Abstract

Enantiomerically enriched aromatic secondary alcohols and its derivatives are important chiral intermediates utilized widely in pharmacy, chemical, hormone, spices and chiral auxiliary materials. Thus, the key factors affecting the asymmetric reduction were successfully analyzed using R. mucilaginosa CCTCC M2014255 resting cells. The optimal temperature, buffer pH, co-substrate and its concentration, resting cells concentration were systematically investigated. Under the optimized conditions, acetophenone and its derivatives were effectively asymmetrically reduced by R.mucilaginosa CCTCC M2014255 while the conversion reached >99.0 % and e.e. of product were >99.0 %, respectively. These results provide a theoretical and technical support for realizing industrialized production of enantiomerically enriched aromatic secondary alcohols by microbial catalytic asymmetric synthesis.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Background

As the versatile chiral drug intermediates, single enantiomers of phenylethanol and its derivatives are utilized as the starting material to synthesize various chiral drugs such as (S)-clorprenaline, (S)-fluoxetine, (R)-atomoxetine and (R)-salbutamol [1, 2]. In order to gain phenylethanol and its derivatives with enantiomerically pure state, the efficient method is the catalytic asymmetric synthesis [3–6]. Recently, the asymmetric reduction of carbonyl compounds by biocatalysts has attracted extensive attention due to the performance under milder reaction conditions, shorter reaction time, environmental benignancy and the excellent stereoselectivity of the reaction [6, 7].

The biocatalysts was divided into isolated enzyme catalysis and incubated whole-cell catalysis [8–10]. In contrast, incubated whole-cell catalysis can save not only the processes of separation and purification of enzymes, but also the co-factor regeneration system such as nicotinamide adenine dinucleotide phosphate (NADPH) or (NADH). When prochiral ketoneswere asymmetrically reduced by carbonyl reductase, coenzyme NAD(P)H as a hydrogen donor was needed in the reduction reaction. However, glucose and other cheap energy substances can be utilized to regenerate the coenzyme NAD(P)H required by carbonyl-reductase in the whole-cell based catalysis [11–13].

Microbial resting cells are starved cells suspended in physiological saline or buffer for a period to consume intracellular nutrients. Although resting cells are in hibernation without reproduction, they still contain a variety of enzymes and the abilities to degrade or synthesis of proteins and lipids and secret proteins outside to support some vegetative tissues [14, 15]. Therefore, there are growth and catalytic properties for microbial resting cells under the reaction conditions without nitrogen source. So far, many literatures on catalytic asymmetric reduction reaction by resting cells have been reported [16, 17]. Narancic et al. found that highly efficient Michael-type addition of acetaldehyde to β-nitrostyrenes by whole resting cells of Escherichia coli expressing 4-oxalocrotonate tautomerase [18]. Moreover, our previous work also showed that the efficient asymmetric reduction of acetone acid ethyl ester to (S)-lactic acid ethyl ester by yeast resting cells [19]. Nevertheless, there are only few microorganisms reported to catalyze acetophenone to aromatic secondary alcohols with (S)-absolute configuration used in the industry, due to the low catalytic activity and stereoselectivity. Taken together, finding a microbial catalyst with high catallytic activities and stabilities is an effective way to promote asymmetric reduction for industrial application. In the present study, the effects of important variables on the bioreduction of acetophenone and its derivatives with R. mucilaginosa CCTCC M2014255 resting cells obtained by rescreening were systematically investigated.

2 Results and Discussion

2.1 Comparison of the Biocatalytic Asymmetric Reduction of Acetophenone with R. mucilaginosa CCTCC M2014255 and Other Potential Microorganisms

Eight strains microorganisms with the abilities of asymmetric reduction of acetophenone to (S)-1-phenylethanol were isolated and purified from sewage and the neighboring soil samples from a chemical factory in Chengdu. As can be shown in Table 1, the strain WD-B5 with high biotransformation activities and inheritable qualities was obtained by rescreening. Based on the analysis of physiological and biochemical characteristics and 26S rDNA D1/D2 domain sequence with its general morphology, WD-B5 deposited at China Center for Type Culture Collection (CCTCC) with number CCTCC M2014255 was identified as Rhodotorula mucilaginosa.

2.2 Catalytic Activity and Stability of R. mucilaginosa CCTCC M2014255 Cells

To assess the stability of catalytic activity of strain cells, R. mucilaginosa CCTCC M2014255 was sub-cultured for 20 generations. The results showed that the asymmetric reduction capability of the first, fifth, tenth, fifteenth and twentieth generation strains were quite stable while the conversion always reached >40.8 %, and the e.e. of product was stable at >96.3 %.

2.3 Effects of Several Key Variables on the Biocatalytic Asymmetric Reduction of Acetophenone to (S)-Aromatic Secondary Alcohols with R. mucilaginosa CCTCC M2014255 Cells

To gain a deeper insight into the reduction and improve the initial reaction rate, the effects of several important variables were systematically investigated such as reaction time, temperature, buffer pH, co-substrate concentration, cell concentration and substrate concentration. As shown in Fig. 1, the conversion raised accompanied with the progress of the reaction and reached the maximum at 36 h. However, the conversion did not increase after 36 h, which was due to the inhibition of the cell growth and product accumulation [20]. Moreover, the results showed that e.e. of product showed small changes after 36 h, thus, the best conversion time was 36 h.

As we all know, the effects of temperature on the enzymatic reaction had two sides. The activity, the selectivity and the stability of a biocatalyst and the equilibrium of reactions can be affected by temperature [21]. To explore the effect of temperature on the reaction, the bio-reduction was conducted at different temperatures. As shown in Fig. 2, the conversion increased markedly in the range of 20–30 °C. The substrate conversion reached the highest at 30 °C. However, the substrate conversion ratio decreased while the temperature kept rising from 30 to 38 °C, which could be attributed to the partial denaturation and deactivation of the enzymes at a higher temperature. On the other hand, the e.e. values of products showed no significant variation in the range of 20–38 °C. Hence, the optimum temperature of asymmetric reduction was considered as 30 °C, which was similar to the optimum temperature 25 °C of a novel carbonyl reductase from Acetobacter sp. CCTCC M209061 [22].

The initial pH of the reaction not only affects the configuration and stability of the enzymes, but also affects the substrate dissociation which in turn affects the reduction rate markedly. Therefore, a suitable pH will promote the combination of enzymes and substrate, improve the enzymatic activity and reaction rate [23]. To investigate the influence of pH on catalytic activity of R. mucilaginosa CCTCC M2014255, the conversion and e.e. of the product were both detected while the phosphate buffer solution was pH 5, 6, 6.2, 6.6, 6.8, 7.0 and 8.0 respectively. As shown in Fig. 3, the catalytic activity of the cells reached maximum with pH 7.0. The conversion dropped significantly with pH from 7.0 to 8.0 while the e.e. of product was still over 99.0 %. However, the conversion and e.e. of the product were the minimum while the pH was 9.0, indicating that oxidoreductases from R. mucilaginosa CCTCC M2014255 were more tolerant in acidic environment. Obviously, the optimal initial pH of the reaction system was 7.0 corresponding a broad pH optimum of a novel ketoreductase from the Cyanobacterium Synechococcus sp. Strain PCC7942 between pH 7.0 and pH 9.0 [24].

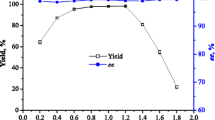

It is well known that the asymmetric reduction of acetophenone to (S)-1-phenylethanol is catalyzed by the intracellular oxidoreductase and coenzyme NAD(P)H as an electron donor. The reductions could proceed efficiently without adding expensive coenzyme NAD(P)H only if a co-substrate (glucose, glycerol or other energy substances) is present, which can be used to realize the regeneration of NADPH by the whole-cell [25]. Therefore, according to previous studies [19], glucose was selected as the auxiliary substrate to regenerate NADPH in this study. As shown in Fig. 4, a small amount of substrates were catalyzed without adding glucose in the reaction system (control), indicating that a certain amount of energy substances and coenzymes had already been accumulated in microbial cells prior to the reduction. Furthermore, the substrate conversion was markedly influenced as glucose concentration increasing from 0 to 2 %. When the glucose concentration was up to 2 %, the substrate conversion reached the maximum. However, the substrate conversion began to decline as the glucose concentration further increased. The possible reasons for this phenomenon might be due to the changes of osmotic pressure in the cells. Considering the e.e. of product kept constantly above 98.5 % with the tested range of glucose concentration, the optimal glucose concentration was settled to be 2 %.

Effect of glucose concentration on the asymmetric reduction of acetophenon to (S)-aromatic secondary alcohols by R. mucilaginosa CCTCC M2014255. Reaction conditions: 10 mL phosphate buffer (0.1 mol/L, pH 7.0), 2 g resting cells, 60 mmol/L acetophenone, 36 h, 150 r/min, 30 °C, different concentrations of glucose

In this study, the amount of incubated whole cells (cell loading) has also been taken into account in order to save biocatalyst as much as possible. When the amount of substrate was fixed, the conversion reaction had an obvious enhancement as the yeast cell loading increased. As shown in Fig. 5, the conversion reached the maximum when the resting cell loading increased to 0.25 g/mL. However, the substrate conversion lowered as the cell loading increased. This observation suggests that excessive cells could not be uniformly dispersed and not be sufficiently contacted with the substrate in reaction system. In this study, lots of cells deposited to the wall of flask bottles were observed while the cell concentration was too high. Moreover, The e.e. of product remained constant (about 99.0 %) in the range of cell loading.

Effect of resting cell concentrations on the asymmetric reduction of acetophenone to (S)-aromatic secondary alcohols by R. mucilaginosa CCTCC M2014255. Reaction conditions: 10 mL phosphate buffer (0.1 mol/L, pH 7.0), 2 % (W/V) glucose, 60 mmol/L acetophenone, 36 h, 150 r/min, 30 °C, gradient concentrations of resting cells

Under the improved reaction conditions, the best transition temperature was 30 °C; the pH was 7.0; the auxiliary substrate glucose concentration was 2 %; the amount of resting cells was 0.25 g/mL and the reaction time was 36 h. The suitable concentration of substrate was also examined under these conditions. As shown in Fig. 6, the conversion increased to the maximum value 96.8 % with the range of substrate concentration from 40 to 50 mmol/L, while the e.e. of product was constantly over 99.0 %. However, the substrate conversion decreased while the substrate concentration exceeded 50 mmol/L and the potential reason may be some substrate inhibitory effect. Taken together, the most suitable substrate concentration was 50 mmol/L, which was similar to the optimal substrate concentration 40 mmol/L in the reduction of prochiral ketones with whole-cell of Acetobacter pasteurianus GIM1.158 [11].

Effect of substrate concentrations on the asymmetric reduction of acetophenon to (S)-aromatic secondary alcohols by R. mucilaginosa CCTCC M2014255. Reaction conditions: 10 mL phosphate buffer (pH 7.0), 2 % (W/V) glucose, 36 h, 150 r/min, 30 °C, 0.25 g/mL(wet weight) resting cells, gradient concentions of acetophenone

To further improve the conversion and reduce the toxicity of substrate to the strain cells, addition of substrates were divided into twice. For example, in the initial reaction, 50 % substrates (acetophenone) were added, and the other half were added after 12 h. In these conditions, both of the maximum conversion and the e.e. of product were more than 99.0 %.

2.4 Stereoselective Reduction of Various Prochiral Carbonyl Compounds

To rationally evaluate the potential of R. mucilaginosa CCTCC M2014255 cells for the biocatalytic asymmetric reduction of carbonyl compounds, under the above mentioned conditions for acetophenone, eight derivatives of acetophenone, such as o-chloroacetophenone, o-methoxyacetophenone, o-methylacetophenone, p-fluoroacetophenone, propiophenone, 2-acetylthiophene and 2-acetylpyridine were tested for reduction. The results were shown in Table 2, the conversions of acetophenone, o-chloroacetophenone and o-methylacetophenone were higher (>90.0 %) respectively to give the product with (S)-configuration. The results showed the oxidoreductases of R. mucilaginosa CCTCC M2014255 had similar enantioselectivities of substrate, facially with related structure. However, the conversion of other derivatives was lower than that of acetophenone itself indicating the elaborated conversion conditions of acetophenone derivatives need to be further explored which also proved that enzymes had the high selectivity and specificity characteristics.

3 Conclusions

The conditions of asymmetric reduction of acetophenone to (S)-1-phenethylalcohol by R. mucilaginosa CCTCC M2014255 were systematically studied. The improved conditions are 30 °C, pH 7.0, 2 % glucose, resting cell concentration 0.25 g/mL (wet weight), the final substrate concentration 50 mmol/L adding in batch: 0 h; 50 %, 12 h; 50 %, 2 % ethanol for dissolution of substrate. The conversion could reach >99.0 % with e.e. >99.0 %. Under improved conversion conditions, the R.mucilaginosa CCTCC M2014255 could asymmetrically reduce acetophenone and its derivatives with better substrate transformation abilities.

In future work, to further increase the production and reduce the toxicity of high concentration of substrate on microbial cells, on one hand, we will try other methods such as cell immobilization, ionic liquid reaction system [26]. On the other hand, to obtain a new biocatalysts by genetic mutation or recombination through analyzing protein structure of carbonyl reductase from R.mucilaginosa CCTCC M 2014255 [27–29].

4 Materials and Methods

4.1 Biological and Chemical Materials

R. mucilaginosa CCTCC M2014255 was isolated and purified from sewage and the neighboring soil samples from a chemical factory in Chengdu, Sichuan, China. (R)-1-phenylethanol and (S)-1-phenylethanol (99 % purity) were purchased from Sigma-Aldrich. Acetophenone (ACP), other prochiral ketones and the corresponding alcohols were obtained from Chengdu Asta Tech Trading Co. Ltd (Chengdu, China). All other chemical and biochemical reagents (analytical grade) were from Chengdu Kelong Chemical Reagent Company.

4.2 Strain Cell Cultivation

R. mucilaginosa CCTCC M2014255 strain cells were activated firstly. A full ring of strain cells from the bottom of the activated slant medium were inoculated in a 20 mL seed medium for 24 h with the condition of 30 °C, 150 r/min. Then, seed culture liquid was inoculated in a 50 mL fermentation medium with 5 % final concentration. Fermentation conditions: 30 °C, 150 r/min and 48 h. The fermentation medium with pH 7.0 contains 10 g/L peptone, 5 g/L yeast extract, 2 g/L KH2PO4, 5 g/L (NH4)2SO4 and 20 g/L Glucose. Seed medium was yeast extract peptone dextrose (YPD) medium and slant medium was potato dextrose agar (PDA) medium.

4.3 Resting Cell Collection and Biocatalytic Asymmetric Reductions of Prochiral Ketones

2 g strain cells were collected by centrifuging at 4 °C, 6000 r/min for 10 min. Then, the collected strain cells were repeatedly purged for three times by 0.1 mol/L phosphate buffer (pH 6.6) and suspended with 10 mL 0.1 mol/L phosphate buffer (pH 6.6) with 60 mmol/L final substrate concentration and 2 % (w/v) glucose. The conditions of biocatalytic asymmetric reductions were 30 °C, pH 6.6, 150 r/min, 24 h. At the end of reactions, the product and the residual substrate were extracted by ethyl acetate (1:1, v/v) and dried by MgSO4. The substrate conversion and product e.e. value were determined by GC analysis. Substrate conversion (C) and enantiomeric excess (e.e.) was calculated as follows:

C 0 was the initial concentration of the substrate (mmol/L), C P was products concentration when the reaction was terminated (mmol/L), C S and C R represented the concentration of (R)-1-phenylethanol and (S)-1-phenyl ethanol (mol/L) respectively.

4.4 GC Analysis

Products were analyzed by GC instrument with an FID detector and β-DEX120 capillary column (30 m × 0.32 mm × 0.25 μm). Detection conditions: carrier gas was nitrogen (>99.9 %), injector temperature was 220 °C, the column temperature was 110–120 °C, FID detector temperature was 200 °C; split ratio was 1:100; the injection volume was 100 μL. The retention time of products were as follows.

The column temperature was held at 115 °C: (R)-1-phenylethanol (17.65 min), (S)-1-phenylethanol (18.77 min); (R)-p-fluorophenethylicalcohol (21.20 min), (S)-p-fluorophenethylicalcohol (23.81 min). The column temperature was held at 110 °C: (R)-o-chlorophenethylic alcohol (21.03 min), (S)-o-chlorophenethylicalcohol (23.07 min); (R)-o-methylphenethylicalcohol (20.00 min), (S)-methylphenethylicalcohol (22.30 min); (R)-o-methoxyphenethylicalcohol (18.03 min), (S)-o-methoxyphenethylicalcohol (19.27 min); (R)-phenylpropanol (24.13 min), (S)-phenylpropanol (26.53 min); (R)-1-thiophen-2-yl-ethanol (18.47 min), (S)-1-thiophen-2-yl-ethanol (20.02 min). The column temperature was held at 120 °C: (R)-1-pyridin-2-yl-ethanol (14.05 min), (S)-1-pyridin-2-yl-ethanol (16.68 min).

4.5 The Stability of Catalytic Activities of R. mucilaginosa CCTCC M2014255

R. mucilaginosa CCTCC M2014255 strain cells was sub-cultured for 20 generations. The asymmetric reduction of acetophenone to (S)-phenylethanol by the first, fifth, tenth, fifteenth, twentieth generation strains in an aqueous phase was investigated.

4.6 Several Key Variables of the Biocatalytic Asymmetric Reduction of Acetophenone to (S)-Phenylethanol with R. mucilaginosa CCTCC M2014255 Resting Cells

To further improve the conversion and e.e. of product, the key variables of the biocatalytic asymmetric reduction of acetophenone with R. mucilaginosa CCTCC M2014255 resting cells were studied, such as reaction temperature, buffer pH, different co-substrates and their concentration, cell concentration, substrate concentration and the way of substrate addition. Finally, some prochiral ketones such as o-chloro-acetophenone, o-methoxy-acetophenone, o-methyl-acetophenone, p-fluorine-acetophenone, propiophenone, 2-acetylthiophene and 2-acetylpyridine, were used as substrates in order to investigate the substrate ranges of R.mucilaginosa CCTCC M2014255 strain cells.

References

Schmid A, Dordick JS, Hauer B, Kiener A, Wubbolts M, Witholt B (2001) Industrial biocatalysis today and tomorrow. Nature 409:258–268

Kroutil W, Mang H, Edegger K, Faber K (2004) Recent advances in the biocatalytic reduction of ketones and oxidation of sec-alcohols. Curr Opin Chem Biol 8:120–126

Wan Y, Wang X, Liu N (2014) Interaction of beta-cyclodextrin as catalyst with acetophenone in asymmetric reaction: a theoretical survey. J Mol Model 20:2268

Trost BM, Bartlett MJ (2015) ProPhenol-catalyzed asymmetric additions by spontaneously assembled dinuclear main group metal complexes. Acc Chem Res 48:688–701

Barron-Jaime A, Narvaez-Garayzar OF, Gonzalez J, Ibarra-Galvan V, Aguirre G, Parra-Hake M, Chavez D, Somanathan R (2011) Asymmetric transfer hydrogenation of prochiral ketones in aqueous media with chiral water-soluble and heterogenized bifunctional catalysts of the RhCp*-type ligand. Chirality 23:178–184

Dudzik A, Snoch W, Borowiecki P, Opalinska-Piskorz J, Witko M, Heider J, Szaleniec M (2015) Asymmetric reduction of ketones and beta-keto esters by (S)-1-phenylethanol dehydrogenase from denitrifying bacterium Aromatoleum aromaticum. Appl Microbiol Biotechnol 99:5055–5069

Zhang R, Zhang B, Xu Y, Li Y, Li M, Liang H, Xiao R (2013) Efficicent (R)-phenylethanol production with enantioselectivity-alerted (S)-carbonyl reductase II and NADPH regeneration. PLoS One 8:e83586

Pennacchio A, Sannino V, Sorrentino G, Rossi M, Raia CA, Esposito L (2013) Biochemical and structural characterization of recombinant short-chain NAD(H)-dependent dehydrogenase/reductase from Sulfolobus acidocaldarius highly enantioselective on diaryl diketone benzil. Appl Microbiol Biotechnol 97:3949–3964

Naik HG, Yeniad B, Koning CE, Heise A (2012) Investigation of asymmetric alcohol dehydrogenase (ADH) reduction of acetophenone derivatives: effect of charge density. Org Biomol Chem 10:4961–4967

Soni P, Banerjee UC (2006) Enantioselective reduction of acetophenone and its derivatives with a new yeast isolate Candida tropicalis PBR-2 MTCC 5158. Biotechnol J 1:80–85

Du PX, Wei P, Lou WY, Zong MH (2014) Biocatalytic anti-Prelog reduction of prochiral ketones with whole cells of Acetobacter pasteurianus GIM1.158. Microb Cell Fact 13:84

Schroer K, Zelic B, Oldiges M, Lutz S (2009) Metabolomics for biotransformations: intracellular redox cofactor analysis and enzyme kinetics offer insight into whole cell processes. Biotechnol Bioeng 104:251–260

Yang C, Ying X, Yu M, Zhang Y, Xiong B, Song Q, Wang Z (2012) Towards the discovery of alcohol dehydrogenases: NAD(P)H fluorescence-based screening and characterization of the newly isolated Rhodococcus erythropolis WZ010 in the preparation of chiral aryl secondary alcohols. J Ind Microbiol Biotechnol 39:1431–1443

Munger J, Bajad SU, Coller HA, Shenk T, Rabinowitz JD (2006) Dynamics of the cellular metabolome during human cytomegalovirus infection. PLoS Pathog 2:e132

Julsing MK, Kuhn D, Schmid A, Buhler B (2012) Resting cells of recombinant E. coli show high epoxidation yields on energy source and high sensitivity to product inhibition. Biotechnol Bioeng 109:1109–1119

Zilbeyaz K, Kurbanoglu EB (2010) Highly enantiomeric reduction of acetophenone and its derivatives by locally isolated Rhodotorula glutinis. Chirality 22:849–854

Kurbanoglu EB, Zilbeyaz K, Ozdal M, Taskin M, Kurbanoglu NI (2010) Asymmetric reduction of substituted acetophenones using once immobilized Rhodotorula glutinis cells. Bioresour Technol 101:3825–3829

Li J, Wang P, He JY, Huang J, Tang J (2013) Efficient biocatalytic synthesis of (R)-[3,5-bis(trifluoromethyl)phenyl] ethanol by a newly isolated Trichoderma asperellum ZJPH0810 using dual cosubstrate: ethanol and glycerol. Appl Microbiol Biotechnol 97:6685–6692

Wang D, Zhang Q, Li W, Qi NC, Guo CX, Yang ZR, Zhang J (2011) Asymmetric reduction of ethyl pyruvate to (S)-ethyl lactate by yeast resting cells. Chin J Catal 6(6):1035–1039

Kratzer R, Pukl M, Egger S, Vogl M, Brecker L, Nidetzky B (2011) Enzyme identification and development of a whole-cell biotransformation for asymmetric reduction of o-chloroacetophenone. Biotechnol Bioeng 108:797–803

Rafiqul IS, Sakinah AM, Zularisam AW (2015) Enzymatic Production of Bioxylitol from Sawdust Hydrolysate: screening of Process Parameters. Appl Biochem Biotechnol 176:1071–1083

Chen XH, Wei P, Wang XT, Zong MH, Lou WY (2014) A novel carbonyl reductase with anti-Prelog stereospecificity from Acetobacter sp. CCTCC M209061: purification and characterization. PLoS One 9:e94543

Wang P, Cai JB, Ouyang Q, He JY, Su HZ (2011) Asymmetric biocatalytic reduction of 3,5-bis(trifluoromethyl) acetophenone to (1R)-[3,5-bis(trifluoromethyl)phenyl] ethanol using whole cells of newly isolated Leifsonia xyli HS0904. Appl Microbiol Biotechnol 90:1897–1904

Holsch K, Havel J, Haslbeck M, Weuster-Botz D (2008) Identification, cloning, and characterization of a novel ketoreductase from the cyanobacterium Synechococcus sp. strain PCC 7942. Appl Environ Microbiol 74:6697–6702

Kawano S, Yano M, Hasegawa J, Yasohara Y (2011) Purification and characterization of an NADH-dependent alcohol dehydrogenase from Candida maris for the synthesis of optically active 1-(pyridyl)ethanol derivatives. Biosci Biotechnol Biochem 75:1055–1060

Zhang J, Fu LL, Tian M, Liu HQ, Li JJ, Li Y, He J, Huang J, Ouyang L, Gao HY, Wang JH (2015) Design and synthesis of a novel candidate compound NTI-007 targeting sodium taurocholate cotransporting polypeptide [NTCP]-APOA1-HBx-Beclin1-mediated autophagic pathway in HBV therapy. Bioorg Med Chem 23:976–984

Sugiyama Y, Senda M, Senda T, Matsuda T (2015) Crystallization and preliminary crystallographic analysis of acetophenone reductase from Geotrichum candidum NBRC 4597. Acta Crystallogr F Struct Biol Commun 71:320–323

Contente ML, Serra I, Brambilla M, Eberini I, Gianazza E, De Vitis V, Molinari F, Zambelli P, Romano D (2016) Stereoselective reduction of aromatic ketones by a new ketoreductase from Pichia glucozyma. Appl Microbiol Biotechnol 100:193–201

Janeczko T, Bakowski W, Walczak E, Robak M, Dmochowska-Gladysz J, Kostrzewa-Suslow E (2015) Biotransformation of acetophenone and its halogen derivatives by strains. Ann Microbiol 65:1097–1107

Acknowledgments

This work was supported by grants from scientific research project of Sichuan Provincial Health Department (No. 130295), open project of key laboratory of environmental and applied microbiology of Chinese academy of sciences (No. KLCAS-2014-04), national innovation experiment program for university students (Nos. 201513705006 and 201413705002), science and technology support program of Sichuan Science and Technology Department (No. 2016GZ0364).

Authors Contributions

DW carried out the whole study and participated in its design. ZY helped to conceive of the study and coordination. JZ carried out the biotransformation test. YH participated in GC analysis. JH participated in the design of the study and helped to revise the manuscript. LH participated in its design. All authors read and approved the final manuscript.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interests.

Rights and permissions

About this article

Cite this article

Wang, D., Yang, Z., Zhang, J. et al. The Asymmetric Reduction of Acetophenone and Its Derivatives to (S)-Aromatic Secondary Alcohols by Rhodotorula mucilaginosa CCTCC M2014255 Resting Cells. Catal Lett 146, 1079–1086 (2016). https://doi.org/10.1007/s10562-016-1730-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-016-1730-9