Abstract

A series of field bioassays was conducted to evaluate the effects of electric infrared (IR) penetration on microbial disinfection and insect control as well as on the organoleptic characteristics of dried black currants (Corinthian currants, Vitis vinifera L. var. Apyrena). A continuous IR processor was placed in the production line of an industrial facility and was used for the field assays. In a series of bioassays, currants were fed into the IR processor and examined with and without process agitation at different treatment parameters including retention times (ranging from 30 to 35 s) and various peak temperatures (45, 50, 55, 60, 65, 70 and 75 °C). Samples of processed currants were randomly selected for microbial analysis, as well as for determination of organoleptic characteristics. Infrared treatment resulted in a significant reduction of total viable counts, yeasts and moulds by factors ranging from 10 to 300. Increase of treatment time and peak temperature was positively correlated with microbial reduction. Sensory attributes were not affected up to 60 °C, while crystalline texture and overall acceptance were affected by IR treatment at 70 °C. With respect to currant phenolics, antioxidants that have potential benefits to human health, IR heating resulted in almost the same effect up to 65 °C, i.e. approximately 20 % reduction; higher peak temperatures further lowered total phenolic values. 5-hydroxymethylfurfural (HMF) formation was low up to 55 °C, while increased at higher temperatures; however, values still remained low as compared with dried fruit HMF levels. In another series of bioassays, golden sultanas were artificially infested with larvae of Ephestia elutella and adults of Oryzaephilus surinamensis and Tribolium confusum and treated with IR in agitating flow process at different peak temperatures (45, 50, 55, 60, 65 and 70 °C). Finally, a batch series of non-agitated flow process tests were conducted in glass Petri dishes. Briefly, O. surinamensis and T. confusum adults were exposed to IR penetration for different time exposure intervals (1, 2, 3, 4, 5, 8, 10 and 20 s) with and without the presence of currants and sultanas. In the bioassays with infested sultanas, all IR treatments with agitation provided complete control of the insect species tested, since IR-treated sultanas were found free of insects even 1 year after treatment. For exposure intervals higher than 4 s in the non-agitated flow process, all adults of O. surinamensis and T. confusum were killed in glass Petri dishes consisting of insects only and without the presence of currants and sultanas. In contrast, the presence of currants and sultanas in the non-agitated flow process reduced significantly the killing rate efficacy of IR against the insect species tested, especially on the individuals located beneath the sultanas and currants and where the infrared light could not penetrate them. Our results suggest that electric infrared heating with light source penetration could be a valuable tool for rapid and successful reduction of the microbial load and post-harvest insect disinfestation of dry currants and sultanas, provided that adequate agitation within the infrared process chamber is achieved so that sultanas and currants could be penetrated consistently in a three-dimensional manner.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Key message

-

Insecticidal and microbicidal effects of infrared heating by electric infrared light source penetration techniques were evaluated.

-

Infrared heating provided effective control against storage insects, as long as agitation allowed a three-dimensional treatment of the commodity.

-

The population of bacteria and the counts of yeasts and moulds were significantly reduced and in some cases completely inactivated.

-

Currants sensory attributes and organoleptic characteristics in total were not affected up to 60 °C.

Introduction

Currants or Corinthian raisins (Vitis vinifera L. var. Apyrena) are naturally sun-dried grapes. They are produced from a special type of black grape, resulting in black to dark purple coloured dried berries. In Greece, Corinthian raisins annual production is approximately 35.000 metric tons, representing more than 3 and 80 % of the global-dried vine fruits and currants production, respectively (Chiou et al. 2014).

While currants are dried in the vineyard or stored in the warehouse, they can be infested by various stored-product insect pests. Several species, such as the almond moth, Ephestia cautella Walker (Lepidoptera: Pyralidae), the tobacco moth, E. elutella Hübner (Lepidoptera: Pyralidae), the Indian meal moth, Plodia interpuntella Hübner (Lepidoptera, Pyralidae), the dried fruit beetle, Carpophilus hemipterus (L.) (Coleoptera, Nitidulidae) and the sawtoothed grain beetle, Oryzaephilus surinamensis (L.) (Coleoptera, Sylvanidae), are often responsible for post-harvest infestations of currants (Alfaifi et al. 2014; Cetinkaya et al. 2006; ICGFI 1995). Since currants are often stored for a long period before processing and packaging, insect pests can develop high populations, leading to the deterioration of the final product. Currently, chemical treatments of the infested commodity, using fumigants as phosphine or residual insecticides, are repetitively used against post-harvest infestations (Fields and White 2002). However, the development of resistance to phosphine and several commonly used insecticides has decreased in many cases the efficacy of chemical control (Collins et al. 1993; Guedes et al. 1996; Nayak et al. 2013; Opit et al. 2012; Pimentel et al. 2010; Subramanyam et al. 1989; Zettler and Cuperus 1990). Moreover, the public demand for more environmentally friendly approaches for food processing, as well as the concerns about human health risks that derive from pesticides have provided a strong impetus for the exploitation and development of new techniques and technologies for disinfestation and sterilization of agricultural products. Vail et al. (1991) studied the efficacy of a granulosis virus against P. interpunctella on raisins, to conclude that high level of control can be achieved with this virus. Similarly, cold (10 °C) and controlled atmosphere (5 % O2) storage were also tested with success against this species in raisins (Johnson et al. 2002).

Electric infrared (IR) light source penetration technique is a novel method, which is based on the application of electromagnetic radiation (0.78 up to 1000 μm wavelength), in order to heat the exposed commodities (Ramaswamy et al. 2012). When irradiating foodstuff a heating source transfers energy to the commodity without increasing the temperature of the surrounding air (Khir et al. 2011). Infrared heating has some undisputable advantages over other techniques that cause sterilization and disinfestation: it offers controlled, rapid heating, there are no residues in the commodity, it is cost efficient and highly effective in lowering the microbial content and disinfecting the product, and consequently in extending its quality and increasing its shelf-life (Ramaswamy et al. 2012). Infrared processing technology has recently found many applications in food industry, like dehydration, roasting, pasteurization and microbial decontamination (Gabel et al. 2006a, b; Khir et al. 2011, 2014; Nazari 2014; Ramaswamy et al. 2012; Shi et al. 2008).

The effectiveness of gas-fired infrared in disinfesting cereal grains and rice was first studied in the 60’s and 70’s (Cogburn 1967; Cogburn et al. 1971; Kirkpatrick and Tilton 1972; Kirkpatrick et al. 1972; Kirkpatrick 1975; Tilton et al. 1972, 1983; Tilton and Schroeder 1961, 1963). Lately, flameless catalytic infrared heating has been tested against some major stored-product insects on grains (Khamis 2009; Khamis et al. 2010, 2011a, b, c). For instance, Khamis et al. (2010) reported high levels of mortality against all life stages of the lesser grain borer Rhyzopertha dominica (F.) (Coleoptera: Bostrychidae) using a flameless catalytic infrared emitter. However, there is currently no information available on the efficacy of electric infrared heating against stored-product insects related with dried fruits, and particularly currants.

The objectives of the present study were: 1. to determine the effective IR heating conditions for the microbial decontamination of currants, 2. to study the effect of electric infrared heating on disinfestation of commonly present pests to the organoleptic characteristics, antioxidant content, and Maillard intermediate reaction products of currants (Capuano and Fogliano 2011), and 3. to study the effect of electric infrared heating on E. elutella, O. surinamensis and the confused flour beetle Tribolium confusum Jacquelin du Val (Coleoptera: Tenebrionidae).

Materials and methods

Reagents and chemicals

Folin–Ciocalteu reagent, sodium carbonate and methanol were purchased from Merck (Darmstadt, Germany). 5-Hydroxymethylfurfural and concentrated hydrochloric acid (37 % w/v) were purchased from Sigma (Steinheim, Germany).

Test insects and commodity

All species were reared at the Laboratory of Entomology and Agricultural Zoology at 25 °C, 65 % relative humidity (r.h.) and continuous darkness. From the species tested, T. confusum and O. surinamensis were reared on wheat flour and cracked oats, respectively. Ephestia elutella was reared on whole meal wheat flour with 5 % yeast. For both beetle species, adult beetles <1 month-old were used in the tests. In the case of E. elutella, third- and fourth-instar larvae were selected for experimentation. Untreated and clean currants and sultanas were used in the bioassays, which were taken from the 2013 Greek harvest. Currants and sultanas were inspected for the presence of insects before being used for the experiments and were found to be free of adult or larval stages of insects.

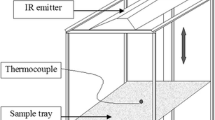

Electric infrared light source heating treatment

The bioassays were conducted in the production facilities of the Agricultural Cooperatives’ Union of Aeghion S.A. A continuous IR processor test pilot designed and manufactured by Mr. Andrew Karagiannis, founder and managing director of irtech, was used in all bioassays. The continuous, stainless-steel IR processor including its feeder compartment had a total footprint of L = 5.0 m, W = 1.2 m, H = 1.8 m with a total electric power consumption of 25 kW and capable of processing up to 600 kg per hour.

Field assay series 1: effect of electric infrared light source heating on currants organoleptic characteristics, microbial content and phenolic antioxidants

Currants were fed into the continuous IR processor which had the flexibility to perform testing with different process parameters. The following peak temperatures were tested: 45, 50, 55, 60, 65, 70 and 75 °C, while the retention time (the time currants were processed into the IR processor) varied from 30 to 35 s. The IR processor had a wide range of adjustable process parameters such as product feed rate, retention time, flow rate, volume/mass rate, IR wavelength, IR power intensity, IR pulse rate, product agitation rate, including peak temperature control in order to set and perform the appropriate operation for efficient and effective treatment. At the exit of the IR processor, samples of currants (approximately 200 g each) were taken for determination of the organoleptic characteristics and analysis of microbial content and phenolic antioxidants. Samples were always taken in duplicate. One of the samples was forwarded for microbial content analysis and the other one for analysis of the organoleptic characteristics and phenolic content of currants. Two untreated samples of currants (approximately 200 g each) were taken just before the entrance of the IR processor and served as controls. Samples were stored at room temperature. All analyses were carried out within 1 month.

The organoleptic characteristics including appearance, texture (hardness, crystalline texture), flavour, odour, aroma and general acceptance of currants were evaluated before and after infrared treatment, by 10-trained panellists. Each sensory attribute was evaluated by hedonic sensory tests and rating tests, on which the sensory panel had been trained. First, the samples were evaluated using a 9-point hedonic scale, including point 1 (dislike extremely), 5 (neither like nor dislike) and 9 (like extremely). The product was considered as acceptable when rating score was above 5 (Mestdagh et al. 2008). Τhe intensity of sensory characteristics was evaluated by using a 1–9 rating scale as well (1 = very slightly/not at all detectable, 9 = extremely detectable).

For microbial analyses, appropriate currants dilutions (10−1, 10−2, 10−3) were prepared in peptone water; sample homogenization was carried out by Bag Mixer (Interscience, France) for at least 2 min. Yeasts and moulds determination and total viable count were performed by the pour plate count on Dichloran-Glycerol Agar Base (DG18 CM729 Oxoid, Hampshire, England) and Standard Plate Count Agar (APHA Oxoid CM0463B, Hampshire, England), respectively. Plating was performed in triplicates and the enumeration was based on the average. Incubation was conducted at 25 °C for 96–144 h for yeasts and moulds and at 30 °C for 48 h with respect to total viable counts. Microbial counts were expressed as total number of microorganisms per g of sample (CFU/g = Average plate count multiplied by dilution factor).

Currants phenolic content was analysed as previously described (Chiou et al. 2014) by extracting mechanically homogenized currant samples (approx. 1.5 g) with acidified methanol (methanol/HCl 0.1 % v/v, 4 × 5 mL). Total phenolic content was determined spectrophotometrically according to Arnous et al. (2002). All data were acquired using a Specord 200 (Analytik Jena AG, Germany) UV–Vis spectrophotometer. Absorbance was read at 750 nm; results were expressed as gallic acid equivalents (GAE) per 100 g of currants.

5-Hydroxymethylfurfural (HMF) was analysed as previously described (Murkovic and Pichler 2006), by extracting mechanically homogenized currant samples (approx. 1 g) with methanol (2 mL). For HMF determination, an HPLC system (Agilent Technologies, model 1050, Waldbronn, Germany) combined with quaternary pump, auto-sampler, diode array detector (HP-1050), fluorescence detector (HP-1046A) and data analysis software was used. RP-HPLC analysis was performed as previously described (Murkovic and Pichler 2006) with modifications. Briefly, methanol (20 %) in water was used as elution solvent in isocratic mode on a Purospher STAR, RP-18 endcapped (250–4.6 mm, 5 µm) column (Merck, Darmstadt, Germany) at flow rate 0.8 mL/min. Aliquots of 10 μL were subjected to HPLC analysis with UV (280 nm) detection. External standard quantification was performed based on a series of ten different standard concentrations.

Field assay series 2: effect of electric infrared light source heating on stored-product insects

Lots of 5 kg of sultanas were artificially infested with 40 larvae of E. elutella and 100 adults of each O. surinamensis and T. confusum. These particular species were selected because they were the main stored-product insects present in the storage facilities of a commercial facility in southern Greece. Currants were continuously fed into the IR processor as described above and served as the baseline of a continuous agitating flow system. Infested sultanas were fed into the IR processor and tested for different IR treatment conditions. The following treatments were tested: uninfested and untreated control, infested and untreated control, infested control, processed through the IR processor without IR penetration using only conductive heating and infested sultanas treated with IR heat penetration at various exposure conditions. The following peak temperatures were tested: 45, 50 55, 60, 65 and 70 °C, while the retention time was set to 33 s. Sultanas were chosen as commodity for this bioassay because of their bright brown colour, clearly differentiated from dark coloured currants. Since currants are coloured black to dark blue, infested sultanas served as the marker in the continuous flow of black currants which made easier the recognition of the introduced insects at the exit of the processor, where sultanas were collected in transparent plastic boxes (50 × 30 × 20 cm). After treatment, sultanas were stored in the plastic boxes at 25 °C and continuous darkness. After 3 months, a subsample (200 g) of the initially treated quantity of sultanas was taken from each box, and the number of live insects present was estimated. In the case of E. elutella adults, the total number of alive individuals present in each box was recorded. Sampling of the initial quantity was repeated 4, 6 and 12 months after treatment, as described above. Each treatment was replicated three times (three lots of sultanas).

In another series of bioassays, insects were exposed to IR heating with non-agitating flow process in glass Petri dishes. Adults of O. surinamensis and T. confusum were used in these tests. Ten individuals were placed in each Petri dish, with separate dishes for each species. Insects were exposed to IR heating for different exposure intervals (2, 4, 8, 10 and 20 s) using the IR processor without agitation flow process as IR source. The following treatments were tested: insects alone, insects with currants and insects with sultanas. Mortality of the exposed individuals was assessed visually immediately after the dish was removed from the processor. The same procedure was repeated three times (three dishes).

Data analysis

Data from the bioassay with the artificially infested sultanas were submitted to one-way ANOVA to determine differences among treatments within each insect species, life stage and sampling period, with the JMP 7 software (SAS Institute Inc., Cary, North Carolina, USA). In the tests with the glass Petri dishes, mortality data were submitted to a two-way ANOVA to determine differences among treatments, with percentage of mortality as the response variable and the exposure interval and the presence or absence of product as the main effects. In all cases, means were separated using the Tukey HSD test at the 5 % level (Zar 1999). With respect to organoleptic characteristics, microbial content, HMF and phenolic antioxidants presence, results presented are the average of the obtained values. Data handling was carried out using Microsoft Excel. For the statistical analysis, linear regressions and one-way ANOVA were applied using SPSS (SPSS 20.0 for Windows, Chicago, IL, USA). Tukey’s multiple range tests were performed post hoc to evaluate differences among groups. A P-value of less than 0.05 was considered significant.

Results

Field assay series 1: effect of electric infrared light source heating on currants organoleptic characteristics, microbial content, HMF and phenolic antioxidants

Panellists evaluated the appearance, texture (hardness and crystalline texture), colour, odour, taste and flavour of currants before and after IR heat treatment with agitation by using a 9-point rating scale (Fig. 1). Electric Infrared heating at temperatures 45, 50, 55 and 60 °C did not statistically affect the sensory attributes in total as compared to the control, i.e. untreated currants. Overall acceptance was statistically lower for samples treated at temperatures higher than 60 °C, whereas samples treated at 65 °C and 70 °C were not statistically different from each other. Heating at 70 °C significantly affected appearance and crystalline texture while at 75 °C all evaluation parameters were statistically lower. Colour, aroma, smell and taste were statistically affected only at 75 °C. Weak positive correlations between overall acceptance and appearance (r = 0.272, P < 0.05), colour (r = 0.334, P < 0.05), taste (r = 0.374, P < 0.05) and aroma (r = 0.365, P < 0.05) were found. Furthermore, overall appearance was negatively correlated, though weakly, with hardness (r = 0.323, P < 0.05) and crystalline texture (r = 0.320, P < 0.05). No correlation was observed between overall acceptance and odour.

Total microbial and yeast and mould counts before and after electric infrared heating are reported in Table 1. In all cases, a reduction of targeted microorganisms after infrared treatment was observed, whereas increase of temperature was found to be positively correlated (P < 0.05) with microbial reduction. No statistically significant differences were observed among heating treatments at 70 and 65 °C, as reductions of 2.6 and 2.5 log were obtained, respectively, for total viable count (375- and 333-fold reduction). With respect to yeasts and moulds, infrared treatment at 70 °C achieved 3.8 log reduction (6000-fold reduction), while at 65 °C total inactivation occurred. Electric Infrared heating at 60 °C did not affect the microbial population, however, inactivated yeasts and moulds in total. Total microbial and yeast and mould counts were reduced by 0.55 and 0.60 log CFU/g, respectively, in currants treated at 55 °C (3.6- and 4.0-fold reduction, respectively). IR treatments at 45 and 50 °C resulted in 0.62 log (4.2-fold) and 0.25 log (1.8-fold) reduction of total viable count, respectively, and 1.07 log (11.8-fold) and 1.45 log (28.7-fold) reduction of yeasts and moulds, respectively.

Total phenolic content of the untreated samples was 311 ± 39 mg GAE/100 g. After infrared heating, phenolic content was found in the range of 200 ± 8 to 252 ± 5 mg GAE/100 g (Fig. 2), being lower than that of the untreated samples. Infrared heating resulted in almost the same effect up to 65 °C, while higher temperatures, i.e. 70 and 75 °C, further lowered total phenolic values.

Untreated currants HMF content was 15.2 ± 5.6 mg/kg while after infrared heating it was found in the range of 23.4 ± 0.8 to 154.1 ± 6.6 mg/kg (Fig. 3). HMF formation was rather the same up to 55 °C, while higher temperatures increased HMF values.

Field assay series 2: effect of electric infrared light source heating on stored-product insects

In the bioassay with the artificially infested sultanas, the number of live insects was in almost all cases significantly affected by the IR treatments with agitated flow process at all sampling periods at the P < 0.01 level (Table 2). At all samplings, the highest number of individuals was recorded at the infested and not treated control, with O. surinamensis adults being the most abundant taxa (Table 3). In contrast, in all IR-treated sultanas with agitation, no presence of insects was detected at all samplings and complete control of the tested insects was in all cases achieved (Table 3). Number of T. confusum adults were low even in the controls. Insects, mainly O. surinamensis, were found also in the untreated and uninfested control (Table 3), indicating that the sultanas used in the bioassay were also naturally infested by insects.

In the bioassay with the non-agitated IR treatment in glass Petri dishes mortality of O. surinamensis and T. confusum adults was significantly affected by the exposure interval, as well as the presence of the product and the associated interaction (Table 4).

All individuals of O. surinamensis and T. confusum were killed after exposure longer than 4 s to non-agitated IR penetration without product (Table 5). In contrast, the presence of currants and sultanas reduced significantly the efficacy of non-agitated IR penetration against the insect species tested (Table 5). The type of commodity did not affect significantly the mortality levels of both insects tested (Table 5).

Discussion

Greece is the main producer of currants with more than 80 % of their global production being of Greek origin (Chiou et al. 2014). Sun-drying of currants is followed by bulk storage in warehouses, where, due to the favourable climatic conditions, they are vulnerable to insect infestations. During this stage, the commodity is attacked by several moth (mostly P. interpunctella, E. cautella and E. kuehniella) and beetle (mostly Oryzaephilus spp. and Carpophilus spp.) species, which are commonly found in dried fruits globally (Ahmed 2001; Alfaifi et al. 2014; Buchelos 1980; Cetinkaya et al. 2006; ICGFI 1995). The withdrawal of methyl bromide from developed countries (Bell 2000; Hagstrum and Flinn 2014) resulted in a thorough redesign of the pest control strategies for these commodities, which is currently based on the structural applications with pesticides (mostly pyrethroids) as well as on fumigation of the product with phosphine, as a pre-shipment treatment. However, both techniques are associated with serious concerns about human health and environmental hazards. At the same time, several strains of major stored-product insect species are now possibly resistant to residual insecticides and/or phosphine, which consists an additional implication regarding pre-shipment applications. Cetinkaya et al. (2006) investigated the effectiveness of ionizing radiation for the disinfestation of dried raisins, figs and apricots and reported that low radiation doses could effectively control post-harvest insect infestations. Food irradiation though does not have consumer’s acceptance, due to public concerns about the safety of facilities using radioactive isotopes (Phillips and Throne 2010). Lately, Khamis (2009) studied extensively the effect of flameless catalytic infrared radiation on stored wheat insects and wheat quality and reported that IR was effective for the control of R. dominica (Khamis et al. 2010), T. castaneum (Khamis et al. 2011a) and the rice weevil Sitophilus oryzae (L.) (Coleoptera: Curculionidae) (Khamis et al. 2011c). Our study describes for the first time the effect of non-ionizing Infrared light source penetration on stored-product pests of currants. No insect infestation was recorded on artificially infested sultanas even 1 year after treatment with infrared heating. In contrast, in the artificially infested, untreated control samples numerous insects were present, mainly O. surinamensis adults and E. elutella larvae, at most samplings. Tribolium confusum did not reproduce successfully on dried sultanas, which indicates that this species, despite the fact that it can be recorded on dried fruit, it is mostly associated with amylaceous products (Aitken 1975). We used T. confusum for our tests, since this species was found relatively often in currants and sultana warehouses of the area, but, in general, O. surinamensis was the dominant beetle species in these commodities, and the presence of T. confusum can be considered as rather opportunistic. Nevertheless, Buchelos (1980) found both T. confusum and T. castaneum in currants and sultanas that were stored in Peloponnese, suggesting that this species is likely to occur in low numbers. The fact that adults and larvae of O. surinamensis and E. elutella emerged from untreated and uninfested sultanas suggested that these two species were present on the sultanas or currants at the initiation of the experiment, indicating the presence of a considerable naturally occurring population in the untreated commodity. Also, given that the commodity that was to be treated was visually examined before the initiation of the experiments, we assume that most of the populations of O. surinamensis and E. elutella were at the egg or young larval stages. The complete suppression of insects’ presence in IR-treated currants and sultanas suggests that IR has also ovicidal activity against these two insect species. Khamis et al. (2011c) found that eggs were the most tolerant stage of S. oryzae to infrared radiation, while Kirkpatrick (1975) reported only 8 % mortality of eggs of S. oryzae that had been previously exposed to infrared radiation. Consequently, the results that are reported here clearly indicate that this specific IR application can be used for long-term protection of currants, at least for the species range tested here (Table 5).

Our tests with the glass Petri dishes show that in the presence of product, practically, IR had no effect on insects, as the commodity absorbed all infrared penetration due to non-process agitation, and insects were “invulnerable” under the commodity. Moreover, this was evident regardless of the type of the commodity, the species and the exposure interval. Hence, practically, the existence of a screw conveyor system is essential for the distribution of heat that is produced by the IR, and, without this system, insect control would have been low. In a study with the application of ozone on grains, McDonough et al. (2011) found that a screw conveyor system was critical to obtain high insect mortality and fungal control, as, apparently, this system distributed the gas better in the entire grain mass, as compared with the application of ozone in a two-dimensional conveyor belt. Our results for currants confirm the above observation for the importance of this screw conveyor system during the application of IR that allows a three-dimensional treatment of the commodity. Additional experimental work is needed to examine if this system also enhances the efficacy of other techniques and substances that are applied directly on the grain, such as the application of grain protectants. Finally, although the present results show that, to some extent, T. confusum was more tolerant than O. surinamensis, practically, IR was ineffective for both species, at the glass-dish tests in the presence of product, even at exposures as high as 20 s, which were destructive for the commodity. Kirkpatrick and Tilton (1972) tested the heat tolerance of several stored-product insect species and T. confusum and O. surinamensis were both ranked as the most susceptible to heat.

As mentioned earlier, electric infrared light source heating is becoming an important process in the food sector, offering several advantages over the conventional heating systems; besides other applications, IR heating has been successfully used in food pasteurization (Rastogi 2012). Bacteria, yeasts, moulds and spores can be inactivated by the application of IR heating (Krishnamurthy et al. 2008a). Moreover, inactivation of pathogen bacteria, namely E. coli (Sawai et al. 2000), Bacillus subtilis (Hamanaka et al. 2006), Listeria monocytogenes (Huang 2004) and Staphylococcus aureus (Krishnamurthy et al. 2008b) has been demonstrated. IR heating has been shown to effectively inactivate microorganisms in several kinds of food including meat products (Braeckman et al. 2009; Huang 2004; Huang and Sites 2008), milk (Krishnamurthy et al. 2008b), eggs (James et al. 2002), fruits (Tanaka et al. 2007), vegetables (Gabel et al. 2006a, b), nuts (Brandl et al. 2008) and spices (Staack et al. 2008). Herein, the population of bacteria was reduced from 0.25 to 2.57 log CFU/g; counts of yeasts and moulds were reduced from 0.60 to 3.77 log CFU/g while, depending upon treatment temperature, in some cases complete inactivation was achieved. Similar results have been observed for figs where fungal count was reduced to 1 log10 CFU/mL (Hamanaka et al. 2011) and for strawberries where pathogenic microorganisms were reduced from 2.5 to 5.2 log, after 30 and 10 s of IR treatment, respectively (Tanaka et al. 2007). Corinthian currants are consumed lavishly as snacks; they also serve as parts of traditional recipes in cakes and other bakery products. Under the perspective of expanding currants uses in other food formulations, such as chocolate, bacteria and yeast and mould control becomes a crucial parameter. Thereat, infrared heating may provide a fast and efficient method, effective in reducing total viable count and population of yeasts and moulds, depending upon treatment temperature. This is considered important, given that at the same time currants sensory attributes in total are not affected up to 60 °C, while the product remains under rather acceptable ranges even after treatment at temperatures as high as 75 °C. Food exposure at high temperatures is well known to significantly affect both its nutritional quality and sensory attributes; in this context, currant sensory properties were considered necessary to evaluate after infrared heating. There is only limited literature with respect to the effect of infrared heating on food organoleptic characteristics (Heist and Cremer 1990; Shyue et al. 1996; Yung et al. 2008).

Polar phenolic compounds are unambiguous plant antioxidants, and their consumption being largely associated with several beneficial heath effects (Del Rio et al. 2013). In our study, infrared heating resulted in almost the same effect up to 65 °C, i.e. a 19–24 % reduction in Corinthian currants total phenol content. The phenolic content was further lowered at higher temperatures. It is worth mentioning; however, that in all cases values for currants total phenols was within the range of those previously reported for untreated currants (Chiou et al. 2007, 2014). Zilic et al. (2013) reported that total phenolics in maize grains were lower after infrared heating for 50 and 100 s at 110–140 °C; an up to 48 times decrease was observed after infrared heating at 140 °C for 100 s. Contrary to that, IR heating significantly increased fresh-cut mango phenolics after treatment for 5 min (Sogi et al. 2012). An increase of total phenol content has also been observed after infrared heating of soybean at 100 °C for 40 s (Zilic et al. 2014). Lee et al. (2003) reported that heat treatment, including infrared, could liberate and activate low molecular weight natural antioxidants since many of natural plant antioxidants are found in bound forms. On the other hand, enzymatic activities may account for phenolics losses. In the case of Thomson seedless grapes, polyphenol oxidase was affected by temperature and inhibited by sugars; however, inactivation has been found to occur after treatment at 70 °C for 10 min (Zheng et al. 2012). Further research on individual phenolics compounds fate during infrared heating will clarify the behaviour observed with respect to Corinthian currant phenolic antioxidants.

HMF is an intermediate Maillard reaction product formed by the dehydration of sugars under acidic environment (Capuano and Fogliano 2011). Dried fruit HMF content has been reported in the range of 1–2900 mg/kg (Capuano and Fogliano 2011; Karadeniz et al. 2000; Murkovic and Pichler 2006). In sultanas and Thompson, seedless raisins (Vitis vinifera L. cv. sultanina) ranges between 3.6 to 55.0 mg/kg have been reported (Çaglarirmak 2006; Karadeniz et al. 2000; Şevik et al. 2014). Currant HMF content, found in the present study, is hence in the range of reported values for dried vine fruits and in the lower ranges for dried fruits in general. Although HMF may be formed at low temperatures, thermal treatments drastically increase HMF formation, food HMF content may be considered as directly related to the heat load applied (Capuano and Fogliano 2011). Radiation heating applied in the present study only slightly affected currant HMF content for treatments up to 55 °C, while higher temperatures further increased HMF content. However, HMF content remained under dried fruit HMF reported values even at 75 °C. Given that thermal treatment applied in the present study is rather short, this finding may be considered as expected (Kowalski 2013).

The results of the present work show that IR, under the conditions evaluated here, can be an effective and viable alternative for the disinfection and disinfestations of dried fruits, without any loss in the basic organoleptic characteristics. Nevertheless, additional experimental work is needed to assess the viability of this technique, by means of cost-effectiveness and compatibility with other dried fruit processing technologies.

References

Ahmed M (2001) Disinfestation of stored grains, pulses, dried fruits and nuts, and other dried foods. In: Molins RA (ed) Food irradiation: principles and applications. Wiley, New York, pp 77–101

Aitken AD (1975) Insect Travelers, I: Coleoptera. In: Technical Bulletin, Vol. 31. HMSO, London

Alfaifi B, Tang J, Jiao Y, Wang S, Rasco B, Jiao S, Sablani S (2014) Radio frequency disinfestation treatments for dried fruit: model development and validation. J Food Eng 120:268–276

Arnous A, Makris DP, Kefalas P (2002) Correlation of pigment and flavanol content with antioxidant properties in selected aged regional wines from Greece. J Food Compos Anal 15:655–665

Bell CH (2000) Fumigation in the 21st century. Crop Prot 19:563–569

Braeckman L, Ronsse F, Cueva HP, Pieters J (2009) Influence of combined IR grilling and hot air cooking conditions on moisture and fat content, texture and color attributes of meat patties. J Food Eng 93:437–443

Brandl MT, Zhongli P, Huynh S, Yi Z, McHugh TH (2008) Reduction of Salmonella Enteritidis population sizes on almond kernels with infrared heat. J Food Prot 71:897–902

Buchelos CTh (1980) Moth populations at a typical flour mill. Ann Benaki Instit Phytopathol 12:188–197

Çaglarirmak N (2006) Ochratoxin A, hydroxymethylfurfural and vitamin C levels of sun-dried grapes and sultanas. J Food Process Preserv 30:549–562

Capuano E, Fogliano V (2011) Acrylamide and 5-hydroxymethylfurfural (HMF): a review on metabolism, toxicity, occurrence in food and mitigation strategies. LWT—Food Sci Technol 44:793–810

Cetinkaya N, Ozyardımci B, Denli E, Ic E (2006) Radiation processing as a post-harvest quarantine control for raisins, dried figs and dried apricots. Radiat Phys Chem 75:424–431

Chiou A, Karathanos VT, Mylona A, Salta FN, Preventi F, Andrikopoulos NK (2007) Currants (Vitis vinifera L.) content of simple phenolics and antioxidant activity. Food Chem 102:516–522

Chiou A, Panagopoulou EA, Gatzali F, De Marchi S, Karathanos VT (2014) Anthocyanins content and antioxidant capacity of Corinthian currants (Vitis vinifera L., var. Apyrena). Food Chem 146:157–165

Cogburn RR (1967) Infrared radiation effect on reproduction by three species of stored-product insects. J Econ Entomol 60:548–550

Cogburn RR, Brower JH, Tilton EW (1971) Combination of gamma and infrared radiation for control of the Angoumois grain moth in wheat. J Econ Entomol 64:923–925

Collins PJ, Lambkin TM, Bridgeman BW, Pulvirenti C (1993) Resistance to grain protectant insecticides in coleopterous pests of stored cereals in Queensland. Aust J Econ Entomol 86:239–245

Del Rio D, Rodriguez-Mateos A, Spencer JPE, Tognolini M, Borges G, Crozier A (2013) Dietary (poly)phenolics in human health: structures, bioavailability, and evidence of protective effects against chronic diseases. Antioxid Redox Signal 18:1818–1892

Fields PG, White NDG (2002) Alternatives to methyl bromide treatments for stored-product and quarantine insects. Annu Rev Entomol 47:331–359

Gabel MM, Pan Z, Amaratunga KSP, Harris LJ, Thompson JF (2006a) Catalytic infrared dehydration of onions. J Food Sci 71:351–357

Gabel MM, Pan Z, Amaratunga KSP, Harris LJ, Thompson JF (2006b) Catalytic infrared dehydration of onions. J Food Sci 71:351–357

Guedes RNC, Dover BA, Kambhampati S (1996) Resistance to chlorpyrifosmethyl, pirimiphos-methyl, and malathion in Brazilian and US populations of Rhyzopertha dominica (Coleoptera: Bostrichidae). J Econ Entomol 89:27–32

Hagstrum DW, Flinn PW (2014) Modern stored-product insect pest management. J Plant Prot Res 54:205–210

Hamanaka D, Uchino T, Furuse N, Han W, Tanaka SI (2006) Effect of the wavelength of infrared heaters on the inactivation of bacterial spores at various water activities. Int J Food Microbiol 108:281–285

Hamanaka D, Norimura N, Baba N, Mano K, Kakiuchi M, Tanaka F, Toshitaka UT (2011) Surface decontamination of fig fruit by combination of infrared radiation heating with ultraviolet irradiation. Food Control 22:375–380

Heist J, Cremer ML (1990) Sensory quality and energy use for baking of molasses cookies prepared with bleached and unbleached flour and baked in infrared, forced air convection, and conventional deck ovens. J Food Sci 55:1095–1101

Huang L (2004) Infrared surface pasteurization of turkey frankfurters. Innov Food Sci Emerg Technol 5:345–351

Huang L, Sites J (2008) Elimination of Listeria monocytogenes on hotdogs by infrared surface treatment. J Food Sci 73:27–31

ICGFI International Consultative Group on Food Irradiation (1995) Code of good irradiation practice for insect disinfestation of dried fruits and tree nuts. ICGFI Document No 20, Vienna, IAEA

James C, Lechevalier V, Ketteringham L (2002) Surface pasteurization of shell eggs. J Food Eng 53:193–197

Johnson JA, Vail PV, Brandl DG, Tebbets JS, Valero KA (2002) Integration of nonchemical treatments for control of postharvest pyralid moths (Lepidoptera: Pyralidae) in almonds and raisins. J Econ Entomol 95:190–199

Karadeniz F, Durst RW, Wrolstad RE (2000) Polyphenolic composition of raisins. J Agric Food Chem 48:5343–5350

Khamis M (2009) Effects of flameless catalytic infrared radiation on stored wheat insects and wheat quality. M.Sc. thesis, Kansas State University, Manhattan

Khamis M, Subramanyam Bh, Flinn PW, Dogan H, Jager A, Gwirtz JA (2010) Susceptibility of various life stages of Rhyzopertha dominica (Coleoptera: Bostrichidae) to flameless catalytic infrared radiation. J Econ Entomol 103:1508–1516

Khamis M, Subramanyam Bh, Flinn PW, Dogan H, Gwirtz JA (2011a) Susceptibility of Tribolium castaneum (Coleoptera: Tenebrionidae) life stages to flameless catalytic infrared radiation. J Econ Entomol 104:325–330

Khamis M, Subramanyam Bh, Dogan H, Gwirtz JA (2011b) Flameless catalytic infrared radiation used for grain disinfestation does not affect hard red winter wheat quality. J Stored Prod Res 47:204–209

Khamis M, Subramanyam Bh, Dogan H, Flinn PW, Gwirtz JA (2011c) Effects of flameless catalytic infrared radiation on Sitophilus oryzae (L.) life stages. J Stored Prod Res 47:173–178

Khir R, Pan Z, Salim A, Hartsough BR, Mohamed S (2011) Moisture diffusivity of rough rice under infrared radiation drying. Food Sci Technol 44:1126–1132

Khir R, Pan Z, Thompson JF, El-Sayed AS, Hartsough BR, El-Amir MS (2014) Moisture removal characteristics of thin layer rough rice under sequenced infrared radiation heating and cooling. J Food Process Preserv 38:430–440

Kirkpatrick RL (1975) Infrared radiation for control of lesser grain borers and rice weevils in bulk wheat. J Kansas Entomol Soc 48:100–104

Kirkpatrick RL, Tilton EW (1972) Infrared radiation to control adult stored-product Coleoptera. J Ga Entomol Soc 7:73–75

Kirkpatrick RL, Brower JH, Tilton EW (1972) A comparison of microwave and infrared radiation to control rice weevils (Coleoptera: Curculionidae) in wheat. J Kansas Entomol Soc 45:434–438

Kowalski S (2013) Changes of antioxidant activity and formation of 5-hydroxymethylfurfural in honey during thermal and microwave processing. Food Chem 141:1378–1382

Krishnamurthy K, Jun S, Irudayaraj J, Demirci A (2008a) Efficacy of infrared heat treatment for inactivation of Staphylococcus aureus in milk. J Food Process Eng 31:798–816

Krishnamurthy K, Khurana HK, Soojin J, Irudayaraj J, Demirci A (2008b) Infrared heating in food processing: an overview. Compr Rev Food Sci Food Saf 7:2–13

Lee S-C, Kim J-H, Jeong S-M, Kim D-R, Ha J-U, Nam KC, Ahn DU (2003) Effect of far-infrared radiation on the antioxidant activity of rice hulls. J Agric Food Chem 51:4400–4403

McDonough MX, Campabadal CA, Mason LJ, Maier DE, Denvir A, Woloshuk CP (2011) Ozone application in a modified screw conveyor to treat grain for insect pests, fungal contaminants and mycotoxins. J Stored Prod Res 47:249–254

Mestdagh F, De Wilde T, Delporte K, Van Peteghem C, De Meulenaer B (2008) Impact of chemical pre-treatments on the acrylamide formation and sensorial quality of potato crisps. Food Chem 106:914–922

Murkovic M, Pichler N (2006) Analysis of 5-hydroxymethylfurfual in coffee, dried fruits and urine. Mol Nutr Food Res 50:842–846

Nayak MK, Holloway JC, Emery RN, Pavic H, Bartleta J, Collins PJ (2013) Strong resistance to phosphine in the rusty grain beetle, Cryptolestes ferrugineus (Stephens) (Coleoptera: Laemophloeidae): its characterisation, a rapid assay for diagnosis and its distribution in Australia. Pest Manag Sci 69:48–53

Nazari SH (2014) Impact of using infrared irradiation energy in food processing. Energy Educ Sci Technol Part A 32:1387–1396

Opit GP, Phillips TW, Aikins MJ, Hasan MM (2012) Phosphine resistance in Tribolium castaneum and Rhyzopertha dominica from stored wheat in Oklahoma. J Econ Entomol 105:1107–1114

Phillips TW, Throne JE (2010) Biorational approaches to managing stored-product insects. Annu Rev Entomol 55:375–397

Pimentel MAG, Faroni LRD, da Silva FH, Batista MD, Guedes RNC (2010) Spread of phosphine resistance among Brazilian populations of three species of stored product insects. Neotrop Entomol 39:101–107

Ramaswamy R, Krishnamurthy K, Jun S (2012) Microbial decontamination of food by infrared (IR) heating. In: Ngadi MO, Demirci A (eds) Microbial decontamination in the food Industry: novel methods and applications. Elsevier Ltd, New York, pp 450–471

Rastogi NK (2012) Recent trends and developments in infrared heating in food processing. Crit Rev Food Sci Nutr 52:737–760

Sawai J, Sagara K, Kasai S, Igarashi H, Hashimoto A, Kokugan T, Shimizu M, Kojima H (2000) Far infrared irradiation induced injuries to Escherichia coli at below the lethal temperature. J Ind Microbiol Biotechnol 24:19–24

Şevik R, Şen L, Nas S (2014) Determination of color quality and hmf content of unprocessed sultanas obtained from different vineyards. Int J Res Agric Food Sci 2:32–42

Shi J, Pan Z, McHugh TH, Wood D, Hirschberg E, Olson D (2008) Drying and quality characteristics of fresh and sugar-infused blueberries dried with infrared radiation heating. Food Sci Technol 41:1962–1972

Shyue BH, En CL, Fu JW, Sheu DW (1996) The study on processing of smoked mackerel slices by far infrared heating. Food Sci Taiwan 23:801–808

Sogi DS, Siddiq M, Roidoung S, Dolan KD (2012) Total phenolics, carotenoids, ascorbic acid, and antioxidant properties of fresh-cut mango (Mangifera indica L., cv. Tommy Atkin) as affected by infrared heat treatment. J Food Sci 77:C1197–C1202

Staack N, Ahrné L, Borch E, Knorr D (2008) Effect of infrared heating on quality and microbial decontamination in paprika powder. J Food Eng 86:17–24

Subramanyam B, Harein PK, Cutkomp LK (1989) Organophosphate resistance in adults of red flour beetle (Coleoptera: Tenebrionidae) and sawtoothed grain beetle (Coleoptera: Cucujidae) infesting barley stored on farms in Minnesota. J Econ Entomol 82:989–995

Tanaka F, Verboven P, Scheerlinck N, Morita K, Iwasaki K, Nicolai B (2007) Investigation of far infrared radiation heating as an alternative technique for surface decontamination of strawberry. J Food Eng 79:445–452

Tilton EW, Schroeder HW (1961) The effect of infrared radiation on immature insects in kernels of rough rice. Rice J 64:23–25

Tilton EW, Schroeder HW (1963) Some effects of infrared irradiation on the mortality of immature insects in kernels of rough rice. J Econ Entomol 56:727–730

Tilton EW, Brower JH, Brown GA, Kirkpatrick RL (1972) Infrared radiation to control adult stored-product Coleoptera. J Ga Entomol Soc 7:73–75

Tilton EW, Vardell HH, Jones RD (1983) Infrared heating with vacuum for control of the lesser grain borer, (Rhyzopertha dominica F.) and rice weevil (Sitophilus oryzae (L.)) infesting wheat. J Ga Entomol Soc 18:61–64

Vail PV, Tebbets JS, Cowan DC, Jenner KE (1991) Efficacy and persistence of a granulosis virus against infestations of Plodia interpunctella (Hübner) (Lepidoptera: Pyralidae) on raisins. J Stored Prod Res 27:103–107

Yung SS, Wen CS, Ming HC, Jean YH (2008) Effect of far infrared oven on the qualities of bakery products. J Culin Sci Technol 6:105–118

Zar HJ (1999) Biostatistical Analysis. Prentice-Hall Inc., Upper Saddle River

Zettler JL, Cuperus GW (1990) Pesticide resistance in Tribolium castaneum (Coleoptera: Tenebrionidae) and Rhyzopertha dominica (Coleoptera: Bostrichidae) in wheat. J Econ Entomol 83:1677–1681

Zheng Y, Shi J, Pan Z (2012) Biochemical characteristics and thermal inhibition kinetics of polyphenol oxidase extracted from Thompson seedless grape. Eur Food Res Technol 234:607–616

Zilic S, Mogol BA, Glu GA, Serpen A, Babi M, Gökmen V (2013) Effects of infrared heating on phenolic compounds and Maillard reaction products in maize flour. J Cereal Sci 58:1–7

Zilic S, Mogol BA, Akıllıoglu G, Serpen A, Delica N, Gokmen V (2014) Effects of extrusion, infrared and microwave processing on Maillard reaction products and phenolic compounds in soybean. J Sci Food Agric 94:45–51

Acknowledgments

This study was supported by the research grant “Integrated management of insect pests and microbial infestation during processing, storage and transportation of currants by using non-chemical, ecologically compatible methods: sustainability in practice” (Grant Number 1422-BET-2013, General Secretariat for Research and Technology, Greek Ministry of Education, Research and Religious Affairs).

Author contribution statement

CGA, AC and VK conceived and designed research. CGA, CIR, AKa, EN, EP and AKo conducted experiments. CGA, AC, CIR and VK analysed data. CGA, AC, CIR and VK contributed to writing the paper with CGA as the lead. All authors reviewed and approved the final manuscript.

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by M. Traugott.

Rights and permissions

About this article

Cite this article

Athanassiou, C.G., Chiou, A., Rumbos, C.I. et al. Effects of electric infrared heating with light source penetration on microbial and entomological loads of dried currants and their organoleptic characteristics. J Pest Sci 89, 931–943 (2016). https://doi.org/10.1007/s10340-015-0727-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10340-015-0727-2