Abstract

In this paper the formulation of a simplified model for predicting pore water pressure build-up under seismic loading is updated and applied to different soils. The model is directly based on the results of cyclic laboratory tests and it is based on the damage parameter concept, avoiding any arbitrary equivalence criterion necessary to compare the seismic demand to the cyclic strength of liquefiable soils. The model is suitable to be implemented into non-linear coupled seismic response analyses since it operates in the time domain. The analytical formulation is fully described and the calibration and the physical meaning of the model parameters are analysed in detail. Simple applications show the practical usefulness of the model with respect to other literature approaches.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

An accurate prediction of excess pore pressure build-up induced by seismic action is a challenging issue for assessing the seismic safety of structures in saturated soils. The increase of pore pressure determines a decrease of effective confining stress, with reduction in soil stiffness and strength. This phenomenon greatly affects the non-linear dynamic soil response and can lead to liquefaction.

Moreover, the increase of pore pressure induces degradation of mechanical soil properties, significantly changing the amplitude and frequency content of the surface ground motion; thus, several researchers have shown the importance of predicting excess pore pressure in reliably evaluating the seismic soil response (e.g. Montoya-Noguera and Lopez-Caballero 2014; Kramer et al. 2015).

In seismic response analysis, the variation of pore water pressure can be evaluated with two different kinds of methods:

-

1.

‘decoupled’ approaches, where the amount of excess pore pressure is computed adopting semi-empirical relationships starting from the solution of a seismic response analysis in total stress;

-

2.

‘coupled’ approaches, that allow computing the time history of excess pore water pressure carrying out non-linear dynamic analyses in effective stress by using either a simplified or an advanced soil constitutive model (Hashash et al. 2010).

The decoupled approach, commonly adopted in simplified liquefaction analysis, is suggested by several guidelines and design standards (Koester et al. 1999; AGI 2005; USBR 2015) and sometimes implemented in numerical codes (e.g. Quake/W, GEO-SLOPE International Ltd 2014). The irregular time history of shear stress, computed as output of a ground response analysis should be preliminarily converted into an equivalent series of uniform stress cycles. This procedure permits to compare the seismic demand induced by the earthquake with the soil resistance obtained from laboratory tests in which harmonic loading is usually adopted. According to the initial studies by Seed et al. (1975), the irregular time history of shear stress related to an accelerogram can be transformed into an equivalent number of cycles, Neq, having an amplitude equal to 65% of the maximum shear stress, τeq = 0.65 · τmax, that would produce an increase of pore pressure equal to that cumulated at the end of the irregular time history.

A large number of procedures has been developed for evaluating the equivalent number of cycles corresponding to an earthquake of given magnitude (e.g. Seed et al. 1975; Annaki and Lee 1977; Liu et al. 2001; Green and Terri 2005). These procedures, however, are rather complex and their results strictly depend on the adopted equivalence criterion and on the techniques for choosing and counting the stress cycles that significantly affect the pore pressure build-up (Biondi et al. 2012).

The equivalent number of cycles is then the input parameter of semi-empirical pore pressure generation models, such as those summarized by Hashash et al. (2010). The earliest models were referred to a stress-based approach (Seed et al. 1975; Booker et al. 1976); subsequently, Dobry et al. (1985) proposed a strain-based model, where the pore pressure build-up is triggered only when a threshold shear strain is exceeded.

Since the major drawback of both approaches is the requirement of an equivalent number of cycles to represent earthquake shaking, Green et al. (2000) introduced an energy-based model for the generation of pore pressure. The model does not require the computation of an equivalent number of cycles, but its parameters are not simple to be calibrated on the basis of laboratory test results.

Another class of models that does not require to compute the seismic demand in terms of equivalent number of cycles of uniform shear stress includes formulations within the framework of the “endochronic theory” (Valanis 1971; Bažant and Krizek 1976). Finn and Bhatia (1982) applied the endochronic theory to express the pore pressure build-up in a cyclic laboratory test as a monotonically increasing function of a single variable called “damage parameter”, which can be computed for both cyclic test data and irregular time histories. This variable is directly related to parameters defining the stress or strain history (i.e. stress or strain amplitude and number of cycles or, alternatively, the length of stress or strain path). Since the effect of stress/strain history is to induce pore pressure build-up and weaken the resistance of soil, the variable is called “damage parameter”. In this case, the application of the endochronic theory led to a ‘black-box’ approach that eliminates the need for measuring the complex mechanical parameters of soil behaviour in undrained cyclic conditions.

More recently, Ivšić (2006) and Park et al. (2015) proposed a new formulation for the ‘damage parameter’ that account for a threshold value of the cyclic stress ratio, below which no excess pore pressure is triggered, as experimentally observed in stress-controlled cyclic tests.

In this paper, an updated formulation of the simplified model proposed by Park et al. (2015) is presented. The development of the model is described and retraced in the following Sect. 2. The approach is based on simple empirical relationships and the model parameters can be straightforward calibrated on the results of laboratory tests, as described in Sect. 3. In the same context, the physical meaning of the model parameters is widely analysed, assessing their dependency on constitutive factors and state variables. Section 4 describes an application of the proposed model for predicting excess pore pressure build-up in a representative volume element. Finally, a comparison among pore water pressure predictions obtained applying different models based on the formulation of “damage parameter” is proposed and discussed in details.

2 The pore pressure model

The pore water pressure model hereafter proposed is based on the definition of the so-called “damage parameter”, κ, that synthesizes the effect of the cyclic variation of stress/strain on the undrained soil response.

This parameter is an increasing variable during the loading history that can be directly correlated with the pore pressure accumulation as follows:

where ru= Δu/σ’0 is the ratio between the excess pore pressure, Δu, and the initial effective stress, σ’0 (vertical stress in cyclic simple shear or mean effective stress in different conditions). Following a stress-based approach, the damage parameter can be expressed as a transformation function T of a variable representing the stress accumulation related to an irregular loading history. For instance, the damage parameter can be expressed as:

where η is the normalized length of the shear stress path, defined as follows:

By definition, the variable η is monotonically increasing during cyclic shear loads since an increment in the length of the shear stress path is determined by both increasing or decreasing shear stress (Ivšić 2006).

With reference to a stress-controlled cyclic test, the normalized stress path length corresponding to one cycle with a given maximum shear stress level, τmax, is four times the cyclic stress ratio, CSR, i.e. the ratio between the modulus of shear stress, |τmax|, and the initial effective stress. In this case, the length of the normalized stress path at the end of the N-th cycle of a stress-controlled test is equal to:

For instance, the above described variable is used to interpret the experimental data shown in Fig. 1. Pore pressure ratio, measured by Silver and Park (1976) carrying out stress-controlled undrained cyclic tests on Silica sand, are reported as a function of number of cycles (Fig. 1a) and as a function of the normalized stress path length (Fig. 1b). The pore pressure ratio, ru, is an increasing function of η and, at equal stress path length, ru increases with CSR.

Experimental data from stress-controlled cyclic triaxial tests on Crystal Silica sand (mod. after Silver and Park 1976): pore pressure ratio vs. number of cycles (a), normalized length of the shear stress path (b)

Based on this evidence, the transformation T can be expressed as an increasing function of CSR, like the different relationships proposed by several authors, summarized in Table 1.

Finn and Bhatia (1982) proposed an exponential function of the stress ratio, CSR, where λ is an experimentally determined constant.

Ivšić (2006) suggested a transformation T that takes into account the experimental evidence that the damage (thus, pore pressure build-up) only occurs if the stress ratio exceeds a threshold value, below which no coupling takes place. This threshold stress ratio, CSRt, is conceptually analogous to the volumetric threshold strain, γv, observed in strain-controlled cyclic tests (Vucetic 1994).

Based on the same experimental evidences, more recently, Park et al. (2015) formulated a slightly different relationship for the transformation T, namely:

where the parameters CSRt and α can be evaluated from the cyclic resistance curve obtained from laboratory tests, being CSRt the asymptotic value of cyclic stress ratio as the number of cycles tends to infinite, and α is a coefficient related to the slope of the cyclic resistance curve in a log–log scale.

With reference to cyclic stress-controlled tests, the physical meaning of the damage parameter can be easily deduced from Eq. (5), as the product of two factors: the first, η/CSR, is proportional to the number of cycles (see Eq. 3), while the second, (CSR − CSRt)α, takes into account the amplitude of the applied stress ratio exceeding the threshold value.

With reference to a monotonic stress history (Fig. 2), the damage parameter evaluated by Eq. (5) is equal to:

i.e. in the case of monotonic loading, the damage parameter is only related to the amount of shear stress ratio exceeding the threshold value. As an example, two different monotonic loading histories are plotted in Fig. 2 together with the damage functions computed by Eq. (6): since the two stress histories are characterized by the same final shear stress ratio, both induce the same final value of κ.

If a uniform cyclic stress history is applied, the damage parameter accounts for the stress accumulation through a factor proportional to the number of cycles; in this case, the damage increases up to a maximum value corresponding to the number of cycles at liquefaction, NL. With reference to the results of cyclic laboratory tests, the number of cycles at liquefaction, NL, is univocally related to the cyclic resistance ratio, CRR, i.e. the stress ratio corresponding to the load applied during the test. Several researchers proposed analytical expressions for the cyclic resistance curve CRR:NL, generally based on a power function (Park and Ahn 2013; Boulanger and Idriss 2014; Mandokhail et al. 2016). In this work, the relationship proposed by Park and Ahn (2013) is adopted, by rewriting it as follows:

where (Nr, CSRr) is a reference point on the cyclic resistance curve and the exponent α describes the dependency of the cyclic resistance from the number of cycles (Fig. 3a).

Combining Eqs. (5) and (7) for CSR equal to CRR, the damage parameter at liquefaction, κL, can be expressed as follows:

The relationship (8) shows that damage at liquefaction assumes a constant value depending on the parameters describing the cyclic resistance curve, α, CSRr and CSRt. Therefore, any point on the cyclic resistance curve is associated to the same damage level, κL (Fig. 3a); furthermore, in the N − CSR plane it is possible to draw different “iso-damage” curves (Fig. 3b), which express at any value of CSR the number of cycles necessary to obtain a damage corresponding to a given percentage of κL.

The normalized damage, defined as the ratio between the damage, κ, corresponding to a generic point along the stress path and that evaluated at liquefaction, κL, can be defined as follows:

Combining Eqs. (7) and (9), the normalized damage is equal to the ratio between the generic number of cycles and the number of cycles at liquefaction, NL, as shown in the following:

Equation (10) results particularly convenient in the practical use of the model, since all the existing semi-empirical expressions between the pore pressure ratio, ru, and the number of cycles, N, built on the stress-based framework (e.g. Seed et al. 1975; Booker et al. 1976), can be adopted in the present model by expressing them in terms of damage parameter.

The analytical functions, h(κ), including those reported in Table 1, are mainly based on the best-fitting of laboratory data. Finn and Bhatia (1982) proposed a rational function of κ, where F, G, H, I are best-fit coefficients. A similar expression was adopted by Ivšić (2006) in combination with a power function. Booker et al. (1976) developed another simple relationship, where ru is an inverse harmonic function of the ratio N/NL raised to a power 1/2β. Based on Eq. (10), Park et al. (2015) re-formulated Booker et al. (1976) relationship as follows:

Equation (11) needs the calibration of a unique coefficient β, which can be determined from stress-controlled cyclic tests. Booker et al. (1976) recommended β = 0.7 for clean sands, while Polito et al. (2008) correlate the value of β to the fine content, relative density and shear stress ratio.

More recently, Khashila et al. (2017) adopted a power function to express the relationship between the excess pore pressure from uniform strain-controlled tests and the normalized number of cycles:

where r is a coefficient determined from laboratory tests.

Porcino et al. (2015) studied the undrained cyclic behaviour of a moderately cemented grouted sand and proposed a more general expression that combines a power and an exponential function, as follows:

where a′, b′ and c′ are model parameters which are dependent on the degree of cementation induced by grout and the initial density of the clean sand.

All the above relationships were defined for clearly identified soil types, loading conditions and laboratory tests, but they are hardly extended to general conditions.

In this study, a polynomial relationship between ru and normalized damage is proposed, as follows:

where a, b, c and d are curve-fitting parameters (Fig. 4). This expression allows for describing the experimental dependency of ru on N/NL for different kinds of soils, as it will be discussed in the following Sect. 3.2.

Experimental data from stress-controlled cyclic triaxial tests on Crystal Silica sand (mod. after Silver and Park 1976): pore pressure ratio versus normalized damage parameter

3 Calibration of model parameters

The application of the model requires 7 independent parameters: 3 for the cyclic resistance curve [Eq. (7), i.e. the shape coefficient, the horizontal asymptote value and a coordinate of the reference point], and 4 for the pore pressure relationship [Eq. (14)], which can be straightforward back-figured from the experimental data of stress-controlled cyclic tests.

3.1 Cyclic strength parameters

Park and Ahn (2013) provided an extensive validation of the relationship proposed to model the cyclic resistance curve (Eq. 7). Hereafter, the same relationship has been adopted to reproduce the cyclic resistance of different soils, trying to identify the main factors influencing the model parameters.

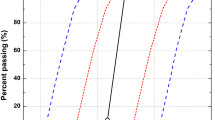

Cyclic resistance curves measured on different kind of soils are shown in Fig. 5: full symbols refer to clayey soils (Boulanger and Idriss 2006) whereas open symbols denote sandy and silty materials (Liyanathirana and Poulos 2002) and small crosses pertain to a sandy gravel (Ishihara et al. 1996). The experimental data resulting from cyclic triaxial tests (CTX) have been preliminarily converted to cyclic simple shear conditions of the direct simple shear tests (DSS), using the procedure proposed by Castro (1975). All the data were best-fitted by Eq. (7), with the numerical values of the parameters listed in Table 2. CSRt and α values relevant to clayey soils seem to respectively increase and decrease with plasticity index. The exponent α has definitely higher values in the case of clayey soils, if compared to silts and sands, highlighting the low sensitivity of the cyclic resistance of fine-grained plastic soils to the number of cycles. On the other hand, the value of α decreases with grain size in the case of non-cohesive soils.

The asymptotic value of the cyclic resistance curve, CSRt, is not always clearly detectable from the experimental data, as for the clayey soils shown in Fig. 5. In such cases, Ivšić (2006) suggests to estimate the threshold shear stress ratio, CSRt (Fig. 6a), from the “backbone” shear stress–strain curve of the soil, considering the shear stress, τt, corresponding to the volumetric threshold strain, γv (see for example Fig. 6b). This latter is commonly assumed as the shear strain corresponding to the onset of pore pressure build-up observed during resonant column or torsional shear tests (Fig. 6c). It can alternatively be estimated as a function of the index properties, if experimental data are not available (Matasovic and Vucetic 1993; Derakhshandi et al. 2008; El Mohtar et al. 2014).

It is well known that the cyclic resistance of soil is strongly influenced by constitutive factors, such as fine content and plasticity, and state variables typically, density and confining pressure. A collection of experimental data is here after presented for studying the influence of the above-mentioned factors and variables on the parameters describing the cyclic resistance curve.

In the following, the shear stress ratio corresponding to a number of cycles Nr = 15, was chosen as CSRr, in order to easily compare different experimental results. Moreover, in all the cases in which the cyclic resistance curve shows a clear asymptotic trend, CSRt was evaluated by applying a straightforward regression analysis of the experimental data points. When CSRt could not be clearly inferred in this way, it was estimated on the basis of cyclic resistance curves plotted in the reference papers.

Figures 7a–d reports the data of four clean sands with varying relative density: Monterey (De Alba et al. 1976) and Ottawa (Carraro et al. 2003) are rounded quartz sands, while Coimbra (Viana da Fonseca et al. 2015) is an angular quartz sand, and Cabo Rojo (Sandoval and Pando 2012) is a calcareous sand.

Cyclic resistance curves of clean sands for different values of relative density: a Monterey sand from shaking table test (De Alba et al. 1976); b Ottawa sand from CTX (Carraro et al. 2003); c Cabo Rojo sand from CTX (Sandoval and Pando 2012); d Coimbra sand from DSS test (Viana da Fonseca et al. 2015); model parameters: e CSRr, CSRt and f α, plotted versus relative density

The liquefaction susceptibility seems to be somehow influenced by sand mineralogy: the calcareous sand from Cabo Rojo is less susceptible to liquefaction if compared with the quartz sands, but at the same time it seems more sensible to a variation in relative density. On the other hand, the sub-rounded quartz sand from Coimbra is the most susceptible to liquefaction, but it is the least sensitive to a density variation. It can be argued that, in the case of clean sand, as susceptibility to liquefaction increases, the sensitivity of cyclic resistance to relative density decreases.

Summarising, an increase in relative density induces an overall increase of the cyclic strength of clean sands; this implies a related increase of the reference and threshold shear stress ratios, CSRr and CSRt, as shown in Fig. 7e.

The steepness of the cyclic resistance curve seems to be also influenced by relative density, as shown in Fig. 7f, where the parameter α, plotted as a function of the relative density, is always decreasing with Dr. In this case it is not recognizable any dependency on the mineralogy and shape of the sand particles.

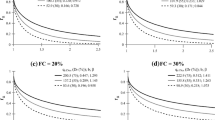

In order to assess the influence of non-plastic fine content, FC, on the parameters describing the cyclic resistance curve, Fig. 8a–d compare experimental data relevant to sands with variable FC, at the same global void ratio. The behaviour of a tailings sand (Troncoso and Verdugo 1985), is compared with that of a Greek sand (Xenaki and Athanasopoulos 2003) taken from Shinias-Marathon site, an Indian silty sand collected from the power plant site at Dhuvaran in Gujarat, India (Swamy et al. 2010) and an artificial sand-silt mixtures made of clean quartz sand with well-rounded grains and non-plastic silt, taken from Assyros in Greece (Papadopoulou and Tika 2008).

Cyclic resistance curves of sands with different non-plastic fine content: a Tailings sand (Troncoso and Verdugo 1985); b Shinias-Marathon sand (Xenaki and Athanasopoulos 2003); c Indian sand (Swamy et al. 2010); d Assyros sand (Papadopoulou and Tika 2008); model parameters: e CSRr, CSRt and f α, plotted versus the percentage of fine content FC

The role of non-plastic fines on liquefaction susceptibility is still a controversial matter. Recent studies agree on the existence of a threshold value of non-plastic fine content below which the liquefaction susceptibility increases with FC and above which the cyclic resistance increases with FC. This experimental evidence can be explained in the framework suggested by Thevanayagam et al. (2002) that identifies a threshold fine content determining the transition from a sand-like to a silt-like behaviour; this threshold is related to the fabric of the mixture. As FC increases, fines tend to occupy the space among grains, which remain in contact each other. Up to the FC at which the pores are completely filled with fine particles, these latter do not contribute to the transmission of inter-particle forces. A further increase of FC leads the fines to push apart the grains and to participate to the transfer of contact stresses (Papadopoulu and Tika 2008). The cyclic resistance curves collected in Fig. 8 confirm the above described behaviour that, in turn, is reflected by the overall trends of the model parameters. As a matter of fact, within the range of FC considered, CSRr and CSRt decrease with the percentage of non-plastic fine content, indicating a reduction of cyclic resistance; α conversely increases with FC, highlighting an increasing sensitivity to the number of cycles.

The effects of plastic or cementing fine additives has a different impact on liquefaction susceptibility respect to the non-plastic fine. Figure 9 reports the cyclic resistance of various sands treated by adding different percentage of bentonite (El Mohtar et al. 2014) and Portland cement (Clough et al. 1989; Nakamichi and Sato 2013), or by using indigenous bacteria for inducing significant quantities of calcite precipitation in sands (Burbank et al. 2013). The above treatments always induce an improvement of the cyclic strength, also for low content of additive. In terms of model parameters, treated soils exhibit greater values of reference and threshold shear stress ratios, with lower values of α than the untreated soils (Fig. 9e, f).

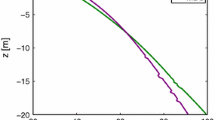

Finally, the influence on the cyclic resistance curve of the effective confining pressure applied during the tests has been evaluated, by comparing the results reported in Fig. 10. A decrease of the cyclic strength with the applied confining stress is visible for all the four sands considered: Crystal silica sand (Liyanathirana and Poulos 2002), Ottawa sand (Amini and Qi 2000), Cabo Rojo sand (Sandoval and Pando 2012) and Assyros sand (Papadopoulou and Tika 2008). Consequently, the shear stress ratios, CSRr and CSRt, decrease with the effective stress, while the parameter α remains almost constant.

Cyclic resistance curves of clean sands for different effective confining pressures: a Crystal silica (Liyanathirana and Poulos 2002); b Ottawa sand (Amini and Qi 2000); c Cabo Rojo sand (Sandoval and Pando 2012); d Assyros sand (Papadopoulou and Tika 2008); model parameters: e CSRr, CSRt and f α plotted versus the effective confining pressure

Table 3 schematically summarises the effects of constitutive and state variables on the model parameters.

3.2 Pore water pressure accumulation parameters

As previously shown for the cyclic resistance, the trend of pore pressure accumulation during cyclic laboratory tests is also strongly influenced by initial fabric and grain size distribution of the tested material (Seed et al. 1976; El Hosri et al. 1984; Sze and Yang 2014). As, for example, shown by the envelope curves reported in Fig. 11a–b, two distinct mechanisms can be distinguished:

Pore pressure relationship proposed in this study versus Booker et al. (1976) model, as fitted to experimental data for a silt, b silty sand, c sand and d gravelly sand

-

1.

“runaway behaviour”, featured by large strain increments associated with a sudden build-up of excess pore water pressure, resulting in an abrupt loss of shear strength and stiffness, which is typical of liquefiable sands;

-

2.

“cyclic failure”, featured by a progressive gentle excess pore pressure build-up, usually observed in the case of fine grained materials.

The variability of the observed behaviour is hardly reproduced by the relationships available in literature and reported in Table 2. For this reason, as already stated, in this study the pore pressure build-up is modelled as a more ‘flexible’ function of the normalized damage parameter, by adopting the polynomial relationship reported in Eq. (14).

The parameters a, b, c and d of Eq. (14) can be straightforward calculated by curve-fitting of experimental pore water pressure records. It is worth noting that the parameters a and c are not independent, but they are linked each other through a limiting value of pore pressure ratio, ru,lim, assumed as the attainment of liquefaction condition. As a matter of fact, from Eq. (14) it follows that:

Should the liquefaction criterion ideally correspond to null effective stress ratio, ru is forced to yield unity for N/NL = 1; it follows that a + c = 1, which implies:

To better highlight the flexibility of the proposed relationship, Fig. 11 shows the test results obtained on 4 different types of soils: silt (Pekcan et al. 2004), silty sand (Porcino and Diano 2016), clean sand (Polito 1999) and gravelly sand (Flora and Lirer 2013), fitted with the relationships suggested by Booker et al. (1976) and in this study. Table 4 reports the numerical values of the pore pressure parameters relevant to both models. It can be noted that the proposed model reproduces the experimental data more accurately than the relationship by Booker et al. (1976), particularly with reference to the behaviour of fine grained soils.

In order to explore the dependency of the model parameters on the main factors governing the pore pressure increase, several literature data have been selected showing the effects of relative density, Dr, clay fraction, CF, cyclic stress ratio, CSR, and effective confining pressure, σ’0. The data reported in Fig. 12 were fitted with Eq. (14), and the model parameters were plotted as a function of the above-mentioned factors.

The relative density and the clay fraction have a similar effect on the pore pressure build-up; as a matter of fact, as density increases the behaviour evolves from a ‘runaway’ to a ‘cyclic failure’ mode (Fig. 12a, b). A similar effect is observed following an increase in clay fraction (Fig. 12c, d). As a consequence, the shape of the pore pressure curve changes, evolving from double to single concavity. In turn, the parameters a and b respectively increase and decrease as Dr or the percentage of clay fraction increases; the parameter d does not seem to exhibit any peculiar trend. On the other hand, the cyclic stress ratio, CSR, and the effective confining pressure, σ’0, applied during cyclic tests seem to have a minor influence on the model parameters, at least for the soils considered in this case (Fig. 12e–h).

4 Application

The model formulation implies that, for a harmonic stress history with constant amplitude, CSR, the damage parameter, κ, is proportional to the number of cycles and it can be written as:

where Δκ = (CSR − CSRt)α is the constant increment of the damage parameter related to each quarter of cycle of the stress history (Fig. 13a). For a series of harmonic loads with variable amplitude, such as that reported in Fig. 13b, the damage parameter can be expressed as:

where CSRi is the maximum amplitude of the i-th half-cycle of the time history (Fig. 13b).

This latter expression of the damage parameter can be easily extended to any irregular shear loading history, expressed as:

In this case, the damage cumulated at the i-th half-cycle can be written as:

where \( \tau_{max,j}^{ * }\) is the local maximum at the j-th cycle, κ0 is the damage parameter cumulated at the end of the i-1 half cycle and Δκi is the increment of damage at the current i-th computation step. The application of Eq. (20) requires that the entire time history τ*(t) should be known, since the local maximum value, \( \tau_{max,j}^{ * }\), should be used to compute the damage at the i-th cycle. For this reason, Eq. (20) is suitable if a decoupled approach is adopted for the evaluation of the pore pressure accumulation. This typically applies when the time history of the shear stress is preliminarily computed carrying out a seismic response analysis in total stress conditions.

In order to extend the implementation of the model to a coupled approach, it is necessary to express Eq. (20) in the time domain. This can be simply done by imposing a zero limit to the time interval corresponding to a half cycle. The expression (20) of the damage function becomes:

where κ0 is the damage cumulated at the last reversal point of the function (τ* − CSRt) reached at the time instant t (Fig. 13c). The parameter κ0 can be defined as follows:

i.e. κ0 is a stepwise function assuming the value of the damage parameter gained at the time step (t − dt) every time the stress ratio reaches a local maximum value, or when τ* = CSRt (see the dashed line in Fig. 13c).

The increment of the damage parameter, dκ, in the time interval dt is given by:

where τ *0 = \(\tau_{max}^{ * }\) if \(\dot{\tau }_{{}}^{ * } (t) < 0\) and \(\tau_{0}^{*}\) = CSRt otherwise (dash-dot blue curve in Fig. 13c).

Figure 14 shows an example of application of above equations in the case of a saw-tooth loading and an irregular time history of shear stress (Fig. 14a). The damage parameter was computed with reference to a cyclic resistance curve modelled on the basis of α, CSRr and CSRt. As a result of the application of Eqs. (21), (22) and (23), the damage parameter increases when the cyclic stress ratio exceeds the threshold value, CSRt, otherwise it remains constant (thick lines in Fig. 14b).

Once the pore pressure ratio is expressed as a function of the damage parameter (Fig. 14c), the time history of excess pore water pressure (Fig. 14d) can be predicted by Eq. (14).

Both time histories induce liquefaction at the same value, κL, of the damage parameter. The excess pore pressure increases gradually under the saw-tooth loading (blue lines in Fig. 14b, d), whereas in the case of irregular time history the accumulation of ru is concentrated in the first 10 s, where the stress ratio significantly exceeds CSRt, (black lines in Fig. 14b, d).

In both cases, after the condition of liquefaction (ru= 1) is reached for κ = κL, subsequent peaks of shear stress ratio still induce potential damage increments (see Fig. 14b) but are ineffective in producing any further increase of excess pore pressure (see Fig. 14d).

The effectiveness of the proposed method was finally evaluated by interpreting a set of experimental data collected on a silty sand by Porcino and Diano (2016).

The experimental dataset results from cyclic simple shear tests carried out on undisturbed samples of silty sand recovered from the foundation of a dyke, at 6.5 m depth from the crest of the embankment (Tonni et al. 2015; Porcino and Diano 2016).

More in details, the results of five cyclic simple shear tests carried out on a silty sand with 40% of fine content were considered. All the tests were carried out applying an isotropic effective confining stress σ’0 = 130 kPa and the stress ratio CSR varied between 0.17 and 0.26.

The cyclic resistance curve was defined by Eq. (7), following the procedure described in Sect. 3.1 (Fig. 15a). The threshold value of the shear stress ratio, CSRt, was estimated from the normalized shear modulus curve (Fig. 15b) through the volumetric threshold strain, γv, measured by resonant column tests (Tonni et al. 2015).

The performance of the simplified model was also compared with those of other endochronic-type methods, already described in Sect. 2 (see Table 1).

Table 5 reports the values of the parameters calibrated for each of the four models considered. The parameters calibrated for Eq. (7) have the same values as those required for Park et al. (2015) model. The threshold, CSRt, of the shear stress ratio, needed to define the relationship by Ivšić (2006), was assumed to be the same as that computed in the above-mentioned models, while the exponent δ was calibrated in order to have the best fitting on the experimental data. Finally, the parameter λ required by Finn and Bhatia (1982) relationship was defined as the mean value of the exponents computed for any couple of tests, as suggested by the same Authors.

The parameters of the ru equations reported in Table 1 were all calibrated on the residual excess pore pressure ratio data reported by Porcino and Diano (2016).

Both Eq. (14) proposed in this study and the expression by Park et al. (2015) directly fit the experimental data, published in terms of pore pressure ratio, ru, versus the cyclic ratio, N/NL. Conversely, Finn and Bhatia (1982) and Ivšić (2006) relationships should be calibrated on the ru:κ data. In this case, it was necessary to preliminarily manipulate the results of laboratory tests, by converting the cyclic ratio, N/NL, into the corresponding damage parameter, before proceeding with the calibration.

Table 5 summarizes the numerical values of the parameters, while the comparison between the experimental data and the prediction of the models is reported in Fig. 16. The parameters of Eq. (14) were determined by a non-linear regression analysis, returning an adjusted coefficient of determination, adj.R2, equals to 0.9799. The expression by Booker et al. (1976) adopted by Park et al. (2015) is definitely less suitable to describe the considered data, since it is an inverse sinusoidal function (Fig. 16c). The hyperbolic function proposed by Finn and Bhatia (1982) is capable to catch the experimental trend (Fig. 16a), while those suggested by Ivšić (2006) are less flexible (Fig. 16b). The first relationship by Ivšić (2006) is characterized by a higher adj.R2 value, so only this latter was considered in the simulations. As previously discussed in Sect. 3.2, this example confirms that the proposed model can successfully simulate both ‘runaway’ and ‘cyclic failure’ pore pressure build-up modes, while the other relationships are capable to well reproduce just one mode of pore pressure accumulation.

The four endochronic-type models were then used to simulate one of the cyclic simple shear tests by Porcino and Diano (2016), carried out by applying a CSR equal to 0.17, (marked with a black triangle on the cyclic resistance curve of Fig. 15a). The load applied during the laboratory test was reproduced through a sinusoidal time history of the shear stress with an amplitude of 22 kPa and a frequency of 0.1 Hz (Fig. 17a). Figure 17b shows the related shear stress ratio history, τ* and the increasing trend of the damage parameter, as computed by Eq. (20).

The results of the different simulations were compared to the experimental results of the test as reported by Porcino and Diano (2016), in terms of pore pressure ratio versus the number of cycles, ru:Ν (Fig. 18). The model proposed in this study appears capable to perfectly catch both the time of initial liquefaction and the trend of the pore pressure ratio.

The relationship proposed by Booker et al. (1976) and adopted by Park et al. (2015) reproduces a trend quite different from the experimental results, but it matches quite well the onset of initial liquefaction (NL = 20), because it is based on the same cyclic resistance curve adopted in this study.

The relationship proposed by Finn and Bhatia (1982) is able to reproduce the observed experimental data, but predicts a pore pressure ratio indefinitely increasing above unity beyond the number of cycles at liquefaction. Conversely, Ivšić (2006) relationship predicts a pore pressure ratio asymptotically approaching unity (or 1.01) for an infinite number of cycles.

In other words, the above models do not necessarily predict ru = 1 for a defined κ = κL, like conversely assumed by the model adopted by Park et al. (2015) and that proposed by the Authors. Such limitations make the above analytical formulations inapplicable to a straightforward implementation for predicting the pore pressure build-up under irregular time histories.

5 Conclusions

The paper proposes a simplified model able to simulate the increase of excess pore pressure induced by irregular shear loading, by adopting an endochronic-based damage parameter which permits avoiding the use of empirical criteria to convert the seismic demand into equivalent number of loading cycles. The model is based on simple analytical relationships, and allows for a straightforward calibration of the parameters on the results of cyclic laboratory tests.

The model is highly versatile, since it is capable to reproduce the experimental behaviour of different soils both in terms of cyclic resistance curve and pore pressure build-up. As a matter of fact, the model parameters defining the cyclic resistance curve reflect its dependency on both constitutive and state variables, i.e. relative density, fine content and plasticity, and effective confining stress. Furthermore, the polynomial function proposed herein to model the pore pressure build-up appears more effective in reproducing both runaway and cyclic failure mechanisms with respect to other simplified models proposed in literature, as for instance the well-known relationship by Booker et al. (1976). As a future development, the adopted formulation could be modified to account also for the dependency of the pore pressure function on the applied cyclic stress ratio.

A further version of the model could be also proposed through re-definition of the damage parameter in terms of length of the shear strain path, following the strain-based approach originally adopted by Finn and Bhatia (1982). This alternative choice would allow for a model calibration based on the results of strain-controlled cyclic laboratory tests.

The model can predict excess pore pressure up to liquefaction by following approaches with increasing level of complexity, i.e. from simplified to advanced dynamic analyses. The best benefit of the model is that it can be implemented into coupled seismic response analyses using non-linear time-domain methods for the solution of the ground motion equations, at least for 1D propagation of shear waves. In addition, the model can be used in conjunction with one-dimensional consolidation equations allowing for investigating also on the effects of equalisation, redistribution and dissipation of excess pore pressure on surface and in-depth ground motion, as well as on the post-liquefaction deformation and stability.

Indeed, the model has been already implemented in the one-dimensional code SCOSSA (Tropeano et al. 2016) and successfully applied for reproducing the seismic ground motion and pore pressure build-up recorded in seismic centrifuge tests and well-instrumented test sites, as detailed by Chiaradonna (2016) and Tropeano et al. (2018).

References

AGI (2005) Aspetti geotecnici nella progettazione in zone sismiche. Guidelines of the Italian Geotechnical Society. Associazione Geotecnica Italiana (in Italian)

Amini F, Qi GZ (2000) Liquefaction testing of stratified silty sands. J Geotech Geoenviron Eng ASCE 126(3):208–217

Annaki M, Lee KL (1977) Equivalent uniform cycle concept for soil dynamics. J Geotech Eng Div ASCE 103(GT6):549–564

Bažant ZP, Krizek RJ (1976) Endochronic constitutive law for liquefaction of sands. J Soil Mech Found Div ASCE 102(EM2):225–238

Biondi G, Cascone E, Di Filippo G (2012) Affidabilità di alcune correlazioni empiriche per la stime del numero di cicli di carico equivalente. Ital Geotech J 2:11–41 (in Italian)

Booker JR, Rahman MS, Seed HB (1976) GADFLEA—A computer program for the analysis of pore pressure generation and dissipation during cyclic or earthquake loading. Earthquake Engineering Center, University of California, Berkeley

Boulanger RW, Idriss IM (2006) Liquefaction susceptibility criteria for silts and clay. J Geotech Geoenviron Eng, ASCE 132(11):1413–1426

Boulanger RW, Idriss IM (2014) CPT and SPT liquefaction triggering procedures. Report No UCD/GCM-14/01, University of California at Davis, California, USA

Burbank M, Weaver T, Lewis R, Williams T, Williams B, Crawford R (2013) Geotechnical tests of sands following bioinduced calcite precipitation catalyzed by indigenous bacteria. J Geotech Geoenviron Eng ASCE 139(6):928–936

Carraro J, Bandini P, Salgado R (2003) Liquefaction resistance of clean and nonplastic silty sands based on cone penetration resistance. J Geotech Geoenviron Eng ASCE 129(11):965–976

Castro G (1975) Liquefaction and cyclic mobility of saturated sands. J Geotech Eng Div ASCE 101(GT6):551–569

Chiaradonna A (2016) Development and assessment of a numerical model per non-linear coupled analysis on seismic response of liquefiable soils. Dissertation, University of Napoli ‘Federico II’

Clough GW, Iwabuchi J, Rad NS, Kuppusamy T (1989) Influence of cementation on liquefaction of sands. J Geotech Eng 115(8):1102–1117

De Alba P, Seed HB, Chan CK (1976) Sand liquefaction in large-scale: simple shear tests. J Geotech Eng Div ASCE 102(GT9):909–927

Derakhshandi M, Rathje EM, Hazirbaba K, Mirhosseini SM (2008) The effect of plastic fines on the pore pressure generation characteristics of saturated sands. Soil Dyn Earthq Eng 28:376–386

Dobry R, Pierce WG, Dyvik R, Thomas GE, Ladd RS (1985) Pore pressure model for cyclic straining of sand. Civil Engineering Department, Rensselaer Polytechnic Institute, Troy

El Hosri MS, Biarez J, Hicher PY (1984) Liquefaction characteristic of silty clay. In: Proceedings of the 8th world conference on earthquake engineering, Prentice-Hall Eaglewood Cliffs, NJ, vol 3, pp 277–284

El Mohtar CS, Bobet A, Drnevich VP, Johnston CT, Santagata MC (2014) Pore pressure generation in sand with bentonite: from small strains to liquefaction. Geotechnique 64(2):108–117

Finn WDL, Bhatia S (1982) Prediction of seismic porewater pressures. In: Proceedings of the 10th international conference on soil mechanics and foundation engineering, Stockholm, Norway, vol 3, pp 201–206

Flora A, Lirer S (2013) Small strain shear modulus of undisturbed gravelly soils during undrained cyclic triaxial tests. Geotech Geol Eng 31(4):1107–1112

GEO-SLOPE International Ltd. (2014) Dynamic modeling with QUAKE/W. An engineering methodology. GEO-SLOPE International Ltd., Calgary, Alberta, Canada. http://downloads.geo-slope.com/geostudioresources/books/8/15/quake%20modeling.pdf. Accessed 23 Mar 2018

Green RA, Terri GA (2005) Number of equivalent cycles concept for liquefaction evaluations—revisited. J Geotech Geoenviron Eng ASCE 131(4):477–488

Green RA, Mitchell JK, Polito CP (2000) An energy-based pore pressure generation model for cohesionless soils. in: John Booker memorial symposium developments in theoretical geomechanics, Rotterdam, The Netherlands, pp 383–390

Hashash YMA, Phillips C, Groholski DR (2010) Recent advances in non-linear site response analysis. In: The 5th international conference in recent advances in geotechnical eartqhuake engineering and soil dynamics, San Diego, CA. CD-Vol OSP 4

Ishihara K, Yasuda S, Nagase H (1996) Soil characteristics and ground damage. Spec Issue Soil Found 36:109–118. https://doi.org/10.3208/sandf.36.Special_109

Ivšić T (2006) A model for presentation of seismic pore water pressures. Soil Dyn Earthq Eng 26:191–199

Khashila M, Hussien MN, Karray M, Chekired M (2017) Use of pore pressure build-up as damage metric in computationof equivalent number of uniform strain cycles. Can Geotech J. https://doi.org/10.1139/cgj-2017-0231

Koester JP, Sharp MK, Hynes ME (1999) Technical bases for Regulatory Guide for soil liquefaction. U.S. Army Corps of Engineers, NRC Job Code W6246

Kondner RL, Zelasko JS (1963) Hyperbolic stress-strain formulation of sands. In: Proceedings of the 2nd panamerican conference on soil mechanics and foundation engineering, Sao Paulo, Brazil. Associação Brasileira de Mecânica dos Solos, vol 1, pp 289–324

Kramer SL, Asl BA, Ozener P, Sideras SS (2015) Effects of liquefaction on ground surface motions. In: Sakr M, Ansal A (eds) Perspective on earthquake geotechnical engineering. Springer, Cham, pp 285–309

Liu AH, Stewart JP, Abrahamson NA, Moriwaki Y (2001) Equivalent number of uniform stress cycles for soil liquefaction analysis. J Geotech Geoenviron Eng ASCE 127:1017–1026

Liyanathirana DS, Poulos HG (2002) Numerical simulation of soil liquefaction due to earthquake loading. Soil Dyn Earthq Eng 22:511–523

Mandokhail SJ, Park D, Yoo JK (2016) Development of normalized liquefaction resistance curve for clean sands. Bull Earthq Eng 15(3):907–929

Matasovic N, Vucetic M (1993) Cyclic characterization of liquefiable sands. J Geotech Eng ASCE 119(11):1805–1822

Montoya-Noguera S, Lopez-Caballero F (2014) Effect of coupling excess pore pressure and deformation on nonlinear seismic soil response. Acta Geotech 11(1):191–207

Nakamichi M, Sato K (2013) A method of suppressing liquefaction using a solidification material and tension stiffeners. In: Proceedings of the 18th international conference on soil mechanics and geotechnical engineering, Paris, France

Papadopoulou A, Tika T (2008) The effect of fines on critical state and liquefaction resistance characteristics of non-plastic silty sands. Soils Found 48(5):713–725

Park T, Ahn JK (2013) Accumulated stress based model for prediction of residual pore pressure. In: Proceedings of the 18th international conference on soil mechanics and geotechnical engineering, Paris, France

Park T, Park D, Ahn JK (2015) Pore pressure model based on accumulated stress. Bull Earthq Eng 13(7):1913–1926

Pekcan O, Çetin KO, Bakir BS (2004) Cyclic Behavior of Adapazari Silt and Clay Mixtures. In Proceeding of the 3rd international conference on earthquake geotechnical engineering—3ICEGE, Berkeley, California, USA

Polito CP (1999) The effects of non-plastic and plastic fines on the liquefaction of sandy soils. PhD Dissertation in Civil Engineering, Virginia Polytechnic Institute, USA

Polito CP, Green RA, Lee J (2008) Pore pressure generation models for sands and silty soils subjected to cyclic loading. J Geotech Geoenviron Eng ASCE 134(10):1490–1500

Porcino D, Diano V (2016) Laboratory study on pore pressure generation and liquefaction of low-plasticity silty sandy soils during the 2012 earthquake in Italy. J Geotech Geoenviron Eng ASCE. https://doi.org/10.1061/(ASCE)GT.1943-5606.0001518

Porcino D, Marcianò V, Granata R (2015) Cyclic liquefaction behaviour of a moderately cemented grouted sand under repeated loading. Soil Dyn Earthq Eng 79:36–46. https://doi.org/10.1016/j.soildyn.2015.08.006

Sandoval EA, Pando MA (2012) Experimental assessment of the liquefaction resistance of calcareous biogenous sands. Earth Sci Res J 16(1):55–63

Seed HB, Idriss IM, Makdisi F, Banerjee N (1975) Representation of irregular stress time histories by equivalent unifrom stress series in liquefaction analyses. Earthquake Engineering Research Center, University of California, Berkeley

Seed HB, Martin PP, Lysmer J (1976) Pore-water pressure changes during soil liquefaction. J Geotech Eng Div ASCE 102(GT4):323–346

Silver ML, Park TK (1976) Liquefaction potential evaluated from cyclic strain-controlled properties tests on sands. Soils Found 16(3):51–65

Swamy KR, Boominathan A, Rajagopal K (2010) Undrained response and liquefaction behavior of non-plastic silty sands under cyclic loading. In: Proceedings of the 5th international conference on recent advances in geotechnical earthquake engineering and soils dynamics, San Diego, California, USA

Sze HY, Yang J (2014) Failure modes of sand in undrained cyclic loading: impact of sample preparation. J Geotech Geoenviron Eng 140(1):152–169

Thevanayagam S, Shenthan T, Mohan S, Liang J (2002) Undrained fragility of clean sands, silty sands and sandy silts. J Geotech Geoenviron Eng 128(10):849–859

Tonni L, Gottardi G, Amoroso S, Bardotti R, Bonzi L, Chiaradonna A, d’Onofrio A, Fioravante V, Ghinelli A, Giretti D, Lanzo G, Madiai C, Marchi M, Martelli L, Monaco P, Porcino D, Razzano R, Rosselli S, Severi P, Silvestri F, Simeoni L, Vannucchi G, Aversa S (2015) Interpreting the deformation phenomena triggered by the 2012 Emilia seismic sequence on the Canale Diversivo di Burana banks. Ital Geotech J 2:28–58 (in Italian)

Troncoso JH, Verdugo R (1985) Silt content and dynamic behaviour of tailing sands. In: 10th International soil mechanics and foundation engineering, vol 3, pp 1311–1314, San Francisco, California

Tropeano G, Chiaradonna A, d’Onofrio A, Silvestri F (2016) An innovative computer code for 1D seismic response analysis including shear strength of soils. Géotechnique 66(2):95–105

Tropeano G, Chiaradonna A, d’Onofrio A, Silvestri F (2018) Numerical model for non-linear coupled analysis of seismic response of liquefiable soils. Computers and Geotechnics (submitted)

USBR (2015) Design Standards No. 13: Embankment Dam. Chapter 13: Seismic Analysis and Design. U.S. Bureau of Reclamation. https://www.usbr.gov/tsc/techreferences/designstandards-datacollectionguides/finalds-pdfs/DS13-13.pdf Accessed 13 May 2017

Valanis KC (1971) A theory of viscoplasticity without a yield surface. Arch Mech (Archiwum Mechaniki Stosowanej) 23(4):517–555

Viana Da Fonseca A, Soares M, Fourie AB (2015) Cyclic DSS tests for the evaluation of stress densification effects in liquefaction assessment. Soil Dyn Earthq Eng 75:98–111

Vucetic M (1994) Cyclic threshold shear strains in soils. J Geotech Eng Div ASCE 120(12):2208–2228

Xenaki V, Athanasopoulos G (2003) Liquefaction resistance of sand-silt mixtures: an experimental investigation of the effect of fines. Soil Dyn Earthq Eng 23(3):1–12

Acknowledgements

This work was carried out as part of WP1 ‘Seismic response analysis and liquefaction’ of the sub-project on ‘Earthquake Geotechnical Engineering’, in the framework of the research programme funded by Italian Civil Protection through the ReLUIS Consortium.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chiaradonna, A., Tropeano, G., d’Onofrio, A. et al. Development of a simplified model for pore water pressure build-up induced by cyclic loading. Bull Earthquake Eng 16, 3627–3652 (2018). https://doi.org/10.1007/s10518-018-0354-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10518-018-0354-4