Abstract

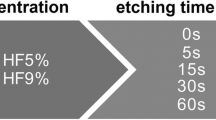

This study aimed to evaluate the effect of three hydrofluoric acid (HF) etching periods on the micro-tensile bond strength between two CAD–CAM ceramic systems [Vita Suprinity (VS) and feldspathic CEREC blocs (CB)] and a composite resin. The ceramics were categorized into six groups based on the surface conditioning protocol used, as follows: G1: CB-HF 5% for 20 s; G2: CB-HF 5% for 40 s; G3: CB-HF 5% for 60 s; G4: VS-HF 5% for 20 s; G5: VS-HF 5% for 40 s; G6: VS-HF 5% for 60 s. Scotchbond Universal was applied onto the pretreated ceramic surfaces and covered with Filtek Z350 XT composite resin. After 24 h, the specimens were cut into microbars (n = 16) and a micro-tensile bond strength test (μTBS) was carried out. An optical microscope was used to examine the fractured microbars. The results showed statistically significant differences between the factors tested (p < 0.01). Moreover, the mean MPa of G1(17.27), G2(13.03), G3(12.82), G4(15.83), G5(21.66), and G6(14.50) was seen to significantly differ. The predominant failure type observed was adhesive, and all three periods of HF etching produced satisfactory bonding between the composite resin and CB. An etching time of 40 s provided the highest μTBS value for VS.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The use of computer-aided milled techniques for the fabrication of ceramic blocks (CAD/CAM blocks) in restorative dentistry has increased substantially since the introduction of the CEREC CAD/CAM system into the dental market over 25 years ago[1]. This increase in popularity can be attributed to lower rates of wear of ceramic restorations [2] and long-term clinical success[3].

Feldspathic glass ceramics, the first ceramic used in the field of dentistry, exhibit excellent esthetic properties, and are suitable for the manufacture of veneers, inlays, onlays, and anterior and posterior crowns. However, there have been reservations with regard to their ability to withstand masticatory forces in the posterior areas, leading to the development of reinforced ceramics (e.g., zirconia-reinforced lithium silicate) that are capable of withstanding greater forces.

Zirconia-reinforced lithium silicates have several advantages including acceptable esthetics and greater ability to withstand masticatory forces[4], thus making them suitable for the fabrication of inlays, onlays, veneers, anterior and posterior crowns, and prosthetic abutments [5]. Furthermore, in contrast to pure zirconia composites, these materials exhibit acid sensitivity as they contain low concentrations (10%) of zirconia and their glass matrices are made up of lithium silicate[6].

Effective bonding of ceramic restorations to the dental structure is dependent on the use of adhesive bonding systems [7], the majority of which typically require pre-treatment of the internal surfaces of the ceramic restorations and the use of adhesives that can bind with resin cement.

The convenience of self-etching adhesives have made them increasingly popular and have also highlighted the advantages of universal adhesives designed to bond to tooth structures as well as other materials following self-etching or etch-and-rinse technique [8]. The latter technique mainly relates to the presence of the acidic resin monomer, 10-MDP, which chemically bonds to metal ions [9].

Both feldspar ceramics and zirconia-reinforced lithium silicates exhibit acid sensitivity and are susceptible to hydrofluoric acid etching, a technique used to create micromechanical retentive surfaces through the formation of superficial irregularities that can interact with resinous materials. Feldspar ceramics typically require hydrofluoric acid etching for a period of 60 s [10], while zirconia-reinforced lithium silicates require it for 20–40 s only[6]. However, it has been suggested that shorter or longer acid etching times may significantly influence the bond strength between resinous materials and the etched substrates.

Hydrofluoric acid etching can also be used to efficiently repair fractured or chipped ceramic restorations [11], a common problem despite the advent of more stable materials such as CAD/CAM blocks. Repair systems, in addition to altering the physical properties of the restorations, also contain chemical agents such as silane, which are capable of increasing bond strength between the resin and ceramic [12], thus increasing repair life.

The purpose of this study was to evaluate and compare the effect of three different 5% hydrofluoric acid etching durations on the micro-tensile bond strength (μTBS) of zirconia-reinforced lithium silicate and feldspar-based CAD–CAM ceramics to a composite resin to test the hypothesis that micro-tensile bond strength would vary with acid etching periods.

Materials and methods

Sample preparation

The materials used in this study have been listed in Table 1. This study used a total of 24 previously milled CAD/CAM ceramic blocks, of which 12 were made up of Vita Suprinity zirconia-reinforced lithium silicate ceramics and were crystallized. The 12 remaining blocks, made up of CB feldspar ceramics, did not undergo the crystallization process in keeping with the manufacturer’s recommendations. Four samples of each ceramic type were placed in the center of an acrylic matrix that was 4 cm high and 2 cm in diameter using self-curing acrylic resin (Jet, Clássico, São Paulo, SP, Brazil). The top face of each ceramic was then removed and flattened using a cutting machine with a diamond saw (Extec, London, England) at a constant speed of 500 rpm and water cooling. Each specimen was polished with a rotational polishing device using 200-, 400-, and 600-grit silicon carbide abrasive paper under a steady stream of water to form a uniform surface.

The specimens were then divided into six groups based on the hydrofluoric acid etching time, as shown in (Table 2).

Specimen preparation and μTBS testing

The samples in each group were conditioned using 5% hydrofluoric acid for the relevant period of time, washed with running water, and air dried for 5 s. Thereafter, the Scotchbond Universal adhesive system was applied for 20 s, followed by a light air blast for 5 s and light-curing using 1470 mW/cm2 (Elipar Deep Cure 3M-ESPE, St. Paul, MN, USA) for 20 s, as per the manufacturer’s instructions. Following application of the adhesive, the composite resins (Filtek 350 XT, 3M-ESPE, St. Paul, MN, USA) were placed on the ceramic surface in three layers (each 2 mm thick) and each layer was light-cured for 20 s using a silicon (3M-ESPE, St. Paul, MN, USA) matrix as a guide.

Finally, the acrylic cylinder was positioned over the composite resin block and filled with a self-curing acrylic resin, transforming the sample into a single body within the acrylic resin. After 24 h, the specimens were vertically sectioned into serial slabs and then into sticks using a water-cooled diamond blade on a low speed cutting saw. Sixteen samples made up of ceramic/adhesive/resins with cross-sectional areas of approximately 0.90 mm2 were obtained for each ceramic-surface-treatment combination. The specimens were then attached to the universal testing machine (DL-2000 EMIC, São José dos Pinhais, Brazil) using cyanoacrylate (Super Bonder Gel, Loctite Brazil Ltda, São Paulo, Brazil) and stressed to failure with a low cell of 50 N and a crosshead speed of 0.5 mm/min. The failure load (N) was recorded and the surface area (mm2) for each sample was used to calculate the μTBS in MPa with the help of the Mtest software (T-Systems, São Paulo, Brazil).

Failure analysis

The mode of failure was determined by visually examining all specimens using an optical microscope at 150 × magnification (Olympus DF, Planapo IX, Tokyo, Japan) immediately after fracture. The failure modes were classified into adhesive failures at the composite resin–ceramic interface, cohesive failures within the resin and ceramic blocks, or mixed adhesive–cohesive failures, and the predominant failure pattern was determined using the proportions observed.

Atomic force microscope analysis

To characterize the surface micro-topography, additional ceramic plates (5 × 5 × 1 mm) from each group (n = 1/per group) were prepared for analysis using an atomic force microscope (AFM; Dimension Icon, Bruker, Billerica, Massachusetts) with tip model RTESPA 6 (T: 3.75 mm, f0:300 kHz, L:125 mm, k: 40 N/m, W: 35 mm) and Peak Force Tapping of 60 × 60 μm2. Three-dimensional images were generated for each sample using NanoScope Analysis 1.40 (Bruker, Billerica, Massachusetts).

Statistical analysis

The μTBS values were analyzed using the two-way ANOVA (restorative material x etching strategy) test followed by post-hoc multiple comparisons using Tukey’s test. A p value ≤ 0.05 was considered statistically significant, and all analyses were carried out using SPSS v17 (SPSS Inc., Chicago, USA).

Results

The results of the ANOVA test showed that the factors “Ceramics” (p = 0.0019), “Time” (p = 0.0006), and their interaction were statistically significant (p = 0.0010), while Tukey’s test showed significant differences between the groups (p < 0.05). The Vita Suprinity 40-s group (group 5) exhibited the highest μTBS value and this was significantly different from the other groups. No statistically significant (p > 0.05) differences were observed between groups 1 (17.27 MPa), 2 (13.03 MPa), 3 (12.82 MPa), 4 (15.83 MPa), and 6 (14.50 MPa), as shown in Table 3.

The AFM images for zirconia-reinforced lithium silicate and feldspar-based CAD–CAM ceramics have been shown in Fig. 1a–h. After completion of etching, the feldspar-based ceramics exhibited a constant topography of peaks and valleys, while zirconia-reinforced lithium silicate surfaces showed less roughness and a relatively smoother homogenous surface. Longer etching times produced increased surface roughness for both materials. These observations reiterate the conditioning characteristics of each ceramic surface, with feldspathic being more susceptible to acid conditioning and zirconia exhibiting resistance to it.

The representative Atomic Force Microscopy (AFM) images for the feldspar-based ceramics groups: A Untreated, B 20-s acid etching, C 40-s acid etching, D 60-s acid etching and the Zirconia-reinforced lithium silicate ceramics groups: E Untreated, F 20-s acid etching, G 40-s acid etching, H 60-s acid etching

Failure type analysis

The frequencies of failure types in each group have been shown in Table 4. Adhesive failures were found to be the predominant type observed in this study.

Discussion

The results of this study showed that the micro-tensile bond strength values of feldspar ceramic CB did not vary with the duration of acid etching, while VS ceramics exhibited the highest μTBS value after etching for a period of 40 s. Therefore, our hypothesis that the micro-tensile bond strength of CAD/CAM ceramics to composite resin would vary with acid etching duration was partially rejected.

No statistically significant differences in μTBS values were observed when the CB feldspar ceramics were conditioned with 5% hydrofluoric acid for 60-, 40-, and 20-s periods, suggesting that the two shorter etching periods may be as effective as the traditional 60 s with regard to the formation of roughness and irregularities that promote micromechanical retention of ceramic surfaces with resinous materials. This was further supported by the fact that the AFM images indicated that HF acid applied either for 20 or 40 s effectively produced the desired surface required for resin bonding.

A previous study conducted by Venturini et al. [10] showed that etching feldspar ceramics with different (3, 5, or 10%) concentrations of hydrofluoric acid for 60 s did not influence the stability of the bond strength between the ceramic and resinous materials. Murillo-Gomez, Palma Dibb, and De Goes[13] demonstrated a penetration depth of 403 µm in Empress Cad ceramics when etched with acid for 60 s as per the manufacturer’s recommendations, and the composition of feldspar ceramics suggest that they may demonstrate a similar pattern. Therefore, as veneers are typically approximately 0.3 mm in thickness, it is possible that the hydrofluoric acid could leak through the restoration, making it more fragile and also leading to long-term color changes. This suggests that it may be beneficial to use shorter hydrofluoric acid etching durations in such circumstances.

Feldspathic porcelain has been scientifically shown to be effective in bonding to resinous materials when etched with hydrofluoric acid [14], making it a popular choice for fabrication of CAD/CAM blocks. The traditional acid etching duration of 60 s, used for most commercial brands of this material, typically produces a surface topography resembling honeycombs[15], although Ramakrishnaiah et al. [16] reported a faster increase in surface porosity width than depth with longer etching durations, resulting in relatively large, wide, and shallow pores. This increase in pore width was produced when the glassy phase of the material dissolved and disintegrated faster than the crystalline phase, suggesting that the composition of the ceramics themselves influenced the surface topography obtained after hydrofluoric acid etching for different periods. Also, the protocol to be followed for the application of resinous materials on CAD/CAM blocks must be rigorous and follow the manufacturer’s guidelines [17]. A study conducted by Emsermann et al. [18] which assessed the adhesive impact of different standard surface pretreatments methods recommended by the manufacturers of CAD/CAM composite resins, including HF etching, showed that grit blasting had a more favorable effect on the adhesive performance on CAD/CAM resins than HF etching and tribochemical silica coating. On the other hand, HF etching of PICN (polymer-infiltrated ceramic network) materials plus silane application is considered the preferred surface pre-treatment for VITA Enamic, a material which consists of 86 wt% feldspathic ceramic and polymeric network (14 wt%), suggesting a more favorable scenario for HF etching when faced with feldspathic ceramic materials.

VS ceramics, made of zirconia-reinforced lithium silicate, combine the esthetic properties of lithium silicate with the high resistance to masticatory forces exhibited by zirconia, producing an effective restorative material. Moreover, they exhibit superior mechanical properties such as hardness, flexural strength, modulus of elasticity, and fracture strength when compared to lithium disilicate glass ceramics [5]. Although the manufacturers suggest hydrofluoric acid etching for a period of 20 s and Hu et al. [19] demonstrated that this resulted in a relatively smooth surface with small notches that could be attributed to the specific microstructures formed by thin and densely compacted crystals, the current study found that a longer etching period of 40 s promoted a significant increase in micro-tensile bond strength. Ramakrishnaiah et al. [16] examined the effect of prolonged 5% hydrofluoric acid etching periods (40, 80, and 160 s) on VS ceramics and found that a duration of 40 s produced increased pore size that appeared as elongated sulci, caused by the higher solubility of the glassy phase around the lithium silicate crystals. Conversely, etching for 80 and 160 s resulted in exposure of irregularly oriented crystals and formation of scratch-like gaps due to extensive loss of the glassy phase. Moreover, some of the crystalline particles were also seen to be torn. Therefore, the higher bond strength values observed after hydrofluoric acid etching for 40 s could be explained by the formation of a superficial topography that favored micromechanical retention.

In contrast, Sato et al. [6] showed no differences in bond strength following hydrofluoric acid etching VS for 20 and 40 s. Traini et al. [4] reported that VS ceramic surfaces treated with 4.9% hydrofluoric acid for 20 s produced the best results with regard to preservation of the microstructure, while a duration of 40 s caused surface degradation. Increasing the concentration of hydrofluoric acid to 9.5% and etching for periods of 20 and 40 s were seen to cause progressive surface degradation with significant material destruction. Al-Thagafi et al.[20] examined different etching protocols for this ceramic and reported higher values after blasting the material with tribochemical silica and silanization. The findings of these studies as well as those of the current study suggest that it would be beneficial for the manufacturers to review the VS conditioning protocol.

While hydrofluoric acid etching promotes micromechanical retention with resinous materials, silanes provide the chemical bonding. Silanes are organofunctional molecules [e.g., MPS (3-methacryloxypropyltrimethoxysilane)] that contain two functional groups capable of reacting and joining with ceramic and resinous materials. The hydrolyzable functional groups react with the silicon-bonded hydroxyl groups (Si–OH) present in ceramics, while the organic functional groups react with Bis-GMA and HEMA monomers in adhesives and composite resins [21]. With the aim of simplification, Scotchbond adhesives contain silane in their composition to avoid the additional step of silane application. However, previous studies have shown that prior application of silanes on hydrofluoric acid etched ceramics increased bond strength when Scotchbond Universal adhesives were used. Therefore, this procedure may be indicated for cementation and repair of silica-based ceramic restorations.

The increased use of ceramic restorations in dentistry has produced a demand for fracture repair protocols, and it is well known that successful repair of such restorations require hydrofluoric acid etching of the ceramic surfaces. Repair systems, in addition to promoting physical changes in ceramics, also have chemical agents that promote chemical adhesion of resins with ceramics [12]. Previous studies have reported a range of bond strength values observed following application of silanes to the conditioned ceramic surfaces, and this procedure has also been reported to increase the longevity of the repairs [22]. Alternative conditioning methods are available for zirconia systems, and Tokar et al. [23] demonstrated that repair bond strength could be increased by the application of Er, Cr: YSGG lasers with different pulses. Furthermore, it is essential to identify and eliminate the cause of breakage prior to commencing repair.

A systematic review of protocols for restoration repair [24] showed that certain clinical steps such as surface roughening using a diamond bur, hydrofluoric acid etching of silicate ceramics, and application of an adhesive/bonding agent were consistently recommended, while mechanical surface conditioning techniques such as air abrasion using aluminum oxide or silica-coated aluminum oxide were recommended for specific materials only. Based on the findings of the current study, conditioning of feldspar ceramics for 20 s and VS for 40 s followed by application of silane and adhesives on the fractured ceramic is recommended prior to replacement of the missing part with direct composite resin. It is also essential to emphasize the protective measures required when repairing ceramics intraorally. The use of 5% hydrofluoric acid for porcelain repair has been discussed regarding its safety [25]. Precautions as the need for the use of protective glasses for patient and dental team, tight rubber-dam isolation, defective surface easy to control and away from gingival margins, thoroughly rinsing and suction are some necessary measures. Once 5% HF is an affordable and accessible product for clinicians to use when faced to the need of intraoral repair of ceramic restorations [26].

In the present study, adhesive failures were most frequently observed (90%), necessitating evaluation of the bonding interface in most specimens. This high prevalence of adhesive failures could be attributed to the micro-tensile testing methodology selected. This method typically uses specimens with small areas, resulting in even distribution of forces applied at the joint interface level and reduction of cohesive fractures in the substrates [27]. Pashley et al. [28] reported that one of the main advantages of micro-tensile testing was the possibility of determining the location of almost exclusively adhesive failures at the interface, thus allowing analysis of the real bond strength at the bond-interface level.

Since VS ceramics exhibited superior bond strength values compared to feldspathic ceramics in the current study, their use in the preparation of restorations is recommended. Moreover, simplification of the cementation protocol by hydrofluoric acid etching of CB feldspar ceramics for a period of 20 s to produce surfaces favorable for micro-retention of the adhesive material is also recommended.

In conclusion, within the limitations of this study, feldspar ceramic blocks etched for 20, 40, and 60 s using 5% hydrofluoric acid resulted in effective bonding to the composite resin. Moreover, hydrofluoric acid etching of VS ceramics for a period of 40 s provided the highest bond strength value with composite resin.

References

Mörmann WH, Brandestini M, Lutz F, Barbakow F. Chairside computer-aided direct ceramic inlays. Quintessence Int. 1989;20:329–39.

Zhi L, Bortolotto T, Krejci I. Comparative in vitro wear resistance of CAD/CAM composite resin and ceramic materials. J Prosthet Dent. 2016;115:199–202.

Otto, T. Up to 27-years clinical long-term results of chairside Cerec 1 CAD/CAM inlays and onlays. Int J Compt Dent. 2017; 20:315–29. http://www.quintpub.com/userhome/ijcd/ijcd_20_3_otto_p315.pdf

Traini T, Sinjari B, Pascetta R, Serafini N, Perfetti G, Trisi P, et al. The zirconia-reinforced lithium silicate ceramic: lights and shadows of a new material. Dent Mater J. 2016;35:748–55.

Elsaka SE, Elnaghy AM. Mechanical properties of zirconia reinforced lithium silicate glass-ceramic. Dent Mater. 2016;32:908–14.

Sato TP, Anami LC, Melo RM, Valandro LF, Bottino MA. Effects of surface treatments on the bond strength between resin cement and a new zirconia-reinforced lithium silicate ceramic. Oper Dent. 2016;41:284–92.

Blatz MB, Sadan A, Kern M. Resin-ceramic bonding: a review of the literature. J Prosthet Dent. 2003;89:268–74.

Perdigão J, Swift EJ Jr. Universal adhesives. J Esthet Restor Dent. 2015;27:331–4.

Yoshida Y, Nagakane K, Fukuda R, Nakayama Y, Okazaki M, Shintani H, et al. Comparative study on adhesive performance of functional monomers [Internet]. J Dent Res. 2004. https://doi.org/10.1177/154405910408300604.

Venturini AB, Prochnow C, Rambo D, Gundel A, Valandro LF. Effect of hydrofluoric acid concentration on resin adhesion to a feldspathic ceramic. J Adhes Dent. 2015;17:313–20.

Özcan M, Vallittu PK. Effect of surface conditioning methods on the bond strength of luting cement to ceramics. Dent Mater. 2003;19:725–31.

Swift EJ Jr, LeValley BD, Boyer DB. Evaluation of new methods for composite repair. Dent Mater. 1992;8:362–5.

Murillo-Gómez F, Palma-Dibb RG, De Goes MF. Effect of acid etching on tridimensional microstructure of etchable CAD/CAM materials. Dent Mater. 2018;34:944–55.

Akyıl MŞ, Yılmaz A, Bayındır F, Duymuş ZY. Microtensile bond strength of resin cement to a feldspathic ceramic. Photomed Laser Surg. 2011;29:197–203.

Borges GA, Sophr AM, de Goes MF, Sobrinho LC, Chan DCN. Effect of etching and airborne particle abrasion on the microstructure of different dental ceramics. J Prosthet Dent. 2003;89:479–88.

Ramakrishnaiah R, Alkheraif AA, Divakar DD, Matinlinna JP, Vallittu PK. The effect of hydrofluoric acid etching duration on the surface micromorphology, roughness, and wettability of dental ceramics. Int J Mol Sci [Internet]. 2016. https://doi.org/10.3390/ijms17060822.

Soares CJ, Giannini M, de Oliveira MT, Paulillo LAMS, Martins LRM. Effect of surface treatments of laboratory-fabricated composites on the microtensile bond strength to a luting resin cement. J Appl Oral Sci. 2004;12:45–50.

Emsermann I, Eggmann F, Krastl G, Weiger R, Amato J. Influence of pretreatment methods on the adhesion of composite and polymer infiltrated ceramic CAD-CAM Blocks. J Adhes Dent. 2019;21:433–43.

Hu M, Weiger R, Fischer J. Comparison of two test designs for evaluating the shear bond strength of resin composite cements [Internet]. Dent Mater. 2016. https://doi.org/10.1016/j.dental.2015.11.023.

Al-Thagafi R, Al-Zordk W, Saker S. Influence of surface conditioning protocols on reparability of CAD/CAM zirconia-reinforced lithium silicate ceramic. J Adhes Dent. 2016;18:135–41.

Lung CYK, Matinlinna JP. Aspects of silane coupling agents and surface conditioning in dentistry: an overview. Dent Mater. 2012;28:467–77.

Stokes AN, Hood JAA, Tidmarsh BG. Effect of 6-month water storage on silane-treated resin/porcelain bonds [Internet]. J Dent. 1988. https://doi.org/10.1016/0300-5712(88)90132-7.

Tokar E, Polat S, Ozturk C. Repair bond strength of composite to Er, Cr:YSGG laser irradiated zirconia and porcelain surfaces. Biomed J. 2019;42:193–9.

Kanzow P, Wiegand A, Schwendicke F, Göstemeyer G. Same, same, but different? A systematic review of protocols for restoration repair. J Dent. 2019;86:1–16.

Bertolini JC. Hydrofluoric acid: a review of toxicity. J Emerg Med. 1992;10:163–8.

Hickel R, Brüshaver K, Ilie N. Repair of restorations–criteria for decision making and clinical recommendations. Dent Mater Elsevier BV. 2013;29:28–50.

El Zohairy AA, De Gee AJ, Mohsen MM, Feilzer AJ. Microtensile bond strength testing of luting cements to prefabricated CAD/CAM ceramic and composite blocks. Dent Mater. 2003;19:575–83.

Pashley DH, Sano H, Ciucchi B, Yoshiyama M, Carvalho RM. Adhesion testing of dentin bonding agents: a review. Dent Mater. 1995;11:117–25.

Funding

The authors did not receive support from any organization for the submitted work. All authors certify that they have no affiliations with or involvement in any organization or entity with any financial interest or non-financial interest in the subject matter or materials discussed in this manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author(s) declares that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

da Cunha, P.F.J.S., Tavares, J.G., Spohr, A.M. et al. Examining the effects of acid etching duration on the bond strength between two CAD/CAM materials and one composite resin. Odontology 110, 113–119 (2022). https://doi.org/10.1007/s10266-021-00644-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10266-021-00644-x