Abstract

Isomaltulose, as a safe sucrose substitute, is widely used as a functional sweetener due to its promising properties, such as slower digestion, prolonged energy release, and less cariogenicity. The transformation of sucrose to isomaltulose by free sucrose isomerase (SIase) or microbial cells harboring the SIase gene has received considerable attention in the industry. Heterologous expression of SIase in food-safe grade strains has become a hot topic due to its broad applicability in the food industry. Thanks to rapid developments in genetic engineering technology, SIases from different sources have been heterogeneously expressed in Escherichia coli, which significantly increased the enzyme’s titer. This review presents a systematic and detailed summary of the contemporary biotechnological approaches employed for isomaltulose production, including the source, structural determination, catalysis mechanism, heterologous expression, catalytic reaction condition optimization of SIase, and immobilization of cells. In addition, protein engineering, heterologous expression in food-grade safety strains, fermentation optimization strategies, and immobilization techniques of SIase are introduced in detail. Towards the end, the review is wrapped up with the concluding remarks, and future strategies are outlined for improving the biological production of isomaltulose.

Graphical Abstract

Summary of biological isomaltulose production from sucrose catalyzed by sucrose isomerase.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Isomaltulose (or Palatinose), as an isomer of sucrose, has similar physical properties and taste to sucrose [47]. In the 1957s, Weiden Hagen. R and Lorenz. S first discovered isomaltulose [66]. Compared with sucrose, isomaltulose has a broad market application prospect in food due to its good acid stability, very low hygroscopicity, and high safety [2, 52, 65]. As a new sweetener, isomaltulose has the advantages of low sweetness (approximately 50% of the relative sweetness of sucrose), non-caries, and low calorie, which is especially suitable for diabetes and obesity [11, 51]. Moreover, isomaltulose is also a kind of reducing sugar, which can be used to produce new functional edible sugar alcohols as a precursor [31]. Given the excellent properties [57], isomaltulose has been approved as a safe sucrose substitute and attracted the whole world’s attention, leading to a market growth rate of more than 10%. Isomaltulose has been used as a sucrose substitute and approved as food for specified health uses due to its dental properties in Japan since 1985. In the USA, isomaltulose is approved as “generally regarded as safe” (GRAS) by Food and Drug Administration (GRN No.184), and used in a range of dietary supplements and foods. It was authorized by the Commission of the European Communities as a novel food or novel food ingredient (notified under document number C (2005) 2776). With the rapid growth of market demand, the production of isomaltulose has gained considerable research attention around the globe.

At present, the biochemical conversion of sucrose to isomaltulose is the common means for isomaltulose production [63], reaching a scale of more than 10,000 tons annually worldwide. Bioconversion methods mainly include single enzyme conversion [4], free cell conversion [1, 79], and immobilized cell conversion [24]. The critical factor in bioconversion is sucrose isomerase (SIase) (EC 5.4.99.11), also known as isomaltulose synthase, α-glucosyltransferase, or trehalulose synthase. In nature, isomaltulose, a reserve material during periods of low carbon availability, is present in low quantities in many bacteria [48]. Numerous microorganisms have been recognized for their ability to produce SIase with different levels of isomaltulose production. Currently, SIase is mainly obtained by microbial fermentation. Escherichia coli (E. coli) is one of the ideal industrial strains for producing target products by microbial fermentation [17, 46]. With the rapid development of genetic engineering technology, SIases from different sources were heterogeneously expressed in E. coli, which significantly increased the enzyme's production level [28]. Owing to its wide involvement in the food industry [35], the heterologous expression of SIase in food-safe grade strains has gained increasing interest.

Based on the literature reported during the last decade and the recent advance, this review systematically describes the source, catalysis mechanism, and heterogeneous expression of SIase. Among them, the protein engineering of SIase, the heterologous expression in food-grade safety strains, and the fermentation optimization strategies to improve exocrine levels were mainly presented (Fig. 1).

2 The Information of SIase

2.1 Source and Structure

In the 1950s, Protaminobacter rubrum (P. rubrum) producing SIase was firstly screened and isolated from wastewater discharged from the beet plant. In recent decades, researchers have found that most of SIase are derived from bacteria [39]. The representative SIase production strains, include P. rubrum [39], Erwinia rhapontici (E. rhapontici) [27], Serratia plymuthica (S. plymuthica) [22], Klebsiella planticola (K. planticola) [19], Enterobacter sp.[24], Klebsiella sp.[76, 78], Pantoea dispersa (P. dispersa) [68], and Klebsiella pneumonia (K. pneumonia) [58]. The formation of isomaltulose (6-o-α-D-glucopyranosyl-D-fructose) and trehalulose (1-o-α-D-glucopyranosyl-D-fructose) was obtained from sucrose by isomerization of SIase [18] (Fig. 2). During the isomerization of sucrose to isomaltulose and trehalulose, small amounts of D-glucose and D-fructose can also be produced as by-products by hydrolysis. According to the main product catalyzed by the enzyme, the SIase production strains were categorized into two types: isomaltulose production strains and trehalulose production strains [41]. The isomaltulose production strains include E. rhapontici NX-5 [27], Enterobacter sp. FMB-1 [24], P. dispersa UQ68J [68], P. rubrum CBS574.77 [68], E. rhapontici WAC2928 [68], S. plymuthica ATCC15928 [22], Klebsiella sp. LX3 [22], K. planticola CCRC19112 [19], and K. planticola MX-10 (Zhng et al. 2004), from which isomaltulose catalyzed by SIase accounted for 60–90% of all products.

In Protein Data Bank (PDB), the crystal structure of SIase from many sources has been resolved by X-ray diffraction (Table 1). The native SIases from Klebsiella sp. LX3, P. mesoacidophila MX-45, P. rubrum CBS574.77, and E. rhapontici NX-5 are representative (Table 1). SIase is a single subunit molecule (Fig. 3), which belongs to the glycosidase 13 (GH13) family. Similar to enzymes from the GH13 family, the tertiary structure of SIase from different sources has high homology and is composed of three domains (N-terminal domain, C-terminal domain, and sub-domain). The N-terminal domain is an (β/α)8-barrel super-secondary structure, which is the most important part of SIase (the enzyme's catalytic center). Multiple amino acid sequence comparisons of various SIase revealed that the N-terminal domain contained five highly conserved amino acids, Asp241, Glu295, Asp369, His145, and His368, which are located in the catalytic pocket of SIase and involved in the catalysis of the substrate. The sub-domain is a short loop rich structure, which is involved in substrate (sucrose) binding [48]. The C-terminal domain consists of two antiparallel β-sheets, which are related to the structural stability of SIase [15]. Unlike the GH13 family of enzymes, an RLDRD sequence consisting of five amino acids (Arg, Leu, Asp, Arg, Asp) in the proximity of the active site is unique to SIase, which is mainly responsible for sucrose isomerization [39] (Fig. 3). The RLDRD sequence (e.g., in SIase from Klebsiella sp.) is highly conserved in enzymes. In the process of sucrose isomerization, this sequence plays a significant role, which can ultimately affect the specificity and proportion of products [76, 78].

2.2 Reaction Mechanism

The SIase from S. plymuthica ATCC 15,928 was purified, and the reaction mechanism was studied by Véronèse and Perlot [59]. The reaction mechanism was based on the intramolecular rearrangement of sucrose that simultaneously produces two different isomerization products (isomaltulose and trehalulose) [54]. After the cleavage of glucoside bond (α1−β1) of sucrose, glucose moiety remains tightly bound to the active site of the enzyme, while, the fructosyl group is loosely attached. In this case, the fructose moiety is allowed to rotate and change its position freely, and then two different sucrose isomers are formed by intramolecular rearrangement.

By studying the catalytic mechanism of SIase, Ravaud et al. [48] speculated that the SIase proceed using a two-step double-displacement mechanism, which is similar to other GH13 enzymes. In the process of SIasecatalyzing sucrose to form isomaltulose, the formation and breakdown of a covalent glucosyl-enzyme intermediate were completed through the transition state of carboxyl ions from Glu at the enzyme active site. To complete the hydrolysis of sucrose, Glu acts as an acid catalyst, protonizing the oxygen on the substrate glycoside bond by providing a proton. Then, the Asp of the active site attacks the C1 hydrogen atoms on sucrose by the nucleophilic attack, deprotonizing the C1 hydrogen atoms and resulting in the formation of the β-glucosyl-enzyme intermediate. The free fructosyl group’s tautomerism leads to the formation of sucrose isomer (isomaltulose or trehalulose).

SIase contains a unique sequence, RLDRD, which is closely related to isomerization (Fig. 3). The conservation of this sequence affects the specificity and proportion of the final product [37]. Site-directed mutants of Arg325 and Arg328 were used for enzyme transformation, and found that the amount of isomaltulose in the end product was reduced, while the yield of trehalulose was slightly increased [25].

2.3 Protein Engineering

Although natural SIase can be used for isomaltulose biosynthesis, some problems still resisted in industrial production, such as poor thermolability or low conversion rate. Given that protein engineering based on structure information can improve the application performance of wild enzyme [14, [74], various protein engineering approaches have been developed (Table 2). The main purpose of protein modification of SIase is mainly reflected in three aspects: improving enzyme thermostability, increasing product ratio of isomaltulose, and reducing by-products. For example, eplacement of Glu498 and Arg310 with proline of SIase (PalI) from Klebsiella sp. strain LX3 by site-directed mutagenesis resulted in an 11-fold increase in the half-life of PalI at 50 °C, which significantly increased the thermostability of PalI and slightly improved the product ratio of isomaltulose [77]. Given that S. plymuthica AS9 SIase was unstable, B-factor-based site selection combined with site-directed mutagenesis was employed to improve its thermostability by constructing three mutants (E175N, K576D, E175N/K576D) [15]. The mutants exhibited increased optimal temperature (from 30 °C to 35 °C) and displayed improved isomaltulose yield as compared to the wild-type enzyme. In order to reduce by-product formation during the isomaltulose biosynthesis catalyzed by SIase from S. plymuthica, a semi-ration protein-engineering strategy resembling a “Battleship strategy” was employed, resulting in a high active SIase with enhanced product specificity [45]. Given the low product specificity of isomaltulose by SIase from P. dispersa UQ68 J (Sim1), residues of Tyr296 and Gln299 of Sim1, which were located close to the substrate-binding site, were changed. The results showed that the mutant of Q299E significantly improved the conversion rate of isomaltulose from 90.28 to 94.16% [33]. Moreover, to explain the underlying molecular mechanisms of SIase from Rhizobium sp, the variant F164L was obtained using a random-mutagenesis approach, which improved the product ratio of isomaltulose by 55.1% [32].

3 Heterogenic Expression of SIase

3.1 In E. coli

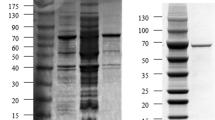

Given that E.coli is one of the ideal industrial strains for the production of target products, SIase genes from different microorganisms (such as K. planticola, P. dispersa, K. pneumoniae, Enterobacter sp, E. rhapontici, and S. plymuthica) have been successfully cloned and expressed in E.coli (Table 3). The biochemical properties of SIase were shown in Table 3. Most of the optimum pH values ranged from 5.0–6.0. It was reported that pH is related to SIase enzyme activity and product specificity. For example, the activity of SIase form Enterobacter sp. FMB-1 is significantly reduced outside the pH (5.0–6.0) [4]. SIase form K. planticola UQ14 S shows no isomerization activity and a little hydrolysis activity at pH 3.0. However, when the value of pH increased, the hydrolysis activity is decreased, and the isomaltulose becomes the main product [69]. Most SIases exhibit lower thermal stability, except the SIase from Enterobacter sp. FMB-1 showing an optimal temperature at 50 °C (Table 3). Temperature also affects the ratio of product composition. As for P. dispersa UQ68 J SIase, isomaltulose production is significantly inhibited above 40 °C [69]. In addition, SIases from different sources exhibit different enzymatic properties (Table 3). The Michaelis constant (Km) has a wide range of values from 30.1 mM [15] to 257 mM [27], depending on different sources of SIases.

3.2 In food-Grade Safety Strains

Given that the application of isomaltulose in the food industry and E. coli is unsuitable for commercial isomaltulose biosynthesis due to the presence of cell wall pyrogens and endotoxin synthesis [56], the heterogeneous expression of SIase in safe food-safety grade hosts, such as Lactococcus lactis (L. lactis), Yarrowia lipolytica (Y. lipolytica), Bacillus subtilis (B. subtilis), and Saccharomyces cerevisiae (S. cerevisiae), attracts more and more attention (Table 4). Like the recombinant SIases in E. coli, most recombinant SIases in food-grade safety strains own weakly acidic optimal pH and low thermal stability (Table 4). Depending on the microbial sources, the conversion rate of isomaltulose varies significantly (Table 4). The bacterial system of L. lactis, a non-pathogenic, non-invasive Gram-positive bacterium, has been examined as an efficient expression system for recombinant protein production and secretion [38]. Park et al. [44] first reported the heterologous expression of SIase from Enterobacter sp. FMB-1 in L. lactis MG1363. The recombinant SIase from L. lactis was successfully secreted extracellularly by using an auto-inducible promoter (P170) and an optimized signal peptide (SP310mut2). The recombinant L. lactis MG1363 was employed for isomaltulose, with a conversion yield of 72%.

Like L. lactis, B. subtilis is also considered a suitable candidate for expressing industrially relevant proteins [16]. Using shuttle plasmid pHA01, SIase from E. rhapontici NX-5 was overexpressed in an engineered B. subtilis WB800, which effectively solves the food safety problem of isomaltulose production [71]. Moreover, SIase from P. dispersa UQ68J was heterologously expressed in the yeast Y. lipolytica, a “generally recognized as safe” (GRAS) microbe, by employing the expression vector pINA1312 [81].

Except for intracellular expression, SIase could also be displayed on the surface of cells or spores in food-grade safety strains for isomaltulose production. Protein display technology has made great progress in recent years. Compared to intracellular expression of enzyme, the living whole-cell biocatalyst is easily produced by microbial cultivation techniques when enzyme molecules are simultaneously synthesized and self-immobilized on the cell surface [7]. In addition to prokaryotic expression systems, yeast expression systems, such as S. cerevisiae and Y. lipolytica, are also used to produce heterogeneous expression proteins [64]. SIase from Enterobacter sp. FMB-1 has been successfully displayed on the cell surface of S. cerevisiae EBY100, using a glycosylphosphatidylinositol (GPI) anchor attachment signal sequence for anchoring protein [24]. Using the cell wall protein Pir1 as an anchor protein [26] or a constructed GPI (a cell wall protein anchor signal sequence) [82], P. dispersa UQ68 J SIase was displayed on the Y. lipolytica cell surface. Unlike cell surface display, SIase from E. rhapontici NX-5 was displayed on B. subtilis 168 spores using CotX as the anchoring protein. The anchored SIase showed relatively high bioactivity for the economical production of isomaltulose from agricultural residues [75].

4 Optimization Strategies for Improving SIase Expression

The expression level of wild-type SIase from different microbial sources is often low, so various optimization strategies were carried out for enhancing the expression of SIase (Table 5). Optimization of fermentation medium composition is a common method to improve enzyme activity or expression level, and the key points of optimization are the composition and content of carbon sources, nitrogen sources and inorganic salts. For instance, the fermentation medium component of recombinant E. coli was optimized through response surface method (RSM). The results showed that the optimal media contained: cane molasses 10.65 g/L, corn steep 22.22 g/L, NaCl 7.57 g/L, MgSO4·7H2O 0.52 g/L, KH2PO4 4.46 g/L. Among the components, cane molasses, corn steep, and NaCl are the most useful carbon sources, nitrogen sources, and inorganic salt. Under optimal fermentation conditions, the final SIase activity was 29.1 U/ml, increasing 21.4 times compared to that of the original strain (1.3 U/ml) [62]. To develop an economical industrial medium, the concentration of untreated cane molasses, yeast extract, and corn steep liquor was optimized for SIase production, leading to a relatively high SIase activity of 14.5 U mg−1 DCW−1 in the recombinant E. coli [29]. The inducer lactose is also often used as an optimization factor during the fermentation process. For example, the rate of lactose induction was optimized, and the results showed that the enzyme level was the highest under the rate of 0.4 g/(L·h) lactose.

In addition to medium composition optimization, signal peptide, or promoter optimization is also a common method to improve enzyme expression or secretion [34, 83]. For instance, to improve the expression level of SIase from P. dispersa UQ68J, optimizing signal peptide and fermentation conditions were employed. The results showed that Pel B signal peptide, glycine concentration (3 g/L), and lactose concentration (0.5%) were key factors. The total enzyme activity and extracellular enzyme activity were up to 2640 and 1981 U/mL, respectively, which were the highest expression level of SIase [34]. To enhance the expression of SIase from Brevibacillus choshinensis, Papr-E signal peptide and optimal medium composition (glucose 10 g/L, polypeptone 15 g/L, and beef extract 15 g/L) were used, leading to SIase activity of 485.5 U/mL [83]. In addition, a modified nucleotide sequence encoding SIase from P. dispersa UQ68 J was heterologous expression in E.coli JM109 using expression plasmid pET11. The modification of the native gene increased expression level (14–19%) of the total cellular protein [50].

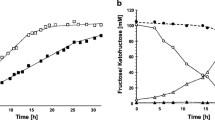

5 Optimizing Reaction Conditions for Isomaltulose Biosynthesis by SIase or Cells Harboring Siase Gene

Free SIase or cells harboring the SIase gene can be used for converting sucrose to isomaltulose. Application condition optimization, including substrate concentration, temperature, pH, enzyme amount, and reaction time, is a common method for isomaltulose production (Table 6). In an enzyme-catalyzed reaction system, substrate (sucrose) concentration is the key point of optimization. For example, K. pneumoniae NK33 SIase, the conversion rate of isommalone was 76.8%, with a sucrose concentration of 40% using K. pneumoniae NK33 SIase [3]. The recombinant cells harboring SIase from Enterobacter sp. FMB-1 were implemented for catalysis reaction, resulting in the conversion rate of isomaltulose by 78% with sucrose concentration of 6% [4]. To maintain the stability of enzymatic properties during the reaction, the optimum reaction temperature and pH of the enzyme reaction system are often the same or adjusted slightly according to the optimum conditions of SIase itself. At the optimum temperature and pH of SIase, the conversion rate of isomaltulose by 7.4% was obtained [24]. In addition to the above factors, the amount of enzyme added and reaction time also affect the final product's yield. As the amount of enzyme increased, the conversion rate of isomaltose also increased,when the amount of enzyme was 20 U/g, the conversion rate of isomaltulose reached a maximum of 86.9%. After that, the conversion rate is slightly decreased with the increase of enzyme amount (Cheng 2015. By overexpressing SIase from P. dispersa UQ68J in yeast Y. lipolytica, an engineered strain S47 was constructed, leading to a 95% conversion rate of isomaltulose with sucrose concentration of 600 g L−1 after 72 h [81]. Moreover, E. rhapontici NX-5 SIase displayed on the surface of B. subtilis 168 spores was applied for isomaltulose production, and the productive spores converted 92% of sucrose after 6 h under the optimal conditions [75].

6 Immobilization Technologies for Isomaltulose Production

6.1 Cell Immobilization

Immobilized cells or enzymes have a wide range of applications, and a variety of immobilized cells or enzyme systems have been successfully used in industrial production [53, 60, 73]. In the last few decades, most of the works report the isomaltulose production by immobilization of microbial cells, such as E. rhapontici, Erwinia sp, and S. plymuthica, which have been immobilized using different strategies to improve isomaltulose productivity or enhance the application performance of the immobilized cells (Table 7). Compared to isomaltulose production by free cells, cell immobilization shows several potential advantaged, including minimum downstream processing, reusability of biocatalyst, and improved operational stability [6]. In the production of isomaltulose, there are two main methods for cell immobilization: alginate entrapment and chitosan cross-linking with glutaraldehyde (Table 7). By using columns of E. rhapontici NCPPB 1578 cells entrapped in alginate gel pellets, isomaltulose production was achieved, obtaining a yield of 0.2 g isomaltulose per gram wet weight of cells per hour and an improved operational stability of the immobilized cells (8,625 h of half-life) [5]. Mundra et al. [40] increased the isomaltulose yield by 40% and achieved a maximum isomaltulose production of 140 g L−1 h−1 by RSM optimization of the immobilized E. rhapontici NCPPB 1578 cells. The optimized immobilization process by RSM and calcium alginate was implemented in Erwinia sp. D12 cell immobilization for isomaltulose production, leading to an isomaltulose conversion rate of 50–60% by using transglutaminase cross-linking in cell immobilization [20]. By comparing with different treatments of Erwinia sp. D12 strain, a maximum conversion (53–59%) was obtained using granules of sonicated immobilized cells [21]. In addition to the abovementioned microorganisms, some other microorganisms were also used for isomaltulose production by cell immobilization utilizing alginate entrapment, such as Klebsiella sp [30, 42], P. rubrum [12] and recombinant E. coli [27, 29]. By using immobilized Klebsiella sp. LX3 cells, more than 87% of isomaltulose, was obtained [30]. Immobilized pellets of P. rubrum CBS574.77 in calcium alginate led to a higher isomaltulose conversion rate (more than 90%) [12]. In addition, recombinant E. coli cells producing SIase from E. rhapontici NX-5 were also immobilized, which showed productivity of 0.45 g isomaltulose g pellet−1 h−1 under 30 batches [29].

S. plymuthica ATCC15928 has also been widely employed to produce isomaltulose. Chitosan cross-linking with glutaraldehyde, another simple and effective cell immobilization method, was developed for forming immobilized S. plymuthica ATCC15928 cells, which resulted in the highest conversion rate of isomaltulose (94%) [23]. The perfect operational stability of immobilized cells was also achieved with a half-life of 155 days. Immobilized S. plymuthica ATCC15928 cells in hollow fiber bioreactors were used to produce isomaltulose, leading to specific productivity of 16.8 g m−2 h−1 and a half-life (42 days) of immobilized enzymes [22]. Furthermore, immobilized cells of S. plymuthica ATCC15928 in calcium alginate were studied for isomaltulose production in a packed bed bioreactor, and the highest conversion rate of isomaltulose (81.26%) was obtained during seven days in a continuous process [43].

6.2 SIase Immobilization

Although cell immobilization has many advantages, it also has some disadvantages compared with enzyme immobilization, such as cell autolysis and lower product purity caused by cell metabolism. Immobilized SIases from different microbial sources have also been carried out to enhance the production efficiency of isomaltulose in recent years (Table 7). The commonly used methods of SIase immobilization, include crosslinking, embedding, and adsorption (Table 7). Contesini et al. developed two different techniques to immobilize the crude SIase from Erwinia sp. D12 by entrapment (low methoxyl pectin microcapsules) and adsorption (Celite), achieving isomaltulose conversion rate of 30% and 60%, respectively [10]. By immobilizing SIase from Erwinia sp 12 onto Celite, Contesini et al. [9] obtained an isomaltulose conversion rate of 65% by immobilized SIase under the optimal reaction conditions. With a strong constitutive promoter, a high level of secreted SIase was obtained by overexpressing the SIase gene from P. dispersa UQ68J in Y. lipolytica. Then by immobilizing the recombinant SIase onto polyvinyl alcohol-alginate, the stability of the SIase was significantly improved, resulting in isomaltulose production of 620.7 g L−1 with a yield of 0.96 g g−1. The conversion rate of sucrose remained above 90% after 13 batches under optimal conditions [80]. In addition to the immobilization methods of entrapment and adsorption, an innovative approach was developed for immobilizing SIase on ε-poly-L-lysine modified mesoporous [70]. The immobilized SIase displayed good operational stability with a half-life period up to 114 h under continuous reaction, and the conversion rate of sucrose remained at around 95% after 16 batches. The stability and reusability of SIase PalI from Klebsiella sp. LX3 were studied by sodium alginate embedding and glutaraldehyde crosslinking. The results showed that the residual activity of the immobilized enzyme by sodium alginate embedding and glutaraldehyde crosslinking was more than 95% and 60%, respectively, compared with that of the free enzyme (below 30%) after stored at 4 oC for 20 days. In addition, the residual enzyme activity by glutaraldehyde crosslinking was 80% after 12 batches for reuse [63]. SIase from recombinant B. pumilus was immobilized by adsorption crosslinking with chitosan as carrier and glutaraldehyde as a cross-linking agent. The maximum conversion rate of isomaltulose reached 87.8% under optimal conversion conditions [36].

7 Conclusions and Future Prospects

Nowadays, the market demand for isomaltulose, as a safe sucrose substitute, is increasing rapidly. SIase is responsible for the commercial biological production of isomaltulose from sucrose. The transformation from sucrose to isomaltulose by SIase or microbial cells harboring SIase gene has received extensive attention in the industry. Significant progress has been made in the biological production of isomaltose; however, some problems still exist in industrial production, such as the low secretion level from food safety grade strain, weak thermal stability, and poor application performance of SIase. To solve the above problems, attempts can be made from two aspects of strain and enzyme. In consideration of the high protein expression capacity, approximately one-third of protein for therapeutics is produced in E. coli. Given contamination with large amounts of endotoxins by E. coli [13] and the application characteristics of isomaltulose in the food industry, E. coli-based cell-free protein synthesis, a promising platform for protein expression, can be used [67]. In addition to E. coli, studies on the heterogeneous expression and secretion of SIase have been tried in food-grade safety microorganisms, but the secretion levels of SIase are still low, requiring urgent improvement in genetic engineering or fermentation condition optimization. For example, the recombinant proteins in corynebacterium glutamicum were enhanced by constructing a bicistronic gene expression system [55].

Compared to the immobilized cell, the immobilization technologies of SIase for isomaltulose production are relatively immature, which need to be improved. Moreover, some SIase possess poor thermal stability, and although some SIases were modified with related protein engineering, the improvement was not noticeable. To improve the application performance of SIase in industrial production, key sites of SIase need to be further explored and modified.

References

Ahn SJ, Yoo JH, Lee HC, Kim SY, Noh BS, Kim JH, Lee JK (2003) Enhanced conversion of sucrose to isomaltulose by a mutant of Erwinia rhapontici. Biotechnol Lett 25:1179–1183

Amano T, Sugiyama Y, Okumura J, Fujii N, Kenny GP, Nishiyasu T, Inoue Y, Kondo N, Sasagawa K, Enoki Y (2019) Effects of isomaltulose ingestion on postexercise hydration state and heat loss responses in young men. Exp Physiol 104:1494–1504

Aroonnual A, Nihira T, Seki T, Panbangred W (2007) Role of several key residues in the catalytic activity of sucrose isomerase from Klebsiella pneumoniae NK33-98-8. Enzyme Microb Technol 40:1221–1227

Cha J, Jung J, Park S, Cho M, Seo D, Ha S, Yoon J, Lee O, Kim Y, Park C (2009) Molecular cloning and functional characterization of a sucrose isomerase (isomaltulose synthase) gene from Enterobacter sp. FMB-1. J Appl Microbiol 107:1119–1130

Cheetham PS (1984) The extraction and mechanism of a novel isomaltulose-synthesizing enzyme from Erwinia rhapontici. Biochem J 220:213–220

Cheetham PSJ (1987) Production of isomaltulose using immobilized microbial cells. Methods Enzymol 136:432–454

Chen YP, Hwang IE, Lin CJ, Wang HJ, Tseng CP (2012) Enhancing the stability of xylanase from Cellulomonas fimi by cell-surface display on Escherichia coli. J Appl Microbiol 112(3):455–463

Cheng S, Duan XG, Wu J (2015) Studies on the preparation of sucrose isomerase and its application for the production of isomaltulose. Food Ferment Ind 41(5):41–47

Contesini FJ, de Oliveira CP, Grosso CRF, Sato HH (2013) Single-step purification, characterization and immobilization of a sucrose isomerase from Erwinia sp. Biocatal Agric Biotechnol 2:322–327

Contesini FJ, Ibarguren C, Grosso CRF, de Oliveira CP, Sato HH (2012) Immobilization of glucosyltransferase from Erwinia sp. using two different techniques. J Biotechnol 158:137–143

de Groot E, Schweitzer L, Theis S (2020) Efficacy of isomaltulose compared to sucrose in modulating endothelial function in overweight adults. Nutrients 12:141

de Oliva-Neto P, Menão PT (2009) Isomaltulose production from sucrose by Protaminobacter rubrum immobilized in calcium alginate. Bioresource Technol 100:4252–4256

de Vries I, Schreiber S, Boßmann D, Hellmann Z, Kopatz J, Neumann H, Beutel S (2018) Single-use membrane adsorbers for endotoxin removal and purification of endogenous polysialic acid from Escherichia coli K1. Biotechnol Rep 17:110–116

Dong Qilei W, Lingqia LS, Qiaoling Z (2020) Stucture-guided engineering of a Thermobifida fusca cutinase for enhanced hydrolysis on natural polyester substate. Bioresour Bioprocess. https://doi.org/10.1186/s40643-020-00324-8

Duan X, Cheng S, Ai Y, Wu J (2016) Enhancing the thermostability of Serratia plymuthica sucrose isomerase using B-factor-directed mutagenesis. PLoS ONE 11(2):e0149208

Guan C, Cui W, Cheng J et al (2015) Construction and development of an auto-regulatory gene expression system in Bacillus subtilis. Microb Cell Factories. https://doi.org/10.1186/s12934-015-0341-2

Guo L, Diao W, Gao C, Hu G, Ding Q, Ye C, Chen X, Liu J, Liu L (2020) Engineering Escherichia coli lifespan for enhancing chemical production. Nat Catal 3:307–318

Harish B, Uppuluri KB (2017) Sucrose Transforming Enzymes. Microb Enzyme Technol Food App 102–120

Huang J, Hsu L, Su Y (1998) Conversion of sucrose to isomaltulose by Klebsiella planticola CCRC 19112. J Ind Microbiol Biot 21:22–27

Kawaguti HY, Carvalho PH, Figueira JA (2011) Sato HH (2011) Immobilization of Erwinia sp D12 cells in alginate-gelatin matrix and conversion of sucrose into isomaltulose using response surface methodology. Enzyme res 1:791269

Kawaguti HY, Sato HH (2011) Production of isomaltulose obtained by Erwinia sp. cells submitted to different treatments and immobilized in calcium alginate. Food Sci Technol 31:257–263

Krastanov A, Blazheva D, Stanchev V (2007) Sucrose conversion into palatinose with immobilized Serratia plymuthica cells in a hollow-fibre bioreactor. Process Biochem 42:1655–1659

Krastanov A, Blazheva D, Yanakieva I, Kratchanova M (2006) Conversion of sucrose into palatinose in a batch and continuous processes by immobilized Serratia plymuthica cells. Enzyme Microb Technol 39:1306–1312

Lee GY, Jung JH, Seo DH, Hansin J, Ha SJ, Cha J, Kim YS, Park CS (2011) Isomaltulose production via yeast surface display of sucrose isomerase from Enterobacter sp. FMB-1 on Saccharomyces cerevisiae. Bioresource Technol 102:9179–9184

Lee HC, Kim JH, Kim SY, Lee JK (2008) Isomaltose production by modification of the fructose-binding site on the basis of the predicted structure of sucrose isomerase from “Protaminobacter rubrum”. Appl Environ Microbiol 74:5183–5194

Li L, Wang H, Cheng H, Deng Z (2017) Isomaltulose production by yeast surface display of sucrose isomerase from Pantoea dispersa on Yarrowia lipolytica. J Funct Foods 32:208–217

Li S, Cai H, Qing Y, Ren B, Xu H, Zhu H, Yao J (2011) Cloning and characterization of a sucrose isomerase from Erwinia rhapontici NX-5 for isomaltulose hyperproduction. Appl Biochem Biotechnol 163:52–63

Li S, Ren B, Lin L, Xu H, Cai H (2011) Cloning expression and application of sucrose isomerase from Erwinia rhapontici. J Nanjing U Technol: Nat Sci Ed 33:84–89

Li S, Xu H, Yu J, Wang Y, Feng X, Ouyang P (2013) Enhancing isomaltulose production by recombinant Escherichia coli producing sucrose isomerase: culture medium optimization containing agricultural wastes and cell immobilization. Bioproc Biosyst Eng 36:1395–1405

Li X, Zhao C, An Q, Zhang D (2003) Substrate induction of isomaltulose synthase in a newly isolated Klebsiella sp. LX3. J Appl Microbiol 95:521–527

Lina B, Jonker D, Kozianowski G (2002) Isomaltulose (Palatinose®): a review of biological and toxicological studies. Food Chem Toxicol 40:1375–1381

Lipski A, Watzlawick H, Ravaud S, Robert X, Rhimi M, Haser R, Mattes R, Aghajari N (2013) Mutations inducing an active-site aperture in Rhizobium sp. sucrose isomerase confer hydrolytic activity. Acta Crystallogr D Biol Crystallogr 69:298–307

Liu H, Xing X, Lu F, Li Y (2016a) Functional Modification of the Substrate-Binding Site for Isomaltulose Production Based on Predicted Structure of Sucrose Isomerase from Pantoea dispersa UQ68 J. International Conference on Applied Biotechnology. Pages 59–68

Liu J, Wu J, Chen S (2016) Expression and production optimization of sucrose isomerase from Pantoea dispersa in Escherichia coli. Chin J Biotechnol 32:1070–1080

Mateo-Gallego R, Pérez-Calahorra S, Lamiquiz-Moneo I, Marco-Benedí V, Bea AM, Fumanal AJ, Prieto-Martín A, Laclaustra M, Cenarro A, Civeira F (2020) Effect of an alcohol-free beer enriched with isomaltulose and a resistant dextrin on insulin resistance in diabetic patients with overweight or obesity. Clin Nutr 39:475–483

Menghua G, Cheng S, Wu J et al (2019) Immobilization of Sucrose Isomerase by Adsorption and Crosslinking Method for the Synthesis of Isomaltu(l)ose. J Food Sci Biotechnol 38(4):104–110

Miyata Y, Sugitani T, Tsuyuki K-i, Ebashi T, Nakajima Y (1992) Isolation and characterization of Pseudomonas mesoacidophila producing trehalulose. Biosci Biotech Bioch 56:1680–1681

Morello E, Bermudez-Humaran LG, Llull D, Sole V et al (2008) Lactococcus lactis, an efficient cell factory for recombinant protein production and secretion. J Mol Microbiol Biotechnol 14:48–58

Mu W, Li W, Wang X, Zhang T, Jiang B (2014) Current studies on sucrose isomerase and biological isomaltulose production using sucrose isomerase. Appl Microbiol Biot 98:6569–6582

Mundra P, Desai K, Lele S (2007) Application of response surface methodology to cell immobilization for the production of palatinose. Bioresource Technol 98:2892–2896

Nagai-Miyata Y, Tsuyuki K-i, Sugitani T, Ebashi T, Nakajima Y (1993) Isolation and characterization of a trehalulose-producing strain of Agrobacterium. Biosci Biotech Bioch 57:2049–2053

Orsi DC, Kawaguti HY, Sato HH (2009) Glucosyltransferase production by Klebsiella sp. K18 and conversion of sucrose to palatinose using immobilized cells. Braz J Microbiol 40:66–72

Orsi DC, Sato HH (2016) Isomaltulose production using free and immobilized Serratia plymuthica cells. African J Biotechnol 15:835–842

Park JY, Jung JH, Seo DH, Ha SJ, Yoon JW, Kim YC, Shim JH, Park CS (2010) Microbial production of palatinose through extracellular expression of a sucrose isomerase from Enterobacter sp. FMB-1 in Lactococcus lactis MG1363. Bioresource Technol 101:8828–8833

Pilak P, Schiefner A, Seiboth J, Öhrlein J, Skerra A (2020) Engineering a highly active sucrose isomerase for enhanced product specificity using a ‘battleship’strategy. ChemBioChem 21:1–10

Pontrelli S, Chiu TY, Lan EI, Chen FY, Chang PC, Liao JC (2018) Escherichia coli as a host for metabolic engineering. Metab Eng 50:16–46

Pravin D, Ashish M, Maneesha S (2017) Isomaltulose (Palatinose) – An emerging carbohydrate. Food bioscience 18:46–52

Ravaud S, Robert X, Watzlawick H, Haser R, Mattes R, Aghajari N (2007) Trehalulose synthase native and carbohydrate complexed structures provide insights into sucrose isomerization. J Biol Chem 282:28126–28136

Ravaud S, Watzlawick H, Haser R, Mattes R, Aghajari N (2005) Expression, purification, crystallization and preliminary X-ray crystallographic studies of the trehalulose synthase MutB from Pseudomonas mesoacidophila MX-45. Acta Crystallogr F 61:100–103

Roy SK, Iyappan S, Varghese S, Addala AD, Agarwal M, Raju KR, Pandey B (2017) Polynucleotide for recombinant expression of isomaltulose synthase. Patent No US 9(695): 411B2

Rubio-Arraez S, Ferrer C, Capella JV, Ortolá MD, Castelló ML (2017) Development of lemon marmalade formulated with new sweeteners (isomaltulose and tagatose): Effect on antioxidant, rheological and optical properties. J Food Process Eng 40(2):e12371

Shyam S, Ramadas A, Chang SK (2018) Isomaltulose: Recent evidence for health benefits. J Funct Foods 48:173–178

Sneha H, Beulah K, Murthy PS (2019) Enzyme immobilization methods and applications in the food industry. Enzyme Food Technol 645–658

Stéphanie R, Xavier R, Hildegard W, Richard H, Ralf M, Nushin A (2009) Structural determinants of product specificity of sucrose isomerases. FEBS Lett 583:1964–1968

Sun M, Gao X, Zhao Z, Li A, Wang Y, Yang Y, Liu X, Bai Z (2020) Enhanced production of recombinant proteins in Corynebacterium glutamicum by constructing a bicistronic gene expression system. Microb Cell Factories 19:1–12

Thorsted A, Tano E, Kaivonen K, Sjölin J, Friberg LE, Nielsen EI (2020) Extension of pharmacokinetic/pharmacodynamic (PK/PD) time-kill studies to include LPS/endotoxin release from E. coli exposed to cefuroxime. Antimicrob Agents Ch 64(4):02070–02119

Tian Y, Deng Y, Zhang W, Mu W (2019) Sucrose isomers as alternative sweeteners: properties, production, and applications. Appl Microbiol Biot 103:8677–8687

Tsuyuki K-i, Sugitani T, Miyata Y, Ebashi T, Nakajima Y (1992) Isolation and characterization of isomaltulose-and trehalulose-producing bacteria from Thailand soil. J Gen App Microbiol 38:483–490

Véronèse T, Perlot P (1999) Mechanism of sucrose conversion by the sucrose isomerase of Serratia plymuthica ATCC 15928. Enzyme Microb Technol 24:263–269

Verma ML, Kumar S, Das A, Randhawa JS, Chamundeeswari M (2020) Chitin and chitosan-based support materials for enzyme immobilization and biotechnological applications. Environ Chem Lett 18:315–323

Wang Bingbing ZY, Xianzhen Li (2019) Comparison of Immobilization Methods of Sucrose Isomerase PalI with Embedding and Crosslinking. J Food Ence Technol 37(1):36–40

Wang C, Li S, Xu H, Wei Y, Cai H (2011) Optimization of Fermentation Medium of Sucrose Isomerase by Recombinant Escherichia coli through Response Surface Method. Chin Biotechnol 31:92–97

Wang ZP, Wang QQ, Liu S, Liu XF, Yu XJ, Jiang YL (2019) Efficient conversion of cane molasses towards high-purity isomaltulose and cellular lipid using an engineered Yarrowia lipolytica strain in fed-batch fermentation. Molecules 24:1228

Wang GY, Zhang Y, Chi Z, Liu GL, Wang ZP, Chi ZM (2015) Role of pyruvate carboxylase in accumulation of intracellular lipid of the oleaginous yeast Yarrowia lipolytica ACA-DC 50109. Appl Microbiol Biotechnol 99(4):1637–1645

Walter t, Marhöfer S, Dörr T (2016) Isomaltulose in fondants. Patent No.: US 9,510,607 B2

Weiden Hagen R, Lorenz S (1957) Ein neues bakterielles Umwandlungsprodukt der Saccharose. Angew Chem 69(20):641–641

Wilding KM, Hunt JP, Wilkerson JW, Funk PJ, Swensen RL, Carver WC, Christian ML, Bundy BC (2019) Endotoxin-free E. coli-based cell-free protein synthesis: Pre-expression endotoxin removal approaches for on-demand cancer therapeutic production. Biotechnol J 4(3):1800271

Wu L, Birch R (2004) Characterization of Pantoea dispersa UQ68J: producer of a highly efficient sucrose isomerase for isomaltulose biosynthesis. J Appl Microbiol 97:93–103

Wu L, Birch RG (2005) Characterization of the highly efficient sucrose isomerase from Pantoea dispersa UQ68J and cloning of the sucrose isomerase gene. Appl Environ Microbiol 71:1581–1590

Wu L, Liu Y, Chi B, Xu Z, Feng X, Li S, Xu H (2015) An innovative method for immobilizing sucrose isomerase on ε-poly-l-lysine modified mesoporous TiO2. Food Chem 187:182–188

Wu L, Wu S, Qiu J, Xu C, Li S, Xu H (2017) Green synthesis of isomaltulose from cane molasses by Bacillus subtilis WB800-pHA01-palI in a biologic membrane reactor. Food Chem 229:761–768

Xu Z, Li S, Li J, Li Y, Feng X, Wang R, Xu H, Zhou J (2013) The structural basis of Erwinia rhapontici isomaltulose synthase. PLoS ONE 8(9):e74788

Yang SY, Choi TR, Jung HR, Park YL, Han YH, Song HS, Bhatia SK, Park K, Ahn JO, Jeon WY (2019) Production of glutaric acid from 5-aminovaleric acid by robust whole-cell immobilized with polyvinyl alcohol and polyethylene glycol. Enzyme Microb Technol 128:72–78

Yang X, Wu L, Li A, Ye L, Zhou J, Yu H (2020) The engineering of decameric d-fructose-6-phosphate aldolase A by combinatorial modulation of inter-and intra-subunit interactions. Chem Commun 56:7561–7564

Zhan Y, Zhu P, Liang J, Xu Z, Feng X, Liu Y, Xu H, Li S (2020) Economical production of isomaltulose from agricultural residues in a system with sucrose isomerase displayed on Bacillus subtilis spores. Bioproc Biosyst Eng 43:75–84

Zhang D, Li N, Lok SM, Zhang LH, Swaminathan K (2003a) Isomaltulose synthase (PalI) of Klebsiella sp. LX3 crystal structure and implication of mechanism. J Biol Chem 278:35428–35434

Zhang D, Li X, Zhang LH (2002) Isomaltulose synthase from Klebsiella sp. strain LX3: gene cloning and characterization and engineering of thermostability. Appl Environ Microbiol 68:2676–2682

Zhang D, Li N, Lok SM, Zhang LH, Swaminathan K (2003b) Isomaltulose synthase (PalI) of Klebsiella sp. LX3. Crystal structure and implication of mechanism. J Biol Chem 278:35428–35434

Zhang H, Yang F, Xue T (2018a) Screening mutation of high isomaltulose producing strain using atmospheric and room temperature plasmas. Journal of Dalian Polytechnic University:2

Zhang P, Wang ZP, Liu S, Wang YL, Zhang ZF, Liu XM, Du YM, Yuan XL (2019) Overexpression of secreted sucrose isomerase in Yarrowia lipolytica and its application in isomaltulose production after immobilization. Int J Biol Macromol 121:97–103

Zhang P, Wang ZP, Sheng J, Zheng Y, Ji XF, Zhou HX, Liu XY, Chi ZM (2018) High and efficient isomaltulose production using an engineered Yarrowia lipolytica strain. Bioresource Technol 265:577–580

Zheng Y, Wang Z, Ji X, Sheng J (2019) Display of a sucrose isomerase on the cell surface of Yarrowia lipolytica for synthesis of isomaltulose from sugar cane by-products. 3 Biotech 9(5):179

Zou LWJ, Chen S (2019) Expression and fermentation optimization of recombinant sucrose isomerase in Brevibacillus choshinensis. J Food Sci Biotechnol 38(1):22–28

Acknowledgements

Not applicable

Funding

This study was funded by financial support from the Natural Science Foundation of Jiangsu Province (BK20170459), China; the National Natural Science Foundation of China (21808075); All authors are grateful to their representative institutes for providing literature facilities.

Author information

Authors and Affiliations

Contributions

Conceptualization, LL Literature review, LL Writing-Original Draft Preparation, LL, and MB Figures, LL, Tables, LL, Writing-Review & Editing, LL, and MB Revisions & Final editing, LL, and MB

Corresponding author

Ethics declarations

Conflict of interests

The authors report no conflicting interest in any capacity, competitive or financial.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, L., Bilal, M., Luo, H. et al. Studies on Biological Production of Isomaltulose Using Sucrose Isomerase: Current Status and Future Perspectives. Catal Lett 151, 1868–1881 (2021). https://doi.org/10.1007/s10562-020-03439-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-020-03439-x