Abstract

In this study, polyurethane foam (PUF) was chemically treated to immobilize Streptomyces thermotolerans 11432 for semi-continuous production of acetylisovaleryltylosin (AIV). Based on experimental results, positive cross-linked PUF (PCPUF) was selected as the most effective carrier according to immobilized cell mass. The effect of adsorption time on immobilized mass was investigated. AIV concentration (33.54 mg/l) in batch fermentations with immobilized cells was higher than with free cells (20.34 mg/l). In repeated batch fermentations with immobilized S. thermotolerans 11432 using PCPUF cubes, high AIV concentrations and conversion rates were attained, ranging from 25.56 to 34.37 mg/l and 79.93 to 86.31 %, respectively. Significantly, this method provides a feasible strategy for efficient AIV production and offers the potential for large-scale production.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Acetylisovaleryltylosin (AIV), which is acetylated in the 3′-OH position and substituted with isovaleric acid in the 4″-OH position of tylosin, is always produced through tylosin biotransformation by S. thermotolerans ATCC 11416 in industry [11, 12, 21, 22, 31]. The two corresponding enzymes in the biosynthesis process are acetyltransferase (AcyA) and isovaleryltransferase (AcyB), respectively [1, 20, 21] (Supplementary Fig. S1). AIV is strongly toxic even to macrolide-resistant bacterial strains due to its strong affinity for 70s ribosomes and its high permeability to the cell membranes of pathogenic bacteria [22].

Streptomyces species have been the focus of many researchers since they produce various therapeutically important antibiotics [5, 10, 28]. Despite the large amount of experimental data published in the scientific and patent literature [12, 21, 22], there are very few reports on immobilized fermentations for conversion from tylosin to AIV as a means for enhancing AIV production.

Owing to its high added value, immobilization of filamentous microorganisms in secondary metabolite production processes has gained popularity among industrial microbiologists and biochemical engineers [7, 8, 13, 14, 17, 18]. The advantages of immobilized cells in fermentation processes, such as higher cell densities, improved gas–liquid mass transfer, and the possibility of conducting long-term runs without cell loss, can benefit industrial production significantly [8, 16, 17]. These features favor lower operational costs, and immobilized fermentations are also less prone to contamination [27]. On the other hand, one of the most important factors affecting the behavior of such processes was the adequate diffusion of the fermentation components, particularly nutrients, from the bulk liquid phase to the bio-particles through their immobilized cell-containing pores [7, 14, 15].

The rationale for choosing cell carriers included higher antibiotic yields, higher operational stability, greater resistance to environmental disturbances, and lower effective operational costs. The materials screened should fulfill various requirements including nontoxic nature, easy availability, reusability, and high surface area for cell attachment. The adsorption capacity and binding strength were also important factors that determine the selection of an ideal support material [30].

PUF (Supplementary Fig. S2) is a kind of inert material with excellent mechanical properties, such as high resistance and elasticity, bulk availability, and very low commercial cost [19, 23]. PUF has high porosity (near 97 %) and a large adsorption surface. Moreover, PUF offers great advantages over particulate resins or porous beads in industrial-scale immobilization because the open macrostructure of PUF can markedly lower diffusion resistance and provide excellent mass transfer properties. As an elastic material, the flexibility of PUF also provides good stability and resistance to compression deformation, which is essential for reactor design in industrial applications. Therefore, applications of PUF as a support matrix for immobilization have attracted much attention [4, 6, 25]. In this study, several chemical treatment protocols used to improve further the adsorptive properties of PUF were compared for their effectiveness.

The objectives of this investigation were to (1) assess the effects of different chemical treatments on immobilization of cells on PUF, (2) demonstrate the feasibility and stability of AIV production with immobilized S. thermotolerans 11432 through estimating parameters including AIV concentration, cell release, and cycle index in repeated batch shake flask cultivation. For comparison, free cell fermentation in corresponding shake flasks was also conducted. To the best of our knowledge, this is the first study reporting fermentations using immobilized S. thermotolerans 11432 for AIV production, which might be applied to AIV production in industry.

Materials and methods

Strain and medium

S. thermotolerans 11432 used in the present investigation was genetically modified (overexpression of AcyB) [35] in our laboratory, and is based on S. thermotolerans ATCC 11416, purchased from ATCC, USA. Seed medium for S. thermotolerans 11432 consisted of 10 g/l soluble starch, 10 g/l soybean flour, 1.0 g/l yeast powder, 1.0 g/l yeast extract, 1.0 g/l MgSO4·7H2O, 0.5 g/l K2HPO4, and pH 7.2. Fermentation medium consisted of 30 g/l soluble starch, 20 g/l soybean flour, 4.0 g/l yeast powder, 1.0 g/l yeast extract, 5.0 g/l MgSO4·7H2O, 1.0 g/l K2HPO4, and pH 7.2.

Materials and reagents

PUF was bought from China Luoyang Di Filtration Material Co., Ltd. Tylosin and AIV were purchased from Germany DR. Ehrenstorfer GmbH. Acetonitrile, ammonium acetate, and acetic acid were of analytical grade. Polyethyleneimine, glutaraldehyde, and other chemicals were of reagent grade and are all commercially available.

acyB cloning

The acyB1-B2 gene has low activity in the original host. The gene was cloned into plasmid pUWL201apr [9], and then the recombinant plasmid carrying acyB1-B2 was transferred into S. thermotolerans ATCC 11416 by intergeneric conjugal transfer. Through screening of a variety of recombinant strains, strain S. thermotolerans 11432, with high production capacity, was obtained.

Preparation and treatment of immobilized carrier

The PUF was cut into 2.0 cm × 2.0 cm × 2.0 cm squares and rinsed with sterile water three times and finally air dried. Different PUF cubes were chemically treated as follows.

-

Positive PUF (PPUF): PUF was submerged in 4 % HCl for 24 h.

-

Cross-linked PUF (CPUF): PUF was soaked in 4 % (w/v) glutaraldehyde at 35 °C for 3 h.

-

Positive CPUF (PCPUF): CPUF was rinsed with distilled water and then submerged in 4 % HCl for 10 h.

-

Polyethyleneimine-coated PUF (PEPUF): PUF was soaked in 0.2 % (w/v) polyethyleneimine (PEI) solution for 2 h at 35 °C and then flushed with distilled water to remove excess solution.

All PUF cubes (including PPUF, CPUF, PCPUF, and PEPUF) were thoroughly washed with distilled water. All of the cubes were oven-dried at 50 °C. Then, the PUF cubes were added to seed medium and autoclaved at 121 °C for 20 min before inoculation.

Cell immobilization and cell release

S. thermotolerans 11432 cells were immobilized on PUFs following the method of Ishida [13] with a slight modification. S. thermotolerans 11432 spores from a plate culture stored at 4 °C were incubated in seed medium until logarithmic phase was reached (3 days at 30 °C and 220 rpm). Then, a 10 % (v/v) inoculum from this preculture was transferred into a second seed medium flask containing 5 PUF cubes and incubated under the same culture conditions. The mass of immobilized cells was measured by mass deviation: PUFs with immobilized cells were picked out and washed with distilled water until the wash water was free of released cells, and then lyophilized. The mass of immobilized cells was determined by measuring the weight of lyophilized PUFs carrying cells minus the pre-determined weight of PUF.

Cell release from the PUFs during fermentation was measured by mass deviation: a fixed volume of suspension of bioconversion medium containing biomass was filtered through a pre-dried, pre-weighed micro-filter and washed several times with sterile water. After drying until the weight of the lyophilized filter remained constant, cell release was determined by comparing the weight of the lyophilized filter minus the initial weight of the filter.

Bioconversion trials in shake flasks

A preculture in seed medium was prepared by adding spores from a plate culture stored at 4 °C to a 250-ml shake flask containing 50-ml seed medium. After 3 days of incubation at 30 °C and 220 rpm, 10 % (v/v) inoculum from this preculture was added to a 250-ml shake flask with 50-ml seed medium and PUF cubes. At various times later, PUF cubes were picked out from this second seed culture and washed with distilled water until the wash water was free of released cells, and then transferred into fermentation medium. The bioconversion flasks were incubated at 30 °C and 220 rpm. After 24 h of incubation, sterile solutions of tylosin and leucine, dissolved in fermentation medium, were added to the fermentation medium to final concentrations of 150 mg/l and 20 g/l, respectively. Flasks without PUF were kept as a control group. The total conversion medium was collected for analysis every 12 h after substrate addition. All aseptic techniques were done in a laminar air flow cabinet. All pretreatment experiments were carried out in triplicate.

Repeated batch cultivation

In the repeated batch process, after attaining the maximum production of AIV, fermentation medium was replaced with fresh sterilized fermentation medium supplemented with tylosin and leucine (150 mg/l and 20 g/l, respectively, as described above) and the process was repeated for six cycles of 48 h. The tylosin concentration, AIV concentration, and cell release in each cycle were investigated.

HPLC analysis

Tylosin, 3-O-Acetyltylosin (AT), 4″-O-Isovaleryltylosin (IT), and AIV in the conversion medium were measured by HPLC. One milliliter of conversion medium was filtered through a 0.2-µm PTFE syringe filter and transferred to a sterile sampling vial. Samples were analyzed by HPLC (Agilent 1100) using a solvent delivery system and a variable-wavelength UV–Vis detector equipped with a sample injector fitted with a 10-µm sample loop. The chromatographic separations were carried out on an Ultrasphere* Octyl C8 reversed-phase column (250 × 4.6 mm i.d.; 5 µm particle diameter, 300 Å average pore size) using a mobile phase consisting of acetonitrile:0.15 M ammonium acetate:acetic acid (45:45:10) at a flow rate of 1 ml/min. Peak detection was performed at 280 nm. Tylosin, its final bioconversion product, AIV, and its intermediates, AT and IT, were separated and measured using the HPLC. The retention time of authentic reference samples, tylosin, AT, IT, and AIV, were 5.3, 5.9, 13.8, and 17.5 min, respectively. AT and IT were also detected and verified by mass spectrometry (data not shown).

Scanning electron microscopy

PUF cubes with immobilized S. thermotolerans 11432 were washed with distilled water and then lyophilized for 24 h. Samples were covered with a gold film and observation was done on a HTTACHI S-4800 scanning electron microscope (SEM).

Results and discussion

Effects of different PUF cube treatments on immobilization of S. thermotolerans 11432

Various treatments have been described which can activate functional groups of PUF or change its surface roughness, both of which are conducive to the growth and immobilization of bacteria [34, 37]. SEM images of the walls of PUFs exposed to various treatments are shown in Supplementary Fig. S2.

Acid treatment of PUF forms a cationic film on the surface and therefore, enhances hydrophobic and electrostatic interactions [33], which are conducive to the adsorption of S. thermotolerans 11432. Supplementary Fig. S2b shows the walls of PPUF. Glutaraldehyde, as bifunctional crosslinking agent, reacts with amino groups of PUF thereby strengthening its crosslinking ability. Therefore, cells immobilized on CPUF remain tightly attached and retain good activity. Supplementary Fig. S2c shows the coating membrane of CPUF, prepared as described above. PCPUF as shown in Supplementary Fig. 2d has both the advantages of CPUF and PPUF. PEI is a branched cationic polymer, with high density of ionized tertiary, secondary, and primary amino groups. Several immobilization protocols using PEI have previously been reported [2, 6, 18, 29, 32]. The charged character and amine content of this treatment reagent give PEPUF cubes a spacer arm which can be very useful in immobilization. PEPUF cubes are shown in Supplementary Fig. S2e.

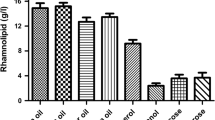

Effects of immobilization protocols on the mass of immobilized S. thermotolerans 11432

Effects of different treatments of PUF cubes on immobilization were evaluated according to the mass (dry weight) of attached cells. The results depicted in Fig. 1 showed that different immobilization protocols had a great influence on the mass of attached cells. It was found that all of the different protocols screened improved the mass of immobilized cells compared with the control group, where untreated PUF cubes were added to the second seed culture shake flasks. Cultures with PCPUF attained the maximum 9.1 mg/g of immobilized cell mass after 12 h of adsorption (which was 4.35-fold higher than the control group) with no further significant increase with the extension of immobilization time. SEM results (Supplementary Fig. 2f) showed the morphology of S. thermotolerans 11432 immobilized on the walls of PCPUF cubes.

The immobilization ability of treated PUF cubes decreased in the following order: PCPUF > PEPUF > CPUF > PPUF > PUF as shown in Fig. 1. Bacterial cells adhered to the surface of the PUF cubes and also extended into the pores as the bacterial cells grew. Quek et al. [26] and Yamaguchi et al. [36] have also reported that high numbers of immobilized cells could be due to cell surface hydrophobicity or the introduction of cells into PUF by liquid flow.

Determination of the optimal adsorption time of PCPUF

To further determine the optimal adsorption time of PCPUF, shake flask fermentations with PCPUF cubes were carried out, and the masses of immobilized cells and corresponding AIV concentrations at various times were determined. At different adsorption times, PCPUF cubes with immobilized cells were picked out of the second seed cultures, washed with distilled water until the wash water was free of released cells, and then transferred into fermentation medium. AIV concentration was measured by HPLC after 48 h of fermentation (Supplementary Fig. S3). The time course of fermentation showed that the maximum immobilized cell mass (9.2 mg/g PCPUF) was obtained using PCPUF cubes that had incubated for 10 h in the second seed culture. In the subsequent fermentation using these PCPUF cubes, 33.31 mg/l AIV concentration was attained (Fig. 2). No significant increase of AIV and immobilization mass was achieved with extended immobilization time in the second seed cultures.

Batch fermentation

In batch fermentations the optimum adsorption time for PCPUF was 10 h. Adding PCPUF cubes sharply increased cell mass accumulation and AIV concentration as compared with free cell fermentations as shown in Fig. 3. This suggested that biomass accumulation played an important role for an effective conversion process from tylosin to AIV.

Adding PCPUF cubes dramatically increased AIV accumulation compared with the control (Fig. 4a). In control experiments, the final amounts of accumulated AIV and tylosin were about 20.34 and 35.71 mg/l, respectively. In flasks containing PCPUF cubes, 33.54 mg/l of AIV and 17.93 mg/l of tylosin were attained. Furthermore, in fermentations with immobilized cells, the amounts of AIV remained stable after 48 h which indicated good activity and stability for the process. However, in free cell fermentations, AIV concentration required more time (60 h) to reach the maximum and dropped slightly after 60 h (Fig 4a).

AIV, tylosin concentration (TC) (a) and intermediates AT and IT concentration (b) in fermentation with free and immobilized cells. (FM-TC tolysin concentration in fermentation with immobilized cells, FM-AIV AIV concentration in fermentation with immobilized cells, FM-AT AT concentration in fermentation with immobilized cells, FM-IT IT concentration in fermentation with immobilized cells)

As shown in Fig. 4b, higher amounts of the intermediate IT were obtained when using PCPUF cubes compared with free cell fermentations, presumably due to the increased biomass of cells in the fermentation with immobilized cells. However, the increases in concentration of AT and IT were more remarkable than that in biomass (Fig. 4b). This indicated that the bioconversion of tylosin was disproportionately enhanced, which might have resulted from the activation or increased expression of corresponding enzymes. Further study is needed to determine whether immobilization increased the expression of acyB and other related enzymes. On the other hand, another possible mechanism for the increased production in immobilized cultures could be related to physiological differences between immobilized cells growing at a solid–liquid interface and free cells growing in liquid medium [24]. Alternatively, the addition of PCPUF cubes to shake flask fermentations might increase the liquid turbulence so as to increase dissolved oxygen concentrations, which could be more conducive to bioconversion of tylosin to AIV [10].

Repeated batch cultivation

Given the promising results obtained in shake flasks, repeated batch fermentations were carried out to determine the stability of S. thermotolerans 11432 immobilized on PCPUF cubes, and AIV production under repeated batch growing conditions.

In the repeated batch process, after attaining the maximum production of AIV in the first batch, the fermentation medium was replaced with fresh sterilized fermentation medium, and the process was repeated for six cycles. The tylosin, AIV concentration, and cell detachment at each cycle were determined, and the bioconversion of tylosin was also calculated.

As shown in Fig. 5, the AIV concentration and bioconversion of tylosin by PCPUF-immobilized S. thermotolerans 11432 were higher than that seen in free cell fermentations. Maximum AIV concentration and bioconversion reached 34.37 mg/l and 86.31 %, respectively, in the third cycle then decreased to 25.56 mg/l and 79.93 % after the sixth cycle.

AIV, tylosin concentration (TC), cell release (a) and tylosin conversion (b) in repeated batch fermentation. Each cycle was carried out for 24 h in shaker at 220 rpm. (FM-AIV AIV concentration in fermentation with immobilized cells, FM-TC tylosin concentration in fermentation with immobilized cells)

These results indicated that PCPUF-immobilized S. thermotolerans 11432 achieved higher bioconversion of tylosin compared with free cell fermentations. A significant advantage of fermentations using immobilized cells over free cells was that immobilized cells can be repeatedly used under specified fermentation conditions. It has been reported that immobilization carriers can also help to stabilize cell membranes and increase cell permeability. Thus, immobilized cells were protected and higher bioconversions were realized [3].

Conclusions

Our studies showed that PCPUF cubes are a promising material for immobilization of S. thermotolerans, when compared with PUF, PPUF, CPUF, and PEPUF. Optimum immobilization conditions with respect to adsorption time for maximal immobilized mass and AIV concentration were determined such that 33.31 mg/l of AIV was achieved after bioconversion fermentations using PCPUF cubes which had immobilized 9.2 mg/g PCPUF of cell mass during a 10-h incubation at the second seed culture stage. In batch cultures, 33.54 mg/l of AIV was detected in fermentations with PCPUF cubes prepared under optimal adsorption conditions, which was 1.65 times the conversion achieved using free cells. Improved production of intermediates AT and IT by PCPUF cubes in immobilized fermentations indicated that the immobilization process enhanced the bioconversion of tylosin significantly. In the repeated batch process, the activity of the immobilized S. thermotolerans 11432 cells and the AIV concentrations attained were stable over six cycles with the bioconversion of AIV ranging from 86.31 to 79.93 %. There are very few reports of immobilization of S. thermotolerans for conversion from tylosin to AIV. Therefore, this provides a feasible strategy for efficient AIV production and offers the potential for large-scale production.

References

Arisawa A, Kawamura N, Narita T, Kojima I, Okamura K, Tsunekawa H et al (1996) Direct fermentative production of acyltylosins by genetically-engineered strains of Streptomyces fradiae. J Antibiot 49:349–354

Alons Morales N, López Gallego F, Betancor L, Hidalgo A, Mateo C, Fernandez-Lafuente R (2004) Reversible immobilization of glutaryl acylase on sepabeads coated with polyethyleneimine. Biotechnol Prog 20:533–536. doi:10.1021/bp0342248

Beg QK, Bhushan B, Kapoor M, Andondal GS (2000) Production and characterization of thermostable xylanase and pectinase from Streptomyces sp. QG-11-3. J Ind Microbiol Biotechnol 24:396–402. doi:10.1038/sj.jim.7000010

Budriene S, Romaskevic T, Pielichowski K (2007) Synthesis and characterization of polyurethane microspheres and their application for immobilization of maltogenase. Polym Adv Technol 18:67–71. doi:10.1002/pat.797

Challis GL, Hopwood DA (2003) Synergy and contingency as driving forces for the evolution of multiple secondary metabolite production by Streptomyces species. Proc Natl Acad Sci 100(suppl2):14555–14561. doi:10.1073/pnas.1934677100

Cui C, Tao Y, Li L, Chen B, Tan T (2013) Improving the activity and stability of Yarrowia lipolytica lipase Lip2 by immobilization on polyethyleneimine-coated polyurethane foam. J Mol Catal B Enzym 91:59–66. doi:10.1016/j.molcatb.2013.03.001

Devi S, Sridhar P (1999) Optimization of critical parameters for immobilization of Streptomyces clavuligerus on alginate gel matrix for cephamycin C production. World J Microbiol Biotechnol 15:185–192. doi:10.1023/A:1008814427427

Devi S, Sridhar P (2000) Production of cephamycin C in repeated batch operations from immobilized Streptomyces clavuligerus. Process Biochem 36:225–231. doi:10.1016/S0032-9592(00)00194-1

Du L, Liu RH, Ying L, Zhao GR (2012) An efficient intergeneric conjugation of DNA from Escherichia coli to mycelia of the lincomycin-producer Streptomyces lincolnensis. Int J Mol Sci 13(4):4797–4806. doi:10.3390/ijms13044797

Elibol M (2002) Product shifting by controlling medium pH in immobilized Streptomyces coelicolor A3(2) culture. Process Biochem 37:1381–1386. doi:10.1016/S0032-9592(02)00019-5

Huang G, Okamoto R, Hikita A (1997) Optimization of conditions for conversion of tylosin to a novel antibiotic, acetyl-isovaleryl tylosin (AIV), Streptomyces thermotolerans and scale-up to 200-liter pilot-scale fermentor. J Ferment Bioeng 84:77–81. doi:10.1016/S0922-338X(97)82790-0

Huang GW, Okabe M, Kahar P, Tsunekawa H, Park Y (2001) Optimization of tylosin feeding rate profile in production of Acetyl-Isovaleryl Tylosin (AIV) from tylosin by Streptomyces thermotolerans YN554. J Biosci Bio-Eng 5:504–508. doi:10.1263/jbb.91.504

Ishida BK (1988) Improved diosgenin production in Dioscorea deltoidea cell cultures by immobilization in polyurethane foam. Plant Cell Rep 7:270–273. doi:10.1007/BF00272540

Khang YH, Shankar H, Senatore F (1988) Modeling the effect of oxygen mass transfer on β-lactam antibiotic production by immobilized Cephalosporium acremonium. Biotechnol Lett 10:861–866

Kurosawa H, Matsumura M, Tanaka H (1989) Oxygen diffusivity in gel beads containing viable cells. Biotechnol Bioeng 34:926–932. doi:10.1002/bit.260340707

Kim IC, Kim CH, Hong SI, Hong SW (2001) Fed-batch cultivation for the production of clavulanic acid by an immobilized Streptomyces clavuligerus mutant. World J Microbiol Biotechnol 17:869–872. doi:10.1023/A:1013895617923

Kim CJ, Chang YK, Chun GT, Jeong YH, Lee SJ (2001) Continuous culture of immobilized Streptomyces cells for kasugamycin production. Biotechnol Prog 17:453–461. doi:10.1021/bp010020k

López-Gallego F, Betancor L, Hidalgo A, Hidalgo A, Alonso N, Fernández-Lafuente R, Guisán JM (2005) Co-aggregation of enzymes and polyethyleneimine: a simple method to prepare stable and immobilized derivatives of glutaryl acylase. Biomacromolecules 6:1839–1842. doi:10.1021/bm050088e

Liu S, Lin B, Yang X, Zhang Q (2007) Carbon-nanotube-enhanced direct electron-transfer reactivity of hemoglobin immobilized on polyurethane elastomer film. J Phys Chem B 111:1182–1188. doi:10.1021/jp065344b

Okamoto R, Nomura H, Tsuchiya M, Tsunekawa H, Fuknmoto T, Inui T, Takeucki T, Umezawa H (1979) The activity of 4″-acylated tylosin derivatives against macrolide-resistant Gram-positive bacteria. The Journal of antibiotics 32:542–546

Okamoto R, Fukumoto T, Nomura H, Kiyoshims K, Takamatsu A, Takeuchi T (1980) Physico-chemical properties of new acyl derivatives of tylosin produced by microbial transformation. J Antibiot 33:1300–1308

Okamoto R, Tsuchiya M, Nomura H, Iguchi H, Kiyoshima K, Hori S, Inui T, Sawa T, Takeuchi T, Umezawa H (1980) Biological properties of new acyl derivatives of tylosin. J Antibiot 33:1309–1315

Ozdemir E (2009) Biomimetic CO2 sequestration: 1. Immobilization of carbonic anhydrase within polyurethane foam. Energy Fuels 23:5725–5730. doi:10.1021/ef9005725

Papagianni M, Joshi N, Moo-Young M (2002) Comparative studies on extracellular protease secretion and glucoamylase production by free and immobilized Aspergillus nigercultures. J Ind Microbiol Biotechnol 29:259–263. doi:10.1038/sj.jim.7000289

Pires-Cabral P, da Fonseca MMR, Ferreira-Dias S (2009) Synthesis of ethyl butyrate in organic media catalyzed by Candida rugosa lipase immobilized in polyurethane foams: a kinetic study. Biochem Eng J 43:327–332. doi:10.1016/j.bej.2008.11.002

Quek E, Ting YP, Tan HM (2006) Rhodococcus sp. F92 immobilized on polyurethane foam shows ability to degrade various petroleum products. Bioresour Technol 97:32–38. doi:10.1016/j.biortech.2005.02.031

Schügerl K, Bayer T, Niehoff J, Oller M, Zhou W (1988) Influence of cell environment on the morphology of molds and the biosynthesis of antibiotics in bioreactors. In: Proceedings of 2nd conference on bioreactor fluid dynamics. Elsevier, Amsterdam 132: 229–243

Srinivasulu B, Prakasham RS, Jetty A, Srinivas S, Ellaiah P, Ramakrishna SV (2002) Neomycin production with free and immobilized cells of Streptomyces marinensisin an airlift reactor. Process Biochem 38:593–598. doi:10.1016/S0032-9592(02)00182-6

Shu C, Cai J, Huang L, Zhu XC, Xu ZN (2011) Biocatalytic production of ethyl butyrate from butyric acid with immobilized Candida rugosa lipase on cotton cloth. J Mol Catal B Enzym 72:139–144. doi:10.1016/j.molcatb.2011.05.011

Survase SA, van Heiningen A, Granström T (2013) Wood pulp as an immobilization matrix for the continuous production of isopropanol and butanol. J Ind Microbiol Biotechnol 40:209–215. doi:10.1007/s10295-012-1219-5

Tsuchiya M, Suzukake K, Hori M, Sawa T, Taken T, Umezawa H (1981) Studies on the effects of 3-acetyl-4″-isovaleryltylosin against multiple-drug resistant strains of Staphylococcus aureus. J Antibiot 34:305–312

Torres R, Pessela BCC, Mateo C (2004) Reversible immobilization of glucoamylase by ionic adsorption on sepabeads coated with polyethyleneimine. Biotechnol Prog 20:1297–1300. doi:10.1021/bp049943g

Weaire DL, Hutzler S (2001) The physics of foams. Oxford University Press, Oxford

Wei P, Chen J, Lu Y (2010) High density cultivation of Dictyostelium discoideum in a rotating polyurethane foam-bed bioreactor. World J Microbiol Biotechnol 26:1117–1123. doi:10.1007/s11274-009-0278-x

Weihua W (2014) Overexpression of acyB and Immobilization of Streptomyces thermotolerans on Polyurethane foam to improve production of Acetylisovaleryltylosin. MS thesis. Tianjin University, 2014

Yamaguchi T, Ishida M, Suzuki T (1999) An immobilized cell system in polyurethane foam for the lipophilic micro-alga Prototheca zopfii. Process Biochem 34:167–172. doi:10.1016/S0032-9592(98)00084-3

Zarzyka I (2014) The modification of polyurethane foams using new boroorganic bolyols. II. Polyurethane foams from boron-modified hydroxypropyl urea derivatives. Polym-Plast Technol Eng 53(2):207–215. doi:10.1080/03602559.2013.844236

Acknowledgments

We are grateful for the financial support from the National Natural Science Foundation of China (Grant No. 31370091) and Natural Science Foundation of Tianjin (Grant No. 10JCYBJC10300).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Zhu, H., Wang, W., Liu, J. et al. Immobilization of Streptomyces thermotolerans 11432 on polyurethane foam to improve production of Acetylisovaleryltylosin. J Ind Microbiol Biotechnol 42, 105–111 (2015). https://doi.org/10.1007/s10295-014-1545-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-014-1545-x