Abstract

Rising worldwide concern about the quantity and quality of water available to living beings calls for efficient technologies of water treatment. Nanomaterials are promising adsorbents to remove contamination from aqueous solution, and magnetic nanomaterials based on iron have attracted attention because magnetic materials are easy to separate. Here, we review iron magnetic nanomaterials applied for water and wastewater treatment, with focus on toxic elements, pharmaceuticals and pesticides. Major advances are: coprecipitation is the most used method for synthesis of iron magnetic nanoparticles, followed by solvothermal and hydrothermal methods. Magnetite is the most common magnetic nanoparticles applied as magnetic adsorbent. In general, magnetic nanocomposites are superparamagnetic, and the highest magnetization is sought for core–shell structures, reaching 65 emu/g. Most reports focus on removal of toxic metals. Adsorption is explained by the Langmuir isothermal model, kinetic patterns being correlated with pseudo-second-order equations. Overall, iron-based magnetic nanocomposites display promising performances for pollutant removal, yet few investigations report the toxic impacts of magnetic nanoparticles on the environment.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Industrial growth and urbanization have led to the release of pollutants in environment making; sometimes, the water is unfit for consumption (Mehta et al. 2015; Khan and Malik 2019). Several substances with harmful potential have been detected in aquatic systems (Petrie et al. 2014). Many contaminants are not eliminated during wastewater treatment and are not biodegraded in the environment. The commitment and scarcity of water resources and the limitations of available water treatments indicate that the search for new technologies to recover contaminated water is an urgent matter (Zhang et al. 2016). Therefore, nanotechnology has received attention as a proposal of advanced treatment complementary to the conventional (Zhang et al. 2016; Lu and Astruc 2018; Madhura et al. 2019).

Nanomaterials are defined as materials with physical dimensions in the range of 1 to 100 nm. The nanometer-sized results in unique properties are not typically found in the material on the micrometric scale, such as large surface area, high reactivity, rapid kinetics, and specific affinity (Lu and Astruc 2018). In water treatment, the nanomaterials can be used in several processes, such as adsorption, catalytic oxidation, and disinfection (Zhang et al. 2016). Perhaps adsorption is the most studied given the simplicity for operation, flexibility, and high efficiency (Mehta et al. 2015; Singh et al. 2018). The use of nanomaterials as adsorbents has been described in different works (Khajeh et al. 2013) such as carbon nanotubes (Kumar et al. 2014; Dutra et al. 2018; Zhang et al. 2019a), graphene oxide (Gao et al. 2012; Nam et al. 2015; Baig et al. 2019; Sánchez-García et al. 2019), metal nanoparticles (Oliveira et al. 2018; Jin et al. 2019), among others. Iron-based magnetic nanoparticles have been suggested as a promising adsorbent in the removal of organic and inorganic pollutants, with the additional advantages of relatively low cost, environmentally friendly, and easy to separation and recover from the aqueous solution (Tang and Lo 2013; Wang et al. 2013; Chen et al. 2016a). Therefore, the methods for the synthesis and characterization of iron-based magnetic nanomaterials will be described and discussed so the reader can have a critical point of view of the challenges and state of the art. Moreover, a survey and discussion of the applications in adsorption processes including recovery and reuse, with particular focus on the removal of toxic elements, pharmaceutical-derived compounds, and pesticides in aqueous solutions will be made.

Iron-based magnetic nanoparticles

Magnetic nanoparticle applications are diverse; in water treatment, the iron-based magnetic nanoparticles mainly used are the nanoscale zero-valent iron, Fe3O4 that is known as magnetite, and ɣ-Fe2O3 that is known as maghemite (Zhang et al. 2016; Mohammed et al. 2017). The nanoparticles exhibit superparamagnetic behavior; therefore, magnetic properties are present only under the action of an external magnetic field (Chen et al. 2016a). The magnetic properties enable the separation of the material after the water treatment, making the recovery and reuse afterward a possibility (Mehta et al. 2015). Besides, iron nanoparticles are naturally abundant and present a low cost, low toxicity to the environment when compared to nanoparticles of other metals, and great adsorption capacity, due to the possibility of functionalization or coating the surface with other materials, eg., polymers, graphene oxide, and silica (Xu et al. 2012b; Silva et al. 2014; Reddy and Yun 2016). The efficiency of iron nanoparticles has been proved in the adsorption of inorganic and organic substances from contaminated water.

The mechanism of contaminant removal by iron-based nanoparticles will depend on the oxidation states of iron, including adsorption, chemical reduction, and reductive precipitation, according to Fig. 1 (Tang and Lo 2013). Fe0 and Fe2+ solid materials remove contaminants from the water via chemical reduction. Adsorption and reductive precipitation also occur on the iron oxides or hydroxides surfaces (Zhang et al. 2016). The adsorption mechanism includes hydrogen bonding, π-π interactions, complexation, electrostatic interactions, chemisorption, and ion exchange. Surface hydroxyl groups and surface charge of iron oxides are responsible for the interactions (Singh et al. 2018). For Fe3O4 nanoparticles, both physical and chemical adsorptions were reported. While for ɣ-Fe2O3 nanoparticles, the main contaminant removal mechanism is the physical adsorption (Tang and Lo 2013).

Mechanisms of toxic metal removal from aqueous solution by iron-based nanoparticles. For zero-valent iron, the toxic metal removal occurs via the adsorption, reduction, and reductive precipitation processes. For magnetite, the toxic metal removal occurs through the adsorption and reduction processes, while for maghemite, the removal mechanism occurs mainly by adsorption

Since 90s, the nanoscale zero-valent iron was first synthesized and used in pollutants removal from water and wastewater, including pilot projects (Mueller et al. 2012; Ma et al. 2013). The production of nanoscale zero-valent iron is commonly performed by chemical reduction employing iron salts and sodium borohydride (Crane and Scott 2012). Since zero-valent iron is a strong reducing agent, nanoscale zero-valent iron acts mainly on the degradation of a wide range of pollutants (Grieger et al. 2010; Tang and Lo 2013), such as chlorinated organic contaminants (Xiu et al. 2010) and heavy metals (Boparai et al. 2011; Tajuddin Sikder et al. 2014; Arancibia-Miranda et al. 2016). Nanoscale zero-valent iron in aqueous media usually presents as a core–shell structure with the inner layer of Fe0 and the outer layer of iron oxides or hydroxides. The Fe0 core can be oxidized to Fe2+ and Fe3+ and, subsequently, to iron oxide, causing the chemical reduction of the pollutants (Crane and Scott 2012; Zhang et al. 2016). Besides, surface sorption and reductive precipitation of contaminants may occur, mainly inorganic elements, through the outer layer of iron oxides or hydroxides (Tang and Lo 2013). On the other hand, the hydroxide or oxide layer formed on nanoscale zero-valent iron surface during the reaction considerably decreases the effective use of nanoscale zero-valent iron and, to avoid it, a second metal is usually added, resulting in bimetallic nanoparticles, including Fe and Ag (Gallo et al. 2019), Fe and Cu (Hu et al. 2010) and Fe and Ni (Zhou et al. 2014c; Mansouriieh et al. 2016).

The iron oxides magnetite and maghemite exhibit a spinel crystal structure (Tombácz et al. 2015); however, the magnetite, Fe3O4, presents Fe cations in the divalent and trivalent state coordinated by O2− ions in the interstitial tetrahedral and octahedral sites, whereas maghemite, ɣ-Fe2O3, presents Fe cations only in the trivalent state (Shokrollahi 2017; Abdullah et al. 2019). Both are ferrimagnetic at room temperature as a result of super-exchange interactions between magnetic ions and O2−. Bulk magnetite possesses high saturation magnetization among the different iron oxides of around 92–100 emu/g. Maghemite has a saturation magnetization lower values than that of magnetite, ranging from 60 to 80 emu/g (Ramimoghadam et al. 2014). In contrast, iron oxide nanoparticles that are smaller than 20 nm often display superparamagnetic behavior at room temperature and magnitude of saturation magnetization lower than that bulk magnetic materials, although magnetic properties depend strongly on the nanoparticles shape and the methods used in the synthesis (Teja and Koh 2009; Chen et al. 2016a). Larraza et al. (2012) used the solvothermal method for the synthesis of Fe3O4 nanoparticles and obtained cube-shaped structures with a saturation magnetization of 87.4 emu/g. Values of saturation magnetization around 60 emu/g have been reported for spherical-shaped Fe3O4 nanoparticles synthesized by the coprecipitation method (Davodi et al. 2017; Huong et al. 2018).

Another group of iron oxides that have recently attracted attention is the spinel ferrites, whose general composition is MF2O4, where M is Li, Ni, Mg, Zn, Cu, Co, Mn, among others (Chen et al. 2016a; Singh et al. 2018). Compared to magnetite, spinel ferrites nanoparticles have more strong magnetic proprieties (Reddy and Yun 2016; Nadar et al. 2018). Studies show that Fe3O4 magnetization can be improved by incorporating a metal element into the structure (Xu et al. 2013; Bakhshayesh and Dehghani 2014). Typically, saturation magnetization of nanometer-sized magnetite was reported as about 50 emu/g (Liu et al. 2012a). Besides, ferrites generally have high stability in an acid medium (Tu et al. 2012a, b).

Different methods can be used to synthesize iron oxide nanoparticles (Teja and Koh 2009), including coprecipitation (Sun et al. 2014), sol-gel (Stanicki et al. 2015), hydrothermal (Mao et al. 2016), and solvothermal (Chella et al. 2015). Coprecipitation is widely reported as a relatively simple and low-cost method (Xu et al. 2012b; Mohammed et al. 2017; Shokrollahi 2017). The formation of magnetite and maghemite occurs from aqueous precipitation of Fe(II) and Fe(III) salts with alkali at a suitable aging time (Chen et al. 2016a). Maghemite can also be formed from the oxidation of magnetite (Shokrollahi 2017). The chemical reactions expressed by Eqs. (1) and (2) present the formation of magnetite and maghemite from the oxidation of magnetite (Ramimoghadam et al. 2014).

Generally, the irreversible aggregation of magnetic nanoparticles is inevitable due to van der Waals interactions and magnetic forces, which decreases the surface area and limits the sorption capacity (Arancibia-Miranda et al. 2016; Martínez-Fernández and Komárek 2016). Also, as iron tends to oxidize, the stability of the magnetic nanoparticles is compromised in an aqueous medium. Thus, a typical method is to use matrix materials to isolate, accommodate, and stabilize magnetic nanoparticles, forming a magnetic nanocomposite (Chen et al. 2016a; Zhang et al. 2016). Several matrices can be employed to form a magnetic nanocomposite and will be presented and discussed in the following section.

Synthesis and characterization of magnetic nanocomposites

The magnetic nanocomposite is a multiphase material in which at least one of the constituent phases is a magnetic nanoparticle. In general, the magnetic nanocomposite is prepared by embedding magnetic nanoparticles into various materials, such as polymers, silica, and carbon (Behrens and Appel 2016), nominated as matrix. Nanocomposites can combine the advantages of two or more materials with distinct physicochemical properties and are promising to be applied in many processes, such as water and wastewater treatment (Abdullah et al. 2019; Khan and Malik 2019).

Magnetic nanoparticles can be incorporated into inorganic or organic matrices (Zhang et al. 2016; Wang et al. 2018), depending on the characteristics of the material used (Chen et al. 2016a). For example, the magnetic nanoparticles may be coated by a coating agent, eg., silica or dispersed in the pores of carbonaceous material, eg., activated carbon (Baghdadi et al. 2016). Figure 2 illustrates the structure of some typical magnetic nanocomposites. In some cases, to obtain higher stability, magnetic nanoparticles or magnetic nanoparticles matrix can be functionalized. In many works, functionalization is performed by the insertion of amino groups (Donia et al. 2012; Guo et al. 2014; Zhou et al. 2014a; Masoumi et al. 2016; Kheshti and Hassanajili 2017; Li et al. 2017b; Langeroudi and Binaeian 2018).

Different approaches to the preparation of magnetic nanocomposites are described in the literature. The core–shell structure nanocomposites are prepared from the encapsulation of the magnetic nanoparticles in a matrix, which acts coating the magnetic core (Lu and Astruc 2018; Nadar et al. 2018). Alternatively, core–shell type nanocomposites can be prepared coating layer by layer, in which the magnetic nanoparticles are functionalized and subsequently coated (Nadar et al. 2018). Core–shell structures are represented by X@Y, where X is the core and Y is the shell. For non-core–shell structure nanocomposites, the most used technique is the mixing of magnetic nanoparticles with the matrix under the influence of sonication to prevent aggregation. The magnetic nanoparticles can be synthesized separately and then mixed with the matrix or synthesized together with the matrix (Chen et al. 2016a; Li et al. 2018).

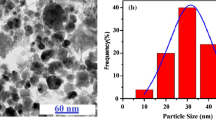

The determination of the physical and chemical properties of the material prepared is fundamental to evaluate the efficiency of the adopted synthesis and correlates to performance material as adsorbent (Mehta et al. 2015; Singh et al. 2018). Different analytical techniques are employed to characterize iron-based magnetic nanocomposites. X-ray diffraction, transmission electron microscopy, scanning electron microscopy, saturation magnetization, and nitrogen sorption are the most used techniques. Other analytical techniques are also used, such as Fourier transform infrared spectroscopy and photoelectron X-ray spectroscopy. If taken together, the analytical techniques are complementary and provide information on the morphology, structure, texture, and composition of the magnetic nanoparticles (Ramimoghadam et al. 2014; Dendisová et al. 2018).

Therefore, the synthesis and characterization techniques of magnetic nanocomposites of inorganics and organics matrices applied for water treatment by adsorption are discussed, with the emphasis on toxic elements, pesticides, and pharmaceutical-derived compounds. Table 1 summarizes the main data reported about the subject.

Magnetic iron-inorganics nanosorbents

The majority widely used inorganic materials for the synthesis of magnetic nanocomposites for adsorptive purposes are activated carbon, carbon nanotubes, zeolites, clays, and minerals (Chen et al. 2016a; Zhang et al. 2016; Lu and Astruc 2018), where the clay minerals (Arancibia-Miranda et al. 2016; Javanbakht et al. 2016), zeolite (Liu et al. 2014a; Arancibia-Miranda et al. 2016), hydroxyapatite (Dong et al. 2010; Feng et al. 2010; Zhuang et al. 2015), and silica-based materials (Zhang et al. 2013; Kheshti and Hassanajili 2017; Peng et al. 2018) were the most studied.

Many materials are naturally occurring, relatively low cost, and environment-friendly (Zhang et al. 2016) and are applied in the removal of toxic elements in aqueous solution (Zhang et al. 2013; Zhuang et al. 2015; Javanbakht et al. 2016; Kheshti and Hassanajili 2017). However, inorganic materials can be easily functionalized, enabling the adsorption of organic pollutants (Chen et al. 2016a). Amino groups can be used, and the introduction onto the surface of magnetic nanoparticles usually occurs by grafting technique. Due to the good structure preservation of nanoparticles after post-modification, grafting technique has become the more common method in performing surface modification of nanocomposites, mainly toward silica bases materials (Wang et al. 2010; Egodawatte et al. 2015; Kheshti and Hassanajili 2017).

Nevertheless, grafting technique requires long reaction times and uses toxic organic solvents, eg., toluene. Aiming strategy to more environmentally friendly, the functionalization of magnetic nanoparticles surface can be performed by direct synthesis (Zhang et al. 2013). The preparation of molecules that have amino groups is introduced into the reaction medium at the end of the synthesis (Qu et al. 2011).

Silica-based nanomaterials

Silica is one of the most used inorganic materials in the preparation of magnetic nanocomposites for the treatment of water by adsorption due to good chemical stability, large specific surface area and structure that allows functionalization (Tombácz et al. 2015; Morin-Crini et al. 2019). Silica can act as a coating of the magnetic nanoparticles that will be dispersed in a carbonaceous or polymeric matrix, for example, or act as a mesoporous matrix to disperse and stabilize the magnetic nanoparticles (Mallakpour and Naghdi 2018).

In the majority works reported in the literature, silica-based magnetic nanocomposites are prepared by employing magnetite as silica-coated magnetic nanoparticles. In general, Stöber’s method is used for coating magnetite nanoparticles with a silica shell, where the sol-gel method is used through the tetraethoxysilane hydrolysis and subsequent condensation of silicic acid in alcoholic solution (Stöber et al. 1968). Generally, the obtained nanomaterial exhibits uniform core–shell structure, Fe3O4@SiO2, being applied for the adsorption of inorganic elements in aqueous systems.

In the studies reported by Emadi et al. (2013), Fe3O4@SiO2 nanomaterial was synthesized by combining coprecipitation and sol-gel methods and applied to the removal of Zn(II) in aqueous solutions. The X-ray diffraction spectra revealed the formation of Fe3O4 crystalline phase with characteristic 2θ peaks at 30.4°, 35.6°, 43.3°, 57.3°, and 62.8°. The Fourier transform infrared spectrum exhibited adsorption bands around 580–610 cm−1 corresponding to Fe–O bonds and are attributed to the formation of the Fe3O4 phase, while silica coating was confirmed by the bands at 970 and 1088 cm−1 corresponding to symmetric stretching of Si–O and Si–O–Si, respectively. The transmission electron microscopy results of the Fe3O4@SiO2 revealed the formation of nanospheres with an average diameter of 30 nm, while the saturation magnetization for Fe3O4 and Fe3O4@SiO2 was 65.5 and 31.5 emu/g, respectively. The decrease in Fe3O4@SiO2 saturation magnetization was explained by considering the diamagnetic contribution of the silica shells surrounding the Fe3O4 nanoparticles.

Similar materials were obtained by Wang et al. (2010) and Zhang et al. (2013) and applied to the removal of metal ions, but the nanospheres were functionalized with amino groups using 3-aminopropyl trimethoxysilane by grafting technique. The Fourier transform infrared spectrum exhibited adsorption bands at 1563 cm−1 due to vibrational modes of N–H bonds that are attributed to amino groups, indicating that –NH2 groups were introduced onto the surface of Fe3O4@SiO2 particles. The insertion of amino groups was also be proved by pH of point of zero charge, whose value increased from 1.4 to 6.0 for Fe3O4@SiO2 and Fe3O4@SiO2–NH2, respectively (Wang et al. 2010). In the works of Wang et al. (2010), saturation magnetization values toward Fe3O4 and Fe3O4@SiO2–NH2 were 68.0 and 34.0 emu/g, respectively. The materials synthesized by Zhang et al. (2013) had saturation magnetization of 63.9 emu/g for Fe3O4 and 29.3 emu/g for Fe3O4@SiO2–NH2. Therefore, the results suggest that the loading of –NH2 on Fe3O4@SiO2 had little influences on the magnetic properties of core–shell structure materials, as the saturation magnetization values for Fe3O4@SiO2 and Fe3O4@SiO2–NH2 nanocomposites were approximate.

Another strategy to synthesize amino-functionalized Fe3O4@SiO2 nanospheres was adopted by Kheshti and Hassanajili (2017) for aqueous Zn(II) removal. The magnetic nanoparticles were prepared by the coprecipitation method and coated of silica through a two-step, forming mesoporous magnetic nanocomposite. In the first step, the magnetic core Fe3O4 was coated by silica following the Stöber method. In the second step, Fe3O4@SiO2 nanospheres were coated whit one more silica layer, forming the Fe3O4@SiO2@meso–SiO2 microspheres. The microspheres were functionalized with groups amino by grafting technique using 3-aminopropyl trimethoxysilane. The average pore size value of the Fe3O4@SiO2@meso–SiO2 was 2.85 nm, proving the formation of a mesoporous material. Saturation magnetization was 32 emu/g, which is in agreement with the values found for Fe3O4@SiO2 nanospheres.

On the other hand, the specific surface area was larger than the area found for Fe3O4@SiO2–NH2 materials synthesized by Zhang et al. (2013) and Wang et al. (2010) due to the formation of a mesoporous silica shell, suggesting that a high specific surface area is desirable for materials that are employed in adsorption processes. Besides, a higher surface area can facilitate surface loading with amino groups, increasing the adsorption sites in the material.

Although the silica-based magnetic nanomaterials commonly have a spherical morphology, other particle shapes are observed. The method of synthesis and the conditions employed, eg., temperature, reagent ratio, and agitation form, may influence material morphology (Mallakpour and Naghdi 2018). Egodawatte et al. (2015) prepared a mesoporous Fe3O4–SiO2–NH2 material following a synthesis route similar to Kheshti and Hassanajili (2017), but with a single silica coating. Unlike the material obtained by Kheshti and Hassanajili (2017), the nanocomposite did not have a core–shell structure. Transmission electron microscopy images showed that iron oxide nanoparticles were embedded into the mesoporous silica. The surface area of the material was 540 m2/g, which is a greaterthan other silica-based magnetic nanocomposites. Nevertheless, the saturation magnetization was lower than that reported values, being equal to 4.4 emu/g (Egodawatte et al. 2015). A possible reason is that the low-value saturation magnetization for nanocomposite may be related to the small saturation magnetization value of nanoparticles used. The saturation magnetization of Fe3O4 nanoparticles was 29 emu/g.

The use of maghemite as magnetic nanoparticles in silica-based materials is less common. In the studies of Peng et al. (2018), maghemite was incorporated into the matrix of a mesoporous silica called santa barbara amorphous-15. The typical synthesis of santa barbara amorphous occurs in acidic medium using the triblock copolymer called Pluronic P123 as an organic driver and tetraethoxysilane as a silica source (Li et al. 2010). The authors proposed a one-step method for the synthesis of ɣ-Fe2O3–santa barbara amorphous-15 nanocomposite without the addition of mineral acid. The ferrous sulfate solution was used as the precursor of iron oxide and acid source. The acidity generated by the FeSO4 solution catalyzed the hydrolysis of tetraethoxysilane. Transmission electron microscopy images showed that ɣ-Fe2O3–santa barbara amorphous-15 exhibits highly ordered hexagonal matrix incorporates with magnetic nanoparticles of size about 10 nm estimated by X-ray diffraction. The material presented the average pore size of 5.8 nm, confirming as a mesoporous material. The surface area was 1043 m2/g higher than that reported in other studies that used acid for the mesoporous silica called santa barbara amorphous-15 synthesis (Dai et al. 2012; Liang et al. 2013). However, saturation magnetization had a low value of 6.53 emu/g compared to other silica-based magnetic nanocomposites reported.

The data in Table 1 show that the specific surface area and saturation magnetization were the properties that had the most variable values varied for silica-based magnetic nanocomposites. In general, the mesoporous materials have a high specific surface area, and functionalization with amino groups led to a reduction in surface area and pore volume, as compared to non-functionalized material due to the presence of –NH2 groups on the silica surface. For example, in the works of Egodawatte et al. (2015), the surface area and pore volume of Fe3O4–SiO2 were 970 m2/g and 0.7 cm3/g, respectively, and for the Fe3O4–SiO2–NH2 the values were 540 m2/g and 0.38 cm3/g. However, the presence of –NH2 groups is desirable because of metal ion adsorption, and the groups can act as complexation sites (Wang et al. 2010).

Based on the presented above, materials with core–shell structures showed the highest saturation magnetization values. In core–shell structure, the magnetic nanoparticle coating with silica acts as a protective layer, stabilizing the magnetic nanoparticles. Although the studies suggest the formation of magnetite, there is also the formation of maghemite from the oxidation of Fe3O4. Since maghemite has a saturation magnetization value lower than magnetite, the magnetic properties of the nanocomposite will depend on the stability of the magnetic nanoparticles. Despite the difference in saturation magnetization values for the materials presented in Table 1, all exhibited superparamagnetic behavior and were of easy separation of the aqueous solution by the external magnetic field. In Table 1, it is possible to observe that coprecipitation is widely employed for the synthesis of magnetic iron oxide; however, the major drawback of the coprecipitation method is difficult to control the particle size and shape (Qu et al. 2011).

On the other hand, in the solvothermal method, controlling the particle size and shape is simpler, once the temperature and pressure of synthesis are controlled (Abdullah et al. 2019). Nonetheless, the magnetic nanoparticles obtained by the solvothermal method in the work conducted by Zhang et al. (2013) had mean particle size values of 7 nm, and saturation magnetization values of 63.9 emu/g, which were similar to the values found for Fe3O4 obtained by the coprecipitation method, with size range 11–12 nm and saturation magnetization 68–65.5 emu/g (Wang et al. 2010; Emadi et al. 2013). Due to the cost-effectiveness and green approach, the coprecipitation method is more viable for the preparation of nanocomposites.

Clay-mineral and zeolites-based nanomaterials

Among the different materials used for the synthesis of magnetic nanocomposites, clay minerals and zeolites possess unique properties, since the interlayer spaces and edges provide sites to host and stabilize magnetic nanoparticles. Moreover, the surface can be modified by acids, alkalis, surfactants, or other organic matters, enabling the possibility of generating material with hydrophilic or hydrophobic characteristics. Also, the clay minerals and zeolites have the advantages of low cost and being environmentally friendly (Crane and Scott 2012). Some of the studies that used magnetic nanocomposites based on clay minerals and zeolites are reported in Table 1.

Zeolite is a hydrated aluminosilicate highly crystalline with a cage-like structure, containing exchangeable cations in the structure (Ji et al. 2012; Salem Attia et al. 2014). Due to the adsorbing properties, natural or synthetic zeolites have been combined with magnetic nanoparticles. Clay minerals also can be used as a matrix to obtain magnetic nanocomposites, and the most commonly reported clay for used is bentonite. Bentonite is part of the smectite group, in which the significant portion is montmorillonite (Kaur et al. 2015). Montmorillonite is a type 2:1 clay, characterized by laminar organization, consisting of two tetrahedral layers of silica and a central octahedral layer of aluminum oxide (Chen et al. 2015). Both zeolite and montmorillonite possess a negative charge due to the isomorphous substitution process, providing a high cation-exchange capacity of ions (Arancibia-Miranda et al. 2016).

In summary, in clay or zeolite nanocomposites, magnetic nanoparticles are dispersed on the matrix surface, where the morphologies should influence the performance. In zeolites, magnetic nanoparticles occupy the surface of zeolite forming clusters (Yamaura and Fungaro 2013). In clays, the nanocomposite morphology will depend on the type of the clay mineral used. For example, in sepiolite, a type 2:1 magnesium hydrosilicate, the magnetic nanoparticles are loaded onto the sepiolite fibrous structure (Liu et al. 2014a), while for the montmorillonite matrix, the magnetic nanoparticles cover the flaky structure of montmorillonite (Ai et al. 2011).

The most common procedure for the synthesis of zeolite-based magnetic nanocomposite consists of mixing magnetic nanoparticles with the zeolite matrix. Salem Attia et al. (2014) reported a one-step synthesis of maghemite-zeolite nanocomposite and evaluated the adsorptive capacity for arsenic in aqueous solution. Iron oxide was produced by coprecipitation in the presence of the matrix. The Fe3O4–zeolite was then oxidized in air at 300 °C for 3 h to obtain ɣ-Fe2O3–zeolite. The X-ray diffraction pattern of the ɣ-Fe2O3–zeolite showed characteristic peaks of the ɣ-Fe2O3 phase. Typical absorption bands of Fe–O bonds in ɣ-Fe2O3 structure around 628, 580, and 447 cm−1 in the infrared spectrum confirmed the formation of the maghemite phase. The magnetic nanoparticles addition to the zeolite increased the surface area value from 65 to 126 m2/g for zeolite and ɣ-Fe2O3–zeolite, respectively. Javanbakht et al. (2016) also performed a one-step synthesis using chitosan-coated clinoptilolite for Pb(II) removal. In the dispersive energy spectroscopy spectrum, the peaks related to the binding energies of O, Na, Al, Si, K, Ca, Fe3O4, C, and N were observed, proving the formation of material chitosan–clinoptilolite–Fe3O4. The surface area for clinoptilolite–Fe3O4 was higher, 47 m2/g, than that found for chitosan–clinoptilolite–Fe3O4, 28 m2/g. However, the adsorption capacity was lower than that of chitosan–clinoptilolite–Fe3O4, which will be discussed further in "Application in adsorption processes" section, showing the importance of chitosan in the adsorption process of the evaluated metal. Saturation magnetization was also reduced from 39.21 emu/g to 9.50 emu/g for clinoptilolite–Fe3O4 and chitosan–clinoptilolite–Fe3O4, respectively. The decrease in saturation magnetization values was attributed to the chitosan coating layer. However, in practice, the nanocomposite was easily separated from the aqueous solution by a permanent magnet.

Some authors report that synthesis under the hydrothermal conditions improves nanoparticle dispersion on the zeolite surface. A better dispersion was verified in the work of Yuan et al. (2011), whose synthesis of Fe3O4–zeolite was conducted at 100 °C under hydrothermal conditions for 16 h. Transmission electron microscopy images revealed that the magnetic nanoparticles were well dispersed on the zeolite surface. Besides, Fe3O4–zeolite nanocomposite had a high surface area, 571 m2/g, compared to other magnetic zeolites. On the other hand, saturation magnetization was low, 3.7 emu/g. The low saturation magnetization was attributed to the low Fe3O4 content in Fe3O4–zeolite nanocomposite, whose value was 5 wt%.

Due to excellent surface properties, montmorillonite is one of the most common clay minerals used in the manufacture of magnetic nanocomposites (Larraza et al. 2012). Several strategies have been followed to incorporate magnetic nanoparticles in the silicate clay structures, including coprecipitation of iron salts in a solution containing a clay suspension described in the work of Kalantari et al. (2015). Fe3O4–montmorillonite was prepared in one-step by coprecipitation of Fe3+ and Fe2+ salts with the 1:2 molar ratio in the presence of montmorillonite. Transmission electron microscopy images showed that Fe3O4–montmorillonite nanoparticles had a diameter of about 8.24 nm. The saturation magnetization for the nanocomposite was 2.9 emu/g. Fe3O4–montmorillonite exhibited superparamagnetic behavior; normally Fe3O4 nanoparticles less than 20 nm diameter show superparamagnetism (Teja and Koh 2009). The surface area of montmorillonite was 121 m2/g, and the value increased with the addition of magnetic nanoparticles to 211 m2/g (Kalantari et al. 2015). The enhancement in the surface area of montmorillonite after the functionalization with magnetic nanoparticles is commonly observed. The increase in surface area is attributed to an enhanced basal space of montmorillonite by the intercalation of Fe, a phenomenon reported for expandable clays (Arancibia-Miranda et al. 2016; Uddin 2017).

Another strategy was adopted by Larraza et al. (2012), in which the magnetic nanoparticles synthesized by the solvothermal method were coated with polyethyleneimine polymer. A cationic exchange achieved the intercalation of the magnetite nanoparticles coated with polyethyleneimine polymer among montmorillonite platelets. Transmission electron microscopy images indicated that the material showed a high degree of exfoliation of the montmorillonite sheets and good dispersion of Fe3O4 nanoparticles on both the surface and among the layers of the nanocomposite. X-ray diffraction patterns of montmorillonite and Fe3O4-polyethyleneimine-montmorillonite presented characteristic peaks at 2θ equal to 8.92° and 6.2°, corresponding to an interlayer distance of 0.99 and 1.42 nm, respectively. The increase in interlayer distance value was confirming the insert of polymer-coated nanoparticles between the layers of the clay. The increase is justified by the fact that montmorillonite is one of the most expandable minerals. The saturation magnetization value of Fe3O4 nanoparticles was 87.4 emu/g very close to the bulk values. However, a saturation magnetization for nanocomposite decreased, 4.2 emu/g. The authors attributed the reduction in saturation magnetization value to the lower content of magnetic nanoparticles in the nanocomposite.

In addition to the synthesis method, the magnetic nanoparticles/matrix ratio may influence the physicochemical and magnetic properties of the nanocomposite. Yan et al. (2016) synthesized the bentonite magnetic nanocomposites by the one-step solvothermal method using different mass ratio bentonite–Fe: bentonite–Fe3O4-0.5, bentonite–Fe3O4-1.0, bentonite–Fe3O4-2.0, and bentonite–Fe3O4-5.0. The nanocomposites exhibited sizes of about 10–50 nm and spherical shape, and showed characteristic X-ray diffractiondiffraction peaks and Fourier transform infrared spectroscopy absorption bands from the bentonite and Fe3O4 phases, indicating that the lamellar structure of bentonite was not collapsed at high temperature and pressure during the solvothermal reaction. Furthermore, all nanocomposites showed superparamagnetic behavior with saturation magnetization values for bentonite–Fe3O4-0.5, bentonite–Fe3O4-1.0, bentonite–Fe3O4-2.0, and bentonite–Fe3O4-5.0 of 37.4, 34.1, 22.7, and 15.1 emu/g, respectively, were lower than 46.6 emu/g of Fe3O4. On the other hand, the surface area of the nanocomposites was larger than the area values for pure bentonite and Fe3O4, whose values were 89, 104, 111, and 124 m2/g for bentonite–Fe3O4-0.5, bentonite–Fe3O4-1.0, bentonite–Fe3O4-2.0, and bentonite–Fe3O4-5.0, respectively. In the adsorption studies, the authors selected bentonite–Fe3O4-2.0 nanocomposite to evaluate removal metal ions due to the considerable surface area and magnetization of material. The coprecipitation synthesis also provided a Fe3O4–bentonite material similar to that obtained by the solvothermal method, with spherical particles of diameter around 10 nm and a surface area of 141 m2/g (Hashemian et al. 2015).

Other methods such as sol-gel may also be used for the synthesis of clay mineral nanocomposites, although few studies are reported. Sol-gel method can lead to material contamination by side-products of the reactions, which result in a post-treatment of the products. Thus, synthesis can become difficult and time-consuming (Teja and Koh 2009). Kaur et al. (2015) synthesized a magnetic bentonite nanocomposite by the sol-gel method using MgFe2O4 ferrite as magnetic nanoparticles. Stoichiometric amounts of ferric nitrate and magnesium nitrate were added in 5 wt% bentonite solutioncontaining citric acid. Ammonium hydroxide solution was added dropwise, and the mixture was stirred for 10 h at 100 °C until a gel formed. The gel was dried and calcined at 300 °C for 3 h. X-ray diffraction analysis showed that the phase purity of MgFe2O4 was maintained during the synthesis process, but the presence of broad peaks of the nanocomposite suggests a lower ordering degree in MgFe2O4–bentonite. Saturation magnetization value for MgFe2O4 was 13.22 emu/g, and for MgFe2O4–bentonite was 5.69 emu/g. The lower saturation magnetization of MgFe2O4–bentonite was attributed to the addition of non-magnetic clay to magnetic nanoparticles. The specific surface area was 61 and 75 m2/g for MgFe2O4 and MgFe2O4–bentonite, respectively. The small increase in the surface area may be related to the amount of bentonite used in nanocomposite synthesis (Kaur et al. 2015).

Although clay minerals have a more extensive application for metals removal, polar organic molecules can also interact with adsorption sites of the magnetic nanocomposites (Uddin 2017). Sepiolite was used as an adsorbent to remove the atrazine herbicide from aqueous solution (Liu et al. 2014a). The sepiolite–Fe3O4 nanocomposite was prepared by the coprecipitation method. The results showed that the specific surface area increased from 71 m2/g for the natural sepiolite to 112 m2/g in sepiolite–Fe3O4. The increase in the specific surface area is due to the expansion capacity of 2:1 clays, corroborating with the results presented by Kalantari et al. (2015) for montmorillonite.

As can be observed, the embedded of magnetic nanoparticles changes some properties of clays, such as surface area. Another property that can be modified is the adsorbent surface charges. The magnetite has a point of zero charge of pH 8.3 (Larraza et al. 2012), and Fe3O4 addition can shift the isoelectric point of magnetic nanocomposite to higher pH values. Moreover, the higher the iron ions concentration, the larger is the shift of isoelectric point toward higher pH. The phenomenon was observed by Liu et al. (2014a), whose non-magnetic sepiolite clay isoelectronic point changed from 6.9 to 7.7 for the magnetic sepiolite clay. Hence, controlling the content of nanoparticles in the nanocomposite during synthesis enables the possibility to obtain materials with an adequate point of zero charge for desired contaminant removal.

Hydroxyapatite-based nanomaterials

It is considered the most important inorganic biomaterial and can be applied in different areas (Dong et al. 2016). In the case of water treatment, hydroxyapatite exhibits excellent potential in adsorb metals in naturals water and wastewater (Feng et al. 2010; Zhuang et al. 2015). To facilitate the separation from the water, hydroxyapatite has been combined with magnetic nanoparticles. In situ precipitation is the most common strategy of combining hydroxyapatite with magnetic nanoparticles. In brief, magnetic nanoparticles are added to the mixture solution of calcium salts, for example, Ca(NO3)2 and CaCl2, and phosphate ion. Additionally, modifications in the synthesis route may result in materials with distinct morphologies and textural properties.

Dong et al. (2010) prepared a hydroxyapatite–Fe3O4 adsorbent for the removal of Pb(II) in aqueous solution. Fe3O4 nanoparticles were synthesized by coprecipitation, and hydroxyapatite was combined with Fe3O4 by in situ precipitation. The scanning electron microscopy micrographs showed that a nano-flake-like irregularly shaped particle composed the hydroxyapatite–Fe3O4 material. The specific surface area was 109 m2/g. Feng et al. (2010) synthesized a hydroxyapatite magnetic nanocomposite to the adsorption of Cd(II) and Zn(II) by a similar route, but the mixture was aged at room temperature for 12–24 h without stirring. Scanning electron microscopy analysis revealed that hydroxyapatite–Fe3O4 had aspherical shape and formed aggregates, which resulted in a rough surface and porous structure. The specific surface area, 143 m2/g, was one of the largest reported for magnetic hydroxyapatite, thus suggesting that the aging process should contribute to the increase in the porosity of the material. The saturation magnetization value was 59.4 emu/g, greater than the commonly reported value for pure magnetite nanoparticles. Therefore, the saturation magnetization value found for hydroxyapatite–Fe3O4 nanocomposite indicates the presence of another magnetic constituent besides magnetite. Maghemite presence was confirmed by X-ray diffraction analysis (Feng et al. 2010).

In situ precipitation was also the synthesis method employed by Zhuang et al. (2015), but Ca2+ and PO42− ions were not simultaneously precipitated. Initially, CaCO3–Fe3O4 was formed and following the hydroxyapatite–Fe3O4. Also, sodium dodecyl sulfate was added as a surfactant, which acts as dispersing agents and stabilizing the nanoparticles. Scanning electron microscopy images showed that uniform nanoparticles constructed the hydroxyapatite–Fe3O4 microspheres obtained. Thus, sodium dodecyl sulfate may have played a significant role in achieving a monodisperse structure (Teja and Koh 2009; Tombácz et al. 2015), resulting in the surface area reduction with a value of 59 m2/g, which is lower than the area for the materials obtained without the surfactant addition.

Core–shell structures can also be obtained for hydroxyapatite magnetic nanocomposites by surface-controlled precipitation. The synthesis of Fe3O4@hydroxyapatite nanocomposite was the focus of the work of Yang et al. (2014a). The researchers opted for the solvothermal method for the synthesis of magnetic nanoparticles to control the size and shape of nanoparticles. Also, Fe3O4 was functionalized with l-aspartic acid to facilitate the coating of magnetic nanoparticles with hydroxyapatite. From the scanning electron microscopy and transmission electron microscopy images obtained for the material present the formation of the core–shell structure. The magnetic properties of pure magnetite and Fe3O4@hydroxyapatite nanocomposite were evaluated, and both showed superparamagnetic behavior. Therefore, hydroxyapatite did not affect the magnetic behavior of magnetite in the nanocomposite. Fe3O4@hydroxyapatite had a saturation magnetization of 43.9 emu/g, which was ca. 49% of that of pure magnetite, in agreement with the composition of nanocomposite, with a Fe3O4/hydroxyapatite weight ratio of 1:1.

Elemental analysis techniques were used to indicate the experimental Ca/P molar ratio in the hydroxyapatite magnetic nanocomposite. In hydroxyapatite–Fe3O4 nanocomposite synthesized by Feng et al. (2010), the molar ratio Ca/P was determined by X-ray dispersive energy spectroscopy, and the value was 1.65. A similar value was found for Fe3O4@hydroxyapatite by inorganic analysis, which molar ratio Ca/P was 1.63 (Yang et al. 2014a). The experimental values are close to the stoichiometric ratio of the hydroxyapatite of 1.67, demonstrating that the synthesis strategy used was capable of fabricating magnetic adsorbent of hydroxyapatite (Feng et al. 2010).

Magnetic iron-biopolymer nanosorbents

Magnetic nanoparticles can be incorporated into a polymer matrix through the porous structure of polymers. Concerning water treatment, biopolymers have some advantages compared to synthetic polymers such as non-toxicity, biocompatibility, biodegradability, and low cost (Donia et al. 2012). Therefore, biopolymers have been widely employed in water purification. Moreover, biopolymers exhibit characteristics such as hydrophilicity that allows a greater interaction of the adsorbent with the water molecules in comparison with synthetic polymer (Liu et al. 2012b). Chitosan, cellulose, and alginate are the most reported materials in literature as a polymeric matrix for magnetic nanoparticles (Lofrano et al. 2016; Brião et al. 2020). Researches on the use of magnetic biodegradable nanocomposites focus on biomedical applications, eg., magnetic resonance tomography, hypothermictherapy, drug delivery (Spiridonov et al. 2017), although some studies have evaluated the potential as an adsorbent for water treatment according to Table 1.

Polymeric nanocomposites can be obtained by adopting three main strategies: (i) simple mixing of the components—the magnetic nanoparticles are directly introduced and grafted into the polymer; (ii) in situ synthesis of the nanoparticles—metal ions are preloaded into the polymer matrix and the target nanoparticles synthesized; (iii) in situ matrix polymerization—the magnetic nanoparticles are added during the polymerization of the monomers (Lofrano et al. 2016; Mallakpour and Naghdi 2018).

Cellulose-basednanomaterials

Cellulose is the most abundant renewable biopolymer and very promising raw material available at low cost for the preparation of various functional polymers (Donia et al. 2012). Some studies report the use of cellulose as a sorbent, mainly in the removal of metallic ions (Hokkanen et al. 2013; Anirudhan et al. 2016). However, cellulose could not be satisfactorily applied in adsorbing pollutants (Hokkanen et al. 2013). Hence, studies on the application of materials based on magnetic cellulose have been carried out.

The application of cellulose is limited due to low adsorption capacity as well as low physical stability (Anirudhan et al. 2009; Luo et al. 2016). Therefore, in the preparation of cellulose-based magnetic nanocomposites, there is a need for chemical modification of the cellulose matrix. Some attempts have been made, including modification with amino groups (Donia et al. 2012). Graft copolymerization is one of the most promising methods for modification of the polymeric substances, for instance, lignocellulosic (Anirudhan et al. 2009). Amino-cellulose synthesis involves (1) grafting of glycidyl methacrylate using cerium initiated polymerization and (2) ring-opening reaction of epoxy groups with amine, such as ethylenediamine and tetraethylenepentamine (Sun et al. 2014). Donia et al. (2012) obtained a microporous material Fe3O4–cellulose–NH2 with a pore diameter lower than 2 nm and surface area of 138 m2/g employing copolymerization. The amino group content was determined volumetrically and found to be 6 mmol/g, confirming the functionalization of cellulose.

Sun et al. (2014) also opted for the cellulose modification with amino groups through glycidyl methacrylate grafting followed by reaction with ethylenediamine. In the study, the magnetic nanoparticles were coated with silica because the nanocomposite was applied under acidic conditions. As discussed earlier, iron oxides materials tend to oxidize or dissolved under acidic conditions. SiO2 has been reported to be a suitable supporting matrix to immobilize Fe3O4 due to stability in the acid environment. The saturated magnetization and isoelectric point values of Fe3O4@SiO2@cellulose and Fe3O4@SiO2@cellulose@NH2 were measured to be 12.3 and 10.1 emu/g and 2.81 e 7.92, respectively. The decrease in saturation magnetization value was expected since Fe3O4@SiO2@cellulose@NH2 had a lower Fe3O4 content, 14.8%, compared to Fe3O4@SiO2@cellulose, 19.1%. The increase in the isoelectric point after functionalization was attributed to the protonation of the amino groups present in Fe3O4@SiO2@cellulose@NH2, indicating that the nanocomposite was positively charged at pH below 7.92. The result was desirable for the removal of the studied contaminant, Cr(VI), as will be detailed below.

Another possibility of increasing the adsorption capacity of cellulose nanocomposites is to combine cellulose with materials with high surface area and surface modifiability. Clay is a good option due to biocompatibility and low toxicity. Fe3O4–bentonite–cellulose nanocomposite showed a high saturation magnetization, whose value was 78 emu/g (Luo et al. 2016). In contrast, the adsorption capacity was not improved as expected. The Fe3O4–bentonite-cellulose adsorption capacity for Pb(II) was 2.8 mg/g. For Fe3O4–bentonite, adsorption capacity was 81.5 mg/g for Pb(II) (Yan et al. 2016).

Cellulose-based magnetic nanocomposites can also be obtained by the biosynthetic route as a proposal for the green synthesis. Zhu et al. (2011) proposed the synthesis of a magnetic nanocomposite of bacterial cellulose via fermentation of Gluconacetobacter xylinum. Magnetic nanoparticles were synthesized by coprecipitation and embedding into bacterial cellulose with pH controlling. Nanocomposites with different Fe3O4 amounts were produced, obtaining a nanocomposite with a Fe content of 14% and another containing 33%. Increasing the Fe content in Fe3O4–bacterial cellulose nanocomposites from 14 to 33%, the corresponding saturated magnetization increased from 12 to 41 emu/g. The authors chose to use Fe3O4–bacterial cellulose 33% Fe in the adsorption tests. However, Cr(VI) adsorption capacity was 65 mg/g, lower than the value found for the amino-cellulose magnetic nanocomposite, 171.5 mg/g. Thus, functionalization with amino groups has been shown to improve cellulose performance for Cr(VI).

Chitosan-based nanomaterials

Chitosan is the second most naturally abundant polysaccharide with singular characteristics such as high reactivity, excellent chelation behavior, and chemical stability, making chitosan one of the most studied adsorbents in the removal of several classes of pollutants (Ren et al. 2013; Shukla et al. 2015; He et al. 2016). The amino and hydroxyl groups of chitosan can act in reactive sites for chemical modification (Wang et al. 2017). Therefore, chemical modification of chitosan is of interest in the last years, either chitosan used as a polymer matrix for magnetic nanoparticles or as a functionalizing agent (Gutha and Munagapati 2016; Brião et al. 2020).

Chitosan can be prepared in various ways, depending on the application. In several studies, chitosan has been used in the form of flakes, powder, gel, and beads, as adsorbent. Although the flakes, or powder form, are the most used, in the adsorption processes the flakes morphology is a disadvantage due to the low porosity (Liu et al. 2012b); thus, chitosan beads have been employed in the synthesis of chitosan-based adsorbents. Chemical cross-linking of chitosan with glutaraldehyde is usually employed to improve the mechanical properties of biopolymer spheres (He et al. 2016).

Many approaches have been used to synthesize iron oxide chitosan nanocomposites, and the most used are (i) simple mixing of components and (ii) synthesis of magnetic nanoparticles in situ. The chitosan functionalization was also evaluated by chemical modification with cyanoguanidine (Wang et al. 2013), ethylenediaminetetraacetic acid (Ren et al. 2013), polyethyleneimine (Wang et al. 2017), Shiff's base as 4-((pyridine-2-illimino) methyl) benzaldehyde (Gutha and Munagapati 2016), among others. Fourier transform infrared spectroscopy was the main technique used to confirm the chemical modification of chitosan. In the spectrum of chitosan, the characteristic absorption bands appear around 3424 and 1376 cm−1, due to the stretching vibrations of N–H and C–N bonds of amino groups, respectively (Ren et al. 2013). Chemical modifications of chitosan occur in the amino groups, where the bands tend to disappear, and new bands are formed, such as bands at 1637 and 1662 cm−1 for amide and imine, respectively (Gutha and Munagapati 2016).

The specific surface area of magnetic chitosan nanocomposites reported in the studies was less than 10 m2/g. For example, the specific surface area of unmodified magnetic chitosan nanocomposite and modified magnetic chitosan nanocomposite was 0.5 m2/g and 5.2 mg2/g, respectively (Zhang et al. 2014; Soares et al. 2019). However, some studies pointed out that biopolymers such as chitosan are good sorbents of gases, which may decrease the accuracy of specific surface area measurement by the Brunauer–Emmett–Teller method. Thus, magnetic chitosan nanocomposites may have been underestimated for the specific surface area value (Zhang et al. 2014).

The magnetic properties of chitosan nanocomposites depend on the synthesis route employed. For the magnetic nanocomposite whose chitosan was not subjected to the modification process, the saturation magnetization value was higher than the modified chitosan nanocomposites. In work conducted by Tran et al. (2010), the chitosan–Fe3O4 nanocomposite and the uncoated Fe3O4 nanoparticles showed saturation magnetization of 54 and 55 emu/g, respectively. Similar magnetization values were attributed to the thin chitosan coating that not affecting the magnetic properties of the beads. On the other hand, functionalization generally decreases the saturation magnetization of the magnetic nanocomposite. Gutha and Munagapati (2016) prepared Fe3O4 nanoparticles with the magnetization of 67.6 emu/g, but the value was reduced to 29.6 emu/g for 4-((pyridin-2-ylimino) methyl) benzaldehyde modified chitosan nanocomposite.

Also, the magnetization decrease for Fe3O4–chitosan-(4-((pyridine-2-illimino) methyl)) benzaldehyde may be due to the cross-linking of chitosan-(4-((pyridine-2-illimino) methyl)), which reduced the relative percentage of iron oxide in the nanocomposite. The decrease in saturation magnetization value was also observed for cyanoguanidine, and ethylenediaminetetraacetic acid modified chitosan nanocomposites, whose saturation magnetization values were 21.6 and 18.2 emu/g, respectively (Ren et al. 2013; Wang et al. 2013).

The presence of amino groups in the polymeric matrix provides excellent properties for chitosan in the adsorption of metal ions. Thus, most studies with magnetic chitosan nanocomposites aim at the removal of toxic metals in water. Despite the high magnetization value of non-functionalized chitosan magnetic nanocomposite, chitosan functionalization aims to increase the adsorption capacity. Chitosan has been widely used as a biosorbent to remove metal ions from aqueous solutions; however, few studies are on the removal of pharmaceutical-derived compounds and pesticides in water using chitosan.

To improve the adsorption capacity of chitosan nanocomposite for diclofenac antibiotic removal, Soares et al. (2019) proposed chemical modification of the chitosan surface with N-(2-hydroxypropyl)-3-trimethylammonium chloride to obtain quaternary chitosan. Quaternary chitosan was coupled with a silane group and then combined with silica-coated magnetic nanoparticles to form Fe3O4@SiO2–Si-quaternary chitosan nanocomposite. The magnetic quaternary chitosan exhibited an adsorption capacity for diclofenac of 240.4 mg/g, which is four times greater the value observed for magnetic chitosan (Zhang et al. 2014).

Alginate-based nanomaterials

Alginate is a non-toxic, biocompatible, and biodegradable biopolymer extracted from seaweed (Esmat et al. 2017). Alginate is composed of mannuronate and guluronate units, each containing one carboxylate group (Bée et al. 2011). The use of alginate-based materials as adsorbents is related mainly to the presence of carboxylic groups in the alginate structure, which enable alginate-based materials to form complexes with metal ions in aqueous solutions (Idris et al. 2012). The use of magnetic nanoparticles in alginate beads improves the adsorption capacity because of the increase in specific surface area (Bée et al. 2011). Citric acid is commonly used as a coating of magnetic nanoparticles (Bakr et al. 2015).

The most adopted strategy for the synthesis of alginate-based magnetic nanocomposites was the simple mixing of the components. Magnetic nanoparticles were prepared by coprecipitation and, in some cases, coated with citrate (Bée et al. 2011; Idris et al. 2012; Bakr et al. 2015). Gel alginate was the most commonly used material due to the easy handling compared to powder materials. In the presence of divalent cations, especially Ca2+ ions, the alginate can easily form cross-linked gel matrices (Esmat et al. 2017; Bakr et al. 2015). In the synthesis of magnetic alginate nanocomposite, the magnetic nanoparticles are added in an alginate solution and mixed understirring in the presence of calcium chloride.

Based on the findings in the literature, maghemite and ferrite were the nanoparticles chosen for the preparation of magnetic alginate nanocomposites. ɣ-Fe2O3-alginate nanocomposites prepared by Bée et al. (2011)and Idris et al. (2012) exhibited similar magnetic properties with saturation magnetization values of 32.2 and 35.0 emu/g, respectively. In both works, a similar synthesis route was employed. Magnetite nanoparticles were prepared by coprecipitation and then oxidized to maghemite using ferric nitrate at 90 °C. The obtained maghemite was coated with citric acid and dispersed in water as citrate ferrofluids, while ɣ-Fe2O3–alginate was synthesized by adding citrate ferrofluid in an alginate solution. The suspension was then added dropwise into a CaCl2 bath for the formation of the magnetic beads. Transmission electron microscopy images showed that the average size of the nanoparticles decreased from 15 to 9 nm when maghemite was coated with citrate. The scanning electron microscopy images showed that the pure alginate surface exhibited the smooth texture while the surface of the ɣ-Fe2O3–alginate was rough, indicating that the maghemite nanoparticles were entrapped in the polymer (Idris et al. 2012). Citrate ions have a significant role in the preparation of maghemite nanoparticles as citrate ions can enhance the dispersion of the nanoparticles in the polymer matrix, reducing aggregation of the magnetic nanoparticles. Citrate ions increases the stability of magnetic nanoparticles by providing the nanocomposite with high saturation magnetization compared to other biopolymer-based nanocomposites.

Alginate nanocomposites with ferrite were prepared similarly to maghemite nanocomposites. In the study by Esmat et al. (2017), cobalt ferrite was used uncoated with citrate ions. The saturation magnetization of CoFe2O4 was 48.5 emu/g, and for CoFe2O4–alginate there was a reduction of about 50%. Besides, both pure ferrite and nanocomposite did not exhibit superparamagnetic behavior. The hysteresis loop indicated that the materials were ferrimagnetic, i.e., the materials remained magnetized in the absence of the external magnetic field.

Bakr et al. (2015) also synthesized alginate nanocomposite with nickel ferrite in a citrate medium. NiFe2O4 and NiFe2O4–alginate exhibited superparamagnetic behavior and saturation magnetization values, 21.8 and 15.4 emu/g, respectively, which corresponds to a decrease of approximately 30%. Compared to the Esmat et al. (2017) study, the citrate ions addition resulted in a stabilization of alginate nanocomposites' magnetic nanoparticles. Besides that, citrate might improve the material's adsorption capacity due to the presence of surface binding groups (Lofrano et al. 2016).

In situ coprecipitation synthesis has been reported for the preparation of alginate magnetic nanocomposites. Nanogel alginate was prepared by adding thiacalix[4]arenetetrasulfonate for greater material stability. Thiacalix[4]arenes are macrocyclic oligomers that can exist in a relatively rigid and stable cone structure. The nanogel was mixed with the iron salt solution for in situ coprecipitation of magnetic nanoparticles, resulting in a high saturation magnetization value of 45.6 emu/g. Scanning electron microscopy and transmission electron microscopy images showed that the magnetic nanogel had a rod-like morphology. X-ray diffraction analysis indicated that the nanocomposite had a crystalline structure, which justifies a high saturation magnetization value. Noteworthy that, the crystalline nature of the material can have contributed to a low adsorption capacity, between 13.5 and 20.0 mg/g, for the evaluated metal ions (Lakouraj et al. 2014).

Magnetic iron-polymer nanosorbents

Adsorbents composed of magnetic cores and polymeric shells have received great concern recently in water treatment. The advantages of polymer-based magnetic nanocomposites are not only the easy and rapid separation of the aqueous solution in the presence of a magnetic field, but also the selectivity of magnetic polymer toward target pollutants. Also, the functional modification is possible by the specific ligand on the surface of polymeric matrixes to improve the adsorption capacity and selectivity (Zhao et al. 2014; Chávez-Guajardo et al. 2015).

The embedded magnetic nanoparticles in the polymeric matrix can be carried out either during the synthesis in an insitu or exsitu process (Lofrano et al. 2016). While the in situ method refers to the fabrication of nanoparticles from precursors with the presence of another phase material, the ex situ or post-synthesis method coats polymer pre-synthesized nanoparticles using specific processing, usually in situ polymerization (Davodi et al. 2017). The ex situ process is the most reported and, in most cases, yields core–shell nanoparticles. However, the synthesis of well-defined core–shell structured magnetic composites requires the surfactant-directing polymerization approach to modify and stabilize the magnetic cores (Han et al. 2013).

Conducting polymers appear as a promising material for the functionalization of magnetic nanoparticles; polyaniline deserves special attention because of the excellent environmental stability and the presence of electron-donating groups on the polymer chains (Han et al. 2013; Kumar and Jain 2014). Another polymer that has been reported as a matrix for magnetic nanoparticles is polydopamine due to the numerous surface-active functional groups, such as amino and hydroxyl groups (Li et al. 2017b).

Chávez-Guajardo et al. (2015) synthesized the polyaniline magnetic nanocomposite employing maghemite as a magnetic nanoparticle. Magnetic nanoparticles were prepared by the coprecipitation method, in which the formation of the maghemite phase was confirmed by Fourier transform infrared spectroscopy analysis. The spectrum exhibited characteristic peaks of Fe–O vibrational mode in 577 cm−1 and 637 cm−1, corresponding to the phase ɣ-Fe2O3. Polyaniline-ɣ-Fe2O3 nanocomposite was obtained by in situ polymerization using aniline as a precursor. Although sodium dodecyl sulfate surfactant was used in the synthesis, the material exhibited an irregular morphology. The surfactant-free synthesis via in situ polymerization has also been reported. Han et al. (2013) used by the solvothermal method for the synthesis of Fe3O4 nanoparticles, which led to the formation of the Fe3O4@polyaniline nanocomposite with well-defined core–shell structure. Both syntheses with surfactant and surfactant-free synthesis provided nanocomposites with similar adsorption capabilities of ca. 200 mg/g toward Cr(VI).

On the other hand, the Fe3O4@polyaniline nanocomposite obtained by the surfactant-free route presented a higher saturation magnetization than polyaniline-ɣ-Fe2O3 nanocomposite using surfactant. The saturation magnetization for Fe3O4@polyaniline was 58.1 emu/g, while for polyaniline-ɣ-Fe2O3, the saturation magnetization was 30 emu/g. The solvothermal method makes easy to control the size and shape and, consequently, the magnetic properties. Thus, contributing to the high saturation magnetization value in surfactant-free synthesis, maghemite has a saturation magnetization lower than magnetite.

Another way of synthesizing a magnetic polymer is to use the molecular imprinting technique, where template-shaped cavities are created in the polymer to form specific sites to generate a molecular recognition based on the enzyme–substrate recognition. According to Ekberg and Mosbach, "host–guest" or "template" polymerization terms are also used to refer to selective polymers (Ekberg and Mosbach 1989). The synthesis process is divided into the following three steps: (1) copolymer formation; (2) cross-linking of the copolymer in the presence of magnetic nanoparticles and the template molecules to form model molecules; and (3) solvent washing for the removal of the template molecules from the polymeric matrix (Zheng et al. 2014).

The material prepared by the molecular imprinting technique has cavities capable of selectively retaining the template molecule. Thus, the molecular imprinting technique becomes useful for the preparation of materials that can adsorb molecules such as pesticides and pharmaceutical-derived compounds that are difficult to remove (Xu et al. 2012a). Besides, studies have shown that magnetic molecularly imprinted polymers have saturation magnetization value of 35.0 emu/g, which is greater than 22.0 emu/g of the corresponding magnetic non-imprinted polymer (Masoumi et al. 2016).

As with magnetic inorganics nanosorbents, the chemical and magnetic properties of polymeric magnetic nanocomposites will depend on the architecture (Kumar and Jain 2014). Studies have shown that magnetic nanocomposites having the same type of structure, i.e., core–shell, exhibited different saturation magnetization values. Davodi et al. (2017) synthesized Fe3O4 e Fe3O4@polydopamine with saturation magnetization values of 57.9 and 44.7 emu/g, respectively. Transmission electron microscopy images showed that the magnetic core was covered by a thin layer of thickness 0.86 nm, which may have contributed to a nanocomposite with considerable saturation magnetization value. In work reported by (Li et al. 2017b), Fe3O4@NH2-polydopamine saturation magnetization value was 10.7 emu/g. According to the authors, the lower saturation magnetization value can be attributed to the presence of amino groups in the nanocomposite, giving the material a rough surface. The insertion of amino groups became the Fe3O4 content low in the nanocomposite, which the value was 16.2wt%. Though the point of zero charges of Fe3O4@NH2-polydopamine was higher, pH of point of zero charge 4.0, than the value of Fe3O4@polydopamine, pH of point of zero charge 3.0 (Davodi et al. 2017). Implying that Fe3O4@NH2-polydopamine will be positively charged in a greater pH range, favoring the adsorption of Cr(VI), which is negatively charged in acidic conditions (Li et al. 2017b).

Most reports focus on the functionalization effect on the chemical and magnetic properties and performance of the polymeric nanocomposites. However, magnetic core content seems to play a crucial role in the properties and adsorption capacity of magnetic nanocomposites. Pan et al. (2012) verified that the removal of Hg(II) by polymeric magnetic nanocomposite was dependent on the amount of Fe3O4 in the material. As expected, the higher the Fe3O4 content in the nanocomposite, the greater the saturation magnetization value. Otherwise, nanocomposite with higher Fe3O4 content did not present the highest adsorption capacity. Although the addition of Fe3O4 provided a higher adsorption capacity for some nanocomposites, the authors concluded that the material performance might be an integrated result of both the number of functional groups onto the polymeric matrix and Fe3O4 content also, that the ratio between the magnetic nanoparticles and matrix is an important parameter to be evaluated in the synthesis.

Magnetic iron-carbon nanosorbents

Activated carbon is reported to be one of the best adsorbents for water and wastewater treatment due to high porosity and large surface area (Gupta et al. 2013). However, with the discovery of fullerene C60 in 1985, the use of carbonaceous nanomaterials as adsorbents became the focus of researches. Numerous types of nanostructured carbonaceous materials and functionalized forms have been evaluated as adsorbents (Azzouz et al. 2018). The application of carbon nanomaterials as nanoabsorbers is mainly focused on carbon nanotubes, graphene, and graphene oxide. However, the high cost and low regeneration restrict the use of the materials (Ahmadi et al. 2017). Therefore, the search for the development of carbon-based magnetic materials is underway. Table 1 shows a summary of reported magnetic iron oxide nanocomposite using nanostructured carbonaceous as matrices. The following are some synthesis approaches as well as the chemical, structural, and magnetic properties of carbon-based magnetic nanocomposites.

Carbon-coated nanomaterials

Activated carbon is the main carbonaceous material used as a matrix for the synthesis of magnetic carbon nanocomposites (Siddiqui et al. 2018). The great specific surface area of ca. 1400 m2/g and porous structure of activated carbon favor the dispersion of magnetic nanoparticles in the matrix (Baghdadi et al. 2016). Magnetically activated carbon nanocomposites are mainly prepared by a two-step method in which magnetic nanoparticles are synthesized and combined with activated carbon (Baghdadi et al. 2016; Kang et al. 2016). The one-step method through in situ coprecipitation has also been reported (Zarandi et al. 2016; Danalıoğlu et al. 2017). In some cases, activated carbon is treated with nitric acid to increase the hydrophilicity of activated carbon (Baghdadi et al. 2016). Besides, nitric acid treatment significantly reduces the point of zero charge of the activated carbon. The reported point of zero charge values of the magnetic acid-treated activated carbon nanocomposites and activated carbon is pH 2.0 and 6.5, respectively. Therefore, the addition of acid produces nanocomposites formed by acid carbon. Acid carbons have a higher density of oxygen-containing functional groups, such as carboxyls, carbonyls, phenols, lactones, and quinones, which significantly influence adsorption and reactivity of activated carbon (Kang et al. 2016). Other agents may be used for chemical modification of activated carbon, such as chitosan. In drug removal, chitosan is added to Fe3O4–activated carbon to improve adsorbent performance (Danalıoğlu et al. 2017).

Magnetically activated carbon nanocomposites generally have a porous structure with magnetic nanosized particles monodispersed in the pores. Most of the pores consist of mesopores (Kang et al. 2016). The addition of magnetic nanoparticles causes a decrease in nanocomposite surface area, which may be due to pore blockage of the activated carbon structure by oxygen-containing functional groups and magnetite nanoparticles (Baghdadi et al. 2016). Despite the decrease, high surface area magnetic activated carbon nanocomposites were obtained. Kang et al. (2016) prepared Fe3O4–activated carbon nanocomposites with an area of 1241 m2/g and a total pore volume of 0.549 cm3/g employing a high surface area commercial activated carbon of 1378 m2/g. However, the nanocomposite surface area value will depend on the activated carbon surface. Fe3O4–activated carbon-chitosan nanocomposite with a smaller area of 204 m2/g was reported by Danalıoğlu et al. (2017) using activated carbon with a area of 560 m2/g.

The findings presented in the studies suggest that the saturation magnetization of magnetically activated carbon nanocomposites seems not to be dependent on the strategy of synthesis adopted, but on the mass ratios of Fe3O4/activated carbon in the nanocomposite. The nanocomposite prepared by magnetic nanoparticles coprecipitation and mixing of the components with the mass ratio Fe3O4/activated carbon of 1:8 exhibited saturation magnetization of 5.06 emu/g (Baghdadi et al. 2016). The nanocomposite with the mass ratio Fe3O4/activated carbon of 1:10 synthesized by in situ coprecipitation presented saturation magnetization of 4.7 emu/g (Do et al. 2011). Although saturation magnetization values are lower than to other magnetic nanocomposites, increasing the amount of activated carbon in the nanocomposite improved the adsorption capacity of the materials, because the incorporation of magnetic nanoparticles in the activated carbon matrix decreases the specific surface area of the nanocomposite. Both the in situ coprecipitation method and the simple mixing of the component method provided superparamagnetic behavior nanocomposites, once both Fe3O4 nanoparticles were obtained with a size less than 50 nm.

Magnetic carbon nanocomposites can also be prepared by coating the magnetic nanoparticles with carbon to form a core–shell structure. The outer carbon layer, which contains abundant functional groups such as carboxylic and hydroxyl groups, can increase stability and corrosion resistance of magnetic nanoparticles, and improve the adsorptive properties (Mao et al. 2016). Glucose is the main carbon precursor employed in the synthesis of magnetic carbon nanocomposites. In the synthesis of nanocomposites, one- or two-step process can be used, and generally, the hydrothermal method for Fe3O4@C synthesis is employed. The hydrothermal method was proven to effectively produce core–shell magnetic carbon nanocomposites with some advantages such as easier control of size, morphology, and crystalline phase of magnetic nanoparticles (Huong et al. 2018). However, the amount of carbon used during the coating has a very significant effect on nanocomposite morphology.

Huong et al. (2018) synthesized Fe3O4@C nanocomposite by using a two-step process of coprecipitation and hydrothermal method. The carbon content in Fe3O4@C nanocomposite was controlled by adjusting the mass ratio of glucose precursor from 1.25 to 10 wt%. Transmission electron microscopy images showed that most Fe3O4 nanoparticles had a quasi-spherical shape with an average size of 20 nm and that were coated by carbon. When loading C content was 1.25 wt%, a thin layer covering magnetic nanoparticles was observed, forming a core–shell structure. By increasing the C content for 2.5wt%, the thickness of the carbon layer increased significantly, and in the core–shell structure of Fe3O4@C nanocomposite was vanished, forming a structure of iron oxide nanoparticles encapsulated in carbon. Besides, at higher loading C content, equal to or greater than 2.5 wt%, large aggregation of Fe3O4 nanoparticles was also found, which may decrease the stability of the magnetic nanoparticles. The change in the structural morphology of nanocomposite influenced the adsorption process reducing considerably, ca. 25%, the removal efficiency of As(V) by nanocomposite with C content of 10 wt%compared to Fe3O4@C at the content of 1.25 wt%. The same behavior was reported by Chen et al. (2016b) employing one-step hydrothermal synthesis. The authors evaluated the morphological and structural characteristics of the nanocomposites obtained with 0.3, 0.6, and 1.1 g glucose and selected the nanocomposite prepared with 0.6 g glucose for the Cr(VI) adsorption experiments. The sample with low C content of 0.3 g glucose had almost no surface area, while the sample with high C content of 1.1 g glucose had poor morphology due to encapsulated magnetic nanoparticles.

The coating of magnetic nanoparticles with carbon also plays an important role in the magnetic behavior of the nanocomposite. Depending on the thickness of the C layer, larger particle size nanocomposites can be obtained that can give the material non-superparamagnetic behavior. Fe3O4@C nanocomposite prepared by Mao et al. (2016) one-step hydrothermal method consisted of particles with an average size of 140 nm. The magnetization curve showed the hysteresis loops, indicating that the material did not exhibit superparamagnetic behavior. The magnetization curve of Fe3O4@C nanocomposite synthesized by Chen et al. (2016b), using the same synthesis route, also presented hysteresis loops attributed to the large particle size, whichwas greater than 130 nm.

Still, Mao et al. (2016) observed that heat treatment is another parameter that interferes with the chemical and magnetic properties of Fe3O4@C nanocomposites. Fourier transform infrared spectroscopy analyses for Fe3O4@C nanocomposite before and after thermal treatment showed that the process modified the material. A characteristic band of C=O vibrational mode in the nanocomposite was observed before calcination and disappeared in the calcined nanocomposite. Also, a new band appeared at 2000 cm−1, indicating the existence of C=C bonds on the adsorbent surface. The changes in the surface of the material caused an increase in the specific surface area, whose values were 18 and 79 m2/g for the nanocomposites before and after the heat treatment, respectively. On the other hand, the heat treatment may be responsible for the low saturation magnetization value of 9.91 emu/g compared to other core–shell nanocomposites. The authors associated the low saturation magnetization to the transformation of the magnetite into other weaker magnetic phases, such as ɣ-Fe2O3 and Fe3C.

The reported results show that the synthesis approaches used have a significant influence on the characteristics of carbon-based magnetic nanocomposites. For example, nanocomposite formed by carbon-coated iron oxide nanoparticles showed adsorption capacity for ciprofloxacin of 90.1 mg/g, which was equal to the value found by magnetic active carbon nanocomposite, but with the saturation magnetization about 50% greater (Mao et al. 2016; Danalıoğlu et al. 2017). Enabling to obtain a material with magnetic activated carbon compatible performance with superior magnetic properties. However, to achieve a better performance, Fe3O4@C must be thermally treated, which could make the synthesis process more laborious and increase the cost. Hence, the cost–benefit assessment should be performed looking for a material that combines efficiency and feasibly in water and wastewater treatment.