Abstract

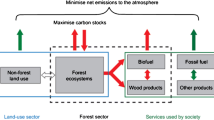

Forests provide wood products and feedstock for bioenergy and bio-based products that can mitigate climate change by reducing carbon emissions. In order to assess the effects of forest products on reducing carbon emissions, we analyzed the carbon balance for individual carbon pools across the forest supply chain over a long period of time. We simulated particular forest supply chain activities pertaining to even-aged management of pine stands in South Korea to demonstrate our methods. Two different rotation scenarios (i.e., 40 and 70 years) were assessed over the 280-year time horizon in terms of temporal changes in carbon stock in each carbon pool along the supply chain, carbon transfer between carbon pools, substitution effects, and delayed carbon release by wood products. We found that the average carbon stock level was higher for the 70-year rotation scenario, but the total amount of gain in carbon was higher for the 40-year rotation at the end of the time horizon. This study confirms that forest products and energy feedstock can both reduce carbon emissions and increase carbon storage. However, the complexity of carbon accounting along the supply chain warrants a thorough evaluation from diverse perspectives when it is used to assess forest carbon management options.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The utilization of forest products and biomass has emerged as a key strategy in South Korea to address a variety of environmental and energy issues (Korea Forest Service 2009). Forest biomass used to produce timber products, bio-based materials, and feedstock for bioenergy can potentially mitigate climate change by storing carbon for a long period of time or replacing fossil fuels and fossil-fuel-based materials with renewable sources (van Kooten et al. 2009; Becker et al. 2011).

Numerous studies have attempted to assess the potential of forest biomass to reduce carbon emissions (e.g., Winjum et al. 1998; Liski et al. 2001; Perez-Garcia et al. 2005; Green et al. 2006; Eriksson et al. 2007; Profft et al. 2009; Mathieu et al. 2012; Peckham and Gower 2013). Avoided carbon emissions through the storage of carbon in harvested wood products (HWPs) or substitution of fossil fuels and fossil-fuel-based materials is usually referred to as “carbon storage and substitution effects.” Under certain circumstances, avoided carbon emissions due to these effects could exceed the amount of carbon stored in a forest itself in the long run [Perez-Garcia et al. 2005; Intergovernmental Panel on Climate Change (IPCC) 2014].

Questions still remain regarding strategies that are often proposed as forest-based climate change solutions. Managing forest carbon to mitigate climate change is a complicated task because it requires not only an understanding of the impact of the entire carbon-cycle over a long period of time, but also the proper assessment of carbon reduction in the atmosphere and carbon storage in forests and forest products.

In order to be certain that measures deliver the promised reductions in carbon emissions, many studies have conducted comprehensive analyses of the carbon balance across wood supply chains for the life cycle of timber products. For example, Perez-Garcia et al. (2005) analyzed the effects of wood products for house construction on energy displacement in the northwestern USA by tracking carbon fluxes from reforestation to the final use of wood products. They combined a forest growth model with other simulation models to address multiple uses of wood products and their associated emissions. A life cycle assessment was employed to analyze the carbon budget from sequestration to substitution through wood product supply chains. Profft et al. (2009) simulated carbon fluxes from forest stands to wood products in central Germany by using timber sale and wood processing data in the region. They quantified carbon stocks in wood products to demonstrate their contributions to reducing carbon emissions.

Although previous studies attempted to assess a full carbon budget through simulated wood supply chains, most of them suffered from incomplete supply chains or a lack of detail in their simulations (Proftt et al. 2009). For example, numerous studies did not account for mill residues, of which large portions are currently used in many places as a source of other types of wood product or bioenergy (Liski et al. 2001; Perez-Garcia et al. 2005; Eriksson et al. 2007). Most of the previous studies did not consider individual tree characteristics in estimating the array of timber products. Mathieu et al. (2012) is one of the few studies that used an individual tree growth model. They integrated the growth model with a stem bucking model to identify the highest value log grades and products from individual stems. Avoided carbon emissions due to the displacement of fossil fuels is another component often missing from carbon budget analysis in many studies.

In this study, we used a series of simulation models to track activities along a comprehensive cradle-to-grave wood supply chain in South Korea for the purpose of estimating carbon balance and transfer along the chain over a long period of time. We adapted the supply chain modeling framework from Mathieu et al. (2012), and used distance-independent individual tree growth and log-processing models that were locally developed and parameterized for forest stands in South Korea. Unlike Mathieu et al. (2012), who examined the effects of thinning intensity on carbon balance, our study aimed to assess the carbon balance of the most common even-aged management systems in South Korea with varying rotation ages. In addition, we make the first attempt to analyze annual net carbon fluxes in individual carbon pools. Unlike the calculation of average carbon stock used in most previous studies, we believe net carbon fluxes provide different and useful insights when comparing the benefits of different forest carbon management options.

Materials and methods

The accounting method used in this study tracks carbon balances from forest stands to end-use wood products and product disposal. The method accounts for annual net carbon fluxes in forests and HWPs, as well as avoided emissions by using forest biomass as a renewable material or energy source. Our carbon accounting also includes carbon emissions from logging operations, HWP manufacturing and recycling, and methane emissions caused by HWP disposal in landfill. We define positive fluxes as those that remove carbon from the atmosphere or other carbon pools, whereas negative fluxes represent the release of carbon into the atmosphere or transfer of carbon to other carbon pools.

Estimating carbon balances in forest stands and HWPs involves multiple simulation models to represent each stage in the supply chain (Fig. 1). The following four simulation models were employed in this study: a distance-independent tree growth simulator, a logging operations simulator, a production simulator, and an end-use simulator. The growth simulator estimates a forest carbon pool including both aboveground and belowground biomass. It also estimates the number of trees and their sizes through thinning and regeneration harvest according to given silvicultural treatment schedules. The logging operation simulator transforms the harvested trees into logs and logging residues and simulates transportation to respective production facilities. The production simulator converts these logs and residues into end-use wood products depending on product specifications and log size classes. These products become the inputs to the HWP carbon pool, which are then divided into two categories: HWPs still in use, and HWPs disposed of in landfill. During the simulation, new HWPs are counted as those still in use, and HWPs disposed of after a given lifetime are merged into the carbon pool in the landfill which is eventually released to the atmosphere in the form of methane gas. The end-use simulator estimates the carbon fluxes associated with the use of HWPs and HWPs disposed of through the entire simulation.

The following sections describe each simulator in details and their application developed for typical pine stands and wood supply chains in South Korea.

Growth simulator

A distance-independent tree growth simulator developed by Kwon and Chung (2004) was used for forest growth prediction in this study. The growth simulator predicts annual growth of individual trees throughout their lifetime using a series of projection functions. These functions estimate annual diameter growth, mortality and crown ratio of individual trees, providing full tree profiles at any given period of time. The simulator is also able to predict tree growth while considering individual tree-level competition, enabling one to account for the effects of different treatment options, such as thinning (Fig. 2).

The simulator employs aboveground and belowground biomass allometric equations developed and locally parameterized by Son et al. (2012) to estimate dry weights of tree boles, branches, foliage and roots. A ratio of carbon to dry biomass of 0.501 was used to estimate the amount of carbon stored in the dry biomass of each tree component (Son et al. 2010). Equation 1 developed by Aber and Melillo (1991) was used to estimate degradation of dead organic matter on the forest floor.

where X t is the biomass at time t, X 0 is the initial biomass, k is a constant for annual biomass loss, and t is time in years; k = 0.16 for forest residuals (i.e., tops, limbs, unusable parts of trees after processing logs) and 0.5 for snags and roots (Perez-Garcia et al. 2005). All biomass amounts in this study are estimated on a dry weight basis.

Logging operation simulator

The logging operation simulator was designed to simulate typical timber harvesting and transportation processes in South Korea. We assumed that timber logs and logging residues would be sent to facilities for wood products or bioenergy production. It was also assumed that the same harvesting system and equipment were used for both thinning and the final cut. In South Korea, timber logs are usually cut to 3.6 m in length, and only about 15 % of logging residuals are collected for utilization (Korea Forest Service 2010). The remaining residues were assumed to be left on site as dead organic matter. It is unique that our simulator accounts for the amount of fossil fuels used during logging operations. The field-measured machine productivity and fuel consumption collected in our previous study were used and converted into carbon (Table 1). The tonne of oil equivalent (TOE) for fuel consumption was estimated to account for the amount of energy consumed for the logging operations (Eq. 2).

The estimated TOE was then converted into carbon emissions using carbon emission factors of 0.783 for gasoline and 0.837 for diesel (IPCC 2006). The amount of fossil fuel consumption during logging operations was divided by a fossil energy ratio of 0.8337 (Sheehan et al. 1998) to account for the total fossil energy input that also includes energy consumption for fossil fuel production and delivery.

where \( X_{p}^{k} \) is the amount (L) of fuel k consumed in operation p, and FCV k is a fuel-specific calorific value in kilocalories per liter (7400 and 8450 kcal l−1 were used for gasoline and diesel, respectively). A factor of 1/107 kcal is used to convert the total thermochemical calories to TOE.

Production simulator

We considered three different types of production facilities where timber and forest biomass are processed into different products: sawmill, pulp and paper mill, and bioenergy facility. All the production facilities were assumed to be situated in the same area, 45 km from the forest of interest, but the log specifications required for each facility varied (Table 2).

The typical wood production from the timber harvesting of pine stands was considered to categorize HWPs common to the current Korean forest industry. We assumed that four types of wood products are typically produced from Korean pine trees: sawn wood, industrial roundwood, pulp and paper, and wood pellets (Table 2). Industrial roundwood is a timber product produced from relatively small-diameter pine trees for use in construction and fencing. Other wood products, such as laminated lumber, plywood and wood-based panels, were not considered in this study because they are usually produced from imported timber or other tree species in South Korea (Korea Forest Service 2013).

The number of log pieces and their dimensions from individual trees were determined by a wood-processing simulation model developed by Kwon et al. (2013). The model is able to maximize product volumes based on log size and possible saw log dimensions for merchandising (Table 3). The model also estimates the amount of biomass residuals (i.e., sawdust) produced from log processing. The residuals from the sawmill were assumed to be sent to the bioenergy production facility. We considered wood pellets as the main bioenergy product because of their popularity in South Korea (Lee et al. 2009). The amount of wood pellets produced per unit volume of residuals was estimated using a conversion factor of 0.4 bone-dry tonnes (BDT) per cubic meter (Korea Forest Service 2010).

To estimate the amount of pulp and paper products, we used a conversion factor of 0.225 BDT m−3 (Korea Forest Service 2010). We assumed that demand for biomass feedstock for energy product was high enough that forest and mill residuals would not be used for pulp and paper production. Carbon emissions related to the production of each HWP were estimated using life cycle inventories available in South Korea (Table 4). We assumed that sawn wood and industrial roundwood would have the same manufacturing process in a sawmill.

End-use simulator

The end-use simulator was developed to estimate the carbon fluxes associated with the use of HWPs and the HWPs disposed of. Our end-use simulator does not specify individual end-use products (e.g., furniture, construction materials, etc.) and volume produced from each HWP, but estimates carbon fluxes based on the estimated lifetime of end-use product categories (Winjum et al. 1998; Liski et al. 2001; Perez-Garcia et al. 2005). We assumed each HWP would have a different lifetime depending on its use, i.e., either a long-term (e.g., building material, furniture, office supplies, etc.) or short-term lifetime (e.g., construction-aid material, packing material, paper, etc.). The results of the previous studies (Jeon and Cha 2011; Korea Ministry of Environment 2013) were adapted to classify different HWPs into different lifetime categories and estimate the product volume in each category; 70 % of sawn wood, 55 % of industrial roundwood, and 40 % of pulp and paper products fell into a long-term lifetime category. The remainder of the products were considered to have a short-term use. Wood pellets for bioenergy were assumed to be directly consumed thus classified under short-term use.

We estimated the substitution effects from the use of these products as an alternative source of materials and energy. For material substitution, we assumed wood products would substitute for fossil-fuel-intensive materials, such as steel, concrete and plastics. For energy substitution, the use of wood pellets and recycled HWPs would substitute for fossil fuels for heating purposes. The substitution factors (megagrams per cubic meter carbon equivalents) in Table 4 were used in end-use simulation to assess avoided emissions resulting from substituting HWPs for fossil-fuel-based materials or energy.

The HWP carbon pool contains two categories: products still in use, and products disposed of. The HWPs in use were disposed of annually depending on their disposal rate (Table 5). The discarded HWPs can be either recycled or sent to the landfill site. Recycled products can be used for energy wood or remanufactured as second-use HWPs (Table 5). For example, 61 % of all the disposable pulp and paper was sent to landfill at the end of their useful lifetime. The other 29 % was burned for energy production and the remaining 10 % was recycled into second-use products. This 10 % is then sent back to the production simulator and goes through the same pathway as new products (Fig. 3). Carbon emissions from the recycling process were calculated by applying the carbon emission factors (megagrams per cubic meter carbon equivalents) from HWP production in Table 4 to the amount of recycled HWPs. It was assumed that all the second-use HWPs were disposed of at the landfill.

We also assumed that a landfill site would accumulate a fraction of the disposed HWPs, and a certain amount of methane would be released from the landfill HWPs. A decay rate of 0.04 year−1 was used to calculate the annual amount of decomposition of landfill HWPs, and 50 % of the total amount of landfill HWPs was assumed to decompose under anaerobic conditions (Pipatti et al. 2006; Mathieu et al. 2012). Methane emission was then converted into carbon dioxide equivalents using a factor of 21 (Solomon et al. 2007) and converted into an equivalent amount of carbon emission using the carbon/carbon dioxide factor of 12/44 (IPCC 2006).

Management scenarios

We applied our simulation models to even-aged management systems developed for pine stands (Pinus koraiensis) in the central part of South Korea. As a representative of typical pine stands in South Korea, we used 1 ha of a pine stand located in Seoul National University Forest (37°29′N, 127°29′E), Gwangju, Geyonggi province, that has been managed for timber production. The most common silvicultural prescriptions for pine stands have a rotation of 40 or 70 years with single or multiple thinnings during the rotation (Korea Forest Research Institute 2005). We chose 280 years as a time horizon for a fair comparison of the two rotation-age scenarios. It was assumed that the same rotation of thinning and final cut (clear cutting) would repeat seven and four times during the time horizon, respectively, for the 40- and 70-year-rotation age scenarios. We ran our models for the two scenarios to analyze the effects of forest management regimes on the carbon balance of the wood supply chain. For each scenario, we estimated annual net carbon fluxes in each carbon pool on a per hectare basis along the supply chain.

Results and discussion

Results from the simulators

The growth simulator predicted a higher mean annual increment for the 40-year rotation scenario. This means that the 40-year rotation could produce a larger timber volume on an annual basis but at the expense of larger diameter trees, compared to the 70-year rotation (Table 6). Due to a larger timber volume to be harvested and processed, the logging operations simulator also estimated a larger amount of emissions on an annual basis for the 40-year-rotation scenario (Table 7).

Relatively larger diameter logs that can be produced by the 70-year rotation allow the production of more preferable timber products of higher value, such as sawn wood. This is reflected in the results obtained from the production simulator (Fig. 4). A larger proportion of sawn wood products were estimated for the 70-year-rotation scenario, while the proportions of industrial roundwood, and pulp and paper were smaller compared to those of the 40-year-rotation scenario.

The results of the end-use simulator include substitution effects from use of HWPs, carbon emissions from HWP production and recycling processes, and methane emissions from landfill HWPs (Fig. 5). For these elements, we presented the accumulated carbon fluxes over the 280-year time horizon instead of over one rotation because each HWP has a different lifetime, and therefore carbon fluxes do not repeat exactly over the rotation.

Accumulated substitution effects (a), carbon emissions from HWP processing (b), carbon emissions from landfill disposal of HWPs (c), and total carbon fluxes by the use of HWPs (d) over the 280-year time horizon under each rotation scenario. HWP processing includes emissions from logging operations, HWP manufacturing, and HWP recycling

Annual net carbon fluxes over the time horizon

Figures 6 and 7 present annual net carbon fluxes over the 280-year time horizon. These net carbon fluxes were analyzed based on the results from the simulators by classifying the estimated carbon fluxes into two carbon pools (i.e., forest stand and HWPs) and other additional fluxes. Other fluxes include substitution effects as well as carbon emissions caused by the use and disposal of HWPs. A forest stand provides positive carbon fluxes while growing. Negative fluxes occur when the stand is harvested through either thinning or at the final cut (Figs. 6a, 7a). Degraded dead organic matter also contributes to negative fluxes within the stand. When the forest stand is harvested, carbon is transferred into HWPs, representing positive fluxes from the HWP standpoint (Figs. 6b, 7b). However, the amount of carbon stored in HWPs is much smaller than the amount of carbon removed from the stand, mainly because of a low product recovery rate and logging residues left on site. Disposed of HWPs, especially those from the short-term use of HWPs, contribute negative fluxes shortly after HWPs are produced.

Other positive fluxes come from fossil fuel substitution effects by biomass products that are assumed to be produced and consumed right after HWP production (Figs. 6c, 7c). Other negative fluxes include carbon emissions from logging operations, HWP production and recycling, and methane emissions from landfill HWPs.

Accumulated net carbon fluxes over the time horizon are presented as carbon stock in Fig. 8, and calculated as the sum of the aforementioned annual net fluxes of individual carbon pools including substitution effects shown in Figs. 6 and 7. The cumulative effects of the positive and negative carbon fluxes from different carbon pools make the carbon stock fluctuate, but they also make the range of carbon stock gradually rise over time. The results show that carbon sequestered by forests eventually goes back to the atmosphere through HWPs and forest residues, making the cycle carbon neutral. Carbon emissions from logging operations, and HWP manufacturing and recycling processes contribute to the net release of carbon. This amount is, however, smaller than the substitution effects that can be gained by the use of wood products as alternative materials or an energy source. This makes the carbon fluxes positive, resulting in an increase of carbon stock level over time for both rotation scenarios.

It is noteworthy that carbon stock levels under the two rotation scenarios fluctuate in different shapes and magnitudes, continuously intersecting each other. The 40-year rotation can produce a larger volume of HWPs but in a different diameter distribution of logs than the 70-year rotation. A different volume in forest growth and timber production affects carbon emissions from logging operations and HWP manufacturing, while different diameter distributions affect wood product arrangements and their lifetimes, therefore time of carbon release. This complexity makes it difficult to conclude which rotation age is more beneficial from forest carbon management perspective within the time horizon evaluated in this study. For example, if the time horizon is around 75 years, the 40-year rotation would result in a higher carbon stock at the end of the time horizon. However, the 70-year rotation becomes more beneficial in storing carbon when the time horizon extends to 200 years. The 40-year rotation appears to be a better management strategy than the 70-year rotation from the perspective of accumulated carbon fluxes when the least common multiple of the two rotation ages (i.e., 280 years) was used as the time horizon.

Most previous studies (Liski et al. 2001; Perez-Garcia et al. 2005; Mathieu et al. 2012) that compared multiple forest management regimes (i.e., rotation length, thinning intensity) suggested a particular regime as a more effective way to manage their carbon budget of forests. Those studies used the average carbon stock level \( (\bar{x}) \), the sum of carbon stocks sustained in each year \( \left( {\sum\nolimits_{i = 1}^{n} {x_{i} } } \right) \) divided by years (n), as a measure of the benefits of different carbon management strategies. When we applied the similar measure to our study (i.e., average carbon stock level), the results show that the 70-year rotation could maintain a higher carbon stock level than the 40-year rotation (see horizontal lines in Fig. 8). However, the average carbon stock level is a different measure from the accumulated carbon fluxes that represent total loss or gain in carbon stock over a certain time horizon. According to the accumulated carbon fluxes, the 40-year rotation appears to be able to store more carbon by the end of the 280-year planning horizon despite its lower average carbon stock level.

Conclusions

This study analyzed the carbon balance across the forest supply chain over a relatively long period of time. Our study suggests that diverse aspects of the carbon balance should be examined when carbon benefits are assessed for different forest management strategies. These aspects include, but are not limited to, the carbon balance within carbon pools across the entire forest supply chain, carbon exchange among different carbon pools, substitution effects, and delayed carbon release by wood products. The length of rotation in an even-aged management system affects not only the amount of carbon sequestered by the forest, but also the possible array of wood products, changing substitution effects and time of carbon release.

Our study shows that a positive carbon balance could be realized by utilizing wood products regardless of the rotation ages examined for even-aged pine stands in Korea. The positive carbon balance was mainly due to substitution effects and delayed carbon emissions by wood products. This confirms the roles of forest products and energy feedstock in mitigating climate change, as they can both reduce carbon emissions and increase carbon storage. Future studies should develop more thorough and holistic approaches and utilize more realistic data from diverse forest stands to fully assess the carbon benefits of different forest management strategies.

References

Aber JD, Melillo JM (1991) Terrestrial ecosystems. Saunders College Publishing, Philadelphia

Becker DR, Moseley C, Lee C (2011) A supply chain analysis frame work for assessing state-level forest biomass utilization policies in the United States. Biomass Bioenerg 35:1429–1439

Chung J, Han H, Kwon K, Seol A (2013) Development of a carbon budget assessment model for woody biomass processing and conversion. Centre for Climate Change forestry research paper. Korea Forest Service, Republic of Korea (in Korean)

Eriksson E, Gillespie AR, Gustavsson L, Langvall O, Olsson M, Sathre R, Stendahl J (2007) Integrated carbon analysis of forest management practice and wood substitution. Can J For Res 37:671–681

Green C, Avitabile V, Farrell EP, Byrne KA (2006) Reporting harvested wood products in national greenhouse gas inventories: implication for Ireland. Biomass Bioenerg 30:105–114

IPCC (2006) 2006 IPCC guidelines for national greenhouse gas inventories. In: Eggleston S, Buendia L, Miwa K, Ngara T, Tanabe K (eds) National greenhouse gas inventories programme. IGES, Japan

IPCC (2014) 2013 Revised supplementary methods and good practice guidance arising from the Kyoto protocol. In: Hiraishi T, Krug T, Tanabe K, Srivastava N, Baasansuren J, Fukuda M, Troxler TG (eds). IPCC, Switzerland

Jeon JN, Cha JH (2011) Development of Korean protocol for forest carbon offset project of harvested wood products (HWPs) in forest management sector. Centre for Climate Change forestry research working paper 3. Korea Forest Service, Republic of Korea (in Korean)

Korea Forest Research Institute (2005) Standard manual for sustainable forest management. Republic of Korea, Seoul (in Korean)

Korea Forest Service (2009) Climate change and forestry. Republic of Korea, Daejeon (in Korean)

Korea Forest Service (2010) Timber use survey in Korea. Republic of Korea, Daejeon (in Korean)

Korea Forest Service (2013) Timber use survey in Korea. Republic of Korea, Daejeon (in Korean)

Korea Ministry of Environment (2013) Waste occurrence and disposal in Korea. Republic of Korea, Sejong (in Korean)

Kwon S, Chung J (2004) Development of individual-tree distance-independent simulation model for growth prediction of Pinus koraiensis stands. J Kor For Soc 93:43–49 (in Korean with an English abstract)

Kwon K, Han H, Seol A, Chung H, Chung J (2013) Development of a wood recovery estimation model for the conversion processes of Larix kaempferi. J Kor For Soc 102:484–490 (in Korean with an English abstract)

Lee JI, Kim IS, So HJ (2009) A study on the energy utilization of woody biomass. Gyeonggi Research Institute policy report 2009-35. Republic of Korea, Suwon (in Korean)

Liski J, Pussinen A, Pingoud K, Mäkipää R, Karjalainen T (2001) Which rotation length is favourable to carbon sequestration? Can J For Res 31:2004–2013

Mathieu F, François N, Nicolas R, Frédéric M (2012) Quantifying the impact of forest management on the carbon balance of the forest-wood product chain: a case study applied to even-aged oak stands in France. For Ecol Manage 279:176–188

Peckham SD, Gower ST (2013) Simulating the effects of harvest and biofuel production on the forest system carbon balance of the Midwest, USA. GCB Bioenerg 5:431–444

Perez-Garcia J, Lippke B, Comnick J, Manriquez C (2005) An assessment of carbon pools, storage, and wood product market substitution using life-cycle analysis results. Wood Fiber Sci 37:140–148

Pipatti R, Svardal P, Silva Alves JW, Gao Q, López Gabrera C, Mareckova K, Oonk H, Scheehle E, Sharma C, Smith A, Yamada M (2006) Solid waste disposal. In: Eggleston S, Buendia L, Miwa K, Ngara T, Tanabe K (eds) IPCC guidelines for national greenhouse gas inventories, vol. 5, waste. IGES, Japan

Profft I, Mund M, Weber GE, Weller E, Schulze ED (2009) Forest management and carbon sequestration in wood products. Eur J For Res 128:339–413

Sheehan J, Camobreco V, Duffield J, Graboski M, Shapouri H (1998) Life cycle inventory of biodiesel and petroleum diesel for use in an urban bus. NREL/SR-580-24089, USDA final report

Solomon S, Qin D, Manning M, Chen Z, Marquis M, Averyt KB, Tignor M, Miller HL (2007) Contribution of Working Group I to the fourth assessment report of the International Panel on Climate Change. Cambridge University Press, NewYork

Son YM, Lee KH, Kim RH, Pyo JK, Park IH, Son YH, Lee YJ, Kim CS (2010) Carbon emission factors on the major tree species for forest carbon inventory. Korea Forest Research Institute (KFRI) research report 10-25. Republic of Korea (in Korean)

Son YM, Lee KH, Kwon SD, Pho JK (2012) Tree volume, biomass and yield table in South Korea. Korea Forest Service, Republic of Korea (in Korean)

Van Kooten GC, Laaksonen-Craig S, Wang Y (2009) A meta-regression analysis of forest carbon offset costs. Can J For Res 39:2153–2167

Winjum JK, Brown S, Schlamadinger B (1998) Forest harvests and wood products: sources and sinks of atmospheric carbon dioxide. For Sci 44:272–284

Acknowledgments

This study was carried out with the support of the R&D Program for Forestry Technology (project no. S211315L020110) of the Korea Forest Service.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article has been submitted for the special feature entitled “Climate change mitigation and adaptation in the forestry sector”.

About this article

Cite this article

Han, H., Chung, W. & Chung, J. Carbon balance of forest stands, wood products and their utilization in South Korea. J For Res 21, 199–210 (2016). https://doi.org/10.1007/s10310-016-0529-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10310-016-0529-2