Abstract

A series of heteropoly acid bisalts of N-octyl ethoxylated octadecylamine with high acid strength and excellent emulsifying capacity have been prepared via the partial replacement of protons in neat phosphotungstic acid. These ionic liquids exhibit good activity and selectivity in the hydration of α-pinene, even in the absence of a co-catalyst such as chloroacetic acid. The “excellent emulsifying capacity at the reaction temperature and the liquid–liquid separation at room temperature” for the obtained organic heteropolyacid bisalts catalysts enable their easy recovery and reusability, as demonstrated by a six-run recycling test.

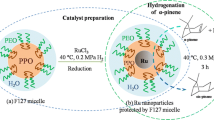

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Environment-friendly technologies for biomass resource utilization are the key to promote sustainable chemistry. For example, hydration of α-pinene, an important means of improving the added value of turpentine, affords α-terpineol, a versatile fine chemical used in perfumes, pharmaceuticals, and functional polymers [1]. The industrial-scale two-step preparation of terpineol using an aqueous mineral acid (primarily, H2SO4) has several drawbacks, such as corrosion of the equipment by the strong acid, environmental pollution, and poor recovery. Organic acids such as chloroacetic acid or trichloroacetic acid, whose carboxyl group acts as the key catalytic species, can be used in place of mineral acids for the efficient conversion of α-pinene into terpineol via a single step [2]. The good solubility of these organic acid catalysts in both the aqueous and α-pinene phases enhances their performance but results in poor separability and repeatability, as in the case of aqueous mineral acid. Furthermore, exposure to chloroacetic acids may cause severe damage to the skin, eyes, respiratory tract, and mucous membranes, and lead to central nervous system depression in humans; these acids are also hazardous to aquatic life. Hence, a number of studies on solid acid catalysts, such as microporous and mesoporous molecular sieves [3, 4], solid super acids [5, 6], modified clay and oxides [7, 8], and heteropoly acids [9], have been carried out to realize clean hydration of α-pinene. Despite the case of separation, these solid acids result in the formation of a solid–liquid–liquid three-phase system when used for the hydration of α-pinene, which is unfavorable for mass transfer. For this reason, an organic acid (such as chloroacetic acid or trichloroacetic acid) must be used as a co-catalyst in the above process [3–8], thus hindering the effort to establish an environment-friendly target technology.

Acid-functionalized ionic liquids, a class of catalysts combining the advantages of both aqueous acids and solid acids, have been employed in many acid catalyzed reactions. Ionic liquids with the [HSO3-PMIM]H2PO4, [PEOIM-SO3H]H2PO4 and [AC18-n]HSO4 [10–13] structures have been employed in the hydration of α-pinene to produce α-terpineol. However, these ionic liquids also suffer from insufficient acidity or emulsifying capacity, thus requiring chloroacetic acid as a co-catalyst. In recent years, heteropolyacid organic salts, which possess the features of both ionic liquids and heteropoly compounds, have gained attention because of their potential acidity, oxidizability, and self-separation ability [14–24]. Herein, we report novel heteropolyacid bisalts of N-octyl ethoxylated octadecylamine [C8H17-AC18-n]H2PW12O40, which possess both strong acidity resulting from the protons and excellent emulsifying capacity derived from the organic cation. One-step hydration of α-pinene to α-terpineol can be realized using these [C8H17-AC18-n]H2PW12O40 catalysts, without the need for a conventional carboxylic acid-based co-catalyst.

2 Experimental

2.1 Materials and Methods

All chemicals were of analytical grade and used without further purification. FT-IR spectra of the catalyst samples in KBr discs were recorded on a Nicolet-510P FT-IR instrument. Thermogravimetric (TG) analysis was carried out using a NETZSCH-TG 209 F1 Libra instrument, in a dry N2 atmosphere over the temperature range of 30–800 °C at a heating rate of 20 °C/min. The acidity of the prepared catalysts was determined by potentiometric titration [14, 25]. A mixture containing 0.5 g of the sample and 30 mL of acetonitrile was mixed to obtain a stable potential, and then titrated against a 0.05 mol/L acetonitrile solution of n-C4H9NH2. The initial potential and jump potential were registered using a pH meter to determine the acid strength and total acid amount of the catalyst samples.

Photographs of the vesicles formed in the emulsification reaction were recorded using a confocal laser scanning microscope (Leica, TCS-SP5-II).

2.2 Catalysts

A certain amount octadecylamine and ethanol (solvent) were mixed in an autoclave and refrigerated for at least 2 h, after which epoxyethane was added. The resulting mixture was stirred at room temperature for 2 h, heated to 60 °C, and allowed to react at this temperature for 5 h. Then, the mixture was cooled and distilled to remove ethanol, affording intermediate (I). The average degree of polymerization, n, was determined by measuring the mass gain of the intermediate. Subsequently, equimolar amounts of intermediate (I) and chlorinated octane were reacted in an autoclave at 90 °C for 10 h under 5 MPa N2 to give intermediate (II). Finally, an aqueous solution of phosphotungstic acid was added dropwise into the three-necked glass reactor containing an aqueous solution of intermediate (II) at 80 °C (equimolar amounts of the two compounds were used). Reaction of intermediate (II) and phosphotungstic acid for 6 h, followed by decompression–dehydration, afforded the [C8H17-AC18-n]H2PW12O40 catalysts (Scheme 1).

2.3 Hydration

Batch experiments were performed using 1 mmol of [C8H17-AC18-n]H2PW12O40 catalyst and 0.3 mol of water in a three-necked glass reactor equipped with a condenser, thermometer, and mechanical agitator. The mixture was stirred thoroughly at a rate of 500 rpm and heated to 80 °C. Then, 0.06 mol of α-pinene was added to obtain an emulsion, which was maintained for 8 h. After 8 h, the reaction mixture was standinged for layered. The upper layer comprising the product was separated, dried over anhydrous magnesium sulfate, and analyzed by gas chromatography using a GC HP 9790 system with a flame ionization detector (FID) and an OV-1701 column (30 m × 0.32 mm × 0.25 μm) to determine the catalytic performance. The aqueous phase containing the catalyst could be conveniently separated from the product phase and reused without further treatment.

3 Results and Discussion

Previously reported ionic liquids such as [MIMPS]H2PO4 [10] and [AC18-20]HSO4 [12, 13] resulted in poor conversion of α-pinene (9.4 and 1.0 %, respectively) when used for the hydration of α-pinene in the absence of chloroacetic acid as a co-catalyst.

In contrast, hydration of α-pinene in the presence of chloroacetic acid alone resulted in much better performance, i.e., 92.7 % conversion of α-pinene and 50.6 % selectivity for α-terpineol. The excellent catalytic performance of chloroacetic acid can be attributed to its suitable acidity and good solubility in both the water and organic phases. For this reason, heteropolyacid bisalts of N-octyl ethoxylated octadecylamine, [C8H17-AC18-n]H2PW12O40, have been designed and prepared. The protons of the bisalts can act as acidic active groups [26] because of the strong acidity of phosphotungstic acid, and the N-octyl ethoxylated octadecylamine will have a strong emulsifying effect in the hydration system to allow for better contact between the substrate and water molecules.

Table 1 illustrates that the prepared [C8H17-AC18-n]H2PW12O40 ionic liquids exhibit sufficient acid strength (~640 mV) to promote the activation of α-pinene. The acid density of these ionic liquids decreases with an increase in the degree of polymerization because of the dilution of the acid sites by the organic cations. For the same reason, both the acid strength and acid density of [C8H17-AC18-100] hydrogen phosphotungstate are lower than those of dihydrogen phosphotungstate.

Moreover, all the dihydrogen phosphotungstates, [C8H17-AC18-n]H2PW12O40, were soluble in water but insoluble in α-pinene when n ≥ 100, which was advantageous for the separation of the catalyst from the organic phase.

Table 2 shows the catalytic performance of the [C8H17-AC18-n]H2PW12O40 ionic liquids for the hydration of α-pinene. A typical gas chromatograph of the reaction mixture is presented in Fig. 1. The GC–MS analysis of the same sample indicated that Peak 1 is α-pinene and Peaks 2–9 are the hydration products of α-pinene. The other unnumbered peaks are all isomerization products of α-pinene. When using H3PW12O40, which shows acidity but no emulsifying capacity, the conversion of α-pinene was complete (100 %), but isomerization products were mainly formed; hence, the actual yield of the target α-terpineol was very poor. In contrast, the normal salt [C8H17-AC18-100]3PW12O40 that has no acidity did not exhibit catalytic activity. When both [C8H17-AC18-n]+ and H+ were introduced into the heteropoly compound as counter cations, the conversion of α-pinene decreased with the increasing degree of polymerization because of the low acid density. However, the hydration-to-isomerization ratio increased considerably, resulting in a maximum selectivity for α-terpineol of 46.5 % at n = 125. This value is close to the selectivity obtained when the reaction is catalyzed by chloroacetic acid, which can be attributed to the effective contact among α-pinene molecules, water molecules and protons. As expected, the catalytic performance of [C8H17-AC18-100]2HPW12O40, which has lower acid strength and acid density was far inferior to that of the corresponding dihydrogen phosphotungstate.

When the [C8H17-AC18-100]H2PW12O40 ionic liquid was employed for the hydration of α-pinene, an emulsification–separation phenomenon was observed, as shown in Fig. 2. Micrographs of this emulsion recorded using real-time laser scanning confocal microscopy are shown in Fig. 3. Relatively uniform micelles with sizes of around 40–100 μm, as commonly detected in oil-in-water type emulsions [27], were formed because of the emulsification ability of the catalyst. Thus, it could be inferred that a reaction microenvironment is established in which α-pinene is surrounded by the aqueous phase (Fig. 4). In this reaction microenvironment, the phosphotungstic acid anions, which act as soft bases, coordinate with and stabilize the carbonium ion intermediates from α-pinene activated by the protons of the bisalt; this accounts for the observed increase in reaction activity and selectivity.

Figure 2 shows that when the emulsion system for the hydration is cooled and allowed to stand for a sufficient time, it segregates into two clear phases, indicating good self-separation of the [C8H17-AC18-100]H2PW12O40 ionic liquid catalyst from the product phase. Figure 3 also reveals the gradual demulsification of the emulsion formed in the hydration system after a long settling time. Furthermore, no W was detected in the upper product phase by ICP-AES (Prodigy XP, Leeman, 20 °C), indicating the absence of [C8H17-AC18-100]H2PW12O40 catalyst residue in the product phase.

On the other hand, when [C8H17-AC18-n]H2PW12O40 ionic liquids (n < 100) were used for the hydration of α-pinene, emulsion systems were formed under stirring at 80 °C, but demulsification after the reaction was difficult.

Tables 3, 4, 5, and 6 show the effects of catalyst dosage, amount of water, reaction temperature, and reaction time on the catalytic performance when [C8H17-AC18-100]H2PW12O40 was used to catalyze the hydration of α-pinene. The catalyst dosage has a more remarkable influence on the conversion of α-pinene than on the selectivity for α-terpineol (Table 3), implying that the concentration of protons obtained from the bisalt is the key factor for catalytic activity. Table 4 shows that the amount of water has a small influence on the conversion of α-pinene and selectivity for α-terpineol when n(α-pinene):n(water) is lower than 1:5.

Both conversion and selectivity are notably influenced by the reaction temperature. At high temperatures, a greater amount of activated α-pinene is generated, which interacts with water molecules to undergo hydration. However, the selectivity for α-terpineol decrease at higher temperatures. Taking both conversion and selectivity into consideration, we found that 80 °C is the optimal temperature for conversion of α-pinene into α-terpineol (Table 5). Table 6 shows that the effect of the reaction time on the performance is similar to that of the catalyst dosage. The conversion of α-pinene notably increases when the reaction is prolonged, but the selectivity for α-terpineol hardly changes with the reaction time.

The reusability of [C8H17-AC18-100]H2PW12O40 under the optimal reaction conditions (0.06 mol α-pinene, n(α-pinene):n(catalyst):n(water) = 60:1:300, 80 °C, 8 h) was investigated using a six-run recycling test. It can be seen in Fig. 5 that reuse of the untreated catalyst phase leads to an increase in catalytic conversion and a small decrease in α-terpineol selectivity, which can be attributed to the consumption of water in the hydration reaction, resulting in a higher concentration of the catalyst.

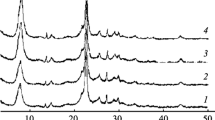

The IR spectra (KBr disc) of [C8H17-AC18-100]H2PW12O40 before and after use in the reaction are shown in Fig. 6. Characteristic bands due to the Keggin phosphotungstic acid radical are seen at 1079, 978, 896, and 819 cm−1. The bands at 3409 cm−1 for –OH stretching vibrations; 2918 and 2871 cm−1 for saturated C–H stretching vibrations; 1455 cm−1 for C–H bending vibrations; 1350 cm−1 for N–CH2 bending vibrations; 1108 cm−1 for C–O–C asymmetric stretching vibrations; and 951 cm−1 for C–O–C symmetric stretching vibrations confirm the presence of [C8H17-AC18-100]+ in the ionic liquid. The IR spectrum of [C8H17-AC18-100]H2PW12O40 after use shows that there is no obvious structural change in the catalyst during hydration.

In the TG curve of [C8H17-AC18-100]H2PW12O40 (Fig. 7), the mass loss of 57.12 % at 201.25 °C can be attributed to the breakage of polyoxyethylene ether chains ((CH2CH2O)100H). Moreover, almost all the organic fraction will decompose by 279.25 °C with a total mass loss of 60.55 % (W (organic fraction/ionic liquid catalyst) = 61.58 %). The decomposition of H3PW12O40 is observed above 279.25 °C with a 2.67 % mass loss, which can be interpreted as the evaporation of H3PO4. The above information indicates the stable nature of this ionic liquid below 201.25 °C, which accounts for its good reusability.7

4 Conclusions

In summary, we have achieved efficient hydration of α-pinene using a heteropolyacid bisalt of N-octyl ethoxylated octadecylamine catalyst [C8H17-AC18-100]H2PW12O40, without a co-catalyst. The strong acidity and emulsifying ability of the [C8H17-AC18-100]H2PW12O40 ionic liquid enhance its catalytic performance and self-separation ability. With the use of this clean, reusable, and easily removed novel catalytic system, 76.9 % conversion of α-pinene, as well as 44.3 % selectivity for α-terpineol could be achieved. In addition, no residual catalyst was detected in the product phase, confirming the good separability of the catalyst.

References

Satoh K, Sugiyama H, Kamigaito M (2006) Green Chem 8(10):878

Roman-Aguirre M, Dela Torre-Saenz L, Wilber AF, Robau-Sánchez A, Aguilar Elguézabal A (2005) Catal Today 107–108:310

Mukesh KY, Mallikarjun VP, Raksh VJ (2009) J Mol Catal A 297(2):101

Wijayati N, Pranowo HD, Triyono J, Chuah GK (2013) Int J Chem Eng Appl 4(4):178

Yu ST, Liu FS, Xie CX, Li L (2004) Fine Chem 21(3):178

Wang YM, Liu TC, Zhou MC, Tang H (2004) Chem Ind For Prod 24(B08):57

Comelli N, Avila MC, Volzone C, Ponzi M (2013) Cent Eur J Chem 11(5):689

Avila MC, Comelli NA, Rodríguez-Castellón E, Jimenez-Lopez A, Carrizo Flores R, Ponzi EN, Ponzi MI (2010) J Mol Catal A 322(1–2):106

Castanheiro JE, Ramos AM, Fonseca I, Vital J (2003) Catal Today 82(1–4):187

Ji KH, Liu SW, Yu ST, Liu FS, Xie CX (2007) Chem Ind For Prod 6:77

Liu SW, Li L, Yu ST, Xie CX, Liu FS, Song ZQ (2011) Chin J Catal 32(3):468

Qi CJ, Li L, Liu SW, Yu ST (2012) J Qingdao Univ Sci Technol (Nat Sci Ed) 33(4):345

Li L, Liu Y, Yu ST, Liu SW, Xie CX, Liu FS (2015) Res Chem Intermed 41:2407

Shi J, Pan G (2008) Chin J Catal 29:629

Leng Y, Wang J, Zhu DR, Ren XQ, Ge HQ, Shen L (2009) Angew Chem Int Ed 48:168

Leng Y, Wang J, Zhu D, Wu YJ, Zhao PP (2009) J Mol Catal A 313(1–2):1

Dai Y, Li BD, Quan HD, Lv CX (2010) Chin Chem Lett 21:678

Ivanova S, Nitsch X, Romero-Sarria F, Louis B, Centeno MA, Roger AC, Odriozola JA (2010) Stud Surf Sci Catal 175:601

Yang HW, Qi XF, Wen L, Lv CX, Cheng GB (2011) Ind Eng Chem Res 50(19):11440

Li KX, Chen L, Wang HL, Yan ZC (2011) Appl Catal A 392(1–2):233

Leng Y, Wang J, Zhu DR, Shen L, Zhao PP, Zhang MJ (2011) Chem Eng J 173(2):620

Leng Y, Jiang PP, Wang J (2012) Catal Commun 25(5):41

Leng Y, Qiu XQ, Jiang PP, Wang J (2012) Chin J Catal 33(7):1224

Li H, Qiao YX, Hua L, Hou ZS, Feng B, Pan ZY, HuY Wang XR, Zhao XG, Yu YY (2010) ChemCatChem 9(2):1165

Vazquez P, Pizzio L, Caceres C, Blanco M, Thomas H, Alesso E, Finkielsztein L, Lantano B, Moltrasio G, Aguirre J (2000) J Mol Catal A 161:223

Yuan B, Zhao WS, Yu FL, Xie CX (2014) Catal Commun 57:89

Ashby N, Binks B (2014) Phys Chem Chem Phys 2:5640

Acknowledgments

The financial support provided for this research by the National Science Foundation of China (31470595, 31270615 and 21106074), Opening Foundation of Beijing National Laboratory for Molecular Sciences (20140141), and “The Taishan Scholar Program of Shandong” is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yuan, B., Zhong, H., Liu, P. et al. Heteropolyacid Bisalt of N-octyl Ethoxylated Octadecylamine: An Efficient and Reusable Catalyst for Carboxylic Acid-Free Hydration of α-Pinene. Catal Lett 146, 929–936 (2016). https://doi.org/10.1007/s10562-016-1709-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-016-1709-6