Abstract

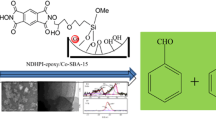

Mesoporous molecular sieve SBA-15 immobilized N,N-dihydroxypyromellitimide (NDHPI) was prepared by a new method, which was realized through the coupling NDHPI with pre-grafted glycidoxypropyl chains of glycidoxypropyl-SBA-15. SBA-15 immobilized N-hydroxyphthalimide (NHPI) by impregnation method was also prepared for comparison. The two catalysts were characterized by Fourier transform infrared spectroscopy, N2 adsorption–desorption technique, thermogravimetric analyses, X-ray diffraction, scanning electron microscope, transmission electron microscope and X-ray photoelectron spectroscopy. Then the catalysts and N,N-bis(salicylidene) ethylenediiminocobalt (Cosalen) complex were used into oxidation of toluene with molecular oxygen. The more active and reusable catalyst was the immobilized one coupled by NDHPI with glycidoxypropyl-SBA-15, which improved the total selectivity of benzaldehyde and benzyl alcohol to 46.0 % with the conversion of toluene 14.8 % at 90 °C for 7 h.

Graphical Abstract

Mesoporous molecular sieve SBA-15 immobilized N,N-dihydroxypyromellitimide (NDHPI) was prepared by a new method, which was realized through the coupling NDHPI with pre-grafted glycidoxypropyl chains of glycidoxypropyl-SBA-15. SBA-15 immobilized NHPI by impregnation method was also prepared for comparison. Their structure was characterized and their catalytic performance combined with Cosalen complex in the molecule oxidation of toluene were compared. Their reusability performance was also discussed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Selective catalytic oxidation of toluene by molecular oxygen to benzaldehyde, benzyl alcohol and benzoic acid is an important transformation in chemical industry. However, improving the conversion of toluene and selectivity of value-added intermediates remains a challenge [1]. The SINA process is a very important industrial process for preparation of caprolactam, Among them, liquid-phase oxidation of toluene is catalyzed by cobaltous salts at 165 °C and 1.0 MPa with toluene conversion of 14–15 % and benzoic acid selectivity of 92–93 % [2], but only small amounts of benzaldehyde and benzyl alcohol are obtained as by-products. Benzaldehyde and benzyl alcohol are essential intermediates in the manufacture of various chemicals, such as pharmaceuticals, food stuff, dyes, perfume, and resins [3, 4]. Currently, benzaldehyde and benzyl alcohol are produced mainly by hydrolysis of benzal chloride [5, 6]. However, the above process inevitably produces a trace amount of chlorine, and thus, its use is prohibited in the pharmaceuticals and food stuff industries. For this reason, much attention has been paid to find out new eco-friendly methods for production of benzaldehyde and benzyl alcohol via controlled toluene oxidation with molecular oxygen. Moreover, benzaldehyde and benzyl alcohol are more susceptible to secondary oxidation to benzoic acid, thus resulting in lower selectivity. Hence, many efforts have been made to develop some efficient and selective catalytic systems for controlled oxidation of toluene with molecular oxygen, including copper (II) complexes [7], Mnsalen complex [8], and manganese or cobalt tetraphenylporphyrin [9, 10].

N-Hydroxyphthalimide (NHPI) is widely recognized as a carbon-radical-producing catalyst for various free-radical-mediated reactions [11]. Ishii and his group [12, 13] developed an oxidizing system NHPI/O2/Co(II), which is able to efficiently catalyze the oxidation of a large variety of organic compounds under mild conditions at moderate oxygen pressure and temperature. The oxidation of toluene was carried out in the presence of NHPI (10 mol%) and Co(OAc)2 (0.5 mol%) in acetic acid solution for 20 h under ambient conditions produced benzoic acid in 81 % yield [14]. Jiang et al. [15] also prepared Benzoic acid from aerobic oxidation of toluene using manganese dioxide (MnO2) and NHPI as catalysts. In order to improve the selectivity of benzaldehyde and benzyl alcohol among the products, our team has investigated liquid-phase solvent-free oxidation of toluene using an SBA-15-immobilized N,N-bis(salicylidene) ethylenediiminocobalt (Cosalen) complex and NHPI as catalyst [16]. Among the NHPI-catalyzed oxidation systems combined with metal salt and complex, the immobilization and recycle of metals was already investigated. A silica gel supported cobalt(II) Schiff base complex was used as an effective and reusable catalyst into selective oxidation of alkyl aromatics in combination with NHPI under oxygen at atmospheric pressure [17]. However, a major problem is that NHPI as a main catalyst can decompose to phthalimide and phthalic anhydride, or form inactive trimers [18, 19], thus requiring a larger amount of NHPI for the reaction. Recovery and recycle of NHPI remains a significant limitation that restricts the application of NHPI. To our knowledge, little work has been done regarding the reuse of NHPI. The use of a novel supported NHPI promoter by a coupling reaction was reported, but in acetic acid as a solvent [20]. In the aerobic oxidation of cumene, Melone et al. [21] recovered the catalyst NHPI at the end of the oxidation process by removal of polar co-solvent, with consequent precipitation of NHPI. The resulting filtered mixture is treated with non-basic supports, the adsorbing solids can be regenerated by washing with a polar solvent, allowing the recovery of residual catalyst. Immobilization of NHPI on silica has been achieved by impregnation in the oxidation of cycloalkanes with favorable results [22], but the loss of the active site NHPI was unavoidable.

SBA-15 mesoporous silica is a useful heterogenous carrier with high thermal stability, contains regular arrays of uniformly-sized channels [23–25]. The amorphism of the pore walls gives rise to a substantial number of silanol groups, thus facilitating the grafting of catalytically active groups. N,N-dihydroxypyromellitimide (NDHPI), an analogue of NHPI, involves two hydroxyimide moieties. As reported, the catalytic activity of a hyroxyimide moiety of NDHPI is comparable to that of NHPI [26, 27]. In this work, SBA-15-immobilized NHPI through normal impregnation method and SBA-15-immobilized NDHPI through covalent bonding with Si–OH groups of SBA-15 by a new method were prepared and comparatively used as catalysts into toluene oxidation.

2 Experimental

2.1 Preparation of Catalysts

2.1.1 Impregnation of NHPI on SBA-15

1.0 g NHPI was dissolved in 100 mL of a CH3CN solution. The mixture was added with 4.0 g of SBA-15, stirred and refluxed for 12 h. Then the solvent was evaporated by a rotary vacuum evaporator, and the powder was vacuum-dried for another 12 h at 70 °C. The obtained catalyst was coded as NHPI/SBA-15(ip) (Fig. 1a).

2.1.2 Preparation of Grafted NDHPI on SBA-15

Firstly, synthesis of NDHPI [28] as follows: Hydroxylamine hydrochloride (38.4 mmol) and triethylamine (Et3N) (38 mmol) were dissolved in 120 mL of ethanol. After stirring for 10 min, the solution was added with 1,2,4,5-benzenetetracarboxylic anhydride (19.6 mmol) and refluxed for 8 h. The resulting red solution was poured into ca. 200 mL of H2O. The product precipitated as a yellow powder, which was filtered and vacuum-dried at 50 °C. Secondly, A suspension of activated SBA-15 (4.0 g) in dry toluene (120 mL) was refluxed and stirred with 3-(glycidoxypropyl)trimethoxysilane (GPTMS, 12 mmol) under dry nitrogen for 24 h. Then the solid was separated and washed in the Soxhlet apparatus with dry diethyl ether and CH2Cl2, denoted as glycidoxypropyl-SBA-15. Thirdly, a suspension of pre-evacuated glycidoxypropyl-SBA-15 (4.0 g) and NDHPI (1.0 g) in dry THF (120 mL) was stirred under nitrogen at room temperature for 24 h. The modified solid was separated and successively washed with diethyl ether and trichloromethane (CHCl3) in the Soxhlet apparatus. The obtained catalyst was coded as NDHPI/propul-2-propanol-SBA-15 (Fig. 1b).

2.2 Characterization of Catalysts

Fourier transformed infrared spectroscopy (FTIR) was recorded in KBr disks with a Thermo Nicolet 380 FTIR spectrometer. The porous structures of the catalysts were determined by analyzing the results of nitrogen adsorption at 77 K in a NOVA-2200e Quanta chrome apparatus. Thermogravimetric analysis (TGA) was performed on NETZSCH TG-209 under N2 atmosphere from 30 to 800 °C, with a heating rate of 10 °C/min. The X-ray diffraction (XRD) spectra of the samples were obtained using a Rigaku D/Max-2550 diffractometer with Cu Kα as radiation source and graphite monochromator at 40 kv and 300 mA. Scanning electron microscopy (SEM) analysis was performed on a Jeol JSM-6610LV instrument equipped with a tungsten filament. Transmission electron microscopy (TEM) microphotograph was carried out on a PHILIPS TECNAI-20 electron microscope operating at 200 kV. Further characterization of the elemental composition was conducted with X-ray photoelectron spectroscopy in Kratos AXIS UltraDLD.

2.3 Catalytic Procedures

Toluene (5.0 g, 55 mmol), NHPI or NDHPI-immobilized materials (2 mol% NHPI/NDHPI, mol%: n/n (toluene)) and Cosalen (0.02 mol%) in acetonitrile (4.0 g, 97 mmol) were in turn introduced into a 50 mL Teflon-lined and magnetically-stirred autoclave equipped with a block heater and a thermometer. The reaction was carried out at required temperature under an oxygen atmosphere (1.6 MPa) for hours. After that, the catalyst was removed from the reaction mixture by filtering separation and then the conversions of substrates and product selectivity were calculated based on GC analysis in an Agilent GC-6820 instrument equipped with HP-Innowax capillary column and a flame ionization detector. Cyclohexanone was used as internal standard. The injection and detector temperature was 250 °C, the column temperature was maintained initially at 80 °C for 2.5 min, followed by increases to 220 °C at a rate of 20 °C/min, and then this temperature was held constant for 9 min.

3 Results and Discussion

3.1 Characterization of Catalysts

3.1.1 FTIR Results

Figure 2 compares the FTIR spectra of NHPI/SBA-15 (ip) with pure NHPI and unloaded SBA-15. Symmetric and asymmetric carboxyl stretches of NHPI could be observed at 1790 and 1710 cm−1, respectively. The broad peak at 3150 cm−1 corresponds to NO–H vibrations, the signal at 877 cm−1 and 698 cm−1 is attributed to aromatic C-H out of plane bending vibration. Aromatic C–C skeletal deformations were observed at 1610, 1500, and 1463 cm−1. The broad peak at 3440 cm−1 for SBA-15 was a fingerprint of silanol groups; Si–O vibrations were visible within 1250-1000 cm−1. Spectrum c demonstrates that nearly all NHPI vibrations were recovered after impregnation.

In Fig. 3, the spectrum d of glycidoxypropyl-SBA-15 shows two bands at 2928 and 2859 cm−1 due to the asymmetric and symmetric vibration absorptions of –CH2 respectively, and some weaker bands at 1464 and 1389 cm−1 due to the rocking absorption of C–H. These bands confirm the presence of glycidoxypropyl groups on the surface of SBA-15. However, the characteristic absorption bands of the glycidoxypropyl groups at 910 cm−1 are too weak to be seen clearly. The presence of –CH2 absorption bands confirms the success in surface functionalization of SBA-15. The spectrum e of NDHPI/propul-2-propanol-SBA-15 shows nearly all glycidoxypropyl-SBA-15 vibrations: two bands at 3520 and 3430 cm−1 corresponding to the asymmetric and symmetric vibration absorptions of N–OH respectively; the weaker absorption bands at 3035 cm−1 to the stretching vibration absorption of C-H in aromatic ring; the bands at 1410–1554 cm−1 to the absorption of C=C in aromatic ring; the bands at 665 and 704 cm−1 to the out-of-plane flexural vibration absorptions of C–H in aromatic ring. Therefore, these results confirm that NDHPI was chemically bonded to the surface of SBA-15 by the glycidoxypropyl group function.

3.1.2 Results of N2 Adsorption Test

The N2 adsorption–desorption isotherms of immobilized samples all correspond to type IV of the international union of pure and applied chemistry (IUPAC) classification (Fig. 4), indicating the nature of mesoporosity. On the BJH pore size distribution curves computed from the desorption branch of the isotherms, all samples display a narrow pore size distribution with a centered peak, indicating that immobilization of NHPI or NDHPI did not affect the original pore structure of the parent SBA-15. The corresponding calculated parameters are listed in Table 1. Compared with parent support SBA-15, a significant decrease in specific surface area and pore volume can be observed on both immersion sample and modified samples. As for NDHPI/propul-2-propanol-SBA-15, the surface areas and pore volume reduced gradually with the process of modification, which further confirm that the silylation and immobilization of NDHPI were successful.

3.1.3 Results of TGA

TGAs of all samples conducted within 30–800 °C are shown in Fig. 5. Typical weight-loss curves were plotted as a function of temperature for each functionalized sample. Weight loss occurred in three steps. The first step below 150 °C is related to the loss of physisorbed water on the surfaces of mesoporous SBA-15. The second step from 150 to 370 °C was due to the loss of NHPI or its analogue NDHPI. The third step from 275 to 525 °C was attributed to the combustion of glycidoxypropyl groups inside the pores of SBA-15. These TGAs indicate that organosilanes and NHPI (or its analogue NDHPI) were successfully incorporated into SBA-15.

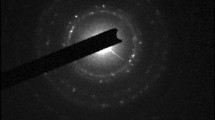

3.1.4 Results of XRD

XRD patterns of SBA-15 and NDHPI/propul-2-propanol-SBA-15 are shown in Fig. 6. The XRD pattern of parent SBA-15 show three well-resolved peaks at 0.89°, 1.50° and 1.72°, which are indexed to (100), (110) and (200) reflections of ordered hexagonal mesophase. It’s worth to note that the intensity of peaks corresponding to (110) and (200) planes of SBA-15 decreases after immobilization of NDHPI. Further, the comparison of the XRD patterns reveals that the mesoporous structure is rather intact even after the NDHPI loading.

3.1.5 Results of SEM and TEM

The SEM image in Fig. 7a showed that the catalyst NDHPI/propul-2-propanol-SBA-15 still had the characteristic fiberlike morphology. The particles try to aggregate and remain stacked over each other. The TEM images of the catalyst in Fig. 7b shows well ordered nanochannels and the nanochannels were arranged on 2D hexagonal structure over very large scales. This indicated that the uniform structure of SBA-15 was well maintained even after the NDHPI loading. The results are in good agreement with the XRD patterns.

3.1.6 Results of XPS

In order to explore the chemical environment of N elements in the surface of the NDHPI and NDHPI/propul-2-propanol-SBA-15 catalysts, their X-ray photoelectron spectroscopy (XPS) were measured. Figure 8 depict the N 1S spectra of the different samples. The N 1S core-level spectra of nitrogen atoms with only one binding energy at 402.0 eV as for the sample of NDHPI, which corresponded to N–OH. The spectra of NDHPI/propul-2-propanol-SBA-15 showed an N 1S signal, which fitted to two peaks 400.4 and 402.0 eV. The BE of two peaks at 400.4 and 402.0 eV were assigned to N–O–C [29] and N–OH, respectively. Theoretically, permolecular NDHPI containing two N–OH groups, one of them was condensed with epoxy groups after immobilization, the area ratio of N 1S peak of reserved N–OH should be 50 %, while the analysis result was 33 % from XPS, which was due to the excess 3-(glycidoxypropyl) trimethoxysilane was added in preparation process, and the two N–OH moieties of a part of NDHPI were both reacted with the glycidoxypropyl group. These results testified that a part of NDHPI species were incorporated into the SBA-15 framework in the form of N–O–C, and the steric effect also made some N–OH of NDHPI left for activation reaction.

3.2 Activity and Stability of Catalysts

The catalytic activity and stability of NHPI/SBA-15 (ip) and NDHPI/propul-2-propanol-SBA-15 in the toluene oxidation with molecular oxygen were investigated. Cosalen was used as a cocatalyst. After the reaction, each catalyst was recovered and reused at the same conditions. The results of catalytic activity and stability are presented in Table 2. Firstly, the toluene oxidation reaction did not occur with SBA-15 carrier. When NHPI or NDHPI was introduced with Cosalen as co-catalyst in the presence of CH3CN, the activity of the homogeneous system was much enhanced, the conversion of toluene reached 13.6 and 26.8 %, respectively. It’s obvious that NDHPI has higher activity than equivalent NHPI, As to heterogeneous system, NHPI/SBA-15 (ip) was more active in the oxidation; the conversion rate of toluene and the selectivity of benzaldehyde and benzyl alcohol are 17.5, 28.7, and 7.4 %, respectively. However, the reused catalyst was nearly inactive, which indicated that the active site NHPI cannot be uniformly dispersed on the surface of SBA-15 and can easily escape from the carrier after the first run reaction. Through the ring-opening condensation of NDHPI with the glycidoxypropyl-SBA-15, the immobilized material achieved encouraging results. The conversion rate of toluene, the selectivity of benzaldehyde and benzyl alcohol are 14.8, 37.3, and 8.3 %, respectively, at 90 °C after 7 h reaction. The activity of NDHPI/propul-2-propanol-SBA-15 was slightly lower than NHPI/SBA-15 (ip), but it should be noted that the activity did not decrease and actually increased modestly when the recovered catalyst was used in the second run. Despite no explicit explanation for the moment, it is demonstrated as a useful grafting method using GPTMS as a silylation agent for immobilization of NDHPI. Obviously, the condensation can proceed easily without the contamination of by-product, and the steric effect also leaves enough N–OH of NDHPI for activation. The isolated catalytic sites in immobilized complexes could protect the structure of active N–OH groups. Thus, the active component grafted on the support did not degrade rapidly as was observed in solution, and then much outperformed the catalyst prepared by simple impregnation. Moreover, the heterogeneous catalyst resulted in a favorable product distribution with relatively higher selectivity of benzaldehyde and benzyl alcohol as well as moderate conversion under mild condition. It’s worth to note that the conversion of toluene decreased sharply to 1.8 % in absence of Cosalen, which further confirm that the co-catalyst system consisting of the immobilized NDHPI prepared in this investigation and the Cosalen has a higher catalytic activity.

4 Conclusions

We prepared two types of SBA-15-immobilized NHPI and its analogue NDHPI by impregnation, or by coupling onto pre-grafted 3-(glycidoxypropyl) trimethoxysilicane. Their catalytic performances combined with Cosalen in the toluene oxidation with molecular oxygen were investigated. NDHPI/propul-2-propanol-SBA-15 prepared by the new method was proved to be active, and remained active after recycle. Moreover, the catalyst resulted in a favorable product distribution with relatively high selectivity of benzaldehyde and benzyl alcohol under mild condition. The optimization of the preparation process was under proceeding.

References

Li XQ, Xu J, Wang F, Gao J (2006) Catal Lett 108:137

Tang SW, Liang B (2007) Ind Eng Chem Res 46:7826

Sheldon RA, Kochi JK (1981) Metal-catalyzed oxidations of organic compounds. Academic Press, New York

Satrio JAB, Doraiswamy LK (2001) J Chem Eng 82:43

Kantam ML, Sreekanth P, Rao KK (2002) Catal Lett 81(3):223

Deng W, Luo WP, Tan Z, Liu Q, Liu ZM, Guo CC (2013) J Mol Catal A 372:84

Wurtele C, Sander O, Lutz V, Waitz T (2009) J Am Chem Soc 131(22):7544

Mac Leod TCO, Kirillova MV, Pombeiro AJL, Schiavon MA, Assis MD (2010) Appl Catal A 372:191

Huang G, Luo J, Deng CC (2008) Appl Catal A 338:83

Guo CC, Liu Q, Wang XT (2005) Appl Catal A 282:55

Ishii Y, Sakaguchi S (2006) Catal Today 117(1–3):105

Ishii Y, Nakayama K, Takeno M, Sakaguchi S, Iwahama T, Nishiyama Y (1995) J Org Chem 60:3934

Ishii Y, Sakaguchi S, Iwahama T (2001) Adv Synth Catal 343:393

Yoshino Y, Hayashi Y, Iwahama T, Sakaguchi S, Ishii Y (1997) J Org Chem 62:6810

Jiang J, Jing YY, Zhang YF, Zhang N, Jiao JM, Zhu WM, Xue HZ, Zong YL, Yang GY (2011) Catal Lett 141:544

Deng Y, Yuan P, Yuan X, Wu J, Luo HA (2013) Chem J Chin U 34:2617

Chen L, Li BD, Xu QX, Chin DB (2013) Chem Lett 24:849

Koshino N, Saha B, Espenson JH (2003) J Org Chem 68(24):9364

Ueda C, Noyama M, Ohmori H, Masui M (1987) Chem Pharm Bull 35:1372

Rajabi F, Clark JH, Karimi B (2005) Org Biomol Chem 3:725

Melone L, Prosperini S, Ercole G, Pastori N, Punta C (2014) J Chem Technol Biotechnol 89:137

Hermans I, Deun JV, Houthoofd H (2007) J Catal 251:204

Hu Q, Li JJ, Hao ZP, Li LD, Qiao SZ (2009) Chem Eng J 149:281

Zhao DY, Feng JL, Huo QS (1989) Science 279(5350):548

Wang SB (2009) Microporous Mesoporous Mater 117:1

Sawatari N, Sakaguchi S, Ishii Y (2003) Tetrahedron Lett 44:2053

Chen KX, Jia L, Dao RN, Yao J, Wang CM, Chen ZR, Li HR (2013) ChemPhysChem 14:179

Saha B, Koshino N, Espenson JH (2004) J Phys Chem A 108:425

Titantah JT, Lamoen D (2007) Diam Relat Mater 16:581

Acknowledgments

This study was financially supported by the National Natural Science Foundation of China (No. 21376200), Hunan Provincial Natural Science Foundation of China (No. 14JJ2065), Hunan Provincial Colleges Innovation Platform Open Foundation (No. 13K044).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, M., Li, X., Bao, L. et al. A New Method for Immobilization of NDHPI on SBA-15 Carrier Used as Catalyst for Selective Oxidation of Toluene. Catal Lett 146, 383–390 (2016). https://doi.org/10.1007/s10562-015-1635-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-015-1635-z