Abstract

The study presents the results of neutron activation analysis (NAA) of contemporary pottery from Tigray Regional State, northern highland Ethiopia. This is the first regional-scale study of ceramic composition of Tigray’s pottery and is part of an ethnoarchaeological study of the material and social contexts of pottery production and consumption in Tigray’s Eastern (Misraqawi), Central (Mehakelegnaw), and North-western (Semien Mi’irabawi) zones. The analysis identifies clear compositional groups with strong regional patterns, an encouraging result for the use of NAA to study Tigray’s ancient pottery trade. Significantly, the study further contributes to discussions of how mutually constituted social identities of potters and consumers affect compositional patterning in the distribution of pottery in market networks.

Résumé

L’étude présente les résultats de neutron activation analysis (NAA) de la poterie contemporaine de l’État régional de Tigray, dans les hautes terres du nord de l’Éthiopie. Ceci est la première étude régionale de la composition céramique de la poterie du Tigray et fait partie d’une étude ethnoarchéologique des contextes matériels et sociaux de la production et de la consommation de poteries dans le Tigray oriental (Misraqawi), central (Mehakelegnaw) et nord-ouest (Semien Mi ‘irabawi) zones. L’analyze identifie des groupes de composition clairs avec des modèles régionaux forts, un résultat encourageant pour l’utilization du NAA pour étudier le commerce de la poterie ancienne de Tigray. De manière significative, l’étude contribue également aux discussions sur la façon dont les identités sociales mutuellement constituées des potiers et des consommateurs affectent la structuration de la composition de la poterie dans les réseaux de marché.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

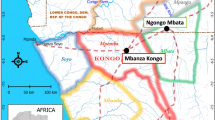

The results of neutron activation analysis (NAA) of contemporary pottery from Tigray Regional State, northern highland Ethiopia are presented. This is the first regional-scale ceramic compositional analysis of Tigray’s ceramics and is one aspect of a long-term ethnoarchaeological project that investigates social and material contexts of pottery production in Tigray’s Eastern (Misraqawi), Central (Mehakelegnaw), and North-western (Semien Mi’irabawi) zones (Fig. 1). The study contributes to the investigation of ceramic trade in this region and to discussions of how social contexts of marginalized and casted pottery production and consumption affect ceramic compositional patterning.

Some of Africa’s earliest complex societies developed in Tigray including the Pre-Aksumite polities of the first millennium BCE, the Aksumite kingdom of the first millennium CE, and the Ethiopian state of the second millennium CE. The rise of these polities is strongly associated with elite participation in long-distance trade that linked northeast Africa, southern Arabia, the Red Sea, and the Indian Ocean (e.g., Curtis 2008; Lunde and Porter 2004; Phillipson 2012), and Aksumite pottery has been found in ancient ports in India and on the Red Sea coast (Tomber 2005; Zazzaro et al. 2014). To date, scientific analyses of Tigray’s archaeological ceramics are limited to petrographic analyses of samples from specific sites and time periods, and to specific elite vessel-types (e.g., de Roux 1976a, b; Gautier 1976; Porter 2004; Weiss et al. 2016; Wolf and Nowotnick 2010). NAA was conducted previously on only four archaeological specimens from Yeha (Al Kital et al. 1969). Only Harlow’s (2011) MA thesis on contemporary eastern Tigray pottery, which is part of this project, has combined NAA and mineralogical analysis of non-elite functional ware.

Compositional studies of contemporary utilitarian pottery at a regional scale can inform future investigation of trade in the region’s past, including comparative data to query histories of production areas and the differences between elite and non-elite trading patterns over time. We neither suggest nor anticipate that pottery production and resource areas remained unchanged for 3000 years, but it is reasonable to assume that if contemporary pottery forms clear compositional groups in each of the three study areas, then it is likely that ancient pottery made in these areas will do so as well. It should be remembered that contemporary pottery is the current manifestation of the region’s ceramic history. As more ceramic compositional analysis is conducted in Tigray, archaeologists will situate contemporary production into longer-term practices to produce a clearer understanding of the region’s social, technological, and economic history. We caution that the sample size is small—241 ceramic and raw material specimens—and should be considered as a starting point for future analysis.

The overall objective of this project is to determine how contexts of casted/marginalized pottery are materially and spatially constituted. We recognize that ceramic composition alone is insufficient evidence to infer that pottery was made by casted or marginalized potters. Such inference requires multiple lines of evidence that were collected by this project. This evidence includes documentation of all stages of pottery chaînes opératoires, additional interview material provided by project participants, maps of potter and non-potter villages, plans of potter and non-potter domestic compounds, and comparative studies of other occupational specialists. A series of papers will address this rich dataset, but only a portion of this data can be adequately addressed here. In this paper, we explore how contexts of casted/marginalized pottery production and its consumption affect compositional patterning at sub-regional and regional scales, in order to move the understanding and discussion of these contexts and their variability forward.

Sampling Strategy and Methods

This study was conducted over five field seasons between 2007 and 2015 in northern Tigray. Pottery-making was investigated in villages in Eastern Tigray east of the market towns of Edaga Hamus and Sinkata, in and near the towns of Yeha and Gendebta in Central Tigray, and in and near the town of Selekeleka in North-western Tigray (Fig. 1). In interviews, potters were asked about their pottery-making history, learning networks, changes that they had experienced in pottery practices over time, where they collected raw materials and problems associated with accessing these materials, seasonality of pottery-making, preferred markets and changes in market patterns, product volume, types of vessels produced, customer preferences and tastes, potter relationships with the mainstream community, and their experiences of marginalization over time. Studies of pottery chaînes opératoires included querying the choices that potters use to collect clay and temper and to make ceramic paste. We accompanied potters to temper and clay extraction sites when possible, but clay mining was so contentious in some communities that we did not visit them in case our presence would make matters worse. Landholders of clay sources were interviewed separately to determine their perspectives on potters and clay mining. Consumers and merchants were interviewed in markets and in their homes to determine where they purchased pots, criteria for selecting pottery in the market, their views on changes in pottery markets over time, and their perspective on potters and pottery production. Fired pottery was collected directly from potters interviewed, from potter and non-potter households in house-to-house survey, and fired pottery was purchased from potters in markets. We asked potters interviewed in markets the name of their home villages to determine potential trade and variability within and among study areas. In the eastern study area, Diana Harlow (2011) obtained 100–200 g specimens of raw clay and temper from potters and from geological sources that potters claimed to use. All specimens were exported to the University of Calgary with permits issued by the Ethiopian Authority for Research and Conservation of Cultural Heritage (ARCCH) and the Geological Survey of Ethiopia.

Fired vessels from the North-western and Central Tigray study areas were broken to obtain approximately 1 cm2 specimens that were sent to MURR for NAA. The ceramic and raw material specimens were prepared and analyzed following MURR’s standard practices thoroughly described elsewhere (Glascock 1992; Neff 2000). Harlow’s Eastern Tigray sample preparation varied slightly from MURR protocols in that ceramic specimens were ground to powder, and clay specimens were fired to 400 °C prior to submission. Data analysis consisted of visual inspection of elemental scatterplots. The potential for further multivariate statistical refinement and testing of the groups was limited due to the relatively small number of members in each of the identified groups. Groups were formed without any bias of geographic origin and the strong resulting geographic patterns revealed in the groups serves as additional support for the validity of the group assignments.

Geological Context

Tigray is located on the northern Ethiopian plateau, a topography of high flat-topped hills and deeply incised river valleys with a complex geology (Beyth 1972; Tesfamichael et al. 2010, pp. 11–12). Tectonic events uplifted the eastern edge of the northern plateau, which rises 3100 m asl and tilts westward dropping about 1000 m in elevation from the eastern to the north-western study area over a distance of approximately 155 km. The eastern study area has a surface geology of Enticho sandstone composed mainly of quartz (Avigad et al. 2007, pp. 90–93), which is underlain by Adigrat sandstone composed mainly of quartz and secondary minerals including clays (Getaneh 2002, p. 186) used by the potters. Mineralogical analysis indicates that these clays are composed mainly of quartz, albite, and kaolinite, the only clay mineral found in the eastern clay sample (Harlow 2011, p. 43, 54–55). Geology east of Edaga Hamus is comprised of the Pre-Cambrian Matheos and Didikama rock formations (Geological Survey of Ethiopia and Kazmin 1973) that are sources of schist and talc tempers (Harlow 2011, pp. 43–44).

The central and north-western study areas have a basement of crystalline rocks covered by sedimentary rocks (Takazze sandstones) overlain by the Ethiopian Plateau flood basalts that were intruded by trachytic lavas and syenite in the form of plugs and domes (Abbate et al. 2015, p. 56; Ferrari et al. 2015). These are part of a regional magmatic district that includes the Aksum-Adwa phonolite-trachyte volcanic field that extends from Enda Selassie to Adigrat (Natali et al. 2013, Fig. 1).

Social Context and Compositional Analysis

In many societies in sub-Saharan Africa, certain categories of artisans form endogamous castes or communities of occupational specialists that are socially marginalized for practicing a despised craft (e.g., Lyons 2014; Wade 2012). Casted/marginalized artisans experience similar prejudicial treatment from other members of society, although the nature and degree of these practices varies considerably across Africa and even between different types of craft within the same society. Casted/marginalized artisans experience insults, sometimes violence, and they are often subjected to social avoidance practices by members of mainstream society. These include proscriptions against sex and intermarriage, the sharing of food and drink, spatial segregation within communities or regions, and artisans can be restricted from holding land, political office, and accessing community resources (e.g., Arthur 2006, 2014; David 2012; Frank 1998; Freeman and Pankhurst 2003; Kohtamaki 2010; LaViolette 2000; Lyons 2014; Robion-Brunner 2010; Wayessa 2016). Society may perceive artisans as different categories of people who can be feared for their occult capacities and/or ritual impurity (Dilley 2000; Sterner and David 1991; Van Beek 1982). Caste and occupational specialization are viewed by researchers as part of the process of forming complex societies (Haaland and Haaland 2007; Smith 2013; Tamari 1991, 2005), and these practices also structure social differences and inequities in the daily life of ordinary people.

Despite its significance, the origin of casted/marginalized craft production is yet to be materially demonstrated. Ethnoarchaeologists and archaeologists have begun to use pottery chaînes opératoires to infer local, regional, and even continental interactions and histories of casted and non-casted potter groups (e.g., Dietler and Herbich 1998; Gosselain 1994, 2001, 2008a, b; Gosselain and Livingstone Smith 2005; Livingstone Smith 2000; Mayor 2010; Stahl et al. 2008; Sterner and David 2003). The chaînes opératoires approach assumes that the potter’s technological choices at each stage of pottery production are learned as a member of a potter community. The suite of technological choices of a given potter community forms their technological style or material identity. These identities are not imposed by researchers, but are explicitly recognized by potters, customers, and other potter communities as part of a specific potter group’s identity (e.g., Nicklin 1979; Gosselain 2008b, p. 72; Mahias 1993). Technological styles are not static, and potter communities respond to sociopolitical change and interaction with other groups by modifying paste recipes (e.g., Gijanto 2011; Gokee 2011), adopting new practices (e.g., Gosselain and Livingstone Smith 2005; Mayor 2010), or as a means for potters to change their identity consciously (Gosselain 2008a, p. 173). The potter’s technological choices in selecting raw materials and preparation of ceramic paste are demonstrably affected by social practice (Gosselain and Livingstone Smith 2005).

The combined social context of pottery production and its consumption is often absent in ceramic studies (see Dietler and Herbich 1994; Stahl 2016), even though this relationship is critical to understanding how assemblages form and change over time, and how pottery becomes geographically distributed. In particular, where pottery is only produced by marginalized or casted potters, then both the potter’s and customer’s identities are mutually constituted in the production and consumption of pottery in daily practice. Dilley (2010) demonstrates that this process of identity-making can include consumer practices of ignorance. For instance, in Tigray, non-potters often claim ignorance of pottery skills and knowledge, even when this is untrue, because they believe that those who embody this knowledge are morally inferior people (Lyons and Freeman 2009). The question asked here is: How do consumers affect ceramic compositional patterning in contexts where social identity matters in the making and purchasing of pots?

Dean Arnold (2000), a recognized authority of ceramic compositional analysis, concluded that because there are so many social, environmental, and other factors that affect paste composition, it can tell us very little about the social organization of production. However, Arnold’s research in the Americas did not include contexts where potters were stigmatized. In Africa, potters have different social status that includes, but is not limited to, potter castes, socially marginalized but not casted potters, and contexts where anyone can make pots and sell them as a market commodity. Researchers working in West and Central Africa (Gosselain 2001, 2008a, b, 2016; Gosselain and Livingstone Smith 2005; Livingstone Smith 2000; Livingstone Smith and Van der Veken 2007-2009) suggest that endogamous potter groups have a more restricted membership and produce more homogeneous paste recipes than non-endogamous ones at the micro-local scale, because pottery knowledge circulates where potters live, interact, and constitute their identities, and where they sell their pots from their backyard or local markets. Livingstone Smith’s (2000) research in the Faro Department of Cameroon concluded that potters could collect clay from the same source but prepare the clay and proportion the temper differently depending on where and how they learned to make paste. Potters had three types of social status in the Faro Department: potters who were members of the blacksmith caste, female potters from the blacksmith caste who were married to farmers and who could participate in village life, and Muslim groups where pottery-making was not casted but was perceived as socially demeaning. Livingstone Smith mapped paste preparation techniques into four geographic zones that matched the three types of potter social status. When the potters’ social status was combined with language, the regional patterning of technical practices coincided with regional identities. These studies raise the possibility that social contexts of production affect ceramic compositional patterning. What is needed are comparable studies to better understand if and how different social contexts of production and consumption produce different compositional patterns across landscapes.

Study Areas

A total of 122 potters were interviewed in the three study areas, and many potters were interviewed multiple times. Additional interviews were conducted with potters in markets, local administrators, merchants, and with farmer-consumers in all areas. All potters were female, ethnically Tigrayan, Tigrinya-language speakers, and members of the Ethiopian Orthodox Tewahedo Church. Most potters work full-time and rely on pottery for all or a significant part of their household incomes, although some griddle-makers in eastern Tigray were part-time specialists. Pottery is made from mid-September to mid-June and stops when summer rains make it too difficult to mine clay and temper, to fire pots, and to carry them to market. Potters stated that they adhere to Sunday and religious holiday proscriptions against heavy work, but they can decorate and/or burnish pots on these days. Potters are not found in all villages or districts of Tigray and potters and customers stated that they thought this was because they lacked clay in those areas, and for the reason that most people do not like making pots because of its stigma. In a previous study in the Gulo-Makeda district 35 km north of Edaga Hamus, Lyons and Freeman (2009) found that even where raw materials were readily available, and women knew how to make their own griddles and cooking bowls (tsahale), they did so clandestinely and infrequently and preferred to purchase pots in the market because pottery-making was viewed as shameful. Only four potters were located in the Gulo-Makeda study area, three from the same family, and they rarely made pots for sale. The term “potter village” used in this paper refers to villages where large numbers of women (e.g., 20% or more of village households) produce market pottery as a significant component of their household economy. Potter villages tend to cluster spatially, and often specialize in producing vessels (atro), bread-baking griddles (mogogo), or more recently coffee pots (jebena). Coffee drinking was discouraged by the church as a pagan custom, but it was consumed by nineteenth-century elite (Pankhurst 1990, p. 314–316), and older farmers interviewed stated that it became popular in rural areas after the 1960s/1970s.

Tigray’s contemporary market potters are marginalized and most potters claimed to have become potters out of economic necessity, with exceptions noted below. Women learn from neighbors and sometimes kin, but the act of embodying pottery skills and knowledge and using these skills to make pots for market is socially viewed as shameful, polluting, and dangerous to the potters, their children, and the well-being of other people and the environment (see Lyons 2014). While prejudice has lessened in recent years, Tigrayan society still considers marriage with potters to be disgraceful, potters tend to marry within pottery village clusters, they are insulted in public, and they can be victims of violence particularly when mining clay. Until the late twentieth century, Beta Israel women—members of a Jewish subgroup known derogatively as Kayla in Tigray and as Falasha in the highlands more broadly—produced pottery and formed an endogamous caste in Ethiopia’s Central highlands and in Tigray’s North-western and Central zones (Crummey 2000; Quirin 2010; Salamon 1999). The Beta Israel were evacuated to Israel during and following Ethiopia’s civil war (1974–1991). Despite proscriptions against intermarriage, a few Beta Israel women married Christians in the Selekeleka area during the twentieth century or earlier and spread pottery-making to nearby communities. Today, Christian potters in Ebalay, located 2 km north of Selekeleka, claim to make pottery using the same methods taught to them by their Beta Israel teachers. The relationship between the Beta Israel and Central Tigray potters is unclear but like Selekeleka area potters, contemporary potters in Central Tigray are adamant that they are not Kayla. Nevertheless, several vessel-makers interviewed in Adi Keshi and Demba Arr Arr, located 2 km northeast of Yeha, and in Adinfas in the Gendebta area, were married to carpenters, another craft that is associated, but not exclusively so, with the Beta Israel (Salamon 1999, p. 32). Several potters in Adi Keshi and Demba Arr Arr stated that they were expected to become potters after marrying into these villages.

All of the potters said that they are reluctant to teach their daughters to make pottery and want them to have better occupations. However, potters’ daughters are legitimate peripheral learners (Lave and Wenger 1991) who help collect raw materials and fuel, decorate pots, and carry pots to market. They observe their mothers making pots in daily practice. Potters work alone in domestic workshops after a short apprenticeship, but they continue to learn and to teach others when they gather to mine temper, and when they travel as a group to clay sources and markets. Gosselain (2016) refers to these locations as the potters’ “spaces of experience” or Wenger’s (1998) “geography of practice,” where potters have face-to-face interaction with other potters and share pottery information, and where they encounter customer tastes and expectations. These interactions are further situated in shared historic relations and experiences (see Gosselain 2016, p. 49) and sub-regional identities (Lyons 2007). Routine market interactions of potters and customers, all coming from different villages in each sub-region, facilitate constellations of shared pottery practices, assemblages, and esthetics that contribute to the geographic distribution of Tigray’s three sub-regional wares (see Gosselain 2016, p. 46; Roddick and Stahl 2016; Wenger 1998). Each sub-region’s ware is unique but composed of a common assemblage. Sub-regional identities, including those materialized in sub-regional wares, are nested in larger regional-scale identity-making processes, evident in assemblage and culinary commonality.

Raw Material Acquisition, Processing, and Paste-Making

This is not a comprehensive survey of all pottery-making communities in northern Tigray, but the three study areas represent three distinct wares: unburnished blackware in the Eastern Zone, burnished orangeware in the Central Zone (including some small highly burnished black pots), and slipped redware in the North-western Zone. All three wares have similar assemblages composed of the same functional types to produce similar cuisine with the same heat treatments. However, each of these wares has a distinct chaîne opératoire and esthetic.

Eastern Tigray

Fifty-five potters were interviewed between 2007 and 2010 in seven pottery-making villages and a sole potter in one community located east of Edaga Hamus and Sinkata (Fig. 2). The two largest potter villages are Adi Ayfela and Aba Makreita, and a large number of griddle-makers are located in two other villages: Mariam Agamat and Hadush Adi. Adi Ayfela and Aba Makreita have the preferred temper and clay sources respectively. Potters in these two villages have an arrangement to share clay and temper sources with each other and to some extent with other potter villages in this cluster, although many griddle-makers in Hadush Adi used closer clay and temper sources. People interviewed on the history of local pottery production stated that vessel-making was an ancient practice in Adi Ayfala, Adi Geba, and in Aba Makreita. Griddle-making in the other villages was introduced by women from Sinkata in the 1990s. Older potters and customers, including those from Gulo-Makeda, stated that Edaga Hamus was always eastern Tigray’s big pottery market, but it had declined in the past decade. Pottery exchange in this area was disrupted by warfare during the civil war and the Ethiopian-Eritrean border dispute (1998–2000). Elderly Gulo-Makeda farmers recalled that Edaga Hamus area potters, and others from Adigrat and Debra Damo, came to their villages to sell pots during the civil war. Older potters also recalled taking their pots at night to Sinkata and Adigrat markets when daytime movement was restricted by threat of enemy bombers. Merchants bought their pots in Adigrat and sold them in Eritrea. One potter claimed that they did more business with Eritrea than Tigray during the civil war. Potters also remembered that merchants came from Hawzen to Sinkata market to purchase their pots, but they got better prices in Adigrat. Prior to the Ethiopian-Eritrean border dispute, Zalambessa was a large market town on the Eritrean border located 60 km north of Edaga Hamus. Zalambessa potters also sold pots in Gulo-Makeda and the Edaga Hamus market. Zalambessa was destroyed in 1998, the border was closed, and customers in Gulo-Makeda stated that this caused markets in Fatsi (a small local market) and Adigrat to expand. Very few Edaga Hamus area potters sold in Adigrat market in 2005, and some stated that Adigrat was now too far, comments that reflect the reality of changing consumer tastes. Gulo-Makeda farmers stated that they bought more plastic and metal vessels in the early 2000s because there were no potters in their area, and because industrial products were “cleaner” and more “modern.”

Ninety-six specimens were submitted for NAA from eastern Tigray. The sample included 32 raw clay specimens obtained from geological sources (including 3 comparative specimens from Adi Ahoune located in Gulo-Makeda) or directly from the potters who claimed to use these sources; 25 raw temper specimens collected from potters and geological sources; 22 fired clay specimens obtained directly from potters; and 17 fired pots purchased in local and regional markets.

Temper specimens were submitted for X-ray diffraction (XRD) analysis to the University of Alberta. The results demonstrate that the three main temper outcrops mined by the potters were chlorite schist at Adi Ayfela, a micaceous schist at Hadush Adi, and talc at Hadush Adi (Harlow 2011, pp. 88–89). A talc source was also located in Adi Ayfela. Mines varied from shallow pits to deep caverns and tunnels cutting several meters into the source. Temper is mined in coarse pieces and then beaten on bedrock with a wooden baton into coarse powder that is sieved with a fine fraction winnowing basket (manfeet) (ca. 0.5 × 0.1 cm screen).

Harlow’s (2011, pp. 54–55) laser diffraction particle size analysis of seven clay samples obtained from potters’ clay sources found that the quantity of clay content ranged from ca. 18–31% (common in sub-Saharan raw materials, see Gosselain and Livingstone Smith 2005), and the only clay present is kaolinite, an inelastic clay for potting. Clay is dried in the sun, levigated in a pot of clean well-water, and stones and plant material are removed manually. Levigation improves kaolin workability (Rice 1987, p. 118). In all three areas, levigation produced a slightly thickened liquid clay that is mixed with temper in volume ratios of about 2 temper: 1 clay. Potters all stated that too much clay causes the vessels to crack.

All potters claimed that clay is only found in grazing land, even though clay is available in river valleys, and all clay sources including Aba Makreita are in grazing land. Gosselain and Livingstone Smith (2005) found that in cross-cultural ethnographic studies in sub-Saharan Africa, potters come to perceive that clay is found only in certain areas of their environment, even when this is not true. We suggest that the perception that clay is found only in grazing land is related to women’s traditional land rights. Grazing land was village communal land and the only place where poor local women, who had no land tenure rights until 1993, could source clay. Older women said that at that time they could collect clay from these sources freely. After the civil war, the government allocated grazing land to individual landholders, who now try to prevent potters from mining historic sources because it causes soil erosion, it damages grass grown for livestock, and because potters profit from land that is not their own. Potters stated that the situation forces them to “steal” the clay at night, early in the morning, or when the owner is absent. Potters work individual pits and dig down through a red clay or soil to the desired fine black clay that they describe as having little grit when “tasted” with the teeth. The process is done quickly, frequently in the dark, and the women risk being beaten if caught. A few potters said that they negotiate for clay with landholders at times, but they would not disclose these arrangements. The problem of accessing clay has increased in the past few decades as large numbers of women turned to pottery-making as a consequence of poverty triggered by war, drought, and poor agricultural production.

Central Tigray

Twenty-nine potters and 18 non-potters were interviewed in 12 communities in and near Yeha and south of Yeha in the Gendebta area (Fig. 3), and 20 potters, merchants, and wholesalers were interviewed in 6 local markets in 2015. Eighty-one fired pottery specimens were collected directly from potters and merchants in local markets and submitted for NAA. The main vessel-making community in the study area today is Adi Keshi but women also claimed to have made pottery in adjacent Demba Arr Arr until recently; Casey encountered isolated vessel-makers in the Gendebta area, and several coffee-pot makers stated that they came from potter families. Coffee-pot makers are dispersed in Adi Bahari, Adinfas, and Gendebta in the Gendebta area. Customers and potters described Yeha market as an enormous pottery market with all types and sizes of pots until about 2005, when plastic and metal containers gutted the market. A demand for Gendebta coffee pots developed in the past decade with an estimated 500 potters now engaged in this industry. Coffee pots are mainly commissioned by local wholesalers from Gendebta and Adi Bahari who sell these into regional and national networks as far as Addis Ababa. Potters also sell coffee pots directly to customers in Gendebta, Adwa, and Yeha markets.

Yeha potters stated that they freely access a friable light pink-colored stone that has a fine-grained texture, possibly trachyte or phonolite (de Roux 1976a; Weiss et al. 2016), for temper. Temper is said by potters to occur everywhere and is mined from surface deposits. The Adi Keshi temper source is located on a volcanic plug north of the village in a place called Wutu or Wuta. Gendebta potters collect temper from many exposed sources in their area. Temper is dried and then ground into powder using an old saddle quern (metahan) and is often used unsieved.

Weiss et al. (2016, p. 241) report that contemporary potters use clays present in fluvial deposits found along river banks and on mountain slopes near Yeha, observations compatible with our own. Adi Keshi potters stated that they use a black sticky clay, (possibly smectite), free from grit that balls when pressed between the fingers. Potters also claimed that clay is freely mined along the river valley east of Adi Keshi (Fig. 3). Until 2010, clay was mined on a hillslope on the eastern side of Adi Keshi, but this land was recently allocated to a landholder who stated that she stopped potters from taking the clay because it caused soil erosion. Potters found a new source nearby that they said was a good one.

Gendebta area potters described the experience of accessing clay as dangerous and difficult, a problem related to the rapid development, intensity, and scale of the coffee pot trade. Potters identified four local clay sources but would not show us these locations for fear of retaliation from landholders. One man in his eighties reported that at least two of these were old sources used by both his wife and mother. In 2015, potters claimed that they rotate between sources to avoid conflict with owners and usually take clay at night without permission. Potters stated that problems in accessing clay, the need to use multiple sources, and the recent large-scale specialization in coffee pots has resulted in a shift from the preference for fine black clay to a grayish yellow or brown clay found at the same sources.

Potters process clay in the same way as do potters in Eastern Tigray; clay is dried in the sun, pounded, or ground and then sieved with a manfeet before levigation in a pot of clean well-water, and other materials are removed manually. The liquid clay is mixed with temper in volume ratios of 2 temper: 1 clay. Central Tigray potters also claim that too much clay makes vessels crack.

North-Western Tigray

Eighteen potters, two wholesalers, and four merchants were interviewed in eight communities in and near Selekeleka in 2015 (Fig. 4). The main vessel-making communities are Ebalay and Dershan, and the griddle-making communities are Akatsl and Selekeleka. Griddle-making in Akatsl was introduced by a Beta Israel woman from Ebalay who married an Akatsl man during the civil war. She taught her Christian neighbors griddle-making to improve their economy and in 2015, 422 of 472 Akatsl households relied on this industry for household income. Sixty-three fired-pottery specimens were collected from potters and non-potters in these communities for NAA.

Vessel-makers use a highly friable light-colored stone temper (possibly syenite) from exposed bedrock in Ebalay and Dershan, and griddle-makers mine a friable red or white stone temper from several sources near Akatsl. A second light-colored temper that easily crumbles to fine powder is also mined near Akatsl. One potter stated that she adds this second temper to her paste to give her griddles a good ringing sound called katchel when tapped with a stone, a feature that draws customers. All temper is either pounded or ground and then sieved with a coarse-fraction winnowing basket (mihea) with a ca. 1.1 × 0.3 cm screen.

All Ebalay and Dershan vessel-makers stated that they freely access the same clay sources used by their Beta Israel teachers from surface deposits on the south side of Ebalay. These potters claimed that good pots cannot be made with only one type of clay; rather, they mix equal volumes of yellow clay (bula) and black clay (lema). The yellow clay is soaked in water to form a workable mass. In a manner similar to the other two study areas, the black clay is levigated resulting in a liquid clay from which stones are removed manually. The black clay is very elastic and, based on potters’ descriptions, bula helps to temper its elastic quality in order to build stronger vessels. Vessel-makers combine equal volumes of each of the two clays with an equivalent volume of temper to the total mixed-clay volume (e.g., paste is at least 50% temper). Potters apply a fine red clay slip to the surfaces of all pots and griddles before firing. The slip clay comes from a source in Akatsl and from termite soil (guila) or laterite found in Adi Keyeti north of Selekeleka.

Akatsl and Selekeleka griddle-makers use black clay (lema) that they must take surreptitiously from private grazing land located in the neighboring community of Akabsat, or from less-preferred sources in Akatsl and a farmer’s field in southeast Selekeleka. Taking clay causes tension with farmers, but Akatsl and Akabsat potters stated that the potters have a reciprocal arrangement to share temper and clay sources in their respective communities, similar to the practice reported in eastern Tigray between Adi Ayfela and Aba Makreita. Clay is sun-dried, ground, and then levigated in a pot with well-water. Stones and debris are removed manually from the liquid clay. Griddle-makers use the same paste recipe as their counterparts in eastern Tigray (60% temper by volume), and some griddle-makers make thick cooking bowls with the same paste. Cooking surfaces on griddles and cooking bowls are painted with the red clay slip as well, mixed with a small amount of an unknown variety of vegetable oil, and burnished before firing to achieve a very red color.

Contemporary Pottery Distribution Networks

Large market centers are located along the major highway running north-south in the eastern study area through Wukro, Sinkata, Edaga Hamus, and Adigrat and east-west from Adigrat through Enticho, near Yeha, Gendebta, Adwa, Aksum, Selekeleka, and Enda Selassie with smaller market centers along secondary roads. These trade routes have considerable antiquity (Sernicola and Phillipson 2011; Wolf and Nowotnick 2010) but very little is known of early market history. Today, markets in each sub-region occur on a weekly schedule, and pottery production is organized to meet the potter’s preferred markets. Potters use commercial vehicles to transport pots if they can circumvent transport regulations that prohibit moving pots in mini busses, and if they can afford both the fee and pottery breakage in this mode of transport. Otherwise, potters transport pots by foot or more rarely by donkey. Most potters rent space in shops or leave pots with a relative or friend to sell in future market days rather than transporting them home. Potters in all areas reported that since the civil war, big pot sales had declined because of the availability of cheap and lighter-weight plastic and metal containers. There was also a shift during this time from payment for pots with grain to cash, although grain is still exchanged in some areas.

Today, potters distribute pots in five networks described below.

1. Potter’s home

Many potters claimed to never sell pots from their homes, and most farmers also stated that they purchased their pots in local and regional markets. However, some potters in eastern Tigray and in Yeha said that they sometimes make pots for local women who either supply some or all of the raw materials in exchange for half of the pot cost, or who come to their homes and order pots on commission. Older potters bitterly recall farmers similarly confronting them in their homes with lumps of clay and/or temper, demanding them to make pots. It is possible that potters prefer to sell in the market with a group in order to avoid local abuse on their doorstep. In all the markets, potters sit together based on their pottery specialization and home village, and state that they support one another and socialize.

2. Local markets (≤ 20 km from potter’s village)

All potters sold pots in at least one large market located within 20 km of their village, and all large potter villages are located within 2–10 km of at least one large market. Potters in the eastern study area have two large markets—Edaga Hamus and Sinkata—that occur on the same day, a situation created during the civil war by the Derg government, who changed many markets to Saturday. Edaga Hamus (literally “Thursday market”) was one of the markets shifted to Saturday. Potters tend to go to the closest of these two markets, but they may have sold pots in both when the markets were on different days. Depending on vessel size, and if potters’ children help carry pots, potters in all areas produce 5–12 pots per week, and griddle-makers 3–15 griddles per week. Potters carry pots to local markets on their backs and in their hands. One Yeha area potter recalled that about 50 years ago she and her mother-in-law routinely walked to Mezbir and Ahssa markets, both located within 20 km from their home, carrying 3–5 pots each, walking 2 to 3 h in each direction. This was when there was a much greater demand for pots. Today, most potters receive commissions in the market and deliver orders either in the market or to the customer’s home or business. Most of the potters stated that market commissions come from regular customers who are familiar with the quality of their pots. Potters bring large pots to market only if they are purchased on commission because they are heavy and demand for them is low.

3. Long-distance markets (20–40+ km from the potter’s village)

Eastern Tigray potters stated that there were fewer potters in Adi Ayfela in the recent past, and these potters traveled as a group to more distant markets by foot or truck. These markets are all within the Eastern Administrative Zone, within a 40-km radius of Adi Ayfela, and include Hawzen, Wukro, Atsbi, and Adigrat markets. Older Ayfela farmers also stated that they traveled to Hawzen market to purchase their pots in the past. Today, some Central Tigray potters from Yeha and Gendebta travel 28 km by foot west to Adwa market, and Michels (2005, p. 35) claimed that Yeha’s potters were the main suppliers of pottery to Adwa market in 1974. One wholesaler also claimed to take large pots from the Gendebta/Yeha area to Humera 380 km west. In the Selekeleka area, griddle-makers routinely sell in or near Enda Selassie 30 km west. In 2015, only one Selekeleka potter sold griddles and cooking bowls in Axum market (37 km east), but Michels (2005, pp. 35, 41) claims that Selekeleka’s Beta Israel were the main suppliers of pots in Axum’s market in 1974. The Beta Israel told Michels that they sold pots directly from their backyard, and had other people sell their pots in markets. In 2015, Ebalay potters also told Lyons that their parents sold the Beta Israel’s pots in Selekeleka and Axum because both markets fell on Saturday, the Jewish Sabbath. For several decades, many Ebalay and Dershan vessel-makers and/or wholesalers have taken their pots by truck to markets at Sheraro (ca. 70 km northeast) and Humera (ca. 300 km west) where potters stated that there are no resident potters. One potter told us that sometimes pots are still exchanged for grain in Sheraro.

4. Itinerant potters

Potters traveled to some non-potter villages until the late 1990s. Farmers in Adi Ahoune recalled that one potter came from Debra Damo each year to make beer cups (shashat) and used local clay and temper, although one customer thought that she brought her own temper. Some Yeha potters traveled once or twice to Humera to make pots for the local population because they had no potters, and one merchant stated that he took clay from Yeha to Humera for the potters to make pots. One of these potters told us that the clay in Humera was poor for making pots, but researchers warn that potters’ perceptions of the workability of unfamiliar clays and tempers are socially learned and unreliable as evaluations of different raw materials (Gosselain 1994; Nicklin 1979). Indeed, one potter in Demba Arr Arr traveled to make pots in a village in Western Tigray; she found the clay and temper to be good there and was uncertain why there were no local potters.

5. Wholesalers

Small-scale traders routinely purchase small numbers of pots from potters in markets and distribute these through sub-regional market networks. The Afar, who are Muslims and consider pottery-making to be demeaning, also buy coffee pots in Edaga Hamus market to take to the Danakil. Wholesalers move much larger volumes of pots over regional, national, and sometimes international boundaries. Wholesalers work in all three areas. In eastern Tigray, potters state that Hawzen merchants purchase their pots in Sinkata and Edaga Hamus markets and sometimes from their homes, but these merchants’ networks are unknown. In 1974, Selekeleka’s Beta Israel potters were renowned for making high-quality pots. Wholesalers purchased their pots in Axum market and distributed them to markets in Asmara, Gondar, and Addis Ababa (Michels 2005, p. 41). Today, mostly male wholesalers contract griddle-makers in Akatsl and Selekeleka and coffee-pot makers in the Gendebta area. Potters and wholesalers stated that the wholesaler arranges truck transport to pick-up contracted vessels at an agreed-upon location on the road and near potter villages. Each griddle-maker produces 20–30 griddles per week for their wholesaler, and coffee-pot makers produce 30–40 per week. Wholesalers stated that these pots are taken to urban centers including Axum, Gondar, Mekelle, and Addis Ababa where they are sold to other merchants. One Gendebta wholesaler took pots to Mekelle and Humera with stops along the way. He has a constant demand for large water and beer pots in Humera, Sheraro, and Gondar that he purchases from two potters in Amoai, about one hour’s walk from Gendebta. He claimed that he could sell 1000 pots every month but can only transport 30 pots per month on a grain truck (the full grain sacks protect the big pots in transit). An Adi Bahari merchant takes coffee pots to Mekelle and said that all of the best coffee-pot makers are under contract to long-distance wholesalers, who sell their pots in Mekelle and Addis Ababa. One shop keeper in Mekelle specifically requests pots from his best coffee-pot maker.

In sum, potters in all three areas routinely distribute their pottery up to 40 km from their homes, and some potters today or in the recent past traveled to sell or to make pots well beyond this distance. Small-scale merchants distribute pots to other markets in sub-regional networks. In all three areas, wholesalers move pots across zonal boundaries, and in some cases circulate specific pot types at national and international scales.

Consumers

Pottery production and distribution are affected by consumer tastes and shared histories of interaction. In all three areas, potters and consumers stated that their main criterion in selecting pots is durability, although potters claimed that good decoration was important to urban customers. Potters attract market customers by tapping vessels with a stone to make a ringing sound which shows the strength of their vessels, which one potter in Akatsl claimed was enhanced by using a specific temper, as noted above. Temper forms a minimum of 50–60% of pottery paste in all areas. Eastern Tigray potters and their customers, including those interviewed in Gulo-Makeda, stated that pottery from the Adi Ayfela area was renowned in eastern markets for its durability, which they attributed to the quantity and quality of Adi Ayfela temper. Customers state that they can gauge the amount of temper by looking at the surface of the pots, and potters reported that customers demand “lots of temper” (similar requests for clay types are reported in Niger by Gosselain 2008a, p. 163). Edaga Hamus potters were disdainful of a white talc temper mined near Adigrat and sold in eastern markets. This temper gives pottery fabric a similar sheen to the Adi Ayfela schist temper, but potters were unanimous in the belief that this “counterfeit” would produce weak pots. Nevertheless, talc temper sources, including one in Adi Ayfela, are mined and used by potters including griddle-makers in the eastern study area. One Gendebta coffee-pot wholesaler considered Gendebta pots to be the most durable, followed by those from Adi Bahari, and then Adinfas. Durability is an important concern for wholesalers who transport pots over long-distances.

Potter reputation is linked to vessel durability. Consumers in all three regions perceive that quality pots are made by skilled potters who use the “correct” clay and temper. Many potters claimed regular market customers who know the quality of their vessels through personal experience, and Yeha potters provide customers with a guarantee to replace pots that break to maintain good customer relations and their reputations. Reputation is also linked to known historic potter communities. The Adi Keshi potters near Yeha, like those from Adi Ayfela in eastern Tigray, have a history of quality pottery production that draws market customers. Selekeleka potters appropriated the Beta Israel’s reputation as producers of high-quality pottery because they use the Beta Israel’s manufacturing practices and clay and temper sources. However, reputation does not eliminate prejudice. Akatsl griddle producers stated that customers, who suspect that the potter tempered the griddle with salt instead of rock temper, will taste the griddle with their tongue before purchase.

Only Central Tigray potters claimed that customers select vessels by form, stating that vessel bodies must be shaped “like a ball.” Gendebta area coffee-pot makers were particularly concerned with decoration. We speculate that the reason for this is because most coffee pots are contracted by wholesalers who distribute them to distant markets, where individual potter reputation has no consumer value and where urban consumers are thought to be attracted by decoration.

Neither customers nor potters were familiar with pottery from other sub-regions, beyond limited observation of the few pots brought by traders to sell in large markets and the few who had traveled. One woman in Adi Keshi had a blackware beer fermentation pot (tserma) that her mother-in-law purchased decades ago in Adigrat. This was one of three eastern blackware vessels observed in any context outside of eastern Tigray. The other two vessels are a sherd from a potter’s yard in Adi Keshi and a vessel in Mekelle market (see below). While there are formal distinctions in the pottery assemblages in the three sub-regional wares (Lyons forthcoming), a basic difference of these wares is color. Unburnished eastern blackware is made black by smudging vessels at the end of firing. If pots come out of the smudge “red,” then they are fired again to make them black. Potters stated that only black pots are attractive to customers in eastern markets; in the eastern and north-western study areas, potters and customers stated that they would not buy Central Tigray orangeware pots, because they perceived them to be less durable and thought that they would break in the fire. Selekeleka potters apply a red clay slip to vessels and griddles before firing because their customers prefer “very red pots.” Enticho is on the dividing line between orangeware and blackware and potters can sell both in its market. One coffee-pot maker from a village just east of Gendebta stated that a wholesaler from Adigrat bought orange and burnished black coffee pots from her village. If the wholesaler’s customers wanted more black pots, then he re-fired orange ones to make them black!

Compositional Analysis: Results

We have identified ten pottery compositional groups in the regional study that are subdivided into three primary clusters (Table 1). Clusters 1 and 2 are also groups 1 and 2 respectively, and cluster 3 is further divided into eight groups, each of which separates from the rest of the specimens in the cluster 3 sample. The small sample size prevents the use of robust multivariate statistical methods such as Mahalanobis distance calculations, but the groups separate well enough in elemental plots that further statistical justification is unnecessary.

Cluster 1 (n = 23)

All specimens in cluster 1 are from eastern Tigray and are tempered with chlorite schist. This cluster is separated from the other clusters by higher concentrations of chromium (Fig. 5). Further attempts to divide this cluster were unsuccessful, so cluster 1 is also group 1.

Cluster 2 (n = 17)

Cluster 2 separates from the rest of the sample by low concentrations of rare-earth metals (Fig. 5). These specimens were tempered with talc or micaceous schist. This group is more chemically diverse than group 1 and, as with cluster 1, there are no internal groupings so cluster 2 is group 2. Ten specimens in group 2 were collected in markets: nine in eastern Tigray and one from Mekelle market that is likely a trade item from eastern Tigray.

Cluster 3 (n = 143)

Cluster 3 is 78% of the total ceramic sample submitted for analysis. Cluster 3 comes from the Central and North-western study areas, and this cluster is further divided into eight groups (Table 1). While these eight groups share some compositional similarity based on a shared geology, they do not share the same production areas or raw material sources. There is no single elemental plot that shows the separation of the various groups within cluster 3, so the groups are described and justified in the order that they were identified. Important to provenance studies, these groups fall into geographic areas that are discussed further below.

Group 3a (n = 7)

Specimens in group 3a separate from the rest of cluster 3 by higher concentrations of tantalum and other rare-earth metals (Fig. 6).

Group 3b (n = 7)

Specimens in group 3b separate from the rest of cluster 3 by higher concentrations of cesium, scandium, and other elements. There is no clear pattern as to what groups of elements are driving the separation (Fig. 7).

Group 3c (n = 30)

Group 3c is the largest group within cluster 3. Specimens in group 3c separate from the rest of cluster 3 in having the lowest chromium concentrations within this cluster (Fig. 8).

Group 3d (n = 25)

Specimens in group 3d separate from the rest of cluster 3 by higher concentrations of cesium (Fig. 9). There is some overlap with group 3 members (see below).

Group 3e (n = 18)

Specimens in group 3e separate from the other specimens in cluster 3 in a plot of tantalum and hafnium (Fig. 10).

Group 3f (N = 3)

Group 3f is a small cluster of three specimens that separate from the other specimens in cluster 3 in plots of tantalum with numerous other elements including terbium and hafnium (Fig. 11). This sample is too small to determine the reason for its separation from the other members of cluster 3.

Group 3g (n = 27) and Group 3 (n = 26)

It is difficult to further separate group 3, but it was possible to identify a possible split (group 3g) with the remaining specimens classified in a more general group 3 (Fig. 12). Both groups 3 and 3g are entirely from the Central Tigray study area providing little justification for the separation; however, there are subtle differences in the ceramic types that might make the separation more meaningful.

Geographical Separation of Cluster 3 Groupings

The subtle separations of these eight groups from the rest of cluster 3 and from each other have strong geographical patterning (Table 2).

Central Tigray Groups 3, 3c, 3d, and 3g (n = 80)

All specimens in groups 3, 3d, and 3g (n = 80) come from the Central Tigray study area. Fourteen of 26 specimens in group 3 were collected in and near Yeha, and 11 of these specimens are from the Gendebta area. All but two specimens in group 3d (n = 23) come from the Gendebta area (the remaining two are from local markets), and all of these specimens are from coffee pots. The overlap in the plots of group 3 and group 3d (Fig. 9) make it possible that some specimens in group 3 could be assigned just as easily to group 3d.

Twenty-five of 27 specimens in group 3g come from vessels made in the Yeha area. The small variation between group 3 and group 3g is likely because 14 of 26 specimens in group 3 are from the Yeha area also.

North-Western Tigray Study Area Groups 3a, 3b, 3c, 3e, and 3f (n = 63)

There are subtle variations within these groups that separate by village and vessel type. All specimens in groups 3a (n = 7) and 3b (n = 7) and 20 of the 28 specimens in group 3c were collected from griddle-makers living in Akatsl and on the east side of Selekeleka (Table 2). Selekeleka griddle-makers all originate in Akatsl and they use the same sources. Only three of the 29 specimens from Akatsl are cooking bowls made of the same paste as griddles.

The remaining nine group 3c specimens in the north-west sample come from the vessel-making communities of Ebalay and Dershan. Two specimens in group 3c were obtained in Central Tigray, possibly as trade items (Table 1).

Sixteen of the 18 specimens in group 3e come from Ebalay and the remaining two come from Dershan. The compositional similarity of these two communities is likely because these vessel-makers use the same Ebalay clay sources. Some Dershan potters also take temper from the Ebalay source, but others took temper from sources closer to Dershan.

Ceramic Compositional Groups and Raw Materials

Raw materials for analysis were collected only in Eastern Tigray. This sample is unique in the clear compositional association of ceramic specimens and raw materials, which is rare in NAA of ancient ceramic samples. The reason for the compositional association may be because the raw material sampling is ethnographically informed or because of social factors that restrict access to raw materials discussed below.

Clay (n = 32)

All raw clay specimens are from eastern Tigray and have a remarkably uniform chemical signature. With one exception, all specimens plot within ceramic group 2. This close association of the clay with group 2 is shown in a scatterplot of chromium and tantalum values (Fig. 13). Specimen DHE055 is an exception and falls between group 1 and group 2. Clay in this specimen comes from the Daga geological source, the most easterly village in the eastern study area. DHE049 is a second specimen from this source; it falls in group 2, although it is slightly separated from other clay specimens in that cluster (Fig. 13). Both of these specimens show an enrichment in transition metals (especially Cr, V, and Sc) relative to all other clay specimens in the dataset (Boulanger and Glascock 2012, pp. 6–7). Three comparative raw clay specimens from Adi Ahoune (DHE001–003) show depletion in alkali metals (e.g., Rb, Na, K, Cs) and slight enrichment of titanium relative to other clay specimens analyzed. The Adi Ahoune and Daga specimens have distinctive compositions but too few specimens were submitted to evaluate these differences rigorously. Nevertheless, the chemical distinction in the two samples raises the possibility that local distinctions might be found in pottery within Tigray’s Eastern Zone.

Temper (n = 25)

The choice of talc or chlorite schist temper in Eastern Tigray separates the sample from this area into clusters 1 and 2. Temper group 1 (n = 14) is chlorite schist from Adi Ayfela and temper group 3 (n = 9) is talc temper from Hadush Adi (n = 9) (Fig. 14). Temper group 2 is composed of two specimens of talc temper, one from the geological source in Adi Ayfela and one from Adigrat market, probably from a source located near Adigrat. The separation of the Eastern Tigray sample (clusters 1 and 2) from cluster 3 from Central and North-western Tigray is the result of chemical distinctions in both clay and temper. The presence of talc temper will generally result in the apparent dilution of most trace elements because talc is primarily composed of elements not measured by NAA (Mg and Si), while schist temper will often have the opposite effect because schist is relatively enriched in many of the trace elements measured by NAA (Boulanger and Glascock 2013, p. 7). Specifically, the use of chlorite schist as a tempering agent results in an enhanced transition-metal profile (particularly chrome), specimens with micaceous schist are enriched in REEs with moderate levels of transition metals, and the use of talc is diluted in all elements including in REEs (Fig. 15). The Central and North-western Tigray samples have relatively higher concentrations of Rb, Ta, most REEs, and lower ones of most transition metals. The tempering of any clays in eastern Tigray with talc or schist temper will increase their chemical distinction from that of Central and North-western Tigray pottery. Geological specimens and specimens from potters using schist and talc sources showed that each geological source has a unique chemistry. Significant to provenance studies, the chloritic schist source at Adi Ayfela is variable in composition and significantly different from other temper-source specimens. In short, the geological sources of chlorite schist and micaceous schist/talc tempers reveal meaningful subgroup structures between and within mineralogy/lithology classifications. Micaceous pastes also characterize archaeological pottery from eastern Tigray in different time periods (D'Andrea et al. 2008, p. 164).

Market Samples

The market samples in Eastern Tigray were purchased in Edaga Hamus, Adigrat, Wukro, Hawzen, and Degum (Fig. 2). All specimens are blackware and all were assigned to ceramic groups 1 and 2. One specimen (DHE065) collected in Mekelle market (Tigray’s capital) (Fig. 1) was assigned to group 2 and is likely from eastern Tigray.

Boulanger and Glascock (2013, p. 7) determined that three specimens from Sinkata market (DHE167,169,170), and DHE100 from the yard of a potter in Adi Keshi, cluster together regardless of how the data are projected, suggesting that DHE100 is made of the same raw materials as the specimens obtained from Sinkata market 65 km away. These four specimens are chemically similar to two specimens (DHE018, DHE074) made by two potters from Aba Makreita in the eastern study area. DHE100 is from a fragment of a blackware beer cup (shashat), a type rarely made by potters in Central and North-western Tigray, but they were a common market specialization in Eastern Tigray until the recent availability of cheap plastic tumblers. The potters, who claimed to have made DHE018 and DHE074, both sold pottery in Sinkata market and one sold pottery to small-scale traders. DHE100 was likely traded from the Sinkata market by one of these potters or another Aba Makreita potter who used the same sources.

Nine samples dispersed in compositional groups 3a, 3b, and 3c are griddle specimens collected from electric stove shops in Axum, 30 km east of Selekeleka. The shopkeepers and griddle wholesalers confirmed that the griddles came from Akatsl and Selekeleka.

Discussion

Clear chemical distinctions between compositional groups in this study are the result of both clay and temper chemistry, but temper tends to have a stronger profile because it typically composes more than half of all paste recipes by volume. The strongest compositional distinction is between samples from Eastern and Central/North-western Tigray. Compositional groups from Central and North-western Tigray are classified as a single cluster arising from their common underlying geology. Subtle variations that separate Central Tigray and North-western Tigray compositional groups in cluster 3 likely are related to chemical variations in the common geology and in clays used in these areas. Because the presence or absence of certain kinds of temper is strongly controlled by local and regional geology, it is anticipated that pottery produced outside of these three study areas will have different compositional profiles. This hypothesis is supported by analysis of a limited sample obtained from neighboring village markets. All specimens of market pottery were easily distinguished from locally manufactured pottery in all areas.

Can paste composition inform archeologists about the social organization of pottery production? Arnold (2000) has argued that paste is uninformative in inferring social organization of production but he did not investigate contexts of casted and marginalized pottery production. For instance, Stahl (2016) used NAA and other physical analyses to demonstrate a link between pottery-making and metal-working from slag-tempered pottery in an archaeological context in Ghana. Stahl does not infer production by a smith-potter caste as is found in this area today, but her study shows that paste composition can contribute information on social contexts of production where potters and smiths were working closely. Ethnoarchaeological studies also can provide detailed information on social contexts of production by integrating contexts of consumption (see Dietler and Herbich 1994; Sillar 1997; Stahl 2016). We suggest that contexts of production and consumption have an effect on ceramic compositional patterning, particularly where different social identities of producers and consumers are mutually constituted in these practices as is the case of casted/marginalized pottery production in Tigray and possibly in similar contexts elsewhere.

Compositional group formation practices typically employed at MURR focus on developing clearly distinct groups, even if this requires leaving 20–30% of specimens unassigned. The dataset in this study is remarkable in the lack of any unassigned ceramic specimens. Typically, historic/ethnographic, as well as industrialized, production settings have lower rates of unassigned samples due to more uniform raw material use and relatively small numbers of producers. We suggest that potters’ marginalized status works similarly. Rice (1981) argued that where elites control clay sources, paste homogeneity increases because fewer sources are used for production, but Arnold (2000) found that when landholders demanded too much for their clay, potters just went elsewhere, resulting in greater paste variability rather than homogeneity. Again, Arnold studied potters who were not marginalized socially. Tigrayan potters have two contexts for clay access. In the historic vessel-making villages of Ebalay and Adi Keshi, potters freely access specific clay sources near their villages, and they are permitted to seek new local clay sources when needed. In the second context, where pottery production increased rapidly in scale and intensity in eastern Tigray, Akatsl, and Gendebta, village potters persist in taking clay surreptitiously from historically known sources in privately held grazing land because they cannot go elsewhere to source clay, and because they believe that appropriate clay is found only in grazing land. Both situations tend to homogenize paste composition of local potter communities because potters use few and rarely new sources (with the caveat that variation can occur within sources), sometimes with potter villages colluding to share sources that neither party owns. It is worth considering that the high temper content of paste recipes in all three areas is related to the widespread societal perception that potters endanger the fertility of people, land, and animals through clay mining (Lyons 2014). Only temper is collected without censure in the study areas. Temper sources are located in places potters and farmers in eastern Tigray described with terms meaning “antiseptic” or “sterile,” usually located on steep untillable land, similar to temper locations in the other two areas.

Previous ethnoarchaeological studies in West and Central Africa focused on potter social status and paste homogeneity, suggesting that practices of caste endogamy restricted membership in potter communities and produced homogeneous paste distributions at the micro-local scale. We suggest that what restricts membership in Tigray’s potter groups is not just endogamy or endogamy-like practices, but widely held societal perceptions that pottery-making is demeaning, polluting, and dangerous. Endogamy and these perceptions do not necessarily co-occur. When Tigrayan women choose to join a potter community of practice, they learn how to prepare paste using specific resources and recipes and other technological practices, and they become socially marginalized in the process of doing so. Marginalized potter communities of practice also produce homogeneous pastes at the local scale. While this is important in investigating trade from particular source areas, it does not explain compositional patterning across the region. In Tigray, the potters’ and consumers’ “spaces of experience” have constellated well beyond the micro-local scale. Tigrayan potters exchange some pots locally, but where potters are not uniformly scattered among villages as in the Central African cases, then market distribution is necessary sometimes over vast areas (e.g., Arthur 2014; LaViolette 2000). Ceramic compositional homogeneity is thought to dissipate in market distributions where many potters using many different sources sell to customers, who then take the pots to their respective villages (Arthur 2014). The question then is: Do casted/marginalized potters and their customers, who mutually constitute their differential social status in the making and selling of pots, create a different “consumption zone” of compositional patterning than do non-stigmatized potter specialists, whose relationship with customers is irrelevant to identity-making? In a study of Luo potters in Kenya, Dietler and Herbich (1994) found that a small number of market pottery specialists produced most of the pots used in a region through market distribution. Pottery-making and its consumption was unimportant in constituting Luo social identities. Pottery was distributed in markets as a commodity; consumers purchased pottery regardless of the identity of the potters and styles of their pots. This context is unlikely to produce a definable consumption zone because anyone can make pots, and anyone can buy them in the market. Dietler and Herbich (1994, p. 469) concluded, “As soon as the consumption group is larger than the production group, pottery becomes a product made for exchange; and exchange implies a change of context and meaning.” But this is not the case in Tigray where pottery-making matters to social identity-making of both producers and consumers.

Similar to the Luo, Tigray’s potters distribute the majority of their pots in markets within a 40-km radius of their homes. They differ from the Luo in that this distribution occurs within sub-regional geographic consumption zones of blackware, orangeware, and redware, and within a social context of casted/marginalized production and consumption that is held at the regional level. In all three study areas, pottery producers and consumers share the same ethnicity, language, and cuisine. Customers perceive that the ware produced in their sub-region is more durable and esthetically pleasing than that produced in other study areas. We found very little intrusion of outside wares into rural houses or markets visited in each sub-region despite substantive interconnecting road networks and the presence of small-scale traders and wholesalers. This is significant because it suggests that Tigray’s potters do not enjoy unlimited distribution of their products in markets beyond the sub-regional scale. We suggest that this is because esthetic tastes and material expectations of pots are created, modified, and reproduced through mutual interactions of potters and their principal sub-regional consumers over long-term interactions. It is important to consider that where society holds strong ontological perceptions of potters as polluting and inferior people, then consumers also constitute their identities of ritual purity and superior social status by being seen purchasing their pots. Although Vander Linden (2001) concluded that the ritually impure nature of the Dowayo potter caste in Cameroon precluded a privileged economic relationship with customers, Dowayo pottery was made only by a potter caste that was perceived to be ritually impure by other members of their society. While Dowayo potters used a variety of distribution practices, and Vander Linden argued that customers were only seeking the best pots from the best potters, their products were consumed by members of the same social group and rarely crossed ethnic boundaries. We suggest that buying a pot in Tigray is not just an economic transaction as suggested by Vander Linden for the Dowayo example, but a public performance of the purchaser’s and the potter’s relative status, regardless of whether individual customers select their pots based on their perception of individual potter reputations. Consumers determine pottery value and the potter’s economy either in the volume and type of grain exchanged for pots, or in what they are willing to pay in cash (Lyons 2014). Consumers shape pottery traditions by imposing their changing tastes and expectations on potter communities that serve their needs over time. In doing so, consumers are socially invested in the ware that a constellation of pottery-producing communities feed into markets in each sub-region. In this context, the potter-customer relationship circumscribes the geographic circulation and concentration of a specific ware, one that mutually constitutes social identities and ontologies shared by potters and consumers in their overlapping and long-term sub-regional spaces of experience. Consumers also play a role in sub-regional and regional identity-making. Distinct sub-regional identities are partly made material in sub-regional wares, but all three wares are composed of similar functional assemblages that format a common regional cuisine, which in turn helps constitute a regional identity. Market distribution creates compositional heterogeneity within each consumption zone, but this heterogeneity (e.g., the given set of participating communities of pottery practices) is limited by the social context of production and consumption.

Sub-regional wares circulate outside of consumption zones through wholesalers. At this geographic scale of production, social identities may not be constituted in the process of buying pots from retailers in distant markets. However, the social perception of the moral and social inferiority of potters is a widespread phenomenon in the northern and central highlands, and compositional patterning at this geographic scale remains untested.

Conclusion

This study demonstrates clear compositional patterns that separate the three study areas, showing strong potential to reconstruct regional-exchange patterns in Tigray using NAA. Nuances in the chemistry within compositional clusters and groups show potential to determine resource areas tied to specific sources. It is encouraging that potential trade items, while rare, were identified in the sample and possibly to the level of the village whence the specimen originated. Compositional clusters and groups identified also coincide with broader sub-regional esthetic divisions and distinct chaînes opératoires: eastern blackware, central orangeware, and north-western redware. Future research should include increased sampling in these study areas and in other potter communities in the region. We anticipate that the compositional groups presented here will be modified and further clarified with a larger sample. The study further suggests that that the social relationship between potter and consumer in a context of marginalized and casted pottery production can produce a geographically circumscribed consumption zone. Such a zone encompasses a limited number of pottery source areas, in contexts where social identities of potters and consumers are mutually constituted, and where these identities matter in daily practice. This could be further tested with additional ethnoarchaeological sampling in this region, and with compositional analysis from archaeological pottery across the region and from different time periods when it becomes available. This will contribute to understanding the history of casted/marginalized pottery production in this region in conjunction with other lines of evidence.

References

Abbate, E., Bruni, P., & Sagri, M. (2015). Geology of Ethiopia: A review and geomorphological perspectives. In P. Billi (Ed.), Landscapes and landforms of Ethiopia, world geomorphological landscapes (pp. 33–64). New York: Springer.

Al Kital, R. A., Chan, L.-H., & Sayre, E. V. (1969). Neutron activation analysis of pottery sherds from Hajar bin Humeid and related areas. In G. W. Van Beek & H. B. Humeid (Eds.), Investigations at a pre-Islamic site in South Arabia (pp. 387–398). Publications of the American Foundation for the Study of Man, 5). Baltimore: Johns Hopkins Press.

Arnold, D. (2000). Does the standardization of ceramic paste really mean specialization? Journal of Archaeological Method and Theory, 7(4), 333–375.

Arthur, J. W. (2006). Living with pottery: Ceramic ethnoarchaeology among the Gamo of southwestern Ethiopia. Salt Lake City: University of Utah Press.

Arthur, J. W. (2014). Pottery uniformity in a stratified society: An ethnoarchaeological perspective from the Gamo of southwest Ethiopia. Journal of Anthropological Archaeology, 35, 106–116.

Avigad, D., Stern, R. J., Beyth, M., Miller, N., & McWilliams, M. O. (2007). Detrital zircon U-Pb geochronology of cryogenian diamictities and Lower Paleozoic sandstone in Ethiopia (Tigrai): Age constraints on neoproterozoic glaciation and crustal evolution of the southern Arabian-Nubian shield. Precambrian Research, 154, 88–106.

Beyth, M. (1972). To the geology of Central-western Tigre. Doctoral dissertation, Rheinischen Friedrich-Wilhelms-Universitat, Bonn.

Boulanger, M., & Glascock, M. D. (2012). Ethnoarchaeological study of ceramic production in Eastern Tigray, Ethiopia. Third report on chemical characterizations of pottery, clay and temper. Unpublished report. Archaeometry Laboratory, University of Missouri Research Reactor.

Boulanger, M., & Glascock, M. D. (2013). Ethnoarchaeological study of ceramic production in Eastern Tigray, Ethiopia. Fourth report on chemical characterizations of pottery, clay and temper. Unpublished report. Archaeometry Laboratory, University of Missouri Research Reactor.

Crummey, D. (2000). Land and society in the Christian kingdom of Ethiopia. Urbana: University of Illinois Press.

Curtis, M. C. (2008). New perspectives for examining change and complexity in the northern Horn of Africa during the first millennium BCE. In P. R. Schmidt, M. C. Curtis, & Z. Teka (Eds.), The archaeology of ancient Eritrea (pp. 329–348). Trenton: Red Sea Press.

D'Andrea, A. C., Manzo, A., Harrower, M. J., & Hawkins, A. L. (2008). The pre-Aksumite and Aksumite settlement of NE Tigrai, Ethiopia. Journal of Field Archaeology, 33, 151–176.

David, N. (Ed.). (2012). Metals in Mandara Mountains society and culture. Trenton: Africa World Press.

de Roux, H. (1976a). Aperçu sur la fabrication de la poterie à Yéha (Tigré). Annale D’Éthiopie, 10, 305–316.

de Roux, H. (1976b). Note sur des tessons céramiques de Degum (Tigré). Annale D’Éthiopie, 10, 71–80.

Dietler, M., & Herbich, I. (1994). Ceramics and ethnic identity: Ethnoarchaeological observations on the distribution of pottery styles and the relationship between the social contexts of production and consumption. In D. Binder & F. Audouze (Eds.), Terre cuite et société: La céramique, document technique, économique, culturel. XIVe Recontre Internationale d'archéologie et d'histoire d'Antibes (pp. 459–472). Juan-les-Pins: Editions APDCA.