Abstract

Clostridium acetobutylicum is a natural producer of butanol, butyrate, acetone and ethanol. The pattern of metabolites reflects the partitioning of redox equivalents between hydrogen and carbon metabolites. Here the exogenous genes of ferredoxin-NAD(P)+ oxidoreductase (FdNR) and trans-enoyl-coenzyme reductase (TER) are introduced to three different Clostridium acetobutylicum strains to investigate the distribution of redox equivalents and butanol productivity. The FdNR improves NAD(P)H availability by capturing reducing power from ferredoxin. A butanol production of 9.01 g/L (36.9% higher than the control), and the highest ratios of butanol/acetate (7.02) and C4/C2 (3.17) derived metabolites were obtained in the C acetobutylicum buk- strain expressing FdNR. While the TER functions as an NAD(P)H oxidase, butanol production was decreased in the C. acetobutylicum strains containing TER. The results illustrate that metabolic flux can be significantly changed and directed into butanol or butyrate due to enhancement of NAD(P)H availability by controlling electron flow through the ferredoxin node.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Butanol has higher energy content, low vapor pressure, is less hygroscopic and is more tolerant to water contamination in gasoline blends compared with ethanol and methanol, which facilitate its use in existing feedstocks for many energy and chemical products [8]. Traditional butanol production is primarily derived from non-renewable petroleum, a dwindling resource whose use creates significant global environmental concerns. Butanol can be produced in large scale by anaerobic microorganisms that belong to the genus Clostridium through the acetone–butanol–ethanol fermentation (ABE fermentation), which was one of the oldest industrial fermentation processes known and once considered the second largest industrial fermentation process in the world [15, 25]. Clostridium acetobutylicum has been mostly used for butanol production, and its key metabolic pathways, genetic manipulation, and the biphasic fermentation for butanol production have been well studied and developed [4, 13, 14], which make it a suitable native producer of butanol for further strain development.

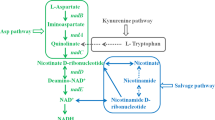

For biosynthesis of certain chemicals, it is essential to focus on the central carbon network that provides the intermediates, energy, and redox balance [9, 19]. In many particular instances, genetic modifications are employed to position the redox balance and channel the reducing power that is a major limiting factor for fermentative products [19]. NAD(P)H is one of the most important cofactors in cellular redox balance for biosynthesis of components inside these organisms [12, 24]. NAD(P)+ and NAD(P)H are constantly consumed and regenerated in cellular metabolism to achieve redox balance, which is essential for continuous catabolism and anabolism [5]. In fact, metabolic flux toward NAD(P)H-consuming reactions will be redirected when cellular redox imbalance is generated [2]. The yield of some target compounds, for example, succinate and ethanol can be significantly increased by enhancing the availability of NAD(P)H in E. coli [2] and Clostridium thermocellum [6], respectively. It is a reducing power consuming process for complete butanol production from glucose by C. acetobutylicum (Fig. 1). Thus, the production of butanol could be enhanced if NAD(P)H regenerating systems have been optimized.

Schematic presentation of the strategy of this work for changing the cellular redox states of Clostridium acetobutylicum. The metabolic pathways contains genes ferredoxin–NAD+ oxidoreductase (FdNR); trans-enoyl-coenzyme A (CoA) reductase (Ter); pyruvate:ferredoxin oxidoreductase (pfor); ferredoxin–NAD+ oxidoreductase (fnor); acetate kinase (ack); phosphotransacetylase (pta); thiolase (thl); beta-hydroxybutyryl-CoA dehydrogenase (hbd); crotonase (crt); butyryl-CoA dehydrogenase (bcd); phosphotransbutyrylase (ptb); butyrate kinase (buk); alcohol dehydrogenase (adh); butanol dehydrogenase (bdh); aldehyde–alcohol dehydrogenase (adhE2); acetoacetate decarboxylase (adc) and coenzyme A transferase (ctfAB)

Reduced ferredoxin functions are a key role of an electron carrier and it is able to transfer electrons to the iron hydrogenase for H2 production. The cellular reduced ferredoxin (Fdred, while Fdox represents the oxidized ferredoxin) can also be utilized for reduction of NAD(P)+ via a ferredoxin–NAD(P)+ oxidoreductase, and then the proton motive force generated is used to drive the phosphorylation of ADP in some organisms [23]. In this study, the exogenous genes for ferredoxin–NAD(P)+ oxidoreductase (FdNR) from Chlorobium tepidum TLS and trans-enoyl-coenzyme reductase (TER) from Treponema denticola have been introduced in several different Clostridium acetobutylicum strains to change the cellular redox state and modify the availability of various reduced cofactors. The FdNR (EC 1.18.1.2) used in this study is derived from the green sulfur bacteria Chlorobium tepidum TLS and is capable of reducing both NADP+ and NAD+, preferentially NAD+, in the presence of Fdred (reaction 1), while the TER (EC 1.3.1.38) from Treponema denticola utilizes NAD(P)H as the sole electron donor to catalyze the reduction of crotonyl-CoA in a simplified version of the more complicated bifurcating reaction typical in Clostridia (reaction 2).

Materials and methods

Strains and culture conditions

The strains and plasmids used in this study are shown in Table 1. E. coli Top10 was cultivated at 37 °C in Luria–Bertani (LB) medium supplemented with 25 μg/mL of chloramphenicol when necessary. C. acetobutylicum ATCC824-derived strains were cultivated in an improved clostridial growth medium (CGM) containing 2.0 g (NH4)2SO4, 0.5 g KH2PO4, 1.0 g K2HPO4, 0.01 g MnSO4 · 2H2O, 0.1 g MgSO4 · 7H2O, 0.015 g FeSO4 · 7H2O, 0.01 g CaCl2, 0.02 g CoCl2, 0.02 g ZnSO4, 1.0 g yeast extract, 2.0 g tryptone and 50.0 g glucose in an anaerobic chamber (Coylab, MI, US) at 37 °C. For the solid medium, C. acetobutylicum strains were grown anaerobically on 2 × YTG (30 g tryptone, 20 g glucose, 10 g yeast extract, 4 g NaCl per liter, pH 5.8) agar plates at 37 °C supplemented with 25 μg/mL of thiamphenicol when necessary.

Clostridium acetobutylicum ATCC 824, C. acetobutylicum ATCC824 buk-, and C. acetobutylicum M5 were used in this study. Butyrate kinase was inactivated in strain C. acetobutylicum ATCC824 buk- to decrease butyrate production [10]. The degenerate C. acetobutylicum M5 cannot produce butanol and acetone because this strain has lost the megaplasmid pSOL1 that is essential for solvent formation [7].

Plasmid construction

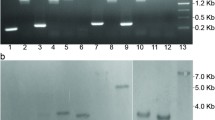

The genes for FdNR from Chlorobium tepidum TLS and Ter from Treponema denticola have been codon and expression optimized and synthesized by GenScript Ltd (Piscataway, NJ, USA). FdNR and Ter were amplified using the FdNR-F, FdNR-R primer pair and Ter-F, Ter-R primer pair, respectively (Supplementary Table 1). Then FdNR and Ter were sub-cloned between HindIII and EcoRI sites downstream of the ptb promoter from pSOS94 and placed into the C. acetobutylicum expression vector, pJIR750 using T4 DNA ligase (Roche, Basel, Switzerland) [3] to obtain the plasmids pJIR750-FdNR and pJIR750-Ter, respectively.

Transformation

The recombinant plasmids pJIR750-FdNR and pJIR750-Ter were electrotransformed into C. acetobutylicum ATCC824, C. acetobutylicum M5 and C. acetobutylicum ATCC824 buk- following the improved protocol reported described previously [16]. The C. acetobutylicum cells were incubated at 37 °C under anaerobic conditions until the OD600 reached 0.6–0.8 (logarithmic phase). Then the cultures were washed twice using cold ETM buffer (270 mM sucrose, 0.6 mM Na2HPO4·12H2O, 4.4 mM NaH2PO4·2H2O, 10 mM MgCl2. 6H2O), and the cells were resuspended in 1–2 mL ET buffer (270 mM sucrose, 0.6 mM Na2HPO4·12H2O, 4.4 mM NaH2PO4·2H2O). The competent cells were mixed and incubated with the plasmids and electrotransformed under conditions of 2000 V, 25 μF of capacitance and 200 Ω of resistance. After culturing in a 5-mL tube with pre-heated CGM for 20 h, the recovered cells were spread onto 2 × YTG agar plates with thiamphenicol and incubated at 37 °C under anaerobic conditions. Single colonies were picked and verified using colony PCR and DNA sequencing. The pJIR750 vector also was transformed into the three different C. acetobutylicum strains to be used for the control strains in culture experiments.

Batch fermentation

Bach fermentation was carried out in 250-mL capped bottles containing 50 mL CGM. All the glycerol stocks of the recombinant strains were inoculated into CGM containing 25 μg/mL of thiamphenicol and cultivated anaerobically. When the OD600 reached 0.8, the culture was inoculated into the capped bottles at an initial inoculum ratio of 10% (vol/vol). Samples were taken every 24 h, centrifuged, and the supernatant was used for analysis of solvent production. The fermentation experiments were performed in triplicates.

Analytical methods

Residual glucose and the main fermentation products including acetate, ethanol, butanol, butyrate, and acetone were determined using a Shimadzu 20A LC System high-performance liquid chromatography (Shimadzu Corporation, KS, USA) with a refractive index detector (RID-10A), and equipped with an Aminex HPX-87H HPLC column (Bio-Rad Laboratories Inc., CA, USA). A 0.5 mM H2SO4 solution was used as the mobile phase at a flow rate of 0.5 mL/min and the column was kept at 30 °C. In addition, cell density was analyzed by determining the OD600 of the C. acetobutylicum cell suspension using a spectrophotometer (Shimadzu UV-2600, TX, USA).

Results and discussion

Expression of the FdNR and TER in the three different C. acetobutylicum strains

The FdNR from Chlorobium tepidum can efficiently catalyze reduction of both NADP+ and NAD+ in the presence of ferredoxin and reaction center complex. However, the TER of T. denticola has been functionally identified as a NAD(P)H-dependent reductase that catalyzes the reaction of crotonyl-CoA to butyryl-CoA as its most active substrate [20]. These two exogenous genes have been introduced into the three different C. acetobutylicum strains to study their influence on the cellular reducing power availability and the correlation of higher proportions of the more reducing equivalents requiring C4-derived metabolites (butanol and butyrate) production to the presence of these genes. As shown in Fig. 1, a key enzyme pyruvate–ferredoxin oxidoreductase (PFOR) of C. acetobutylicum central metabolism catalyzes the oxidative decarboxylation of pyruvate to generate acetyl-CoA, CO2 and Fdred. As an electron carrier, this Fdred plays a key role in the transfer of electrons to the iron hydrogenase for H2 production under appropriate conditions. Actually, there is more than one enzyme that acts in this particular reaction. A molecule of NADH is typically generated from pyruvate to acetyl-CoA; however, in Clostridia the pyruvate–ferredoxin oxidoreductase is the main enzyme responsible for this conversion. Thus, the introduced FdNR could capture a fraction of the Fdred to generate NAD(P)H, resulting in a lowering of the loss of reducing equivalents to form H2 rather than a carbon-based metabolite. In the pathway of butanol production from acetyl-CoA, despite the supplemental redox generated by the recombinant FdNR, there are still another four reactions that require of NAD(P)H consumption. However, the formation of acetate from pyruvate does not require reducing power. Therefore, the ratio of butanol to acetate was used to represent the relative redox status in the process of butanol production from pyruvate, and in non-solvent-producing strains, the ratio of butyrate to acetate would be affected. The total cellular NADH levels of all the C. acetobutylicum strains had been also detected (Supplementary Fig. 1). However, the total cellular NADH levels are greatly affected by the substrates, products, oxygen uptake and culture conditions. Thus, the ratio of butanol to acetate is more suitable to reflect the redox status in the process of butanol production pathway.

In this study, Fig. 2 shows the ratios of butanol/acetate of the three C. acetobutylicum strains with the expression of pJIR750-FdNR (C. acetobutylicum ATCC824 pJIR750-FdNR, C. acetobutylicum ATCC824 buk- pJIR750-FdNR and C. acetobutylicum M5 pJIR750-FdNR) or pJIR750-TER (C. acetobutylicum ATCC824 pJIR750-TER, C. acetobutylicum ATCC824 buk- pJIR750-TER and C. acetobutylicum M5 pJIR750-TER). The C. acetobutylicum strains containing pJIR750 (C. acetobutylicum ATCC824 pJIR750, C. acetobutylicum ATCC824 buk- pJIR750 and C. acetobutylicum M5 pJIR750) were used as controls. It was found that the ratio of butanol/acetate of the C. acetobutylicum strains ATCC824 and C. acetobutylicum ATCC824 buk- with expression of the exogenous FdNR was higher than the corresponding controls. Especially the butanol/acetate ratios of the strain C. acetobutylicum ATCC824 buk- pJIR750-FdNR was 45.6% higher than that of the control. We also have observed a rapid increase in the butanol/acetate ratio in cultures of C. acetobutylicum ATCC824 buk-. The effect on the butanol/acetate ratio was noticeable in the C. acetobutylicum ATCC824 buk- cultures. After the acidogenic stage (24 h), the butanol/acetate ratio was 1.5 in C. acetobutylicum ATCC824 buk- pJIR750-FdNR and was nearly 7.0 at 72 h. Compared to C. acetobutylicum ATCC824 buk- the highest butanol/acetate ratio of wild-type strain C. acetobutylicum ATCC824 (2.70) is much lower, indicating that carbon flux could be diverted into butanol production due to the inactivation of the butyrate kinase in the C. acetobutylicum ATCC824 v- strain. However, expression of TER has negative effects on the butanol/acetate ratio. The butanol/acetate ratios of both C. acetobutylicum ATCC824 pJIR750-TER (1.87) and C. acetobutylicum ATCC824 buk- pJIR750-TER (3.86) are lower than the corresponding controls. Since C. acetobutylicum M5 cannot produce butanol, the ratio of butyrate/acetate is employed to describe redox status of this degenerate strain. Similar to the C. acetobutylicum ATCC824 and C. acetobutylicum ATCC824 buk-, more butyrate but less acetate has been produced in cultures of M5 pJIR750-FdNR. In addition, the butyrate/acetate ratio is increased by 55.31% with the expression of FdNR and decreased by 9.89% with the expression of TER in C. acetobutylicum M5 compared to the control strain, respectively.

These results indicate the introduced enzyme FdNR can divert redox to NAD(P)H, and generate a more reduced pattern of metabolites, such as butanol and butyrate in C. acetobutylicum. The generated reducing power obtained as NAD(P)H by FdNR that is otherwise used in the production of hydrogen thereby increased the in vivo availability of NAD(P)H that can be used for longer chain and higher alcohol production. Actually, in other microorganisms, such as E. coli, the productivity of the target compound succinate can be increased and the by-product formate reduced by enhancing the NADH availability through heterologous expression of an exogenous NAD+-dependent formate dehydrogenase [2]. In this study, expression of the exogenous FdNR in the three different C. acetobutylicum strains indeed helps to enhance the reducing power availability for longer chain length acids and solvent molecules. This increase in NAD(P)H availability significantly changed the final metabolite concentration pattern under anaerobic conditions.

Effects of the FdNR and TER on biomass and butanol (butyrate) production

The redox conditions and biomass accumulation of the three C. acetobutylicum strains have been studied. Figure 3 shows growth of the different C. acetobutylicum strains with expression of FdNR and TER. After 96-h batch fermentation, all the wild-type strains with expression of pJIR750 have the highest biomass accumulation. The recombinant strains with expression of the FdNR have less biomass than that of the wild type but higher than the strains with TER. All the three C. acetobutylicum strains show similar trends in growth. Generally, the improved cellular NAD(P)H level results in more yield of biomass. Verho et al. have expressed an exogenous NADP-dependent d-glyceraldehyde-3-phosphate dehydrogenase (NADP–GAPDH) in Saccharomyces cerevisiae and deleted the gene zwf1 in the pentose phosphate pathway that is essential for a competing reaction, which regenerated NADPH to facilitate anaerobic pentose fermentation to ethanol [22]. However, it is also found that biomass accumulation of S. cerevisiae increased (< 5.0%) when the NADPH availability was enhanced by the genetic engineering of the redox reactions [22]. The decreased biomass accumulation of the C. acetobutylicum strains with higher NAD(P)H availability is inconsistent with the previous reports and may be due to the large amount of substrate converted to metabolites vs cell mass in this organism. C. acetobutylicum has a typical two-stage growth process in batch culture. The cells first accumulate biomass and produce acetate and butyrate and later solvents of butanol, acetone, and ethanol. The possible reason for the low biomass accumulation in C. acetobutylicum strains when expressing FdNR is that the regenerated NADPH could lead to the faster production of acids, which when combined with butyrate accumulation causes a shorter period of biomass accumulation in metabolism as the cells move toward the solvent production phase. Therefore, the strains with higher ratio of NAD(P)H/NAD(P)+ would generate less biomass compared with the control. As a result, it is valuable to find that the efficiencies of butanol transformation from glucose (yield of butanol/glucose) of C. acetobutylicum strains can be enhanced by the improved NAD(P)H availability. In addition, since TER functions as the NAD(P)H oxidase, theoretically, yield of biomass will be decreased when ratio of cellular NADH has been consumed [11]. All the three C. acetobutylicum strains with expression of TER have lower biomass accumulation compared with the other strains. The reason for the reduced biomass can be explained by the imbalance of the redox cofactors. The imbalanced redox conditions caused by expression of a NAD(P)H-oxidoreductase may lead to increased energy dissipation or diversion in the C. acetobutylicum strain, resulting in reduction of biomass yield. Since the reaction catalyzed by TER is less energy conserving than that catalyzed by the bifurcating Bcd complex that includes electron-transferring flavoproteins, the cell energetics may be lower when TER is used as a partial substitute in this major reaction of metabolism. Otherwise, the diverted free energy captured in NADH might have been utilized for oxidative phosphorylation in aerobic respiring organisms [21].

The production of butanol and butyrate has been evaluated (Fig. 4). It is found that butanol production of the strains C. acetobutylicum ATCC824 pJIR750-FdNR and C. acetobutylicum ATCC824 buk- pJIR750-FdNR was higher than the corresponding controls, while both strains with TER had lower butanol production compared with the controls. The highest butanol production of the C. acetobutylicum ATCC824 buk- pJIR750-FdNR is 9.01 g/L that is 36.9% higher than the control, and also higher than that of the strain C. acetobutylicum ATCC824 pJIR750-FdNR (7.6 g/L). Butyrate production of C. acetobutylicum M5 pJIR750-FdNR was higher than the control and C. acetobutylicum M5 pJIR750-TER. The results illustrated that butanol or butyrate could be increased in the C. acetobutylicum strains with expression of FdNR. Atsumi et al. (2008) reported that a more than twofold increase of n-butanol production could be achieved in E. coli with enhanced reducing power by deleting the native pathway competing for both carbon flux and NAD(P)H consumption [1]. In addition, the similar results show that yield of some target compounds can be significantly increased by enhancing the cellular ratio of NAD(P)H/NAD(P)+ [2, 6]. Except for butanol or butyrate, production of other NAD(P)H-consuming chemical compounds, such as ethanol, was not improved significantly by the regenerated reducing power. The results illustrated that ethanol production has not been influenced by the changed NAD(P)H availability.

It seems that FdNR not only regenerated the available NAD(P)H but promoted the carbon flux to butanol or butyrate, resulting in proper fermentation balance and increased butanol production. Butyrate production was decreased modestly in the C. acetobutylicum strains with expression of TER compared with the controls. One explanation could be that the carbon flux was dissipated due to consumption of reducing power by TER. Thus, the enzymatic activity of butyryl-CoA dehydrogenase (Bcd) was probably lower because the process of crotonyl-CoA to butyryl-CoA was under competition by a less energetically favorable reaction for the cell. In addition, butyrate production of C. acetobutylicum ATCC824 buk- pJIR750-FdNR was less than that of C. acetobutylicum ATCC824 pJIR750-FdNR due to the inactivation of the butyrate kinase in buk- strains. However, it was surprising to find that C. acetobutylicum ATCC824 buk- pJIR750 produced more butyrate than C. acetobutylicum ATCC824 pJIR750. The reason could be that there is an alternative pathway for diverting butyryl-CoA to butyrate (e.g., the partial action of the broad specificity acetate kinase on the substrate) when the cellular reducing power is insufficient. Another explanation is carbon flux tends to butyrate formation from butyryl-CoA since there is no requirement for reducing power in the pathway; however, two more molecules of NADPH are needed for butanol production from butyryl-CoA. Although the production of the butanol is not very high (no more than 10 g/L) in this work, the strategy for titer improvement through enhancing NADPH availability could be employed in other hyper-butanol-producing strains and under more optimized culture conditions.

Redox states of the recombinant C. acetobutylicum strains

It is essential to achieve a redox balance for cellular metabolism and synthesis of commodity compounds. Under anaerobic growth and in the absence of an alternate oxidizing agent, the regeneration of NAD(P)+ is achieved through fermentation, using NADH to reduce metabolic intermediates. In this study, we have demonstrated that the desired butanol or butyrate production could be improved when enhanced NAD(P)H availability was achieved. The results illustrate that carbon flux distribution in the central metabolic pathways is associated with the cellular redox states. Figure 5 shows the theoretical flux from the glycolysis pathway to butyrate accompanied with the distribution of reducing power according to the production of butanol, butyrate, acetate, and consumption of glucose in early exponential stage of growth or in non-solvent-producing organisms. In the wild-type C. acetobutylicum strain, about one-third of carbon flux is passed to acetoacetyl-CoA from pyruvate and acetyl-CoA (Fig. 5a). Theoretically, 0.67 mol of butyrate can be obtained assuming 1:1 butyrate to acetate production as is found in reported studies of early phase cultures of C. acetobutylicum [17]. At the same time, 2 mol of the NADH generated from glycolysis is distributed into the pathway of butyrate production. 0.67 mol of acetate which is equivalent to one-third of the flux from acetyl-CoA can be produced. In addition, 2.67 mol of Fdred that is derived from the corresponding one-third of the 2 mol of NADH distribution from glycolysis and the 2 mol NADH from transformation of pyruvate is used as electron carriers for H2 production.

Metabolic flux from pyruvate to butyrate was redistributed when the exogenous FdNR was overexpressed in C. acetobutylicum strain in early phase cultures or as shown in the early phase culture of the non-solvent-producing degenerate C. acetobutylicum M5. The changes of butyrate production and biomass suggested that an over-supply of NAD(P)+ from the introduction of FdNR affects the intracellular redox balances, which probably enforce an alteration in the cellular flux through NAD(P)+-consuming enzymes for redox cofactor balance. The theoretical carbon flux redistribution can be seen in Fig. 5b and is close to that composition found in the early stage of C. acetobutylicum M5 bearing the FdNR. NAD(P)H is increased in the system because the exogenous FdNR has captured the lost redox that is originally utilized by H2 production and it is now consumed by the other reactions such as the reduction of crotonyl-CoA to butyryl-CoA to balance the reduced cofactor pool. The regenerated NAD(P)H accumulates in addition to the original normal cellular NADH and the reducing power has been redistributed in the metabolic pathways. According to the Fig. 5b, the additional 0.58 mol of NAD(P)H that is captured by the FdNR from H2 production is added to NAD(P)H pool. Therefore, a total of 2.58 mol of NAD(P)H is available for the pathway of butyrate production. Accordingly, 2.86 mol of Fdred is required as electron carriers, however, only 2.28 mol of total Fdred and NAD(P)H is utilized for H2 production. The carbon flux from acetyl-CoA to butyrate production is also changed, and 0.86 mol of butyrate is produced in these early acid phase cultures. The flux from acetyl-CoA to acetate is reduced to 0.28 mol. Thus, the ratio of butyrate/acetate for the C. acetobutylicum strain with expression of FdNR is increased to 3:1, compared to 1:1 of the wild type (Fig. 5).

However, if we look at solvent phase, we can examine the ratio of butanol to acetate, and while this is more complex to analyze or fully interpret we can make some comments. In addition, we calculated the ratio of C4 (butanol and butyrate)/C2 (acetate and ethanol)-derived metabolites from all the C acetobutylicum strains after 96-h batch fermentation (Table 2). The highest ratio of C4/C2 is 3.17, which was obtained from C. acetobutylicum ATCC824 buk- pJIR750-FdNR. Similar to the results of Fig. 2, C4/C2 ratios of C acetobutylicum strains with expression of FdNR are all higher than the controls and the corresponding strains with TER. The results suggest that the increased NADH availability in vivo is probably channeled towards acetyl-CoA condensation and reduction to favor and drive the carbon flux to formation of longer chain metabolites such as butanol and butyrate, that can utilize and recycle the additional NAD(P)H. Thus, the ratios of C4/C2, butanol/acetate and production of butanol (or butyrate in M5 strains) are all increased due to the enhanced NADH availability with expression of the exogenous FdNR.

Conclusions

This work demonstrates an increase in NAD(P)H availability in three different Clostridium acetobutylicum strains by introducing an exogenous ferredoxin–NAD(P)+ oxidoreductase (FdNR). In contrast, introduction of a trans-enoyl-coenzyme reductase (TER) did not lead to increased C4 compounds or increased butanol. The production proportions of desired compounds butanol and butyrate have been significantly improved, as well as ratios of butanol/acetate and C4/C2-derived metabolites under the enhanced redox states from different recombinant C acetobutylicum strains. The strategy of this work is useful for microbial production processes in which control of the redox proportioning within the network is limiting for a desired pathway.

References

Atsumi S, Cann AF, Connor MR, Shen CR, Smith KM, Brynildsen MP, Chou KJ, Hanai T, Liao JC (2008) Metabolic engineering of Escherichia coli for 1-butanol production. Metab Eng 10:305–311

Balzer GJ, Thakker C, Bennett GN, San KY (2013) Metabolic engineering of Escherichia coli to minimize byproduct formate and improving succinate productivity through increasing NADH availability by heterologous expression of NAD(+)-dependent formate dehydrogenase. Metab Eng 20:1–8

Bannam TL, Rood JI (1993) Clostridium perfringens-Escherichia coli shuttle vectors that carry single antibiotic resistance determinants. Plasmid 29:233–235

Bennett GN, Rudolph FB (1995) The central metabolic pathway from acetyl-CoA to butyryl-CoA in Clostridium acetobutylicum. FEMS Microbiol Rev 17:241–249

Berríos-Rivera SJ, Bennett GN, San KY (2002) Metabolic engineering of Escherichia coli: increase of NADH availability by overexpressing an NAD(+)-dependent formate dehydrogenase. Metab Eng 4:217–229

Biswas R, Zheng T, Olson DG, Lynd LR, Guss AM (2015) Elimination of hydrogenase active site assembly blocks H2 production and increases ethanol yield in Clostridium thermocellum. Biotechnol Biofuels 12(8):20

Clark SW, Bennett GN, Rudolph FB (1989) Isolation and characterization of mutants of Clostridium acetobutylicum ATCC 824 deficient in acetoacetyl-coenzyme A:acetate/butyrate: coenzyme A-transferase (EC 2.8.3.9) and in other solvent pathway enzymes. Appl Environ Microbiol 55:970–976

Cooksley CM, Zhang Y, Wang H, Redl S, Winzer K, Minton NP (2012) Targeted mutagenesis of the Clostridium acetobutylicum acetone-butanol-ethanol fermentation pathway. Metab Eng 14:630–641

Fortman JL, Chhabra S, Mukhopadhyay A, Chou H, Lee TS, Steen E, Keasling JD (2008) Biofuel alternatives to ethanol: pumping the microbial well. Trends Biotechnol 26:375–381

Green EM, Boynton ZL, Harris LM, Rudolph FB, Papoutsakis ET, Bennett GN (1996) Genetic manipulation of acid formation pathways by gene inactivation in Clostridium acetobutylicum ATCC 824. Microbiology 142(Pt 8):2079–2086

Heux S, Cachon R, Dequin S (2006) Cofactor engineering in Saccharomyces cerevisiae: expression of a H2O-forming NADH oxidase and impact on redox metabolism. Metab Eng 8:303–314

Holm AK, Blank LM, Oldiges M, Schmid A, Solem C, Jensen PR, Vemuri GN (2010) Metabolic and transcriptional response to cofactor perturbations in Escherichia coli. J Biol Chem 285:17498–17506

Lee J, Jang YS, Choi SJ, Im JA, Song H, Cho JH, do Seung Y, Papoutsakis ET, Bennett GN, Lee SY (2012) Metabolic engineering of Clostridium acetobutylicum ATCC 824 for isopropanol-butanol-ethanolfermentation. Appl Environ Microbiol 78:1416–1423

Lee J, Yun H, Feist AM, Palsson BØ, Lee SY (2008) Genome-scale reconstruction and in silico analysis of the Clostridium acetobutylicum ATCC 824 metabolic network. Appl Microbiol Biotechnol 80:849–862

Lütke-Eversloh T, Bahl H (2011) Metabolic engineering of Clostridium acetobutylicum: recent advances to improve butanol production. Curr Opin Biotechnol 22:634–647

Mermelstein LD, Welker NE, Bennett GN, Papoutsakis ET (1992) Expression of cloned homologous fermentative genes in Clostridium acetobutylicum ATCC 824. Biotechnology 10:190–195

Meyer CL, Papoutsakis ET (1989) Increased levels of ATP and NADH are associated with increased solvent production in continuous cultures of Clostridium acetobutylicum. Appl Microbiol Biotechnol 30:450–459

Lin YL, Blaschek HP (1983) Butanol production by a butanol-tolerant strain of Clostridium acetobutylicum in extruded corn broth. Appl Environ Microbiol 45:966–973

San KY, Bennett GN, Berríos-Rivera SJ, Vadali RV, Yang YT, Horton E, Rudolph FB, Sariyar B, Blackwood K (2002) Metabolic engineering through cofactor manipulation and its effects on metabolic flux redistribution in Escherichia coli. Metab Eng 4:182–192

Tucci S, Martin W (2007) A novel prokaryotic trans-2-enoyl-CoA reductase from the spirochete Treponema denticola. FEBS Lett 581:1561–1566

Vemuri GN, Eiteman MA, McEwen JE, Olsson L, Nielsen J (2007) Increasing NADH oxidation reduces overflow metabolism in Saccharomyces cerevisiae. Proc Natl Acad Sci USA 104:2402–2407

Verho R, Londesborough J, Penttilä M, Richard P (2003) Engineering redox cofactor regeneration for improved pentose fermentation in Saccharomyces cerevisiae. Appl Environ Microbiol 69:5892–5897

Wang S, Huang H, Moll J, Thauer RK (2010) NADP+ reduction with reduced ferredoxin and NADP+ reduction with NADH are coupled via an electron-bifurcating enzyme complex in Clostridium kluyveri. J Bacteriol 192:5115–5123

Zhao H, Van der Donk WA (2003) Regeneration of cofactors for use in biocatalysis. Curr Opin Biotechnol 14:583–589

Zheng YN, Li LZ, Xian M, Ma YJ, Yang JM, Xu X, He DZ (2009) Problems with the microbial production of butanol. J Ind Microbiol Biotechnol 36:1127–1138

Acknowledgements

The work was supported by Department of Energy Grant DE-SC0014462 and Natural Science Foundation of Fujian Province of China (No. 2016J01148; 2016J01147). Some preliminary experiments were supported by Army Research Office, grant number W911NF0910119.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All the authors declare that he/she has no conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Qi, F., Thakker, C., Zhu, F. et al. Improvement of butanol production in Clostridium acetobutylicum through enhancement of NAD(P)H availability. J Ind Microbiol Biotechnol 45, 993–1002 (2018). https://doi.org/10.1007/s10295-018-2068-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-018-2068-7