Abstract

In the globalization era, assessing the resilience and sustainability of suppliers is a key issue in supply chains (SCs). The literature survey shows data envelopment analysis (DEA) and analytic hierarchy process (AHP) are the two most effective approaches for evaluating suppliers. To take full advantage of these powerful approaches, we propose a novel data envelopment analytical hierarchy process (DEAHP) model. To this end, first, we combine the multiplier form of the slacks-based measure (SBM) model with goal programming (GP) and a common set of weights model to reduce the possibility of alternative optimal solutions. Then, we try to reduce the number of alternative optimal solutions of CSW. Next, to find the range of optimal weights, by setting the optimal objective functions to a constant value, minimum and maximum weights of inputs and outputs are calculated. Finally, to choose the weights, three strategies are suggested. Using the optimal weights, we calculate the pairwise comparison matrix and rank suppliers. To demonstrate the usefulness of the proposed approach, a case study in the resin industry is given.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Over the last few years, the adoption of sustainable development strategies has been the main focus of many organizations (Giannakis et al., 2020; Zhan et al., 2021). Due to globalization, managers and decision-makers of supply chains (SCs) need to incorporate the sustainability aspects such as economic, environmental, and social into their decisions (Almasi et al., 2021). Manufacturing sustainable products is a response to forces coming from different stockholders such as consumers, governments, and non-governmental organizations (NGOs) (Azadi et al., 2015; Tsai et al., 2021). The resilience of SCs is another strategic topic that has been the focus of initiatives. Resilient SCs can absorb interruptions and maintain their basic function and structure (Jabbarzadeh et al., 2018).

One of the most important topics of supply chain management (SCM) is to evaluate and select suppliers (Zhan et al., 2021). Since suppliers significantly contribute to the sustainability objectives, sustainable supplier selection is a strategic decision in all organizations (Rashidi et al., 2020). To select sustainable suppliers, organizations need to consider sustainability aspects in the performance evaluation of suppliers (Tang & Yang, 2021). However, addressing the sustainability aspects in supplier selection problems needs to deal with many criteria. This, in turn, is a major challenge for organizations, which managers of SCs should take into account (Jain & Singh, 2020).

On the other hand, natural and man-made disasters such as earthquakes, floods, and fires have led to unexpected disruptions in SCs (Sakib et al., 2021). In the long term, such disruptions can affect the productivity and profitability of SCs (Jabbarzadeh et al., 2018). Thus, resilient SC is necessary for absorbing external shocks and protecting buyers from unexpected shortages (Hosseini et al., 2019). Since the performance of SCs can be affected by suppliers, resilience criteria should be considered in supplier selection problems (Amindoust, 2018). Therefore, SCs need to be resilient and sustainable to face any disruption and meet sustainability objectives (Thomas et al., 2016). Fahimnia and Jabbarzadeh (2016), Zahiri et al. (2017), Ivanov (2018), and Marchese et al. (2018) explored relations between resilience and sustainability aspects in SCs. Nevertheless, the literature shows that resilience and sustainability have been addressed independently (Amindoust, 2018). In other words, most of the existing studies of supplier selection problems consider either resilience criteria or sustainability criteria. Therefore, there is a vital need to develop and apply advanced frameworks and approaches to evaluate and select resilient-sustainable suppliers.

Supplier selection is a multiple criteria decision-making (MCDM) problem (Yadav & Sharma, 2015). The most popular methods for supplier selection problems are data envelopment analysis (DEA), analytic hierarchy process (AHP), analytic network process (ANP), goal programming (GP), the technique for order of preference by similarity to ideal solution (TOPSIS), fuzzy logic, and genetic algorithms (Chul Park & Lee, 2018; Rashidi & Cullinane, 2019; Ramanathan, 2007; Sevkli et al., 2007; Zhang et al., 2012; Yadav & Sharma, 2015; Bajec et al., 2021; Wang et al., 2004; Kull & Talluri, 2008; Demirtas & Üstün, 2008; Sarkar et al., 2018; Karsak & Dursun, 2014; Dai & Blackhurst, 2012; Scott et al., 2013). Among the integrated approaches for selecting suppliers, the data envelopment analytical hierarchy process (DEAHP) has received substantial attention (Bajec et al., 2021).

The main objective of this paper is to develop a novel DEAHP approach for assessing the resilience and sustainability of suppliers. To decrease the possibility of alternative optimal solutions (weights), the slacks-based measure (SBM) model is combined with GP and a common set of weights (CSWs) model. Furthermore, by setting the value of optimal objective functions to a constant value, we find the range of optimal weights. Then, we calculate the minimum and maximum weights of inputs and outputs. In addition, to select the preferred weights, we propose three strategies based on the range of optimal weights of inputs and outputs. Also, we use the optimal weights to calculate the pairwise comparison matrix of AHP. In summary, the main contributions of this paper are as follows:

-

For the first time, GP and CSW of SBM are used to determine the AHP weights.

-

The secondary goal is used to determine the weights so that the distance between CSW of inputs and outputs and the weights of inputs and outputs of the DMU under evaluation is minimized.

-

The range of optimal weights of inputs and outputs is calculated.

-

Using the optimal weights of AHP, the DMUs are ranked.

-

A real case study is given.

The rest of this paper is as follows. In Sect. 2, we review the related literature. Section 3 presents the proposed model. A case study is given in Sect. 4. Finally, concluding remarks are provided in Sect. 5.

2 Literature review

2.1 Sustainable and resilient suppliers

In today’s competitive environments, organizations have become more reliant on sustainable and resilient suppliers. Stockholders need to take the sustainability dimensions into account (Almasi et al., 2021). Thus, criteria such as transparency, organizational culture, and strategy should be taken into account to evaluate suppliers (Alexander et al., 2014; Sharma et al., 2020). In sustainable SCs, organizations should consider culture, strategy, waste, and public safety to evaluate suppliers (Carter & Rogers, 2008).

On the other hand, unexpected events such as man-made and natural disasters can affect the performance of sustainable SCs (Moats et al., 2021). To benefit from resilient SCs, suppliers should have the least vulnerability. Moreover, risk management using advanced approaches is recommended in resilient SCs (Bottani et al., 2019). Furthermore, suppliers need to be responsive to the changes of demands (Parkouhi et al., 2019). Fahimnia and Jabbarzadeh (2016) discussed that the sustainability dimensions of SCs are extremely sensitive to the variations in resilience levels. Therefore, to select suppliers, sustainability and resilience should be taken into account (Amindoust, 2018).

2.2 Suppliers evaluation and selection approaches

Performance evaluation and selection of suppliers is one of the most essential issues in SCM. As addressed by Dutta et al. (2021), DEA is the most popular approach in supplier selection problems. Talluri et al. (2006) presented a chance-constrained DEA model for performance evaluation and selection. To select suppliers, Farzipoor Saen (2007) presented a DEA model in the existence of both cardinal and ordinal data. Ahmady et al. (2013) proposed a fuzzy DEA model with double frontiers for performance measurement of suppliers. To evaluate and select suppliers, Azadi et al. (2015) proposed a fuzzy enhanced Russell measure (ERM) model. Izadikhah and Farzipoor Saen (2020) proposed a context-dependent DEA model for ranking sustainable suppliers. Tavassoli et al. (2020) proposed a stochastic-fuzzy DEA model to evaluate the sustainability of suppliers. Bhutta and Huq (2002) applied AHP for selecting the suppliers. Chan et al. (2008) proposed a fuzzy DEA model to measure the performance of global suppliers. Rezaei and Ortt (2013) developed a fuzzy AHP model for supplier segmentation. Pishchulov et al. (2019) proposed a modified voting AHP model to evaluate and select sustainable suppliers.

Some scholars have combined DEA and AHP methods to evaluate suppliers. Ramanathan (2007) applied DEA for measuring supplier efficiency using total cost of ownership (TCO) and AHP. To evaluate and select suppliers, Sevkli et al. (2007) integrated AHP and DEA and proposed a DEAHP model in which AHP is applied for determining local weights and DEA is used for calculating the efficiency scores. Zhang et al. (2012) presented a hybrid method for integrating activity-based costing (ABC) and DEAHP to measure the performance of suppliers. Yadav and Sharma (2015) developed an MCDM model for evaluating and selecting suppliers based on the DEAHP model. Bajec et al. (2021) proposed a distance-based DEAHP model for selecting suppliers based on sustainability criteria.

2.3 DEA, AHP, and DEAHP

Charnes et al. (1978) presented DEA for evaluating the efficiency of decision making units (DMUs). Visani and Boccali (2020) identified several advantages of DEA. Since DEA does not require pre-definition of a specific production function, it can be used for assessing the efficiency of DMUs. Furthermore, DEA can identify inefficiency sources of DMUs. Moreover, the inputs and outputs of DEA can have different units of measurement. Because of the numerous advantages of DEA, it has been used in different settings (Azadi et al., 2020; Azar et al., 2016; Zarei Mahmoudabadi et al., 2018). Charnes et al. (1978) (CCR) and Banker et al. (1984) (BCC) are two basic DEA models. The DEA models are categorized into radial and non-radial models (Azadi & Farzipoor Saen, 2013). The radial models include the CCR ratio form (the radial model under constant return to scale (RTS) technology), and the BCC model (the radial model under variable RTS). Compared with the radial models, non-radial models do not need any special treatment on the input and output orientations.

AHP, for the first time, was proposed by Saaty (1980). Ho and Ma (2018) discussed that due to simplicity, user-friendly, and flexibility, AHP has been applied in many areas. AHP provides decision-makers an accurate judgment, implicit weights through the assessment, and sensitivity analysis (Chul & Lee, 2018). To determine the weights and priorities, AHP produces the most reliable results (Schoemaker & Waid, 1982). AHP uses a pairwise comparison matrix in different layers (Ishizaka et al., 2011; Luthra et al., 2016).

To take full advantage of DEA and AHP, Sinuany‐Stern et al. (2000) used DEA for each pair of units. Ramanathan (2006) proposed the DEAHP technique. In DEAHP, local weights are derived from a judgment matrix and it aggregates local weights to get the overall weights. In DEAHP, rows and columns of the pairwise comparison matrix are considered as DMUs and outputs, respectively. In DEAHP, the efficiency scores are interpreted as local weights of the DMUs (Sevkli et al., 2007). Korpela et al. (2007) proposed a DEAHP model for selecting warehouse operators. To evaluate suppliers, Zhan et al. (2021) integrated DEAHP and ABC model. Lin et al. (2011) used DEAHP to measure the economic performance of local governments in China. They applied AHP to determine the weighted values of DMUs. Then, weighted values were incorporated into the DEA. Mirhedayatian and Farzipoor Saen (2011) showed that DEAHP generates counter-intuitive priority vectors for inconsistent pairwise comparison matrices. To tackle this issue, they proposed a new version of DEAHP for generating weights that are consistent with the decision maker's opinion. Over the last decade, some scholars have proposed other DEAHP models with different applications (Singh & Aggarwal, 2014; Rakhshan et al., 2015; Lai et al., 2015; Chul & Lee, 2018; Keskin & Köksal, 2019; Kuo et al., 2021).

2.4 Knowledge gap

Due to the complexity of evaluating and selecting resilient and sustainable suppliers, it is crucial to develop advanced and effective methods. However, there is no paper for assessing the resilience and sustainability of suppliers using DEAHP. The idea of DEAHP has not yet been introduced with the CSW concept. Furthermore, in DEAHP, there might be alternative optimal weights. In this paper, the knowledge gaps are filled by developing a novel DEAHP model. The proposed model is applied for evaluating resilient and sustainable suppliers.

3 Proposed model

In this section, we develop our DEAHP model based on the SBM, CSW, and GP models for evaluating resilient-sustainable suppliers. Table 1 depicts the used notations in this study.

AHP is one of the MCDM techniques and was proposed by Saaty (1990). AHP has been widely used. Using decision-maker preferences (weights), it selects the best alternative given multiple criteria. Here, a brief explanation of the AHP technique is presented:

Firstly, the decision-making problem is converted to a hierarchy, in which the decision-making goal is at top of the hierarchy. The criteria and alternatives are in the lower tiers of the hierarchy. Secondly, a pairwise comparison matrix is formed. The pairwise comparisons are done using a 1 to 9 measurement scale. Using a 1 to 9 scale, an h × h matrix is formed. Note that \(a_{qk}\) implies the weight of criterion q over k, \(\frac{{w_{q} }}{{w_{k} }}\). Also, \(a_{qk} = \frac{1}{{a_{kq} }}\). and \(a_{qq} = 1\). Expression (1) shows the pairwise comparison matrix based on the manager judgment where \(a_{qk}\) shows the weight of the qth criterion over the kth criterion.

Thirdly, the local weights of criteria are calculated. Finally, the rank of alternatives is determined given the criteria. Assume that \(w_{k} ,{ }\left( {k = 1, \ldots ,l} \right)\) is the local wght of the kth criterion. Also, assume that \(w_{qk} ,{ }\left( {q = 1, \ldots ,h} \right)\) is the local weight of alternative q terms of criterion k; and \(\omega_{q} ,{ }\left( {q = 1, \ldots ,h} \right)\) is the global weight of the qth alternative. Note that \(\left( {w_{1} , \ldots ,w_{l} } \right)\) should satisfy \(\mathop \sum \nolimits_{k = 1}^{l} w_{j} = 1\) and \(w_{k} \ge 0,{ }\left( {k = 1, \ldots ,l} \right)\). The global weight of the alternatives is obtained by Expression (2).

Apart from the merits of the AHP, however, it relies on the subjective judgments of decision-makers. DEA is a technique that does not rely on the subjective judgments of decision-makers. In particular, a multiplicative form of DEA determines the optimal weights of inputs and outputs. Thus, the optimal weights, which are obtained by DEA can be used in AHP. For each pair of DMUs p and f, every entry of the matrix A is formed as follows:

where \(E_{pf}\) is the efficiency of \(DMU_{f}\) using the optimal weights of \(DMU_{p}\). In the pairwise comparison matrix, the entries below the main diagonal are inverse of the entries above the main diagonal. To aggregate the pairwise comparison matrices, Aczél and Saaty (1983) used the geometric mean. Thus, the geometric mean of all entries of a row is calculated. To normalize the obtained weights, every geometric mean is divided by the summation of the geometric means. The new column is called eigenvector.

Since there might be multiple optimal solutions, many models he been proposed to find the best alternative optimal solution. Obtaining other optimal solutions can generate different solutions with similar objective function value for managers. This enables managers to choose the best solution among alternative solutions given their situation. Thus, deriving the other optimal weights from the DEA multiplier model is important for decision-makers.

The common set of weight (CSW) method is a widely used method in DEA as not only it maximizes the efficiency of the DMU under evaluation but also it maximizes the efficiency of all DMUs, simultaneously. Given the importance of the CSW method, we incorporate it into the SBM model. Also, for the first time, the weights obtained from the SBM multiplier model are used in the AHP. The reason for choosing the SBM model is that the SBM is one of the most efficient and accurate models of DEA (Tone, 2001).

Assuming constant RTS and \(x > 0\) and \(y > 0\), the following envelopment version of the linear SBM model is presented:

The optimal objective function of Model (4) represents the efficiency score of the DMUo, which is shown in Expression (5).

One of the classical DEA models is the CCR (Charnes-Cooper-Rhodes) model, which evaluates the performance of DMUs based on radial changes (Charnes et al., 1978). Consider the multiplier input-oriented CCR Model (6), which is as follows:

where \(\theta^{*}\) and \(\frac{1}{{\theta^{*} }}\) are the efficiency scores in the input-oriented and output-oriented CCR models, respectively. Also, Tone (2001) proved that \(\rho_{1}^{*} \le \theta^{*}\)., where \(\rho_{1}^{*}\) is theBM efficiency score. Model (7) is the dual of Model (6).

where \(v\) and \(u\) are weight vectors of the inputs and outputs, respectely. Since Model (7) is the dual of Model (6), for any DMUo, \({\varvec{u}}^{*} Y_{o} = \theta^{*} .\) As addressed by Dyson et al. (2001), zero weights lead to inaccurate performance evaluation. Therefore, the weights should be considered equal or larger than \(\varepsilon\). Choosing suitable \(\varepsilon\) is very important. From constraint (a) of Model (7), it can be concluded that \({\varvec{v}} = \left[ {\frac{1}{{X_{o} }}} \right]\), where \(\left[ {\frac{1}{{{\varvec{x}}_{{\varvec{o}}} }}} \right] = \left( {\frac{1}{{x_{1o} }}, \ldots , \frac{1}{{x_{mo} }}} \right)\). Thus, we have \(\left( {v_{1} , \ldots ,\user2{ }v_{1} } \right) = \left( {\frac{1}{{x_{1o} }}, \ldots , \frac{1}{{x_{mo} }}} \right). \) Also, given the \({\varvec{v}} \ge {\upvarepsilon }\), the intersection of \({\varvec{v}} = \left[ {\frac{1}{{X_{o} }}} \right]\) and \({\varvec{v}} \ge \varepsilon\). is not empty. In other words, the constraints of Model (7) do not violate each other. Therefore, according to \({\varvec{v}} = \left[ {\frac{1}{{X_{o} }}} \right]\), it can be concluded that the weight of the inputs is known. The CCR multiplier model determines the weights freely. Now, consider the dual of Model (4), which is as follows (Tone, 2001):

At this juncture, consider the following variable transformation (9):

Given the variable transformation (9), Model (8) is converted to the following linear model:

Using the optimal solution of Model (10), the relative efficiency score of the DMUo is obtained by \(1 + {\mathbf{u}}^{*} y_{o} - {\varvec{v}}^{*} x_{o}\). As introduced by Tone (2001), in constraints (b) and (c), we have \(\left[ {\frac{1}{{{\varvec{x}}_{{\varvec{o}}} }}} \right] = \left( {\frac{1}{{x_{1o} }}, \ldots , \frac{1}{{x_{mo} }}} \right) \). and \(\left[ {\frac{1}{{{\varvec{y}}_{{\varvec{o}}} }}} \right] = \left( {\frac{1}{{y_{1o} }}, \ldots , \frac{1}{{y_{so} }}} \right).\)

Remark 1

To obtain a feasible solution of Model (10), assume that input and output weights equal to \(\left( {{\varvec{v}}_{1} ,{ } \ldots ,{ }{\varvec{v}}_{{\varvec{m}}} } \right){ } = { }\frac{1}{m }\left( { \frac{1}{{ x_{1o} }}, \ldots , \frac{1}{{ x_{mo} }}} \right) = \left( { \frac{1}{{ mx_{1o} }}, \ldots , \frac{1}{{ mx_{mo} }}} \right)\) and \(\left( {{\varvec{u}}_{1} ,{ } \ldots ,{ }{\varvec{u}}_{{\varvec{s}}} } \right) = \frac{{1 - {\varvec{v}}x_{o} + {\mathbf{u}}y_{o} }}{s}\left( { \frac{1}{{ y_{1o} }}, \ldots , \frac{1}{{ y_{so} }}} \right) = \left( { \frac{{1 - {\varvec{v}}x_{o} + {\mathbf{u}}y_{o} }}{{s y_{1o} }}, \ldots , \frac{{1 - {\varvec{v}}x_{o} + {\mathbf{u}}y_{o} }}{{ s y_{so} }}} \right).\) Thus, we have \({\mathbf{u}}y - {\varvec{v}}x = 0\). Therefore, the corresponding objective value of \({\text{DMU}}_{{\text{o}}}\). is \({\mathbf{u}}y_{o} - {\varvec{v}}x_{o} = 0.\)

The super-efficiency version of Model (10) is Model (11), which is used to rank DMUs. Note that the efficient DMUs determined by Model (11) have a super-efficiency score greater than or equal to 1. Therefore, using the super-efficiency scores the efficient DMUs can be ranked.

Note that constraints (b) and (c) of Model (11) do not let the weights be zero. This is an important feature of the SBM model, which increases its discrimination power compared with the radial models. The right-hand side of constraints (b) and (c) of Model (11) are not only non-zero but also greater than the ε. Thus, to maximizing the efficiency score, associated with the inputs and outputs, the non-zero weights, which form constraints (b) and (c) of Model (11), are obtained.

Consider Fig. 1 in which the efficiency frontier with constant RTS (CRTS) is depicted. In Fig. 1, \(DMU_{A}\) and \(DMU_{C}\) are projected on the efficiency frontier (points A' and C'). The green dotted line shows the output increase of DMUC and the red dotted line shows the input decrease of DMUA. The results of input-oriented DEA models are applicable for managers as the results of output-oriented DEA models cannot be easily implemented by managers (Cooper et al., 2011). In Fig. 1, point B' shows changes in both input and output. Note that in the SBM model, changes in inputs and outputs are considered, simultaneously.

DEA determines the best non-negative weights of inputs and outputs, which is called optimistic evaluation. If, in the optimistic situation, the DMUo is inefficient, there will not be better weights to change the inefficient DMUo to an efficient DMUo. Using the CSW approach, the efficiency of all DMUs is maximized, simultaneously.

Now, consider DMUs A and B in Fig. 2. Note that in the CSW model, we are looking for a minimum distance of all DMUs from a hyperplane. In other words, we wish to maximize the efficiency of DMUs compared with the hyperplane. In Fig. 2, the efficiency of all DMUs is maximized compared with the hyperplane L. In the classical DEA model, however, each DMU is compared with the hyperplanes of the production possibility set (PPS). Point A' is the projection of point A on the constructing hyperplanes of the PPS, a hyperplane passing through points G and C. Point B' is the projection of point B on the constructing hyperplanes of the PPS, a hyperplane passing through points G and L. Also, points A'' and B'' are the projection of points A and B on the hyperplane, respectively, which the hyperplane is formed by the CSW.

Model (12) is a multi-objective model, which maximizes the efficiency of all DMUs, simultaneously.

To convert the multi-objective Model (12) into a single-objective mol, Davoodi and Rezaei (2012) used goal programming. Consider constraint (a) in Model (12). The upper bound of constraint (a) is zero. Moreover, consider the multi-objective function of Model (12). It is clear that constraint (a) is the jth objective function, which should be zero. Therefore, zero is the upper bound (goal). As a result, Model (13) is introduced.

Remark 2

According to Remark 1, Model (13) is also feasible as we consider the feasible solution introduced in Remark 1 along with \({\updelta }_{j} = {\upsigma }_{j} = 0\). for all j. In this case, the objection function value of Model (13) equals zero.

Without loss of generality, constraint (a) of Model (13) can be written as \(\frac{{\left( {{\mathbf{u}}{\text{y}}_{j} + {\updelta }_{j} } \right)}}{{\left( {{\varvec{v}}x_{j} - {\upsigma }_{j} } \right)}} = 1\). Using the optimal solution of Model (13), the CSW \(\left( {{\mathbf{u}}^{*} ,{ }{\mathbf{v}}^{*} } \right)\) is obtained to maximize the efficiency of all DMUs. Also, using the CSW obtained from Model (13), the CCR efficiency score can be calculated by the following equation:

By solving Model (13), it is still possible to have alternative optimal solutions. Therefore, we try to reduce the probability of alternative optimal solutions by the secondary goal. Note that the classical DEA models measure the efficiency score of DMUo from the optimistic aspect. Therefore, we try to minimize the difference between the efficiency score obtained from the SBM model and the efficiency score obtained from the CSW obtained from Model (13). In other words, Model (17) chooses the weights that satisfy the constraints and have a minimum distance from the weights obtained by Model (11). Note that Model (11) maximizes the efficiency of DMUo and does not maximize the efficiency of other DMUs. The efficiency score obtained from the SBM model takes into account all possible inefficiencies of inputs and outputs. Therefore, we should have

In the objective function of Model (17), to deal with the difference, p-norm is introduced. To measure the distance, it is common to use p = 1 or p = ∞ (Balf et al., 2012). Without loss of generality, we consider p = 1, i.e., norm 1. Thus, we use the following expression:

As a result, Model (17) is presented as follows:

Remark 3

According to Remark 1, Model (17) is feasible. As such, constraints (c) and (d) are satisfied. Therefore, constraint (a) is satisfied in equity. Note that \(\rho_{o}^{*}\) is the optimal objective value of Model (3). Also, Model (3) is the linear counterpart of SBM model. Therefore, as it is clear, \(\frac{{{\mathbf{u}}{\text{y}}_{o} }}{{{\varvec{v}}x_{o} }}\) shows the radial efficiency in input-oriented CCR model, which is more or equal to \(\rho_{o}^{*} .\) Thus, constraint (b) is also satisfied.

The objective function of Model (17) minimizes the difference between the weights obtained from Model (17) and the weights, \({\varvec{u}}_{0}^{*}\) and \({\varvec{v}}_{0}^{*}\), obtained from SBM (3). Constraint (a) of Model (17) represents the efficiency of \(DMU_{j}\) (j = 1,…,n), which should be less than or equal to one. In constraint (b) indicates that efficiency scores should be greater than or equal efficiency calculated from CSW model (11). Note that such a relationship was shown in Expression (15). Constraints (c) and (d) impose restrictions on the weights of inputs and output. Thus, the feasible region of Model (17) is not enlarged, which means it becomes smaller or remains unchanged. In this way, we minimize the possibility of multiple optimal solutions. Consider Expressions (18) and (19), where \({\varvec{Z}}\) is free in sign. Using variable transformation, Model (17) is converted to a linear model, which is as Model (21).

Consider the following definitions for variables \({\varvec{Z}}^{1}\) and \({\varvec{Z}}^{2}\):

Thus, it is clear that

Although constraint (20) is nonlinear, it is redundant in Model (21). Therefore, it is removed from the model. Note that in Expression (18), the free variable Z is defined as the difference between the two non-negative variables. Also, the coefficients of variables \({\varvec{Z}}^{1} \left( i \right) \) and \({\varvec{Z}}^{2} \left( i \right)\) for each i are symmetric to each other. As a result, both variables cannot be in a basic matrix (Bazaraa et al., 2008). Therefore, always, at least one of the two variables is zero. Thus, constraint (20) is redundant and can be removed from Model (21). Also, Model (21) is linear. Similarly, these sorts of relationships can be written for the variable \({\text{ Q}}\left( {\text{r}} \right)\). According to the above discussions, we have the following linear model:

Remark 4

Based on the feasible solution introduced in Remark 3, Model (21) is feasible as we consider relations (18) and (19) for \({\varvec{Z}}^{1} ,\) \({\varvec{Z}}^{2} ,\) \({\varvec{Q}}^{1} ,\) and \({\varvec{Q}}^{2}\). Thus, we have a feasible solution for Model (21).

Model (21), the objective is to find those weights that have the minimum differences from the optimal weight of CSW Model (13). Also, according to Eqs. (18) and (19), the objective function of Model (21) is replaced by expressions \(|{\varvec{v}}_{0i}^{*} - {\varvec{v}}_{i}^{{}} | = \left| {{\varvec{Z}}\left( {\text{i}} \right)} \right| = {\varvec{Z}}^{1} \left( i \right) + {\varvec{Z}}^{2} \left( i \right)\), and \( \left| { {\varvec{u}}_{0r}^{*} - {\varvec{u}}_{r}^{{}} } \right| = \left| {{\varvec{Q}}\left( r \right){ }} \right| = {\varvec{Q}}^{1} \left( r \right) + {\varvec{Q}}^{2} \left( r \right)\), for all i and r. Note that.

Next, for each \(DMU_{o}\)., the range of changes for optimal weightsan be measured. Therefore, m + s models are introduced to find the minimum optimal weights for each m + s input and output’s weights. Similarly, m + s models are introduced to find the maximum optimal weights for each m + s input and output’s weights. Therefore, the range of each m + s input and output’s weight can be obtained for each \(DMU_{o} , o \in \left\{ {1, \ldots ,n} \right\}\).

Remark 5

Note that the optimal solution of Model (21) is a feasible solution for Models (22) and (23). Therefore, Models (22) and (23) are feasible.

Using Models (22) and (23), the minimum and maximum values of \(v_{1} \) are obtained. Similarly, for the remaining m − 1 input weight, i.e., \({\varvec{v}}_{2}\) to \({\varvec{v}}_{m}\), we solve Models (22) and (23). Likewise, we solve Models (22) and (23) for s output weight, i.e., \({\varvec{u}}_{1} , \ldots ,{ }{\varvec{u}}_{s}\), to obtain the minimum and maximum value of the optimal weight for each output. In this way, for all m + s input and output weights, the range of changes for the optimal weights is determined. Thus, we obtained the two optimal weight categories, one for the upper limit and the other for the lower limit of the range. Also, we can consider this range as an interval.

Theorem 1

Consider the ith input weight. If the upper and lower bounds of Expression (24) are equal, then the unique optimal weight for the ith input will be obtained. Moreover, this unique optimal weight equals the optimal weight of Model (21). This can be repeated for output weights.

Proof

Models (22) and (23) obtain the minimum and maximum values of the optimal weight of each input and output, respectively. Therefore, if the values of the uppernd lower bounds of the corresponding weights of the optimal inputs are equal, the minimum and maximum values of the optimal weights of each input will be equal. Since there is no other value between the minimum and maximum values of the weights, the obtained weight is unique. Therefore, this unique weight is the optimal solution of Model (21) as well. Similarly, this argument can be made for output weights. □

Theorem 2

If Model (21) has the alternative optimal solutions, the weights lie within the intervals defined in (24).

Proof

Note that in Models (22) and (23), the minimum and maximum weights of each input and output are obtained, respectively. Without loss of generality, suppose the first input component is considered. In this case, the weight range for the input weight is \(\left[ {Min {\varvec{v}}_{1}^{*} ,{ }Max {\varvec{v}}_{1}^{*} } \right]\). If Model (21) has the alternative solution for the weight of the first input, this means that \(Min {\varvec{v}}_{1}^{*} \ne { }Max {\varvec{v}}_{1}^{*}\). Therefore, \(Min {\varvec{v}}_{1}^{*} < Max {\varvec{v}}_{1}^{*}\). Thus, any optimal weight of the first input obtained from Model (21) lies within the interval \(\left[ {Min {\varvec{v}}_{1}^{*} ,{ }Max {\varvec{v}}_{1}^{*} } \right]\).□

Now, according to Model (21), the probability of alternative optimal solution is minimized. Since some constraints are added to Model (21), the feasible region of Model (21) is not increased. Thus, any alternative optimal weight is not less than and more than the lower and upper bounds of the optimal weight interval.

Definition 1

To get unique optimal weights, three strategies are suggested:

-

(1)

Optimistic viewpoint (100% risk): \(\left( {{\varvec{v}}_{i}^{{}} ,{\varvec{u}}_{r}^{{}} } \right) = \left( {Min {\varvec{v}}_{i}^{*} ,{ }Max {\varvec{u}}_{r}^{*} } \right), \forall i, \forall r,\).

-

(2)

Pessimistic viewpoint (0% risk): \(\left( {{\varvec{v}}_{i}^{{}} ,{\varvec{u}}_{r}^{{}} } \right) = \left( {Max u_{r}^{*} ,{ }Min {\varvec{v}}_{i}^{*} } \right), \forall i, \forall r,\)

-

(3)

Neither optimistic nor pessimistic (\(\alpha\)% risk):

$$ \left( {{\varvec{v}}_{i}^{{}} ,{\varvec{u}}_{r}^{{}} } \right) = \left( { \alpha \left( {Min {\varvec{v}}_{i}^{*} } \right) + \left( {1 - \alpha } \right)\left( {Max {\varvec{v}}_{i}^{*} } \right),{ }\left( {1 - \alpha } \right)\left( {Min {\varvec{u}}_{r}^{*} } \right) + \alpha \left( {Max {\varvec{u}}_{r}^{*} } \right) } \right), \forall i, \forall r. $$

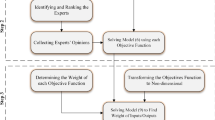

In the third strategy, \(\alpha\)% represents the risk. If \(\alpha = 0\), then the irdtrategy is converted to the pessimistic viewpoint. If \(\alpha = 1\), the third strategy is converted to the optimistic viewpoint. If \(0 < \alpha < 1\), \(\alpha\) depends on the manager's decision. According to Definition (1), a unique set of weights can be selected according to managers’ decisions. Thus, the unique weights can be used to construct the pairwise comparison matrix in the AHP method. Figure 3 shows the required steps for our proposed model.

According to Fig. 3, in the first step, the multiplier SBM model is solved. Next, the SBM common set of weights model is solved to find CSWs that maximize all the DMUs at the same time. To decrease the alternative optimal weights, distance from the optimal CSWs is minimized to reduce the disparity of weights. Then, the optimal weights’ intervals are determined. In this step, if a unique set of weights is obtained, then stop. Otherwise, three strategies given the optimistic and pessimistic viewpoints are suggestions. Afterward, the weights are used in AHP.

4 Case study

Azar Resin Company (ARC) is one of the leading and biggest resin producers in Iran.Footnote 1 In 1995, the ARC was founded in Qazvin province. The ARC manufactures three types of resins, including polyamide resins, alkyd resins, and amino resins. The company wishes to evaluate and select the most resilient and sustainable suppliers. Evaluation and selection criteria of resilient-sustainable suppliers are derived from papers such as Azadi et al. (2015), Amindoust (2018), Ramezankhani et al. (2018), Parkouhi et al. (2019), Hendiani et al. (2020), and Tayyab and Sarkar (2021). Also, to get a better idea of the evaluation criteria, some meetings are arranged with managers and decision-makers in different departments, including research and development (R&D), production planning, and quality control. Table 2 summarizes the inputs and outputs for selecting resilient and sustainable suppliers.

In this study, the inputs include [x1]: Price of raw materials (106$), (economic); [x2]: Transportation cost (103$), (economic); [x3]: Green space cost ($/m2), (environmental); [x4]: Eco-design cost ($/m2), (environmental); [x5]: Recycle costs (103$), (environmental); [x6]: Costs for work safety and labour health ($ per person), (social); [x7]: Employee satisfaction, (social), and [x8]: Lead time (hour), (resilient). The outputs include [y1]: Quality (economic), [y2]: Flexibility (economic); and [y3]: Average inventory (105 Tons) (resilient). To convert qualitative factors (eemployees’ satisfaction, quality, and flexibility) to quantitative factors, 5-point Likert scale is used.

Figure 4 shows the hierarchy of resilient-sustainable supplier selection problem. The top-level of the hierarchy represents the final target of the problem, while the second level of the hierarchy has four main criteria. The third level is associated with sub-criteria of resilient-sustainable suppliers followed by the suppliers (DMUs).

Table 3 presents the dataset of forty suppliers of the ARC.Footnote 2

Using Definition 1 and Model (21), the optimal unique weights are presented in Table 4. Table 4 reports the normalized optimal weights of inputs and outputs.

Table 5 shows the efficiency scores obtained from the classical SBM model (10), SBM super-efficiency model (11), and CSW SBM model (13).

Figure 5 compares the results of Models (10) and (13). As is seen, the efficiency scores obtained from Model (13) are smaller than or equal to Model (10). However, there is no guarantee that the set of weights to be unique.

Table 6 shows the efficiency score of each DMU, which its optimal weights are used in other DMUs. For instance, the efficiency score in row #1 and column #2 implies that the optimal weights of supplier 1 are used to calculate the efficiency score of supplier 2. Using Models (21), (22), (23), and Definition (1) with a defined risk, according to managers opinion, the efficiency scores in the main diagonal of the matrix are calculated by the optimal weights of the DMU under evaluation.

Table 7 shows the pairwise comparison matrix using the normalized optimal weights of Table 3. Note that each entry of Table 7 is calculated using Expression (3). As is seen, the numbers below the main diagonal of the matrix are inversely proportional to the numbers above the main diagonal of the matrix. All diagonal numbers equal 1.

Now, the geometric mean of each row is calculated and the obtained values are normalized. The summation of normalized weights equals 1. The new normalized column is called an eigenvector (Aczél & Saaty, 1983). Table 8 summarizes the final results. The last column of Table 8 reports the values obtained from the DEAHP method. According to the results of the SBM super-efficiency (Model 11), it is clear that due to the existence of non-extreme efficient DMU in the PPS, there are more than one efficient DMUs. Thus, DMUs cannot be fully ranked. The SBM efficiency (Model 10) has a similar drawback. Using the DEAHP method and CSW SBM efficiency (Model 13), all the DMUs can be fully ranked. However, the CSW SBM efficiency (Model 13) may lead to multiple optimal weights.

To get unique optimal weights of DEA, Definition 1 can be used. Using Definition 1, the feasible region becomes smaller and the possibility of alternative optimal weights is reduced. Since we have got unique optimal weights, we do not use Definition 1. If there is a weight interval, one of the strategies can lead to a unique optimal weight.

4.1 Managerial implications

The proposed approach helps managers of supply chains to evaluate the resilience and sustainability of suppliers. In other words, the hierarchical structure of the proposed approach can address the complexity of evaluating the resilience and sustainability of suppliers. The proposed method helps to select the most resilient and sustainable supplier. Furthermore, our approach can help managers and decision-makers of supply chains to deal with multiple criteria. This, in turn, increases the decision making capabilities of managers.

Figure 6 compares the results of Models (10), (11), (13), and the DEAHP method. As is seen, As is seen, most suppliers in SBM efficiency (Model 10) have the same efficiency scores. Thus, SBM efficiency (Model 10) cannot fully rank suppliers. Also, the DEAHP method is compared with CSW SBM efficiency (Model 13). As is seen, the DEAHP method has more discrimination power than CSW SBM efficiency (Model 13). Generally, the DEAHP method has a very high discrimination power than other models.

5 Conclusions and future researches

There is considerable emphasis on sustainability in many settings. However, resilience, as a key factor, should be considered in SCs (Moats et al., 2021). Resilient SCs can resist against rapid and unpredictable disruptions (Fahimnia & Jabbarzadeh, 2016). In this paper, we proposed a novel DEAHP method for evaluating resilient and sustainable suppliers. In addition, for the first time, we applied GP and CSW in SBM for determining the AHP weights. The proposed model decreased the possibility of alternative optimal weights by addressing the distance between CSW of inputs and outputs and the weights of inputs and outputs of the DMU under observation. Moreover, we reduced the number of alternative optimal weights of the CSW model. Also, we determined the range of changes of optimal weights and calculated the minimum and maximum weights of inputs and outputs. Furthermore, to choose suitable weights, we proposed three strategies. We calculated the pairwise comparison matrix and ranked the suppliers via the optimal weights. We presented several theorems, proofs and remarks for our developed model. To show the usefulness of our proposed approach, a case study was given in resign industry to evaluate the resilience and sustainability of suppliers. We ran different models, including SBM super-efficiency, SBM, CSW SBM efficiency, and our DEAHP. The results of the case study demonstrate how well the developed model can assess resilient and sustainable suppliers. A flowchart was provided to show the required steps of the proposed model. We also discussed some managerial insights of our proposed model such as addressing the complexity of assessing the resilience and sustainability of suppliers and dealing with a variety of criteria.

Here, a couple of topics are suggested for prospective scholars. There might be dual-role factors in supplier selection problems. The dual-role factors are the factors that play the role of inputs and outputs, simultaneously. Developing a new DEAHP model in the existence of dual-role factors can be an interesting topic. In this paper, we proposed our new model based on the SBM model. However, there are other DEA models such as range adjusted measure (RAM), free disposal hull (FDH), and enhanced Russell graph measure (ERGM). Using the mentioned models, new DEAHP models can be developed.

Notes

Due to the request of most suppliers, we cannot disclose the name of suppliers.

References

Aczél, J., & Saaty, T. L. (1983). Procedures for synthesizing ratio judgements. Journal of Mathematical Psychology, 27(1), 93–102.

Ahi, P., & Searcy, C. (2015). An analysis of metrics used to measure performance in green and sustainable supply chains. Journal of Cleaner Production, 86, 360–377.

Ahmady, N., Azadi, M., Sadeghi, S. A. H., & Saen, R. F. (2013). A novel fuzzy data envelopment analysis model with double frontiers for supplier selection. International Journal of Logistics Research and Applications, 16(2), 87–98.

Alexander, A., Walker, H., & Naim, M. (2014). Decision theory in sustainable supply chain management: A literature review. Supply Chain Management, 19(5–6), 504–522.

Almasi, M., Khoshfetrat, S., & Rahiminezhad Galankashi, M. (2021). Sustainable supplier selection and order allocation under risk and inflation condition. IEEE Transactions on Engineering Management, 68(3), 823–837.

Amindoust, A. (2018). A resilient-sustainable based supplier selection model using a hybrid intelligent method. Computers & Industrial Engineering, 126, 122–135.

Amindoust, A., Ahmed, S., Saghafnia, A., & Bahreininejad, A. (2012). Sustainable supplier selection: A ranking model based on fuzzy inference system. Applied Soft Computing, 12(6), 1668–1677.

Azadi, M., & Farzipoor Saen, R. F. (2013). A combination of QFD and imprecise DEA with enhanced Russell graph measure: A case study in healthcare. Socio-Economic Planning Sciences, 47(4), 281–291.

Azadi, M., Izadikhah, M., Ramezani, F., & Hussain, F. K. (2020). A mixed ideal and anti-ideal DEA model: An application to evaluate cloud service providers. IMA Journal of Management Mathematics, 31(2), 233–256.

Azadi, M., Jafarian, M., Farzipoor Saen, R. F., & Mirhedayatian, S. M. (2015). A new fuzzy DEA model for evaluation of efficiency and effectiveness of suppliers in sustainable supply chain management context. Computers & Operations Research, 54, 274–285.

Azadi, M., Mirhedayatian, S. M., Farzipoor Saen, R., Hatamzad, M., & Momeni, E. (2017). Green supplier selection: A novel fuzzy double frontier data envelopment analysis model to deal with undesirable outputs and dual-role factors. International Journal of Industrial and Systems Engineering, 25(2), 160–181.

Azar, A., Zarei Mahmoudabadi, M., & Emrouznejad, A. (2016). A new fuzzy additive model for determining the common set of weights in data envelopment analysis. Journal of Intelligent & Fuzzy Systems, 30(1), 61–69.

Bajec, P., Tuljak-Suban, D., & Zalokar, E. (2021). A distance-based AHP-DEA super-efficiency approach for selecting an electric bike sharing system provider: One step closer to sustainability and a win-win effect for all target groups. Sustainability, 13(2), 549.

Balf, F. R., Zhiani Rezai, H., Jahanshahloo, G. R., & Hosseinzadeh Lotfi, F. (2012). Ranking efficient DMUs using the Tchebycheff norm. Applied Mathematical Modelling, 36(1), 46–56.

Banker, R. D., Charnes, A., & Cooper, W. W. (1984). Some models for estimating technical and scale inefficiencies in data envelopment analysis. Management Science, 30(9), 1078–1092.

Bazaraa, M. S., Jarvis, J. J., & Sherali, H. D. (2008). Linear programming and network flows. John Wiley & Sons.

Bhutta, K. S., & Huq, F. (2002). Supplier selection problem: A comparison of the total cost of ownership and analytic hierarchy process approaches. Supply Chain Management: An International Journal, 7(3), 126–135.

Bottani, E., Murino, T., Schiavo, M., & Akkerman, R. (2019). Resilient food supply chain design: Modelling framework and metaheuristic solution approach. Computers & Industrial Engineering, 135, 177–198.

Carter, C. R., & Rogers, D. S. (2008). A framework of sustainable supply chain management: Moving toward new theory. International Journal of Physical Distribution & Logistics Management, 38(5), 360–387.

Chan, F. T., Kumar, N., Tiwari, M. K., Lau, H. C., & Choy, K. (2008). Global supplier selection: A fuzzy-AHP approach. International Journal of Production Research, 46(14), 3825–3857.

Charnes, A., Cooper, W. W., & Rhodes, E. (1978). Measuring the efficiency of decision making units. European Journal of Operational Research, 2(6), 429–444.

Chul, P. S., & Lee, J. H. (2018). Supplier selection and stepwise benchmarking: A new hybrid model using DEA and AHP based on cluster analysis. Journal of the Operational Research Society, 69(3), 449–466.

Cooper, W. W., Seiford, L. M., & Zhu, J. (2011). Handbook on data envelopment analysis. Springer. ISSN: 978-1-4419-6150-1.

Dai, J., & Blackhurst, J. (2012). A four-phase AHP–QFD approach for supplier assessment: A sustainability perspective. International Journal of Production Research, 50(19), 5474–5490.

Davoodi, A., & Rezai, H. Z. (2012). Common set of weights in data envelopment analysis: A linear programming problem. Central European Journal of Operational Research, 20(2), 355–365.

Demirtas, E. A., & Üstün, Ö. (2008). An integrated multi-objective decision making process for supplier selection and order allocation. Omega, 36(1), 76–90.

Dutta, P., Jaikumar, B. & Arora, M. S. (2021). Applications of data envelopment analysis in supplier selection between 2000 and 2020: A literature review. Annals of Operations Research, 1–56.

Dyson, R. G., Allen, R., Camanho, A. S., Podinovski, V. V., Sarrico, C. S., & Shale, E. A. (2001). Pitfalls and protocols in DEA. European Journal of Operational Research, 132(2), 245–259.

Fahimnia, B., & Jabbarzadeh, A. (2016). Marrying supply chain sustainability and resilience: A match made in heaven. Transportation Research Part e: Logistics and Transportation Review, 91, 306–324.

Farzipoor Saen, R. F. (2007). Suppliers selection in the presence of both cardinal and ordinal data. European Journal of Operational Research, 183(2), 741–747.

Giannakis, M., Dubey, R., Vlachos, I., & Ju, Y. (2020). Supplier sustainability performance evaluation using the analytic network process. Journal of Cleaner Production, 247, 119439.

Hendiani, S., Mahmoudi, A., & Liao, H. (2020). A multi-stage multi-criteria hierarchical decision-making approach for sustainable supplier selection. Applied Soft Computing, 94, 106456.

Ho, W., & Ma, X. (2018). The state-of-the-art integrations and applications of the analytic hierarchy process. European Journal of Operational Research, 267(2), 399–414.

Hosseini, S., Morshedlou, N., Ivanov, D., Sarder, M. D., Barker, K., & Al Khaled, A. (2019). Resilient supplier selection and optimal order allocation under disruption risks. International Journal of Production Economics, 213, 124–137.

Ishizaka, A., Balkenborg, D., & Kaplan, T. (2011). Does AHP help us make a choice? An experimental evaluation. Journal of the Operational Research Society, 62(10), 1801–1812.

Ivanov, D. (2018). Revealing interfaces of supply chain resilience and sustainability: A simulation study. International Journal of Production Research, 56(10), 3507–3523.

Izadikhah, M., & Farzipoor Saen, R. (2020). Ranking sustainable suppliers by context-dependent data envelopment analysis. Annals of Operations Research, 293(2), 607–637.

Jabbarzadeh, A., Fahimnia, B., & Sabouhi, F. (2018). Resilient and sustainable supply chain design: Sustainability analysis under disruption risks. International Journal of Production Research, 56(17), 5945–5968.

Jain, N., & Singh, A. R. (2020). Sustainable supplier selection under must-be criteria through fuzzy inference system. Journal of Cleaner Production, 248, 119275.

Karsak, E. E., & Dursun, M. (2014). An integrated supplier selection methodology incorporating QFD and DEA with imprecise data. Expert Systems with Applications, 41(16), 6995–7004.

Keskin, B., & Köksal, C. D. (2019). A hybrid AHP/DEA-AR model for measuring and comparing the efficiency of airports. International Journal of Productivity and Performance Management, 68(3), 524–541.

Korpela, J., Lehmusvaara, A., & Nisonen, J. (2007). Warehouse operator selection by combining AHP and DEA methodologies. International Journal of Production Economics, 108(1–2), 135–142.

Kull, T. J., & Talluri, S. (2008). A supply risk reduction model using integrated multicriteria decision making. IEEE Transactions on Engineering Management, 55(3), 409–419.

Kuo, K. C., Lu, W. M., & Dinh, T. N. (2021). An integrated efficiency evaluation of China stock market. Journal of the Operational Research Society, 72(4), 950–969.

Lai, P. L., Potter, A., Beynon, M., & Beresford, A. (2015). Evaluating the efficiency performance of airports using an integrated AHP/DEA-AR technique. Transport Policy, 42, 75–85.

Lin, M. I., Lee, Y. D., & Ho, T. N. (2011). Applying integrated DEA/AHP to evaluate the economic performance of local governments in China. European Journal of Operational Research, 209(2), 129–140.

Luthra, S., Mangla, S. K., Xu, L., & Diabat, A. (2016). Using AHP to evaluate barriers in adopting sustainable consumption and production initiatives in a supply chain. International Journal of Production Economics, 181, 342–349.

Marchese, D., Reynolds, E., Bates, M. E., Morgan, H., Clark, S. S., & Linkov, I. (2018). Resilience and sustainability: Similarities and differences in environmental management applications. Science of the Total Environment, 613, 1275–1283.

Mirhedayatian, S. M., & Farzipoor Saen, R. (2011). A new approach for weight derivation using data envelopment analysis in the analytic hierarchy process. Journal of the Operational Research Society, 62(8), 1585–1595.

Moats, M., Alagha, L., & Awuah-Offei, K. (2021). Towards resilient and sustainable supply of critical elements from the copper supply chain: A review. Journal of Cleaner Production, 307, 127207.

Parkouhi, S. V., Ghadikolaei, A. S., & Lajimi, H. F. (2019). Resilient supplier selection and segmentation in grey environment. Journal of Cleaner Production, 207, 1123–1137.

Pishchulov, G., Trautrims, A., Chesney, T., Gold, S., & Schwab, L. (2019). The voting analytic hierarchy process revisited: A revised method with application to sustainable supplier selection. International Journal of Production Economics, 211, 166–179.

Rakhshan, S. A., Kamyad, A. V., & Effati, S. (2015). Ranking decision-making units by using combination of analytical hierarchical process method and Tchebycheff model in data envelopment analysis. Annals of Operations Research, 226, 505–525.

Ramanathan, R. (2006). Data envelopment analysis for weight derivation and aggregation in the analytic hierarchy process. Computers & Operations Research, 33(5), 1289–1307.

Ramanathan, R. (2007). Supplier selection problem: Integrating DEA with the approaches of total cost of ownership and AHP. Supply Chain Management: An International Journal, 12(4), 258–261.

Ramezankhani, M. J., Torabi, S. A., & Vahidi, F. (2018). Supply chain performance measurement and evaluation: A mixed sustainability and resilience approach. Computers & Industrial Engineering, 126, 531–548.

Rashidi, K., & Cullinane, K. (2019). A comparison of fuzzy DEA and fuzzy TOPSIS in sustainable supplier selection: Implications for sourcing strategy. Expert Systems with Applications, 121, 266–281.

Rashidi, K., Noorizadeh, A., Kannan, D., & Cullinane, K. (2020). Applying the triple bottom line in sustainable supplier selection: A meta-review of the state-of-the-art. Journal of Cleaner Production, 269, 122001.

Rezaei, J., & Ortt, R. (2013). Multi-criteria supplier segmentation using a fuzzy preference relations based AHP. European Journal of Operational Research, 225(1), 75–84.

Saaty, T. L. (1980). The analytic hierarchy process. McGraw-Hill.

Saaty, T. L. (1990). An exposition of the AHP in reply to the paper “remarks on the analytic hierarchy process”. Management Science, 36(3), 259–268.

Sakib, N., Hossain, N. U. I., Nur, F., Talluri, S., Jaradat, R., & Lawrence, J. M. (2021). An assessment of probabilistic disaster in the oil and gas supply chain leveraging Bayesian belief network. International Journal of Production Economics, 235, 108107.

Sarkar, S., Pratihar, D. K., & Sarkar, B. (2018). An integrated fuzzy multiple criteria supplier selection approach and its application in a welding company. Journal of Manufacturing Systems, 46, 163–178.

Schoemaker, P. J., & Waid, C. C. (1982). An experimental comparison of different approaches to determining weights in additive utility models. Management Science, 28(2), 182–196.

Scott, J. A., Ho, W., & Dey, P. K. (2013). ‘Strategic sourcing in the UK bioenergy industry. International Journal of Production Economics, 146(2), 478–490.

Sevkli, M., Lenny Koh, S. C., Zaim, S., Demirbag, M., & Tatoglu, E. (2007). An application of data envelopment analytic hierarchy process for supplier selection: A case study of BEKO in Turkey. International Journal of Production Research, 45(9), 1973–2003.

Sharma, R., Kamble, S. S., Gunasekaran, A., Kumar, V., & Kumar, A. (2020). A systematic literature review on machine learning applications for sustainable agriculture supply chain performance. Computers & Operations Research, 119, 104926.

Singh, S., & Aggarwal, R. (2014). DEAHP approach for manpower performance evaluation. Journal of the Operations Research Society of China, 2(3), 317–332.

Sinuany-Stern, Z., Mehrez, A., & Hadad, Y. (2000). An AHP/DEA methodology for ranking decision making units. International Transactions in Operational Research, 7(2), 109–124.

Sun, L., Wang, Y., Hua, G., Cheng, T. C. E., & Dong, J. (2020). Virgin or recycled? Optimal pricing of 3D printing platform and material suppliers in a closed-loop competitive circular supply chain. Resources, Conservation and Recycling, 162, 105035.

Talluri, S., Narasimhan, R., & Nair, A. (2006). Vendor performance with supply risk: A chance-constrained DEA approach. International Journal of Production Economics, 100(2), 212–222.

Tang, Y., & Yang, Y. (2021). Sustainable e-bike sharing recycling supplier selection: An interval-valued Pythagorean fuzzy MAGDM method based on preference information technology. Journal of Cleaner Production, 287, 125530.

Tavassoli, M., Farzipoor Saen, R., & Zanjirani, D. M. (2020). Assessing sustainability of suppliers: A novel stochastic-fuzzy DEA model. Sustainable Production and Consumption, 21, 78–91.

Tayyab, M., & Sarkar, B. (2021). An interactive fuzzy programming approach for a sustainable supplier selection under textile supply chain management. Computers & Industrial Engineering, 155, 107164.

Thomas, A., Byard, P., Francis, M., Fisher, R., & White, G. R. T. (2016). Profiling the resiliency and sustainability of UK manufacturing companies. Journal of Manufacturing Technology Management, 27(1), 82–99.

Tone, K. (2001). A Slacks-Based Measure of Efficiency in Data Envelopment Analysis. European Journal of Operational Research, 130(3), 498–509.

Tsai, F. M., Bui, T. D., Tseng, M. L., Ali, M. H., Lim, M. K., & Chiu, A. S. (2021). Sustainable supply chain management trends in world regions: A data-driven analysis. Resources, Conservation and Recycling, 167, 105421.

Visani, F., & Boccali, F. (2020). Purchasing price assessment of leverage items: A data envelopment analysis approach. International Journal of Production Economics, 223, 107521.

Wang, G., Huang, S. H., & Dismukes, J. P. (2004). Product-driven supply chain selection using integrated multi-criteria decision-making methodology. International Journal of Production Economics, 91(1), 1–15.

Wang, Y. M., & Chin, K. S. (2009). A new data envelopment analysis method for priority determination and group decision making in the analytic hierarchy process. European Journal of Operational Research, 195(1), 239–250.

Wang, Y. M., Chin, K. S., & Poon, G. K. K. (2008). A data envelopment analysis method with assurance region for weight generation in the analytic hierarchy process. Decision Support Systems, 45(4), 913–921.

Yadav, V., & Sharma, M. K. (2015). An application of hybrid data envelopment analytical hierarchy process approach for supplier selection. Journal of Enterprise Information Management, 28(2), 218–242.

Yu, Y., Zhu, W., Shi, Q., & Zhuang, S. (2021). Common set of weights in data envelopment analysis under prospect theory. Expert Systems, 38(1), 12602.

Zahiri, B., Zhuang, J., & Mohammadi, M. (2017). Toward an Integrated Sustainable-resilient Supply Chain: A Pharmaceutical Case Study. Transportation Research Part e: Logistics and Transportation Review, 103, 109–142.

Zarei Mahmoudabadi, Z., Azar, A., & Emrouznejad, A. (2018). A novel multilevel network slacks-based measure with an application in electric utility companies. Energy, 158, 1120–1129.

Zhan, Y., Chung, L., Lim, M. K., Ye, F., Kumar, A., & Tan, K. H. (2021). The impact of sustainability on supplier selection: A behavioural study. International Journal of Production Economics, 236, 108118.

Zhang, X., Lee, C. K. M., & Chen, S. (2012). Supplier evaluation and selection: A hybrid model based on DEAHP and ABC. International Journal of Production Research, 50(7), 1877–1889.

Zhu, Q., Dou, Y., & Sarkis, J. (2010). A portfolio‐based analysis for green supplier management using the analytical network process. Supply Chain Management: An International Journal.

Acknowledgements

The authors would like to thank constructive comments of two anonymous Reviewers.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Azadi, M., Moghaddas, Z. & Farzipoor Saen, R. Assessing resilience and sustainability of suppliers: an extension and application of data envelopment analytical hierarchy process. Ann Oper Res (2022). https://doi.org/10.1007/s10479-022-04790-5

Accepted:

Published:

DOI: https://doi.org/10.1007/s10479-022-04790-5