Abstract

Hydroxyl functionalized polystyrene-co-divinyl benzene beads were prepared via Ugelstads two-step activated swelling procedure as monodisperse particles. The prefunctional monomers p-acetoxystyrene and p-vinylbenzylchloride were used as comonomers with up to 28 % (v/v) of the total monomer load to directly introduce functional groups, which subsequently got hydroxylized. Particle morphology was examined with scanning electron microscopy and porosity by inverse size exclusion chromatography. The particle size ranged from 4.0 to 4.5 µm and porosity was only slightly affected giving mean pore diameters of ≈50 Å and specific surface area of ≈1100 m2/g for all materials. Hydroxylation reaction was monitored by FTIR-spectrometry and for p-vinylbenzylchloride also by XRF spectrometry. While reactivity was good for hydroxylation of p-acetoxystyrene, beads with p-vinylbenzylchloride showed significantly reduced yield in the hydroxylation step. RP-HPLC measurements with a series of homologous alkyl benzenes and acetophenone at different MeCN/H2O ratios gave decreased retention due to increased hydrophilicity of the backbone polymer. Highest hydrophobicity reduction was found for phenol type beads which lost up to 45 % of their RP retention.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Porous polystyrene/divinyl benzene copolymers (PS/DVB) exhibit high pressure and pH stability, so that they are used as common supports in HPLC, ion- and size-exclusion chromatography. The early developments are reviewed by Seidl et al. [1]. The use of porous PS/DVB for modern partioning chromatography was first described by the group of Pietrzyk [2]. Non-porous PS/DVB has gained high interest for fast protein separations [3]. Even until today the vast majority of these particles are made by suspension polymerization, which results in broad particle size distribution [4]. Several procedures had been proposed for the synthesis of monodisperse PS/DVB beads, whereupon Ugelstads activated swelling technique is the one used in this present study to create particles in the desired range of about 5 µm [5–7]. This procedure consists of two independent polymerization steps. The first step is required to obtain stabilizer-free and monodisperse polystyrene seed particles [8, 9]. In the second step these seed particles are treated with a hydrophobic low molecular weight swelling compound (e.g. dodecanoyl peroxide) and the desired monomer/diluent mixture (e.g. divinyl benzene/toluene) is added to yield beads suitable for chromatographic purposes after polymerization [10].

In ion exchange chromatography knowledge about the hydrophilicity of both exchange site and bulk has huge influence regarding selectivity [11, 12]. Relative retention of highly hydrated ions, as for example fluoride, is increased while hydrophilicity of the exchange site is enhanced. This can for instance be achieved by switching from trimethylamine to diethanolmethylamine anchored groups [12]. Bulk hydrophilicity is also heavily contributing to selectivity due to lack or suppression of hydrophobic interaction (van der Waals, π–π) with analyte substances [13]. Bulk hydrophilic polymer beads for ion chromatography are nowadays made from polymethacrylates and therefore are suffering from pH degradation. Beads made from polyvinylalcohol have also been reported [14]. To utilize the advantages of both types of beads, namely pH stable backbone and residual vinyl groups for further functionalization from the PS/DVB beads and the hydrophilicity from polymethacrylate beads, we intend to introduce more hydrophilic monomers to Ugelstads activated swelling procedure which would not be affected by eluent induced hydrolysis. For suspension polymerization synthesis with highly hydrophilic comonomer vinylpyridine was reported [15, 16]. The introduction of this monomer was then accompanied by change of solubility of the growing polymer chain in the diluent phase thus resulting in different pore size distributions. To avoid this pattern we will use more “styrene-like” monomers as there are p-vinylbenzylchloride and p-acetoxystyrene, which will be hydroxylated in a second step. This strategy for seeded polymerization procedures was introduced by Lewandowski et al. in 1997 [17].

The so modified PS/DVB-beads which will be presented in this study are, as already mentioned, synthesized for further functionalization regarding ion chromatography. To evaluate their hydrophilicity, an RP-HPLC experiment was used with a series of alkyl benzenes up to n-butyl benzene as non-polar analytes along with different compositions of acetonitrile/water as eluent. Retention factors k′ were calculated from this set of data and were taken to characterize affinity to the stationary phase.

To ascribe change in retention to altered hydrophilicity and not to change in porosity, inverse size-exclusion chromatography was also conducted as method of choice to investigate the porous properties under chromatographic conditions [18–22]. The morphology in general was examined with scanning electron microscopy and the particle size distribution was also extracted from these images.

For the purpose of the present study protected hydrophilic monomers p-acetoxystyrene and p-vinylbenzylchloride will be varied in quality and quantity during the second swelling stage of Ugelstads activated swelling procedure. These beads are then analyzed by FTIR- and XRF-spectrometry to verify the incorporation of the applied comonomers and their RP-HPLC properties are examined to describe the change in hydrophilicity before and after hydroxylation. As benzyl alcohol and phenolic resins are yielded, we expect to see major difference in hydrophilicity change, when comparing these both types of modified beads, which most likely can be attributed to their different octanol–water distribution coefficients.

Experimental

Materials

Styrene-based seed particles were prepared from distilled styrene (Sigma-Aldrich, Steinheim, Germany) using potassium persulfate (p.a., Fluka, Steinheim, Germany) and sodium chloride (p.a., Sigma-Aldrich, Steinheim, Germany). Ultrapure water was used as received from MilliQ-system (Merck-MilliporeBillerica, MA, USA). Dialysis of the seed particles for removal of remaining monomer and salts was performed in cellophane tubes (Carl Roth, Karlsruhe, Germany, max. pore size 30 Å, MWCO = 20 kDa) against pure water.

For the synthesis of the PS/DVB-beads technical divinyl benzene 55 and 80 % (stabilized, Sigma-Aldrich, Steinheim, Germany), sodium dodecylsulfate (≥98 %, Fluka, Steinheim, Germany), dioctanoylperoxide (Perkadox SE-8, Akzo Nobel, Amersfoort, Netherlands) and nonylphenol ethoxylate (Berol 267, Akzo Nobel, Stenungsund, Sweden) were used without further purification. p-Acetoxystyrene (96 %, Sigma-Aldrich, Steinheim, Germany) and p-vinylbenzylchloride (≥90 %, Sigma-Aldrich, Steinheim, Germany) were used as recieved. Pore extraction was done with toluene and 1,2-dichloropropane (≥99 %, Sigma-Aldrich, Steinheim, Germany).

For hydroxylation sodium hydroxide (p.a., KMF Optichem, Lohmar, Germany), and hydrochloric acid (32 % p.a., Honeywell, Seelze, Germany) were used as received. Methanol (various vendors) was redistilled before use.

Eluent for size exclusion chromatography was tetrahydrofuran (HPLC grade, VWR Prolabo, Darmstadt, Germany) and narrow weight polystyrene standards were purchased from PSS (Mainz, Germany). For HPLC Acetonitrile (HPLC grade, VWR Prolabo, Darmstadt, Germany) and ultrapure water were used. Formic acid (p.a., Sigma-Aldrich, Steinheim, Germany) was used for pH adjustment.

Seed Particle and Porous Bead Synthesis Synthesis

Monodisperse seed particles of 1 µm in diameter were prepared in a soapless emulsion polymerization process as described in Refs. [9, 10]. The detailed recipe is given in Ref. [24]. The monodisperse porous beads of about 4–5 µm in diameter were prepared using Ugelstads activated swelling technique [7] following the procedure given in [23].

Hydroxylation Step

For both p-acetoxystyrene [24] and p-vinylbenzylchloride [25] a modified conversion procedure to its hydroxide form was taken from literature. 5 g of the dried polymer beads was suspended in 200 mL of MeOH/H2O (90/10 v/v) mixture and a solution of 2.5 g sodium hydroxide in 50 mL of MeOH/H2O (90/10 v/v) was added. The flask was then sealed with a septum and a canula for pressure equalization. The suspension was then treated in an ultrasonic bath at 65 °C for 4 h. After cooling the polymer was filtered and washed with 100 mL ethanol and 100 mL acetone. In case of saponification of 4-acetoxystyrene the polymer was also washed with 50 mL 5 % hydrochloric acid. The beads were then dried at 60 °C for 3 days for further use.

Particle Characterization, Column Packing and Chromatographic Measurements

Particle morphology and size distribution were determined using a JEOL JSM-7500F scanning electron microscope and ImageJ software. For the size distribution at least 50 particles were examined. The porous properties, such as total porosity, specific pore volume and specific surface area were calculated from inverse size exclusion chromatography. Additional information on the particle composition was obtained with FTIR using a Bruker Optics Tensor 37 ATR FTIR and 16 scans per sample with a resolution of 4 cm−1 obtaining a transmission spectrum with BRUKERs OPUS software (V. 7.0.129). Relative chlorine content was also monitored via XRF-spectrometry using a Thermo Fisher Scientific ARL OPTIMX WDXRF spectrometer.

The 250 mm × 4 mm i.d. stainless steel columns for size exclusion chromatography and the 50 mm × 4 mm i.d. stainless steel columns for reversed phase characterizations were packed as described in [23].

For size exclusion chromatography the column was equilibrated with THF and a series of 14 monodisperse polystyrene standards along with 1-phenylhexane, propyl benzene and toluene were used in triple determination as analytes to determine the elution volume at 0.5 mL/min and 30 °C. The column was then emptied and the material was dried at 60 °C for 3 days to get its weight. All ISEC measurements were done using a Shimadzu LC10 HPLC system with UV/VIS detection at 254 nm.

To determine the molecular weight of the polystyrene seeds, size exclusion chromatography was conducted. Therefore the same Shimadzu LC10 HPLC system was used, along with same operating conditions, calibration standards and eluent. Measurement was done using a SDV analytical XL column from PSS. The raw aqueous seed particle emulsion was diluted 1:10,000 with THF and 50 µL were injected directly into the chromatographic system.

For reversed measurements at least two columns per batch were equilibrated with 100 mL MeOH/H2O (70/30 v/v) and 50 mL MeCN/H2O (70/30 v/v). Van Deemter curves were recorded by injecting uracil (10 mg/L), benzene, toluene, ethyl benzene, n-propyl benzene, n-butyl benzene (each 100 mg/L) and acetophenone (10 mg/L) at different flow rates ranging from 0.2 up to 1.4 mL/min. Additional different eluent compositions ranging from MeOH/H2O (50/50 v/v) to 90/10 at a flow rate of 0.8 mL/min were measured with the same set of analytes. For the highest p-acetoxystyrene concentration batch 0.1 % (v/v) formic acid was added to the eluent to control the eluent pH. All HPLC measurement were done using an Agilent 1100 HPLC system with UV/VIS detection at 254 nm and a column temperature of 45 °C along with double determination. The peak maximum was used for all further calculation purposes. To consider packaging effects, the k′ RSD had to be below 5 %, otherwise a third column was additionally evaluated.

Results and Discussion

Synthesis Strategy

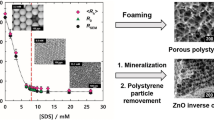

To establish bulk hydrophilicity different from bare PS/DVB material only monomers which are compatible to the second swelling step in the Ugelstad process can be chosen. Their water solubility therefore should range from ≈10 to ≈1000 mg/L, or log P OW from ≈2 to ≈4, respectively [26]. Utilization of vinylpyridine (log P OW ≈1.5) will hence fail. It will also fail due to solvation incompatibility of the growing polymer chain in the diluent/seed particle system, resulting in exclusion of the highly hydrophobic seed polymer.

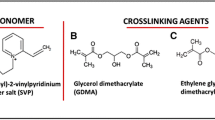

Our approach then was to use monomers which act like styrene and divinyl benzene during swelling and polymerization. These monomers should further bear moieties easily transformable into hydrophilic groups, such as alcohols. For this reason 4-acetoxystyrene (ACS) and 4-vinylbenzylchloride (VBC) were chosen. 4-acetoxystyrene with log P OW = 2.51 (± 0.81) is acting close to toluene [log P OW = 2.49 (± 0.15)] regarding water solubility, which is the default porogenic diluent in our system. The ester moiety is saponified after polymer synthesis, giving a highly hydrophobic phenol integrated into the backbone of the beads [15, 24]. 4-Vinylbenzyl chloride with log P OW = 3.34 (± 0.27) is acting close to divinyl benzene [log P OW = 3.49 (± 0.32)] regarding water solubility, which is the default crosslinker in our system. In this case the benzyl chloride moiety is transformed into benzyl alcohol [25]. All solubility data were taken from literature [27, 28]. Conditions for both reactions are shown in Fig. 1.

For all following synthesis the same seed particle batch was used, to keep the porous by polymer contribution at the same level. The properties of this latex are given in Table 1 and Fig. 2 shows its size distribution along with an exemplary image. The amount of seed latex which is necessary for bead synthesis was determined in a first step by its dry weight and in second and third steps refined to yield a resulting particle with a mean size of 4.3 µm. For an uptake of 200 mL monomer/diluent mixture 60 mL of the seed particle emulsion was finally used.

To create increased hydrophilicity and compare its influence in chromatography, synthesis with 0 % (reference synthesis), 2, 5 and 10 % (v/v) of the functional monomer were conducted. The composition of the monomer/diluent phases for all batches is listed in Table 2. The resulting theoretical composition, assuming 100 % yield and an equal density, is of course without the diluent toluene and also listed in Table 2. For the batches where comonomer was applied, DVB 80 % was used instead of DVB 55 %. This was done to keep crosslinking and particle stability at a high level when introducing a non-crosslinking comonomer. DVB 80 % therefore indicates a m/p-divinyl benzene content of 80 % (n/n) in this used technical mixture. The residual 20 % are m/p-ethylvinyl benzene. DVB 55 % has a correspondingly lower content of the crosslinker.

Particle Size and Morphology

Reference synthesis with DVD 55 % gave a cauliflower-like surface at 4.3 µm mean particle diameter. Applying ACS to the synthesis, the particle diameter is slightly increased up to 4.6 µm at 2 % ACS and is going down to 4 µm at 10 % ACS. Polydispersity is very good for reference and 2 % ACS batch but slightly increased for 5 and 10 %. Particle morphology is similar for all four batches of this series.

For the VBC series there is a likewise trend regarding particle diameter. Maximum can be found at 4.7 µm for 5 % VBC. Polydispersity in this case is very good for all four batches of the series. Particle morphology is similar to the reference synthesis, but with increasing VBC contents more particle agglomeration is occurring. For 5 and 10 % VBC content sedimentation with cyclohexanol/ethanol 40/60 (v/v) was necessary to slurry-pack these batches at reasonable backpressure. Sample imagery is shown in Fig. 3 and size-related data in Table 3. All data presented in this table are prior to hydroxylation.

Porosity

All data regarding porosity were measured under chromatographic conditions with inverse size exclusion prior to hydroxylation. Information obtained this way give access to specific pore volume V Ps and specific surface A s in swollen state. The results are displayed as calibration and integral distribution curves. The surface area was calculated using Eq. 1, where ϕ 50 is the average pore diameter determined through interpolation at R = 50 % from the integral distribution plot [19]. Pore-size ranges according to IUPAC definition [28] were also determined graphically through interpolation of the same data-sets. The total porosity ε t was calculated using Eq. 2 and the results are listed in Table 4. V E,max, V sys,void and V col are referring to the elution volume of the smallest probe molecule, the void volume of the chromatographic system and the column volume, respectively.

Increasing the ACS content of the polymer slightly increases the specific surface area and thus lowering the mean pore diameter. The deviation from the reference can be found for 5 % ACS content with +12 % for the specific surface and −26 % for ϕ 50. Adding more ACS to the polymerization mixture mimics the result of adding a more solvent like diluent to the system. This implies extended solvation of the growing polymer chain and a later collapse of the nuclei [8]. The result for increasing VBC content is showing the reverse effect. VBC is acting like a more nonsolvent type in this system, thus giving lower specific surface area while mean pore diameter is increased. Greatest difference in surface can be found for 10 % VBC with −13 %, while 5 % VBC shows the highest increase for the mean pore diameter with +32 %. The specific pore volume for both series is at constant level of about 1.3 mL/g, except for the 5 % ACS and VBC ones. ISEC calibration curves and integral distribution plots for all batches are shown in Figs. 4 and 5.

FTIR and XRF Spectrometry

To screen the integration of the comonomer and to monitor the results of the hydroxylation FTIR was conducted for both series. In case of ACS series ester signals at 1765 cm−1 (ν C=O) and 1200 cm−1 (ν C–O) were evaluated for monomer integration and conversion. After conversion the phenol signal at 1170 cm−1 (ν C–O) was also evaluated [29]. For the VBC series the benzylchloride signal at 1265 cm−1 (ν C–Cl) and benzylalcohol signal at 1100 cm−1 were interpreted [30]. The relative amount of residual vinyl bonds got estimated from the signal at 988 cm−1 (γ C=C) [31]. Signal strength from the spectra will be presented as absorbance and is therefore proportional to the concentration.

Absorbance vs. volume fraction plots for ACS series (Fig. 6) show good correlation of ester signals regarding the applied amount of comonomer after polymerization. Slope for both signals are close to linear which represents a steady incorporation of the comonomer compared to DVB. Saponification with NaOH gave nearly quantitative conversion as illustrated by almost complete disappearance of the ester peaks. At the same time the phenol signal is steadily increased, which additionally indicates successful conversion. Yields calculated from FTIR data range from 90 % for 2 % ACS to 97 % for 10 % ACS. The relative amount of residual vinyl groups is increased over the whole series due to use of DVB80 instead of DVB55 to maintain particle stability. The conversion procedure does not affect the relative amount of the groups for 2 and 5 % ACS, for 10 % ACS; however, the amount is slightly diminished but still above the reference synthesis.

The VBC series plots also show a steady incorporation of the comonomer into the polymer beads as can be seen from Fig. 7. Conversion of the benzyl chloride moiety to benzylalcohol is, however, quite bad with calculated yields from ν C–Cl signal of about 35 % for 2 and 5 % VBC and 45 % for 10 % VBC, respectively. But growth of the ν C–O benzylalcohol signal is steady over the series, which also indicated partial conversion. Pattern for the residual vinyl group signals is the same as for the ACS series. For VBC series XRF spectrometry was also applied to monitor Chlorine content before and after hydroxylation. Therefore the chlorine K α (1) and K α (2), at 2.622 and 2.620 keV, respectively [32], fluorescence intensity was measured and will be presented as a sum. Except for the reference synthesis with DVB55 there is a steady increase of the chlorine signal vs. its volume fraction, which is in good accordance with data obtained by FTIR. After the hydroxylation procedure there is also no complete disappearance of the chlorine signal, but only diminishment (Fig. 7). Yields calculated from XRF data range from 78.2 for 2 % VBC to 34.8 % for 10 % VBC. All yields calculated from FTIR and XRF are summarized in Table 5. Difference between both methods is quite considerable, particularly for 2 % VBC. Both methods from this point of view can only be regarded as semi-quantitative and results should be interpreted that way.

RP-HPLC Properties

The beads obtained and analyzed were finally packed into identical columns (50 × 4 mm i.d.) under identical conditions to examine their RP-HPLC properties using a benchmark setup, which is described in the experimental section. In a first step van Deemter plots with an eluent composition of MeCN/H2O (70/30 v/v) were recorded to examine retention and performance before and after hydroxylation using a series of alkyl benzene as hydrophobic analytes and acetophenone as a slightly more hydrophilic one. Comparisons for the different batches are shown for 0.8 mL/min flow rate, which is the van Deemter optimum in our setup for the reference batch 35 DVB55. In a second series of measurements the eluent composition was varied from MeCN/H2O (50/50 v/v) to 90/10. For 25 DVB80 10 ACS in its hydroxylated form eluent with 0.1 % (v/v) formic acid was also used for comparison due to the acidic phenol moiety (pK S = 9.99). During all measurements in this section there was no shift in pressure-drop or retention regarding one given set of measuring conditions, so that any degradation of the packed beads can be neglected. However, no long-term stability tests were conducted. Figure 8 shows some sample chromatograms of polymers doped with 10 % ACS as well as the reference batch.

Sample chromatograms for 35 DVB55 (upper), 25 DVB80 10 ACS (middle) and 25 DVB80 10 ACS h (bottom). The measuring conditions are given in the in “Experimental”. The shown order of elution is uracil, acetophenone, benzene, toluene, ethyl benzene, n-propyl benzene and n-butyl benzene

Retention and Performance

The ACS doped batches show decreasing retention factors over the whole series in their unhydroxylated form. Further decrease is observed after hydroxylation reaction. The relative retention compared to the reference batch 35 DVB55 is shown in Fig. 9, along with the relative retention from unhydroxylated to the hydroxylated form.

where k rel, 35 DVB55 is the relative retention normalized to the reference batch and k rel is the relative retention of the hydroxylated compared to its unhydroxylated form. k i,h is the retention factor of the hydroxylated form and k i the corresponding unhydroxylated one.

The overall retention shows slightly nonlinear pattern due to different surface areas of the polymers. When comparing the relative retention between the unhydroxylated and the hydroxylated form, the plot (Fig. 12) shows a steady decrease for the alkyl benzenes. The behavior of the more hydrophilic acetophenone is different. Relative retention is slightly affected for 2 % ACS but hardly for the following 5 and 10 % ACS. This difference in relative retention indicates a different retention mechanism, which seems to be more HILIC like [33].

Plate height was calculated by ChemStation software from Agilent using Eq. 5 for plate number calculation, where w b is the width of the peak at its base.

Reduced plate height for the ACS series is at about the same level, regarding the reference batch, for 2 % ACS but increasing significantly for 5 and 10 %. In this case there is no difference between the alkyl benzenes and acetophenone. Highest loss in efficiency is observed for butyl benzene (328 %), while acetophenone only suffers by 175 % when comparing the reference batch 35 DVB55 to 25 DVB80 10 ACS. The corresponding data are plotted in Fig. 10.

The VBC series beads exhibit a different pattern in terms of retention factors. There is also a decrease over the whole series when looking at the unhydroxylated beads. In contrast to the ACS series beads there is only further decrease in retention for 2 %VBC after hydroxylation of the polymer, but an increase for 5 and 10 % VBC. The absolute change in retention factors is, however, comparatively low regarding the ACS series, which is most likely due to the higher acidity of the phenolic-type resins, where the introduction of the oxygen next to the phenyl induces a much higher change in charge distribution.

The increase in relative retention after hydroxylation for 5 and 10 % VBC is illustrated by Fig. 11. Acetophenone in this case is only prominent for 10 % VBC where its relative retention is increased little above average. The change in surface chemistry seems to affect all analytes to the same extent.

Reduced plate height for the VBC series beads is also increasing with higher hydroxylated VBC content (Fig. 12). The sharp peak for 5 % VBC may result from heavy agglomeration during synthesis and insufficient sedimentation afterwards. When comparing the reference to the 10 % VBC hydroxylated batch the decrease in efficiency is not as high as for the ACS series. Biggest drop in this case is again for butyl benzene (228 %), while for acetophenone its only 127 %.

The reduced plate heights for unmodified as well as for slightly modified beads without hydrolysis step are around 2–4 and therefore competitive to other particulate polymer beads [23] but below the performance of silica based materials [34]. Beads with increased hydrophilicity as the hydrolyzed ACS and VBC materials with more than 2 % of the hidden polarity precursor shows a steep increase for reduced plate heights correlating with the polarity of the test solute. Monolithic stationary phases based on PS/DVB are developed by the group of Svecs [35, 36] and now are commercially available. Their application as separation column for proteins and peptides suggests that they act as replacement for non-porous PS/DVB. Highly porous PS/DVB monoliths suffer from reproducible production and wall fixation problems. Methacrylate-based monoliths showed for the same group of analytes as used in this paper plate heights of 10 µm or higher [37].

Methylene Selectivity

Data obtained in the previous section can also be utilized to characterize methylene selectivity towards the stationary phase using Eq. 6. Linear regression data for both series are shown in Fig. 13, where the slope is plotted against the volume fraction of ACS and VBC, respectively.

Eqn 2 can be described as methylene selectivity. This expression is a simplified form, but sufficient to describe different slopes at a fixed eluent composition using a homologous series of analytes, e.g. alkyl benzenes [38].

Methylene selectivity data indicate a clear decrease in affinity towards the stationary phase for the ACS series polymers. 25 DVB80 10 ACS h shows only 77 % of the affinity compared to the reference batch made from DVB55. Hydroxylation, however, does not seem to influence selectivity that much compared to the reference. The bigger part is already lost by incorporation of the unhydroxylated monomer. To control dissociation of the phenol type moiety HPLC measurement was repeated for 25 DVB80 10 ACS h and the reference batch 35 DVB55 with additional 0.1 % (v/v) of formic acid in the eluent. For the reference this resulted in slightly higher slope of 0.144 and higher retention of all compounds of about 20 % regarding retention factor. This may be attributed to the more polar eluent forcing the hydrophobic analytes onto the hydrophobic stationary phase. For 25 DVB80 10 ACS h the effect is not that big. Retention factors were decreased by about 9 % and the methylene selectivity slope is 0.104. This effect can qualitatively also be explained by the, in this case, more polar stationary phase with phenol groups establishing hydrogen bonds with the acidified eluent.

Data for the VBC series beads also indicate a decrease in methylene selectivity but without a clear trend neither regarding VBC content nor unhydroxylated/hydroxylated form. Although retention factors were affected by the VBC (h) content this is not clearly the case for the methylene selectivity. Maybe conversion of the benzylchloride moiety is not high enough to induce a significant change in this case.

Eluent Strength

For the highest volume fraction of unhydroxylated and hydroxylated ACS and VBC beads the eluent composition was varied from MeCN/H2O (50/50 v/v) to 90/10 to determine parameters for Eq. 7.

Equation 7 represents an expression for the linear solvent strength theory and describes the observed linear relation between the log of the retention factor k′ and the volume fraction of the organic eluent compound \( \varphi \). log k w then represents the calculated retention in pure water [39].

Regression data for these four batches and the reference batch are listed in Table 6. In case of 25 DVB80 10 ACS h the resolution for MeCN/H2O (90/10 v/v) was insufficient, so these data are neglected.

Regression data show a clear trend for the ACS series beads. In this case the slope increases from reference to unhydroxylated further to the hydroxylated form, indicating a bigger influence of the MeCN fraction. At the same time the log k w value is decreasing. The latter is a strong point for increased hydrophilicity on the surface of the stationary phase. The loss in this case ranges from 6 % for benzene to 10 % for butyl benzene. Results for VBC doped polymer is again difficult to explain. The slope is increasing significantly for the unhydroxylated form, while log k w values are kept constant regarding the reference batch. After hydroxylation the slopes are returning to the reference values, while log k w is decreased in the same scale as for the ACS h beads. For all measurements the higher retained compounds are affected more than the early ones.

Comparison of these data to results obtained by Stevenson et al. gives good accordance regarding the decline of log k w [40]. In their case endcapped propyl-phenyl functionalized silica with different ligand densities was used as reversed phase material. They observed decreasing log k w if the ligand density was also decreased. Slope values, however, are difficult to be compared, due ACS and VBC are still bearing π–π-interaction moieties. Their measurements showed an increase of S E with increasing ligand density. Our data showed that with increased hydrophilicity there is a higher dependence of the MeCN fraction in the eluent. When comparing the obtained log k w values to standard C18 phases, like Develosil ODS, with an alike eluent system, both the absolute numbers and the change with increasing n-alkyl chain length gives comparable figures [41].

Conclusion

Preparation of monodisperse PS/DVB beads bearing hydroxide moieties in the form of phenol or benzyl alcohol groups was achieved by introduction of hydrophobic comonomers suitable for Ugelstads activated swelling procedure. Subsequent hydroxylation yielded the desired polymers with good conversion for p-acetoxystyrene and moderate for p-vinylbenzyl chloride. FTIR for p-acetoxystyrene and additional XRF spectrometry for p-vinylbenzyl chloride gave sufficient information about incorporation and conversion of the comonomers. Inverse SEC showed the porous structure to be alike the reference synthesis with pure technical DVB, exhibiting slightly higher specific surface area for p-acetoxy styrene and slightly lower for p-vinylbenzyl chloride, respectively. Decreased retention factors, decreased methylene selectivity and lower log k w values indicate an increased hydrophilicity regarding the stationary phase in reversed-phase HPLC measurements. The change in hydrophilicity is much higher in the phenolic type resins, compared to the benzyl alcohol ones. Future work is going checkout the maximum limit of comonomer content in the polymerization mixture and the improvement of conversion, especially for p-vinylbenzyl chloride doped polymers. Further it will show if this increased hydrophilicity is capable to change selectivity in ion chromatography.

References

Seidl J, Malinsky J, Dusek K, Heitz W (1967) Makroporöse Styrol-Divinylbenzol-Copolymere und ihre Verwendung in der Chromatographie und zur Darstellung von Ionenaustauschern. Adv Polym Sci 5:113–213

Grieser MD, Pietrzyk DJ (1973) Liquid chromatography on a porous polystyrene-divinylbenzene support separation of nitro- and chlorophenols. Anal Chem 45:1348–1353

Maa YF, Horvath C (1988) Rapid analysis of proteins and peptides by reversed-phase chromatography with polymeric micropellicular sorbents. J Chromatogr A 445:71–86

Odian G (2004) Principles of Polymerization, 4th edn. Wiley, New Jersey

Ugelstad J, Söderberg L, Berge A, Bergström J (1983) Monodisperse polymer particles—a step forward for chromatography. Nature 303:95–96

Ugelstad J, Mfutakamba HR, Mork PC, Ellingsen T, Berge A, Schmid R, Holm L (1985) Preparation and application of monodisperse polymer particles. J Polym Sci Polym Symp 72:225–240

Ellingsen T, Aune O, Ugelstad J, Hagen S (1990) Monosized stationary phases for chromatography. J Chromatogr A 535:147–161

Goodwin JW, Hearn J, Ho CC, Ottewill RH (1974) Studies on the preparation and characterisation of monodisperse polystyrene latices. III—preparation without added surface active agents. Colloid Polym Sci 252:464–471

Chung-Li Y, Goodwin JW, Ottewill RH (1976) Studies on the preparation and characterisation of monodisperse polystyrene latices. IV—the preparation of latex particles with a size greater than 1 µm. Prog Colloid Polym Sci 60:163–175

Cheng CM, Vanderhoff El-Aasser MS (1992) Monodisperse porous polymer particles: formation of the porous structure. J Polym Sci A 30:245–256

Slingsby RW, Pohl CA (1988) Anion-exchange selectivity in latex-based columns for ion chromatography. J Chromatogr A 458:241–253

Liang C, Lucy CA (2010) Characterization of ion chromatography columns based on hydrophobicity and hydroxide eluent strength. J Chromatogr A 1217:8154–8160

Fritz JS (2005) Factors affecting selectivity in ion chromatography. J Chromatogr A 1085:8–17

Rokushika S, Yamamoto FM, Kihara K (1993) Factors affecting selectivity in ion chromatography. J Chromatogr A 630:195–200

Luz CL, Coutinho F (2001) The influence of the diluent system on the porous structure formation of copolymers based on 2-vinylpyridine and divinylbenzene.Diluent system: II-n-heptane/toluene. Polymer 42:4931–4938

Kitahara KI, Okuya S, Yoshihama I, Hanada T, Nagashima K, Arai S (2009) Preparation of monodispersed vinylpyridine–divinylbenzene porous copolymer resins and their application to high-performance liquid chromatographic separation of aromatic amines. J Chromatogr A 1216:7409–7414

Lewandowski K, Svec F, Frechet JM (1997) A novel polar separation medium for the size exclusion chromatography of small molecules: uniformly sized, porous poly(vinylphenol-co-divinylbenzene) beads. J Liq Chromatogr Rel Tech 20:227–243

Halasz I, Martin K (1975) Bestimmung der Porenverteilung (10–4000 Ǻ) von Festkörpern mit der Methode der Ausschluß-Chromatographie. Ber Bunsen Ges Phys Chem 79:731–732

Halasz I, Martin K (1978) Pore sizes of solids. Angew Chem Int Ed 17:901–908

Casassa EF (1967) Equilibrium distribution of flexible polymer chains between a macroscopic solution phase and small voids. J Polym Sci B 5:773–778

Casassa EF, Tagami Y (1969) An equilibrium theory for exclusion chromatography of branched and linear polymer chains. Macromolecules 2:14–26

Tuncel A, Tuncel M, Salih B (1999) Electron microscopic observation of uniform macroporous particles. I. effect of seed latex type and diluents. J Appl Polym Sci 71:2271–2290

Lungfiel K, Seubert A (2014) Varying the porous structure of polystyrene/divinylbenzene beads prepared by Ugelstads activated swelling technique and examining its reversed phase HPLC properties. J Chromatogr A 1358:117–127

Amir RJ, Zhong S, Pochan DJ, Hawker CJ (2009) Enzymatically triggered self-assembly of block copolymers. J Am Chem Soc 131:13949–13951

He R, Toy PH, Lam Y (2008) Polymer-supported hantzsch 1,4-dihydropyridine ester: an efficient biomimetic hydrogen source. Adv Synth Catal 350:54–60

Jorgedal A et al. (2010) US patent: 2010/0099803 A1

Tetko IV, Gasteiger J, Todeschini R, Mauri A, Livingstone D, Ertl P, Palyulin VA, Radchenko EV, Zefirov NS, Makarenko AS, Tanchuk VY, Prokopenko VV (2005) Virtual computational chemistry laboratory—design and description. J Comput Aid Mol Des 19:453–463

VCCLAB, Virtual Computational Chemistry Laboratory, http://www.vcclab.org, 2005

Hesse M, Meier H, Zeeh B (2004) Spektroskopische Methoden in der organischen Chemie. Thieme, Stuttgart

Altava B, Burguete MI, Verdugo EG, Luis SV, Vicent MJ (2001) The use of NIR-FT-Raman spectroscopy for the characterization of polymer-supported reagents and catalysts. Tetrahedron 57:8675–8683

Bartholin M, Boisser G, Dubois J (1981) Styrene-divinylbenzene copolymers, 3. Revisited IR analysis. Makromol Chem 182:2075–2085

Deslattes RD, Kessler EG Jr, Indelicato P, deBilly L, Lindroth E, Anton J (2003) X-ray transition energies: new approach to a comprehensive evaluation. Rev Mod Phys 75:35–99

Hemström P, Irgum K (2006) Hydrophilic interaction chromatography. J Sep Sci 29:1784–1821

Guiochon G (2007) Monolithic columns in high-performance liquid chromatography. J Chromatogr A 1168:101–168

Guiochon G (2006) The limits of the separation power of unidimensional column liquid chromatography. J Chromatogr A 1126:6–49

Svec F, Tennikova TB, Deyl Z Eds. (2003) In monolithic materials: preparation, properties and application, Elsevier, Amsterdam

Carbonnier B, Guerrouache M, Denoyel R, Millot MC (2007) CEC separation of aromatic compounds and proteins on hexylamine-functionalized N-acryloxysuccinimide monoliths. J Sep Sci 30:3000–3010

Jandera P (1984) Reversed-phase liquid chromatography of homologous series : a general method for prediction of retention. J Chromatogr A 341:13–36

Schoenmakers PJ, Billiet HAH, Gala LD (1981) Systematic study of ternary solvent behaviour in reversed-phase liquid chromatography. J Chromatogr A 218:261–284

Stevenson PG, Soliven A, Dennis GR, Gritti F, Guiochon G, Shalliker RA (2010) π-Selective stationary phases: (III) Influence of the propyl phenyl ligand density on the aromatic and methylene selectivity of aromatic compounds in reversed phase liquid chromatography. J Chromatogr 1217:5377–5383

Nong C, Yukui Z, Peichang L (1993) Effects of molecular structure on the log k′w index and linear S—log k′w correlation in reversed-phase high-performance liquid chromatography. J Chromatogr A 633:31–41

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Lungfiel, K., Seubert, A. Applying Hydrophilicity to PS/DVB-Beads Via Introduction of Protected Comonomers. Chromatographia 79, 5–17 (2016). https://doi.org/10.1007/s10337-015-3001-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10337-015-3001-0