ESCALAB 250 spectrometer with Al Kα anode as the source. The calibration peak was the C 1s peak at 284.6 eV. The compositions were determined by inductively coupled plasma emission spectroscopy (ICP-AES) using an ICP AES-6300.

2.5 The Testing of Benzyl Alcohol Oxidation

The performance of the catalysts was evaluated using a parallel reactor with 50 mL of reaction flask. Prior to the reaction, the air in the reaction flask was drained by filling oxygen. Then, 87.6 mg of catalyst, 5 mL of toluene (solvent) and 3 mL of benzyl alcohol were added with 0.1 MPa O2, in which the molar ratio of benzyl alcohol to the sum of Pd and Au (Pd/Au molar ratio is calculated as 1) is 10,000:1. The reactor was preheated to 100 °C with a high speed of 900 rpm. After each 1 h, the reaction was stopped and the resulting mixture was cooled to room temperature in an ice bath and collected by filtration. Finally, 0.5 mL of the products mixing with 0.5 mL of mesitylene as internal standard were investigated by gas chromatography (Agilent J&W) equipped with an FID detector and a DB-WAX capillary column (30 m × 0.320 mm, df = 0.25 μm). The kinetic study of the prepared supported bimetallic catalysts was carried out by controlling the appropriate reaction time to make sure that the conversion was lower than 15%. The reaction temperature was changed from 90 to 105 °C but maintained other reaction conditions in agreement with testing of catalytic performance.

3 Results and Discussion

3.1 Characterization of the Catalysts

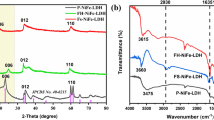

To investigate the crystal structure, XRD analysis of CoAl-LDHs support and the prepared catalysts by different method were performed. The patterns of CoAl-LDH in Fig. 1a exhibit the typical (003), (006), (009) and (110) reflections with excellent symmetry at 2θ ≈ 12.2°, 24.5°, 33.5° and 59.7°, which is roughly in agreement with LDHs materials (JCPDS No. 37-0630), indicating CoAl-LDHs with good crystallinity are successfully synthesized [24]. Based on the diffraction position of (003) facet (2θ = 11.6°), it is calculated that the basal spacing of CoAl-LDHs is 0.722 nm, illustrating that the anion in interlayer is CO32− [25]. The SEM images shown in Fig. 1b reveals that CoAl-LDH displays a layered hexagonal structure of typical LDHs with particle size of ca. two hundreds of nanometers. Furthermore, the corresponding EDS measurements were also carried out to detect the element distributions and contents. As expected, the data demonstrate that Co/Al atomic mole ratios in CoAl-LDH (2.2) roughly correspond to mole portion of each precursor (2.0), and the distributions of Al, Co and O elements in the layers of LDHs are very uniform.

In principle, in the process of LDH inducing reduction of metal ions, the change of Gibbs free energy (∆Gθ) of redox reaction under standard condition should be less than 0. Meanwhile, ∆Gθ is directly related to the standard electromotive force (Eθ) of electron pair involved in the reaction [26, 27]. When Eθ is greater than 0, LDH inducing reduction of metals can occur spontaneously in thermodynamics. Consequently in this work, the prepared CoAl-LDHs are employed as not only the support but also the reducing agent to fabricate catalyst due to the low reduction potential, with the samples derived from sol-immobilization for comparison. XRD results show that the number and position of peaks of PdAu catalysts (Fig. 1a) present no obvious change after loading Pd and Au relative to pristine CoAl-LDHs, regardless of the preparation method. Three points can be focused on this data. Firstly, CoAl-LDHs possesses excellent stability during the process of the catalyst preparation. Secondly, the absence of characteristic diffraction peaks of Au and Pd elements may be due to the detection limit of instrument or high dispersion of active metal on the catalyst surface. Thirdly, relative to pristine support, the diffraction peak of catalysts exhibits a slight shift to higher angle, indicating that the deformation of MO6 octahedron in laminate [28, 29]. Based on the octahedral deformation criterion of LDHs, this phenomenon could be originated from the interaction of active metal precursor and reductive support rather than the entering of the former into laminate owing to their large atom radius [30].

To further explore the distribution of active metal atoms, HRTEM measurement was carried out. As expected, the corresponding images of PdAu catalysts (Figs. 2, 3) show that PdAu nanoparticles obtained by in situ reduction method disperse more homogeneously relative to those by sol-immobilization. To survey the size distribution, more than 200 metal particles are randomly selected. Situ-PdAu/CoAl-LDHs catalyst displays a narrow size distribution from 0.8 to 1.7 nm with the mean size of PdAu particles is 1.2 ± 0.3 nm (Fig. 2a), much smaller than that of Sol-PdAu/CoAl-LDHs (3.0 ± 0.8 nm), displayed in Fig. 3a. The metal dispersions of these two PdAu catalysts are further calculated using the mean size derived from HRTEM analysis by assuming the metal particles to be spherical based on the following equation [31]:

where A is atomic mass, ρ is the density, σ is the average surface area occupied by one active metal atom, L is the Avogadro’s constant. It is significantly observed that the metal dispersion of Situ-PdAu/CoAl-LDHs (73%) is more than twofold higher than that of Sol-PdAu/CoAl-LDHs (31%).

Moreover, HAADF-STEM measurement was also performed, and the images (Figs. 2b, 3b) display the lattice distance of the observed nanoparticles discerning with 0.230 and 0.205 nm, indexed to the planes in PdAu alloy and monometallic Au, respectively [32]. This proves that the reductive site in LDHs can induce the reduction of active metal ions during the process of support spontaneous in situ redox. In addition, the mapping elemental scanning shows that the outer layer of the PdAu nanoparticle is rich in Au, while the intermediate layer is composed of Pd and Au, indicating the formation of Au surface enriched PdAu alloy structure [33].

3.2 Electronic Effect of the Catalysts

To clarify the electronic interaction of metal-support and Pd–Au in this series of samples, XPS analysis was employed, and the results are shown in Fig. 4 and Table 1. Figure 4 illustrates that the core lines of Co 2p are split into two peaks, in which the lower one appears the electron transitions of Co 2p1/2, and the one at higher binding energy (BE) is originated from the electron transitions of Co 2p3/2. Furthermore, the spectra in the Co 2p3/2 region are deconvoluted into three peaks, corresponding to Co3+ (780.9 eV), Co2+ (782.4 eV) and satellite peaks attributed to Co2+ in a high spin state (786.1 eV), respectively [34, 35]. The absence of peaks corresponding to Co0 demonstrates that all the Co2+ precursors have been not reduced. Notably, after introducing the metal precursors, the main peaks in Co 2p3/2 and Co 2p1/2 shift to higher energy (0.2–0.8 eV). Meanwhile, the ratio of Co2+ to Co3+ in the catalysts decreases relative to that of pristine CoAl-LDHs, meaning that part of Co2+ loses electrons to transform into Co3+ during the preparation process of the catalysts.

Similarly, XPS spectra of catalysts within the region of Au 4f7/2 and Pd 3d5/2 (Fig. 5a, b) also contains two main peaks, corresponding to the characteristic peaks of Mδ+ and M0 (Mδ+ = Au+ and Pd2+, M0 = Au0 and Pd0) [36, 37], although Pd 3d5/2 partially overlaps with Au 4d5/2 in Fig. 5b. The presence of Au0 and Pd0 in the catalyst prepared by in-situ reduction method proves that the noble metal ions could capture the lost electrons from Co2+, and then are effectively reduced although without additional reducing agent. Combining with XPS results of Co, it can be concluded that the redox reaction, as shown in Eqs. (1) and (2), indeed occurs in the preparation process of catalyst, consistent with the results obtained by HRTEM. However, part of oxidized Au+ and Pd2+ are also observed, which may be due to the re-oxidation in the air. The Au0/Au+ and Pd0/Pd2+ ratios of catalysts are further calculated, listed in Table 1. Notably, Au0/Au+ ratio in Situ-PdAu/CoAl-LDHs (0.7) is basically similar to that of monometallic Situ-Au catalyst (0.9), while Pd0/Pd2+ ratio of Situ-PdAu/CoAl-LDHs (1.8) is much higher than that of monometallic Pd sample (0.7). Combined with the conclusion from STEM-EDX analysis, this result indicates that Au enriched on the surface of bimetallic PdAu tends to be in the oxidation states than Pd enriched in the interior in the storage or characterization process.

Furthermore, the Pd 3d5/2 and Pd 3d3/2 peaks assigned to Pd0 of Situ-PdAu/CoAl-LDHs shift to higher BE by ca. 0.4 eV compared with the monometallic Pd catalyst (Fig. 5b, Table 1), indicating a decrease in the electron density of Pd in these two catalysts. As expected, negative shifts over the peaks ascribed to metallic Au in these two samples are observed. The decrease in BE of Au and the increase in BE of Pd over bimetallic catalysts could be responsible for the charge transfer from Pd to Au [38]. It is noteworthy that the shifts for the peak corresponding to Pd in Situ-PdAu/CoAl-LDHs are significantly higher (336.9 eV) than those in Sol-PdAu/CoAl-LDHs (335.1 eV), meaning that the active metal in Situ-PdAu/CoAl-LDHs are more electron-deficient. In the previous work, Qi and Zhao et al. [14, 37] discovered the similar high BE value of Pd0 in Pd based catalyst prepared by electroless deposition and self-redox method, originating from the preparation method and the interaction between the as-formed Pd nanoparticles and support. This also accounts for the unusual phenomenon in our situation. Additionally, the surface elemental composition of the materials was further determined by XPS (Table 2). The Pd/Au molar ratios in the surface of Situ-PdAu/CoAl-LDHs and Sol-PdAu/CoAl-LDHs are 0.7 and 0.5, while the ratio in the bulk measured by STEM-EDS are 1.2 and 1.1, respectively. It indicates that Au is enriched on the surface, while the intermediate layer is composed of Pd and Au, which is in agreement with the results of STEM-mapping.

Based on the above results, a possible mechanism of catalysts support inducing the reduction of the active metal is proposed in Scheme 1. Initially, the spontaneous in situ redox reaction occurs between the precursor of active metal and the variable valance Co sites in the support, where active metal ions including Pd2+ and Au3+ are reduced to Pd0 and Au0, while Co2+ is oxidized to Co3+. Meanwhile, the left Co2+ ions could serve as the sites to anchor the reduced metal nanoparticles through the metal-support interaction, contributing that high dispersion of active metal. After the loading, the CoAl-LDHs support is observed to be stable.

3.3 Catalytic Activity Over Selective Oxidation of Benzyl Alcohol

The selective oxidation of benzyl alcohol was employed to evaluate the catalytic behavior including the activity and selectivity of Situ-PdAu/CoAl-LDHs catalysts, with bimetallic Sol-PdAu/CoAl-LDHs and monometallic Pd as well as Au catalysts as control samples. The loading of active metal in catalysts, obtained from ICP analysis, are shown in Table 2. The experimental values of catalysts are slightly lower than theoretical value, but the values are reproducible. Figure 6a exhibits the conversion of benzyl alcohol over these catalysts versus reaction time. It is clearly illustrated that the conversion of bimetallic PdAu catalyst prepared by the spontaneous in situ redox method is higher than that of Sol-PdAu/CoAl-LDHs at any fixed reaction time. When the time raised to 4 h, the conversion of benzyl alcohol over Situ-PdAu/CoAl-LDHs reached 95%, two times higher than that of Sol-PdAu/CoAl-LDHs sample (50%). Turnover frequency (TOF) as an important metric to estimate the intrinsic activity was evaluated at the conversion less than 15%, excluding the effect of mass transfer and heat transfer. The calculation formula is as follow.

Plots of a benzyl alcohol conversion versus reaction time and b benzaldehyde selectivity versus benzyl alcohol conversion over two catalysts, c reusability of Situ-PdAu/CoAl-LDH catalyst. Conditions: 5 mL toluene, 3 mL benzyl alcohol, benzyl alcohol: metal = 10,000:1 (molar ratio), 0.1 MPa O2, 100 °C

Situ-PdAu/CoAl-LDH exhibits 4270 h−1 of TOF, two times higher than that of Sol-PdAu/CoAl-LDHs (2220 h−1). These results demonstrate that PdAu catalyst prepared by the spontaneous in situ reduction method are highly active, which is ascribed to improved dispersion, exposing more active sites for the oxidation of benzyl alcohol [39, 40]. Moreover, the apparent activation energy (Ea), as a vital metric to assess the intrinsic activity, was further investigated. In this study, Ea is obtained from the slope of lnk plotted as a function of T−1 under low conversion (< 15%) to rule out the effect of the mass or heat transfer [41, 42] (Fig. 7). The fitting accuracy for each case suggests that the data are reliable. Ea value of Situ-PdAu/CoAl-LDHs is 62.4 kJ mol−1, comparable to that of the previously reported noble metal catalysts, while the high Ea value is obtained over Sol-PdAu/CoAl-LDHs (76.5 kJ mol−1). This result suggests that the characteristics of Situ-PdAu/CoAl-LDHs could lower the barrier of activation for the reaction, and thus improve the activity. Except for activity, selectivity toward benzaldehyde of the catalysts is also displayed in Fig. 6b. At iso-conversion, higher benzaldehyde selectivity are observed over Situ-PdAu/CoAl-LDHs than that over Sol-PdAu/CoAl-LDHs. It is noteworthy that a significant decrease of selectivity (16%) over Sol-PdAu/CoAl-LDHs is captured with the conversion increasing, while the selectivity over the sample prepared by the spontaneous in situ reduction route only demonstrates ca. 6% of decrease. Especially, when the conversion of benzyl alcohol reaches 95%, benzaldehyde selectivity over Situ-PdAu/CoAl-LDHs is up to 94%, much higher than that of Sol-PdAu/CoAl-LDHs and some reports in Table 3 [43,44,45,46,47,48]. This illustrates that PdAu catalyst derived from the spontaneous in situ route is a more selective catalyst, which could be attributed to surface electron starvation of Pd and Au in the Situ-PdAu/CoAl-LDHs confirmed by XPS analysis, promoting the hydroxyl groups react with O2 to produce benzaldehyde [49, 50]. Furthermore, the recycling experiment was also carried out at 2.5 h corresponding to 80% of conversion to investigate the stability of Situ-PdAu/CoAl-LDHs catalyst (Fig. 6c). The conversion and selectivity fluctuates in a small range, confirming this catalyst keep stable after four cycles.

4 Conclusion

In this work, Co and Al elements were introduced into the layer to fabricate the reductive CoAl-LDH support. This kind of material was simultaneously employed as support and reducing agent to prepare supported PdAu catalyst by in situ spontaneous reduction method. XPS analysis of Situ-PdAu/CoAl-LDHs catalyst revealed Pd and Au precursors underwent the redox process by the reducing Co site in the support, in which Co2+ was oxidized to Co3+, while active metal ions including Au3+ and Pd2+ were reduced to Au0 and Pd0. HRTEM images further confirmed that metallic Pd and Au were successfully reduced by reductive support without the additional reducing regent, and homogeneously distributed on the support with the particle size of 1.2 ± 0.3 nm and the metal dispersion of 73%. However interestingly, the PdAu/CoAl-LDHs catalyst prepared by sol-immobilization method possessed bigger particle size (3.0 ± 0.8 nm) and poor metal dispersion (31%). The selective oxidation of benzyl alcohol was employed as probe reaction to test the catalytic behavior over the synthesized Situ-PdAu/CoAl-LDHs and Sol-PdAu/CoAl-LDHs catalysts. As for intrinsic activity, Situ-PdAu/CoAl-LDHs catalyst exhibited a Ea of 62.4 kJ mol−1, 22% lower than that of Sol-PdAu/CoAl-LDHs (76.5 kJ mol−1). When the reaction time reached to 4 h, the conversion of benzyl alcohol over Situ-PdAu/CoAl-LDHs was 95% and benzaldehyde selectivity still maintained at 94%. Small size of PdAu nanoparticles facilitated the exposure of more active sites for the adsorption and activation of benzyl alcohol, and thus improved the activity. Preferable selectivity was ascribed to the surface electron starvation of active metals that promoted the hydroxyl groups reacting with O2 to produce benzaldehyde.

References

Wu G, Zheng X, Cui P et al (2019) Nat Commun 10:4855

Hunt ST, Milina M, Alba-Rubio AC et al (2016) Science 352:974–978

Wei S, Li A, Liu JC et al (2018) Nat Nanotech 13:856–861

Farmer JA, Campbell CT (2010) Science 329:933–936

Chong S, Zhang G, Zhang N et al (2016) Ultrason Sonochem 32:231–240

Zhang N, Zhang G, Chong S et al (2018) J Environ Manage 205:134–141

Iqbal S, Kondrat SA, Jones DR et al (2015) ACS Catal 5:5047–5059

White RJ, Luque R, Budarin VL et al (2009) Chem Soc Rev 38:481–494

Astruc D, Lu F, Aranzaes JR (2005) Angew Chem Int Ed 44:7852–7872

Li XN, Yuan Z, He SG (2014) J Am Chem Soc 136:3617–3623

Li ZY, Yuan Z, Li XN et al (2014) J Am Chem Soc 136:14307–14313

Cargnello M, Doan-Nguyen VV, Gordon TR et al (2013) Science 341:771–773

Choi HC, Shim M, Bangsaruntip S et al (2013) J Am Chem Soc 124:9058–9059

Qi H, Yu P, Wang Y et al (2015) J Am Chem Soc 137:5260–5263

Sotiles AR, Baika LM, Grassi MT et al (2018) J Am Chem Soc 141:531–540

Wang Q, O’Hare D (2012) Chem Rev 112:4124–4155

Sideris PJ, Nielsen UG, Gan Z et al (2008) Science 321:113–117

Rives V, Arco M, Martín C (2013) J Controlled Release 169:28–39

Meng X, Yang Y, Chen L et al (2019) ACS Catal 9:4226–4235

Li H, Yang T, Jiang Y et al (2020) J Catal 385:313–323

Mekasuwandumrong O, Somboonthanakij S, Praserthdam P et al (2009) Ind Eng Chem Res 48:2819–2825

Mishra G, Dash B, Pandey S (2018) Appl Clay Sci 153:172–186

Chen X, Wu G, Chen J et al (2011) J Am Chem Soc 133:3693–3695

Zhang F, Zhao X, Feng C et al (2011) ACS Catal 1:232–237

Liu X, Zhou A, Pan T et al (2016) J Mater Chem A 4:8421–8427

Zhuo K, Wang J, Zhang Q et al (1999) Carbohyd Res 316:26–33

Jacob KT, Saji VS, Reddy SNS (2007) J Chem Thermodyn 39:230–235

Feng J, He Y, Liu Y et al (2015) Chem Soc Rev 44:5291–5319

Fan G, Li F, Evans DC et al (2014) Chem Soc Rev 43:7040–7066

Cardenas-Lizana F, Hao Y, Crespo-Quesada M et al (2013) ACS Catal 3:1386–1396

Lear T, Marshall R, Lopez-Sanchez J et al (2005) J Chem Phy 123:174706

Han F, Xia J, Zhang X et al (2019) RSC Adv 9:17812–17823

Li Z, Wang R, Xue J et al (2019) J Am Chem Soc 141:17610–17616

Liu ZQ, Cheng H, Li N et al (2016) Adv Mater 28:3777–3784

Ma TY, Dai S, Jaroniec M et al (2014) J Am Chem Soc 136:13925–13931

Chaudhari K, Xavier PL, Pradeep T (2011) ACS Nano 5:8816–8827

Zhao S, Li K, Jiang S et al (2016) Appl Catal B 181:236–248

Shi Y, Yang H, Zhao X et al (2012) Catal Commun 18:142–146

Chen J, Yan D, Xu Z et al (2018) Environ Sci Technol 52:4728–4737

Liu H, Zakhtser A, Naitabdi A et al (2019) ACS Catal 9:10212–10225

Yang P, Pan J, Liu Y et al (2018) ACS Catal 9:188–199

Liu Y, McCue AJ, Yang P et al (2019) Chem Sci 10:3556–3566

Xu J, Shang J, Chen Y (2017) Appl Catal A 542:380–388

Lavenn C, Demessence A, Tuel A (2015) J Catal 322:130–138

Zhang N, Du Y, Yin M (2016) RSC Adv 6:49588–49596

Xie S, Tsunoyama H, Kurashige W (2012) ACS Catal 2:1519–1523

Pritchard J, Kesavan L, Piccinini M et al (2010) Langmuir 26:16568–16577

Chen Y, Lim H, Tang Q (2010) Appl Catal A 380:55–65

Conte M, Miyamura H, Kobayashi S (2009) J Am Chem Soc 131:7189–7196

Feng J, Ma C, Miedziak PJ et al (2013) Dalton Trans 42:14498–14508

Acknowledgements

This work was supported by the National Natural Science Foundations of China (21706009, 21627813, 21908002), China Postdoctoral Science Foundation (2019M660416, 2020T130045), the Fundamental Research Funds for the Central Universities (buctrc201921) and PetroChian Science and Technology Management Department (2016E-0703).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, S., Li, H., Liu, Y. et al. Fabrication of Pd–Au Clusters by In Situ Spontaneous Reduction of Reductive Layered Double Hydroxides. Catal Lett 151, 2355–2365 (2021). https://doi.org/10.1007/s10562-020-03481-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-020-03481-9