Abstract

Gold and gold-based bimetallic catalysts for acetylene hydrochlorination were prepared with HAuCl4•4H2O and BiCl3 as precursors and γ-Al2O3 as the support. Their catalytic performances for acetylene hydrochlorination were tested in a fixed-bed reactor under the fixed reaction conditions of temperature 150 °C, C2H2 hourly space velocity 120 h−1, feed volume ratio V (HCl)/V (C2H2) = 1.05. Then they were analyzed by the characterization methods of BET, XRD, SEM, TG, TPR and XPS. The results showed that the Au/γ-Al2O3 catalyst exhibited a high activity with only 0.1 wt% Au loading but it deactivated easily for both coke deposition and valance change. With the addition of Bi, it inhibited the reduction of Au3+ to Au0 in both the preparation and the reaction process. Besides, the coke deposition was apparently weakened. The best catalytic performance was obtained over 0.1Au5Bi/γ-Al2O3 catalyst with an acetylene conversion of 96 % and a selectivity to VCM of more than 99 % (Au loading, only 0.1 wt%) for running more than 10 h.

Graphical Abstract

The Au–Bi/γ-Al2O3 catalyst can decrease significantly the Au loading from more than 1 to 0.1 wt% with the satisfied acetylene conversion compared with the activity carbon support. The addition of Bi can inhibited the reduction of Au3+ and coke deposition.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Vinyl chloride monomer (VCM) is mainly used for synthesis of polyvinyl chloride (PVC) which is widely used in every aspect of life [1]. In China, about 70 % of VCM products are produced from the acetylene hydrochlorination which is based on the catalyst of HgCl2 supported on the activity carbon [2, 3]. However, the toxicity and volatility of the HgCl2 causes serious troubles in environment and health to human beings encouraging us to search for nonmercuric catalytic systems. Nowadays, Au had been known as an efficient catalyst metal [4, 5]. Hutchings, and M. Conte [6–12] conducted the most representative research on precious metals in acetylene hydrochlorination especially for the gold catalyst and found that gold had high activity in the acetylene hydrochlorination reaction. Its initial activity was higher than HgCl2 catalyst. However, Au-based catalyst is easily deactivated over the process of the reaction, which is attributed to both the reduction of the active Au3+ species to Au0 [8] and the coke deposition [13]. Recently, some researchers attempted to improve the catalytic performance of gold catalysts for the hydrochlorination of acetylene by the addition of a second metal. In our previous study, a bimetallic Au–Cu/C catalyst showed favorable catalytic activity and an acetylene conversion of 99.5 % at 200 h [14]. Zhang et al. [15] reported that the addition of La to an Au-base catalyst improved the stability and extended the catalyst lifetime. Furthermore, an Au–Co catalyst can be used for 50 h without obvious deactivation [16]. Although the stability of the Au catalyst had improved greatly,compared with the HgCl2 catalyst, the high cost with more than 1.0 wt% Au loading still limited severely its industrial application.

The cost of catalyst was dramatically reduced with lower gold metal loading. Therefore exploitation of low Au loading and high stability catalysts may be an urgent issue for Au-base acetylene hydrochlorination catalyst. It can be discovered that most of the researchers were focused on activity carbon as the support of Au-base catalyst for acetylene hydrochlorination reaction. As we all know, activity carbon is a typical microporous materials. However, a reported fact [17] that the deactivited Au-base catalyst can form some 5–20 nm Au0 particles, which can be detected by XRD and be known as a main deactivation reason, indicated that the Au loaded on the mesoporous (2–50 nm) was the key activity site and played an important role to the catalytic performance while some of the Au addition which blocked in the micropores [17] could lead to the high Au loading. This was promoted us to consider whether a mesoporous material used as the support could decrease the Au loading. In addition, activated carbon (AC) as a support has a low mechanical strength and is easily pulverized which causes it difficult to regenerate. Nowadays, γ-Al2O3 was used as the support to prepare Au base catalyst used for CO oxidation [18, 19] and hydrodechlorination of CCl4 [20]. However, as far as we know, there was no literatures reported systematically the application of Au-base catalyst supported on γ-Al2O3 in acetylene hydrochlorination reaction.

In this work, γ-Al2O3 was used as the support to prepare Au-base catalyst for acetylene hydrochlorination and the Au loading decreased significantly. Besides, a second metal addition of Bi with a view to improving the stability of the catalyst and extending its lifetime was investigated in detail.

2 Experimental

2.1 Preparation of Catalysts

The supported gold catalysts were prepared using a wet impregnation technique. About 2.5 g BiCl3 was added into 100 ml 2 mol/L HCl solution trying to avoid BiCl3 hydrolyzed to BiOCl as far as possible. Then the suspension liquid was added dropwise with stirring to the γ-Al2O3 support (50 g, Bao Lai CO. LTD, China) which was washed by superfluous hydrochloric acid previously. Stirring was continued at ambient temperature for 2 h. Then the product was drying for 24 h at 105 °C and it was averagely divided into five parts. One of them was denoted as 5Bi/γ-Al2O3. The others were impregnated with various HAuCl4•4H2O (the content of Au assay 49.7 %) aqua regia solution (1 g HAuCl4•4H2O/100 ml, deionized water was used to make up the volume of all the impregnation liquid to 20 ml) of 1, 2, 4, 6 ml in order to obtain the various Au/Bi weight ratio supported catalyst. The catalysts were named as 0.05Au5Bi/γ-Al2O3, 0.1Au5Bi/γ-Al2O3, 0.2Au5Bi/γ-Al2O3, 0.3Au5Bi/γ-Al2O3, respectively. The 0.1Au/γ-Al2O3 was prepared as same as the above method except that the γ-Al2O3 was not treated with Bi. As a contrast, 0.1Au/AC and 0.1Au0.5Cu/AC catalyst were prepared as the above method with AC as the support. The real loading values are detected by ICP-AES and the results are listed in Table S1.

2.2 Catalyst Characterization

The BET specific surface areas, pore volume and average pore diameter of the catalysts were analyzed by ASAP 2020 surface area and porosity analyzer (Micrometrics Instrument Corporation, USA), degassed for 6 h at 573 K and then analyzed with N2 absorption–desorption at 77 K under liquid nitrogen environment. Temperature programmed reduction (TPR) analysis was carried out on an ASAP 2920 instrument (Micrometrics Instrument Corporation, USA) equipped with a thermal conductivity detector (TCD). The sample (about 200 mg) was pretreated for 1 h at 573 K and decreased to 313 K. Then it was heated up to 873 K at a ramp rate of 10 K/min, under a flow of hydrogen (10 % in Ar, 20 ml/min), recording the TCD signal. The morphology of the fresh and used catalysts was examined by scanning electron microscope (SEM) (NOVA NanoSEM450, FEI company, Holland). XPS data was collected using an Axis Ultra spectrometer with a monochromatized Al-Kα X-ray source, a minimum energy resolution of 0.48 eV (Ag 3d5/2) and a minimum XPS analysis area of 15 μm. Thermo gravimetric analysis (TGA) of samples was conducted on the TG simultaneous thermal analyzer (NETZSCH TG 209 F1 Libra, Germany). About 20 mg of sample was used and heated to 1,073 K under the air atmosphere, flow rate of 50 ml/min, and temperature ramp rate of 10 K/min. TEM experiments used a JEM-2100F electron microscope with the accelerating voltage of 200 kV, a line resolution of 0.14 nm and point-to-point resolution of 0.23 nm.

2.3 Catalytic Test

Catalyst experimental setup is shown in Fig. S1. The catalytic performance in acetylene hydrochlorination was evaluated in a fixed-bed micro-reactor (diameter 10 mm) operating at the pressure of 0.1 MPa and temperature of 150 °C. The reactor was purged with nitrogen to remove water in the reaction system before the reaction process. Hydrogen chloride was passed through the reactor at a flow rate of 50 ml/min for 2 h to activate the catalyst. After the reactor was heated to 150 °C, acetylene (20 ml/min) and hydrogen chloride (21 ml/min) were fed through the heated reactor which contained 10 ml catalyst. The reaction product was analyzed by gas chromatography (GC-920, Al2O3 PLOT column). One result spectrum is shown in Fig. S2. The catalyst activity is determined by the conversion of acetylene (\(X_{{C_{2} H_{2} }}\)) and selectivity of VCM (S VCM ), which are defined as:

where \(\varPhi_{{{\text{C}}_{ 2} {\text{H}}_{ 2} }}\) is residual volume fraction of acetylene and Φ VCM is volume fraction of chloroethylene.

3 Results and Discussion

3.1 Catalytic Performance

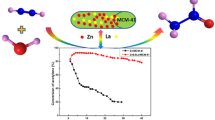

The catalytic performance of Au–Bi/γ-Al2O3 catalysts with different Au/Bi weight ratios for acetylene hydrochlorination is shown in Fig. 1. It can be seen that their selectivity to VCM was remaining at a high level of above 99 % (Fig. 1b). It should be mentioned that 0.1Au/γ-Al2O3 gave an acetylene conversion as high as 96.9 % at 2.5 h despite of its only 0.1 % Au weight loading (Fig. 1a). However, this catalyst exhibited a rather poor stability and the acetylene conversion decreased sharply after running for 3 h. On the other hand, 0.5Bi/γ-Al2O3 catalyst showed 53.8 % acetylene conversion while its stability was even poorer than the 0.1Au/γ-Al2O3 catalyst. With the combining of Au and Bi components, the catalytic performance was significantly improved especially for their stability. As Fig. 1a shown, the catalytic performance was sensitive to the Au weight content. When the Au/Bi weight ratio was 0.05/5, the acetylene conversion was remaining about 82 % even after running for 12 h. With Au/Bi weight ratio reaching to 0.1/5, the acetylene conversion can reach a high value of about 97 %. The high acetylene conversion was near to the 0.1Au/γ-Al2O3 and far higher than the 5Bi/γ-Al2O3 catalyst indicating that the activity center was mainly provided by the Au other than Bi. It should be underlined that it was not better for the catalytic stability when adding an excess of Au. With the increasing of Au/Bi weight ratio from 0.1/5 to 0.3/5, the catalytic stability decreased gradually. Therefore, the optimal Au/Bi weight ratio was 0.1/5 and the acetylene conversion can remain at 96 % even after 10 h running.

Catalytic performance of catalysts: conversion of acetylene a and selectivity to VCM b with running time. Reaction conditions: Temperature (T) = 150 °C, gas hourly space velocity = 120 h−1, Pressure (P) = 0.1 MPa, feed volume ratio V HCl/V C2H2 = 1.05. Filled squares 0.05Au5Bi/γ-Al2O3, filled triangles 0.1Au5Bi/γ-Al2O3, filled circles 0.2Au5Bi/γ-Al2O3, filled inverted triangles 0.3Au5Bi/γ-Al2O3, open squares 5Bi/γ-Al2O3, open circles 0.1Au/γ-Al2O3, open triangles 0.1Au/AC, open diamond 0.1Au0.5Cu/AC

In order to compare the catalyst performance with the Au-base catalyst taking AC as the support, 0.1Au/AC and 0.1Au0.5Cu/AC catalyst were tested under the same reaction conditions and they performed a relatively lower acetylene conversion (47 and 63 %, respectively). It demonstrated that taking the γ-Al2O3 as the support had the advantage of declining the Au weight loading over the AC support. In addition, a higher GHSV experiment for the 0.1Au5Bi/γ-Al2O3 catalyst was carried out and the result was shown in Fig. S3. It can be seen that the acetylene conversion declined to about 81 % when increasing GHSV to 360 h−1. Although it was lower than the reported result taking AC as the support with 1.0 % Au weight loading (Table S2), one-tenth Au while about 15 % acetylene conversion dropping also illustrated a good performance of decreasing the Au loading with the mesoporous γ-Al2O3 as the support.

3.2 Catalyst Characterization

To determine the nature of the supported Au-based catalysts, a detailed structural and chemical study was carried out using a combination of a series of characterization methods.

3.2.1 Catalyst Texture Properties

The N2 adsorption–desorption isotherm of the fresh catalysts (shown in Fig. S4) belongs to type-IV adsorption (IUPAC classification) due to the large number of mesoporous on the γ-Al2O3 surface. The series samples showed almost the same mesoporous structure after loading the active component such as 0.1Au, 5Bi, 0.05Au5Bi, 0.1Au5Bi, 0.2Au5Bi, and 0.3Au5Bi. Pore structure parameters of catalysts are shown in Table S3. As we can see, after loading Au and Bi, the BET surface area, the BJH total pore volume and average pore diameter of the catalysts are reduced slightly, mainly due to the active components covering the surface of the pores in the support and occupying parts of the space. On the other hand, this result may be caused by the phenomenon that some small pore walls were destructed by the impregnation liquid and the reducing of the pores caused the dropping of the catalysts’ BET surface area. After reaction, compared with the fresh catalyst, the BET surface area of the 0.1Au/γ-Al2O3 catalyst reduced from 187.2 to 132.8 m2/g (29.1 % reduction), which may be caused by one of the key mechanisms of catalyst deactivation in the acetylene hydrochlorination reaction-the coke deposition and it will be analyzed in detail in the next chapter. When adding the Bi component, the BET surface area reducing phenomenon relieved apparently. Adjusting the Au ingredient, when Au/Bi weight ratio (w/w) was 0.05–0.1/5, the decreased value of the BET surface area (ΔSBET) reached to the minimum value that was about 22 m2/g (reduced about 11.8 %). However, a further increasing in Au content, the ΔSBET increased sharply which contributed to the reason that the activity of Au to the polymerization of the vinyl chloride or acetylene. The change trend in the total pore volume and average pore diameter before and after the reaction were similar which was consistent with the catalytic performance of the series catalysts (Fig. 1a) and it can explain that it was not better for the catalytic stability when adding an excess of Au described above. Therefore, the adding of Bi can inhibit the coke deposition and the optimal weight ratio for Au/Bi is 0.1/5, at which the used catalyst can achieve the satisfied catalytic performance and may have the least coke deposition.

3.2.2 Coke Deposition on the Used Catalysts

In order to get an insight into the nature of coke deposition, SEM and TGA experiments were conducted. SEM images of both the fresh and used 0.1Au/γ-Al2O3, 0.1Au5Bi/γ-Al2O3 were shown in Fig. S5. It can be seen that, compared with the fresh catalyst (Fig. S5a), there was some chip structure carbon covering on the surface of the 0.1Au/γ-Al2O3 catalyst (Fig. S5c). The pores were filled or blocked by the coke deposition leading to the decreasing of BET surface area and total pore volume described in Table S3. Besides, part of the active sites were covered and catalyst’s activity decreased. It was worth mentioning that, compared with the fresh catalyst (Fig. S5b), there was also some coke deposition displayed on the used 0.1Au5Bi/γ-Al2O3 (Fig. S5d). However, its morphology changed to filiform structure which was considered produced slower than the chip structure. In addition, it was similar with the deposition morphology when Au-base catalyst taking activity carbon as the support [21].

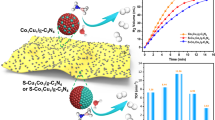

TG analysis was used to evaluate the degree of coke deposition on the surface of catalysts. The TG experiment for used 0.1Au5Bi/γ-Al2O3 under N2 atmosphere (seen in Fig. S6) indicated that the influence of desorbed VCM to the TG result is tiny. The TG profiles of both fresh and used catalysts are shown in Fig. 2. It can be seen from Fig. 2a that the fresh 0.1Au/γ-Al2O3 catalyst had a similar slightly weight loss as same as the γ-Al2O3 support (Fig. S7), indicating that there is little active ingredients vaporized or decomposed and it may be the hydroxyl dehydration effect caused the weight loss. However, the fresh 0.1Au5Bi/γ-Al2O3 catalyst had more weight loss than the fresh 0.1Au/γ-Al2O3 catalyst which may be the reason that BiCl3 or BiOCl (produced by the hydrolysis of BiCl3) can vaporize or decompose under high temperature. On the other hand, the used 0.1Au/γ-Al2O3 for even running 4 h exhibited a serious weight loss (17.3 %, the actual coke deposition is 15.2 % in the range of 100–300 °C; 5.6 %, the actual coke deposition is 4.2 % in the range of 300–600 °C) mainly due to the burning of the coke deposition. With the adding of Bi content, compared with the used 0.1Au/γ-Al2O3, the used 0.1Au5Bi/γ-Al2O3 catalyst running 13 h showed a lighter weight decrease about 7.3 % and the actual coke deposition is 4.4 % in the range of 100–300 °C. In addition, 2.7 % weight loss (actual coke deposition is 1.3 %) is also less than the used 0.1Au/γ-Al2O3 in the range of 300–600 °C. The TG results illustrated that the addition of Bi can effectively inhibited the occurrence of coke deposition.

3.2.3 XRD

Figure 3 displays the XRD patterns of γ-Al2O3 support, the fresh and used 0.1Au/γ-Al2O3 and 0.1Au5Bi/γ-Al2O3 catalysts. The profile of γ-Al2O3 showed broad peaks belonging to the faces (3 1 1), (4 0 0) and (4 4 0) of the γ-Al2O3 phase (JCPDS card No. 43-1308). And the XRD patterns of both the fresh and used 0.1Au/γ-Al2O3 were as same as the γ-Al2O3. As to the 0.1Au5Bi/γ-Al2O3 catalyst, the diffraction peaks of γ-Al2O3 were apparently weakened, which was possible the reason that the adsorption of the Bi on the support can disturb the diffraction for γ-Al2O3 crystal. Apart from the γ-Al2O3 peak, the diffraction peaks of 25.86o, 32.45o, 33.45o et al. belonged to the BiOCl (JCPDS card No.06-0249, Fig. S8) can be also observed indicating that some Bi was adsorbed on the surface as the pattern of BiOCl although we had tried to avoid the BiCl3 hydrolysis with the hydrochloric acid during the catalyst preparation. No discernible Au reflection was detected in both the fresh and used 0.1Au/γ-Al2O3 and 0.1Au5Bi/γ-Al2O3 catalysts as the Au content was below the lower limit of XRD detection or it dispersed well on the surface of the support.

3.2.4 TPR

The TPR profiles show that the fresh 0.1Au/γ-Al2O3 catalyst exhibited one characteristic reduction band between 198 and 250 °C with the peak centers at 218 °C (Fig. 4). The peak corresponds to the reduction of Au3+. While the reduction peak of Au3+ in 0.1Au/γ-Al2O3 was lower than the Au3+ reduction peak of 310 °C in Au/SAC and 228 °C in Au/AC reported [16]. It may be the reason that the different interaction effect between the Au and the support of SAC/AC and γ-Al2O3,and the former interaction was stronger than the latter. With the additive of Bi component, when the amount of Au was between 0.1 and 0.2 wt% (0.05 wt% was below the detection limit), a redshift phenomenon of the reduction band of Au3+ was observed and the reduction peak was 229 °C. However,when the Au content increased to 0.3 wt%, the reduction temperature decreased to 223 °C. In addition, a shoulder peak at 251 °C appeared which was attributed to the reductive of Au+1 [17]. It indicated that an excess of Au content can reduce the interaction effect between the Au and Bi component. And some Au3+ can reduce to Au+1 during the catalyst preparing process. It was reported that the activity of Au catalyst for hydrochlorination reaction of acetylene decreases along the order: Au3+ > Au+ > Au0 [22], and the valence change of Au is one of the main reason for the Au-base catalyst deactivation. The weaken reductive temperature of Au3+ and the valence change of 0.3Au5Bi/γ-Al2O3 was consistent with its catalytic performance compared with the others (shown in Fig. 1).

3.2.5 TEM

Figure 5 displays the TEM images of both fresh and used 0.1Au/γ-Al2O3 and 0.1Au5Bi/γ-Al2O3 catalysts. It can be seen that there are some Au0 particles with the diameter between about 5 and 10 nm loading on the surface of the support while Au0 particles were invisible in Fig. 5b. It indicated that the reductive of Au3+ was inhibited with the additive of Bi in fresh 0.1Au5Bi/γ-Al2O3 during the process of preparation and storage. On the other hand, the Au0 particle size increased slightly in the used 0.1Au/γ-Al2O (Fig. 5c). It should be noted that some tiny particles appeared in the used 0.1Au5Bi/γ-Al2O3 (Fig. 5d) which illustrated that there is an interaction effect between the Bi and Au which can divide the active sites of Au3+ and inhibit the occurrence of carbon deposition.

3.2.6 XPS

XPS experiments were carried out to investigate the valence state and relative amount of the active ingredient Au in 0.1Au/γ-Al2O3 and 0.1Au5Bi/γ-Al2O3 before and after the reaction (shown in Fig. 6). It should be noted that there was a large number of Au0 in both fresh and used 0.1Au/γ-Al2O3 catalyst and the Au3+ peak was not detected even in the fresh sample. It was disagreement with its catalytic performance which was ascribe to that the active component Au3+ can be reduced to Au0 leading to the Au3+ content was too low to below the XPS minimum bound in the preparation and storage process of the catalysts. However, an obvious Au3+ peak was detected in both fresh and used 0.1Au5Bi/γ-Al2O3. Curve fitting was employed to determine the ratio of each Au species in them [17]. In fresh and used 0.1Au5Bi/γ-Al2O3 catalyst, the relative content of Au3+ is 46.7 and 33.3 %, respectively (Table S4). And there was only 11.5 % Au3+ reduced to Au+1. The high Au3+ relative content compared with the other literatures [16] induced that the 0.1Au5Bi/γ-Al2O3 catalyst can achieve an excellent acetylene conversion even for the 0.1 % Au weight loading (Fig. 1a). This indicated that the additive of Bi can inhibit the reduction of Au3+ not only during the process of preparation and storage but also in the reaction course. In addition, XPS experiment results were also provide significant information about the interaction effect between Au3+ active center and Bi species, as mentioned in the TEM result. It should be noted that the binding energy of Au 4f7/2 in fresh 0.1Au5Bi/γ-Al2O3 catalyst showed a significant negative shift (about 0.2 eV) comparing with fresh 0.1Au/γ-Al2O3 catalyst. Such a negative shift had been ascribed to the interaction between Au and Bi. This increased the electron density of Au3+ with the transfer of electron from Bi species to Au3+ center just as the other literatures reported [23, 24]. It was acknowledged that the effect would enhance the electron-donating ability of Au and allow the catalyst to absorb more hydrogen chloride [23, 24].

4 Conclusion

Compared with the traditional Au-base catalyst supported on the AC for acetylene hydrochlorination, the Au/γ-Al2O3 catalyst can decrease significantly the Au loading from more than 1.0 to 0.1 %. However, its stability was poor due to the main deactivation factors of the valence change of Au and coke deposition under the reaction conditions in this study. The addition of Bi can greatly inhibited the reduction of Au3+ to Au0 in both the preparation and the reaction process. Besides, the coke deposition was also apparently weakened. Therefore the catalyst’s stability was improved. The optimal weight ratio of Au/Bi was 0.1/5 and it can run for more than 10 h in the reaction. In addition, the Au-base catalyst supported on the γ-Al2O3 has the advantage of stronger mechanical strength and regeneration capacity over the traditional Au-base catalyst supported on activity carbon.

References

Wei XB, Shi HB, Qian WZ, Luo GH, Jin Y, Wei F (2009) Ind Eng Chem Res 48:128

Hutchings GJ, Grady DT (1985) Appl Catal 17:155

Pirrone N, Cinnirella S, Feng X, Finkelman R, Friedli HR, Leaner J, Mason R, Mukherjee AB, Stracher GB, Streets DG, Telmer K (2010) Atmos Chem Phys 10:5951

Gu HZ, Xu XS, Chen AA, Ping A, Yan XH (2013) Catal Commun 41:65

Chen BB, Zhu XB, Crocker M, Wang Y, Shi C (2013) Catal Commun 42:93

Hutchings GJ (1985) J Catal 96:292

Nkosi B, Adams MD, Coville NJ, Hutchings GJ (1991) J Catal 128:378

Carley A, Heirene C, Willock D, Johnston P, Herzing A, Kiely C, Hutchings GJ (2007) J Catal 250:231

Conte M, Carley A, Attard G, Herzing A, Kiely C, Hutchings GJ (2008) J Catal 257:190

Hutchings GJ (2002) Catal Today 72:11

Conte M, Carley AF, Hutchings GJ (2008) Catal Lett 124:165

Conte M, Davies CJ, Morgan DJ, Carley AF, Johnston P, Hutchings GJ (2014) Catal Lett 144:1

Zhang HY, Dai B, Wei L, Wang XG, Zhang JL, Zhu MC, Gu JJ (2014) J Catal 316:141

Wang SJ, Shen BX, Song QL (2010) Catal Lett 134:102

Zhang HY, Dai B, Wang XG, Xu LL, Zhu MY (2012) J Ind Eng Chem 18:49

Zhang HY, Dai B, Wang XG, Wei L, You H, Gu JJ, Zhang JL (2013) Green Chem 15:829

Conte M, Davies CJ, Morgan DJ, Davies TE, Carley AF, Johnston P, Hutchings GJ (2013) Catal Sci Technol 3:128

Chih HL, Shawn DL, Jyh FL (2003) Catal Lett 89:235

Yeong JC, Chuin TY (2001) J Catal 200:59

Marta LJ, Wojciech J, Magdalena B, Zbigniew K, Leszek K (2009) Top Catal 52:1037

Wang L, Shen BX, Ren RF, Zhao JG (2014) Petro Process Petro 45:38 (in Chinese)

Wang SJ, Shen BX, Xiao WG, Song QL (2010) Acta Petrolei Sin 26:201

Li XY, Wang Y, Kang LH, Zhu MY, Dai B (2014) J Catal 311:288

Huang CF, Zhu MY, Kang LH, Li XY, Dai B (2014) Chem Eng J 242:69

Acknowledgments

We are grateful to the Fundamental Research Funds for the Central Universities (No. WA1214003) and the Technology Development Funds for the Tanggu of Binhai New Area, Tianjin, China (No.2012STHB04-01).

Author information

Authors and Affiliations

Corresponding author

Electronic Supplementary Material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Zhao, J., Cheng, X., Wang, L. et al. Free-Mercury Catalytic Acetylene Hydrochlorination Over Bimetallic Au–Bi/γ-Al2O3:A Low Gold Content Catalyst. Catal Lett 144, 2191–2197 (2014). https://doi.org/10.1007/s10562-014-1371-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-014-1371-9