Abstract

When mining coal below aquifers, the height of the water-conducting zone above the mine panel is widely used as one of the main criteria in assessing mine safety. However, its direct application to backfill mining is quite problematic, and alternative approaches have to be used to more accurately reflect the relevant processes. The compaction characteristics and seepage behavior in crushed key aquiclude strata were experimentally investigated by analyzing the hydrogeological characters of aquiclude strata and aquifers in the Wugou coal mine. The results explained the mechanism of the backfill mining-induced seepage and indicated the feasibility of reconstructing the key aquiclude strata to protect regional water resources. Based on the regional geology and hydrogeological characteristics of the aquiclude strata, various reconstruction forms were analyzed, with the approbation of structural and seepage stability criteria of aquiclude strata. The research results were corroborated by field measurements and provide new theoretical guidance for protecting water resources during mining in China.

Zusammenfassung

Beim Kohlenabbau unter Aquiferen wird gewöhnlich die Höhe der wasserführenden Zone über der Abbausohle als einer der wichtigsten Parameter bei der Beurteilung der Bergbausicherheit verwendet. Die direkte Anwendung im Versatzbergbau ist jedoch problematisch. Zu verwenden sind alternative Ansätze, welche die wichtigen Prozesse genauer berücksichtigen. Die Verdichtungscharakteristika und das Sickerverhalten in zerbrochenen, wichtigen wasserstauenden Schichten wurden experimentell untersucht, indem der hydrogeologische Character der wasserstauenden und der grundwasserführenden Schichten in dem Wugou Kohlenbergbau untersucht wurde. Die Ergebnisse erklärten den Mechanismus der zutretenden Sickerwässer im Versatzbergbau und verwiesen auf die Durchführbarkeit einer Rekonstruktion der wichtigsten Stauhorizonte, um regionale Wasserresourcen zu schützen. Basierend auf der regionalen Geologie und den hydrogeologischen Charakteristika der wasserstauenden Schichten wurden unterschiedliche Möglichkeiten der Rekonstruktion analysiert, unter Prüfung struktureller und Sickerungskriterien der wasserstauenden Schichten. Die Ergebnisse wurden durch Geländemessungen bestätigt und können neue, theoretische Leitlinien für den Schutz von Wasserressourcen im chinesischen Bergbau liefern.

Resumen

Cuando se extrae carbón debajo de los acuíferos, la altura de la zona de conducción de agua sobre el panel de la mina se usa ampliamente como uno de los principales criterios para evaluar la seguridad de la mina. Sin embargo, su aplicación directa en el relleno minero es bastante problemática y se deben utilizar enfoques alternativos para reflejar con mayor precisión los procesos relevantes. Las características de compactación y el comportamiento de infiltración en estratos claves del acuicludo fueron investigados experimentalmente por análisis de las características hidrogeológicas de los estratos y acuíferos en la mina de carbón de Wugou. Los resultados explicaron el mecanismo del relleno de la filtración inducida por la minería e indicaron la viabilidad de reconstruir los estratos clave del acuicludo para proteger los recursos hídricos regionales. Sobre la base de la geología regional y las características hidrogeológicas de los estratos del acuicludo, se analizaron diversas formas de reconstrucción, con la aprobación de los criterios de estabilidad estructural y de infiltración de los estratos del acuicludo. Los resultados de la investigación fueron corroborados por mediciones de campo y brindaron una nueva orientación teórica para proteger los recursos hídricos durante la minería en China.

摘要

在开采含水层下伏煤层时,导水裂隙带高度是评价开采安全性的主要指标。然而,能否将导水裂隙带高度直接应用于充填开采仍存在疑问,必须寻求能更准确反映充填开采特征的其它方法。通过五沟煤矿含水层和隔水层水文地质特征分析,研究了被采动破坏的隔水关键层的压实和渗流效应。研究结果解释了充填开采诱发渗流效应的机理,说明了重塑隔水关键层和保护区域水资源的可行性。在隔水层的区域地质和水文地质特征基础上,分析隔水层的多种重塑形式,给出了隔水层的结构和渗流稳定标准。研究成果得到了现场实测证实,为中国煤炭开采水资源保护提供了新的理论指导。

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The global trend in coal mining is a change from open stoping and sub-level caving to cut-and-fill stoping, which increases coal recovery and decreases environmental damage. The backfilling reduces ground movement and subsidence of the surface, thus reducing fracture-controlled hydraulic flow paths and mitigating the waste of water resources. Coal mining can cause serious groundwater seepage, inrush, and deterioration of the aquatic environment, so coal mining with water protection is crucial, especially in ecologically fragile areas area with severe water shortage. According to incomplete statistics, approximately half of China’s principal collieries have reported water inrush hazards during the past 20 years, resulting in considerable economic losses and casualties (Sun et al. 2017a, b, c; Yang et al. 2016; Zhang and Shen 2004). Moreover, about 5.6 billion m3 of mine water is discharged every year to prevent water disasters, but only 26% of this water is utilized (He et al. 2008; Miao et al. 2008). The shortage of water resources significantly affects the ecological environment and residents. The priority of this problem was admitted by the Chinese authorities, which supported the concept of protection and improvement of the ecological environment by “green, circular, and low-carbon development”. Therefore, innovative mining methods must be developed to ensure effective coal resource exploitation with water protection.

Water inrush is a severe geological hazard in underground engineering. In coal-bearing strata, hard strata possess excellent load-carrying capacity, while softer strata usually provide a good seepage prevention. Both can act as a barrier to the flow of groundwater act (i.e. an aquiclude). Numerous studies have shown that there can be several aquiclude layers between aquifer layers and the working face, and because of their differing mechanical properties and locations, aquiclude capacity is affected by mining in remarkably different ways. A single layer or composite layers that play a pivotal role in water resistance are defined as key aquiclude strata (KAS; Miao et al. 2007). The principle of KAS was proposed to prevent and control roof water inrush and protect water resources (Miao et al. 2008). Kong et al. (2008) further derived the relationship between KAS and key seepage strata. Li et al. (2009) analyzed how fault-linked water inrush is affected by KAS. Pu et al. (2010) built a mechanical model of KAS to analyze their structural stability, considering a seepage system with a destabilizing critical condition. Based on an investigation of the capability of aquiclude strata in a shallow seam mining area in western China, Huang et al. (2010) subdivided water conservation mining into three types: (i) natural water conservation mining, (ii) controllable conservation mining, and (iii) special conservation mining. Sun et al. (2017a, b, c) conducted an experimental investigation on the mechanical properties of aeolian sand-based cemented backfill materials and the stability analysis of KAS. These researchers have refined the theory and improved the methods of conserving water during mining.

In China, solid backfill mining (SBM) technology was elaborated by the China University of Mining and Technology (Huang et al. 2011; Miao et al. 2010; Zhang 2008; Zhang et al. 2009). SBM has unique advantages in handling solid wastes and controlling strata movement. Theoretical analysis and practice indicate that SBM technology with water protection can incorporate a significant amount of solid waste, including coal gangue, aeolian sand, loess, and fly ash. This technology has been used for mining under aquifers and large embankments with a high recovery ratio (Zhang 2014; Sun et al. 2017a, b, c), and makes it possible to mine under complex hydrological conditions in eastern China and in ecologically fragile environments with water shortages in western China.

Previously, the backfill materials’ compaction ratio (BMCR) in gob was used as an essential evaluation index for the backfilling effect, while the critical criterion in traditional coal mining was the height of the water-conducting zone (HWCZ), which permitted the infiltration of recharge water into the working panel. However, recent studies have revealed that the movement of overlying strata can be adequately controlled by backfill materials. In this case, even if the HWCZ approaches or even exceeds (within certain limits) the aquifer strata, the overburden fractures are very slight and easily compacted. Meanwhile, soft KAS (clay or mudstone) can heal themselves when damaged. The swelling of soft strata meeting with water can backfill the mining-induced fractures, thus effectively preventing the formation of an inrush pathway.

To formulate and substantiate the reconstruction of KAS in backfill mining, this paper first presents the test specimens, experimental equipment, detailed testing procedure, and the experimental results with respect to the compaction characteristics and seepage behavior in crushed KAS, based on the hydrogeological conditions in the Wugou coal mine, China. On this basis, three approaches to KAS reconstruction in backfill mining with different strata are presented and discussed, and a mechanical model is used to analyze the seepage instability. Finally, the theoretical estimates are corroborated by in situ field measurements.

Study Area Description

The Wugou coal mine operated by Hengyuan Coal and Electricity Co. Ltd. is located in Huaibei City, Anhui Province. The main coal seam is buried by a 273 m thick, loose aquifer layer, of which the Cenozoic fourth aquifer is a severe threat to shallow coal seam mining. In the past, this coal mine used traditional safe mining methods, which left 36.63 million tons of coal safety pillars in the mine to resist water inrush. After an investigation and research, the SBM technology was adopted to reduce the number and size of pillars, increase the coal recovery rate, and improve the mine’s economics. It was estimated that using SBM will allow an additional 32 million tons of coal to be produced, and will prolong the mine’s service life by 25 years.

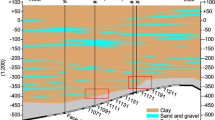

The backfilled area in the Wugou coal mine can be subdivided into the eastern and western areas (Fig. 1). The regional stratigraphy can be reduced to four main aquifer strata and four main KAS. The four main aquifers have a complex composition (mainly gravel, sandy gravel, clay, coarse sand, and medium sand). In this work, the study area was limited to the eastern backfilled area of 2.35 km2, with a length of 2.51 km in the strike direction and 0.93 km in the dip direction, respectively. The thickness of the fourth aquifer in the eastern area gradually thickens from northeast to southwest, from 6.2 to 32.7 m, while the water abundance is gradually enhanced from the north to south, and from the east to west. The KAS are mainly composed of mudstone, siltstone, and fine sandstone (structural strata), with a thickness ratio of 7:2:6; the strata thickness gradually increases from the east to the west (from zero to 125.5 m). Currently, the no. 10 coal seam, with an average thickness of 3.5 m, is the primary source of mineable coal resources. The immediate roof and floor are mainly mudstone and calcareous mudstone, with a thickness of 0–2.3 m. The main floor is siltstone or sandstone. The strata are depicted in Fig. 2.

Mining-induced Seepage Effect and Backfill Reconstruction Feasibility Analysis

Backfill Reconstruction Feasibility Analysis

After traditional mining, the overburden strata can be divided into the: caved, fractured, and continuous zones. Mining increases the porosity and permeability of the aquiclude strata under the aquifers (Fig. 3). Previous scholars assumed that the instability of seepage and associated water inrush hazard occurs when the fractured zone extends to the aquifer strata, which allowed them to use the HWCZ, permitting the infiltration of recharge water into the working panel as the critical criterion. However, recent experimental findings revealed that the fractures in the rock mass can be compacted and closed by the overburden load, and that the action of backfill mining enhances the swelling of soft aquiclude strata, thus effectively preventing the formation of water inrush pathways. In addition, the fractures in the KAS closer to the mined seam develop with a greater porosity, while the upper damaged strata had slight fractures and less porosity. This means they can be approximately controlled by different particle dimensions and arrangement patterns of crushed rock with different porosity. So the seepage characteristic of KAS can be studied by using the permeability experiment of crushed rock with different sizes to simulate the mining-induced effect, and analyzes the reconstruction feasibility of the mining-induced KAS in backfill mining.

Mining-induced Seepage Effect Analysis

The test setup is based on the YAS-5000 electro-hydraulic servo-motor test system and a self-made water flow apparatus. The experimental setup configuration and operation principle are illustrated in Fig. 4. Additionally, a steel chamber with a height of 240 mm and diameter of 100 mm was designed and used in this study for sample crushing. Before each test, KAS samples (mudstone, siltstone, fine sandstone) were completely saturated with water. All tests were carried out at room temperature; the ambient fluid was water with a density of ρw = 1000 kg/m3 and a kinetic viscosity μ = 1.01 × 10−3 Pa·s. The samples of KAS excavated from the Wugou coal mine were prepared and tested under laboratory conditions. The crushed mudstone, siltstone, and fine sandstone particles were separated into four groups based on particle size (2.5–5, 5–10, 10–15 and 15–20 mm, respectively). Each test was repeated three times to increase reliability, and the average value was regarded as the final result. To study the KAS seepage characteristics, three samples of mudstone, siltstone, and fine sandstone were placed into the test device from the bottom up.

The study was conventionally subdivided into three stages. First, mudstone and siltstone samples with a fixed particle size range of 2.5–5.0 mm were used, while the size range of the fine sandstone particles were gradually increased from: (i) 2.5–5.0, to (ii) 5.0–10, to (iii) 10–15, and to (iv) 15–20 mm. Next, the particle size ranges of the mudstone and fine sandstone were fixed at 2.5–5.0 mm and 15–20 mm, respectively, while those of the siltstone were gradually increased from (i) to (iv), as at the first stage. Finally, during the third stage, the particle sizes of the siltstone and fine sandstone were fixed at 15–20 mm, while those of the mudstone were gradually increased from level (i) to (iv) (i.e. 2.5–5.0 mm, 5.0–10 mm, 10–15 mm, to 15–20 mm). At each stage, the thickness ratio of mudstone, siltstone, and fine sandstone was set as 7:2:6. The increasing order of KAS particle sizes from top to bottom represents the actual KAS failure process. Details of the testing procedure and experimental setup can be seen in Fig. 5.

In previous reports, researchers have shown that the non-Darcy (i.e. turbulent flow) seepage properties of crushed single rocks and crushed particle mixtures are related to compaction level, mixture size, particle crushing, arrangement pattern, and pore pathways (Miao et al. 2004, 2011; Ma et al. 2013, 2014). In this study, we investigated the seepage properties of the crushed water-resisting strata with different particle sizes and arrangement patterns to get more insight into the controllability of the KAS with backfill mining. Insofar as the test principle is similar to that used in previous studies (Li et al. 2008), the above aspects can be found in more detail elsewhere (e.g. Ma et al. 2016). Noteworthy is that the adopted scheme implies that after the first level of stress is applied and kept steady, the axial pore pressure control mode is realized in the tests, which corresponds to different velocities of the loading piston travel, namely 0.028, 0.063, 0.090, and 0.120 mm s−1 for axial displacements of 10, 20, 30, and 40 mm, respectively. For a one-dimensional, non-Darcy flow, the relationship between pressure and flow velocity can be expressed as:

where p is pore pressure, z is the vertical axis passing the sample center, ∂p/∂z is the pore pressure gradient, μ is the water kinetic viscosity, k is the permeability of the crushed rock samples, v is the average water flow velocity, ρw is water density, and β is the non-Darcy coefficient. When the experimental value of β is close to zero, the flow satisfies the Darcy law and is considered laminar. The curve between the seepage velocity and pore pressure gradient can be fitted to calculate the seepage property parameters (permeability k and non-Darcy coefficient β) of the rock (Miao et al. 2004, 2011; Ma et al. 2013, 2014).

During the first stage, when the particle sizes of the mudstone were gradually increased, the seepage rate and pore pressure gradient are plotted in Fig. 6a for the particle size of 5–10 mm and axial displacements of 10, 20, 30, and 40 mm. For axial displacements of 10 mm, the same parameters are plotted in Fig. 6b.

The results obtained indicate that the effective porosity of the crushed KAS rocks is strongly influenced by the axial displacement and particle mixture ratio. The main reason is that the pore volumes in the crushed KAS rocks are compacted gradually, so that small particles of crushed rocks can adequately fill the gaps between the mixed strata. At the same axial displacement levels, the effective porosity rises with particle sizes, increasing from top to bottom (fine sandstone, siltstone, to mudstone). In particular, when the particle size of the crushed KAS was increased gradually, at some stage (e.g. when the particle sizes of the fine sandstone, siltstone, and mudstone were 15–20, 5–10, and 2.5–5 mm, respectively), the effective porosity decreased to a minimal value. With increased permeability, the non-Darcy (turbulent) flow seepage phenomenon becomes more pronounced.

Based on the experimental results, the variation of permeability k and non-Darcy coefficient β for the four particle mixture sizes was examined for the above three test stages. The respective curves are presented in Fig. 7, which implies that the experimental permeability k generally decreased as the axial displacement increased, while the non-Darcy coefficient β did the opposite. This can be related to the effective porosity reduction due to compaction, where the small particles filled the pores of the mixed KAS samples. Thus, effective compaction can improve the bearing capacity and impermeability of crushed KAS, as well as induce non-Darcy seepage flow.

In general, when the particle size increases from top to bottom (as in case of mining-induced KAS damage), the permeability increases accordingly. The experimental results obtained on the four mixed rock samples in this study show that the ranking of permeability k in KAS was: stage II(b) > stage I(b) > stage III(b) > stage III(d), while the non-Darcy coefficient β shows the opposite trend. This complies with the assumption that crushed soft mudstone can fill the seepage pathway and effectively mitigate water seepage.

Given this, in the process of backfill mining under an aquifer, the dual effects of the backfill materials and the overlying strata load can cause the mining-induced fractures to gradually be compacted and closed. Soft rock particles (such as clay and mudstone) in the aquifer vicinity can fill the seepage pathway, stabilizing the seepage system in the KAS. In such situations, despite some damage, the KAS still possess some residual water resistance and load carrying capacity. However, the conventional calculation and evaluation methods for the HWCZ no longer accurately reflect actual seepage conditions. Therefore, for the SBM technology, which has significant advantages in the effective exploitation of coal resources and protection of water resources, an alternative theoretical substantiation of the stability of seepage system in KAS under the aquifer is proposed in this study.

Reconstruction of the KAS

Reconstruction Forms

Based on a comprehensive analysis of recent research, the regional geological and hydrogeological characteristics of China’s coal mining areas, the process of mining under a single aquifer was classified into four categories: (I) mines with a shallow buried KAS in the ecologically fragile region in the western areas of China; (II) mines with a hard KAS; (III) mines with a composite KAS in the hydrogeologically complicated deep mining area in eastern China, and (IV) mines with no KAS. The hydrogeological classification of typical KAS and the respective histogram are depicted in Fig. 8.

Using the above classification, the following method of reconstructing the KAS is proposed for backfill mining. In the first case, the KAS are mainly Quaternary clays or sandy clays. Such strata exhibit good performance in aquiclude capacity and self-reparability, protecting valuable local water resources and vegetation. So after backfill mining, even if mining-induced fractures reach the aquifer, they are considered to be allowable, unless a seepage water inrush pathway is formed. For a hard KAS, once the KAS is damaged, it should be repaired from the surface or underground, using a method such as grouting. A composite KAS, composed of both soft and hard rocks, can been further classified into many types according to its characteristics. In this case, both the structural and seepage stability should be satisfied. In the fourth case, the functional backfill materials can be used to cut off and purify the water from the aquifer, constructing a groundwater storage space. The reconstruction forms are depicted in Fig. 9.

Stability Criteria

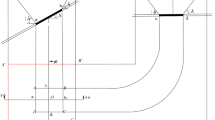

Structural Stability Analysis

According to the key strata in backfill mining (Zhang et al. 2008), the structural stability of KAS in backfill mining cam be effectively simulated with a Winkler elastic foundation (bed) and a beam model (Fig. 10). Under a load of \(q_{0}\), the displacement of the beam and foundation is assumed as \(y(x)\), the stress between the beam and foundation is \(kw(x)\), and the Winkler constant (or proportionality coefficient) k can be calculated as follows:

where \(h_{i}\) is the height of each stratum and \(E_{i}\) is its elastic modulus.

In view of the problem symmetry, consider a half beam for analysis. The beam deflection can be derived as:

The boundary conditions of the beam can be reduced to

The stresses and moments for the finite elastic foundation under study can be derived via (6) and (7), respectively:

The maximum tensile stress and maximum bending moment are related as follows:

According to the maximum normal stress criterion, which is also referred to as the first theory of strength, rock mass failure will occur when the following condition is satisfied:

where σnmax is the maximum normal stress and [σt] is the critical tensile stress of the particular material. Given the actual geological conditions, and experimental determination of the rock mass sample elastic modulus and density in the laboratory, the critical backfill body compression ratio can be assessed.

Seepage Stability Analysis

After backfill mining, the backfill materials can effectively support the overlying KAS. Even if some failure occurs in the structure, the strata still has a residual water-resistance capacity. So after fracture development, compaction, and reconstruction, such a situation is allowable. According to the mining-induced seepage flow theory (Miao et al. 2008), the seepage flow critical K of KAS can be used as an evaluation index:

where hi is thickness of KAS, aφi and βφi are permeability and non-Darcy coefficient with different BMCRs, ci φ is coefficient of acceleration with different BMCRs, p0 and pn are reference and actual pressure values, respectively; ρ and ρ0 are water density and reference pressure, respectively, μ is kinetic viscosity, and φ is BMCR. When K<1, the stratum still has aquiclude capability, and the system is safe, while at K ≥ 1, the stratum loses its aquiclude capacity. In this case, the water seepage flow will develop, which may result in water inrush disasters.

Discussion

There are many ways to study the HWCZ, such as water leakage variation in boreholes, seismic detection, and borehole resistivity. Given the main purpose of this study, water leakage variation and resistivity monitoring in boreholes were adopted to study the structural and seepage stability of the KAS. To measure the height and shape of the water-conducting zone and the damage to the KAS, five boreholes were used to monitor water leakage variations. Along the strike direction, borehole ZK1 was connected to the open-off cuts at 30 m distances. Borehole ZK3 was located in the center of the CT101 backfill longwall panel and ZK4 was 25 m from where mining stopped. Along the inclination direction, boreholes ZK6 and ZK5 were located at distances of 15 and 10 m from the head and tail entries, respectively. Resistivity monitoring was conducted at the open offcuts at 110 m distances. The length and aperture of the borehole was 105 m and 91 mm, respectively; the details of the monitoring scheme are shown in Fig. 11.

After the backfill mining of the CT101 panel, the deformation and fracturing of the KAS were relatively moderate with no caving zone (Zhang et al. 2014; Li et al. 2017). The development of the HWCZ in the overlying strata during the backfill mining was 9.78–10.89 m during the early production period. Based on the water leakage variation test results in the boreholes, the resistivity of the mudstone KAS was about 40 Ω·m; however, as the longwall panel advanced, the HWCZ and resistivity developed and increased. According to the most recent results, the fractures developed to the mudstone and the KAS was partially damaged, but no obvious water seepage was occurred during the backfill mining. These results indicate the feasibility of reconstructing the KAS in backfill mining and the advantages of SBM technology, as applied at this coal mine.

Conclusions

The experimental data, theoretical analysis, and field measurements derived in this study made it possible to draw the following conclusions:

-

1.

The water seepage flow tests of the crushed KAS rocks showed that their seepage properties are controlled by their degree of compaction, particle size range, sample arrangement pattern, and initial pore structure, which explains the mechanism of the backfill mining-induced seepage effect and indicated the feasibility of reconstructing the KAS duing backfill mining.

-

2.

Reconstruction of the KAS in backfill mining was proposed as an innovative evaluation method, with four reconstruction forms based on the geological and hydrogeological characteristics of the KAS. Structural and seepage stability criteria for KAS were analyzed and recommended, respectively.

-

3.

According to the measured water leakage variations and resistivity in the boreholes in the Wugou coal mine, the KAS was partially damaged, but no obvious water seepage was found, indicating the feasibility of reconstructing the KAS during backfill mining and the advantages of SBM technology for mining under a water body and protecting water resources.

References

He XW, Yang J, Shao LN, Li FQ, Wang X (2008) Problem and countermeasure of mine water resource regeneration in China. J China Coal Soc 33(1):63–66

Huang QX (2010) Impermeability of overburden rock in shallow buried coal seam and classification of water conservation mining. Chin J Rock Mech Eng 29(2):3622–3627

Huang YL, Zhang JX, Zhang Q, Nie SJ (2011) Backfilling technology of substituting waste and fly ash for coal underground in China coal mining area. Environ Eng Manag J 10(6):769–775

Kong HL, Chen ZQ, Bu WK, Wang B, Wang LZ (2008) A primary exploration on the relationships among loading key strata, aquiclude key strata and seepage key strata. J China Coal Soc 33(5):485–488

Li SC, Miao XX, Chen ZQ, Mao XX (2008) Experimental study on seepage properties of non-Darcy flow in confined broken rocks. Eng Mech 25(4):85–92

Li QF, Wang WJ, Zhu CQ, Peng WQ (2009) Analysis of fault water-inrush mechanism based on the principle of water-resistant key strata. J Min Safety Eng 26(1):87–90

Li M, Zhang JX, Deng XJ, Ju F, Li BY (2017) Measurement and numerical analysis of water-conducting fractured zone in solid backfill mining under an aquifer: a case study in China. Q J Eng Geol Hydroge 50(1):81–87

Ma D, Miao XX, Chen ZQ, Mao XB (2013) Experimental investigation of seepage properties of fractured rocks under different confining pressures. Rock Mech Rock Eng 46(5):1135–1144

Ma D, Miao XX, Jiang GH, Bai HB, Chen ZQ (2014) An experimental investigation of permeability measurement of water flow in crushed rocks. Transp Porous Media 105(3):571–595

Ma D, Bai HB, Chen ZQ, Li SC, Jiang BY, Huang WX (2016) Non-Darcy seepage properties of mixture particles of crushed gangue under confined compression 33(4):747–753

Miao XX, Liu WQ, Chen ZQ (2004) Seepage theory of mining strata. Science Press, Beijing

Miao XX, Chen RH, Bai HB (2007) Fundamental concepts and mechanical analysis of water-resisting key strata in water-preserved mining. J China Coal Soc 32(6):561–564

Miao XX, Hai PU, Bai HB (2008) Principle of water-resisting key strata and its application in water-preserved mining. J China Univ Min Technol 37(1):1–4

Miao XX, Zhang JX, Guo GL (2010) Study on waste-filling method and technology in fully-mechanized coal mining. J China Coal Soc 35(1):1–6

Miao XX, Li SC, Chen ZQ, Liu WQ (2011) Experimental study of seepage properties of broken sandstone under different porosities. Transp Porous Media 86(3):805–814

Pai H (2010) Study on the theory and application of water-resisting key strata on water-preserved mining. J China Univ Min Technol 39(4):631

Sun Q, Zhang JX, Zhou N, Qi WY (2017a) Roadway backfill coal mining to preserve surface water in western China. Mine Water Environ 2:1–10

Sun Q, Zhang JX, Yin W, Zhou N, Liu Y (2017b) Study of stability of surrounding rock and characteristic of overburden strata movement with longwall roadway backfill coal mining. J China Coal Soc 42(2):404–412

Sun J, Yang H, Zhao G (2017c) Relationship between water inrush from coal seam floors and main roof weighting. Int J Min Sci Technol 27(5):873–881

Yang C, Liu S, Liu L (2016) Water abundance of mine floor limestone by simulation experiment. Int J Min Sci Technol 26(3):495–500

Zhang JX (2008) Study on strata movement controlling by raw waste backfilling with fully-mechanized coal winning technology and its engineering applications. D, China University of Mining and Technology

Zhang JC, Shen BH (2004) Coal mining under aquifers in China: a case study. Int J Rock Mech Min Sci 41(4):629–639

Zhang JX, Miao XX, Guo GL (2009) Development status of backfilling technology using raw waste in coal mining. J Min Saf Eng 26(4):395–401

Zhang JX, Jiang HQ, Deng XJ, Ju F (2014) Prediction of the height of the water-conducting zone above the mined panel in solid backfill mining. Mine Water Environ 33(4):317–326

Acknowledgements

The work was supported by the Fundamental Research Funds for the Central Universities (2017XKZD13).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, J., Sun, Q., Li, M. et al. The Mining-Induced Seepage Effect and Reconstruction of Key Aquiclude Strata During Backfill Mining. Mine Water Environ 38, 590–601 (2019). https://doi.org/10.1007/s10230-019-00614-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10230-019-00614-4