This article presents a brief comparative overview of the methods for controlling phase formation in oil disperse systems, of which those that record the initial phase-forming stages and are used for preventing undesirable complications in oil preparation, production, and transportation processes are investigated. Switch from static to dynamic methods is of special importance for creating steady multiphase, fluid, +flow (flow assurance) conditions for further development of underwater hydrocarbons recovery technologies, including in Russia. The experimental results of determination of the points of onset of wax and salt formation in model oil systems that illustrate their effectiveness for chemical inhibition of pertinent undesirable phenomena at the early phase formation stages are presented.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

High-molecular-weight compounds (asphaltenes, waxes, etc.) and light hydrocarbons (methane, ethane, propane, etc.), which tend to form gas hydrates, as well as stratal water salts are commonly considered as the main problem-creating components because of possible complications in technological oil preparation, recovery, and transportation processes. Most of the investigative studies of these components are aimed at solving the problems of preventing their possible deposition on the equipment walls and/or in the stratum pores during occurrence of the respective technological processes. Because of the need for retaining constancy of properties of the multiphase oil fluid in the flow, which is particularly important for further development of underwater hydrocarbons recovery technologies, including in Russia, snitch from static to dynamic methods for control of deposits in both laboratory practice and for on-line control of fluid properties in the technological process using various transducers, for example, optical fiber transducers, is inevitable [1].

When static methods are used, technological engineers are focused on forestalling the consequences of the final stage of phase transformations in the oil disperse systems (ODS) by the known methods and when dynamic control methods are used, possibility appears for timely adoption of preventive steps at the early stages of phase transformations, which will help prevent development of undesirable events. Most effective could be the methods of chemical inhibition and/or physical design by analogy with medical technologies particularly for early prevention of development of undesirable phenomena in the processes of development of insult and infarct by using appropriate methods.

Within the scope of “flow assurance” (steady flow) direction the main tasks are the following: development of analytical methods for predicting and finding effective methods for prevention of formation of undesirable oil deposits during organization of flow assurance of oil fluid movement in the stratum, pipe, equipment, etc. The concept “flow assurance” itself is a relatively new term in oil industry and it appeared on economic considerations for organizing flow of hydrocarbons from storage tanks to selling points. This term was introduced by Petrobras oil company in the early 1990’s in Portuguese language as Garantia do Escoamento, meaning Flow assurance.

The specific spheres, which are indicated in Fig. 1, are important for ensuring flow assurance and deserves separate investigation, because they are dependent on the type of ODS and the stage of the liquefaction cycle of the whole project. Solution of the problems of ensuring flow assurance is of special importance for upkeep of the existing technical systems, constancy of properties of the multicomponent media, especially in harsh climatic conditions. The goal of the assessment of flow assurance is prediction, based on appropriate mathematical models, of the behavior of ODS during its movement through the pipeline or in technological equipment so as to preclude in advance the problems that may undermine safety, integrity, and efficiency of the production cycle.

To solve these problems, materials and design parameters are selected for calibration of the pipes and strategies are developed for control of the properties of the ODS (commonly emulsions) and use is made of a whole list of available technologies ranging from mechanical removal, prevention of deposit formation (chemical inhibition), physical design (implementation of processes far off from the phase transformation conditions), etc. to formulation of the concept of ODS life cycle in a specific technological process.

The goal of this work is analysis of the methods of control of the initial stages of phase formation in oil systems.

The mechanism of deposits formation is tied with occurrence of phase transitions that underlie the physicochemical principle of many oil technological processes. In conformance with the theory of phase transitions, formation of a new phase occurs via the stage of formation of nanoparticles of critical sizes in the original mother medium and their subsequent growth. Since the onset of nanoparticle growth precedes the appearance of deposits in oil technological processes, which are associated with undesirable formation of macroscopic deposits in the stratum pores and/or on oil technological equipment walls, special attention is focused on methods of determination of the so-called points of onset of growth of disperse particles of oil components upon variation of external conditions that imitate changes in phase state of the oil systems.

In this context, in this work we analyzed the known assessment methods and presented the results of some investigations in the domain of precursors of the first type of phase transformations in oil systems, namely, the so-called onset points, which include onset of precipitation of asphaltenes, crystallization of waxes (WAT — wax appearance temperature in English terminology), and formation of salts 4 (by example of Russian inhibitors). The results of determination of these parameters are important for reliable modeling of the hydrodynamic behavior of multiphase flows, which ensures steady condition of their movement. Note that the kinetics of formation of gas hydrates, including its initial stages, is a subject of numerous investigations [2,3,4].

To determine the onset points of the above-noted phase transformations. a group of standard and investigative methods was developed [5, 6]. From a comparative analysis of the various asphaltene onset point determination methods listed in Table 1 it is evident that methods of optical titration (optical end point determination) of asphaltene-containing systems could be useful for the purposes of modeling and be promising for finding effective asphaltene deposition inhibitors. Optical methods can be implemented in static (manual variant) and dynamic (automatic variant as per ASTM D 6703 method) mode since most other known methods have considerable limitations generally due to low reproducibility (for example, visual method) and difficulties of investigating oils having high asphaltene contents.

The dynamic method of asphaltene onset point determination is promising because it allows variation of measurement pressure and temperature in a wide range, which makes it possible to construct phase diagrams of aspbaltene-containing dispersions, but this method is not as sensitive as optical methods when asphaltene content is low.

Analysis of WAT determination methods listed in Table 2 shows diversity of principles of their determination, which additionally underscores the uncertainty of the earliest standard method of pour point determination in accordance with ASTM-D2500 [16]. Wax microcrystals begin to precipitate from the oil upon attainment of WAT. In general, the flow-ability loss temperature is roughly three degrees higher than the pour point of an oil. Some oils do not congeal at temperatures down to -70°C. In that case, the difference between the WAT and pour point could be as much as 15-20 and even 50-60°C. Wax deposits of oil always contain surfactants (up to 20-40%), water, and mechanical impurities, besides paraffins (20-70%) and the oil itself (up to 45% and more).

Of these asphalt-resin-wax deposits (ARWD), those with prevalence of waxes or asphaltenes are distinct. If the oil temperature falls below the WAT, both ceresines and paraffins (waxes) crystallize, the crystals grow larger, and a 3-D wax network, which consists of variously sized interlinked wax crystals, is formed. This network “reinforces” the oil: the viscosity of the oil increases and then it becomes gelatinous. At a certain temperature the oil being sufficiently “reinforced” by the wax network loses its mobility.

There are various WAT determination methods, of which microscopy in polarized light and static cold finger methods are the main in global research practice even though they are capable of determining appearance of only large wax crystal particles (0.5 mm and above). The method that uses NIR spectroscopy to determine WAT from the change of intensity of optical density due to light scattering at 1100 nm wavelength allows determination of the onset of appearance of wax nanocrystals of 50 nm size.

In investigations of WAT in model systems by KIIIt spectroscopy in static mode with cooling of a temperature-controlled optical cell at the fixed wavelength of 1100 nm, the onset of the wax formation process in the presence of a specified quantity of asphaltenes was determined distinctly (Fig. 2) [30].

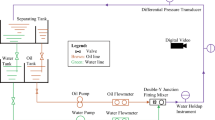

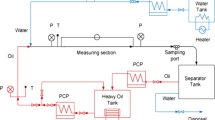

Most of the known methods of determination of the onset of formation of a new phase are characterized by static condition of formation of particles of the new phase (waxes. asphaltenes, salts, etc.) in the bulk of the original static mother phase, which markedly differ from the real hydrodynamic situation in the pipe or in the oilfield equipment. The dynamic variants of determination of initial stages of phase transformations in oil systems implemented in laboratory units, which reproduce laboratory and field conditions, can be considered as maximally close to real hydrodynamic conditions of flow of a moving fluid [29]. Such units can be used for measurements in a laboratory loop consisting of two parallel temperature-controlled lines, through one of which moves the reference fluid with a fixed velocity and through the other, the test fluid. In this case, the start of pressure rise in the system upon cooling is determined in the case of wax precipitation or when cationic and anionic solutions are mixed, which leads to formation of a supersaturated salt solution. Laboratory units reproducing similar conditions are generally called flow loop.

Comparative results of analysis of the onset of salt precipitation in the presence of various inhibitors by the flow loop method under dynamic conditions in the so-called salt loop are plotted in Fig. 3. The essential feature of the dynamic method of determination of the effectiveness of inhibitors of salt deposition consists in pumping of model supersaturated solutions of various compositions through a metallic capillary tube with a diameter of 0.75 loam under set thermobaric conditions. The salt deposits on the capillary tube walls, increasing thereby the fluid pressure at the system inlet. The WinDSL software is used for control of the unit and data processing.

In comparison with the static methods, tests under dynamic conditions correspond to field conditions and can be conducted in a wide range of temperatures and pressures, which makes possible comparison of effectiveness of the proposed inhibitors of salt deposition [31, 32].

Thus, it is possible to acquire initial data for composing a picture of emerging possible complications at the initial stages of phase transformations in oil systems. The advantages of use of flow loop type of methods are obvious because they simulate real situations relating to thermobaric characteristics and hydrodynamic parameters.

References

D. V. Brower, C. N. Prescott. J. Zhang, et al., “Real-time flow assurance monitoring with non-intrusive fiber optic technology,” Offshore Technology Conference, January, 2005.

I. N. Forsdyke, “Flow assurance in multiphase environments,” International Symposium on Oilfield Chemistry. 1997.

E. D. Sloan, Natural Gas Hydrates in Flow Assurance, Gulf Professional Publishing, 2010.

L. E. Zerpa, J. L. Salager, C. A. Koh, et al., Industrial & Engineering Chemistry Research, 50 (1) 188- 197 (2011).

S. A. Mousavi-Dehghani, M. R. Riazi, M. Vafaie-Sefti, et al. Journal of Petroleum Science and Engineering. 42 (2-4), 145-156 (2004).

S. Simon, J. Ruwoldt, and J. Sjöblom. Advance: in Colloid and Interface Science, 277, 102-120 (2020).

K. Oh and M. D. Deo. Energy & Fuels, 16 (3), 694-699 (2002).

B. J. Fulr, C. Cathrea, L. Coates. et al., Fuel, 70 (11). 1293-1297 (1991).

J. S. Buckley, Fuel Science and Technology International, 14 (1-2), 55-74 (1996).

L. T. Vuong, A Simple and Accurate Experimental Technique for Measurement of the Onset of Asphaltene Deposition from Petroleum Reservoir Fluids; M. Sc. Thesis, Chemical Eng. Department, University of Illinois, 1985.

H. Rassamdana, B. Dabir, M. Nematy, et al., AIChE Journal, 42 (1),10-22 (1996).

J. Escobedo and G. A. Mansoori, SPE Production & Facilities, 10 (02), 115-118 (1995).

J. S. Buckley, G. J. Hirasaki, Y. Liu, et al., Petroleum Science and Technology, 16 (3-4), 251-285 (1998).

D. Broseta, M. Robin, T. Savvidis, et al., “Detection of asphaltene deposition by capillary flow measurements,” SPE/DOE Improved Oil Recovery Symposium, January, 2000.

S. Thou, G. Ruthammer, and K. Potsch. “Detection of asphaltenes flocculation onset in a gas condensate system,” In European Petroleum Conference, January, 2002.

V. R Kruka, E. R. Cadena, and T. E. Long, Journal of Petroleum Technology, 47 (08), 681-687 (1995).

N. V. Bhat and A. K Mehrotra, Ind. Eng. Chem. Res., 43, 3451-61 (2004).

Y. Zhao, K. Paso, and J. Sjöblom, Journal of Thermal Analysis and Calorimetry, 117, 403-411(2014).

M. Kok, J. Letoffe, P. Claudy; et al., Fuel, 75 (7), 787-790 (1996).

M. A. Kelland, Production Chemicals for the Oil and Gas Industry, second ed., CRC Press, Boca Raton, Florida (2014).

Z. Huang, S. Zheng, and H. S. Fogler, Wax Deposition: Experimental Characterizations, Theoretical Modeling and Field Practices, CRC Press, Boca Raton, Florida (2015).

J. R. Becker, Paraffin-Crystal-Modifier Studies in Field and Laboratory. Society of Petroleum Engineers, 2001.

T. G Monger-McClure, J. E. Tackett, and L. S. Merrill, SPE Production & Facilities, 14, No. 01, 4-16 (1999).

K. Paso, H. Kallevik, and J. Sjoblom, Energy & Fuels, 23 (10), 4988-1994 (2009).

Y. Zhao, K. Paso, J. Norrman, et al., Journal of Thermal Analysis and Calorimetry, 120 (2), 1427-1433 (2015).

K. Weispfennig and D. W. Jennings, “Effects of shear and temperature on wax deposition: cold finger investigation with a GOM crude oil,” The 5th International Conference on Petroleum Phase Behaviour and Fouling, June 13-17, 2004.

V. N. Glushchenko, L. M Shipiguzov, and I. A. Yurpalov, Neft. Khoz., No. 5, 84-87 (2007).

D. W. Jennings and K Weispfennig, Energy & Fuels, 20 (6), 2457-2464 (2006).

B. Robøle, H. K. Kvandal, and R. B. Schüller, Flow Measurement and Instrumentation, 17, No. 3, 163-170 (2006).

M. V. Yakovleva, L. V. Pakhmesterov, and R. Z. Safieva, Nefteparerab Neftekhin, No. 1,24-29(2014).

M. Ramzi, R. H. El-Sayed. M. Fathy. et al., Int. J. Chem. Sci, 14 (1),16-28 (2016).

A. N. Markin, R. E. Nizamov. and S. V. Sukhoverkhov, Petroleum Chemistry: A Practical Guide [in Russian], Dal’nauka, Vladivostok (2011),p. 288.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimiya i Tekhnologiya Topliv i Masel, No. 2, pp. 51 — 55, March—April, 2020.

Rights and permissions

About this article

Cite this article

Safieva, R.Z. Control of Initial Phase-Forming Stages in Oil Disperse Systems. Chem Technol Fuels Oils 56, 205–211 (2020). https://doi.org/10.1007/s10553-020-01130-w

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10553-020-01130-w