Abstract

The effect of temperature, pressure, space velocity and feed-stream water content in the synthesis of dimethyl ether from methanol over a K-HZSM-5 catalyst was evaluated with respect to the activity, physicochemical properties and deactivation of the catalyst. Increasing the water content in the feed stream allowed to proceed the reaction over a wider temperature range. Despite a decrease in the methanol conversion at low temperatures (<250 °C), methanol conversions and dimethyl ether selectivities of more than 50 and 99%, respectively, were achieved. It was found that deactivation of the catalyst due to coke formation or dealumination occurred depending on the amount of water in the feed stream. Coke as covering the catalyst particle surface deactivates the catalyst. Aromatic compounds entrapped in the pores affect acidity, pore volume, surface area and also conversion. Although catalyst deactivation due to dealumination caused a 20% decrease in the methanol conversion, the stability of K-HZSM-5 is expected to be improved by the addition of a proper amount of water in the feed.

Graphical Abstract

MTD reaction over K-HZSM-5 at a reaction temperature of 340 °C with various LHSV-pressure-water content conditions for 300 h on stream; (red) 10-10-0, (blue) 10-10-50, (black) 20-10-50, where the three numbers correspond LHSV (h−1)-pressure (bar)-percentage of water.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Dimethyl ether (DME) has drawn global attention as an alternative fuel for diesel engines and domestic applications due to it exhibiting lower emission and smoke production than traditional diesel fuel and liquefied petroleum gas (LPG) [1–3]. DME is also used as an aerosol propellant in products such as hair and insecticide spray owing to its environmental benignity and low human health risk in comparison with chlorofluorocarbons and LPG [4]. It is also an intermediate in the production of various chemicals, such as methyl acetate and dimethyl sulfate [4–6]. Thus, global DME demand is expected to grow in the near future.

DME can be generated via a direct method or an indirect method. In the former, syngas conversion to DME (STD) takes place over a hybrid catalyst possessing metallic and acidic functionalities, while in the latter, DME is produced through dehydration of methanol over a solid acid catalyst [7–10]. Recently, STD has drawn the scientist attention and is regarded as a promising route due to its economic value and sustainability [5]; however, further profound studies should be fulfilled to optimize the composition of active catalyst components as well as operating condition for commercial use [8, 11]. Although the methanol to DME (MTD) process is well matured and widely used in industry, further investigations are necessary to ensure improved stability, DME productivity and efficiency.

Since the indirect method was first reported by Mobil in 1965, the MTD process using an ɤ-Al2O3 catalyst has been widely commercialized owing to the ease with which reaction conditions may be controlled, ensuring both high catalytic activity and DME selectivity [8]. However, ɤ-Al2O3 catalysts exhibit low reactivity at low reaction temperatures and in the presence of water due to their hydrophilicity, which narrows the flexibility of their industrial operation using water containing-methanol as a feed. For ɤ-Al2O3, which presents only Lewis acid sites on its surface, methanol molecules adsorb onto the acid sites as alkoxide anions to form ethers [12, 13]. At the same time, water molecules formed during the reaction can competitively adsorb and block the Lewis acid sites, leading to substantial deactivation of the catalyst [14]. In order to overcome the limitations of ɤ-Al2O3, zeolite-based catalysts, such as HZSM-5, have been widely investigated for methanol dehydration to DME owing to their acidic nature. Formation of DME from methanol takes place via various pathways that result from both Brönsted and Lewis acid sites of the zeolite based catalysts [15–18]. Furthermore, according to kinetic investigations, the predominant reaction pathway, in which an adsorbed methanol molecule on a Brönsted acid site after water elimination reacts with a second methanol molecule to form DME, is not significantly inhibited by water molecules [14, 15, 19, 20].

Despite their benefits, formation of hydrocarbon (HC) products, resulted from runaway reaction and deactivation of zeolite catalysts by coking and dealumination during the MTD reaction has limited their use in industrial processes. Although the HCs produced during the reaction could be separated and used as other value-added products, they increase the operating cost for separation and contaminate the whole system. Furthermore, once light olefinic intermediates, such as ethylene, form in consequence of complete dehydration of methoxy species absorbed on the acid sites, the reaction undergoes methanol-to-hydrocarbon rather than MTD and similarly catalyst deactivation by coke formation also follows the same route of the reaction: oligomerization, cyclization, aromatization and condensation of alkylbenzene, resulting in substantial deterioration of the catalyst life time and a low DME yield [21–25]. Hence, modified zeolite catalysts, such as Na-HZSM-5, K-HZSM-5, Ce-zeolite Y and P-HZSM-5, have been studied with the purpose of improving coke resistance and hydrothermal stability in the MTD reaction [8, 10, 26–32]. Of these, alkali metal promoted catalysts, such as Na-HZSM-5 and K-HZSM-5, exhibited enhanced stability and wider operating temperature ranges (OTRs), exhibiting methanol conversion and dimethyl ether selectivity of >50 and 99%, respectively. These results imply that cost reduction may be achievable under flexible operation conditions [20, 27]. Nevertheless, systematic investigation into the effect of reaction parameters on the reactivity and deactivation of the zeolite catalysts, especially K-HZSM-5, has not been reported. Therefore, the objective of the present work is to investigate the influence of a variety of reaction parameters in the MTD reaction, such as temperature, pressure, space velocity and feed-stream water content, on the activity, physicochemical properties and deactivation of a K-modified HZSM-5 catalyst.

2 Experimental

2.1 Catalyst Preparation

Potassium modified HZSM-5 catalyst was prepared by wet impregnation method. NH4-ZSM-5 (NAIKE, SiO2/Al2O3 = 50) was extruded with boehmite (NH4-ZSM-5:γ-AlO(OH) = 80:20). The extrudate was calcined in a tubular furnace under the flow of air at 600 °C for 5 h to prepare HZSM-5. The required amount of KNO3 solution (SAMCHUM, 99.0%) satisfying K/Al molar ratio of 0.6 was mixed with the HZSM-5 and the mixture was dried using a rotary evaporator at 80 °C and 200 torr. The K-HZSM-5 was finally obtained after drying at 110 °C for overnight and calcination at 550 °C for 5 h. The content of K obtained by means of the inductively coupled plasma-atomic emission spectrometer (ICP-AES, Thermo Scientific iCAP 7400) was 1.7 wt% for the K-HZSM-5.

2.2 Catalyst Characterization

The Brunauer-Emmett-Teller (BET) surface area, pore volume and pore diameter were measured by N2 adsorption–desorption isotherm at -196 °C using TriStar 3000 (Micromeritics). Prior to the adsorption–desorption measurements, all of the samples were degassed at 300 °C under 1.0 × 10−6 torr for 4 h.

Powder X-ray diffraction (XRD) was used to identity peak shape and crystallinity for the fresh and spent K-HZSM-5 catalysts. A Rigaku D/MAX IIIB X-ray diffractometer with Cu-Kα radiations was used for bulk phase analysis. All spectra were collected at 2θ values between 3° and 80° using a step size of 0.02° and 2 s per step.

Temperature programmed desorption of ammonia (NH3-TPD) was carried out to determine acidity change of the fresh and spent K-HZSM-5 using the Autochem II 2920 of Micromeritics instrument. Prior to NH3-TPD experiment, all samples were pre-treated at 600 °C under 50 mL/min flow of pure He for 1 h in order to remove adsorbed water and saturated with 15% NH3 (balance He, flow rate: 50 mL/min) for 30 min at 100 °C. After the saturation step, the samples were purged with He for 30 min to eliminate weakly adsorbed ammonia on the surface of the catalysts. Finally, NH3 desorption was performed at a ramping rate of 10 °C/min up to 700 °C under 50 mL/min flow of pure He.

27Al solid-state magic angle spinning (MAS) NMR experiments were performed on Varian Unity INOVA 600 MHz (14.09 T) spectrometer with a 2.5 mm low aluminum-zirconia MAS probe at a rotation rate of 22 kHz. The NMR spectra were obtained at Larmor frequencies of 156.32 MHz using a short RF pulse length of 1.8 µs and a repetition delay time of 2 s.

Elemental Analysis (EA) was carried out to determine carbon content and H/C ratio of carbon deposits formed on the spent K-HZSM-5 catalysts using Thermo Scientific Flash 2000 equipped with a thermal conductivity detector (TCD) after the samples were pretreated with He at 200 °C to remove weakly chemisorbed carbon species.

Ultraviolet/Visible Spectrophotometer (UV/Vis) diffusing reflectance spectra were obtained using SCINCO-4100 spectrometer equipped with a photo diode array detector and a diffuse reflectance attachment.

Scanning electron microscopy (SEM) images of the ZSM-5 catalysts were obtained using a Zeiss Ultraplus Thermal Field Emission Scanning Electron Microscope.

2.3 Catalytic Performance Evaluation

The methanol dehydration reaction was performed in a fixed bed down-flow reactor that consisted of stainless steel tube (9 mm i.d.) loaded with 1 g (approximately 1.8 mL) of catalysts. Prior to the reaction, the catalyst were crushed, sieved (to 20–40 mesh size (or particle size around 0.85 mm)) and then were pretreated under N2 flow (100 mL/min) at 300 °C for 1 h. Methanol and water mixture, in which methanol volume % was controlled from 100 to 50%, was fed into a stainless steel evaporator held at 200 °C with a liquid hourly space velocity (LHSV) of 10 h−1 using HPLC pump (Younglin, SP930D) at 1, 5 and 10 bar, controlled by a back pressure regulator (Veriflo, ABP1). The reaction temperature was varied in the range of 190–400 °C. The effluent gas product was analyzed using an online gas chromatograph (Younglin, YL 6500) equipped with HP-PLOT/Q fused-silica capillary column (0.32 mm ID x 30 m, Agilent) for FID and Carboxen 1000 packed column (2 mm ID x 3.02 m, Agilent) for TCD. Methanol conversion and DME selectivity were defined by the Eqs. 1 and 2, respectively.

3 Results and Discussion

3.1 Effect of Operating Conditions on the Performance of K-HZSM-5

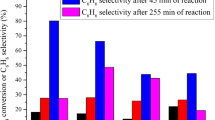

In order to understand the effect of reaction parameters on the catalytic activity for the MTD reaction, the prepared K-HZSM-5 catalyst was investigated with varying the water content in the feed stream, reaction pressure and LHSV, at reaction temperatures between 190 and 400 °C. The average conversions for the initial 5 h of the reaction under each set of reaction conditions are shown in Fig. 1. Prior to catalyst evaluation, pure methanol vapor was fed into the empty reactor tube and the methanol conversion was found to be less than 1% at the abovementioned temperature range. Thus, the possibility of thermal effects on the reactant was ruled out. Then, 0.2 g of K-boehmite, which K loading was adjusted as the same fraction of the K-HZSM-5 catalyst, was evaluated at the same temperature range to understand any contribution of the activity of the binder itself to overall performance of the catalyst. Up to a reaction temperature of 280 °C, methanol conversion showed lower than 1%, whereas it slightly increased by increasing the reaction temperature: 1.4% at 310 °C, 3.3% at 340 °C, 7.4%, at 370 °C and 15.2% at 400 °C and no HC formation occurred (DME selectivity of 100%). The methanol conversion increased with increasing reaction temperature, regardless of other reaction parameters, implying that the MTD reaction activity is directly related to temperature. As shown in Fig. 1a, when pure methanol was fed into the system at 10 bar with an LHSV of 10 h−1, the conversion increased from 23.9% at 190 °C to 78.3% at 220 °C; the system exhibited near equilibrium conversion of methanol to DME between 280 and 340 °C. However, the conversion jumped to 91.2% at 370 °C because of undesirable HCs formation, and the DME selectivity, which was 100% below 370 °C, dropped to 88.1% at 370 °C and 75.9% 400 °C (Fig. 1b). Conversely, with 20% water content in the feed stream, the conversion dramatically dropped at, particularly, low temperatures (4.9% at 190 °C and 19.4% at 220 °C) in comparison to those observed when using pure methanol; however, the conversion remained constant at ca. 80% in the temperature range 280 °C to 370 °C (Fig. 1a). The conversion at 400 °C also increased to 89.1% with a commensurate increase in HCs selectivity from 0 to 15.8%, leading to a decrease in DME selectivity (Fig. 1b). When comparing the catalytic activity with that of the bare HZSM-5 under the same reaction condition, the bare HZSM-5 exhibited not only higher conversion at low temperature range (Fig. S1-A), but also significant HCs formation at the reaction temperature above 280 °C (Fig. S1-B). The modification of the bare HZSM-5 with K is expected to result in the different catalytic activity due to a reduction in strong acid sites, particularly Brönsted acid sites. At a water content of 50% in the reactant feed, the conversion change upon varying the reaction temperature was very similar to that observed for a water content of 20%, but no HC formation observed at any temperature. The methanol conversion changed monotonously and maintained around 81% above 310 °C. In fact, it should be noted that an addition of water (or steam) in feed stream could cause methanol conversion reaction to stabilize by attenuating reaction rate [33]. Accordingly, formation of HCs was suppressed with increasing water content and the exothermic heat effect during the reaction is reduced so that DME production can be more easily stabilized, even at relatively high temperatures.

The methanol conversion increased by factor of 0.3–7 as the reaction pressure increased from 1 to 10 bar in the temperature range 190–400 °C (Fig. 2a); the conversion at 5 bar was maintained at a median of the conversion at 1 bar and 10 bar. Under the reaction condition, K-H-ZSM-5 exhibited above 99% of DME selectivities (Fig. 2b). The reaction temperature, where the conversion and DME yield reached the highest value, decreased with increasing the reaction pressure: 310 °C for 10 bar, 340 °C for 5 bar and 370 °C for 1 bar. No HC formation was observed in any cases. Thus, these results indicate that the reaction pressure is linearly correlated to the activity of the K-HZSM-5 catalyst, but is not related to HCs formation.

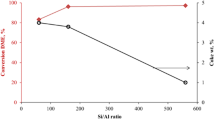

Similar trend was observed with LHSVs of 5 h−1 and 10 h−1 at 10 bar for a water content of 50%: the conversion and DME yield substantially increased at 250 °C and reached the maximum features at 310 °C: 86.1% for LHSV of 5 h−1 and 81.6% for an LHSV of 10 h−1 (Fig. 3). On the other hand, when the LHSV is increased to 20 h−1, no dramatic increase in the conversion was observed but gradually increased to 79.7% at 400 °C (Fig. 3a). Runaway reaction only took place with an LHSV of 5 h−1 at 400 °C, leading to DME production of almost zero (Fig. 3b). In fact, it is generally accepted that conversion decreases with decreasing space time (or increasing space velocity) and our results follow that trend. Furthermore, formation of methoxy group on the Brönsted acid sites has been recently reported to be not only the predominant reaction pathway but also the rate limiting step for the overall methanol conversion reaction at the same time [18, 34]. Accordingly, the HCs formation with the long enough space time (LHSV of 5 h−1) at the high enough reaction temperature (400 °C) can be regarded as a rational consequence.

Aforementioned, the activity of ZSM-5-based catalysts must be stable over a wide temperature range owing to the exothermic nature of the reaction for practical application to the MTD reaction, as temperature runaway can cause auto-acceleration of side reactions and the formation of hydrocarbons as byproducts. Accordingly, OTR affording methanol conversions higher than 50%, with DME selectivity higher than 99%, for each set of reaction conditions is shown in Fig. 4 and the corresponding description and indication of hydrocarbon formation for the each reaction condition are presented in Table 1. The OTR becomes narrow and shifts to lower temperature as the water content in the feed stream decreases. Comparison of OTR between the K-HZSM-5 and the bare HZSM-5 under the same reaction condition (Fig. S1) verifies much broader OTR of the K-HZSM-5: 250– 370 °C for the K-HZSM-5 and 220– 250 °C for the bare HZSM-5. The low catalytic activity for the MTD reaction at 1 bar (Fig. 4d) and 5 bar (Fig. 4e) also results in a narrow OTR in comparison to that at 10 bar (Fig. 4c). The OTR is also limited below 370 °C for an LHSV of 5 h−1 (Fig. 4f) and above 310 °C for an LHSV of 20 h−1 (Fig. 4g). Thus, the widest OTR (Fig. 4c) is obtained when the water content, pressure and LHSV are 50%, 10 bar and 10 h−1, respectively.

3.2 Long Term Stability and Characterization of Deactivated Catalysts

Among the various reaction conditions above, three specific reaction conditions at a fixed reaction temperature (340 °C) were investigated using the K-HZSM-5 catalyst for longer operation times (Fig. 5). Under the 10-10-50 conditions, the methanol conversion remained at ca. 80% for 300 h on stream; however, a reduction in the conversion occurred under the other conditions. For the 10-10-0 conditions, the methanol conversion started to drop from 86% at 170 h and reduced to almost 10% after 260 h on stream. A constant conversion of ~50% was seen after 60 h on stream under the 20-10-50 conditions, despite the conversion drop of ~12% between 30 and 60 h on stream.

MTD reaction over K-HZSM-5 at a reaction temperature of 340 °C with various LHSV-pressure-water content conditions for 300 h on stream; (red) LHSV = 10 h−1, pressure = 10 bar, water content = 0%, (blue) LHSV = 10 h−1, pressure = 10 bar, water content = 50%, (black) LHSV = 20 h−1, pressure = 10 bar, water content = 50%

The XRD patterns of the fresh and spent K-HZSM-5 catalysts after 300 h TOS at a reaction temperature of 340 °C are shown in Fig. 6. The fresh catalyst exhibits characteristic diffraction peaks of the mordenite framework inverted (MFI) structure at 2θ = 23.03°, 23.24° and 23.67°, indicating a monoclinic structure. Relative intensity of the spent catalyst determined via ASTM D5758 method [35] is found to be the lowest: 75.7% for 10-10-0, 80.5% for 10-10-50 and 79.2% for 20-10-50. The reduced relative crystallinity of the spent catalysts could be attributed by adsorbed carbon atoms or/and dealumination. Furthermore, for the spent catalyst used with pure methanol as the feed, the XRD peaks at 23.03°and 23.24° appear as a single peak at 23.11°, indicating that the crystalline structure of the catalyst changes to a tetragonal structure [pattern (b)]. Conversely, no apparent change in the peak shape and peak shift is observed for other spent catalysts. The change in the XRD pattern and the decrease in relative intensity could be caused by carbon atoms bonding with tetrahedrally coordinated aluminum sites, where the Brönsted and Lewis acid sites originated, in the ZSM-5 framework. This result is consistent with previous studies in which the crystalline structure of ZSM-5 was reported to change from orthorhombic to tetragonal after a catalytic reaction with hydrocarbons, due to the formation of coke deposits [36, 37].

NH3-TPD curves of the fresh and spent catalysts collected following different MTD reaction conditions are shown in Fig. 7. Peaks are clearly observed at 181 °C and 358 °C for the fresh HZSM-5, corresponding to the weak and strong acid sites, respectively [curve (a)]. Modification of the HZSM-5 with K results in the disappearance of the NH3 desorption peak at higher temperature, indicating removal of the strong acid sites, which are most probably Brönsted acid sites and expected to be attenuated for the broad OTR. For the spent K-HZSM-5 used under the 10-10-0 conditions [curve (c)], the peak intensity at 181 °C is much lower and the peaks emerging at the same temperature become broader when the water content of the feed stream increases [curve (e)] in comparison to the case of the fresh K-HZSM-5. The peak broadening is presumably caused by the emergence of new acid sites. This indicates that the acidity of a solid acid catalyst during the MTD reaction may vary depending on the reaction conditions.

NH3-TPD curves of the fresh HZSM-5 (a), K-HZSM-5 (b) and the spent K-HZSM-5 collected after MTD reaction at 340 °C for 300 h on stream; (c) LHSV = 10 h−1, pressure = 10 bar, water content = 0%, (d) LHSV = 10 h−1, pressure = 10 bar, water content = 50%, (e) LHSV = 20 h−1, pressure = 10 bar, water content = 50%

The acidity, textural properties and carbon content of the fresh and the spent K-HZSM-5 catalysts are summarized in Table 2. All the spent K-HZSM-5 catalysts contain carbon deposits, with the spent K-HZSM-5 used with pure methanol as a feed (c) exhibiting the highest deposit level. If the first C–C bond is formed via carbonylation of methoxy group on the acid sites under the reaction condition, that possibly results in formation of light olefinic species [38]. Hence, those olefinic carbon species, which are expected to be bonded with Al atoms in the framework and block the micropores as they grow into aromatic coke via the sequence step, induce changes in the XRD pattern at 22° and 24° (Fig. 6b) and cause a decrease in the total acidity as well as textural properties such as surface area and pore volume of the K-HZSM-5 catalyst when pure methanol is used as the reactant. Conversely, the use of water-containing methanol as a feed does not lead to modification of the textural properties and acidity of K-HZSM-5, implying lower carbon deposition in this case. The presence of water in the feed reduces carbon deposition, i.e., coking, by several mechanisms: (i) water acts as a diluent, (ii) water acts a reactant, contributing to partial gasification of the carbon deposits, (iii) water slow down reaction rate and (iv) water competes with methanol for the adsorption of coke formation, leading to attenuation of the rate of coke formation [33, 39–42].

The structural nature of the carbon deposits formed on the K-HZSM-5 catalysts during the MTD reaction was identified using UV–Vis spectroscopy. As shown in Fig. 8, spectrum (a) differs noticeably from the other spectra. In this case, peaks are seen at 285–315 nm, 390–400 nm, 440–510 nm and 540–575 nm, which are attributed to allyl cations or neutral di- and trienes, diphenyl and aromatic cations, polyphenyl cations or alkylaromatic cations and polyaromatic cations, respectively [43–46]. Conversely, the peak at 290–330 nm, indicating the presence of monodienyl cations, is observed in spectra (b) and (c), and a peak (350–360 nm) corresponding to dienyl carbonium is exhibited by the spent catalyst used with an LHSV of 20 h−1 [47]. This indicates that when pure methanol is used as a feed, methyl cation intermediates are formed on the surface of the catalyst during the dehydration of methanol, forming mono- or polyaromatic structures through oligomerization, cyclization, dehydrogenation and aromatization steps; this in turn leads to increased carbon deposition and a decrease in the surface area and pore volume. However, simple-structured oxygenates are formed on the surface of the catalyst with water-containing methanol as the feed; consequently, a low carbon content and increased acidity are observed.

Modification of the acidity and catalytic activity of solid acid catalysts during hydrocarbon and alcohol transfer reactions happens in some cases. When alcohol conversion into other oxygenates or hydrocarbons is carried out over solid acid catalysts, oxygen-containing carbon molecules, such as quinones or hydroxyls, can be formed on the surface depending on the water content in the reactant feed [48, 49]. Furthermore, weak acid sites can be formed on the pentahedrally coordinated Al atoms via the formation of aluminum hydroxyl groups (AlOH). Similarly, such hydroxyl-containing carbon deposits and AlOH could result in the creation of new, weak acid sites when the LHSV is 20 h−1.

27Al MAS NMR analysis was performed to determine the coordination of Al atoms in the K-HZSM-5 framework after the 300 h TOS experiments. As shown in Fig. 9, all the K-HZSM-5 [curve (a)] catalysts exhibit major peaks at 68, 55 and 9 ppm. The peaks at 68 and 9 ppm are associated with tetrahedrally and octahedrally coordinated Al atoms in the alumina binder; on the other hand, the peak at 55 ppm is attributed to tetrahedrally coordinated Al atoms in the K-HZSM-5 framework, on which strong Brönsted and Lewis acid sites are located [50, 51]. In addition, the latter peak from the spent K-HZSM-5 operated under LHSV-bar-water content conditions of 10-10-0 [curve (b)] broadens slightly and shifts to 53 ppm, presumably due to the presence of coke species interacting with the framework Al [52]. However, an additional peak emerges at 50 ppm from the spent K-HZSM-5 operated under LHSV-bar-water content conditions of 20-10-50 [curve (d)]. This proves the appearance of pentahedrally coordinated Al atoms, which is associated with dealumination or the presence of non-framework aluminum [53], with an increase in water throughput but not methanol throughput.

27Al MAS NMR spectra of the fresh K-HZSM-5 (a) and the spent K-HZSM-5 collected after MTD reaction at 340 °C for 300 h on stream; (b) LHSV = 10 h−1, pressure = 10 bar, water content = 0%, (c) LHSV = 10 h−1, pressure = 10 bar, water content = 50%, (d) LHSV = 20 h−1, pressure = 10 bar, water content = 50%

SEM images of the fresh and the spent K-HZSM-5 catalysts are illustrated in Fig. 10. There is no distinguishable change between the surface roughness of the spent catalysts operated under LHSV-bar-water content conditions of 10-10-50 (Fig. 10c) and 20-10-50 (Fig. 10d) in comparison to those of the fresh catalyst. However, the surface of the spent catalyst used under 10-10-0 conditions (Fig. 10b) is completely covered by worm-like nano-sized tubes, which are expected to be coke formed during the MTD reaction: coke precursors adsorbed onto the acid sites block the pores via a fast circulation and spread to external surface of the K-HZSM-5 catalyst. Therefore, the substantial deterioration of the catalysts life time under 10-10-0 condition is mainly resulted from coke formation.

In summary, deactivation of the K-HZSM-5 catalyst is caused by coke formation or dealumination depending on the water content in the methanol feed. In the used catalysts, the pores are mainly filled with aromatic molecules which have been entraped because of coke covering the catalyst particles surfaces; this being the actual reason for deactivation. The entrapped aromatics on acidic sites reduce catalyst acidity and activity up to 90% during the 300 h on stream test. Dealumination also damages the dehydration activity of the catalyst but not as severely as coke formation; further, dealumination does not occur under the specific reaction conditions (10-10-50). Furthermore, the use of water containing methanol is advantageous in broadening the OTR by alleviating runaway reactions. Hence, a proper amount of water in the feed could improve the stability of the K-HZSM-5 catalyst.

4 Conclusion

The MTD reaction over a K-HZSM-5 catalyst was investigated, and the effects of temperature, pressure, space velocity and water content in the feed stream on the activity, physicochemical properties and deactivation of the catalyst were assessed. Although the addition of water in the feed stream decreased the methanol conversion, a DME selectivity of 100% was achieved at high reaction temperatures, without HC formation. The HC formation was not significantly related to the reaction pressure, while the catalytic activity changed linearly with the reaction pressure. As the flow rate of the feed stream increased, the methanol conversion decreased at low temperature and the DME selectivity increased at high temperature. Furthermore, the conversion drop at low temperature (<250 °C) was severe when the flow rate reached transition conditions. Deactivation of the K-HZSM-5 catalyst resulted from coke formation or dealumination under the specific reaction conditions. Catalyst deactivation due to dealumination, which caused a 20% drop in the methanol conversion during the initial period of the reaction, depends on the amount of water in the feed stream. Furthermore, simple-structured oxygenates develop on the surface of the catalyst when using water-containing methanol as the feed. However, aromatic-structured coke is formed on the surface of the catalyst with pure methanol as the feed; this leads to the highest carbon content as well as a decrease in acidity and surface area, thereby resulting in a significant conversion drop (up to 90%) during the 300 h on stream test. Therefore, formation of aromatic-structured coke degrades the catalytic performance of K-HZSM-5 to a greater extent than does dealumination. In conclusion, the reaction parameters for DME synthesis from methanol should be managed appropriately to obtain sufficient DME selectivity as well as catalytic activity.

References

Fleisch T, McCarthy C, Basu A, Udovich C, Charbonneau P, Slodowske W (1995) SAE Trans J Fuel Lubr 104(4):54–59

Semelsberger TA, Borup RL, Greene HL (2006) J Power Sources 156:497–511

Zannis TC, Hountalas DT (2004) Energy Fuels 18:659–666

Olah GA, Goeppert A, Prakash GKS (2009) J Org Chem 74:487–498

Sun J, Yang G, Yoneyama Y, Tsubaki N (2014) ACS Catal 4:3346–3356

Sun M, Yu L, Sun C, Song Y (2003) Gen Rev 20:695–699

Azizi Z, Rezaeimanesh M, Tohidian T, Rahimpour MR (2014) Chem Eng Process 82:150–172

Tang Q, Xua H, Zheng Y, Wang J, Li H, Zhang J (2012) Appl Catal A 413–414:36–42

Baek SC, Lee YJ, Jun KW, Hong SB (2009) Energy Fuels 23:593–598

Jin D, Zhu B, Hou Z, Fei J, Lou H, Zheng X (2007) Fuel 86:2707–2713

Clausen LR, Elmegaard B, Ahrenfeldt J, Henriksen U (2011) Energy 36(10):5805–5814

DeWilde JF, Chiang H, Hickman DA, Ho CR, Bhan A (2013) ACS Catal 3:798–807

Akarmazyan SS, Panagiotopoulou P, Kambolis A, Papadopoulou C (2014) Appl Catal B 145:136–148

Jun KW, Lee HS, Roh HS, Park SE (2002) Bull Korean Chem Soc 23:803–806

Blaszkowski SR, van Santen RA (1997) J Phys Chem B 101:2292–2305

Laugel G, Nitsch X, Ocampo F, Louis B (2011) Appl Catal A 402:139–145

Rutkowska M, Macina D, Mirocha-Kubień N, Piwowarska Z, Chmielarz L (2015) Appl Catal B 174–175:336–343

Moses PG, Nørskov JK (2013) ACS Catal 3:735–745

Carr RT, Neurock M, Iglesia E (2011) J Catal 278:79–93

Ha KS, Lee YJ, Bae JW, Kim YW, Woo MH, Kim HS, Park MJ, Jun K-W (2011) Appl Catal A 395:95–106

Schulz H (2010) Catal Today 154:183–194

Zhang G, Zhang X, Bai T, Chen T, Fan W (2015) J Energy Chem 24:108–118

Guisnet M, Magnoux P (2001) Appl Catal A 212:83–96

Kim S, Sasmaz E, Lauterbach J (2015) Appl Catal B 168:212–219

Ibáñez M, Gamero M, Ruiz-Martínez J, Weckhuysen BM, Aguayo AT, Bilbao J, Castaño P (2016) Catal Sci Technol 6:296–306

Vishwanathan V, Jun KW, Kim JW, Roh HS (2004) Appl Catal A 276:251–255

Kim SD, Baek SC, Lee YJ, Jun KW, Kim MJ, Yoo IS (2006) Appl Catal A 309:139–143

Zhang L, Wang J, Wu P, Hou Z, Fei J, Zheng X (2010) Chin J Catal 31:987–992

Hassanpour S, Yaripour F, Taghizadeh M (2010) Fuel Process Technol 91:1212–1221

Li H, He S, Ma K, Wu Q, Jiao Q, Sun K (2013) Appl Catal B 450:152–159

Rutkowska M, Macina D, Mirocha-Kubien N, Piwowarska Z, Chmielarz L (2015) Appl Catal A 174:336–343

Lee YJ, Kim JM, Bae JW, Shin CH, Jun KW (2009) Fuel 88:1915–1921

Pérez-Uriarte P, Ateka A, Aguayo AT, Gayubo AG, Bilbao J (2016) Chem Eng J 302:801–810

Olsbye U, Saure OV, Muddada NB, Bordiga S, Lamberti C, Nilsen MH, Lillerud KP, Svelle S (2011) Catal Today 171:211–220

ASTM Standard D5758-01, Standard Test Method for Determination of Relative Crystallinity of Zeolite ZSM-5 by X-Ray Diffraction 2011. ASTM International, West Conshohocken. doi:10.1520/D5758-01R11E01

Alvarez AG, Viturro H, Bonetto RD (1992) Mater Chem Phys 32:135–140

Kim S, Sasmaz E, Lauterbach J (2015) Appl Catal B 168–169:212–219

Liu Y, Mîller S, Berger D, Jelic J, Reuter K, Tonigold M, Sanchez-Sanchez M, Lercher JA (2016) Angew Chem 128:5817–5820

Prasad YS, Bakhshi NN, Mathews JF, Eager RL (1986) Can J Chem Eng 64(2):278–284

Gayubo AG, Aguayo AT, Morán AL, Olazar M, Bilbao J (2002) AIChE J 48:1561–1571

Katikaneni SPR, Adjaye JD, Bakhshi NN (1995) Energy Fuels 9 (4):599–609. doi:10.1021/ef00052a005

Katikaneni SPR, Adjaye JD, Bakhshi NN (1995) Can J Chem Eng 73(4):484–497

Pazè C, Sazak B, Zecchina A, Dwyer J (1999) J Phys Chem B 103:9978–9986

Hunger M, Weitkamp J (2001) Angew Chem Int Ed 40:2954–2971

Chung Y-M, Mores D, Weckhuysen BM (2011) Appl Catal A 404(1):12–20

Castaño P, Gutiérrez A, Hita I, Arandes JM, Aguayo AsT, Bilbao J (2012) Energy Fuels 26 (3):1509–1519

Flego C, Kiricsi I, Parker WO Jr, Clerici MG (1995) Appl Catal A 124:107–119

Lisovskii AE, Aharoni C (1994) Catal Rev Sci Eng 36:25–74

Nederlof C, Kapteijn F, Makkee M (2012) Appl Catal A 29:163–173

Dell LAO, Savin SLP, Chadwick AV, Smith ME (2007) Solid State Nucl Mag Reson 134:83-102

Muller M, Harvey G, Prins R (2000) Microporous Mesoporous Mater 34(2):135–147. doi:10.1016/s1387-1811(99)00167-5

Meinhold RH, Bibby DM (1990) Zeolites 10:146–150

Dedecek J, Balgova V, Pashkova V, Klein P, Wichterlova B (2012) Chem Mater 24(16):3231–3239

Acknowledgements

This work was supported by Korea Institute of Energy Technology Evaluation and Planning (KETEP) under “Energy Efficiency & Resources Programs” (Project No. 2012T100201578) of the Ministry of Trade, Industry and Energy, and the core KRICT project (KK1601-B00) from Korea Research Institute of Chemical Technology and C1 Gas Refinery Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Science, ICT & Future Planning (2015M3D3A1064901). The authors would like to acknowledge Korea Basic Science Institute (KBSI) at western Seoul center for 27Al MAS NMR analysis.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Kim, S., Kim, Y.T., Zhang, C. et al. Effect of Reaction Conditions on the Catalytic Dehydration of Methanol to Dimethyl Ether Over a K-modified HZSM-5 Catalyst. Catal Lett 147, 792–801 (2017). https://doi.org/10.1007/s10562-017-1981-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-017-1981-0