Abstract

Metalporphyrin-based porous polymers supporting high dispersed Pd nanoparticle (NP) catalysts (HUST-1-Pd) were prepared with a novel solvent-knitting hyper-crosslinked polymer method using 5-, 10-, 15-, and 20-tetraphenylporphyrin (TPP) as building blocks. The N2 sorption isotherms of the catalysts show that the HUST-1-Pd possesses many ultra-micropores and continuous mesopores. The NPs are assembled on tetraphenylporphyrin structures and show Pd-N4 composition-dependent catalysis for methanolysis of ammonia borane (AB) and hydrogenation of aromatic nitro compounds to primary amines in methanol solutions at room temperature. The nano-palladium reduced by NaBH4 has efficient catalytic activity for AB methanolysis. A variety of R-NO2 derivatives were reduced selectively into R-NH2 via palladium catalyzed tandem reactions with 5–30 min of reaction time with conversion yields reaching up to 90%. The derivatives also give excellent recycling performance (more than 10 times). Furthermore, the turnover frequency (TOF) can reach 87,209 h−1. The HUST-1-Pd compounds represent a unique metal catalyst for hydrogenation reactions in a green environment without using pure hydrogen.

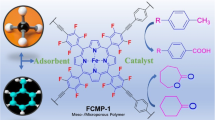

Graphic Abstract

A monodisperse Pd NPs embed in porphyrin-based microporous organic polymer was reported to catalyse the tandem dehydrogenation of ammonia borane and hydrogenation of R-NO2 to R-NH2 at room temperature. The catalyst is efficient and reusable in an environment-friendly process with short reaction times and high yields.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Aniline and its derivatives are important raw chemical materials with more than 4,000,000 tons produced every year [1]. They are used widely for the synthesis of dyes, polymers, agrochemicals, pharmaceuticals, and various fine chemicals [2, 3]. One common route for their preparation is the reduction of their corresponding nitro derivatives in a hydrogen atmosphere [4, 5]. However, hydrogen is hardly dissolvable in a nitro compound solution and is dangerous for transport. The need for an easily transportable source of hydrogen has attracted considerable attention in the context of novel environmentally benign energy sources. We hypothesize that an opportunity exists to empty a “hydrogen storage materials” as a readily available hydrogen source [6]. In this context and in efforts to look ahead for alternatives to petroleum-based fuels, ammonia borane (H3N-BH3, AB) appears attractive in view of its high thermal stability and hydrogen content (19.6% by weight) [7]. Recent reports have focused on several aspects of AB as a hydrogen source and the means to control its H2 release [8]. A large number of studies have reported applications of AB in hydrogenation reactions catalyzed by heterogeneous metal support porous materials like zeolites [9, 10], porous carbon [11], and metal–organic frameworks (MOFs) [12,13,14]. Experimental investigations have demonstrated that hydrogenation of porous catalytic materials is affected by their H2 capture capacity with the reason being that low H2 capture capacity of porous materials decreases the H2 concentrations near the catalytic sites’ hydrogenation performance [15,16,17]. Therefore, there is still a great need to search for new types of heterogeneous catalysts that possess a high H2 adsorption capacity to efficiently ensure hydrogenation under ambient conditions.

To improve the H2 adsorption capacity of porous materials, several strategies can be used, such as increasing surface area, tuning pore size, and introducing H2-philic active sites [18] such as heteroatoms, metal ions and functional groups. Distinguished from other porous materials such as zeolites, porous carbon, and MOFs, the inherent structural features of MOPs show that they are composed of pure organic elements that endow them with high chemical stability, adjustable compositions, and synthetic diversity, which make them more competitive in optimizing H2 adsorption capacity for hydrogenation of nitro compounds. Over the past decade, numerous MOP materials acting as heterogeneous hydrogenation catalyst have been developed [19,20,21]. However, only a few MOPs with high H2 capture have been reported thus far [22, 23]. Therefore, the development of novel MOP materials with a high H2 capacity as a heterogeneous catalyst for efficient hydrogenation under ambient conditions is still highly desired.

Porphyrins are ideal building blocks of porous materials containing nitrogen atoms and a large π-conjugated system that not only enhances their interactions with H2, but also aid in metal ion complexation, demonstrating their potential applications in gas storage and heterogeneous catalysis [24]. Palladium-based catalysts have been shown to facilitate the dehydrogenation of AB and selectively hydrogenate a variety of substrates. Therefore, a catalytic tandem reaction in which Pd serves a dual role to catalyze the dehydrogenation of AB while hydrogenating R-NO2 would be an efficient way to generate R-NH2. Meanwhile, the Pd-porphyrin complexes have been proven to be a series of homogenous catalysts in hydrogenation reactions [25, 26]. Recently, we found a simple and low-cost solvent-knitting hyper-crosslinked polymer method that can knit aromatic compounds to obtain ultra-microporous networks and obviously improve the metal dispersion of knitting materials [27]. Taking these advantages into account, the HUST-1 with ultra-micropores and catalytic activity sites was successfully knitted by using dichloromethane as the external crosslinker and 5-, 10-, 15-, and 20-tetraphenylporphyrin as building blocks under AlCl3 catalysis [28]. After incorporating Pd into the centered square-planar coordination site of porphyrin, the catalyst HUST-1-Pd not only possesses high dispersity of Pd nano particles, but also shows excellent catalytic efficiency for hydrogenation of nitro compounds in the presence of AB and NaBH4. What is more, the catalyst system holds high recycling potential at room temperature and atmospheric pressure.

2 Results and Discussion

The chemical structures of HUST-1 were confirmed by Fourier transform infrared (FTIR) spectroscopy and solid-state 13C cross-polarization magic-angle spinning (CP-MAS) NMR (Supporting Information, Fig. S1), From 13C CP/MAS NMR of HUST-1, the resonance peaks are observed at 127.7 and 138.2 ppm, which are assigned to carbon atoms in the benzene and porphyrin rings, respectively (Fig. S1). The chemical shift at 37.2 ppm signifies the existence of methylene carbon formed by Friedel–Crafts reaction [28]. The FTIR spectra of polymer displays a series of bands around 1650–1600 cm−1 that were assigned to the −C=N– stretching band. The bands around 1250–950 cm−1 and 900–650 cm−1 were attributed to benzene skeleton stretching C–H out-of-plane bending and in-plane bending vibrations of the benzene ring, respectively (Fig. 1, red line).

Following the disappearance of C–H stretching vibrations of the aromatic ring, strong C–H stretching vibrations of methylene near 2960–2920 cm−1 can be easily observed, which indicates the formation of methylene linkage (Fig. 1, blue line). Based on above characterizations, the formation of HUST-1 can be confirmed and the chemical structure of HUST-1-Pd remains after incorporation of Pd2+ and reduction by NaBH4.

The crystal structure of HUST-1-Pd was further studied using power XRD and the typical PXRD pattern is depicted in Fig. 2. In the XRD pattern, one reflection at 2θ = 40° is ascribable to the (111) plane of an fcc crystal structure of Pd(0) [29]. Using the Scherrer equation, we calculated the crystal size of the Pd NPs to be 4.2 nm.

Beside the peak belonging to fcc-Pd, another widening peak appeared at 2θ = 19.5° and is attributed to the amorphous structure of the HUST-1 support. However, compared to original peak at 2θ = 23.2° of HUST-1, the peak migrates about 4°. The results illustrate the support the Pd change in the structure of the metalloporphyrin in the polymer. To determine the Pd content of HUST-1-Pd for catalytic applications, atomic absorption spectroscopy (AAS) analysis was performed on the samples and Pd content was found to be 0.73 wt%. This value was used to determine the loading ratio of HUST-1-Pd for catalytic applications.

The porous properties of HUST-1-Pd and HUST-1 were investigated by nitrogen adsorption analysis at 77 K (Fig. 3). According to IUPAC classification [30], HUST-1-Pd and HUST-1 all showed type I nitrogen adsorption isotherms as shown in Fig. 3a. The high uptake at very low pressures (0–0.1 bar) indicates the materials with abundant micropores. With increasing pressure, the nitrogen uptake featured almost no increased, indicating the existence of little external surface area as evidenced by the presence of very small particles. Therefore, HUST-1 has a predominantly microporous structure in its framework. The sharp increase in the nitrogen uptake at high relative pressure may be attributed in part to interparticulate porosity associated with the meso-structures of the samples. A surface area of 769 and 779 m2g−1 were obtained by applying the Brunauer–Emmett–Teller (BET) model for HUST-1-Pd and HUST-1, respectively. The pore size distribution diagram based on the density functional theory (DFT) method in Fig. 3b, c also showed a typical micro/mesoporous nature of the material, which agreed with the shape of nitrogen sorption isotherms and HR-TEM analysis (Fig. 4c). The hierarchical pore structure and abundant Pd of HUST-1-Pd not only enhances the interaction between the pore walls and the substrate, but is also favorable for catalysis processes. The microporous structure could adsorb and catalyze the reactants, and mesopores are beneficial for accelerating the mass transfer of reactants and products. Compared to HUST-1, the mesopores of HUST-1-Pd sometimes disappears due to the palladium particles occupying some pores.

The morphology and porosity of HUST-1 and HUST-1-Pd were recorded by SEM (Fig. 4a, b). The polymers all exhibited irregular particle-aggregated morphologies that are a property of porousness. The results agree with the characterization of the N2 adsorption–desorption isotherms test. After cooperation with Pd, the morphology of HUST-1-Pd is almost unchanged (Fig. 4b). SEM–EDX spectrum analyses collected from the selected region of the images given in Fig. 4c, d confirms the presence of Pd and N on the support materials.

The TEM images (Fig. 5) indicate that the as synthesized Pd NPs are highly dispersed on the HUST-1 surface and the particle size of Pd NPs was measured and the diameter was found to be about 5.5 nm (Fig. 5b). This size is larger than that measured from XRD, indicating that the as-synthesized NPs are in a polycrystalline structure. A typical distance between crystal fringes of 0.231 nm was calculated from the HR-TEM images (Fig. 5d), which is close to the lattice spacing of the (111) planes of the fcc crystal of Pd (0.223 nm) [31], indicating that the Pd(0) has indeed formed.

To gain further insight into the compositions and confirm the oxidation states of the Pd element, X-ray photoelectron spectroscopy (XPS) analysis of HUST-1-Pd was performed (Fig. 6). The XPS survey spectrum in Fig. 6a clearly shows the presence of Pd in HUST-1-Pd, in addition to carbon, oxygen, and nitrogen. As shown in Fig. 6b, the binding energy for Pd(0) 3d3/2 and 3d5/2 is 341.4 and 336.1 eV, respectively, indicating the presence of zero-valent pd in HUST-1-Pd. However, the Pd(II) still exists at the binding energy of 343.8 and 338.6 eV. We assume that the Pd(II) species were coordinated to Pd-N4 and coated by zero-valent pd so the Pd(II) has been not reduced to Pd(0) [32]. The N1′s binding energy of HUST-1 (Fig. 6d) shows two types of nitrogen: one at 399.1 eV for nitrogen in the free-based porphyrin ring, and another at 400.4 eV for the free secondary amine (–C=C–NH) [33]. However, HUST-1-Pd exhibits N1 peaks at 400.4 and 399.8 eV (Fig. 6c), which are formed due to the coordination of Pd species with porphyrin rings. Notably, as observed from the N1s’ binding energy of HUST-1-Pd, the absence of the peak at 399.1 eV indicates complete metalation in the porphyrin rings [34]. These results confirm that this bottom-up strategy could facilitate a metalloporphyrin-based porous organic polymer with a higher density active site compared to that of the previously reported porphyrin-based polymers.

2.1 Catalytic Properties

Reduction of nitroarenes plays an important role in modern chemistry. To evaluate the catalytic activity of HUST-1-Pd, we chose the tandem reaction of AB dehydrogenation and nitro compound hydrogenation as a model reaction. The reaction was initiated by adding AB to the solution in the flask containing HUST-1-Pd and nitro compounds under magnetic stirring. Thin layer chromatography (TLC) was used to monitor the reaction process and gas chromatography-mass spectrometry (GC–MS) was used to quantify the reaction mixture changes. Nitrobenzene was employed as a model compound in the tandem catalysis over HUST-1-Pd to explore the optimized reaction parameters. Firstly, we tested the catalytic tandem reactions at room temperature in different solvents including water, methanol, ethanol, and mixtures at various ratios. The reaction optimization data is summarized in Table 1; we observed that the suitable solvent methanol and ethanol resulted in 58.3% and 70.4% yields, respectively (Table 1, entries 1 and 2). In water, ethylene glycol and acetonitrile (Table 1, entries 3–5) show low catalytic activity, but it almost has no yields when DMF is changed as the solvent (Table 1, entry 6). More interestingly, the change in the reaction environment from pure solvent to a water solution had a positive effect on the activity in HUST-1-Pd (Table 1, entries 7–9), a mixture of methanol and water (v:v = 2:3) was found to be the best solvent in the reaction. The reaction proceeded smoothly, and nitrobenzene was converted to aniline very rapidly in as short as 2 min with a real nitrobenzene/Pd molar ratio of 2941 at room temperature. The turnover frequency (TOF) was calculated to be 86,337 h−1.

With the optimized conditions, the catalytic results for the tandem reaction with diverse R-NO2 substrates over HUST-1-Pd are summarized in Table 2. All aromatic or aliphatic nitro compounds investigated were converted into their corresponding primary amines with excellent conversion yields (> 95%) in 5–30 min at room temperature. For example, aliphatic nitro compounds such as nitromethane were reduced in excellent yields in 2 min (Table 2, entry 1) and nitrobenzene was reduced to aniline quantitatively also in 2 min (Table 2, entry 2). The nitro groups in p-methyl, m-methyl, o-methoxy, m-chloride, and p-chloride-nitrobenzenes (Table 2, entry 3–7) were also reduce into the related amine products in nearly quantitative conversion yields in 10 min. The results illustrate that slight space steric hindrance was tolerated well in the hydrogenation of nitro compounds by HUST-1-Pd. Moreover, several electron-withdrawing and electron-donating nitroarene derivatives have also been successfully reduced by the presented hydrogenation protocol in 30 min, indicating the high substituent tolerance of the presented catalytic transfer hydrogenation protocol (Table 2, entries 8–10). On the other hand, the presented HUST-1-Pd catalyzed transfer hydrogenation showed almost no yields towards the reduction of benzyl chloride on the aromatic ring (Table 2, entry 11).

The stability and reusability of catalysts are of great importance in their practical application. We test the durability of HUST-1-Pd by performing the tandem reaction on nitrobenzene. The catalyst was separated after each reaction and washed with water/methanol for the next round of reactions. After the tenth consecutive use, the catalyst still showed a conversion yield higher than 95% in the same reaction times (Fig. 7), clearly demonstrating the recyclability and reusability of the catalyst. In addition, the Pd NPs retain high dispersion and their sizes were almost retained after 10 runs (Fig. 8), revealing the good confinement effect of HUST-1 based on its porous structure. The AAS results shows that negligible Pd species can be detected in the reacted solution, which reveals that the leaching of active sites almost does not occur during the reaction.

3 Conclusion

In summary, we have reported a facile route to prepare high-dispersed Pd NP support for porphyrin-based microporous organic polymers. The catalyst was efficient in catalyzing the tandem reaction of the dehydrogenation of AB and hydrogenation of R-NO2 to produce primary amines (R-NH2) at room temperature. In the series of aromatic or aliphatic nitro compounds tested, they were all reduced to the respective primary amines with excellent conversion yields in short reaction times (2–30 min). Furthermore, the catalyst could be easily separated and the yields achieved above 95% after 10 times of reuse. This demonstrates a new strategy to introduce highly-dispersed Pd NPs into porphyrin-based functional polymers through simple steps.

4 Experimental Section

4.1 Materials

Purchased from Aladdin chemical reagent Corp (Shanghai, China) were 5-, 10-, 15-, 20-teraphenylporphyrin and nitro compounds; they were used as received. Dichloromethane, ethanol, HCl, anhydrous aluminum chloride, palladium chloride, and NaBH4 were obtained from Sinopharm Chemical Reagent Co., Ltd. (Shanghai, China) and used as received. Unless otherwise noted, all reagents were obtained from commercial suppliers and used without further purification.

4.2 Preparation of HUST-1 Support Pd NPs

HUST-1 was prepared by using a well-established hyper-crosslinking method; the details of the HUST-1 synthesis procedure can be found in our previous reports [28]. Pd NPs support the HUST-1 by a NaBH4 reduction method. In the typical process, 10 mg of PdCl2 is dissolved in 5 mL of water with the addition of 1 mL aqueous HCl (0.1 mol/L) at room temperature with vigorous stirring. Then, 110 mg HUST-1 powder is added to the above mixture, and the slurry is stirred for 12 h and 5 mL NaBH4(0.5 M) solution is mixed with the slurry for 2 h. The catalyst was centrifugated until separation and washed by water, and lastly dried under vacuum at 60 °C for 12 h.

4.3 General Procedure for HUST-1-Pd Catalyzed Tandem Dehydrogenation of AB and Hydrogenation of Nitro Compounds

The nitro compounds (1 mmol) and HUST-1-Pd catalyst (5 mg) were mixed in 2 mL of a methanol water solution and stirred for 5 min in a 10 mL glass tube at room temperature. Next, AB (1 mmol) was added to the reaction mixture and the glass tube was closed. The reaction was then continued under vigorous stirring at room temperature for a certain time. The progress of the catalytic reaction was monitored by thin layered chromatography (TLC). Most reactions were completed in a time period of 5–30 min. After completion of the reaction, the catalysts were removed by centrifugation at 5000 rpm and washed three times with water and methanol. Then, the catalysts were allowed to dry for the next use. The solvent was removed by using a rotary evaporator; the crude residue was directly purified by column chromatography on silica gel using acetone. The yields of the reduced compounds were determined by 1H NMR with CDCl3 as the solvent depending on the product separated.

4.4 Characterization

FT-IR spectra were recorded on a Bruker Verter 70 Spectrometer using the KBr disk method. The products of hydrogenation were identified by 1HNMR spectra using a Bruker AV400 instrument in CDCl3. Chemical shifts were reported in parts per million (ppm) downfield from tetramethysilane (TMS). The morphologies were observed with a FEI Sirion 200 field SEM and transmission electron microscope (TEM). Pd content data was obtained using ASS on a Perkin Elmer AA-800 (USA). The X-ray photoelectron spectroscopy (XPS) data of samples were collected by Krato AXIS-ULTRA DLD-600 photoelectron spectrograph. N2 sorption properties and specific surface areas of samples were measured using a Micromeritics ASAP 2020 surface area and porosity analyzer. Before analysis, the samples were degassed at 110 °C for 8 h in a vacuum of 10−5 bar. Pore size distribution was calculated by N2 adsorption isotherms employing the Tarazona nonlocal density functional theory (NLDFT) model assuming a slit pore geometry. Total pore volumes were derived from nitrogen sorption isotherms at a relative pressure P/P0 = 0.995.

References

Yang F, Wang M, Liu W, Yang B, Wang Y, Luo J, Tang Y, Hou L, Li Y, Li Z, Zhang B, Yang W, Li Y (2019) Atomically dispersed Ni as the active site towards selective hydrogenation of nitroarenes. Green Chem 21:704

Yang Q, Chen YZ, Wang ZU, Xu Q, Jiang HL (2015) One-pot tandem catalysis over Pd@MIL-101: boosting the efficiency of nitro compound hydrogenation by coupling with ammonia borane dehydrogenation. Chem Commun (Camb) 51:10419

Westerhaus FA, Jagadeesh RV, Wienhöfer G, Pohl M-M, Radnik J, Surkus A-E, Rabeah J, Junge K, Junge H, Nielsen M (2013) Heterogenized cobalt oxide catalysts for nitroarene reduction by pyrolysis of molecularly defined complexes. Nat Chem 5:537

Yang X, Song K, Tan L, Hussain I, Li T, Tan B (2014) Hollow microporous organic capsules loaded with highly dispersed pt nanoparticles for catalytic applications. Macromol Chem Phys 215:1257

Luo L, Duan Z, Li H, Kim J, Henkelman G, Crooks RM (2017) Tunability of the adsorbate binding on bimetallic alloy nanoparticles for the optimization of catalytic hydrogenation. J Am Chem Soc 139:5538

Hartmann CE, Jurcik V, Songis O, Cazin CS (2013) Tandem ammonia borane dehydrogenation/alkene hydrogenation mediated by [Pd(NHC)(PR3)] (NHC = N-heterocyclic carbene) catalysts. Chem Commun (Camb) 49:1005

Rossin A, Peruzzini M (2016) Ammonia-borane and amine-borane dehydrogenation mediated by complex metal hydrides. Chem Rev 116:8848

Yao Q, Lu Z-H, Yang Y, Chen Y, Chen X, Jiang H-L (2018) Facile synthesis of graphene-supported Ni-CeOx nanocomposites as highly efficient catalysts for hydrolytic dehydrogenation of ammonia borane. Nano Res 11:4412

Yang K, Zhou L, Yu G, Xiong X, Ye M, Li Y, Lu D, Pan Y, Chen M, Zhang L, Gao D, Wang Z, Liu H, Xia Q (2016) Ru nanoparticles supported on MIL-53(Cr, Al) as efficient catalysts for hydrogen generation from hydrolysis of ammonia borane. Int J Hydrog Energy 41:6300

Richard J, Cid SL, Rouquette J, Van Der Lee A, Bernard S, Haines J (2016) Pressure-induced insertion of ammonia borane in the siliceous zeolite, silicalite-1F. J Phys Chem C 120:9334

Shang N, Zhou X, Feng C, Gao S, Wu Q, Wang C (2017) Synergetic catalysis of NiPd nanoparticles supported on biomass-derived carbon spheres for hydrogen production from ammonia borane at room temperature. Int J Hydrog Energy 42:5733

Wen M, Cui Y, Kuwahara Y, Mori K, Yamashita H (2016) Non-noble-metal nanoparticle supported on metal-organic framework as an efficient and durable catalyst for promoting H2 production from ammonia borane under visible light irradiation. ACS Appl Mater Interfaces 8:21278

Ma X, Zhou YX, Liu H, Li Y, Jiang HL (2016) A MOF-derived Co-CoO@N-doped porous carbon for efficient tandem catalysis: dehydrogenation of ammonia borane and hydrogenation of nitro compounds. Chem Commun (Camb) 52:7719

Zhou Y-H, Yang Q, Chen Y-Z, Jiang H-L (2017) Low-cost CuNi@MIL-101 as an excellent catalyst toward cascade reaction: integration of ammonia borane dehydrogenation with nitroarene hydrogenation. Chem Commun 53:12361

Altintas C, Erucar I, Keskin S (2018) High-throughput computational screening of the metal organic framework database for CH4/H2 separations. ACS Appl Mater Interfaces 10:3668

Luo S, Zhang Q, Zhang Y, Weaver KP, Phillip WA, Guo R (2018) Facile synthesis of a pentiptycene-based highly microporous organic polymer for gas storage and water treatment. ACS Appl Mater Interfaces 10:15174

Gu S, Guo J, Huang Q, He J, Fu Y, Kuang G, Pan C, Yu G (2017) 1,3,5-Triazine-based microporous polymers with tunable porosities for CO2 capture and fluorescent sensing. Macromolecules 50:8512

Bai Y, Chen BWJ, Peng G, Mavrikakis M (2018) Density functional theory study of thermodynamic and kinetic isotope effects of H2/D2 dissociative adsorption on transition metals. Catal Sci Technol 8:3321

Tang C, Zou Z, Fu Y, Song K (2018) Highly dispersed DPPF locked in knitting hyper-crosslinked polymers as efficient and recyclable catalyst. ChemistrySelect 3:5987

Su J, Chen J-S (2017) Synthetic porous materials applied in hydrogenation reactions. Microporous Mesoporous Mater 237:246

Chen X, Shen K, Ding D, Chen J, Fan T, Wu R, Li Y (2018) Solvent-driven selectivity control to either anilines or dicyclohexylamines in hydrogenation of nitroarenes over a bifunctional Pd/MIL-101 catalyst. ACS Catal 8:10641

Bera R, Mondal S, Das N (2018) Triptycene based microporous polymers (TMPs): efficient small gas (H2 and CO2) storage and high CO2/N2 selectivity. Microporous Mesoporous Mater 257:253

Wang M, Ye C, Xu M, Bao S (2018) MoP nanoparticles with a P-rich outermost atomic layer embedded in N-doped porous carbon nanofibers: self-supported electrodes for efficient hydrogen generation. Nano Res 11:4728

Eghbali P, Nişancı B, Metin Ö (2018) Graphene hydrogel supported palladium nanoparticles as an efficient and reusable heterogeneous catalysts in the transfer hydrogenation of nitroarenes using ammonia borane as a hydrogen source. Pure Appl Chem 90:327

Zhu W, Wang X, Li T, Shen R, Hao SJ, Li Y, Wang Q, Li Z, Gu ZG (2018) Porphyrin-based porous polyimide polymer/Pd nanoparticle composites as efficient catalysts for Suzuki-Miyaura coupling reactions. Polym Chem 9:1430

Kumar S, Thorat KG, Lee WZ, Ravikanth M (2018) Synthesis, structural, spectral, and electrochemical studies of selenabenziporphyrin and its Pd(II) complex. Inorg Chem 57:8956

Fu Y-F, Song K-P, Zou Z-J, Li M-Q (2018) External cross-linked sulfonate-functionalized N-heterocyclic carbenes: an efficient and recyclable catalyst for Suzuki-Miyaura reactions in water. Transit Met Chem 43:665

Wang S, Song K, Zhang C, Yu S, Tao L, Tan B (2017) A novel metalporphyrin-based microporous organic polymer with high CO2 uptake and efficient chemical conversion of CO2 under ambient conditions. J Mater Chem A 5:1509

Karataş Y, Gülcan M, Celebi M, Zahmakiran M (2017) Pd(0) nanoparticles decorated on graphene nanosheets (GNS): synthesis, definition and testing of the catalytic performance in the methanolysis of ammonia borane at room conditions. ChemistrySelect 2:9628

Sheng X, Guo H, Qin Y, Wang X, Wang F (2015) A novel metalloporphyrin-based conjugated microporous polymer for capture and conversion of CO2. RSC Adv 5:31664

Gulcan M, Zahmakiran M, Özkar S (2014) Palladium(0) nanoparticles supported on metal organic framework as highly active and reusable nanocatalyst in dehydrogenation of dimethylamine-borane. Appl Catal B 147:394

Veisi H, Najafi S, Hemmati S (2018) Pd(II)/Pd(0) anchored to magnetic nanoparticles (Fe3O4) modified with biguanidine-chitosan polymer as a novel nanocatalyst for Suzuki-Miyaura coupling reactions. Int J Biol Macromol 113:186

Chandra S, Kundu T, Dey K, Addicoat M, Heine T, Banerjee R (2016) Interplaying intrinsic and extrinsic proton conductivities in covalent organic frameworks. Chem Mater 28:1489

Ding ZD, Zhu W, Li T, Shen R, Li Y, Li Z, Ren X, Gu ZG (2017) A metalloporphyrin-based porous organic polymer as an efficient catalyst for the catalytic oxidation of olefins and arylalkanes. Dalton Trans 46:11372

Acknowledgements

This work was financially supported by the Science and Technology Planning Project of Guangdong Province (2017B030314092), the Fundamental Research Funds of CWNU (17C038) and Meritocracy Research Funds of CWNU (17Y031), Science and Technology Foundation of Sichuan Province (2017JY0015).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Zou, Z., Jiang, Y. & Song, K. Pd Nanoparticles Assembled on Metalporphyrin-Based Microporous Organic Polymer as Efficient Catalyst for Tandem Dehydrogenation of Ammonia Borane and Hydrogenation of Nitro Compounds. Catal Lett 150, 1277–1286 (2020). https://doi.org/10.1007/s10562-019-03028-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-019-03028-7