Abstract

We present an integrated microfluidic system for performing isolation and concentration of Phytophthora ramorum pathogens using a chip whose working principle is based on inertial lateral migration in curving flows. The chip was fabricated from multiple layers of thermoplastic polymers and features an embedded spiral separation channel along with peristaltic microvalves for fluidic operation and process control. A pumping system paired with a fully programmable pressure manifold is used to boost concentration levels by recirculating the sample liquid multiple times through the separation chip, making it possible to reduce sample volumes from 10 to 1 mL or less. The system was calibrated using fluorescent polymer particles with a nominal diameter of 30 µm which is comparable to that of P. ramorum sporangia. The separation process has been shown to be highly effective and more than 99% of the beads can be recovered in the concentrated batch. Experiments conducted with P. ramorum sporangia have shown that a 5.3-fold increase in pathogen content with 95% recovery can be achieved using three subsequent concentration cycles. The utility of the method has been validated by processing a sample derived from infested Rhododendron leaves where a 6.1-fold increase in the concentration of P. ramorum has been obtained after four concentration cycles. Although specifically designed and demonstrated for sporangia of P. ramorum, the method and related design rules can easily be extended to other microbial organisms, effectively supporting bioanalytical applications where efficient, high-throughput separation of target species is of primary concern.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Phytophthora ramorum is a fungal plant pathogen that can have a devastating effect on vegetation in both developed and natural ecosystems (Werres et al. 2001; Tomlinson et al. 2005; Bilodeau et al. 2014). For example, it is the causative agent for the disease called sudden oak death which largely diminished oak tree populations along the western coast line of the USA (Bilodeau et al. 2007). To prevent spreading and distribution of the pathogen, it is imperative that infected plant material is detected and disposed of as early as possible. Testing of survey samples such as leaves, water or soil is commonly performed by culture enrichment and microscopy assessment of colony isolates in combination with molecular diagnostic techniques such as polymerase chain reaction (PCR) where specific gene markers are targeted to identify the pathogen (Rizzo et al. 2005; Bilodeau et al. 2007, 2012; Bilodeau 2011; Martin et al. 2012). Potentially low inoculum densities of P. ramorum in environmental samples, however, require significant enrichment times, which is detrimental to obtaining a timely and reliable analytical response. In addition to improving concentration levels of the target organism, background flora and debris often need to be removed (e.g., through centrifugation or filtration steps) before the sample can be analyzed.

Lab-on-a-chip (LOC) technology is expected to complement and eventually replace traditional methods of sample preparation since it offers the prospect of isolating target organisms with high specificity, processing many samples in parallel, and reducing hands-on engagement. In addition, LOC systems promote the concept of miniaturization and portability so as to enable deployment in the field for on-site testing. With respect to P. ramorum, development efforts in LOC technology have been focused mainly on the detection rather than up-front isolation of the pathogen. For example, Julich et al. (2011) have integrated PCR amplification in combination with electrical readout of DNA hybridization events on a single chip which allows for identification of several Phytophthora species in a multiplex assay. With the notable exception of the bump array technique which has been used by Inglis et al. (2010) for the purification of fungal spores, LOC approaches have not yet been devoted to the separation and concentration of P. ramorum and plant pathogens at large.

Inertial focusing has emerged in recent years as an efficient, technically convenient method for sample preparation using LOC systems (Martel and Toner 2014). Inertial focusing takes advantage of hydrodynamic forces generated within a flowing liquid to bias particles into lateral equilibrium positions. As a result, continuous streams of self-aligned particles are formed within the microfluidic conduit which can be separated using designated sample collection ports. The separation process relies exclusively on the geometrical properties of the particles (e.g., their size and shape) and the velocity profile of the carrier flow (see Sect. 2.1 for details). The method has been demonstrated to be useful in sorting and fractionating cells into distinct populations (Nivedita and Papautsky 2013; Rafeie et al. 2016), microfluidic filtration and detection of pathogens in food samples (Clime et al. 2015a; Ganz et al. 2015) as well as transferring microbial organisms from a relatively complex sample matrix into a clean, co-flowing buffer fluid (Mach and Di Carlo 2010). Another possible application of using inertial focusing is to space cells out evenly with respect to one another, so they can be detected and counted more accurately by using flow cytometry (Hur et al. 2010; Kotz et al. 2013).

Herein, we present a low-cost, all-plastic microfluidic device for concentrating suspensions of P. ramorum pathogens using inertial focusing effects in curving flows (Segré and Silberberg 1961; Clime et al. 2015b). The system entails a set of integrated pneumatic microvalves for controlling liquid motion and has been designed to isolate and collect sporangia with high efficiency in order to lower the limit of detection in non-culture-based assays. Compared to the bump array technique already used in purification of fungal spores (Inglis et al. 2010), the approach presented here has the advantage of minimizing the total solid surface of the device while providing high concentration efficiencies with overall larger microfluidic features. In turn, the device offers the possibility of increasing throughput while enabling larger sample volumes (e.g., 10‒100 mL) to be processed in a reasonable time frame.

2 Concept and design considerations

2.1 Principles of inertial focusing

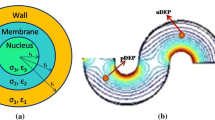

Liquid flows in microchannels are often associated with low Reynolds numbers (Re) and negligible inertia. Due to the laminar (streamline) character of these flows, liquids tend to propagate without lateral mixing and adjacent layers pass one another with no cross-currents perpendicular to the direction of flow. Moreover, at relatively high Péclet numbers (low diffusion regimes), colloidal suspensions of small, buoyancy-neutral particles usually follow the liquid streamlines all along the microfluidic device. This scenario is consistent with the Stokes approximation of the Navier–Stokes equations where inertial contributions to the fluid behavior are neglected as the fluid flow becomes completely predictable and no turbulences are observed. However, experimental studies of flows in circular pipes have shown that under certain circumstances, scattered flowing particles can focus in a reproducible manner on a narrow annulus (“tubular pinch effect”) of radius \( r_{0} = 0.63a \) where a is the radius of the pipe (Fig. 1a, b) (Segré and Silberberg 1961). The effect has been associated with the inertia of the liquid itself (Saffman 1965, 1968) since it is produced by a lateral force proportional to the square of the fluid velocity U that is \( F_{\text{l}} = 6\pi \rho R_{\text{p}}^{4} \left( {U/a} \right)^{2} f\left( s \right) \) where \( \rho \) is the density of the liquid, R p the radius of the particles and f(s) a tabulated phenomenological function that depends on the flow Reynolds number only (Fig. 1a) (Schonberg and Hinch 1989). This force pushes particles away from the center streamline toward the wall, vanishes at \( r = r_{0} \cong 0.63a \) and becomes strongly repulsive as the particles approach the wall (Fig. 1a). In pipes of circular cross section, buoyancy-neutral particles will migrate from the center toward the wall and form an annular distribution of radius \( r_{0} \) (Fig. 1b) (Segré and Silberberg 1961).

Basic principles of inertial focusing. a Graphical representation of the tabulated function \( f\left( s \right) \) for \( Re < 100 \) according to Schonberg and Hinch (1989). b–d Qualitative graphical representation of particle equilibrium positions after inertial focusing in channels of b circular, c square, and d rectangular, high-aspect-ratio cross sections. e Particle equilibrium positions in a curved channel with rectangular cross section in the presence of secondary (Dean) flows. f Microscopy image of a single P. ramorum sporangium obtained with a ×63 magnification lens

In the last few years, the inertial focusing effect has been scaled down to high-throughput separation and filtration applications that make use of microfluidic devices and rectangular cross sectional channels. It has been demonstrated that in such geometries the particles migrate to at least four stable equilibrium positions along the channel periphery (Fig. 1c). Moreover, these equilibrium positions can be reduced to two streams in channels of high-aspect-ratio cross section (Fig. 1d) (Mach and Di Carlo 2010; Kuntaegowdanahalli et al. 2009) or even to one single stream by employing curvilinear channel geometries and related Dean secondary flows (Fig. 1e) (Berger et al. 1983; Gossett and Di Carlo 2009). Compared to particle distributions in pipes of circular cross sections, these new equilibrium configurations have tremendous advantages in practical applications since separation and concentration of particles can be conveniently envisaged by designing proper bifurcations at the separation channel outlet. Several authors (Bhagat et al. 2008; Gossett and Di Carlo 2009) have extensively presented experimental results on the latter effect trying also to capture the observed behavior into simple diagrams or design rules based on dimensionless quantities such as Reynolds number (related to the flow and the particle, respectively) or Dean number. However, a complete description of the mechanisms responsible for inertial focusing effects in curved flows (“twin tubular pinch effect”) and related regimes has emerged only recently (Clime et al. 2015b).

The inertial focusing effect in curving flows is conditioned by two factors: (i) the size of the particles relative to the size of the pipe (channel) which has to be ratio of at least 0.08 (Kuntaegowdanahalli et al. 2009) and (ii) the Reynolds number associated with the liquid flow which has to be high enough so that the focusing occurs in a channel of finite (and reasonable) length (Clime et al. 2015b). In order to avoid formation of twin annuli and other unfocused streams of particles, the former condition has to be reinforced by imposing that (iii) the radius of the particles R p and the overall curvature radius of the channel R obey \( \delta = R_{\text{p}}^{3} R/a^{4} \ge 0.148 \) where \( \delta_{\text{c}} = 0.148 \) is a critical parameter responsible for the separation between two regimes: unfocused (“subcritical”) at \( \delta < \delta_{\text{c}} \) and focused (“supercritical”) at \( \delta > \delta_{\text{c}} \) (Clime et al. 2015b). To satisfy condition (ii), flow with a given Re should undergo a minimum number of turns \( N \ge 36/Re \) in order to obtain well-focused particle streams at the outlet (Clime et al. 2015b). These rules will be applied in Sect. 2.2 to the design of a microfluidic chip for concentrating P. ramorum sporangia. Although specifically formulated for pipes of circular cross section (Clime et al. 2015b), these rules can still be used for rectangular cross sectional channels by employing hydraulically equivalent physical quantities.

2.2 Channel configuration for the inertial focusing of P. ramorum

According to the above mentioned design rules, the geometry of the microfluidic channel for the inertial focalization of P. ramorum must be based on the shape and size of the pathogen itself. Generally, these pathogens present an ovoid shape (Fig. 1f) with an average hydraulic diameter between 20 and 40 μm (Werres et al. 2001). According to rule (i), the hydraulic diameter of the channel capable of focusing particles of this size should be \( D_{\text{h}} \le 250\;\upmu{\text{m}} \) when the smallest particle diameter (20 μm) is taken into account. Larger particles will be focused automatically since for larger particle diameters condition (i) is fulfilled as well. In order to comply with this condition, a separation channel with a depth h = 200 µm (measured on the out-of-plane direction of the chip) has been considered, which is smaller than the required critical hydraulic diameter D h. This ensures proper focusing of particles that are slightly smaller than 20 μm in diameter or are not perfectly spherical in shape, as can be the case for P. ramorum pathogens (Fig. 1f). As for the width of the separation channel, while larger values for this parameter are preferred—in order to achieve flow rates as high as possible—some limitations have to be taken into account. The most important is related to the topology with respect to induced Dean currents which should be kept as simple as possible as to preserve the laminar character of the flow (Dean 1927) and gather particles at unique focusing positions. Secondly, aspect ratios that are too large could induce undesired effects during filling (e.g., generation of air bubbles and parasitic currents) interfering with the inertial focusing mechanism itself. For our experiments, a channel width of w = 600 μm and an aspect ratio of \( \epsilon = w/h = 3 \) for the rectangular cross section have been considered a very good compromise for providing bubble-free continuous flow all along the separation channel as well as efficient and reproducible inertial focusing separation effects.

The two last parameters for the separation channel (radius of curvature and number of turns) are in direct relation with \( \delta \) defined above in (iii) that has to be always smaller than the critical value \( \delta_{\text{c}} = 0.148 \) (Clime et al. 2015b). For a critical size of the separation channel on the same order of magnitude as h, a curvature radius of at least 1.48 cm is obtained. To comply with this requirement, the channel used in this study has been provided with a curvature radius of \( R = 2\;{\text{cm}} \) on average. Moreover, a number of complete turns N = 3 have been considered such that a minimum value for the channel Reynolds number of \( Re = 36/N = 12 \) is ensured. For the separation channel described above, this corresponds to a minimum average flow velocity of \( U_{\text{av}} = 24 \;{\text{cm}}/{\text{s}} \) and a related flow rate of \( Q_{0} = 1.72\;{\text{mL}}/\hbox{min} \). Therefore, a flow rate of \( Q = 2\;{\text{mL}}/\hbox{min} \) has been used for all inertial separation experiments to comply with \( Q \ge Q_{0} \). The actual separation channel implemented on the chip is designed in the form of a spiral fluidic conduit with the inlet (i) at the center of the spiral and a bifurcated outlet by which diluted (d) and concentrated (c) sample liquids are circulated (Fig. 2a, b).

Design and configuration of the microfluidic system. a Exploded view of the chip with pneumatically controlled normally closed valves featuring four thermoplastic elastomer layers. The microfluidic layer L1 (red) accommodates the spiral separation channel, while the fluidic control layer L2 (blue) connects the channel ports \( i,d \) and c to the device outlets (C1–6) through the ports i′, d′ and c′, respectively. Two additional TPE layers—the pneumatic membrane layer L3 (dark gray) and a top layer L4 (light gray) comprising through-holes—are used to close the valves and connect both fluidic (C1–6) and pressure (P1–6) ports to standard Luer connectors (omitted for clarity). b Photograph of the chip after assembly. The fluidic channels have been filled with a colored (red) liquid for better visualization of the spiral separation channel and its fluidic connection to the external ports C1–6. Pressure channels connecting pressure ports P1–6 with the integrated microfluidic valves (V1–6) remained solely filled with air and are visible as light gray lines oriented parallel to the long axis of the chip. c Schematic illustration of the fluidic control system and connectivity for the inertial focusing chip. A programmable pressure manifold is used to control the pneumatic valves. Two syringe pumps are used to collect the sample (S) as well as concentrated (C) and depleted (D) sample liquids. The dashed line depicts the pathway of the depleted sample to the waste. The blue line illustrates the trajectories of both original and concentrated sample. d, e Optical micrographs showing the valve at closed and open positions, respectively. The air channel in (d) is pressurized with p v = 15 psi (1 psi = 6894.76 Pa). Elastic deformation of the membrane closes the fluidic pathway in the central area of the valve. The application of negative pressure (p v = ‒6 psi) detaches the membrane from the surface, giving way for fluid to pass from one side to the other as shown in (e). The flow direction is from bottom to top as indicated by the blue arrow. f Plot of p v versus p f along with linear fit curves and functions for V1 (triangles), V3 (diamonds) and V4 (open circles). The positions of these valves on the chip are detailed in (b) (color figure online)

2.3 Microfluidic chip

The microfluidic chip (Fig. 2a, b) is formed as a hybrid stack comprising four layers of thermoplastic polymer with rectangular geometry (5 by 10 cm). Implementation of the microfluidic conduit (C1‒6) along with coexisting pneumatic control channels (P1‒6) and deformable microvalves (V1‒6) allows for automation of sample manipulation while performing complex pumping protocols (as described in Sect. 2.4). The separation channel (contained in L1) is embedded with an auxiliary layer L2 which is used to connect each of the fluidic outlets to a Luer lock fitting at the upper surface of the chip. L1 is fabricated from a thermoplastic elastomer (TPE) (e.g., Mediprene), while L2 consists of a cyclic olefin copolymer (COC) (e.g., Zeonor). Both layers were processed using hot-embossing lithography (see Sect. 3.1 for details). The combination of TPE and COC is particularly useful since layers can be bonded together through conformal adhesion, developing strong, yet reversible contact at the interface (Roy et al. 2011; Geissler et al. 2014). Chips assembled in this way allow for safe, leak-proof manipulation of fluids beyond the specifications provided herein.

Pneumatic microvalves (Roy et al. 2011; Didar et al. 2013; Geissler et al. 2014) based on the actuation of a thin elastomeric membrane (implemented in L3) are used to control the flux of sample solution in and out of the separation channel. Valves are normally closed (Fig. 2d), while the pneumatic control layer is being connected to an external, home-built pressure manifold. To open the valve, negative pressure is applied to the pneumatic control channel, while liquid is pressurized inside the channel (Fig. 2e). To stop the flow, the manifold is switched to positive pressure, leading to the deformation of the membrane which closes the valve. We tested the resistance of the valves by filling fluidic channels with water and applying pressure to the valve (p v). For a given value of p v, we then increased the pressure of the fluidic channel (p f) until the valve started to fail (as indicated by liquid passing through the gap between the membrane and the seating surface of the fluidic control layer). A plot of p v against p f (Fig. 2f) reveals a linear dependency of the two parameters in the form of \( p_{\text{v}} = k\left( {p_{\text{f}} - p_{\text{b}} } \right) \). Here, \( p_{\text{b}} \) is a remnant parasitic pressure of about 4.4 psi originating from the mechanical properties of the elastomeric membrane and its adhesion to the interface. Parameter k is a dimensionless proportionality constant determined by the geometry of the fluidic channel and the valves (e.g., their width and depth) as well as the dimensions and physical properties of the membrane. We found k to be between 1.3 and 1.9. We attribute this variation to slight differences in the thickness of the membrane as well as inconsistency in the alignment with the seating surface. Using this equation, it is possible to calculate the bias pressure that needs to be overcome for lifting the membrane off the seating surface without applying any pressure on top of the membrane. In general, we found an applied pressure of 15 psi sufficient to firmly close the valves during operation.

2.4 Cyclic pumping

Another important concept used in the present work is to couple the microfluidic separation chip, the actuation pumps and the intermediate collection reservoirs (sample and waste) to an external pneumatic manifold (Fig. 2c), enabling the recirculation of the concentrated sample from the outlet (cc′) back to the inlet (ii′) until a desired level of concentration is achieved, while at the same time, depleted sample collected at port (dd′) is sent to a waste reservoir. Without this, the concentration level would be limited by the width and position of the focused particle stream in the separation channel in relation with the size of the collecting channels in the outlet bifurcation. For example, for monodisperse distributions of beads that are 30 μm in diameter, we observe an average width of ~100 μm for the focused stream (see Sect. 4.1). However, for particles of larger size distributions (as is the case for the P. ramorum sporangia) wider focusing streams are expected, mainly due to the presence of smaller particles. Supposing that these particles can be extracted with a channel of exactly the same size, we can easily evaluate a concentration efficiency of about 1/6 since the width of the separation channel is 600 μm. However, this figure of merit can be reached only if an appropriate trifurcation with a dedicated extraction channel is envisaged for the concentrated sample such that depleted sample liquid is sent to the side channels, while concentrated particles are collected through the middle one. Without the trifurcation design, the anticipated efficiency is even lower (1/3 at most) since simple bifurcated outlets will always extract the portion of clean liquid between the concentrated sample stream and the closest wall into the same channel—liquid that will actually mix with the concentrated particles and contribute to the dilution of the sample.

The overall figures of merit for the concentration setup can be improved regardless of the intrinsic concentration factor of the microfluidic device by repeating the inertial separation step multiple times (cyclic pumping). If we denote with f this intrinsic concentration factor as the ratio of the two volumes at the concentrated sample outlet \( V_{\text{CS}} \) over the initial sample volume V IS (\( f = V_{\text{CS}} /V_{\text{IS}} < 1 \)), we can obtain that after recirculating the concentrated sample through the separation device \( n \) times, a global concentration factor of \( F = f^{n} \) is reached. If a particular target concentration efficiency F would be desired, then the number of cycles \( n = \log_{\text{f}} F \) is to be envisaged. As for the total time, a maximum interval of \( \Delta t_{\infty } =\Delta t_{1} /\left( {1 - f} \right) \) corresponding to an infinite number of cycles is needed, where \( \Delta t_{1} \) is the time required for the first passage of the initial sample volume \( V_{\text{IS}} \). This expression arises as a limit for \( n \to \infty \) of the geometric series \( 1 + f + f^{2} + \cdots + f^{n - 1} = \left( {1 - f^{n} } \right)/\left( {1 - f} \right) \) corresponding to the sum of time intervals for each concentration cycle. For a microfluidic separation channel characterized by \( f = 0.5 \) (a bifurcation where the liquid flow is split in half at the outlet), we easily get \( \Delta t_{\infty } = 2\Delta t_{1} \), suggesting that any desired concentration factor at the outlet can be achieved with the double amount of time for a simple initial passage. The concentration level and related number of cycles are, however, limited in practice by the volumes of the particles themselves, the inherent dead volumes in the microfluidic device and related connectors as well as limitations of the inertial focusing effect itself at high sample concentrations (Kuntaegowdanahalli et al. 2009; Di Carlo et al. 2007).

In the present work, we designed a separation channel with an intrinsic concentration factor of f = 1/2 that is the separation channel ends with a simple bifurcation where flow is split in two equal parts. As for the pumping scheme, 3 or 4 cycles have been typically implemented (e.g., \( n = 3 \) or 4) to obtain overall concentration factors of \( F = f^{3} = 1/8 \) and \( F = f^{4} = 1/16 \), respectively. The total time for three cycles is \( \Delta t_{3} = 7\Delta t_{1} /4 \) where \( \Delta t_{1} \) is as defined above. However, the actual experimental duration is slightly longer than \( \Delta t_{3} \) due to the manipulation of the sample between inlet and outlet ports as well as the intrinsic actuation time for the pneumatic vales. The center of the microfluidic separation channel (ii′) is coupled to the external Luer connectors C3 and C4 through the microvalves V3 and V4, respectively (Fig. 2). The port C3 is used for sample infuse with V3 in open position. Between concentration steps, fluids are directed via the path 〈sample → C4 → V4 → V3 → C3 → syringe S〉 with both V3 and V4 being open. Output syringes C and D (operated using syringe pump 2) are connected to the ports C5 and C2, respectively, withdrawing liquid from the spiral separation channel. In between separation steps, the pump switches automatically to infuse concentrated and diluted sample liquids to the external reservoirs via the pathways 〈syringe C → C5 → V5 → V6 → C6 → sample〉 and 〈syringe D → C2 → V2 → V1 → C1 → waste〉, respectively. The switch of the pumps between infuse and withdraw cycles is synchronized with the LabVIEW interface driving the pressure manifold. The entire operational protocol along with the status of both valves and pumps is detailed in Table 1.

3 Experimental section

3.1 Chip fabrication

Mediprene OF 400 M was received in the form of pellets from Hexpol TPE (Elasto, Åmål, Sweden) and was extruded at 165 °C to form sheets of several meters in length, and 0.3, 1.0 or 2.5 mm in thickness. Master patterns were prepared on 6″ silicon wafers (Silicon Quest International, Santa Clara, CA) using standard photolithography with SU-8 resist (GM1060 and GM1075; Gersteltec, Pully, Switzerland). High-definition transparency photomasks were obtained from Fineline Imaging (Colorado Springs, CO). The resist film was exposed to UV light at 365 nm (Hg i-line) and developed in propylene glycol monomethyl ether acetate (PGMEA; Sigma-Aldrich, Oakville, ON) for several minutes. The wafer was rinsed with PGMEA and isopropanol (Anachemia, Montreal, QC) and dried with a stream of nitrogen gas. Epoxy molds and working stamps were fabricated from the silicon master, using an intermediate replication process with poly(dimethylsiloxane) (PDMS, Sylgard 184; Dow Corning, Midland, MI). The liquid prepolymers of PDMS [10:1 (w/w) elastomer base/curing agent] were poured onto the master followed by curing at 80 °C for 2.5 h. Epoxy resin (CONAPOXY FR-1080; Cytec Industries, Woodland Park, NJ) was prepared using a 5:4 ratio of resin/hardener followed by degassing under reduced pressure. Once applied to the PDMS mold, the resin was cured at 90 °C for 12 h. Upon removal, the cured epoxy mold was hard-baked at 180 °C for 3 h. The working stamps were created by pouring liquid precursor of UV-curable polymer onto the PDMS master. The polymer was cured through UV-exposure at room temperature for 2 min using a flood lamp UV curing system (Dymax ECE 2000UV, Torrington, CT). Hot-embossing of Mediprene was performed with an EVG 520 system (EV Group, Schärding, Austria) at a temperature of 150 °C, an applied force of 10 kN, and a pressure of 10−2 mbar. Zeonor1060R (Zeon Chemicals, Louisville, KY) was embossed at 120 °C and 10 kN. The seating sites of the valves were treated with trichloro(1H, 1H, 2H, 2H-perfluorooctyl)silane (Sigma-Aldrich) in a desiccator for 2 h to prevent the TPE membrane from sticking permanently to the Zeonor surface. In order to selectively expose the chip to silane, an adhesive film with holes at the valves’ locations was applied on the surface of the TPE membrane. Plastic layers were assembled by hand. Zeonor Luer connectors were produced by injection molding using an Engel 150 injection apparatus (Engel, Schwertberg, Austria) operated at temperatures of between 127 and 134 °C, an injection speed of 45–103 mm/s, and a pressure of 25 bar. All fabrication steps were carried out in a clean room (class 1000) environment.

3.2 Pneumatic and fluidic control system

The polymer microvalves (V1‒6) integrated in the microfluidic chip (Fig. 2c) were operated using a home-built manifold entailing 6 independent pressure regulation channels (P1‒6) driven by 12 three-way electromagnetic valves (The Lee Company, Westbrook, CT) whose opening and closing operations were controlled through a LabVIEW interface (National Instruments, Austin, TX). The maximum output pressure was set to 30 psi and is transmitted from the pressure manifold to the membrane of the microvalves through six air channels (P1‒V1 to P6‒V6, Fig. 2c). Negative pressure (e.g., −6 psi) was generated by a peristaltic pump (Virtual Industries, Inc., Colorado Springs, CO) mounted inside the same manifold. Infuse/withdraw of sample solutions was performed by two programmable syringe pumps (Harvard Apparatus, Holliston, MA). Silastic medical-grade tubing with an inner diameter of 0.76 mm and an outer diameter of 1.65 mm (Dow Corning) was used to connect syringes to the chip and additional reservoirs (waste and sample) through six dedicated standard Luer connectors (C1‒6). A 0.2% (v/v) solution of Tween 20 (Sigma-Aldrich) in deionized water was pumped through the chip before each experiment to limit non-specific adhesion of sample content (particles and sporangia).

3.3 Imaging

Experiments with fluorescent particles have been carried out using a suspension of internally dyed (Nile Red) polymer beads with an average diameter of 29.6 μm (Spherotech, Inc., Lake Forest, IL). The sample has been prepared by mixing 200 μL of the original bead suspension with 27 mL of deionized water and 3 mL of glycerol (Sigma-Aldrich) to obtain a number concentration of ~2500 mL. Fluorescence and optical micrographs were recorded using an Eclipse TE-2000-U inverted microscope (Nikon Instruments, Inc., Melville, NY). Images of particle streams were integrated by using the Z-Project feature and an Average Intensity projection type in the ImageJ software (http://imagej.nih.gov/ij/) to obtain a superposition of particle trajectories during several minutes of flow.

3.4 Preparation of sporangia samples

Cultures of P. ramorum isolates SOD03-002 (from Canadian Food Inspection Agency) and CBS101553 were grown over cellophane on 0.5% V8 agar at 20 °C with a 12 h photoperiod for 10 days. Sporangia were harvested by flooding culture plates with 15 mL of sterile water containing 10% (v/v) of glycerol. Flooded plates were rubbed with a glass stick for 1 min to dislodge sporangia. The suspension was then poured through a layer of cheesecloth over a 50-µm nylon mesh. The filtered suspension was kept at 10 °C overnight prior to use. Samples containing 54 (sample A) and 488 sporangia per mL (sample B) were produced through dilution. The content of sporangia was assessed by examining 20 µL aliquots on a gridded microscope slide using optical microscopy imaging. Samples of 10 mL were run through the chip in triplicate. Freshly picked leaves from Rhododendron wounded with a needle were infested using isolates of P. ramorum on culture medium V8 (0.5%). Each leaf was incubated with two culture pellets at controlled temperature and humidity for 9 days (12 h light/dark, 22.5 °C). Prior to experiments, 3 leaves were transferred into a glass beaker and incubated with 15 mL sterile water containing 10% (v/v) of glycerol and filtered as mentioned above. The sample was agitated manually to mediate release of sporangia into the sample solution.

3.5 Lysis of sporangia and isolation of genomic DNA

Sporangia from P. ramorum were isolated through vacuum filtration with Millipore filter paper (40 mm in diameter, 0.45 µm pore size; Fisher Scientific, Ottawa, ON) supported on a 30-mL Büchner funnel (CoorsTek, Golden, CO). Once collected, the filter paper was removed from the funnel and transferred into a tube containing Lysing Matrix A (MP Biomedicals, Santa Ana, CA). The ceramic sphere was removed prior to adding lysis buffer, making garnet flakes the only component of the grinding matrix. A FastPrep homogenizer machine (MP Biomedicals) was used for agitation at a speed of 5.0 for 60 s. Genomic DNA was isolated using a PowerWater DNA Isolation Kit (MO BIO Laboratories, Inc., Carlsbad, CA) according to the recommendations of the manufacturer. DNA samples were eluted in 50 µL aliquots and stored at ‒20 °C until use.

3.6 Real-time PCR for quantification of sporangia content

DNA from P. ramorum was quantified by real-time PCR (qPCR) targeting the mitochondrial region ATP9-NAD9 using reagents and parameters that are described elsewhere (Bilodeau et al. 2014). Amplification was performed on a ViiA7 Real-Time PCR System (Life Technologies, Inc., Burlington, ON). A dilution series (with DNA concentrations confirmed through NanoDrop analysis) was used to produce a standard curve for cycle threshold (C t) values (Table 2). Samples were analyzed by relating C t values to the log10 of sporangia number concentrations (Table 3).

4 Results and discussion

4.1 Design validation using fluorescent particles

The design considerations outlined in Sect. 2.2 have been validated first by using suspensions of fluorescent polymer particles of about 30 µm in diameter, falling in the same size category as sporangia of P. ramorum. The bead suspension was injected through the sample inlet port at a rate of 2 mL/min and the fluorescent particle time-traces recorded at different locations along the fluidic pathway (Fig. 3a). The virtue of the present design is to focus all sporangia-like particles in a stream as narrow as possible in order to facilitate their extraction at the outlet. As confirmed by fluorescence images recorded at the outlet bifurcation region (Fig. 3a), all particles are well focused to a narrow line collected to the concentrated sample outlet, while the dilution sample port (d) is completely depleted of particles. It is also interesting to observe the evolution of the inertial focusing process during the propagation of the flow as well (Fig. 3b). At the sample inlet, particles are uniformly distributed across the channel as indicated by both integrated fluorescence time-trace images and normalized particle distribution plots. As the flow advances in the separation channel, a narrowing of particle distributions into well-defined bands (grayed regions) is observed. Initially, these distributions are slightly moved toward the outer wall of the channel (region 1), but this is rapidly changed in the next loop (region 2) where the distribution is moved toward the inner wall. As the flow propagates, the distribution bands become even more confined (region 3) reaching a stable and extremely narrow configuration at the end of the channel (region 4). The half-width of this final equilibrium time-trace distribution is ~60 μm, corresponding to approximately two particle diameters. The described behavior is in complete agreement with the theory of supercritical inertial focusing mechanism described in detail elsewhere (Clime et al. 2015b).

Fluorescence imaging of particle trajectories within the inertial focusing system. a Schematics of the microfluidic separation channel (top) showing the position of the inlet (ii′), with respect to the internal connection ports for the diluted (dd′) and the concentrated (cc′) sample liquids. The fluorescence micrograph (bottom) shows the focused particle stream at the bifurcation segment of the main separation channel into the two output channels (cc′) and (dd′). b Fluorescence microscopy images of particle streamlines (left-hand) along with the corresponding intensity profiles (right-hand) recorded at different locations along the separation channel. Limits of the channel (positions of the vertical walls) are highlighted with dashed lines, while directions corresponding to the line plots are indicated by the vertical continuous lines. Flow direction on all fluorescent images is from left to right

4.2 Assessment of particle loss

Particles with a relative mass density of 1.1 and a diameter of 40 μm sink in water at a rate of ~90 μm/s. Smaller particles of the same density will sediment slower since sedimentation time is proportional to the squared particle diameter. Sporangia for which a similar density is anticipated will show the same behavior. If an initial sample volume of 10 mL is pumped into the microfluidic chip at a flow rate of 2 mL/min, particles will sediment over a 27-mm distance during the infusion time. This is even larger than the diameter of the syringes used in the pumping system (e.g., a 5-mL syringe has a diameter of 12.06 mm, while a 10-mL syringe has 14.05 mm). In order to avoid losses due to sedimentation, syringes infusing sample solution are implemented with a downward orientation, so that sedimentation is directed toward the syringe outlet and not against syringe walls or the piston surface.

To validate these assumptions, a suspension of fluorescent particles was pumped through the system following the protocol in Table 1. Droplets collected from all three syringes and from critical points on the chip were inspected using fluorescence microscopy imaging (Fig. 4). Analysis of these images confirms a high concentration efficiency and minimal particle loss. For the two concentrations (100 and 1000/mL), almost all particles were sent to the concentration syringe with very few being present in both dilution port and waste reservoir (Fig. 4a). Compared to the initial number of particles, the loss has been estimated to be 5% for the more diluted sample (100/mL) and less than 1% for the more concentrated one (1000/mL). As for the microfluidic connectors (both external and internal) and the pneumatic valves, losses were negligible as revealed by the images in Fig. 4b. Moreover, slight misalignment of the fluidic layers in the assembly process (as apparent for some of the internal connectors) does not lead to trapping of particles since all results indicate minimal losses even at high concentration runs. Consequently, the particle loss observed at both low and high concentrations may be due to sedimentation in the chip connecting tubes and syringes themselves.

Performance assessment using fluorescent particles. a Fluorescence microscopy images of droplets (50 µL) collected at different locations on the microfluidic device after the passage of bead suspensions with two different concentrations. b Combined optical and fluorescence images of (chip-to-world) connectors C1–6, pneumatic valves V1–6 and internal connectors (ii′, dd′ and cc′) at the end of an experiment with a colloidal suspension of fluorescent beads at the highest concentration value (e.g., 1000/mL). Approximate positions of Luer ports, fluidic and air pathways on these images are highlighted with pointed, dashed and continuous lines, respectively

4.3 Concentration of P. ramorum sporangia

Concentration runs using the microfluidic protocol in Table 1 have been performed using 10 mL of samples A and B inoculated with sporangia at initial number concentrations (c 0) of 54 and 488/mL, respectively. At the end of each experiment, liquid was collected from the output syringe (C) as well as from the waste reservoir to perform qPCR analysis. We used a genus-specific TaqMan assay to quantify DNA from sporangia in lysates (see Sects. 3.5, 3.6 for details). Our findings are summarized in Fig. 5. For sample A (Fig. 5a), the output contained 175 sporangia/mL, corresponding to an increase by a factor of 3.2. As can be expected, solution that accumulated in the waste has largely been depleted of sporangia and its concentration has been reduced to 4% (or 0.04c 0). Sample output and waste combined account for 60% of the recovered sporangia. Loss of low-abundant analyte (e.g., through non-specific adsorption) often plagues sample preparation processes. As shown in Fig. 5b, efficiency increases when focusing was performed with sample B. The concentration factor of 5.3 also relates reasonably well to the 5.9-fold reduction in sample volume (e.g., from 10 to 1.7 mL). Under these conditions, it was further possible to recover sporangia from the chip with 94.8% yield.

Concentration efficiency for samples inoculated with P. ramorum. The plots reveal the number concentrations (top) and total counts (bottom) of sporangia found in sample output and waste with respect to the starting material (input) which contained a 54 and b 488 sporangia/mL. Experiments were performed in triplicate using 10 mL sample volume and three concentration cycles (n = 3). The data were determined using qPCR of genomic DNA from P. ramorum in conjunction with a standard curve. Error bars represent SD

The method was further tested using samples prepared from plant material. For this experiment, Rhododendron leaves were inoculated with the target pathogen using culture isolates (see Sect. 3.4 for details). This plant species is particularly susceptible to P. ramorum and thus represents a natural host for the pathogen (Werres et al. 2001). Infection causes leaf blight—a disease which manifests itself through the appearance of dark spots on the foliage (Fig. 6a). Examples of healthy (non-infected) leaves are shown in Fig. 6b and were considered as a control sample. Leaves were thoroughly washed (see Sect. 3.4 for details) in order to disperse microbes from the host into the sample liquid. The solutions derived from both infested and healthy specimens were then flowed through the inertial focusing device for which results are shown in Fig. 6c. The sample solution derived from three infested leaves contained 3655 sporangia/mL after four concentration cycles (n = 4) as evaluated by qPCR measurements and related standard calibration curves. The number concentration increased by a factor of 6.1 with respect to the starting material (subjected to direct filter extraction and lysis as described in Sect. 3.5) which was included in Fig. 6c for comparison. The absence of pathogen in the control sample was confirmed for both inertial focusing device (Fig. 6c) and direct filter extraction (not shown). The demonstration presented here confirms that the method should, in principle, be suitable for samples with low inoculum densities (e.g., plants at the onset of an infection) where sporangia contents are close to or below the detection limit.

Isolation of P. ramorum sporangia from Rhododendron leaves. a Photograph of Rhododendron foliage showing symptoms of leaf blight. Each leaf has been infected using two circular patches of pathogen-containing culture medium. The inset shows a close-up view of disease-affected tissue. b Photograph of healthy leaves. c Sporangia content of three different samples derived from Rhododendron leaves with and without concentration of the pathogen (see text for details). It should be noted that the initial sample volume for healthy leaves was ~8.5 mL instead of 10 mL. Number concentrations were determined using qPCR of genomic DNA from P. ramorum in conjunction with a standard curve

The findings obtained with adjusted test samples A and B suggest an operational window in terms of sample composition wherein suspensions of sporangia can be enriched with high concentration factors and marginal loss of analyte. Although satisfactory from a practical point of view, the concentration efficiency for sporangia remains somewhat lower than that observed for monodisperse distributions of fluorescent particles (see Sect. 4.2). One of the reasons for this discrepancy is likely to originate from the irregular shape of the pathogen itself when compared to perfectly spherical particles as well as the size distribution associated with their populations. Particles with the same equivalent hydrodynamic diameter can behave differently in terms of inertial focusing and lateral migration (Hur et al. 2011). Moreover, sporangia of P. ramorum are relatively fragile and may easily rupture or release their zoospores when subjected to pressure and shear stress in the microfluidic channel, even though this process has been countered to some extent by the addition of glycerol to the initial suspension. Finally, the presence of debris interfering with the focusing process can further diminish the recovery of analyte species (Clime et al. 2015a). We believe that this largely explains the gap between theoretical and observed concentration factors (e.g., 16 vs. 6.1) for P. ramorum sporangia derived from infested Rhododendron leaves.

5 Concluding remarks

In this work, a deterministic approach to the separation and concentration of plant pathogens—more specifically P. ramorum sporangia—has been conceptually introduced and experimentally investigated. Based on the physical properties of the pathogen such as size and mass density, a microfluidic separation channel has been designed that is capable of efficiently concentrating and separating sporangia using lateral inertial migration in curving flows. The separation channel along with auxiliary pneumatic valves and standard commercial connecting tubes has been integrated in an all-thermoplastic microfluidic chip. Sporangia-like fluorescent beads were used to validate particle focusing mechanism and pumping configurations to provide high concentration efficiencies while minimizing losses by sticking and decantation. Excellent results on the concentration of samples inoculated with P. ramorum at different sporangia concentrations have been obtained.

Although the findings presented herein provide a suitable path toward high-throughput sample preparation and parallelization using microfluidics, the current system features just a single separation channel per chip. At its 2 mL/min input flow rate, the device should in principle be able to process 10 mL of sample in less than \( \Delta t = 2\Delta t_{1} = 10\;{ \hbox{min} } \) where \( \Delta t_{1} = 5\;{ \hbox{min} } \) is the time required for the first passage. However, in the actual microfluidic setup, more than double of this time is necessary (e.g., 24 min). The reasons for this difference are twofold. First, the time necessary for the pumping system to move liquids from the outlet back to the inlet and to the auxiliary reservoirs has to be considered. Second, the adhesion properties of the elastomers used in the fabrication of the integrated microfluidic valves lead to a time delay between the pressure pulse coming from the pressure manifold and the actual physical switch of the valve. While the former is related to the flow rate used for the liquid transfer protocol in the pumping system and can always be improved by finding a compromise between faster flow rates and potentially larger dead volumes in the connecting tubes, overcoming the latter limitation requires more thorough investigations related to the intrinsic physical properties of the polymer materials. A larger number of separation channels per chip could drastically improve the figures of merit in terms of throughput and processing speed (Rafeie et al. 2016). Such an implementation would be straightforward to envisage using the layered approach presented herein.

We anticipate that a compact, low-cost microfluidic device based on the method presented herein has great potential in high-throughput sample preparation for rapid bioassays and biomedical diagnostic applications. Integration of both up-front and downstream processing elements would ultimately be required for isolating sporangia from soil or plant material to perform on-site testing or in-depth analysis in a standard laboratory setting.

References

Berger SA, Talbot L, Yao L-S (1983) Flow in curved pipes. Annu Rev Fluid Mech 15:461–512

Bhagat AAS, Kuntaegowdanahalli SS, Papautsky I (2008) Continuous particle separation in spiral microchannels using dean flows and differential migration. Lab Chip 8:1906–1914

Bilodeau GJ (2011) Quantitative polymerase chain reaction for the detection of organisms in soil. CAB Rev Perspect Agric Vet Sci Nutr Nat Resour 6:1–14

Bilodeau GJ, Lévesque CA, de Cock AWAM, Duchaine C, Brière S, Uribe P, Martin FN, Hamelin RC (2007) Molecular detection of Phytophthora ramorum by real-time polymerase chain reaction using TaqMan, SYBR Green, and molecular beacons. Phytopathology 97:632–642

Bilodeau GJ, Koike ST, Uribe P, Martin FN (2012) Development of an assay for rapid detection and quantification of Verticilium dahliae in Soil. Phytopathology 102:331–343

Bilodeau GJ, Martin FN, Coffey MD, Blomquist CL (2014) Development of a multiplex assay for genus- and species-specific detection of Phytophthora based on differences in mitochondrial gene order. Phytopathology 104:733–748

Clime L, Hoa XD, Corneau N, Morton KJ, Luebbert C, Mounier M, Brassard D, Geissler M, Bidawid S, Farber J, Veres T (2015a) Microfluidic filtration and extraction of pathogens from food samples by hydrodynamic focusing and inertial lateral migration. Biomed Microdevices 17:17

Clime L, Morton KJ, Hoa XD, Veres T (2015b) Twin tubular pinch effect in curving confined flows. Sci Rep 5:9765

Dean WR (1927) XVI. Note on the motion of fluid in a curved pipe. Philos Mag Ser 7(4):208–223

Di Carlo D, Irimia D, Tompkins RG, Toner M (2007) Continuous inertial focusing, ordering, and separation of particles in microchannels. Proc Natl Acad Sci USA 104:18892–18897

Didar TF, Li K, Tabrizian M, Veres T (2013) High throughput multilayer microfluidic particle separation platform using embedded thermoplastic-based micropumping. Lab Chip 13:2615–2622

Ganz KR, Clime L, Farber JM, Corneau N, Veres T, Dixon BR (2015) Enhancing the detection of Giardia duodenalis cysts in foods by inertial microfluidic separation. Appl Environ Microbiol 81:3925–3933

Geissler M, Li K, Zhang X, Clime L, Robideau GP, Bilodeau GJ, Veres T (2014) Integrated air stream micromixer for performing bioanalytical assays on a plastic chip. Lab Chip 14:3750–3761

Gossett DR, Di Carlo D (2009) Particle focusing mechanisms in curving confined flows. Anal Chem 81:8459–8465

Hur SC, Tse HTK, Di Carlo D (2010) Sheathless inertial cell ordering for extreme throughput flow cytometry. Lab Chip 10:274–280

Hur SC, Choi S-E, Kwon S, Di Carlo D (2011) Inertial focusing of non-spherical microparticles. Appl Phys Lett 99:044101

Inglis DW, Herman N, Vesey G (2010) Highly accurate deterministic lateral displacement device and its application to purification of fungal spores. Biomicrofluidics 4:024109

Julich S, Riedel M, Kielpinski M, Urban M, Kretschmer R, Wagner S, Fritzsche W, Henkel T, Möller R, Werres S (2011) Development of a lab-on-a-chip device for diagnosis of plant pathogens. Biosens Bioelectron 26:4070–4075

Kotz KT, Petrofsky AC, Haghgooie R, Granier R, Toner M, Tomkins RG (2013) Inertial focusing cytometer with integrated optics for particle characterization. Technology 1:27–36

Kuntaegowdanahalli SS, Bhagat AAS, Papautsky I (2009) Continuous multi-particle separation using deterministic focusing in spiral microchannels. In: Transducers 2009–2009 international solid-state sensors, actuators and microsystems conference, pp 2139–2142

Mach AJ, Di Carlo D (2010) Continuous scalable blood filtration device using inertial microfluidics. Biotechnol Bioeng 107:302–311

Martel JM, Toner M (2014) Inertial focusing in microfluidics. Annu Rev Biomed Eng 16:371–396

Martin FN, Abad ZG, Balci Y, Ivors K (2012) Identification and detection of Phytophthora: reviewing our progress, identifying our needs. Plant Dis 96:1080–1103

Nivedita N, Papautsky I (2013) Continuous separation of blood cells in spiral microfluidic devices. Biomicrofluidics 7:054101

Rafeie M, Zhang J, Asadnia M, Li W, Warkiani ME (2016) Multiplexing slanted spiral microchannels for ultra-fast blood plasma separation. Lab Chip 16:2791–2802

Rizzo DM, Garbelotto M, Hansen EM (2005) Phytophthora ramorum: integrative research and management of an emerging pathogen in California and Oregon forests. Annu Rev Phytopathol 43:309–335

Roy E, Geissler M, Galas J-C, Veres T (2011) Prototyping of microfluidic systems using a commercial thermoplastic elastomer. Microfluid Nanofluid 11:235–244

Saffman PG (1965) The lift on a small sphere in a slow shear flow. J Fluid Mech 22:385–400

Saffman PG (1968) The lift on a small sphere in a slow shear flow—Corrigendum. J Fluid Mech 31:624

Schonberg JA, Hinch EJ (1989) Inertial migration of a sphere in Poiseuille flow. J Fluid Mech 203:517–524

Segré G, Silberberg A (1961) Radial particle displacements in Poiseuille flow of suspensions. Nature 189:209–210

Tomlinson JA, Boonham N, Hughes KJD, Griffin RL, Barker I (2005) On-site DNA extraction and real-time PCR for detection of Phytophthora ramorum in the field. Appl Environ Microbiol 71:6702–6710

Werres S, Marwitz R, Man in’t Veld WA, de Cock AWAM, Bonants PJM, de Weerdt M, Themann K, Ilieva E, Baayen RP (2001) Phytophthora ramorum sp. nov., a new pathogen on Rhododendron and Viburnum. Mycol Res 105:1155–1165

Acknowledgements

This work was supported in part by Canada’s Genomics Research and Development Initiative (GRDI) under the program “Protection of Canadian Biodiversity and Trade from the Impacts of Global Change through Improved Ability to Monitor Invasive Alien and Quarantine Species.” We thank our colleagues Maxence Mounier (NRC), Alex Boutin (NRC), Hélène Roberge (NRC), Hadil Sayed (CFIA), Ian King (CFIA), Émilie Tremblay (CFIA) and Debbie Shearlaw (CFIA) for technical assistance and useful discussion.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Clime, L., Li, K., Geissler, M. et al. Separation and concentration of Phytophthora ramorum sporangia by inertial focusing in curving microfluidic flows. Microfluid Nanofluid 21, 5 (2017). https://doi.org/10.1007/s10404-016-1844-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10404-016-1844-9