Abstract

The detrimental effect of the interaction between basic analytes and silanol groups on the stationary phases during high-performance liquid chromatography (HPLC) separations has been well characterized, and many new stationary phases have been developed to minimize this effect. Similar interactions can happen between basic analytes and silanol groups on glassware surfaces during sample preparation but are often neglected. In this study, we used amitriptyline and its impurity, nortriptyline, as an example to study the effects of sample diluents on their quantitation by HPLC with four different types of glass HPLC vials. Three diluents were studied including water, 100 mM sodium chloride, and 0.1% trifluoroacetic acid. The method performance was evaluated in terms of linearity, precision and accuracy. Low sensitivity and high variability was observed for sample solutions prepared in water, which can be attributed to random adsorption of basic analytes onto the silanol groups of the glassware surfaces. Addition of sodium chloride to increase the ionic strength improved the method performance for both assay and impurity level measurements but did not completely eliminate the interaction with silanols. The most accurate and precise results across all concentration ranges regardless of HPLC vial type were obtained using 0.1% trifluoroacetic acid as the diluent.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

High-performance liquid chromatography (HPLC) is the most commonly used tool for the analysis of organic compounds [1, 2]. The HPLC stationary phases are typically bonded to silica substrates, which contain surface silanol groups that can be deprotonated under typical mobile phase pH (2–8) [3]. On the other hand, the amine groups are mostly protonated at these pH and may interact strongly with the negatively charged silanol sites, causing severe peak tailing [4, 5]. In fact, over the past three decades, column manufacturers have spent a tremendous amount of effort to overcome this issue. High-purity silica substrates have been developed to minimize silanol activities and end-capping techniques have been used to reduce active silanol sites [6]. Refer to a recent review article by Bocian and Buszewski on the influence of the residual silanol groups on the separation of polar compounds [7]. With a high purity and fully endcapped silica substrate, it is possible to analyze basic compounds using 100% water as mobile phase, although it is not a preferred approach as the endcapping ligands (e.g. trimethylsilane) may be hydrolyzed over time, and the silanol activity increases as the column ages.

In addition to creating challenges for HPLC separations, the presence of an amine group also causes problems for sample preparations for quantitative analysis as laboratory glassware contains silanol groups on the surface. It is not practical to make glassware using the high-purity silica (e.g. 99.9999% or higher) that is used as the substrate for HPLC stationary phases due to the substantial increase in cost, nor is it possible to endcap silanols on all laboratory glassware including pipettes, volumetric flasks and HPLC vials. Shimadzu developed LabTotal vial with smooth surface, which reduces surface areas and thus silanol activity [8], but the silanol activity cannot be completely eliminated. Polymer-based labware does not have these issues, but the volumetric precision (e.g. volumetric flask, pipet) is typically not as good as glassware, and other concerns may arise such as leachables when used with organic solvents [9,10,11]. When typical laboratory glassware is used, random adsorption of basic analytes onto the silanol groups on the vial and other glassware surfaces may still occur, which can lead to unpredictable sample losses and increased method variability. This can negatively affect the performance of quantitative analysis, but is often neglected as inappropriate diluents have been used in many compendial methods [12].

One option to mitigate the risk is to select a sample diluent that can help reduce the interaction between basic analytes and the silanol groups on the glassware surfaces. Since this interaction is weak cation exchange in nature, it will be affected by ionic strength and acidity. Therefore, three different diluents were selected including (1) water as control, (2) 100 mM sodium chloride for high ionic strength and (3) 0.1% trifluoroacetic acid for high acidity. The samples used for this study include amitriptyline and its impurity, nortriptyline, which are well known for their reactivity with silanol groups [13, 14]. Specifically, we evaluated linearity, accuracy and precision of quantitation of amitriptyline and nortriptyline across four different HPLC vial types. The goal is to identify diluents that can provide accurate and precise results regardless of the glassware types.

Experimental

Instrumentation

All experiments were conducted on an Agilent 1100 series HPLC system equipped with an autosampler, a quaternary pump and a variable wavelength detector (Agilent, Santa Clara, CA, USA). The maximum operating pressure of the system is 400 bar. Empower II software by Waters (Milford, MA, USA) was used to control the HPLC system and for data acquisition and analysis.

Materials and Reagents

Acetonitrile (HPLC grade), sodium perchlorate monohydrate (HPLC grade) and sodium chloride (≥ 99.0%) were purchased from Fisher Scientific (Fair Lawn, NJ, USA). Amitriptyline hydrochloride (≥ 98.0%), nortriptyline hydrochloride (≥ 98.0%) and trifluoroacetic acid (TFA, ≥ 99.0%) were obtained from Sigma-Aldrich (St. Louis, MO, USA). Purified water was obtained using a Milli-Q Water Purification System (Millipore, Bedford, MA). Four types of 2-mL clear HPLC vials were used including: (A) advantage certified vial kit from Analytical Sales and Services (Pompton Plains, NJ, USA); (B) silanized screw top vials from Agilent Technologies (Santa Clara, CA, USA); (C) silanized snap cap vials from DWK Life Sciences (Millville, NJ, USA); and (D) screw top vial from waters (Milford, MA, USA). The Ascentis Express C18 column (150 mm × 4.6 mm I.D., 2.7 µm core–shell particle) was purchased from Supelco (St. Louis, MO, USA).

Chromatographic Conditions

Unless specified, all samples were analyzed using isocratic conditions on an Agilent 1100 HPLC system equipped with UV detection at 240 nm. Mobile phase A consisted of 0.1% TFA and 50 mM sodium perchlorate in water; mobile phase B was acetonitrile, and the ratio of mobile phase A to mobile phase B was 64:36. The flow rate was 1.8 mL min−1 and the temperature of the column compartment was controlled at 45 °C. The injection volume was 25 µL and the data acquisition rate was 5 Hz.

Sample Preparation

A 0.1 mg mL−1 nortriptyline hydrochloride stock solution was prepared by weighing 10 mg of nortriptyline hydrochloride standard into a 100-mL volumetric flask, dissolve and dilute to volume with water, and mix well. Serial dilution of this stock solution was performed to obtain solutions containing 0.05, 0.1, 0.2, 0.4, 0.5 and 1.0 µg mL−1 nortriptyline hydrochloride, which corresponds to 0.05%, 0.1%, 0.2%, 0.4%, 0.5% and1% relative to the amitriptyline concentration of 0.1 mg mL−1, respectively. The dilution process was repeated using three different diluents: (1) water; (2) 100 mM sodium chloride (NaCl) in water and (3) 0.1% TFA in water.These solutions were used for linearity and precision studies.

A 1 mg mL−1 amitriptyline hydrochloride stock solution was prepared by weighing 100 mg of amitriptyline hydrochloride standard into a 100-mL volumetric flask, dissolve and dilute to volume with water, and mix well. The 1 mg mL−1 amitriptyline hydrochloride stock solution and the 0.1 mg mL−1 nortriptyline hydrochloride stock solution were used to prepare solutions containing 0.1 mg mL−1 amitriptyline hydrochloride spiked with 0, 0.05, 0.1 or 0.2 µg mL−1 nortriptyline hydrochloride, respectively. The dilution process was repeated using three different diluents: (1) water; (2) 100 mM sodium chloride (NaCl) in water and (3) 0.1% TFA in water. These solutions were used for acccuracy and precision studies.

All solutions were prepared only once. Each solution was transferred into four different types of vials as listed in “Materials and Reagents”. For each vial type, 1.0 mL of a prepared solution was added into two separate vials using plastic disposable pipette. For each vial, three consecutive injections were made using the chromatographic conditions described in “Chromatographic Conditions”.

Results and Discussion

HPLC Method Development

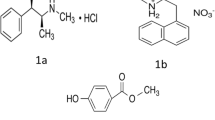

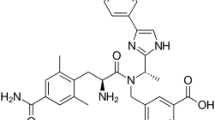

Amitriptyline is known to interact strongly with silanol groups on a silica surface; it is commonly used as a standard to quantify the silanol activity on HPLC columns. Nortriptyline is a known impurity of amitriptyline and was used in this study to assess the behavior of a basic compound at typical impurity level. The structures of both compounds are shown in Fig. 1A.

A Structures of amitriptyline and nortriptyline. B Overlaid chromatograms of blank and a mixture of 0.5 µg mL−1 nortriptyline (peak a) and 0.1 mg mL−1 amitriptyline (peak b). Refer to “Chromatographic Conditions” for chromatographic conditions

The compendial HPLC method [10] for the assay and impurities in amitriptyline hydrochloride utilizes slightly basic phosphate buffer (pH 7.7) and high column temperature (45 °C), a combination that is known to cause degradation of stationary phases and increase silanol activity [1]. Therefore, a new method with low on-column silanol activity and fast separation was developed using 0.1% trifluoroacetic acid (TFA) as the aqueous mobile phase (pH ~ 2.0) and acetonitrile as the organic solvent. At this pH, the residual silanol groups on the column will be fully protonated and will not interact with basic analytes during separation. Both amitriptyline and nortriptyline are fully protonated at this acidic pH, resulting in significant peak tailing due to mass overloading on the HPLC column. To correct this issue, 50 mM sodium perchlorate was added to the aqueous mobile phase, which reduces the electrostatic repulsion between protonated analytes [15], and thus improves the peak shape.

To achieve the separation of nortriptyline from amitriptyline API, two gradient conditions at two different column temperatures were run on the Ascentis Express C18 column. The scouting run data including retention time, peak width and peak area were used to optimize gradient and temperature simultaneously using the ACD/Labs (Advanced Chemistry Development, Canada) LC Simulator [16, 17]. Based on the modelling, a short isocratic method was developed that separated nortriptyline and amitripyline from each other and other impurities, as shown in Fig. 1B. This method was used to evaluate the linearity, precision and accuracy for quantitation of amitriptyline and nortriptyline with respect to diluent and vial types.

Linearity

Linearity was studied for nortriptyline over the range of 0.05 µg mL−1 (quantitation limit, or QL) to 1.0 µg mL−1, which corresponds to 0.05–1% of the amitriptyline assay concentration of 0.1 mg mL−1. Linear regression analysis was performed using JMP software (Version 13.0.0, SAS Institute Inc., Cary, NC, USA) for nortriptyline peak area vs. its concentration with respect to diluent and vial types. The linearity plots are shown in Fig. 2, and the fitting results including correlation coefficient R, y-intercept, residual mean square error (RMSE) and slope are summarized in Table 1.

Although satisfactory linearity was demonstrated for all solutions, there are some notable differences among different diluents. For solutions prepared using 100 mM NaCl or 0.1% TFA as diluent, the fitting results are similar regardless of the vial type as shown in Table 1. The y-intercept and RMSE are small compared to the response of the 0.05% solutions. However, for solutions prepared using water as diluent, the fitting results vary significantly among the four vial types. The correlation coefficient R ranges from 0.992 to 1.000. The y-intercept and RMSE are relatively big compared to the responses of the 0.05% solutions. The biggest difference is among the slopes, which vary from 23,164 to 32,656, and are smaller than those obtained from the solutions prepared using 100 mM NaCl or 0.1% TFA as diluent. The smaller slope can be attributed to the adsorption of nortriptyline onto the active silanol groups on the glassware surfaces when water is used as diluent. For vials with high silanol activities, the loss of nortriptyline due to adsorption to the silanol group increases and the linearity slope decreases. The larger RMSE results from the variation of silanol activities on different vials, and even for the same vial type. When 100 mM NaCl is used as the diluent, the high concentration of Na+ blocks the active silanol site and minimizes the adsorption of nortriptyline. When 0.1% TFA is used as diluent, the silanol groups are protonated and do not adsorb protonated nortriptyline. In addition, TFA may form ion pairs with positively charged basic compounds, which may further reduce the adsorption of nortriptyline. In both cases, the silanol activities are suppressed and the adsorption of nortriptyline is reduced, leading to more consistent linearity.

Precision

To assess the method precision, nortriptyline solutions at 0.05, 0.1 and 0.2 µg mL−1, with and without 0.1 mg mL−1 amitriptyline, were prepared using three different diluents: water, 100 mM NaCl and 0.1% TFA. Each solution was transferred to two separate vials of each type, and three injections were made from each vial. The response factors (RF) were plotted with respect to diluent, vial type and presence of amitriptyline as shown in Fig. 3.

The precision results are summarized in Table 2. In the absence of amitriptyline, the average response factor of nortriptyline in the solutions prepared in water is about 40% lower than those obtained using solutions prepared in 100 mM NaCl or 0.1% TFA, indicating a significant loss of nortriptyline due to adsorption to the glassware surface. Second, there are significant differences in the average response factors and the %RSD with respect to the vial type for solutions prepared in water. It is possible that the silanol activities vary on different vial types, and are not homogeneous even between vials of same type, resulting in variations in response factors. The variation can be reduced by using either 100 mM NaCl or 0.1% TFA as diluent to suppress the silanol activities as discussed in “Linearity”. This approach produced a higher response factor and better precision across all vial types.

The results are quite different for solutions prepared in the presence of 0.1 mg mL−1 amitriptyline. The response factors of nortriptyline prepared using the same diluent appear to be consistent across different vials. The %RSDs of the response factor of nortriptyline are comparable regardless of the diluent type. This can be attributed to the competing adsorption of amitriptyline on glassware surface, whose concentration is 500–2000 times that of nortriptyline. However, the average response factor for the solutions prepared using water as diluent is still about 10% lower than those prepared in 100 mM NaCl or 0.1% TFA, suggesting that there is still loss of nortriptyline due to adsorption to glassware surface, even in the presence of amitriptyline.

It is generally believed that the silanol activities on glassware surfaces do not have a significant impact on analytes at assay level such as 0.1 mg mL−1 amitriptyline. In fact, the response factors of 0.1 mg mL−1 amitriptyline in different diluents did not vary as much as those of nortriptyline at impurity levels (i.e. 0.05–0.2 µg mL−1) as shown in Fig. 3b and Table 2. However, the average response factor of amitriptyline is still significantly lower for solutions prepared in water than those prepared in 100 mM NaCl or 0.1% TFA. In addition, the average response factor of amitriptyline varies among different vial types, suggesting that the interaction of basic analytes and the silanol groups cannot be ignored even at the assay level.

For the solutions prepared using 100 mM NaCl, the response factors are similar across the four different HPLC vial types except for vial type A, in which lower response factors and larger variation were observed. The difference in the average response factors of amitriptyline between vial type A and vial type B is 4.4%, which is significant for assay. Surprisingly, for solutions in 100 mM NaCl and vial type B, the %RSD of the response factors of amitriptyline (3.3%) is higher than that of nortriptyline (1.5%). We believe that this is attributed to the random variation in silanol activities on the surface of the HPLC vials.

On the other hand, consistent response factors were obtained for the solutions prepared using 0.1% TFA, regardless of the vial type. The difference between the highest average response factor of amitriptyline (36,210 from vial type A) and the lowest one (35,985 from vial type D) is 0.6%, which is within the typical error of HPLC analysis.

Accuracy/Recovery

The accuracy was studied by spiking 0.05, 0.1 and 0.2 µg mL−1 of nortriptyline into 0.1 mg mL−1 of amitriptyline, and then comparing the experimentally determined concentration to the nominal concentration to calculate the accuracy. There are two common approaches to calculate the experimental concentration, and both are discussed in the following.

The first approach to calculate the experimentally determined concentration of nortriptyline is to use a nortriptyline solution prepared at the specification level as an external standard as shown in the following:

where CNU is the concentration of nortriptyline sample, ANU is the peak area of nortriptyline in the sample chromatogram, CNS is the concentration of 0.1% nortriptyline standard in µg mL−1 and \(\overline {{{A_{{\text{NS}}}}}}\) is the average peak area of 0.1% notriptyline standard.

The accuracy results are summarized in Table 3. The percent recovery and percent RSD vary among different diluents. When water was used as the diluent, the average percent recoveries range from 121.5 to 162.2%. The positive bias in percent recovery can be attributed to the negative bias in the response factor of the 0.1 µg mL−1 nortriptyline standard solution due to the adsorption of nortriptyline on glassware surface. The variation in the average percent recovery from different vials is mainly due to the difference in the response factors of the 0.1 µg mL−1 nortriptyline standard solution as shown in Fig. 3. Good percent recovery and percent RSD were obtained for solutions prepared in 100 mM NaCl or 0.1% TFA, which can be attributed to the low silanol activities as discussed in “Linearity”.

The second approach is to use 0.1 mg mL−1 amitriptyline as an external standard and apply a correction factor to compensate for the difference in response factors between nortriptyline and amitriptyline. The correction factor is the ratio of the average response factor of amitriptyline vs. the average response factor of nortriptyline from the 0.1-mg mL−1 amitriptyline solution spiked with 0.1 µg mL−1 nortriptyline as shown in Eqs. (2) and (3) in the following:

where CNU is the concentration of nortriptyline sample, ANU is the peak area of nortriptyline in the sample chromatram, CNS is the concentration of 0.1% nortriptyline standard in µg mL−1, \(\overline {{{A_{{\text{NS}}}}}}\) is the average peak area of 0.1% notriptyline standard, CAS is the concentration of 100% amitriptyline standard in µg mL−1 and \(\overline {{{A_{{\text{AS}}}}}}\) is the average peak area of 100% amitriptyline standard.

As shown in Table 3, the accuracy results fell within a tighter range, compared to the results calculated using the first approach. Most consistent results were obtained using 0.1% TFA as diluent, suggesting that silanol activities may still affect the quantitation of nortriptyline when water or 100 mM NaCl is used as diluent.

Conclusions

We have demonstrated that sample diluent has a notable impact on the quantitation of basic compounds in terms of linearity, precision and accuracy. The analytical error is mainly attributed to the adsorption of basic compounds on active silanol groups of glassware surfaces through weak cation exchange. The method performance can be improved by increasing the ionic strength of the diluent to reduce the adsorption of silanol groups, or increasing the acidity of the diluent to neutralize the silanol groups. An alternate approach to minimize the adsorption of basic compound is to increase the diluent pH to neutralize the amine. The latter approach is not commonly used due to concerns over dissolution of silica at high pH or potential degradation of the compound.

The most consistent results were obtained when 0.1% TFA was used as diluent, likely due to protonation of the silanol groups and ion pairing of basic analytes. In case that the analyte is unstable under acidic conditions, increasing ionic strength should be considered. Other cations such as triethylamine may be more efficient at suppressing the silanol activities.

Preparing the impurity standard in the presence of the major component at the assay concentration may help to reduce the impact of silanol activities, especially when the major component is also a basic compound. However, the quantitation results may still vary, and careful selection of diluent is required.

This study was conducted using HPLC analysis due to its high sensitivity and convenience for quantitative analysis. However, the findings in this study should be applicable to the sample preparations of basic analytes for all other analytical techniques. The effects due to the interaction of basic analytes with glassware silanol groups can become detrimental, especially for trace analyses such as quantitation of mutagenic impurities or metabolites.

References

Snyder LR, Kirkland JJ, Glajch JL (1997) Practical HPLC method development. Wiley, New York

Lunn G, Schmuff NR (1997) HPLC methods for pharmaceutical analysis. Wiley, New York

Bard AJ, Faulkner LR (1980) Electrochemical Methods, fundamentals and applications. Wiley, New York, pp 488–510

Buszewski B, Bocian S, Rychlicki G, Matyska M, Pesek J (2012) Determination of accessible silanols groups on silica gel surfaces using microcalorimetric measurements. J Chromatogr A 1232:43–46

Nawrocki J (1997) The silanol group and its role in liquid chromatography. J Chromatogr A 779:29–71

Marshall DB, Cole CL, Connolly DE (1986) Variable reactivity in the chemical modification of silica: effects of initial deactivation on high-performance liquid chromatographic performance. J Chromatogr A 361:71–82

Bocian S, Buszewski B (2012) Residual silanols at reversed-phase silica in HPLC—a contribution for a better understanding. J Sep Sci 35:1191–1200

Murakoshi M, Fukuzawa K, Sato Y, Asakawa N (2018) Adsorption phenomenon and development of low adsorption vials for LC and LC/MS. https://www.shimadzu.com/an/sites/shimadzu.com.an/files/ckeditor/an/hplc/support/vial/adsorption_phenomenon.pdf. Accessed 16 Oct 2018

Guo X, Bruins AP, Covey TR (2006) Characterization of typical chemical background interferences in atmospheric pressure ionization liquid chromatography-mass spectrometry. Rapid Commun Mass Spectrom 20:3145–3150

Mei H, Hsieh Y, Nardo C, Xu X, Wang S, Ng K, Korfmacher WA (2003) Investigation of matrix effects in bioanalytical high-performance liquid chromatography/tandem mass spectrometric assays: application to drug discovery. Rapid Commun Mass Spectrom 17:97–103

van Hout MW, Niederlander HA, de Zeeuw RA, de Jong GJ (2003) Ion suppression in the determination of clenbuterol in urine by solid-phase extraction atmospheric pressure chemical ionisation ion-trap mass spectrometry. Rapid Commun Mass Spectrom 17:245–250

2017 U.S. Pharmacopoeia-National Formulary [USP 40 NF 35]. Volume 1. Rockville, Md: United States Pharmacopeial Convention, Inc; page 2531–2532 for abacavir sulfate, page 2758–2759 for amitriptyline hydrochloride, page 2782–2784 for amoxapine, and page 2913–2914 for azatadine maleate

Neue UD, Serowik E, Iraneta P, Alden BA, Walter TH (1999) Universal procedure for the assessment of the reproducibility and the classification of silica-based reversed-phase packings: I. Assessment of the reproducibility of reversed-phase packings. J Chromatogr A 849:87–100

Neue UD, Alden BA, Walter TH (1999) Universal procedure for the assessment of the reproducibility and the classification of silica-based reversed-phase packings: II. Classification of reversed-phase packings. J Chromatogr A 849:101–116

Xu XN, Yeung E (1998) Long-range electrostatic trapping of single-protein molecules at a liquid-solid interface. Science 281:1650–1653

Wang L, Zheng J, Gong X, Hartman R, Antonucci V (2015) Efficient HPLC method development using structure-based database search, physico-chemical prediction and chromatographic simulation. J Pharm Biomed Anal 104:49–54

Tornblom JK, Bureyko TF, MacKinnon CD (2005) Simulating phenol high-performance liquid chromatography retention times as the pH Changes: mobile phase pH vs. buffer pH. J Chromatogr A 1095:68–73

Acknowledgements

The authors would like to thank David Lavrich for the discussions on data analysis. The authors also would like to thank Tessa Carducci, Erik Regalado, Xiaohua Zhang and Paul Oram for careful review of the manuscript and invaluable discussions.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest in relation to this research.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Rights and permissions

About this article

Cite this article

Zheng, J., Wang, L., Antonucci, V. et al. Effect of Sample Diluents on the Quantitation of Basic Compounds by High Performance Liquid Chromaography. Chromatographia 81, 1631–1639 (2018). https://doi.org/10.1007/s10337-018-3638-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10337-018-3638-6