Abstract

Copper and zinc ions were removed from synthetic acidic aqueous solutions onto cement kiln dust (CKD) particles in a single component system. The objectives of this study were to: distinguish between adsorption and precipitation when both mechanisms are occurring simultaneously; define their individual contributions; and consequently, specify the dominant mechanism. This was achieved by conducting a new experimental procedure for the precipitation phase that depended on CKD leachate in combination with a derivation of a simultaneous adsorption-precipitation equation. High removal efficiencies, approaching 100 %, of the Cu and Zn ions, were attained. Precipitation was the dominant mechanism for removing low concentrations of these metals, while adsorption appears to be more significant in removal of high metal concentrations.

Zusammenfassung

Aus synthetischen sauren wässrigen Lösungen wurden Kupfer- und Zinkionen an Zementstaubpartikeln (CKD)in einem Einkomponentensystem entfernt. Die Ziele der Studie waren, zwischen der Adsorption und der Ausfällung bei einem gleichzeitigem Auftreten beider Mechanismen zu unterscheiden, deren individuelle Wirkung zu bestimmen und somit den dominierenden Mechanismus abzugrenzen. Dazu wurde ein neues experimentelles Verfahren für die Ausfällungsphase durchgeführt. Die Auswertung der Versuche stützt sich auf die Herleitung einer simultanen Adsorptions-Fällungs-Gleichung. Für Cu- und Zn-Ionen wurden hohe Ausscheidungsgrade von nahe 100 % erreicht. Bei niedrigen Konzentrationen war die Ausfällung der dominierende Mechanismus für die Entfernung dieser Metalle. Die Adsorption erscheint bei hohen Metallkonzentrationen signifikanter.

Resumen

Se removieron cobre y cinc desde soluciones acuosas ácidas sobre partículas de polvo de horno de cemento (CKD) en un sistema de un único componente. Los objetivos de este estudio fueron: distinguir entre adsorción y precipitación cuando ambos mecanismos están ocurriendo simultáneamente; definir sus contribuciones individuales y, consecuentemente, especificar el mecanismo dominante. Esto se logró mediante un nuevo procedimiento experimental para la fase de precipitación que dependió del lixiviado CKD en combinación con una derivación de una ecuación de adsorción-precipitación simultánea. Se obtuvieron altas eficiencias de remoción de Cu y Zn, aproximadamente de 100 %. La precipitación fue el mecanismo dominante para la remoción de bajas concentraciones de estos metales mientras que la adsorción aparece como más significativa en la remoción de altas concentraciones de metales.

水泥窑粉尘去除酸性废水金属离子机理

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Cement kiln dust (CKD) is a highly alkaline fine powdery material removed with the exhaust gas from cement kilns and collected at cyclones, electrostatic precipitators, or bag filters. The characteristics of CKD vary from plant to plant depending on kiln feed composition, kiln design and operation, fuel type, and the type of dust control systems (Adaska and Taubert 2008). CKD characteristics even vary from batch to batch within the same plant (Wang and Ramakrlahnan 1990). However, CKD composition is still generally the same, as reported by the IEEE-IAS Cement Industry Committee and U.S. Bureau of Mines (Adaska and Taubert 2008; Haynes and Kramer 1982). Collected data from various cement plants show that production of a metric ton (t) of cement product will generate approximately 41 kg of CKD. The yearly production of cement in the USA alone ranged from 75 to 100 million t and, worldwide, approximately 2.5–3.4 billion t. Therefore, huge quantities of CKD must be appropriately disposed of (Adaska and Taubert 2008; Khanna 2009; Van Oss 2012). Consequently, reuse of CKD waste to improve water quality is attractive in terms of sustainable development and reduced disposal costs (Adaska and Taubert 2008).

There are many conventional processes for removing metals from aqueous solutions, such as chemical precipitation, adsorption, ion exchange, flotation, and electrochemical deposition. Adsorption/desorption and precipitation/dissolution are the main mass transfer mechanisms that govern the interaction of metals with CKD. Many theoretical and experimental studies have investigated these mechanisms, but unfortunately, none of them clearly distinguished between the contributions of the different transfer mechanisms. Studies such as Al-Meshragi et al. (2008) and Waly et al. (2010) dealt with CKD as an adsorbent material based on its fine texture and the composition of its oxides. These studies focused on pure adsorption within a certain pH range as the control mechanism. However, this is not an accurate characterization because the transfer mechanism can be affected by the pH of the solution, which was raised in the referenced cases by addition of lime; consequently, metal hydroxides were precipitated, rather than adsorbed. Other studies (Mackie et al. 2010, 2012; Zaki et al. 2007) dealt with the treatment process as a pure precipitation process due to the high lime content of CKD. A third set of studies, such as Klimantavièiûtë et al. (2005) and Saraya et al. (2011), just considered the interaction between CKD and the contaminants without considering whether the removal was achieved by adsorption or precipitation. Accordingly, the main objective of this study was to distinguish between adsorption and precipitation and to establish the contribution of each mechanism in the removal of copper (Cu) and zinc (Zn) from an aqueous solution treated with CKD.

Materials and Methods

Materials

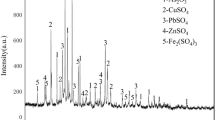

By-product CKD (collected from the An-Najaf Al-Ashraf cement plant, An-Najaf city, Iraq) was used as the reactive material in the batch experiments. The material was analyzed using ASTM C 114 “Standard Test Methods for Chemical Analysis of Hydraulic Cement” in the An-Najaf Al-Ashraf cement plant laboratory (Table 1).

Copper and zinc were selected as representative contaminants. To simulate Cu or Zn contamination, a solution of copper sulfate (CuSO4·5 H2O) or zinc sulfate (ZnSO4·7 H2O) (SD Fine-Chem Ltd, India) was prepared and added to the specimen to obtain a representative concentration.

Batch Mode Sorption Experiments

The primary objectives of the bench-scale experiments were to identify how the CKD removes the metals. The results of these experiments should be useful in designing large-scale tests and determining the required reagent mixture and concentrations. The bench-scale tests also demonstrated the treatment process pathway and allowed us to estimate the removal capacity of our reactive material. Figures 1 and 2 illustrate the general methodology. The right hand path in Fig. 2 illustrates the “tea bag” technique that was used to isolate the precipitated component(s), while the left hand path illustrates the bulk amount of metal released by the addition of the CKD.

First, to determine the total amount of metal removed by both adsorption and precipitation, a series of 250 mL flasks were filled with 100 mL of Cu or Zn solution. A specific dosage of adsorbent was added to the different flasks, and the flasks was agitated at high-speed using an orbital shaker. A fixed volume (20 mL) of the solution was withdrawn from each flask and filtered to separate the adsorbent; a 10 mL clear solution was pipetted out for determination of the residual metal concentration in the solution using the Shimadzu AA–6300 flame atomic absorption (AA) spectrophotometer. The apparent adsorbed–precipitated portion was obtained by mass balance.

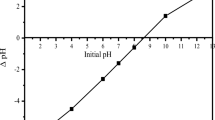

Experiments were conducted with contact times of 15, 30, 60, 90, 120, and 180 min, agitation speeds of 0, 50, 100, 150, 200, and 270 rpm, initial metal concentrations of 25, 100, 500, and 1000 mg/L, and CKD dosages of 0.5, 1, 2.5, and 5 g/100 mL. Then, to determine the amount removed by precipitation, a specific quantity of CKD was added to 100 mL of acidic uncontaminated water (pH = 3) and the solution was continuously stirred at high-speed using an orbital shaker to find the equilibrium time. The solution was then filtered to separate out the CKD, similar to the “tea-bag” experiment described elsewhere (Volesky 2004). This free metal solution was then mixed with the Cu or Zn solution and the resultant solution was filtered after the required equilibrium time.

The target initial concentration of metal were then achieved by adding the required amount of the metal sulfate salt to 10 mL of the solution, while the “tea bag” experiment was completed in the other 90 mL of the sample. The 90 and 10 mL solutions were then mixed to produce 100 mL of CKD-pretreated solution with the desired initial concentration of metal. For example, to produce 100 mL of solution with 100 mg/L of metal, we pretreated 90 mL of blank solution with 5 g of CKD; in a separate container, we prepared a 10 mL solution with a metal concentration of 1000 mg/L to produce, after mixing with the 90 mL that had been pretreated, a 100 mL sample with an initial metal concentration of 100 mg/L.

The residual metal concentration in the filtered solution was quantified by AA analysis, and the precipitated component was obtained by a mass balance calculation. The pH of the solution was measured at each stage of this process using a WTW pH 330i meter; these experiments were conducted under the same conditions used for determination of the total adsorption-precipitation.

Results and Discussion

Effect of Contact Time and Agitation Speed

Two selected values for each contaminant concentration and CKD dosage were sufficient for calibration; this follows the approach of many other studies on the use of CKD to remove metals from aqueous solutions (El-Awady and Sami 1997; Waly et al. 2010; Zaki et al. 2007). The results of the preliminary tests to define equilibrium conditions (contact time and agitation speed) for use in the laboratory batch tests are shown in Figs. 3 and 4. Figure 3 illustrates the effect of contact time on the percent removal of Cu and Zn using different adsorbent dosages and initial metal concentrations at 25 °C, and demonstrates that the removal percentages significantly increased with greater contact time. The initial sorption rate was rapid and then the rate gradually slowed. The slowing of the sorption rate was likely due to the decrease over time of sorption sites on the surface of the CKD. The kinetic data show that the maximum removal efficiency of these metals was achieved at about 30 min. There was no significant change in residual concentrations after 30 min up to 180 min and, consequently, sorption experiments with the other batches were conducted for 30 min.

Figure 4 illustrates the effect of agitation and shows that a significant percentage of Cu2+ and Zn2+ (≤50 %) was removed before shaking, and that the uptake increased with the shaking rate, up to about 200 rpm, at which point approximately 99 % of the Cu2+ and 97 % of the Zn2+ had been removed. There was no significant change in ion removal at higher speeds. These results suggest that increased agitation speed improved contaminant diffusion towards the surface of the reactive media. Thus, proper contact was developed between the sorbate and binding sites, which promoted effective transfer of sorbate to the sorbent sites.

Predominant Mechanisms of Removal Process

The results of total sorption and pure precipitation were obtained and plotted in Figs. 5 and 6 for Cu and Zn, respectively. These results showed that there was a lag in metal removal by pure precipitation relative to that removed by total adsorption–precipitation. This can be attributed to direct contact between CKD and metal ions in the total adsorption–precipitation case, which increased the chance of metal ion attachment on the CKD adsorbent.

Based on these results, the predicted theoretical-uptake values of pure adsorption due to CKD can be specified as a complementary portion of the total sorption, as illustrated in Figs. 5 and 6. As expected, total removal, equal to the sum of adsorption and precipitation, increased with the adsorbent dosage.

Table 2 shows the percentages of precipitation and adsorption from the total removal efficiencies of Cu and Zn ions onto CKD particles. It is clear that the adsorption proportion increased (and the precipitation proportion decreased) when the mass concentration of reactive material was high. Pure precipitation overcame total adsorption-precipitation at low concentrations. This is attributed to the formation of hydroxide ions, which appears to be faster than adsorption, which needs more time to achieve the maximum adsorption capacity. Accordingly, precipitation is the dominant mechanism at low concentrations, while adsorption is significant at high concentrations.

Conclusions

This study showed that adsorptive removal of Cu or Zn onto CKD particles is an important component of the total adsorption–precipitation process. The proportional contribution of adsorption increased (i.e. the share of precipitation decreased) when the mass of reactive material was increased. However, pure precipitation dominated over total adsorption–precipitation at low metal concentrations. This is attributed to the rapid formation of hydroxide ions; more time is required to achieve the maximum adsorption capacity. Thus, precipitation is the predominant mechanism in the removal of low metal concentrations, while adsorption becomes more significant at high metal concentrations.

References

Adaska WS, Taubert DH (2008) Beneficial uses of cement kiln dust. Proc, 2008 IEEE/PCA 50th Cement Industry Technical Conf, IEEE-IAS Cement Industry Committee, Miami, FL, USA, http://www.concretethinker.com/Content/Upload%5C437.pdf

Al-Meshragi M, Ibrahim HG, Aboabboud MM (2008) Equilibrium and kinetics of chromium adsorption on cement kiln dust. Proc, World Congress on Engineering and Computer Science, San Francisco, USA, pp 54–62

El-Awady MH, Sami TM (1997) Removal of heavy metals by cement kiln dust. Bull Environ Contam Toxicol 59:603–610

Haynes BW, Kramer GW (1982) Characterization of U.S. Cement Kiln Dust. USBM Information Circular 8885, US Department of the Interior, Washington, DC

Khanna OS (2009) Characterization and utilization of cement kiln dusts (CKDs) as partial replacements of Portland cement. PhD Thesis, Univ of Toronto

Klimantavièiûtë MG, Virbalytë D, Pakðtas V, Juðkënas R, Pigaga A (2005) Interaction of heavy metal ions with cement kiln dust. Ekologija 1:31–36

Mackie AL, Walsh ME (2012) Bench-scale study of active mine water treatment using cement kiln dust (CKD) as a neutralization agent. Water Res 46:327–334

Mackie AL, Walsh ME, Lake CB (2010) Investigation into the use of cement kiln dust (CKD) for wastewater treatment. PCA R&D Serial No. SN3038, Portland Cement Assoc

Saraya MEI, Aboul-Fetouh ME, Nassar HS, Abd-El-Rahman AM (2011) Removal of direct dyes with cement kiln dust. J Mater Sci Eng B1:97–105

Van Oss HG (2012) Cement. Technical report. Mineral Commodity Summaries, US Geological Survey, Washington, DC

Volesky B (2004) Sorption and bio-sorption. BV-Sorbex Inc, Montreal

Waly TA, Dakroury AM, El-Sayed GO, El-Salam SA (2010) Assessment removal of heavy metals ions from wastewater by cement kiln dust (CKD). J Amer Sci 6:910–917

Wang ML, Ramakrlahnan V (1990) Evaluation of blended cement, mortar and concrete made from type III cement and kiln dust. Constr Build Mater 4(2):78–85

Zaki NG, Khattab IA, Abd El-Monem NM (2007) Removal of some heavy metals by CKD leachate. J Hazard Mater 147:21–27

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sulaymon, A.H., Faisal, A.A.H. & Khaliefa, Q.M. Dominant Mechanisms for Metal Removal from Acidic Aqueous Solutions by Cement Kiln Dust. Mine Water Environ 36, 209–216 (2017). https://doi.org/10.1007/s10230-016-0416-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10230-016-0416-2