Abstract

An easy methodology has been developed for the N-arylation of imidazole with arylboronic acid in absence of base and ligand with the aid of as-synthesized CuO nanoparticles. The CuO nanoparticles have been synthesized via precipitation route. The as-synthesized copper oxide nanoparticles are well characterized by various analytical and spectroscopic techniques, such as powder XRD, Raman spectroscopy, TEM and BET surface area analyses. The CuO nanoparticles appear as spherical in shape with a surface area of 15.4 m2/g. The mentioned reaction successfully proceeds at moderate temperature in presence of the as-synthesized nanoparticles. The protocol is applicable to a wide variety of electronically diverse precursor moieties signifying its well applicability.

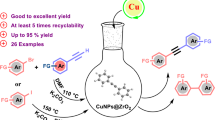

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In modern synthetic organic chemistry, the construction of N-arylated products from N-containing heterocycles have found immense consideration in recent days. The N-arylated products find importance because of their wide applications as structural and functional units in natural products as well as in biological compounds [1,2,3,4,5,6,7,8,9,10,11,12,13,14,15]. A wide number of biologically active compounds such as cyclic AMP phosphodiesterase inhibitors [16, 17], AMPA receptor antagonists [17], cardiotonic agents [18,19,20], thromboxane synthase inhibitors [21, 22] and topical antiglaucoma agents [23] etc. have been prepared from N-arylated products. Traditionally, N-arylated products are obtained by two methods viz. nucleophilic aromatic substitution, which requires activated substrates bearing electron withdrawing groups [13, 17, 19, 20, 24, 25] and classical Ullmann-type coupling, which extensively needs higher temperature and longer reaction time along with the use of stoichiometric amount of copper salt [26,27,28,29,30,31]. In recent years, Buchwald and Hartwig as well as many others developed palladium based protocols for the construction of C–N bond [32,33,34,35,36,37,38,39,40,41]. Considering the issue of high cost of palladium, copper is given more importance for this type of conversion. This continual process of finding new routes with copper catalysts was successfully further enhanced by Chan–Lam for the C–N bond formation reaction using arylboronic acids as aryl source [42,43,44]. Many other literatures demonstrated the use of copper salts as catalyst for C–N bond formation reaction in later time [45,46,47,48]. Collman has developed an efficient catalytic methodology for C–N bond formation using Cu(II) complex with nitrogen chelating bidentate ligands at room temperature [49]. Thus, continuous efforts have been devoted towards the development of mild and efficient routes for this type of reaction. In recent times, arylboronic acid has attained immense attraction as a cross-coupling partner due to its stability, structural diversity and less toxic nature as compared to other aryl halides [50]. Consequently, arylboronic acid has been used as an alternative arylating agent in C–N cross-coupling reaction.

In this era, nanoparticles have found keen attention of the researchers as catalysts for synthetic organic reactions because of their unique property like high surface to volume ratio. And as such, they provide more reaction sites so that higher activity and selectivity can be achieved easily as compared to the bulk materials thereby minimising the formation of undesired products [51,52,53,54,55,56,57,58]. Looking towards the aspects of nanoparticles for organic transformations, we have synthesized CuO nanoparticles to implicate on the Chan–Lam cross coupling reaction. Recent literatures advocated the use of commercial as well as synthesized Cu and CuO nanoparticles for different organic transformations including C–N bond formation reactions [59,60,61,62,63,64]. Suramwar et al. synthesized CuO nanoparticles via a thermal-assisted strategy at reflux temperature using stabilising agent for the N-arylation of indoles [59]. Punniyamurthy and co-workers successfully utilised commercially available CuO nanoparticles for the C–N, C–O and C–S cross coupling reaction [62, 63].

Thus, considering the efficient catalytic properties of Cu based nanoparticles, herein we report the synthesis of CuO nanoparticles via a precipitation route without use of any surfactant or structure directing agent. The as-synthesized CuO nanoparticles are characterized by X-ray diffraction, transmission electron microscopy (TEM), Raman spectroscopy and BET surface area analyses. Further a facile protocol for N-arylation of imidazole with arylboronic acid using the as-synthesized CuO nanoparticles is reported. To minimise the use of harsh reaction conditions as well as costly procedures are seemed to be main concerned area of current research. Consequently, the uses of excess base, higher temperature and complicated catalytic system have been avoided in our report. The newly synthesized CuO nanoparticles have effectively catalyzed the current reaction with greater activity in absence of base and other ligands at a moderate temperature. Below some of the previously reported procedures for C–N coupling [64,65,66,67,68,69] are enlisted in comparison to our report (Table 1).

2 Experimental Section

2.1 Materials Used

Copper nitrate trihydrate (Cu(NO3)2·3H2O), diammonium oxalate monohydrate ((NH4)2C2O4·H2O), Imidazole (C3H4N2), Methanol (CH3OH) and silica gel were supplied by Merck, India. Phenylboronic acid was purchased from SRL Chemical, India. All of the chemicals were of analytical grade and used without any purification. Again, all the experiments were performed with distilled water.

2.2 Characterization Techniques

The powder X-ray diffraction (PXRD) pattern was recorded using a nickel-filtered CuKα (0.15418 nm) radiation source on a Rigaku instrument. Raman spectrum was recorded using a laser micro-Raman system (make: Horiba Jobin Vyon, model: LabRam HR) at room temperature on 488 nm excitation wavelength. Transmission electron microscopic (TEM) investigations were carried out on a FEI-Technai (G2 F20S-TWIN) instrument operating at an accelerating voltage of 200 kV that equipped with a slow-scan CCD camera. The surface areas were determined by Brunauer–Emmett–Teller (BET) method measured by N2 physisorption using a quantachrome instrument (Model: NOVA 1000e). The pore size and pore volume were determined following Barrett–Joyner–Halenda (BJH) method in the same instrument. The 1H NMR spectra were recorded on 400 MHz JEOL, JNM ECS NMR spectrometer using CDCl3 as solvent and TMS (0 ppm) as internal reference. The 13C NMR spectra were recorded at 100 MHz using CDCl3 (77.0 ppm) as standard. The thin layer chromatography observation was carried out on Merck silica gel 60F254 plates using short wavelength (254 nm) of UV light. Silica gel (60–120 mesh) was used for the column chromatography technique for the purification of the crude products.

2.3 Synthesis of Copper Oxide (CuO) Nanoparticles

For the synthesis of copper oxides, 4.832 g of copper nitrate trihydrate (Cu(NO3)2·3H2O) and 2.842 g of diammonium oxalate monohydrate ((NH4)2C2O4·H2O) were dissolved in 100 mL of distilled water separately to form homogeneous solutions, respectively. The molar ratio of Cu(NO3)2·3H2O and (NH4)2C2O4·H2O was kept as 1:1. The (NH4)2C2O4·H2O solution was then added dropwise to the Cu(NO3)2·3H2O solution with vigorous stirring. Subsequently, the mixed solution was then aged for 24 h at room temperature without any disturbance. The resulting precipitate was separated by centrifugation, washed several times with distilled water and dried in an oven at 80 °C for 12 h. Finally, the dried product was sintered at 350 °C for 3 h in air atmosphere.

2.4 General Procedure for the N-Arylation of Imidazole

A 50 mL round bottomed flask was charged with a mixture of imidazole (0.5 mmol) and phenylboronic acid (0.6 mmol) followed by the addition of 15 wt% CuO nanoparticles in 3 mL of MeOH at 60 °C. The progress of the reaction was monitored by TLC. After completion, the reaction mixture was extracted with ethyl acetate (3 × 10 mL). Then, the extracted part was dried over Na2SO4 and concentrated on a rotary evaporator under reduced pressure. The concentrated product was purified by column chromatography over silica gel (eluent:ethyl acetate–hexane) to obtain the pure product. The N-arylated products of imidazole thus obtained were confirmed by 1H and 13C NMR.

3 Results and Discussion

3.1 Catalyst Characterization

After the thermal treatment in air atmosphere at 350 °C for 3 h, the as-obtained product was subjected to PXRD analysis. The X-ray diffraction pattern (Fig. 1a) confirms the formation of the product as monoclinic phase of CuO with lattice constants a = 4.686 Å, b = 3.423 Å, and c = 5.132 Å (JCPDS Card No. 41–0254). The peaks at 32.5°, 35.5°, 38.9°, 48.7°, 52.6°, 58.5°, 61.4°, 66.0° and 68.1° are assigned to the (110), (11-1), (200), (20-2), (020), (202), (11-3), (220) and (22-1) lattice planes of monoclinic CuO, respectively. The high intensity diffraction peaks of the sample confirm its crystallinity and no other impurities are detected. The Raman spectrum of the as-synthesized CuO shows three intense Raman peaks around 287 (Ag), 334 (Bg 1) and 615 (Bg 2) cm− 1 (Fig. 1b). The Raman spectroscopic study indicates that the as-synthesized CuO belongs to the C2h 6 space group with only three Raman active (Ag + 2Bg) modes. This is in accordance with our previous reports [70,71,72,73]. Figure 1c shows the TEM images of the as-synthesized CuO, suggesting that the particles of CuO are spherical in shape with irregular sizes (a maximum of 80 nm in range). A clear lattice fringe with spacing of 0.25 nm, corresponding to the (11-1) planes of monoclinic CuO is also observed (Fig. 1d). The selected area electron diffraction (SAED) measurement of the respective CuO nanoparticles (inset of Fig. 1c) shows a highly crystalline nature with three diffraction rings. These three rings can be attributed to the (200), (020) and (110) lattice planes of monoclinic CuO, respectively.

Further, the textural property of CuO nanoparticles was assessed by N2 adsorption/desorption analysis at liquid N2 temperature. The corresponding adsorption/desorption isotherm and pore size distribution curve (inset) are shown in Fig. 2. The N2 adsorption/desorption isotherm represents the CuO nanoparticles as a mesoporous material. Moreover, a typical surface area of 15.4 m2/g with a pore volume and diameter of 0.013 cm3/g and 5.7 nm, respectively is observed for the as-synthesized CuO nanoparticles. This value of surface area is quite larger than that of usually used commercial CuO powder (ca. 0.1 m2/g) and quite reasonable for the CuO nanomaterials [70, 73, 74].

3.2 Catalytic Activity

To examine the catalytic activity of our as-synthesized CuO nanoparticles, we have selected the N-arylation reaction of imidazole with arylboronic acid. So, we tried to obtain an optimized condition for this reaction. For that purpose, we have chosen phenylboronic acid and imidazole as the model substrates and the reaction was performed by taking MeOH as the solvent at 60 °C. We performed a set of reactions to investigate the amount of catalyst necessary for the reaction. For that, we used different amounts of catalyst loadings (Table 2, entries 1–3). From Table 2, it is observed that 15 wt% of the catalyst loading gave an excellent yield of 94% (Table 2, entry 2). However, 10 wt% loading of the catalyst led to comparatively lower yield than that of the as mentioned earlier (Table 2, entry 1 vs. entry 2). On the other hand, increase in the amount of catalyst to 20 wt%, exhibited similar yield as that of 15 wt% catalyst loading (Table 2, entry 2 vs. entry 3). Thus, by analyzing the results, we took 15 wt% catalyst for the current reaction.

Then we studied the effect of different solvents on our current reaction protocol. For that purpose, we conducted several test reactions by choosing different solvents viz H2O, MeOH, EtOH, THF and 2-Me THF. Lower yield was observed in case of H2O and THF (Table 3, entry 1 & entry 4). Again, no product formation was evident with 2-Me THF (Table 3, entry 5). On the other hand, a relatively good yield (80%) was observed by considering EtOH as solvent (Table 3, entry 2). However, MeOH, on taking as solvent afford excellent yield of desired product with 94% isolated yield (Table 3, entry 3). We also investigated the role of aqueous mixtures of solvents such as H2O:MeOH, H2O:THF and H2O:2-Me THF (Table 3, entries 6–8) for the current reaction. Although some acceptable yields were obtained with the aqueous solvents, they were lower than that of MeOH (Table 3, entry 3 vs. entries 6–8). From these studies, MeOH was considered as the best solvent for our present reaction protocol. Further, we wished to know what happens to the reaction at room temperature. But no product formation was observed (Table 3, entry 9) even after a long time. That suggests the requirement of moderate temperature (60 °C) for this protocol.

Further we investigated the amount of substrates in so far optimized reaction conditions. Test reactions were carried out by choosing different proportions of substrates in order to evaluate their appropriate ratio (Table 4, entries 1–3). Use of 1 equivalent of the imidazole and 1.2 equivalent of the phenylboronic acid exhibited the best result (Table 4, entry 3). The increase in the amount of imidazole or the decrease in the amount of phenylboronic acid did not exhibit good results (Table 4, entries 1 and 2). Therefore, we decided to consider the condition of substrate ratio 1.2:1 of phenylboronic acid and imidazole respectively (Table 4, entry 3).

After these screenings, we obtained an optimized condition for the current reaction protocol. Further, we expanded the scope and limitations of this method to various electronically diverse imidazole and phenylboronic acid moieties (Table 5, entries 1–14). Both the electron withdrawing and the electron donating group containing phenylboronic acid as well as imidazole were seemed to be compatible with our current methodology. Phenylboronic acid with the electron withdrawing –F group at the 4-position showed excellent yield (Table 5, entry 1). But a moderate yield was observed with 4-fluorophenylboronic acid with imidazole containing electron donating –CH3 group at 2-position (Table 5, entry 2).

Similarly, –Cl group containing phenylboronic acid at the 4-position gave good yield with imidazole, but moderate yields were achieved with 4(5)-methyl imidazole and 2-methylimidazole (Table 5, entries 3–5). Similar trends were observed for phenylboronic acid with –OCH3 group at the 4-position. A very good yield was observed for the coupling of 4-methoxyphenylboronic acid with imidazole, but with 4(5)-methylimidazole and 2-methylimidazole, it gave relatively lower yields (Table 5, entry 9 and entries 10 and 11). The electron donating –CH3 group at the 3-position of phenylboronic acid also enhanced the reaction with imidazole and 2-methylimidazole (Table 5, entries 12 and 13). Again, phenylboronic acid with imidazole, 4(5)-methylimidazole and 2-methylimidazole gave good to excellent yield (Table 5, entries 6–8). However, no product formation was observed for electron withdrawing –CN group containing imidazole with phenylboronic acid even after a long time (Table 5, entry 14).

The current methodology provides a base free reaction conditions for the N-arylation of imidazole with arylboronic acid. The basic characteristic of imidazole moiety may provide the required basic conditions to catalyze the reaction. As a result, the reaction mixture after addition of imidazole may lead to the activation of the phenylboronic acid moiety which subsequently leads to the formation of the product [75, 76]. Moreover, CuO surface is also known to be basic in nature which may further enhance the activity under base free condition.

3.3 Recyclability of the CuO Nanoparticles

We performed the recyclability test to check the activity and stability of the CuO nanoparticles. After the 1st cycle, we recovered the catalyst by centrifugation and the catalyst was dried and used for the 2nd cycle. But a decrease in activity of the catalyst was observed and we obtained 60% yield of the cross coupling product in the 2nd catalytic cycle. The reason for this decrease in the activity of the CuO nanoparticles may be due to the change of surface morphology by aggregation of the nanoparticles [77, 78].

4 Conclusions

In summary, we have developed an easy method for the synthesis of CuO nanoparticles. The activity of these as-synthesized CuO nanoparticles have been well explained for the N-arylation reaction of imidazole and phenylboronic acid. One of the main key features of the reaction is that it proceeds under base and ligand free condition. Moreover, the reaction proceeds at moderate temperature which avoids the necessity of harsh temperature for the N-arylation reaction of imidazole with phenylboronic acid. Furthermore, the application of the CuO nanoparticles for this reaction protocol seems to be beneficial because a comparatively lower amount of catalyst loading is necessary to enhance the reaction along with a wide range of substrate tolerance. Thus, it might be an efficient and facile protocol for the synthesis of N-arylated products of imidazole with arylboronic acid.

References

Monnier F, Taillefer M (2009) Angew Chem Int Ed 48:l6954

Li Z-H, Xue L-P, Wang L, Zhang S-T, Zhao B-T (2013) Inorg Chem Commun 27:119

Pai G, Chattopadhyay AP (2016) Tetrahedron Lett 57:3140

Hosseinzadeh R, Aghili N, Tajbakhsh M (2016) Catal Lett 146:193

Wolfe JP, Wagaw S, Marcoux JF, Buchwald SL (1998) Acc Chem Res 31:805

Shen QL, Hartwig JF (2007) J Am Chem Soc 129:7734

Huang Y-Z, Miao H, Zhang Q-H, Chen C, Xu J (2008) Catal Lett 122:344

Gogoi A, Sarmah G, Dewan A, Bora U (2014) Tetrahedron Lett 55:31

Cui Y-L, Guo X-N, Wang Y-Y, Guo X-Y (2015) Sci Rep 5:1

Németh J, Debreczeni N, Gresits I, Bálint M, Hell Z (2015) Catal Lett 145:1113

Hartwig JF (1998) Angew Chem Int Ed 37:2046

Xie Y-X, Pi S-F, Wang J, Yin D-L, Li JH (2006) J Org Chem 71:8324

Venuti MC, Stephenson RA, Alvarez R, Bruno JJ, Strosberg AM (1988) J Med Chem 31:2136

Kantam ML, Yadav J, Laha S, Sreedhar B, Jha S (2007) Adv Synth Catal 349:1938

Nguyen TT, Phan NTS (2014) Catal Lett 144:1877

Martinez GR, Walker KAM, Hirschfeld DR, Bruno JJ, Yang DS, Maloney PJ (1992) J Med Chem 35:620

Ohmori J, Shimizu-Sasamata M, Okada M, Sakamoto S (1996) J Med Chem 39:3971

Sircar I, Duell BL, Bobowski G, Bristol JA, Evans DB (1985) J Med Chem 28:1405

Sircar I, Weishaar RE, Kobylarz D, Moos WH, Bristol JA (1987) J Med Chem 30:1955

Gangor T, Fouquet A, Teulon J-M, Prevost D, Cazes M, Cloree A (1992) J Med Chem 35:4455

Iizuka K, Akahane K, Momose DI, Nakazawa M, Tanouchi T, Kawamura M, Ohyama I, Kajiwara I, Ignchi Y, Okada T, Taniguchi K, Miyamoto T, Hayashi M (1981) J Med Chem 24:1139

Cozzi P, Carganico G, Fusar D, Grossoni M, Menichincheri M, Pinciroli V, Tonani R, Vaghi F, Salvati P (1993) J Med Chem 36:2964

Lo YS, Nolan JC, Maren TH, Welstead WJ Jr, Gripshover DF, Shamblee DA (1992) J Med Chem 35:4790

Antonini I, Cristalli G, Franchetti P, Grifantini M, Martelli S (1983) Synthesis 1983:47

Bambal R, Haznlik RB (1994) J Org Chem 59:729

Ullmann F (1903) Ber Dtsch Chem Ges 36:2382

Ullmann F, Illgen E (1914) Ber Dtsch Chem Ges 47:380

Kiyomori A, Marcoux J-F, Buchwald SL (1999) Tetrahedron Lett 40:2657

Sung S, Sale D, Braddock DC, Armstrong A, Brennan C, Davies RP (2016) ACS Catal 6:3965

Yamamoto T, Kurata Y (1983) Can J Chem 61:86

Gopiraman M, Babu SG, Khatri Z, Kai W, Kim YA, Endo M, Karvembu R, Kim IS (2013) Carbon 62:135

Fors BP, Davis NR, Buchwald SL (2009) J Am Chem Soc 131:5766

Guram AS, Buchwald SL (1994) J Am Chem Soc 116:7901

Guram AS, Rennels RA, Buchwald SL (1995) Angew Chem Int Ed 34:1348

Meiries S, Speck K, Cordes DB, Slawin AMZ, Nolan SP (2013) Organometallics 32:330

Tardiff BJ, McDonald R, Ferguson MJ, Stradiotto M (2012) J Org Chem 77:1056

Hartwig JF (2008) Acc Chem Res 41:1534

Surry DS, Buchwald SL (2008) Angew Chem Int Ed 47:6338

Surry DS, Buchwald SL (2011) Chem Sci 2:27

Cho SH, Kim JY, Kwak J, Chang S (2011) Chem Soc Rev 40:5068

Hartwig JF (2006) Synlett 9:1283

Chan DMT, Monaco KL, Wang R-P, Winters MP (1998) Tetrahedron Lett 39:2933

Lam PYS, Clark CG, Saubernt S, Adams J, Winters MP, Chan DMT, Combs A (1998) Tetrahedron Lett 39:2941

Evans DA, Katz JL, West TR (1998) Tetrahedron Lett 39:2937

Lan JB, Chen L, Yu XQ, You JS, Xie RG (2004) Chem Commun 2:188

Lan J-B, Zhang G-L, Yu X-Q, You J-S, Chen L, Yan M, Xie R-G (2004) Synlett 6:1095

Sreedhar B, Venkanna GT, Kumar KBS, Balasubrahmanyam V (2008) Synthesis 2008:795

Siddle JS, Batsanov AS, Bryce MR (2008) Eur J Org Chem 16:2746

Collman JP, Zhong M, Zhang C, Costanzo S (2001) J Org Chem 66:7892

Hall DG (2005) In: Hall DG ed Boronic acids, Wiley, Weinheim

Alonso F, Riente P, Sirvent J, Yus M (2010) Appl Catal A 378:42

Astruc D, Lu F, Aranzaes JR (2005) Angew Chem Int Ed 44:7852

De Vries JG (2006) Dalton Trans 3:421

Astruc D (2007) Inorg Chem 46:1884

Tamura M, Fujihara H (2003) J Am Chem Soc 125:15742

Zhu Y, Peng SC, Emi A, Zhenshun S, Kemp RA (2007) Adv Synth Catal 349:1917

Tang B-X, Wang F, Li J-H, Xie Y-X, Zhang M-B (2007) J Org Chem 72:6294

Su F-Z, Liu Y-M, Wang L-C, Cao Y, He H-Y, Fan K-N (2008) Angew Chem Int Ed 47:334

Suramwar NV, Thakare SR, Karade NN, Khaty NT (2012) J Mol Catal A 359:28

Xu H-J, Liang Y-L, Cai Z-Y, Qi H-X, Yang C-Y, Feng Y-S (2011) J Org Chem 76:2296

Xu H-J, Liang Y-F, Zhou X-F, Feng Y-S (2012) Org Biomol Chem 10:2562

Jammi S, Sakthivel S, Rout L, Mukherjee T, Mandal S, Mitra R, Saha P, Punniyamurthy T (2009) J Org Chem 74:1971

Rout L, Jammi S, Punniyamurthy T (2007) Org Lett 9:3397

Borah RK, Raul PK, Mahanta A, Shchukarev A, Mikkola J-P, Thakur AJ (2017) Synlett 28:1177

Reddy KR, Kumar NS, Sreedhar B, Lakshmi Kantam M (2006) J Mol Catal A 252:136

Wang L, Jiang Z, Yu L, Li L, Li Z, Zhou X (2010) Chem Lett 39:764

Islam SM, Mondal S, Mondal P, Roy AS, Tuhina K, Mobarok M (2011) Inorg Chem Commun 14:1352

Farahat AA, Boykin DW (2015) Synth Commun 45:245

Devarajan N, Suresh P (2016) ChemCatChem 8:1

Deka P, Deka RC, Bharali P (2016) New J Chem 40:348

Xu JF, Ji W, Shen ZX (1999) J Raman Spectrosc 30:413

Basu M, Sinha AK, Pradhan M, Sarkar S, Pal A, Pal T (2010) Chem Commun 46:8785

Deka P, Hazarika A, Deka RC, Bharali P (2016) RSC Adv 6:95292

Liu Y, Zhu G, Bao C, Yuan A, Shen X (2014) Chin J Chem 32:151

Tromp M, van Strijdonck GPF, van Berkel SS, van den Hoogenband A, Feiters MC, de Bruin B, Fiddy SG, van der Eerden AMJ, van Bokhoven JA, van Leeuwen PWNM, Koningsberger DC (2010) Organometallics 29:3085

van Berkel SS, van den Hoogenband A, Terpstra JW, Tromp M, van Leeuwen PWNM., van Strijdonck GPF (2004) Tetrahedron Lett 45:7659

Deka P, Deka RC, Bharali P (2014) New J Chem 38:1789

Gawande MB, Goswami A, Felpin F-X, Asefa T, Huang X, Silva R, Zou X, Zboril R, Varma RS (2016) Chem Rev 116:3722

Acknowledgements

S.K.D. gratefully acknowledges UGC, New Delhi for Rajiv Gandhi National Fellowship. P.B. also thanks Council of Scientific and Industrial Research (CSIR No: 01(2813)/14/EMR-II), New Delhi for financial support. CIF, IIT Guwahati, India is acknowledged for analytical support.

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Das, S.K., Deka, P., Chetia, M. et al. Spherical CuO Nanoparticles as Catalyst for Chan–Lam Cross-Coupling Reaction under Base Free Condition. Catal Lett 148, 547–554 (2018). https://doi.org/10.1007/s10562-017-2278-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-017-2278-z