Abstract

A bis-quinoline-2-carboxylic acid copper salt as a single crystal was prepared and characterized by X-ray single crystal analysis. The crystal as a catalyst was applied to the Mizoroki–Heck coupling reaction between arylboronic acids and α-olefins. A series of diarylethenes and aryl olefins were synthesized with good to excellent yields at room temperature. The catalytic system exhibited good functional group tolerance and low pollution.

Graphic Abstract

A bis-quinoline-2-carboxylic acid copper salt as a single crystal was prepared and characterized by X-ray single crystal analysis. The crystal as a catalyst was applied to the Mizoroki–Heck coupling reaction between arylboronic acids and α-olefins

.

.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Stilbenoid as important aryl olefins are widely used in important fields such as materials, medical drugs, hygiene, and cosmetics. Diarylethene [1] and its derivatives, as the parent structures of stilbenoid, are structural units for the synthesis of fluorescent materials [2, 3], flavors [4], biologically active [5] and natural product intermediates [6, 7], especially in fluorescent materials and natural products such as piceatannol-mic-4 (anti-inflammatory, antibacterial) [8], piceatannol-mic-5 (anti -biological activity) [9] and DBF (anti-tumor, hypolipidemic) [10]. In addition, Schiff base 2-cyano stilbene [11] and the compound BBU [12] are used in the field of fluorescent materials. The equally important aryl olefins are α,β-unsaturated compounds and their derivatives. These compounds have various physiological activities such as bactericidal, anti-allergic, anti-inflammatory and anti-oxidation [13]. It has been increasingly used in food additives and biopharmaceuticals field. Such as Caffeic acid (anti-bacterial) [14], Sinapic acid (anti-oxidant) [15] (Fig. 1).

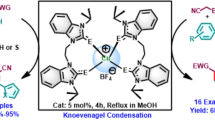

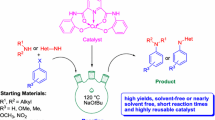

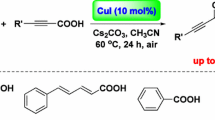

In recent years, due to the wide application of diarylethenes and α,β-unsaturated compounds, it has received great attention to develop an efficient synthesis method. These compounds are mainly obtained by Heck coupling reaction. [16,17,18,19,20,21,22,23,24] Conventional methods employed various transition metal (Pd, Co, Ni, Cu etc.) and phosphine ligands as catalysts [25,26,27,28,29]. In 2013, Liwosz et al. [30] used Cu(OTf)2 and N,N ligand 1,10-phenanthroline as the catalyst to obtain diarylethene and its derivatives through benzyl trifluoroborate and 1,1-diphenylethylene as substrates (Scheme 1a). In 2017, Kurandina et al. [17] reported the use of ferrocene compound as catalyst for the selective synthesis of cinnamyl-trimethylsilane and its derivatives with iodomethyl-trimethylsilane and styrene as substrates (Scheme 1b). In 2018, Hamasaka et al. [31] described Pd NNC-Pincer Complex as an effective catalyst for the Mizoroki–Heck reaction to synthesize butyl (2E)-3-phenyl acrylate and its derivatives with iodobenzene and butyl acrylate as substrates (Scheme 1c). Although these reactions are highly efficient, there are still some disadvantages such as the use of expensive transition metal, the difficulty in synthesizing N, N ligand, poor solubility and environmental pollution caused by substrate halide ion. Therefore, it is the current research focus to explore low cost catalytic reaction system and to develop a ligand with good coordination effect.

Based on the above problems, transition metal Cu(II) is preferred as catalyst because of its stability and low cost, and N,O ligands are preferred due to their ease of preparation and good coordination ability. Arylboronic acids are selected as the substrate because of their good stability, atomic economy and low pollution. Herein, a novel Mizoroki–Heck reaction method for synthesizing diarylethenes and α,β-unsaturated compounds was reported by using bis-quinoline-2-carboxylic acid copper salt as catalyst, arylboronic acid and styrene as substrates (Scheme 1d).

2 Results and Discussion

The synthesized copper complex was characterized by X-ray single crystal analysis. The ORTEP of the molecular structure of the Cu(C10H10NO2)2(H2O) complex is shown in Fig. 2, and the crystal data is listed in the support information. X-ray diffraction analysis indicated that the Cu(C10H10NO2)2(H2O) complex crystallized in the monoclinic system and the space group P 21/c. The molecular structure of the complex contains a Cu atom and two quinoline-2-carboxylic acid (Ligand) units, and the copper atom consists of two quinoline nitrogen (N1, and N2) atoms and two ketone oxygens (O2, O3,) atoms. This paper is to determine the novel copper complex as a catalyst for the Mizoroki–Heck cross-coupling reaction. (CCDC 1892561).

In order to evaluate the catalytic activity of the bis-quinoline-2-carboxylic acid copper salt for the Mizoroki–Heck cross-coupling reaction, phenylboronic acid and styrene were used as the substrates to screen reaction conditions, and the results were summarized in Table 1.

Firstly, catalysts as critical factors for the reaction were screened, compared with some Cu(II) catalysts, Cu(OTf)2 as the catalyst gave a yield of 65% (Table 1, entry 1), while CuSO4 only gave a low yield of 35% (Table 1, entry 2). When quinaldic acid as a ligand was added into the reaction systems of Cu(OTf)2 and CuSO4, the yields were increased to 75% and 40%, respectively (Table 1, entries 3–4). While synthesized Cu complex was used as the catalyst gave a high yield in 95% (Table 1, entry 5). In addition, the ratios of the complex did not affect the reaction very much (Table 1, entries 5–7).

Next, reaction solvents as important factors for the Heck reaction were screened. In an aqueous medium, the reaction yield was a little low (45%) due to poor solubility of the substrates (Table 1, entry 8). MeOH/H2O (1:1) was used as the solvent to give a moderate yield of 79% (Table 1, entry 9). EtOH as the solvent also gave a yield of 85% (Table 1, entry 10). When the non-polar solvent toluene was used, the reaction was unfavorable, and the yield was 60% (Table 1, entry 11). However, polar aprotic solvents such as DMF and DMSO were selected and gave the product yields in 80% and 78%, respectively (Table 1, entries 12 and 13). Therefore, MeOH was an appropriate solvent and could give 95% yield (Table 1, entry 5).

The bases as another important factor were also investigated including organic and inorganic bases. The organic bases such as Et3N, pyridine and nBu3N were employed to give the yields in 95%, 88% and 85%, respectively (Table 1, entries 5, 14–15). For inorganic bases such as K2CO3, Na2CO3 and NaOH, the reactions gave moderate yields in 82%, 83% and 76%, respectively (Table 1, entries 16–18). Therefore, triethylamine was appropriate for this reaction, and the yields decreased with the increase or decrease of its equivalent number (Table 1, entry 5). In addition, when the reaction was heated at 50 °C and 66 °C, the yield decreased to 60% and 40% (Table 1, entries 19–20). Therefore, based on experimental results and previous reports [32, 33], room temperature is best temperature in the reaction work.

Base on above experimental results, it was determined that the optimal reaction system was arylboronic acid (1.0 mmol, 1.0 eq.) and α-olefin (1.5 eq.) as the reaction substrates, bis-quinoline-2-carboxylic acid copper salt (0.50 mol%) as catalyst, MeOH (10 ml) as solvent, Et3N (2.0 eq.) as base, at room temperature for 4 h.

After determining the optimal reaction system, we further explored the substrate range of arylboronic acid and olefins, and the results were summarized in Table 2.

First, using the substrate aryl chloride and phenylboronic acid to react with styrene, the reaction yield of aryl chloride is very low, only 35%, compared to the best yield of boric acid, so the final use of substrate aryl Table 2, entries 1–2). 4-Substituted arylboronic acid with electron withdrawing group such as –NO2, –CHO, –Br and –CN gave high yields of the corresponding product in 90%, 88%, 86% and 85%, respectively (Table 2, entries 3–6). Similarly, the electron-donating such as –CH3 and –OCH3 also gave the corresponding product in high yields (Table 2, entries 7–8). 2-Substituted arylboronic acid with electron-donating or electron withdrawing group, such as –CH3 and –NO2, gave similar yields in 78% and 79%, respectively, but less than that of 4-substituted arylboronic acid because of the steric hindrance effect (Table 2, entries 9–10). In addition, naphthyl substituent was further studied to obtain the target product in good yield of 83% (Table 2, entry 11).

When the olefin was changed to methyl acrylate, phenylboronic acid gave the corresponding product with excellent yield (Table 2, entry 12). 4-Substituted arylboronic acid with electron withdrawing group such as –NO2, –CN and –CHO gave good yields of 94–95% (Table 2, entries 13–15), while 4-substituted arylboronic acid with electron-donating groups such as –OMe and –Me gave yields of 82% and 83% (Table 2, entries 16–17). 2-Nitro phenylboronic acid gave a moderate yield of 78% because of the steric hindrance effect (Table 2, entry 18). In addition, the substrate of 4-substituted diolefins were also extended, the yields of electron-withdrawing group –NO2, –CHO, –CN and electron-donating group –CH3, –OCH3 were similar in medium and upper yield (Table 2, entries 19–24). Both monoolefins and diolefins gave high to excellent yields. Based on this research, non-terminal olefins were studied and synthesized, and the yield only reached 39% (Table 2, entry 25). Therefore, non-terminal olefins also can be applied to this system, but the yield is lower. Finally, when the reaction substrate was detected to be benzylboronic acid, the yield of the product was 75% (Table 2, entry 26). In summary, this reaction showed good functional group tolerance.

In order to insight into the reaction process, control experiments (shown in Scheme 2) were conducted. Firstly, radical inhibition experiment was conducted using TEMPO as blocker (Scheme 2a), phenyl radical [35] was isolated in 26% yield (spectroscopic data are in the Supporting Information), and the desired diarylethene product was not detected, it indicates that the reaction is a radical reaction mechanism. When the reaction was under pure oxygen environment, significant change in yield was not observed (Scheme 2b). However, when the reaction was under nitrogen protection, diarylethene product was pretty low (Scheme 2c), this suggests that oxygen in the air is an important factor in the reaction.

Based on these experimental results and previous literatures [30, 34, 35], a plausible mechanism is assumed as shown in Scheme 3.

Under the action of CuIIcomplex, phenylboronic acid is oxidized by C–B bond split to produce intermediate A. Next, phenyl radical as intermediate B is generated, Cu(II) is reduced to Cu(I). Then intermediate C is generated by an addition of styrene insertion with the intermediate B. Finally, the product diarylethene is obtained by intramolecular eliminates of the intermediate C. Cu(I) is oxidized to Cu(II) in the presence of oxygen in the air.

3 Conclusion

In summary, a novel bis-quinoline-2-carboxylic acid copper salt crystal was synthesized and used as a catalyst to apply to the Mizoroki–Heck cross-coupling reaction. A series of aryl olefins were obtained by the reaction between arylboronic acids and α-olefins with good to excellent yields. This reaction has mild reaction conditions, green solvent and good functional group tolerance.

4 Experimental Section

4.1 Synthesis of Product

The phenylboronic acid (1.0 mmol, 1.0 eq.), α-olefin (1.5 eq.), Et3N (2.0 eq.), MeOH 10 mL, and a complex (0.50 mol%) were sequentially added to a 25 ml reaction flask. The reaction mixture was stirred under reflux and the progress was monitored by TLC analysis. After completion of the reaction, the reaction mixture was extracted with ethyl acetate 3 times (3 × 10 mL).The combined organic layers were dried over anhydrous sodium sulfate. After filtering and removing the solvent, the residue was purified by column chromatography (petroleum ether/ethyl acetate = 8:1 as eluent). Characterization of all synthetic products matched to real samples.

4.2 Synthesis of Complex

The quinaldine acid ligand and copper nitrate were added to a round bottom flask with anhydrous ethanol and diethyl ether as mixed solvent. The mixture was stirred at room temperature for 2 h, filtered and dried to give a pale pink solid.

References

Matsuura R, Jankins TC, Hill DE, Yang KS, Gallego GM, Yang SL, He MY, Wang F, Marsters RP, McAlpine I, Engle KM (2018) Chem Sci 9:8363

Ie Y, Nishida K, Karakawa M, Tada H, Aso Y (2011) J Org Chem 76:6604

Selvarasu C, Kannan P (2017) J Mol Struct 648:77

Sun X, Shen X, Jain R, Lin Y, Wang J, Sun J, Wang J, Yan Y, Yuan Q (2015) Chem Rev 44:3760

Prukała W, Kędzia B (1999) Farmaco 54:584

Huo SQ, Negishi E (2001) Org Lett 3:3253

Dr Prunet J (2003) Angew Chem 42:2826

Dong D, Li H, Tian S (2010) J Am Chem Soc 132:5018

Jun DJ, Li Y, Wang JQ, Tian SK (2011) Chem Commun 47:2158

Harwood HJ Jr, Barbacci-Tobin EG, Petras SF, Lindsey S, Pellarin LD (1997) Biochem Pharm 53:839

Wang L, Zheng Z, Yu Z, Zheng J, Fang M, Wu J, Tian Y, Zhou H (2013) J Mater Chem C 1:952

Qian XM, Melkamu T, Upadhyaya P, Kassie F (2011) Cancer Lett 311:57

Mattila P, Hellström J, Törrönen R (2006) J Agric Food Chem 54:7193

Lin WZ, Navaratnam S, Yao S (1998) Radiat Phys Chem 53:425

Yang J, Marriner GA, Wang XY, Bowman PD, Kerwan S, Stavchansky S (2010) Bioorg Med Chem 18:5032

Gurak AJ, Engle MK (2018) ACS Catal 8:8987

Kurandina D, Parasram M, Gevorgyan PV (2017) Angew Chem 129:14400

Beletskaya IP, Cheprakov AV (2000) Chem Rev 100:3009

Felpin FX, Hardy LN, Callonnec FL, Fouquet E (2011) Tetrahedron 67:2815

Cartney M, Guiry D, Guiry PJ (2011) Chem Rev 40:5122

Magano J, Dunetz JR (2011) Chem Rev 111:2177

Teguo PW, Lee D, Cuendet M, Merillon JM, Pezzuto JM, Kinghorn AD (2001) J Nat Prod 64:136

Kraft A, Grimsdale AC, Holmes AB (1998) Angew Chem 37:402

Martin RE, Diederich F (1999) Angew Chem 38:1350

Yuan LH, Xu Y, Hu XB, Yang GQ, Wu Y (2015) J Mol Catal Chem 396:55

Uno D, Minami H, Otsuka S, Nogi K, Yorimitsu H (2018) Chem Asian J 13:2397

Jadhav SN, Rode CV (2017) Green Chem 19:5958

Roy T, Brandt P, Wetzel A, Bergman J, Brånalt J, Sävmarker J, Larhed M (2017) Org Lett 19:2738

Mboyi CD, Testa C, Reeb S, Genc S, Cattey H, Fleurat-Lessard P, Roger J, Hierso JC (2017) ACS Catal 7:8493

Liwosz TW, Chemler SR (2013) Org Lett 15:3034

Hamasaka G, Ichii S, Uozumi Y (2018) Adv Synth Catal 360:1833

Nishikata T, Noda Y, Fujimoto R, Sakashita T (2013) J Am Chem Soc 135:16372

Farrington EJ, Brown JM, Barnard CF (2002) Angew Chem 41:169

Tobisu M, Koh K, Furukawa T, Chatani N (2012) Angew Chem 51:1363

Wang H, Yu Y, Hong XH, Xu B (2014) Chem Commun 50:13485

Acknowledgements

This work was supported by Fund of Natural Science Foundation of Heilongjiang Province of China (No. B2018012).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Zuo, M., Li, Z., Fu, W. et al. Bis-quinoline-2-carboxylic acid Copper Salt as an Efficient Catalyst for Synthesis of Aryl Olefins by Heck Reaction. Catal Lett 149, 3217–3223 (2019). https://doi.org/10.1007/s10562-019-02885-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-019-02885-6