Abstract

Objective

To investigate the conversion of carbazole into 2′-aminobiphenyl-2,3-diol using carbazole dioxygenase (CARDO) that is a multicomponent enzyme consisting of homotrimeric terminal oxygenases (CarAa), a ferredoxin (CarAc) and a ferredoxin reductase (CarAd) unit, encoded by the carAa, carAc and carAd genes, respectively.

Results

The enzyme subunits containing a GST tag were expressed independently in E. coli. The expressed proteins were purified by one-step immobilized affinity chromatography and three purified proteins could reconstitute the CARDO activity in vitro and showed activity against carbazole as well as against wide range of polyaromatic compounds.

Conclusion

This method provides an efficient way to obtain an active carbazole dioxygenase with high yield, high purity and with activity against a wide range of polyaromatic compounds.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Combustion of fuel rich in sulfur, nitrogen and polycyclic compounds leads to environmental problems like acid rain, particulate matter formation, greenhouse effect and destruction of ozone layer (Gaffney and Marley 2009). Catalysts are used to remove these compounds from refinery feedstocks. However, polyaromatic compounds, such as carbazole (CAR), fluorene, pyrene, phenanthrene etc., are highly recalcitrant to chemical attack (Shong 1999). The combustion of these compounds not only leads to environmental pollution but also affects the efficiency of the fuel (Song and Ma 2003). Biorefining is an alternative technology for the removal of these contaminants. The mechanism of aerobic degradation of polyaromatic compounds involves the incorporation of O2 into one of the aromatic rings by the respective enzymes, leading to the formation of a dihydrodiol. The latter undergoes a number of further degradative steps and can be metabolized by number of enzymes. The specificity of the enzyme for a particular substrate is the major bottleneck in the commercialization of biorefining.

Carbazole dioxygenase (CARDO) has a unique ability to catalyze diverse oxygenation reactions with a broad substrate range (Nojiri et al. 2005). Apart from carbazole, CARDO also can catalyze the dioxygenation of compounds like dibenzofuran (DBF), fluorene, naphthalene, and biphenyl. It also catalyzes the monooxygenation of methylene carbon atoms and the sulfoxidation of sulfides (Nojiri 2012). The ability of CARDO to catalyze the oxygenation of diverse aromatic ring compounds, in addition to carbazole, makes it a suitable candidate for biorefining of fuel. A variety of bacteria, such as Arthrobacter, Burkholderia, Janthinobacterium, Klebsiella etc., can degrade carbazole (Leon and Kumar 2005). Degradation of carbazole is a three step process. The first step is catalyzed by carbazole-1,9a-dioxygenase (CARDO; encoded by carAaAcAd genes) and results in the formation of 2′-aminobiphenyl-2,3-diol. This product is further cleaved by meta-cleavage and a hydrolase to give anthranilic acid. CARDO is a multicomponent enzyme consisting of homotrimeric terminal oxygenases (44-kDa), a ferredoxin (13-kDa) and a ferredoxin reductase (37-kDa) unit, encoded by the carAa, carAc and carAd genes respectively (Kilbane 2006).

Considering the potential of CARDO, it is imperative to validate these findings using purified protein before designing a suitable biocatalyst for biorefining. This is the first report of the expression and purification of CARDO components (CarAa, CarAc and CarAd) in Escherichia coli using pGEX-4T3 vector. The purified protein was further used to validate the substrate range of CARDO.

Material and methods

Bacterial strains, plasmids and reagents

Pseudomonas sp. GBS.5 (16S rRNA sequence Gene Bank accession number JX193073) was isolated in our laboratory (Singh et al. 2013a, b). Cloning vector, ZeroBlunt, was purchased from Invitrogen. Expression vector pGEX-4T3 was from GE life Sciences. E. coli DH5α and E. coli BL21 (DE3) were stored in the laboratory.

CAR (96 % purity) was purchased from Acros Organics (New Jersey, USA). Other polyaromatic hydrocarbons (>98 % purity) [naphthalene, phenanthrene, biphenyl, DBF, dibenzothiophene (DBT), fluorene, fluoranthene and pyrene] were obtained from Sigma Aldrich. Organic solvents and other chemicals were of analytical grade from Qualigen (Mumbai, India) and Merck.

Construction of expression plasmid

The CarAa, CarAc and CarAd genes were amplified by PCR from Pseudomonas sp. strain GBS.5. They were cloned and expressed in E.coli BL-21 (DE3) using the pGEX4T-3 plasmid. The forward primers were designed to contain the BamH1 site and the reverse primers contained EcoR1 site (Supplementary Table 1). PCR consisted of initial denaturation of 94 °C for 10 min, then 30 cycles of 0.5 min denaturation (94 °C), 30 s annealing at 62 °C. The extension was for 1.5 min, 30 s and 1.5 min (72 °C) for carAa, carAc and carAd, respectively, followed by a final extension for 10 min (72 °C). The reaction mixture was then stored at 4 °C until further use. CarAaAcAd were cloned together in E. coli (BL21) using pGEX-4T3 vector as mentioned in Singh et al. (2013a).

Expression and purification of subunits of carbazole dioxygenase

Escherichia coli cells harboring expression vector cloned with carAa, CarAc and carAd gene were cultivated in LB containing ampicillin (100 µg/ml). CarAa, CarAc and CarAd were expressed in soluble form at 25 °C, 0.2 mM IPTG (4 h), 37 °C, 0.5 mM IPTG (4 h) and 16 °C, 0.5 mM IPTG (12 h) respectively. Cells with an empty vector were used as negative control. The pellets from the sample were resuspended in the appropriate buffer and disrupted by sonication.

Carbazole degradation test

The functionality of CARDO (CarAa, CarAc and CarAd) was determined by the degradation of polyaromatic compound at 500 mg/l using purified protein. The standard reaction mix (500 µl) contained 100 mM potassium phosphate buffer (pH 7.0), 0.25 mg polyaromatic compound, 3 mM NADH, 10 mM FMN and each enzyme at 60 µg/ml. The reaction was performed with reciprocal shaking at 30 °C and stopped after 6 h by addition of 0.05 ml 1 M HCl. The samples were collected before and after the reaction and analysed.

The amount of aromatic compound present was determined using GC fitted with 30 m TR-5 (fused 5 % phenyl methylpolysiloxane) capillary column. N2 was used as carrier gas at 1.5 ml/min. Injector and detector were at 270 and 280 °C, respectively. The column was initially at 200 °C and increased to 280 °C at 4 °C/min.

Results and discussion

CARDO is a multicomponent protein consisting of terminal catalytic oxygenase (CarAa), ferredoxin (CarAc), and ferredoxin reductase (CarAd) unit. It is a unique oxygenase with the capability of oxygenation of wide range of polyaromatic compounds in addition to carbazole (Nojiri 2012). There are no reports, however, regarding the degradation of diverse compounds using a purified protein. Nam et al. (2002) and Larentis et al. (2011) reported the overexpression of CARDO in E. coli from Pseudomonas cells. Nam et al. (2002) expressed the components in pET vector with a C-terminal His-tag and concluded that all three purified protein could reconstitute the CARDO activity in vitro. Furthermore, they also showed that in addition to the catalytic unit (CarAa), ferrodoxin encoded by CarAc is indispensable for catalytic activity. However, ferrodoxin reductase encoded by CarAd could be replaced by some unrelated reductase. Larentis et al. (2011) expressed CARDO using pDEST vector in E. coli but the major objective of this study was to study the influence of induction condition and validation of statistical model on the expression of CARDO. Nam et al. (2002) reported the amount of purified CarAa protein as 1.7 mg from 2 l LB medium whereas in our case we were obtained 3 mg purified CarAa protein from 500 ml LB medium. Thus GST purification helps in providing better yield as compared to His-tag purification. Moreover, both the groups reported the functionality of the enzyme using only the degradation of carbazole.

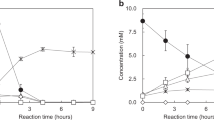

The ability of microorganisms harboring the CARDO gene to utilize wide range of compounds makes it a suitable candidate for biorefining industry. The major objective of the present study was to assess the substrate range of CARDO using purified enzyme and thus evaluate the potential of this enzyme for biorefining of fuel. CarAa, CarAc and CarAd genes were amplified from Pseudomonas GBS.5 using primers mentioned in Supplementary Table 1. They were expressed independently in E. coli (BL-21) using pGEX-4T3 vector with a N-terminal GST tag. The induction conditions were optimized and the proteins were expressed in soluble form with 0.5 mM IPTG at 37 °C (4 h), for CarAa and CarAc and at 16 °C (12 h) for CarAd (Fig. 1). Proteins were purified using glutathione beads and single bands were obtained (Fig. 2) for all the three proteins. There are two important prerequisite for a potential biorefining catalyst. Firstly, it should have the ability to utilize aromatic compounds and secondly it should not affect aliphatic compounds. Thus, the purified protein was used to check the substrate range of dioxygenase enzyme. Substrates were chosen that represent the major aromatic compounds present in diesel: carbazole, DBT, anthracene, phenanthrene, fluorene, fluoranthene and pyrene. The purified protein showed a wide range of PAHs degradation, similar to the parental strain GBS.5. GC spectra (Fig. 3) depicts the decrease in the concentration of carbazole, DBT, anthracene and fluroanthene along with the formation of metabolites whereas no metabolite was detected during the degradation of fluorene, pyrene or phenanthrene. Nojiri (2012) has reported that CARDO catalyzes the degradation of carbazole and DBT resulting in the formation of 2-aminobiphenyl and DBT sulfone, respectively. Thus the additional peaks obtained by GC at RT 3.8 min and RT 4.3 min must correspond to these compounds. Metabolites formed during catalysis of other polyaromatic compounds have not been reported so far. However, a decrease in concentration and the additional peak confirm that CARDO has the capability of utilizing all these polyaromatic compounds. Oxygenases play a key role in degradation of polyaromatic compounds as it catalyzes the first step resulting in the oxygenation of polycyclic compounds and make the compounds susceptible to further degradation via wide range of biological and chemical catalyst.

Expression of carAa, carAc and carAd protein. Lane M: protein size marker ladder with bands of 97, 66, 43, 29 and 20 kDa (from top to bottom); lane Un1, In1, Sol1: uninduced, insoluble and soluble sample of carAa protein; lane Un2, In2, Sol2: uninduced, insoluble and soluble sample of carAc protein: lane Un3, In3, Sol3: uninduced, insoluble and soluble sample of carAd protein

Purification of different subunits of carbazole dioxygenase a CarAa, b CarAc and c CarAd. Lane M: protein marker with bands 43, 66 and 99 kDa band lane L1: flow-through, lane W1, W2: wash fractions of the carAa, carAc and carAd protein respectively, lane E1, E2: elutes of the carAa, carAc and carAd protein respectively

The second prerequisite for a biorefining catalyst is that it should not affect the calorific value of fuel oil. Aliphatic hydrocarbons are the major contributors to fuel value since they account for approximately 66–69 % of the total carbon content of the diesel. Since CARDO has monooxygenation ability, it is crucial to check its effect on aliphatic hydrocarbons present in fuel oil (Ramirez-Corridores and Borole 2007). Figure 4 shows the GC spectra of various aliphatic compounds: pentadecane, hexadecane, heptadecane, octadecane, nonadecane and docosane. Neither decrease in alkane concentrations nor any extra peak corresponding to metabolite was observed. This confirmed that CARDO does not degrade alkanes.

The recombinant biocatalyst showed a wide range of PAHs degradation while did not degrade alkanes which are the prerequisites for a biocatalyst for petroleum refining. Thus, a biocatalyst harboring the carAaAcAd gene cluster of Pseudomonas sp. strain GBS.5 would be a suitable candidate for biorefining.

Conclusion

Biorefining holds a possible solution to the challenges associated with the present chemical refining industries. The ability of the protein encoded by CARDO gene of GBS.5 to utilize wide range of aromatic compounds and not aliphatic compounds contributes to the identification of suitable candidate for dearomatization. This study also reports for the first time a one-step process for the purification of CARDO.

References

Gaffney JS, Marley NA (2009) The impacts of combustion emission on air quality and climate-from coal to biofuels and beyond. Atmos Environ 43:23–36

Kilbane JJ II (2006) Microbial biocatalysts developments to upgrade fossil fuels. Curr Opin Biotechnol 17:305–314

Larentis AL, Sampaio HCC, Martins OB, Rodrigues MI, Alves TLM (2011) Influence of induction conditions on the expression of carbazole dioxygenase components (CarAa, CarAc and CarAd) from Pseudomonas stutzeri in recombinant Escherichia coli using experimental design. J Ind Microbiol Biotechnol 38:1045–1054

Leon V, Kumar M (2005) Biological upgrading of heavy crude oil. Biotechnol Bioproc Eng 10:471–481

Nam JW, Nojiri H, Noguchi H, Uchimura H, Yoshida T, Habe H, Yamane H, Omori T (2002) Purification and characterization of carbazole-1,9a-dioxygenase, a three-component dioxygenase system of Pseudomonas resinovorans strain CA10. Appl Environ Microbiol 68:5882–5890

Nojiri H (2012) Structural and molecular genetic analyses of the bacterial carbazole degradation. Biosci Biotechnol Biochem 76:1–18

Nojiri H, Ashikawa Y, Noguchi H, Nam JW, Urata M, Fujimoto Z, Uchimura H, Terada T, Nakamura S, Shimizu K, Yoshida T, Habe H, Omori T (2005) Structure of the terminal oxygenase component of angular dioxygenase, carbazole 1,9a-dioxygenase. J Mol Biol 351:355–370

Ramirez-Corridores MM, Borole AP (2007) Biocatalysis in oil refining. Stud Surf Sci Catal 164:13

Shong RG (1999) Bioprocessing of crude oil. In: Proceedings of the 217th ACS National Meeting, ACS, Washington DC, pp 1–9

Singh GB, Gupta S, Gupta N (2013a) Carbazole degradation and biosurfactant production by newly isolated Pseudomonas sp. strain GBS.5. Int Biodeterior Biodegrad 84:35–43

Singh GB, Kumar K, Gupta S, Gupta N (2013b) PCR cloning and characterization of carbazole dioxygenase gene from Pseudomonas sp. GBS.5. Int J Biotech Bioeng Res 4:207–214

Song C, Ma X (2003) New design approaches to ultra-clean diesel fuels by deep desulfurization and deep dearomatization. Appl Catal B 41:207–238

Acknowledgments

This work is supported by the research funding provided by Department of Biotechnology, Government of India (Project no BT/PR7574/BCE/8/1001/2013).

Supporting information

Supplementary Table 1—Sequence of the primers used for amplification of different subunits of CARDO (CarAa, CarAc and CarAd.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Khan, S., Adhikari, D.K., Gupta, S. et al. High-level expression, purification and characterization of carbazole dioxygenase, a three components dioxygenase, of Pseudomonas GBS.5. Biotechnol Lett 37, 1945–1952 (2015). https://doi.org/10.1007/s10529-015-1876-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-015-1876-3