Abstract

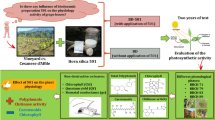

Wounding is a common stress factor for plants, caused by abiotic elements. Plants have the ability to respond to the combined influence of different factors such as temperature fluctuations, radiation, precipitation, CO2 levels, and human-induced impacts. Vitis vinifera L., a resilient species capable of withstanding adverse conditions, offers the opportunity to manipulate quality attributes through viticultural practices. In the 2021 growing season, an experiment was conducted in a commercial vineyard situated in Tekirdağ, Turkey, to investigate the effects of leaf artificial stress treatments on clusters and berries of 21-year-old ‘Merlot’ grapevines (Vitis vinifera L.) grafted on SO4 rootstocks. Employing a completely randomized block design, leaf artificial stress treatments (T0, T1, T2, T3, T4, T5, T6, T7, T8, and T9) were applied from different row directions and at various times. Overall, the artificial stress treatments did not significantly affect measured criteria such as berry weight, diameter, length, dry weight, volume, density, number of seeds, percentage of dry weight, skin area, and the ratio of berry skin area and berry volume (BSA/BVOL). However, notable discrepancies were observed among certain criteria across the treatments. T4 exhibited the highest mean berry weight and diameter, whereas T6 had the lowest. T3 displayed the highest mean berry length, while T6 had the lowest. T8 showed the highest mean berry dry weight, whereas T6 had the lowest. T4 yielded the highest mean berry volume, while T6 had the lowest. T7 had the highest mean berry density, with T4 having the lowest. T4 also had the highest mean number of berry seeds, while T6 had the lowest. The BSA/BVOL ratio remained relatively consistent across treatments, ranging from 4.26 to 4.58, implying that it may be less susceptible to artificial stress treatments compared to other criteria. Further investigations are required to examine the long-term effects of leaf artificial stress treatments and establish direct correlations between these treatments and their responses.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Stress is the mechanical force exerted on a unit area of an object. However, when it comes to living organisms, defining and measuring stress becomes more difficult. What may be considered optimal conditions for one plant may be a source of stress for another. In biological terms, stress can be described as a negative force or condition that limits normal growth and development, ultimately affecting the well-being of living systems such as plants (Jones and Jones 1989).

During the growing season, plant growth and productivity can be negatively impacted by a range of abiotic and biotic stress factors. Low or high temperatures, salinity, drought, and other inanimate stressors can often cause harm to plants. Moreover, many human-made factors can intensify these stressors. Biotic stress from bacteria, fungi, viruses, and other plants can also pose a significant threat. All these factors combined can limit a plant’s ability to reach its full genetic potential and increase its productivity.

Artificial plant wounding is a method employed in grape cultivation to replicate the impact of injuries that are typically caused by pests or diseases. This is accomplished by physically damaging the grapevines with a tool or by exposing them to chemicals that imitate the effects of artificial stress. The purpose of this technique is to enhance the production of specific compounds and improve the physical properties of grapevines, thereby contributing to the overall quality of the wine produced. Artificial wounding stress can serve as a valuable technique for enhancing the production of beneficial compounds in grapes, resulting in improved ripeness, chemical composition, wine quality, and human health (Candar 2023).

Defining the quality of wine is a complex matter as personal preferences and various factors come into play, leading to a lack of consensus among experts (Poni et al. 2018). The morphological features of grape berries and clusters have a significant impact on the characteristics and quality of wine. In the wine industry, an array of different characteristics are employed to describe various attributes. The fruit’s physical appearance is a significant indicator used to evaluate visual qualities such as berry size, shape, and colour, as well as taste, texture, aroma, and flavour (Pelsy 2010; Ferrara et al. 2017). The physical attributes that determine grape berry quality, such as length, width, shape, and colour, are generally intrinsic to the variety, but other criteria such as weight, volume, density, and the skin area to flesh volume ratio are strongly influenced by cultivation techniques.

Irrigation, pruning, canopy management, and other cultivation techniques such as the orientation of vineyard rows and the impact of abiotic and biotic environmental factors are the most significant factors influencing berry quality in wine varieties (Hunter et al. 1995; Mateus et al. 2001; Deloire et al. 2005; Castellarin et al. 2007; Poni et al. 2009; Korkutal and Bahar 2013; Bahar et al. 2017; Korkutal et al. 2017, 2019, 2020, 2021; Candar et al. 2019a, 2020). Although these factors impact the size of the berries, they also influence the proportional distribution of skin, berry flesh, and seeds within the berry. Consequently, these variations also modify the ratio of berry flesh to skin and the quantity of soluble substances that pass from the skin into the wine (Roby and Matthews 2004; Matthews and Nuzzo 2007).

Grape berries are complex and multifaceted biochemical structures that undergo a series of developmental and maturation processes, affecting their size, composition, colour, texture, taste, and aroma. The histological structure of grapes comprises sugars, organic acids, phenolic compounds, minerals, and flavouring agents (Coombe and McCarthy 2000). Berry ripening is a physiological phase that has a significant impact on the berry composition and, as a result, the wine quality, which varies according to the grape variety. During the ripening process, grapes undergo numerous physical and biochemical changes, including alterations in weight, volume, hardness, sugar content, acidity, colour, and aroma. According to Chen et al. (2018), berry size is among the factors affecting grape quality.

Schalkwyk (2004) asserts that the weight and size of grape berries are influenced by multiple factors, including genetic origin, berry set, number of berries per cluster, berry position within the cluster, number of seeds per berry, number of clusters per vine (bud load), climate, water conditions, fertilization, soil type, rootstock, variety, and degree of maturity. The author further notes that the weight of both clusters and berries can vary not only from season to season but also from region to region, even within the same grape variety. To achieve optimal ripening and minimize ripening variability in vineyards, it is necessary to address a range of soil, climate, and cultural factors (King et al. 2015). By understanding the interaction between artificial wounding stress levels, timing, and vineyard orientation, winemakers can make informed decisions regarding vineyard management, ultimately leading to the production of high-quality grapes and wines.

The aim of this manuscript was to examine the effects of varying degrees of artificial stress on Vitis vinifera L. ‘Merlot’ grapevine berries.

Materials and Methods

Location and Plant Material

The experiment was conducted during the 2021 vegetation period in a vineyard located in Tekirdağ, Turkey. The grapevines used were 22- to 23-year-old cv. ‘Merlot’ (Vitis vinifera L.) grown in silty clay loam soil. They were planted in N‑S rows at a distance of 2.60 × 0.90 meters. The plants were grafted onto rootstock SO4 and cultivated using the double-armed Guyot trellising system. Grapevine pruning was carried out by cutting back to a 16- to 18-bud cane to standardize the yield. The yield ranged from 1.50 to 1.85 kg per grapevine and did not cause a statistically significant variation between treatments.

Abiotic Stress Treatments

The study aimed to investigate the abiotic stress response in grapevine leaves by inducing mechanical injury. To ensure uniform distribution of the artificial stress, a custom-made device was designed. The device consisted of a composite pipe handle made of PN25 PPRC (polypropylene random copolymer) and two whipping tips made of PA 66 (polyamide 6.6) material attached to the handle. The artificial stress was inflicted on healthy, fully developed leaves, and the time and direction of the artificial stress were carefully controlled.

The mechanical leaf artificial stress was carried out at different times from the east and west directions of the vineyard rows and in combinations of these two directions. Additionally, artificial stress treatments were applied at four different time points, which were 15 days before harvest, 10 days before harvest, 5 days before harvest, and 3 days before harvest.

The experiment involved nine different treatments, denoted as T1–T9, and a control treatment, T0. Treatment T1 involved artificial stress from the east side 15 days before harvest, followed by artificial stress from the west side 10 days before harvest, and then artificial stress from both sides 5 days before harvest. Treatment T2 involved artificial stress from the east side 15 days before harvest, followed by artificial stress from the west side 10 days before harvest. Treatment T3 involved artificial stress from the east side 15 days before harvest, followed by artificial stress from the west side 5 days before harvest. Treatment T4 involved artificial stress from only the east side 15 days before harvest. Treatment T5 involved artificial stress from the east side 10 days before harvest, followed by artificial stress from the west side 5 days before harvest, and then artificial stress from the east side 3 days before harvest. Treatment T6 involved artificial stress from the east side 10 days before harvest, followed by artificial stress from the west side 5 days before harvest. Treatment T7 involved artificial stress from the east side 10 days before harvest. Treatment T8 involved artificial stress from the east side 5 days before harvest, followed by wounding from the west side 3 days before harvest. Finally, Treatment T9 involved artificial stress from only the east side 5 days before harvest.

The artificial stress was applied to leaves from the fifth to the ninth buds, regardless of main and lateral shoots, resulting in approximately 15–20% of the total leaf area being damaged in each treatment.

Analysis and Measurements

The study recorded phenological development stages based on Lorenz et al. (1995) guidelines, and obtained climate data from the Turkish State Meteorological Service (MGM). To measure berry characteristics, a sample of 18 clusters was taken from three vines in each replication, and berries were randomly selected from all parts. The width and length of 48 representative berries were measured using a digital calliper (Mitutoyo, Japan), and the values were given in centimetres according to the guidelines of the International Organization of Vine and Wine (OIV 2021). The volume of 100 representative berries was determined in cm3 per berry using the overflow method in a measuring cylinder, as described by Bahar et al. (2011). The weight of the berries was measured using an analytical balance scale with a sensitivity of 0.001 g to obtain the fresh weight of the berries, and the weight was given in grams. To determine the dry weight, 48 representative berries were dried in an oven (Elektro-mag, Turkey) at 65–70 °C for 72 h and then weighed again using the analytical balance scale. The dry weight of the berries was given in g berry−1, as recommended by OIV (2021). The fresh weight and dry weight of berries were used to calculate the weight values per 100 berries using proportions. The percentage of dry weight was determined using the formula (dry weight of berries × 100) /fresh weight of berries, as described by Bahar et al. (2011). The density of the berries was calculated by dividing the berry mass by the berry volume. The berry skin area was calculated using the formula 4πr2 and the values obtained were expressed in cm2 berry−1, as per Barbagallo et al. (2011). The ratio of berry skin area to berry flesh volume was determined by dividing the berry skin area by the berry flesh volume, and the resulting value was expressed as a proportion (Palma et al. 2007).

Trial Design and Statistical Analysis

The experiment was designed with a completely randomised block design. The treatments were randomly assigned to blocks, and each block consisted of three replicates of 10 grapevine plants. The data collected from the berries were then subjected to one-way ANOVA to test for statistically significant differences between treatments. Since no statistically significant differences were found, no multiple comparison test was performed. In addition to the ANOVA, bivariate relationships between the data were analysed. Furthermore, a principal component analysis (PCA) was performed to analyse the physical components of the grape clusters and berries. The R statistical environment was used for the data analysis (R Core Team 2016). Finally, a hierarchical cluster analysis (HCA) was applied using JMP 17 statistical software and a heatmap was created.

Results and Discussion

Climate and Phenology

Tekirdağ has a Mediterranean climate, characterized by hot and dry summers and mild winters, falling under the Csa classification according to the Köppen-Geiger climate system. Precipitation is mostly observed during the winter and spring seasons. In contrast, the interior regions have a predominantly continental climate with colder winters compared to the coastal areas.

The Winkler Index (WI-GDD) increased from 1884.00 day-degrees over the period of 1940–2021 to 1992.00 day-degrees in 2021, according to calculations. The Branas Hydrothermic Index (HyI) for 2021 was near the long-term average. However, the Night Cold Index (CI) recorded at 10.60 °C was significantly lower than the long-term average, which is contrary to the trend observed in the past 10 years (Candar et al. 2019b).

In terms of precipitation, the year 2021 followed the long-term average trend, with a total of 530.90 mm, which is slightly less than the 1940–2021 standard of 583.50 mm. It was noticed that the precipitation received in the last part of the year, which is typical in many years, was received at the beginning of the year and at the start of the growing season.

Regarding temperature, the upward trend observed over the past decade appears to persist, with an average temperature increase of approximately 1 °C compared to the 1940–2021 period.

In 2021, the average temperature was recorded as 15.01 °C, and during August, the hottest month, the average temperature was 25.80 °C, exceeding the average of 23.80 °C in the 1940–2021 period.

The budburst (EL 04–07) for cv. ‘Merlot’, based on Lorenz et al. (1995) scale, occurred on 13.04.2021, while flowering (EL 23–25) occurred on 29.05.2021. Veraison (EL 35) was observed on 05.08.2021, and the harvest (EL 38) was conducted on 07.09.2021 when the grape clusters ranged from 20.00–21.00 °Brix, taking into account the overall state of the blocks.

Berry Width and Length

The ANOVA results did not show any statistical significance at the p ≤ 0.05 level for berry width. The mean values of berry widths for each treatment group ranged from 11.21 mm for T0 to 11.86 mm for T7. In comparison, the mean values for berry length appear to be more varied than those for berry width, indicating that the artificial stress treatments may have had a greater impact on this berry characteristic. The range of values for berry length is 0.74 mm, which is larger than the range for berry width, which is 0.65 mm. However, the main effect of artificial stress treatments on berry length was also not statistically significant (Fig. 1).

Similar to our study, Tok Abay (2021) investigated the effects of leaf injury and grapevine stem vibration on berry width and length in cv. ‘Merlot’ and ‘Cabernet Sauvignon’, but found no statistically significant effects. In a similar study, Abay (2022) also reported no significant impact of artificial stresses created by leaf injury and impact on grapevine stem on the width and length of the berry in cv. ‘Cabernet Sauvignon’. These findings align with the view published by Candar (2022) that artificial leaf stress treatments do not significantly affect berry size. Berry size is a key factor in determining the quality of wine grape varieties (Matthews and Nuzzo 2007; Kok et al. 2013), with smaller berries in the same cluster being preferred due to their lower water content and higher skin to pulp ratio. Although not statistically significant, the smallest berry size was observed in the T0 control treatment.

Berry Fresh and Dry Weight

Based on Fig. 2, the mean values of berry fresh weight ranged from 1.14 g for T6 to 1.38 g for T3. However, the means were not statistically significant, indicating that there was no significant difference in berry fresh weight among the different treatments at the p ≤ 0.05 level, as determined by the statistical analysis.

Similarly, the mean values of berry dry weight ranged from 0.22 g for T6 to 0.30 g for T2. However, like the previous, the means were not statistically significant, suggesting that there was no significant difference in berry dry weight among the different treatments at the p ≤ 0.05 level based on the statistical analysis performed.

The results of the berry fresh weight measurements in our study were consistent with those reported by Tok Abay (2021), Abay (2022), and Candar (2022), all of whom failed to find a significant relationship between artificial stress applications and berry fresh weight. However, Candar (2022) observed that the lowest berry fresh weight was detected in the T4 treatment, while the highest fresh weight was observed in the T1 treatment.

In cv. ‘Merlot’, Tok Abay (2021) reported a decrease in berry dry weight with vibration and artificial leaf stress treatments, but an increase with the interaction of defoliation and Botrytis cinerea. In cv. ‘Cabernet sauvignon’, the same study found that artificial leaf stress and defoliation treatments increased berry dry weight. However, Abay (2022) could not determine a significant effect of artificial leaf stress and trunk impact treatments on berry dry weight for ‘Cabernet sauvignon’ grape variety. On the other hand, Candar (2022) reported that artificial leaf stress treatments had significant effects on berry dry weight in cv. ‘Cabernet sauvignon’. These findings suggest that different cultivars may respond differently to artificial stress, primarily due to their genotype.

Berry Volume and Density

The means of berry volume were not statistically significant, similar to the previous results. This suggests that there was no significant difference in berry volume among the different treatments at p ≤ 0.05. The mean values of berry volume ranged from 1.18 cm3 for T6 to 1.47 cm3 for T4, and there was more variability in the mean values of berry volume among the treatments compared to the previous berry characteristics. The mean values of berry density ranged from 0.90 to 1.00 g L−1 for different treatments (Fig. 3). According to the ANOVA test, the differences in berry density among the treatments were not statistically significant at the p ≤ 0.05 level.

Berry density is a significant quality parameter that affects grape and wine quality. Higher berry density is generally associated with better quality grapes and wines due to its correlation with higher sugar and pigment content. However, the study’s results suggest that the applied stress treatments did not have a significant impact on berry density. This may indicate that other factors, such as cultivar, environmental conditions, and management practices, may have a more significant influence on berry density than the applied stress treatments.

The available data are largely consistent with previous studies. In their research, Tok Abay (2021), Abay (2022), and Candar (2022) found that the stress created by artificial leaf stress, vibration, and stem impact did not have a statistically significant effect on berry volume and berry density. Among this literature, only Tok Abay (2021) observed differences in the applications due to the variety and reported that artificial stress decreased berry density in the ‘Merlot’ cultivar compared to the control.

Number of Berry Seeds and Berry Dry Weight %

The means of berry seed number were not statistically significant, suggesting that the different stress treatments did not have a significant effect on the number of seeds in the berries. Notably, there was some variation in the mean number of seeds per berry across the different treatments. For instance, treatments T8 and T4 had the highest mean number of seeds per berry with values of 1.92 and 1.83, respectively, while treatment T6 had the lowest mean number of seeds per berry (1.44). However, as previously stated, these differences were not statistically significant (Fig. 4).

The number of seeds in a berry can be a critical factor in the quality and characteristics of the resulting wine, so further investigation with a larger sample size or different stress treatments may reveal a significant effect on this variable.

The mean berry dry weight (%) values of the different treatments were relatively close to each other. The means were not statistically significant, indicating that the differences between the treatments were not large enough to be considered statistically significant at the 0.05 level. The berry dry weight (%) values ranged from 19.09 to 23.11%, which is a relatively small range. This implies that the different stress treatments did not have a significant impact on the water content of the berries.

Berry dry weight (%) represents the percentage of berry weight that is dry weight and is a measure of the water content in the berries. A higher berry dry weight (%) value indicates that the berries have a lower water content, which can affect the grape’s quality. However, it is essential to note that this is just one aspect of grape quality, and there may be other factors that are influenced by the stress treatments. Overall, the stress treatments did not appear to have a significant impact on grape quality, at least as measured by berry dry weight (%).

Previous studies by Tok Abay (2021) and Abay (2022) also found no significant effect of artificial stress treatments on the number of seeds in grape berries, which is consistent with the results of this study. However, Candar (2022) reported significant differences in the number of seeds in ‘Cabernet sauvignon’ grape cultivar under similar stress treatments. Specifically, the T4 treatment increased the number of seeds in the berry, while the lowest number of seeds was observed in the T9 treatment.

Berry Skin Area and Berry Skin Area to Berry Flesh Volume Ratio

The berry skin area did not differ significantly between the treatments (Fig. 5). The mean values ranged from 5.40 mm2 to 6.25 mm2, with the lowest mean value observed in T6 and the highest in T4.

It is worth noting that the variations in berry skin area between treatments were relatively small compared to other parameters measured, such as berry fresh weight and number of seeds. Nonetheless, berry skin area is an important quality attribute of grapes as it affects the extraction of phenolic compounds during winemaking. This parameter is commonly determined by measuring the surface area of the berry using digital image analysis. The lack of significant differences in skin area between treatments suggests that the treatments did not have a significant effect on this parameter.

Figure 5 shows the mean values of the ratio of berry skin area to berry flesh volume (BSA/BVOL) for each treatment group. The mean BSA/BVOL ratios ranged from 4.26 to 4.58, with the highest ratio observed in T6 and the lowest in T4. However, these differences were not statistically significant.

The BSA/BVOL ratio is an important parameter in grape and wine production as it is associated with grape and wine quality. A higher BSA/BVOL ratio indicates a higher proportion of skin to flesh in the berry, which generally leads to better wine quality due to the increased concentration of phenolic compounds in the skin.

The responses of the ‘Merlot’ grape cultivar to the berry skin area and berry skin area to berry volume ratio criteria were found to be fully consistent with previous studies (Tok Abay 2021; Abay 2022; Candar 2022).

Overall, the results suggest that the artificial stress treatments applied to the grapevine plants did not have a significant effect on the berry measurements taken. However, some treatments consistently showed higher or lower means across multiple variables. For instance, T3, T2, and T4 had higher means, while T6 had the lowest mean in berry fresh weight. Similarly, for berry dry weight, T2 and T4 had higher means, while T6 had the lowest mean. Regarding berry skin area, T2 and T3 had higher means compared to T0, T1, and T6, indicating some variation in this parameter between treatments.

Correlations Between Cluster, Berry Characteristics, and °Brix

Despite not finding significant relationships between cluster and berry characteristics and Brix at the p ≤ 0.05 level based on the ANOVA results, we used the Pearson correlation test to investigate these relationships (Fig. 6).

Pearson correlation between cluster, berry characteristics, and °Brix of artificial stress treatments. Significant correlations are reported for p ≤ 0.001. The colour change and circle size are proportioned to the Pearson Index. Dark green represents negative correlations, claret red represents positive correlations. The size of the circle reflects the magnitude of the Pearson correlation coefficient. bsa/bvol Berry skin area to berry flesh volume ratio, cw Cluster width, bden Berry density, bdw Berry dry weight, bdwper Berry dry weight %, bfw Berry fresh weight, bvol Berry volume, bsa Berry skin area, nobs Number of berry seeds, bw Berry weight, bl Berry length, cl Cluster length, cweight Cluster weight, nobpc Number of berries per cluster

The study’s findings revealed strong and positive correlations between the number of berries per cluster and cluster weight (0.916), and between berry weight and berry length (0.945). Berry fresh weight, berry dry weight, berry volume, and berry skin area also showed strong and positive correlations, with correlation coefficients of 0.681, 0.790, and 0.794, respectively. Berry skin area displayed a full correlation with berry volume, while berry dry weight had a strong and positive relationship with the number of berry seeds (correlation coefficient of 0.603) and berry dry weight % (0.612).

Moderate positive relationships were found among cluster weight, cluster width, and cluster length, with values of 0.505 and 0.483, respectively. Cluster length also showed a moderate positive correlation with the number of berries per cluster, with a correlation coefficient of 0.478. Brix and berry dry weight were found to have a positive and moderate correlation, with a correlation coefficient of 0.504.

Weak positive correlations were observed between cluster width and the number of berries per cluster, with a correlation coefficient of 0.460, Brix and berry fresh weight with a value of 0.418, and Brix and the number of berry seeds with 0.397. Additionally, weak and positive correlations were found between berry width and berry fresh weight, berry fresh weight and the number of berry seeds, and berry fresh weight and berry density, with correlation coefficients of 0.410, 0.400, and 0.411, respectively.

Lastly, only negative correlations were found between berry skin area to berry flesh volume ratio (BSA/BVOL) and berry fresh weight, berry dry weight, berry volume, the number of berry seeds, and berry skin area, with correlation coefficients of −0.805, −0.435, −0.996, −0.363, and −0.998, respectively.

Principal Component Analysis (PCA)

Principal Component Analysis (PCA) was used to evaluate the interaction between artificial stress treatments and the variables under study. A dataset comprising nine treatments and 15 variables was analyzed using the covariance matrix.

The results of the PCA revealed a four-component model that accounted for 87.22% of the total variance. The first principal component explained 39.35% of the overall data variance, while the second and third components explained 22.83% and 13.33%, respectively.

Although the PCA correlation plot (Fig. 7) does not show a distinct separation of the samples based on the treatments and variables, some conclusions can still be drawn. It is important to note that the loading values only indicate correlations between variables and principal components, and do not necessarily imply causation or direct relationships between variables. Nevertheless, they can still provide valuable information about which variables are most significant in explaining the variation in the data.

Principal component analysis (PCA) with the mean values of variables. a Individuals, b biplot (score and loadings plots). All variables are displayed. The size of the arrows indicates the contribution strength of the variable. The size of the circle reflects the magnitude of the contribution to the component. bsa/bvol Berry skin area to berry flesh volume ratio, cw Cluster width, bden Berry density, bdw Berry dry weight, bdwper Berry dry weight %, bfw Berry fresh weight, bvol Berry volume, bsa Berry skin area, nobs Number of berry seeds, bw Berry weight, bl Berry length, cl Cluster length, cweight Cluster weight, nobpc Number of berries per cluster

Samples belonging to the T6 treatment exhibited a significant representation of the variable on the principal component, distinguishing them from the other treatments. T6, T4, and T2 had higher contributions to the component, representing percentages of 34.68, 17.69, and 12.59, respectively.

Individual loadings showed that some treatments had high positive loadings on Dim.1, while others had high negative loadings. Similarly, some treatments had high positive loadings on Dim.2, while others had high negative loadings. Treatments T1 and T5 had high positive loadings on Dim.1, indicating a positive correlation with each other and other variables that had positive loadings on this component. In contrast, treatments T4 and T2 had high negative loadings on Dim.1, indicating a negative correlation with each other and other variables that had negative loadings on this component. Treatments T7 and T8 had high positive loadings on Dim.2, indicating a positive correlation with each other and other variables that had positive loadings on this component. Treatment T6 had a high negative loading on Dim.2, indicating a negative correlation with other variables that had positive loadings on this component. The loading matrix of variables indicates that some variables have high loading values on either Dim.1 or Dim.2, while others have loading values that are relatively balanced between the two dimensions. Brix has a high negative loading value on both dimensions, indicating that it is strongly correlated with both principal components. This means that Brix is an important variable in explaining the variation observed in the data, and variations in Brix may have a significant impact on the overall patterns observed in the dataset. Similarly, berry skin area has a high negative loading value on Dim.1 and a near-zero loading value on Dim.2, suggesting that it is primarily associated with Dim.1.

On the other hand, berry density is found to be strongly correlated with both dimensions but in opposite directions, which means it may have a complex relationship with the other variables in the dataset. Additionally, cluster weight and length were negatively correlated with both principal components, suggesting that they are not strong predictors of the variation in the data. Similarly, cluster weight was found to be in a weak relationship with the other variables in the dataset via less extreme values than other cluster characteristics.

Brix was found to be an important predictor of the variation in the data by high negative loading values on both dimensions. Berry fresh weight was also a good predictor. Berry width and length were strongly correlated with each other and with other variables that have high positive loading values on Dim.2. Berry dry weight (both in grams and %) was moderately correlated with Dim.2, which suggests that it may be more important in explaining variation in that dimension. The number of berry seeds was not as important in explaining the variation in the data as some of the other variables.

Berry skin area was found to have a high negative loading value on Dim.1 and a near-zero loading value on Dim.2. This suggests that berry skin area is primarily associated with Dim.1 and may be less important in explaining variation in Dim.2. This information can be useful when interpreting the results of the PCA, as it suggests that berry skin area is likely to be more closely related to other variables that have a high loading value on Dim.1, such as cluster variables and Brix. By contrast, variables with high loading values on Dim.2, such as berry width, berry length, and berry volume, are likely to be less strongly related to berry skin area.

Interestingly, the variables with the highest loadings on each principal component are related to different aspects of grapevine cluster and berry characteristics. The variables with high loadings on Dim.1 are related to the overall size and weight of the cluster and berry, as well as their sugar content, while the variables with high loadings on Dim.2 are related to the size and shape of the individual berry.

A Heatmap Analysis of Artificial Stress Treatments

The results of the ANOVA indicated that artificial stress treatments did not yield statistically significant outcomes. However, the PCA results revealed that the T6, T4, and T2 treatments emerged prominently in elucidating the variation within the population. Consequently, it is posited that an assessment based on the average values of the chosen variable may hold significance for gauging the effectiveness and outcomes of artificial stress treatments. To explore this further, hierarchical clustering analysis (HCA) was executed on the data using Ward’s method with squared Euclidean distance. This analysis delineated nine clusters among both the artificial stress treatments and variables (Fig. 8).

Heatmap analysis of artificial stress treatments. All variables are displayed. Treatment mean values increase from light green to dark red. bsa/bvol Berry skin area to berry flesh volume ratio, cw Cluster width, bden Berry density, bdw Berry dry weight, bdwper Berry dry weight %, bfw Berry fresh weight, bvol Berry volume, bsa Berry skin area, nobs Number of berry seeds, bw Berry weight, bl Berry length, cl Cluster length, cweight Cluster weight, nobpc Number of berries per cluster

A heatmap was constructed using the variable averages, disregarding clustering in the treatments. Subsequently, aligning with PCA findings, it was observed that the T6 treatment exhibited relatively lower average values in the examined parameters, while the T4 and T2 treatments resulted in higher average values. While this study lacks direct criteria for determining wine quality, the assumption that smaller berry size and increased berry skin area contribute to superior wine properties suggests positive effects of T6 treatments on berry and wine quality. Conversely, T5 demonstrated lower values across various criteria similar to T6. Treatments such as T7, T8, T9, and T3 led to an increase in average values for the examined criteria. Another impact of artificial stress on wine grapes is its influence on the management of berry maturation rate, a challenge exacerbated by the climate crisis. Considering this, the effects of treatments on the °Brix change are deemed significant. T9, T2, T4, and T3 treatments resulted in the accumulation of total soluble solids (TSS) at a level close to the control treatment, whereas T5, T7, T8, and T1 treatments, especially T6, prompted grapevine response to accumulate TSS, consequently slowing down the ripening process.

Conclusions

Based on the available data, it appears that the artificial stress treatments did not result in statistically significant differences in the measured criteria. These criteria include berry weight, diameter, length, dry weight, volume, density, number of seeds, percentage of dry weight, skin area, and BSA/BVOL ratio.

However, there were some notable differences in the means of certain criteria across the treatments. For instance, treatment T4 showed the highest mean for berry weight and berry diameter, whereas treatment T6 displayed the lowest mean values for both criteria. Treatment T3 exhibited the highest mean berry length, while treatment T6 showed the lowest mean value. Treatment T8 had the highest mean berry dry weight, while treatment T6 had the lowest mean value. Treatment T4 displayed the highest mean berry volume, while treatment T6 showed the lowest mean value. Treatment T7 had the highest mean berry density, while treatment T4 exhibited the lowest mean value. Treatment T4 showed the highest mean number of berry seeds, while treatment T6 displayed the lowest mean value.

It is also worth noting that the mean values of BSA/BVOL ratio across the treatments did not vary significantly and were relatively consistent, ranging from 4.26 to 4.58. This suggests that the ratio between the berry’s skin area and flesh volume may be less affected by the artificial stress treatments than other criteria.

Nonetheless, the observed differences in certain criteria between treatments suggest that there might be some impacts of the treatments on grapevine physiology, although additional research may be necessary to gain a full understanding of these effects. Further investigation is required to identify treatments that can notably enhance the quality attributes of grapes.

References

Abay C (2022) The effects of some abiotic stresses on primary and secondary metabolits in cv. Cabernet-Sauvignon (Vitis vinifera L.) (in Turkish with English abstract). Tekirdağ Namık Kemal University, Tekirdağ (Master’s thesis)

Bahar E, Korkutal İ, Kurt C (2011) Water deficit effect on different phenological growth stages in grape berry growing, development and quality (in Turkish with English abstract). Trak Univ J Nat Sci 12:23–34

Bahar E, Carbonneau A, Korkutal I (2017) Vine and berry responses to severe water stress in different stages in cv. Syrah (Vitis vinifera L.). Jotaf 14:62–70

Barbagallo MG, Guidoni S, Hunter JJ (2011) Berry size and qualitative characteristics of Vitis vinifera L. cv. Syrah. Sajev 32(1):129–136. https://doi.org/10.21548/32-1-1372

Candar S (2022) Effects of mechanically induced abiotic stress on berry and cluster physical properties of cv. Cabernet sauvignon grape variety. Cukurova 8th International Scientific Researches Conference, Adana, 15–17 April. Full Texts Book, vol 1, pp 1028–1037. ISBN 9786258377514.

Candar S (2023) How abiotic stress induced by artificial wounding changes maturity levels and berry composition of Merlot (Vitis vinifera L.). Eur Food Res Technol. https://doi.org/10.1007/s00217-023-04318-6

Candar S, Bahar E, Korkutal İ, Alço T, Gülcü M (2019a) The effects of different green pruning applications on berry maturaton in Merlot (Vitis vinifera L.) (in Turkish with English abstract). Adnan Menderes Uni J Agric Sci 16(1):53–61. https://doi.org/10.25308/aduziraat.520923

Candar S, Alço T, Yaşasın A, Korkutal İ, Bahar E (2019b) Evaluation of long term changes for viticultural indices in Turkey Thrace (in Turkish with English abstract). Comujaf 7(2):259–268. https://doi.org/10.33202/comuagri.524811

Candar S, Bahar E, Korkutal İ (2020) Impacts of leaf area on the physiological activity and berry maturation of Merlot (Vitis vinifera L.). Appl Ecol Environ Res 18(1):1523–1538. https://doi.org/10.15666/aeer/1801_15231538

Castellarin SD, Matthews MA, Di Gaspero G, Gambetta GA (2007) Water deficits accelerate ripening and induce changes in gene expression regulating flavonoid biosynthesis in grape berries. Planta 227:101–112. https://doi.org/10.1007/s00425-007-0598-8

Chen WK, He F, Wang YX, Liu X, Duan CQ, Wang J (2018) Influences of berry size on fruit composition and wine quality of Vitis vinifera L. cv. ‘Cabernet Sauvignon’ grapes. Sajev 39(1):67–76. https://doi.org/10.21548/39-1-2439

Coombe BG, McCarthy MG (2000) Dynamics of grape berry growth and physiology of ripening. Aust J Grape Wine Res 6(2):131–135. https://doi.org/10.1111/j.1755-0238.2000.tb00171.x

Deloire A, Ojeda H, Zebic O, Bernard N, Hunter JJ, Carbonneau A (2005) Influence de l’état hydrique de la vigne sur le style de vin. Progr Agric Vitic 21:455–461

Ferrara G, Gallotta A, Pacucci C, Matarrese AMS, Mazzeo A, Giancaspro A, Gadaleta A, Piazzolla F, Colelli G (2017) The table grape ‘Victoria’ with a long shaped berry: a potential mutation with attractive characteristics for consumers. J Sci Food Agric 97(15):5398–5405. https://doi.org/10.1002/jsfa.8429

Hunter JJ, Ruffner HP, Volschenk CG, Le Roux DJ (1995) Partial defoliation of Vitis vinifera L. cv Cabernet Sauvignon/99 Richter: Effect on root growth, canopy efficiency, grape composition and wine quality. Ajev 46:306–314

Jones HG, Jones MB (1989) Introduction: some terminology and common mechanisms. In: Jones HG, Flowers TJ, Jones MB (eds) Plants under stress. Cambridge University Press, Cambridge, pp 1–10

King PD, Smart RE, McClellan DJ (2015) Timing of crop removal has limited effect on Merlot grape and wine composition. Agric Sci 6(4):456–465. https://doi.org/10.4236/as.2015.64045

Kok D, Bal E, Celik S (2013) Influences of various canopy management techniques on wine grape quality of V. vinifera L. cv. Kalecik Karası. Bjas 19(6):1247–1252

Korkutal İ, Bahar E (2013) Influence of different soil tillage and leaf removal treatments on yield, cluster and berry characteristics in cv. Syrah (Vitis vinifera L.). Bjas 19(4):652–663

Korkutal İ, Bahar E, Bayram S (2017) Different soil tillage and leaf removals effects on water stress, berry and cluster properties of cv. Syrah (in Turkish wtih English abstract). J Agric Fac Ege Uni 54(4):397–407. https://doi.org/10.20289/zfdergi.386422

Korkutal İ, Bahar E, Carbonneau A (2019) Early water stress effects on pollen viability, berry set and embryo development in cv. ‘Syrah’ (Vitis vinifera L.). J Hortic Sci 46(4):215–223. https://doi.org/10.17221/110/2018-HORTSCI

Korkutal İ, Bahar E, Güvemli DD (2020) Determination the effects of antitranspirant application on the grape berry and cluster characteristics in veraison and post-veraison period (in Turkish wtih English abstract). J Agric Fac Ege Uni 57(1):83–93. https://doi.org/10.20289/zfdergi.594224

Korkutal İ, Bahar E, Azsöz S (2021) Determination of the effects of leaf removal and cluster thinning applications at different times in cv. Michele Palieri on cluster properties (in Turkish with English abstract). Mustafa Kemal Uni J Agric Sci 26(2):376–386. https://doi.org/10.37908/mkutbd.908853

Lorenz D, Eichhorn K, Bleiholder H, Klose R, Meier U (1995) Phenological growth stages of the grapevine (Vitis vinifera L. ssp. vinifera)-codes and descriptions according to the extended BBCH scale. Aust J Grape Wine Res. https://doi.org/10.1111/j.17550238.1995.tb00085.x

Mateus N, Marques S, Goncalves AC, Machado JM, De Freitas V (2001) Proanthocyanidin composition of red Vitis vinifera varieties from the Douro Valley during ripening: Influence of cultivation altitude. Ajev 52:115–121

Matthews MA, Nuzzo V (2007) Berry size and yield paradigms on grapes and wines quality. Acta Hortic 745:423–436. https://doi.org/10.17660/actahortic.2007.754.56

OIV (2021) Compendium of international methods of wine and musts. Vol 2. https://www.oiv.int/int. Accessed 4 June 2021

Palma L, Novello V, Tarricome L, Frabboni L, Lopriore G, Soleti F (2007) Grape and wine quality as influenced by the agronomical soil protection in a viticultural system of southern Italy. Quaderni Sci Viticole Enol Univ Torino 29:83–111

Pelsy F (2010) Molecular and cellular mechanisms of diversity within grapevine varieties. Heredity 104(4):331–340

Poni S, Bernizzoni F, Civardi S, Libelli N (2009) Effects of pre-bloom leaf removal on growth of berry tissues and must composition in two red Vitis vinifera L. cultivars. J Grape Wine Res 15(2):185–193. https://doi.org/10.1111/j.1755-0238.2008.00044.x

Poni S, Gatti M, Palliotti A, Dai Z, Duchêne E, Truong TT, Ferrara G, Matarrese AMS, Gallotta A, Bellincontro A, Mencarelli F, Tombesi S (2018) Grapevine quality: a multiple choice issue. Sci Hortic 234(14):445–462. https://doi.org/10.1016/j.scienta.2017.12.035

R Core Team (2016) R: a language and environment for statistical computing. R Foundation for Statistical Computing, Vienna

Roby G, Matthews M (2004) Relative proportions of seed, skin and flesh, in ripe berries from Cabernet Sauvignon grapevines grown in a vineyard either well irrigated or under water deficit. Aust J Grape Wine Res 10(1):74–82. https://doi.org/10.1111/j.1755-0238.2004.tb00009.x

van Schalkwyk D (2004) Methods to determine berry mass, berry volume and bunch mass. Wynboer, A Technical Guide for Wine Producers. http://www.wynboer.co.za/recentarticles/0409methods.php3. Accessed 4 Mar 2022

Tok Abay C (2021) The effects of some abiotic and biotic stresses on primary and secondary metabolits in cv. Cabernet-sauvignon and cv. Merlot (in Turkish with English abstract). Tekirdağ Namık Kemal University, Tekirdağ (Master’s thesis)

Acknowledgements

The author would like to thank Elman Bahar for helping in the design of the trial, Ecem Kübra Demirkapı and Özgür Aygan for their contributions to the field and laboratory work, Jannat Khan for English grammar check and visualizations, and İlknur Korkutal for her contribution to the intellectual content of the article.

Funding

This study was not funded from any source.

Author information

Authors and Affiliations

Contributions

The author is responsible for all stages of the study, including the design and carrying out of the experiment, the data collection, and the article’s writing.

Corresponding author

Ethics declarations

Conflict of interest

S. Candar declares that he has no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Candar, S. Understanding the Impact of Artificial Stress on the Morphological Characteristics of cv. ‘Merlot’ Berry and Cluster. Applied Fruit Science 66, 257–267 (2024). https://doi.org/10.1007/s10341-023-01002-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10341-023-01002-7