Abstract

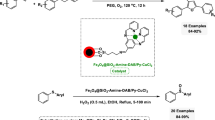

This work reports a green and sustainable route for the synthesis of benzimidazoles via C–N bond formation using carbon dioxide (CO2) as a C1 carbon source. In this work, Cu@U-g-C3N4 catalyst was prepared from urea derived porous graphitic carbon nitride (U-g-C3N4) and CuCl2 and characterized by FT-IR, XRD, XPS, SEM, TPD etc. The Cu@U-g-C3N4 as a heterogeneous recyclable catalyst has been employed first time for the cyclization of o-phenylenediamines (OPD) with CO2 to benzimidazoles using dimethylamine borane (DMAB). The proposed protocol becomes sustainable and efficient due to the use of propylene carbonate/water as a suitable biodegradable, economical and environmentally benign solvent system. The proposed catalytic system showed a wide range of substrate scope for the synthesis of benzimidazoles in good to excellent yields.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The carbon dioxide utilization has become one of the important area of research as it is considered as the most responsible gas for global warming. Therefore, the capture and utilization of CO2 is a straightforward solution to restrain its detrimental effect on the environment [1,2,3]. In recent years, the chemical synthesis involving CO2 fixation has attracted much attention to the chemist. Additionally, the CO2 is non-flammable and economical, easily available carbon feedstock [4] for the production of valuable chemicals such as benzimidazoles, formamides [5], carbonates [6, 7], carbamates [8], oxazolidinones [9], urea [10], methanol [11], formic acid [12], quinazoline-2,4(1H,3H)-diones [13, 14] etc. However, considering thermodynamic stability and kinetic inertness of CO2, it is very difficult to activate and to convert it into value added-chemicals [15]. Most of the reported studies focused on the use of a strong nucleophilic substrate or demands the harsh reaction conditions to activate CO2. Hence, cooperative activation of CO2 with suitable catalyst and substrate is important. Generally, CO2 is used for the formation of C–N, C–C, C–O, and C–H bonds, which offers an environmental friendly route to synthesize the value-added chemicals.

The C–N bond forming reactions between the compounds having nitrogen groups and CO2 are imperative in the industry as well as academia [16]. Benzimidazoles and its derivatives are one of the most important constituents of biologically active compounds. For example, they are used as intermediate in various important drug molecules such as Omeprazole, Rabeprazole, Mebendazole and Albendazole etc (Fig. 1) [17,18,19,20]. The traditional reports utilizes carbon monoxide, formic acid [21], DMF derivatives [22, 23], esters [24], aldehydes [25, 26], nitro methane [27], methanol [28] for the synthesis of benzimidazoles. Notably, these reported methods have certain drawbacks such as toxicity, harsh reaction conditions such as need of high reaction temperature, strongly acidic or basic conditions etc.

The strategies to use CO2 as a C1 source towards the synthesis of benzimidazoles from o-phenylenediamine had few reports in the literature. The Au/TiO2 [30] catalyst was utilized for the conversion of o-nitroanilines into benzimidazoles under CO2 and H2 atmosphere. Liu and co-worker developed RuCl2(dppe)2 [29] catalyst for synthesis of benzimidazole in presence of CO2 and H2 atmosphere but it require very high CO2 and H2 pressure and non-recyclable catalyst was used. Alternatively, Cantat and co-worker developed N-heterocyclic carbene (IPR) catalyzed synthesis of benzimidazole from OPD with CO2 in presence of silane as a hydrogen source at mild reaction condition [31]. This report used expensive ligands, non-recyclable catalyst etc. Recently, Frustrated Lewis Pair (FLP) B(C6H5)3 catalyzed benzimidazole formation starting from OPD and CO2 in the presence of PhSiH3 was reported by Sun et al. [32]. This reports require high temperature, high pressure and catalyst is non-recyclable (Scheme 1).

The selection of solvents plays very crucial role in the fixation of carbon dioxide into valuable chemicals. Traditionally organic solvents such as DMF, DCM, THF, DMSO etc have been utilized. However, toxicity, flammability, environmentally hazardous nature of these solvents imposes their applicability. From a green and sustainable chemistry point of view, replacement of these solvents by greener one will be a great achievement. The use of propylene carbonate as a solvent is an example which can overcome the limitations associated with the traditional organic solvents. The employment of propylene carbonate as a solvent has a number of advantages such as non-toxicity, aprotic, odorless, high boiling point, biodegradable [33]. Based on these benefits propylene carbonate is considered as green, environmental friendly and safe solvent. Moreover, the propylene carbonate score good to excellent in the GlaxoSmithKline (GSK) solvent selection guide [34, 35]. This showing that there is no concern of using propylene carbonate as a solvent at all criteria. Furthermore, on combustion propylene carbonate does not produce oxides of nitrogen and sulfur as it having only carbon, hydrogen and oxygen. Therefore propylene carbonate is a sustainable alternative solvent to DMF, DMSO and DCM.

Recently, g-C3N4 attracted much attention in the last few years due to its high thermal stability, basic property, easy recyclability, low cost, biocompatibility etc. Furthermore, the g-C3N4 is commonly used as a photocatalyst and active support for various metal catalysts. The advantage of these materials (simple recovery and recyclability) as compared to homogeneous catalyst can lead to environmental friendly chemical process. The advantageously, the g-C3N4 has van-der-waals interaction between the single layer of g-C3N4 like graphite which makes it insoluble in number of solvents like DMF, water, toluene, diethyl ether, THF etc [38,39,40]. Therefore g-C3N4 has wide potential in designing of high performance and environmentally benign catalyst. Therefore, our approach is to support less precious metal copper on the U-g-C3N4 to increase its activity towards the synthesis of benzimidazole. As copper nanoparticles (Cu NPs) have advantages such as easy preparation, inexpensive, heterogeneous, high catalytic activity etc, it has enormous application in catalysis as well as in synthesis.

Notwithstanding, previous reports have one or more disadvantages such as the use of expensive catalysts, non-recyclability of catalysts, the need for high reaction temperature and difficult catalyst preparation methods etc. Herein, we report the synthesis, characterization and application of Cu@U-g-C3N4 as an efficient and recyclable catalyst for the synthesis of benzimidazoles by using of OPD, CO2 and DMAB as a reducing agent at 100 °C in propylene carbonate/water as a green solvent medium.

2 Experimental

2.1 Materials and Methods

All chemicals were purchased from Sigma Aldrich, Alfa Aesar and used without further purification. The progress of the reaction was monitored by the thin layer chromatography (silica gel 60 F-254 plates) and the yields for the products were confirmed by gas chromatography (GC) of PerkinElmer Clarus 400 with a flame ionization detector and a capillary column (30 m × 0.25 mm × 0.25 µm) and. All of the products were identified by GC-MS (Shimadzu QP 2010 ultra, Rtx-17, 30 m × 25 mm ID), column flow 3 mL min−1, 70 °C to 220 °C at 10 °C min−1 rise. Products were purified by column chromatography on 100–200 mesh silica gel. NMR spectra were recorded with an Agilent Technologies (1H NMR at 400 MHz, 13C NMR at 100 MHz) spectrometer. The U-g-C3N4 was prepared by pyrolysis of easily available urea [41] and Cu@U-g-C3N4 was prepared by precipitation method with slight modification in previously reported work [42]. We prepared three copper catalyst on the basis of copper loading (Cu@U-g-C3N4-1 = 3% Cu, Cu@U-g-C3N4-2 = 6% Cu, Cu@U-g-C3N4-3 = 10% Cu). The SEM images of these catalysts are shown in supporting information (Fig. S4). The detailed procedure of catalyst preparation is shown in supporting information.

2.2 Experimental Procedure for the Synthesis of Benzimidazoles

Synthesis of benzimidazole from o-phenylenediamine by CO2 and DMAB in presence of Cu@U-g-C3N4 was carried out in high pressure reactor equipped with an overhead stirrer. In a general experiment for the synthesis of benzimidazole, o-phenylenediamine (1.00 mmol), DMAB (3 mmol), PC:H2O (3 mL:1.5 mL), Cu@U-g-C3N4 (20 mg) were loaded into the reactor at room temperature, reactor was sealed, flushed three times with CO2 and 2.5 MPa CO2 pressure was loaded in to reactor, heated to required temperature with stirring (600 rpm). After completion of the reaction, the reactor was cooled to room temperature and the pressure was slowly released. The catalyst was separated by filtration, washed with ethyl acetate and water. The combined mixture was concentrated in vacuo and the products were purified by the column chromatography with silica gel of 100–200 mesh size and petroleum ether-ethyl acetate used as an eluent to afford pure products [36, 37]. The spectroscopic data of all the products were matching with those reported in the literature. All of the products were confirmed by GCMS.

3 Results and Discussion

3.1 Characterization of Catalyst

3.1.1 FT-IR

Fourier Transform Infrared spectra (FT-IR) used for the investigation of various functional groups present in the synthesized catalyst. In our study, we measured the FT-IR spectra of U-g-C3N4 and Cu@U-g-C3N4-2 and shown in Fig. S1 (supporting information). IR spectrum of U-g-C3N4 and Cu@U-g-C3N4-2 is well resolved and the sharp peak at 809 cm− 1 shows the presence of out of plane bending vibration characteristic of triazinecycle. The intense bands came at 1242, 1320, 1412 and 1550 cm−1 were due to the presence of C–N stretching of tri-s-triazine. The peak at 1635 cm−1 was assigned for C=N stretching vibration mode. The broad band peak begins from 2800 to 3500 cm−1 and shows the presence of N-H stretching vibration of the terminal amino group was observed in U-g-C3N4. When we loaded Cu on U-g-C3N4, there is no significant change in the FT-IR spectrum. This shows that Cu NPs and U-g-C3N4 were not forming covalent-bond interaction after loading of Cu on U-g-C3N4.

3.1.2 SEM

Scanning electron micrographs of U-g-C3N4 and Cu@U-g-C3N4-2 are shown in Fig. 2. The SEM images shows stacked layered like structure having the porous morphology of U-g-C3N4 (Fig. 2a, d). It is apparent that the morphology of U-g-C3N4 was not disturbed by the introduction of Cu NPs, this shows that Cu NPs were homogeneously dispersed on the surface of U-g-C3N4 as shown in Fig. 2b. After recycling there was a slight change in the morphology of Cu@U-g-C3N4-2 (Fig. 2c). The TEM images of Cu@U-g-C3N4-2 and reused Cu@U-g-C3N4-2 are shown in Fig. 2e and f respectively. The Fig. 2e and f confirms the formation of porous stacked layered morphology of U-g-C3N4 sheet. The Fig. 2e shows the presences of Cu NPs were dispersed on the surface of the U-g-C3N4, which having average particle size 38.74 nm. Moreover, there was no change in morphology of Cu@U-g-C3N4-2 after fourth recycle which shows that the prepared Cu@U-g-C3N4-2 catalyst was stable (Fig. 2f).

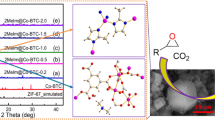

3.1.3 XRD

The XRD pattern confirms the presence two characteristic peaks that are assigned the presence of U-g-C3N4 polymer such as a graphitic stacking structure and match well with the previous report (Fig. 3) [40]. The intense and strong peak at 27.5° is proved that presence of (002) reflection of graphitic interlayer stacking structure of U-g-C3N4. The weak diffraction peak at 13.1° is ascribed to the (100) plane of in planar repeating motifs in U-g-C3N4. After loading Cu, the intensity of the peaks is slightly decreased due to the dilution effect. The new peaks of Cu appeared in the XRD pattern of Cu@U-g-C3N4-2, which can be ascribed to a dispersion of Cu NPs on the U-g-C3N4. The peaks at 42.1, 51.2 and 73.5° shows the presence of face centered cubic structure of Cu having (111), (200), (220) planes.

3.1.4 XPS Analysis

The X-ray photoelectron spectroscopy (XPS) spectrum of Cu@U-g-C3N4-2 was measured and shown in Fig. 4. The survey spectrum shows that there is the existence of C, N, O and Cu elements in the Cu@U-g-C3N4 − 2 catalyst (Fig. 4a). The C 1 s spectrum in Fig. 4c shows two peaks at 284.8 and 288.4 eV. The main peak at 288.4 eV is assigned to sp2 bonded carbon (C=N−C) where as other peak at 284.8 eV corresponding to sp2 carbon (C=C). From Fig. 4b the three N 1 s peaks were attributed at 398.8, 400.1 and 401.3 eV. The major peak at 398.8 eV shows the presence of sp2-hybridized nitrogen attached to a carbon atom (C=N−C), other two peaks at 400.1 and 401.3 eV corresponding to the sp3-hybridized tertiary nitrogen attached to carbon (N-(C)3) and sp3 hybridized nitrogen bonded to one hydrogen atom (C − N−H) respectively. The two major peaks at 932.7 and 952.7 eV shows that there is a shift in the binding energy of Cu 2p3/2 and Cu 2p1/2 respectively, suggesting that Cu(0) (metallic copper) was formed and it indicates that Cu(0) formed in the majority (Fig. 4d). The Peaks at 935 and 955 corresponding to Cu2+ species 2p3/2 and 2p1/2 and also two shake-up lines at 944.1 and 963.0 eV suggesting that Cu2+ present in a paramagnetic chemical shift.

3.1.5 Surface Area Measurement

The surface area measurement of U-g-C3N4 and Cu@U-g-C3N4-2 catalyst were measured by using the SMART SORB 93 instrument. The surface area of U-g-C3N4 and Cu@U-g-C3N4-2 was calculated as 29.6 m2/g and 31.1 m2/g respectively. From these result, it clearly indicates that there was a small increase in surface area of Cu@U-g-C3N4-2, because of the exfoliation of U-g-C3N4 due to the sonication of U-g-C3N4 during the preparation of the catalyst. This shows that Cu NPs did not change the plane structure of U-g-C3N4, which is dispersed on the surface of U-g-C3N4.

3.1.6 TPD Analysis

The basic nature of U-g-C3N4 and Cu@U-g-C3N4-2 were determined by temperature programmed desorption (TPD) analysis. Before analysis, the prepared catalyst was undergone pretreatment with helium gas from 25 °C to 400 °C for 1.5 h to remove the adsorbed moisture and impurities. Then, the sample was cooled to room temperature and then CO2 was passed at 50 °C to saturate the catalyst surface and desorption of CO2 was carried out from 25 to 900 °C temperature with rise of 10°C/min using helium as an inert gas at a flow rate of 20 cm3/min. The CO2 TPD was utilized to determine the basicity of the U-g-C3N4 and Cu@U-g-C3N4-2. The CO2 TPD of U-g-C3N4 shows the peak at 720 °C is due to the desorption of CO2 (Fig. S2), while in the CO2 TPD of Cu@U-g-C3N4-2 shows the broad peak at 680 °C (Fig. S3).

3.2 Reaction Optimization

Initially, the reaction was carried out using OPD (1.0 mmol) as a model substrates in the presence of Cu@U-g-C3N4-2 catalyst (20 mg) and DMAB (3.0 mmol) under a CO2 atmosphere (3.0 MPa) at 100 °C for 24 h, provided 70% yield of benzimidazole (1b) (Table 1, entry 1). No formation of the desired product 1b was noted in the absence of catalyst (Cu@U-g-C3N4-2), this indicates that catalyst is necessary for the desired transformation (Table 1, entry 2). Various solvents used in this reaction have a remarkable effect on the yield of product 1b (Table 1, entries 1–7). The use of non-polar solvent such as toluene gave only 10% yield of 1b (Table 1, entry 3) and the polar solvent such as 1,4-dioxane and acetonitrile (ACN) furnished 40% and 55% yields of 1b, respectively (Table 1, entries 4 and 5). When reaction was carried out in propylene carbonate as a green solvent, 74% yield of 1b was observed (Table 1, entry 6). Considering the fact that DMAB is more soluble in H2O, next, a mixture of propylene carbonate and water was employed in the ratio of 2:1. As per our expectation, this reaction progressed smoothly, furnishing 89% yields of 1b (Table 1, entry 7). After solvent study we screen different Cu@U-g-C3N4-2 catalyst on the basis of Cu loading (Cu@U-g-C3N4-1 = 3%, Cu@U-g-C3N4-2 = 6%, Cu@U-g-C3N4-3 = 10%). Out of these catalysts Cu@U-g-C3N4-2, Cu@U-g-C3N4-3 gave the good to excellent yield as compare to Cu@U-g-C3N4-1 catalyst (Table 1, entries 8, 9 and 10). In the next set of experiments, the effect of the temperature on the reaction system was examined. A slight increase in the yield of the desired product 1b was found when reaction temperature was raised from 100 to 110 °C (Table 1, entries 12). Lowering the temperature to 90 °C from 100 °C, furnished 68% yield of 1b (Table 1, entry 11). Therefore, the optimum temperature for the efficient conversion of 1a is 100 °C. The time studies suggest that 24 h is the ideal reaction duration. Performing the reaction for longer duration has no effect on the yield of 1b (Table 1, entry 14). A significant decrease in the yield of 1b was observed, when reaction were performed for lesser duration (Table 1, entry 13). Next, effect of the CO2 pressure on reaction system was studied. Reducing CO2 pressure to 2.5 MPa form 3.0 MPa led to no change in the yield of 1b (Table 1, entry 15). A further reduction in CO2 pressure to 2.0 MPa resulted into decreased in the yield of 1b (Table 1, entry 16). The other commercial heterogeneous catalyst such as CuO was also screened for this reaction and it produced very poor yield of 1b (Table 1, entry 19). When the reaction was conducted with 2 mmol of DMAB, a decreased in the yield of the 1b was noted (Table 1, entry 18).

No benzimidazole was formed when the reaction was performed in the absence of CO2, this confirms that the propylene carbonate does not act as a CO2 source (Table 1, entry 20). Furthermore, the reaction was optimized with only U-g-C3N4 approached to 32% yield of 1b and it shows that Cu is necessary for the reaction (Table 1, entry 21). The optimized reaction conditions are OPD (1 mmol), CO2 (2.5 MPa), DMAB (3 mmol), Cu@U-g-C3N4-2 (20 mg), Solvent–PC:H2O (3 mL:1.5 mL), at 100 °C for 24 h.

3.3 Substrate Study

After optimization of reaction conditions, attempts were made to explore the substrates scope of ophenylenediamines to give a series of benzimidazoles as shown in Table 2. The electron donating and withdrawing substrates were well tolerated under the optimized reaction conditions furnishing the corresponding products in moderate to good yield. The 4-methyl and 4-methoxy substituted 1,2-diamine gave 90% and 78% yield of corresponding benzimidazoles 2b and 3b respectively (Table 2, entries 2 and 3). N-methyl-1,2-diamine provided the N-methylbenzimidazole (4b) in excellent yield (Table 2, entry 4). Unfortunately, no formation of product was noted when reaction was performed with 2,3-diaminophenol (5a) (Table 2, entry 5). O-phenylenediamine having mono substituted weak electron withdrawing groups such as 4-chloro and 4-fluoro substituted 1,2-diamine provided 85% and 82% yield of 6b and 7b (Table 2, entries 6 and 7). The dichloro deactivate the o-phenylenediamine furnished lower yield of 5,6-dichloro-1H-benzimidazole (8b). Moreover, strong electrron withdrawing nitro group containing substrates such as 3-nitro-1,2-phenylenediamine resulted in 78% yield of 4-nitro-1H-benzimidazole (Table 2, entry 11). The nitrogen heterocyclic substrates 9a and 10a were employed for this reaction and they provided the 80% and 68% yield of corresponding benzimidazole respectively (Table 2, entries 9 and 10). Next, the reaction of anthranilamide was performed which having less nucleophilic amide group. 4-quinazolinone (12b) was successfully achieved from anthranilamide and CO2 with optimized reaction condition to get 56% yield (Table 2, entry 12).

The successful synthesis of benzimidazole and their derivatives by cyclization of diamine with CO2 encouraged us to extend the scope of our protocol to study the reactivity of other less nucleophilic substrates such as 2-aminobenzylamine (13a). At first, 2-aminobenzylamine was employed and it resulted into the formation of 3,4-dihydroquinazoline (13b) and quinazoline (13c) as a side product with overall 80% yield (Scheme 2).

After this, the formylation aniline and its derivatives were carried out using CO2 and DMAB to obtain good yield of corresponding formanilide by the optimized reaction (Scheme 3).

Furthermore, a tentative reaction mechanism for the synthesis of benzimidazole has been developed on the basis of previous reported method [43, 44]. The Cu@U-g-C3N4 catalyst activates the DMAB to form intermediate 2 and catalyzed the insertion of CO2 into B–H bond to form intermediate 3. Then intermediate 3 reacted with diamine to form formamide intermediate 4. Next, the intermediate 4 provide desired product (1a) by cyclization followed by dehydration (Scheme 4).

4 Recyclability Study

The recyclability of any heterogeneous catalysts is very important to determine the suitability of the developed catalysts. The recyclability of the Cu@U-g-C3N4-2 was also studied by using o-phenylenediamine as a model substrate under optimized reaction condition. The catalyst was easily separated from the reaction mixture by simple filtration or centrifugation. After separation wash with water and ethyl acetate to remove organic and inorganic impurity, then dried to 70 °C after each cycle before applying it in the next reaction. This catalyst could be recovered and reused at least four times, without any obvious decrease in catalytic activity (Fig. 5).

5 Conclusion

In summary, we have synthesized and characterized U-g-C3N4 and Cu@U-g-C3N4 catalysts by pyrolysis of urea and facile precipitation method respectively. We have developed heterogeneous recyclable catalyst for the synthesis of benzimidazole from o-phenylenediamine by using CO2 and DMAB as a hydrogen source. High stability and excellent catalytic activity, broad substrate scope, recyclability, use of green solvent makes this protocol an attractive alternative route for the synthesis of benzimidazoles. The developed protocol becomes sustainable due to the use propylene carbonate/water as a green solvent. Furthermore, the developed catalyst recovered easily by simple filtration method and showed good recyclability up to four recycle runs without loss of its catalytic activity.

References

Bhanage BM, Arai M (2014) Transformation and utilization of carbon dioxide. Springer, Berlin, Heidelberg

He M, Sun Y, Han B (2013) Angew Chemie Int Ed 52:9620–9633

Liu Q, Wu L, Jackstell R, Beller M (2015) Nat Commun 6:5933

Aresta M (2006) Carbon dioxide reduction and uses as a chemical feedstock. In: Activation of small molecules. Wiley, Weinheim, pp 1–41

Nale D, Bhanage B (2016) Synlett 27:1413–1417

Saptal VB, Sasaki T, Harada K, Nishio-Hamane D, Bhanage BM (2016) ChemSusChem 9:644–650

Saptal VB, Bhanage BM (2016) ChemCatChem 8:244–250

Nale DB, Rana S, Parida K, Bhanage BM (2014) Appl Catal A Gen 469:340–349

Fontana F, Chen CC, Aggarwal VK (2011) Org Lett 13:3454–3457

Jiang T, Ma X, Zhou Y, Liang S, Zhang J, Han B (2008) Green Chem 10:465

Wesselbaum S, vom Stein T, Klankermayer J, Leitner W (2012) Angew Chemie Int Ed 51:7499–7502

Moret S, Dyson PJ, Laurenczy G (2014) Nat Commun 5:4017

Saptal VB, Bhanage BM (2017) ChemSusChem 10:1145–1151

Nale DB, Saigaonkar SD, Bhanage BM (2014) J CO2 Util 8:67–73

Wang W-H, Feng X, Bao M (2018) Transformation of carbon dioxide to formic acid and methanol. Springer Singapore

Li Y, Cui X, Dong K et al (2017) ACS Catal 7:1077–1086

Vojčić N, Bregović N, Cindro N et al (2017) ChemistrySelect 2:4899–4905

Keri RS, Hiremathad A, Budagumpi S, Nagaraja BM (2015) Chem Biol Drug Des 86:19–65

Zhang J, Wang J-L, Zhou Z-M et al (2012) Bioorg Med Chem 20:4208–4216

Zhou R, Skibo EB (1996) J Med Chem 39:4321–4331

Azizi N, Edrisi M, Abbasi F (2018) Appl Organomet Chem 32:e3901

Nale D, Bhanage B (2015) Synlett 26:2835–2842

Kattimani PP, Kamble RR, Meti GY (2015) RSC Adv 5:29447–29455

Fu R, Yang Y, Ma Y et al (2015) Tetrahedron Lett 56:4527–4531

Mann J, Baron A, Opoku-Boahen Y et al (2001) J Med Chem 44:138–144

Lin S, Yang L (2005) Tetrahedron Lett 46:4315–4319

Aksenov AV, Smirnov AN, Aksenov NA et al (2015) Org Biomol Chem 13:4289–4295

Feng F, Ye J, Cheng Z et al (2016) RSC Adv 6:72750–72755

Yu B, Zhang H, Zhao Y et al (2013) Green Chem 15:95–99

Hao L, Zhao Y, Yu B et al (2014) Green Chem 16:3039

Jacquet O, Das Neves Gomes C, Ephritikhine M, Cantat T (2013) ChemCatChem 5:117–120

Zhang Z, Sun Q, Xia C, Sun W (2016) Org Lett 18:6316–6319

Shaikh A-AG, Sivaram S (1996) Organic carbonates. Chem Rev 96:951–976

Adeleye AI, Patel D, Niyogi D, Saha B (2014) Ind Eng Chem Res 53:18647–18657

Alder CM, Hayler JD, Henderson RK et al (2016) Green Chem 18:3879–3890

Gautam P, Kathe P, Bhanage BM (2017) Green Chem 19:823–830

Parker HL, Sherwood J, Hunt AJ, Clark JH (2014) ACS Sustain Chem Eng 2:1739–1742

Dong G, Zhang Y, Pan Q, Qiu J (2014) J Photochem Photobiol C Photochem Rev 20:33–50

Gillan EG (2000) Chem Mater 12:3906–3912

Wang Y, Wang X, Antonietti M (2012) Angew Chemie Int Ed 51:68–89

Fang H-B, Luo Y, Zheng Y-Z, Ma W, Tao X (2016) Ind Eng Chem Res 55:4506–4514

Huang S, Zhao Y, Tang R (2016) RSC Adv 6:90887–90896

Zhang S, Mei Q, Liu H et al (2016) RSC Adv 6:32370–32373

Saptal VB, Juneja G, Bhanage BM (2018) New J Chem

Acknowledgements

The author Vishal V. Phatake would like to thanks University Grant Commission (UGC), New Delhi, India for providing a Junior Research Fellowship under UGC-NET JRF scheme.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No conflict of interest, for each contributing author.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Phatake, V.V., Bhanage, B.M. Cu@U-g-C3N4 Catalyzed Cyclization of o-Phenylenediamines for the Synthesis of Benzimidazoles by Using CO2 and Dimethylamine Borane as a Hydrogen Source. Catal Lett 149, 347–359 (2019). https://doi.org/10.1007/s10562-018-2608-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-018-2608-9