Abstract

The integration of renewable energy sources into sustainable development practices has become increasingly important. The municipal solid waste (MSW) utilisation presents a promising renewable energy source, provided that it is combined with modern technologies to optimise its energy conversion. The global population growth and the corresponding rise in living standards have resulted in increased consumption of goods and energy. Whilst such consumption boosts economic development, it also contributes to a significant increase in waste generation. In this article, the possibility of using MSW for energy production is examined, along with an overview of the production of waste and treatment activities in the European Union (EU). Europe generates 1.66 billion tonnes of waste yearly, with construction, demolition and MSW being a major contributor. The European Commission’s Waste Legislative Package aims for 60% reuse and recycling readiness by 2025 and a 65% target by 2030, focussing on landfill assessment, waste recycling promotion and other initiatives. In 2020, there were 504 waste to energy (WtE) plants in Europe with 61 million tonnes (137 kg per capita) of total incineration capacity. France has the most WtE (124) plants, whilst Germany has the highest capacity for waste incineration. The total energy produced from waste in 2019 was 41.2 MTOE (million tonnes of oil equivalent), with nearly half of that total was accounted by MSW. This includes non-renewable waste, MSW renewable and non-renewable waste and industrial waste. This statistics represents around 2.5% of the EU’s overall energy supply. The majority of energy recovery is used to generate electricity in electricity-only facilities or either in combined heat and power (CHP). In 2020, there was a 69 million tonnes or 58% decline in the amount of MSW that was landfilled in the EU, which represents 4.0% decline on an annual average. Germany recycled most MSW with 66% approximated recycling rate in 2020. Only eight EU countries have recycling rates that are higher than 50%. On average, WtE plants in the EU monitor around 60% of biogenic CO2 emissions, with the remaining 40% being fossil CO2 emissions. In the light of the EU’s prioritisation of the circular economy, it is imperative that all Member States, including EEA countries, shift from traditional waste disposal methods towards more intelligent waste treatment strategies, such as gasification and pyrolysis, which embody circular economy principles in their waste management policies.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

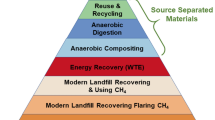

In advanced communities, the continuous production of waste has become such a major issue that it is important to minimise the amount of waste either by reusing or recycling it at any level [1]. The EU waste management policy outlines a hierarchical approach to waste management in order of increasing priority, starting with waste disposal, followed by energy recovery, recycling, reuse and ultimately waste prevention [2]. The increase in the quantity of waste produced presents a significant challenge. On average, EU member states generate approximately 482 kg of waste per capita per year. To achieve effective waste management measures aimed at reducing waste growth, the key factors are public acceptance and behaviour, which are critical to achieving the reduction of waste generation [3, 4]. Despite waste prevention being the highest priority in the waste solution hierarchy, EU waste policies have primarily focussed on targets for waste reduction through recycling. The European Commission has proposed targets for municipal waste reuse and recycling of at least 70% by 2030, including a minimum of 5% for reuse. As a result, the EU’s goals for waste prevention are relatively new, and waste management is still in its early stages [5].

Landfills are rapidly being removed as an ultimate destination for waste in Europe due to legislation regulations and increased taxation, and energy recovery with incineration is becoming the primary method of waste recovery process [6]. Other options are being used, such as chemical recycling (pyrolysis, gasification), composting, land spreading and reuse as material building, whilst research for process optimization is still needed [7]. Usually, methods of recovery are typically costly and their ecological implications is still dubious because of the large amounts of waste produced, the changing waste composition and the high moisture level (content) of the waste due to the process conditions. For this reason, research on the various applications of waste should be continued, taking into account the ecological and economic elements of such waste management [8]. In a circular economy, waste can play an important role given that reuse, recycling and prevention are prioritised in the cycle of waste management. Energy from waste may also be associated with this phase, but in most European countries, waste is still treated as a ‘hassle’ instead a resource, and in order to step towards and achieve a circular economy, this vision needs to be shifted. The European Commission notes that ‘WtE will optimise the contribution of the circular economy to decarburization, in line with the Paris Agreement and the Energy Union Strategy, just by respecting the hierarchy of waste’ [9].

As the economies of EU countries continue to expand, waste generation has become an increasingly pressing issue. Currently, the EU is ranked second globally in terms of MSW, with 392 million tonnes produced. Over the past two decades, the production of MSW in the EU has steadily increased. To mitigate the negative impact of municipal waste on the environment and promote a circular economy, the EU introduced the 7th Environmental Action Plan (EAP) in 2014. The EAP sets a goal of managing solid waste to at least 65% at present, in order to achieve the objective of “zero waste emission” by 2030. To attain these objectives, it is crucial to implement appropriate measures, such as encouraging the development of new technologies and sustainable business models, as well as promoting sustainable resource usage patterns [10]. Furthermore, the responsibility for fulfilling new mandates, such as creating sufficient and sustainable infrastructure for managing waste and implementing collection and sorting systems for various types of waste, has been increasingly assigned to localities and governmental subdivisions. This delegation of responsibility is intended to ensure that waste is handled in an environmentally sound and socially responsible manner [11].

Monitoring the shift towards a circular economy often begins with the observation of waste generation and its management since it marks the conclusion of the unwanted linear economy. Successful avoidance of material loss and environmental preservation can be achieved through the capacity to deter waste disposal and create secondary materials over a prolonged period [12]. Over the past two decades, environmental research has revealed that relying solely on waste recycling is inadequate for achieving a sustainable economy, particularly given the increasing scarcity of global resources. Consequently, waste prevention, material reuse and upcycling have become higher priorities on political agendas than ever before. In 2020, the European Commission introduced a new Circular Economy Action Plan as part of its European Green Deal policy to support this paradigm shift. To streamline the regulatory framework, it is necessary to establish a monitoring framework that can provide policy makers with information on current successful practices, remaining barriers, positive and negative impacts of the transition, and overall progress towards the established goals [13].

EU waste legislation review

EU waste strategy and objectives contain minimal requirements to manage particular types of waste. The targets most relevant to MSW are the targets for the diversion of landfill for biodegradable MSW (Landfill Directive 1999); Recycling goals (Packaging Waste Directive from 1994); Objective for recycling and preparation for recycle (Waste Framework Directive 2008); System Directive on waste, laid down in Council Directives 75/442/EEC (amended by 91/156/EEC) on waste and 91/689/EEC on hazardous waste, forms the basics of the European Waste Legislation [14,15,16]. The Waste Management system consists of two classes of guidelines: those setting out criteria for the operation and authorization of waste disposal premises and those relative to the alternatives for the eradication of particular forms of waste. Apart from these directives, Regulation 259/93/EEC specifies a scheme to control the transportation of waste into and out of the EU. Legislative provisions for waste treatment inside the EU have been established by WFD 2008/98/EC with the aim of protecting the environment and public health from the detrimental impact of waste production. The WFD laid it out a 50% target for the preparation of household and related waste for reuse and recycling, and a 70% target for the preparation of non-hazardous building and demolition waste for recycling, reusing and other material recuperation by 2020 [17]. The Directive requires the relevant bodies to draw up schemes for the management of waste, comprising the form, source and quantity of waste and the current processes for collection. It is also important to draw up prevention programmes to disintegrate the connexion between waste production and economic sustainability [18].

Directive 75/442/EEC describes waste as “any material or item discarded or planned or needed to be discarded by the holder”. Its goal is to compel Member States to support the elimination or waste diminution and its harmful effects by supporting the advancement of sustainable technology, advancement of technological products and techniques for the disposal of waste. In order to assure that waste is eradicated without jeopardising human health, Member States should take the appropriate steps including:

-

Without placing risk to air, water soil, animals and plants;

-

Without creating hassle by sounds or smells;

-

Having without a detrimental effect on the countryside or areas of particular interest [19, 20].

The waste industry sector is working towards establishing a global circular economy, with the aim of minimising material utilisation and waste production. The industry intends to achieve this by reusing and recycling waste, and utilising residual waste for energy recovery. In 2019, the European Commission proposed updated legislative guidelines to encourage Europe’s transition towards a circular economy on waste. The “Towards a Circular Economy” initiative advocates for a fundamental shift from a linear economy, where resources are extracted, used and discarded to a circular economy that promotes sustainable material use and waste reduction across all sectors of the economy. The ultimate goal is to create a circular economy that minimises waste production and material usage, whilst also recycling and reusing waste in the most environmentally friendly and socially responsible manner, and treating unavoidable waste whilst utilising the remaining for resource recovery. Any residual waste is then safely disposed of in a landfill [21].

A key to a circular economy is converting waste into a resource. This will support the ecosystem as well as the economy. The EU Circular Economy Action Plan sets out an action programme with steps spanning the period from production to consumption, management of waste and the secondary feedstock sector to facilitate the alternation to a circular economy. WtE as well as the different energy-generating waste management processes will play a part in the circular economy and in achieving the goals of the EU objective [22]. Different WtE procedures may relate to and build synergy with EU climate and energy policies: In combustion plants, waste co-incineration and in the processing of cement; In dedicated facilities incinerating of waste; From biodegradable sources, waste anaerobic digestion; Generation of fuels derived from waste (liquid, gaseous or solids); And another methods, comprising gasification or pyrolysis [23]. In 2019, the EU adopted a detailed legislative package on waste, including a new Waste Directive, the Landfill Directive, the Packaging Waste Directive, the End-of-Life Vehicles Directive, the Electronic and Electrical Waste Directive, and accumulators and batteries and waste batteries and accumulators [24]. The Commission would implement a waste-to-energy plan within the context of the Energy Union. The legislation scheme on waste sets priorities for the recycling, reduction, reusing and landfilling of waste management for 2030 [25].

The goal is to ensure better harmonisation and interpretation of the by-product and end-of-waste status legal system. In accordance with the definition used by the Organization for Economic Co-operation and Development (OECD) and the European Statistical Oise (Eurostat) for statistical purposes, the plan for a new Waste Directive rejects municipal waste. Thus, MSW is denied as “(a) Household and mixed waste, including: paper and glass metals, cardboard, plastics, textiles bio-waste, textiles, wood, textiles, waste electronics and electrical devices, accumulators and waste batteries; (b) Separately and mixed composed waste from other sources that are similar in design, quantity and composition to household waste; (c) Cleaning waste and waste from street cleaning provisions on the market, including street sweeping, litter bins, park waste and garden maintenance”. Similar waste from food processing facilities and other residues with identical properties of biodegradability, similar in nature, composition and volume is known as biodegradable waste [26].

The European Commission has introduced new goals for municipal waste with the new Waste Legislative Package to examine landfilling, waste recycling and other waste-related objectives to achieve 60% reuse and recycling readiness by 2025 and 65% by 2030. Moreover, new goals have been proposed for minimising municipal waste disposed of in landfills [27], as well as updated targets for packaging waste. Proposed goals include:

-

65% target for recycling and reuse of MSW by 2030.

-

75% target for recycling and reuse of packaging waste by 2030.

-

Minimal reusing and recycling goals for particular products used in packaging waste: 85% of ferrous metal, 85% of aluminium, 75% of wood, 85% of paper and cardboard and 85% of glass.

-

A maximum of 10% of the overall amount of MSW produced was landfilled by municipal waste and a prohibition on the landfilling of the separately collected waste was enforced [28].

Production of waste

Europe is one of the world’s largest producers of waste, with a total of around 1.66 billion tonnes generated every year. This waste can come from various sources, including households, industry and agriculture. The largest contributor to waste production in Europe is construction and demolition waste, accounting for over 40% of the total waste generated. This is followed by MSW, which comprises household and commercial waste and constitutes approximately 30% of the waste generated. Industrial waste, which includes waste generated by manufacturing and production processes, is another significant source of waste in Europe, accounting for approximately 20% of the total waste generated. Agricultural waste, such as manure and crop residue, makes up the remaining 10% of the total waste generated [29]. The amount of waste produced by each sector in 2020 is [30, 31].

-

1.

Manufacturing and construction: 911 million tonnes of waste generated.

-

2.

Mining and quarrying: 308 million tonnes of waste generated.

-

3.

Services: 169 million tonnes of waste generated.

-

4.

Household sector: 98 million tonnes of waste generated.

-

5.

Agriculture, forestry and fishing: 76 million tonnes of waste generated.

-

6.

Energy sector: 53 million tonnes of waste generated.

-

7.

Water supply and treatment: 36 million tonnes of waste generated.

-

8.

Other sectors: 10 million tonnes of waste generated.

Management of waste in Europe

Several processes include MSW treatment: digestion/composting, landfilling, recycling and combustion (incineration) with and without energy recovery. In Europe, WtE technology primarily involves the use of combustion techniques (i.e. incineration) to recover energy from waste, which are primarily based upon moving grates and storage boilers for power and/or heat generation [32]. In 2020, the EU generated more than 2400 million tonnes of non-hazardous waste across various economic activities, with an additional 196 million tonnes of hazardous waste created. Similarly, 1.66 billion tonnes of waste were produced in 2020, excluding major mineral waste, corresponding to 35% of the total waste produced. In addition to construction waste (911 million tonnes) and quarrying and mining waste (308 million tonnes), the highest waste generation rates were reported for services (169 million tonnes), household waste (98 million tonnes) and water and energy sector (89 million tonnes). Between 2013 and 2020, waste production from water and waste services witnessed a surge of 90%, whilst 58% increase in the rate is observed from waste generation from the construction sector. On the other hand, household waste produced by households (excepting major mineral waste) remains constant, whereas waste from production and quarrying/mining activities dropped by 35% and 25%, respectively [33]. The activities contributing to the quantity of waste produced and their corresponding shares, re-elected primarily by various collection and management systems, economic framework and country sizes, have varied significantly across EU Member States. The total quantity of waste produced is related to a country’s economic size and population. High volumes of waste are associated with the production of mineral waste from mining operations, accounting for about two-third of the total waste produced in the EU-28 [34].

A special form of waste comprises bio-waste. This waste mainly consists of organic waste from parks and gardens, household kitchen and food waste, caterers and distribution networks, restaurants and equivalent waste from food processing plants, according to WFD 2008/98/CE. Many biodegradables, such as paper, wood, sludge and paperboard, are often covered other biodegradable waste. When landfilled, because of the potential of GHG emissions, it can create major environmental and climate adverse impacts [35].

Composting and anaerobic digestion are currently the prevailing technologies employed in Europe for the management of bio-waste. Within the EEA member and cooperating countries, approximately 59% of municipal bio-waste generation is subjected to these treatment methods. The known annual capacity of treatment infrastructure in these countries stands at 38 million tonnes, encompassing an installed capacity of 21 million tonnes for bio-waste composting and an additional 17 million tonnes for bio-waste anaerobic digestion. It is worth noting that the actual treatment capacity is expected to exceed these figures significantly due to the absence of data from several European countries regarding their treatment infrastructure capacity [36].

Moreover, it should be noted that the aforementioned treatment capacities are not exclusively allocated to municipal bio-waste treatment. In certain facilities, municipal bio-waste is processed alongside other waste streams, including manure, sewage sludge and waste derived from the food industry. The capacity of installed bio-waste treatment infrastructure varies significantly across European countries, ranging from 356 kg of bio-waste per person to nearly zero. On average, composting facilities currently account for 53% of the bio-waste treatment capacity, whilst anaerobic digestion represents 47% of the capacity. No data is available regarding the volume of home composting [36].

Approximately, recently the EU handles 2248 million tonnes of non-hazardous waste. Nearly 36% was sent to recycling recovery operations, 44% of it was subject to landfilling (disposal operations), and just over 10% was channelize to backfilling for land reclamation in archaeological sites. Only 6% of the waste was incinerated, either solely for incineration purposes or for energy recovery, whilst the remaining waste was managed through alternative means. In some countries, waste disposal dominates, with around 90% of the waste being sent to disposal sites and landfills (Romania, Greece and Bulgaria), whilst other countries (like Denmark, Italy and Belgium) dominate waste recovery. In Sweden, Denmark, Germany and Norway, waste incineration is a widespread choice, with a substantial proportion of waste management options observed. In 2015, the amount of MSW produced reached 255 million tonnes in the European Counties and 243 million tonnes in the EU, comprising approximately 10% of the total waste produced. Approximately half a tonne of waste per year was produced by each individual (477 kg/person in 2015 and 472 kg/person in 2005). Denmark in 2015 (822 kg/person) provided the highest amount of MSW per capita, accompanied by Germany, Cyprus and Switzerland [37].

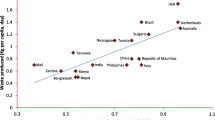

Between 1995 and 2015, the quantity of waste produced in the EU remained at about the same amount, with some variations during this time. However, standardised trends in the generation of MSW across countries were not observed during the same time, with decreasing trends in 10 countries and growing trends in 21 countries (Fig. 1A, [38]). Amongst the various MSW disposal alternatives, 69 million tonnes of waste reusing and recycling has been the first processing option at EU level, followed by 62 million tonnes of landfilling, incineration of 64 million tonnes (with or without energy recovery), and 40 million tonnes of composting. The major producers of MSW are Germany (51 million tonnes), France (33 million tonnes), the United Kingdom (32 million tonnes) and Italy (30 million tonnes). Significant volumes of unused waste are disposed of every year, primarily in Spain (11 million tonnes), France (9 million tonnes) and Italy (8 million tonnes). Germany is the leading country (16 million tonnes) in terms of incineration, followed by France (12 million tonnes) and the UK (10 million tonnes).

Directive 31/1999 on landfills demanding Member States to minimise the quantity of biodegradable MSW entering landfills has directed to major improvements in the management framework in order to prevent landfilling by means of increased recycling, incineration or composting (including fermentation) (Fig. 1B, [38]). Due to the recycling of materials, such as paper, glass, cardboard, textiles, plastics and metals in many countries, overall increase in the recycling rate has risen. As a result, the volume of recycled waste in the EU is increased. (25 million tonnes 52 kg/capita in 1995 to 69 million tonnes 137 kg/capita in 2015).

Incineration of waste in this time has also risen gradually. From 32 million tonnes in 1995 (67 kg/person) to 64 million tonnes in 2015 (128 kg/person), the volume of MSW incinerated in the EU has increased. The total volume of MSW landfilled in the EU has thus decreased by 84 million tonnes from 146 million tonnes (302 kg/person) to 62 million tonnes (120 kg/person) over the same time period, or 58%. As a result, the percentage of MSW sent to landfills decreased significantly in both the EU and European Environment Agency member countries from 1995 to 2015. Specifically, the landfilling rate dropped from 64.3% to 25.7% in the EU and from 63.4% to 25.7% in the EEA member countries.

Figure 2A, [38] provides quantitative details on the type of waste management operations working in different countries in 2015. Virtually no MSW is sent to landfills in Sweden, Switzerland, Denmark, Belgium or Norway. Malta, Greece and Croatia, on the other hand, are still landfilling more than 80% of their generated MSWs. Some Member States (e.g. Denmark, Belgium and Italy) had very high recycling rates, showing recycling waste as a main resource, whilst in others the majority of waste was landfilled (e.g. Greece, Romania and Bulgaria). In 2015, the volume of landfilled MSW ranged from 3.6 kg per capita in Sweden, 1.3 kg per capita in Germany, 3.8 kg per capita in Belgium to 415 kg per capita in Greece, 561 kg per capita in Malta, 476 kg per capita in Cyprus and with an average of 119 kg per capita in the EEA [13, 15]. In the period 1995–2015, most countries decreased landfilling, where six countries have increased the quantity of waste sent to landfills. The improvements in MSW’s care measures at the EU level during 1995 and 2015 are shown in Fig. 2B, [38]. A substantial decline in waste landfill shares can be observed, accompanied by a rise in recycling, composting and incineration shares. Thus, between 1995 and 2015, recycled MSW share increased from 11% to 29%.

Table 1 shows the amount of MSW produced per person in the EU in 1995, 2015 and 2020. Nearly half a tonne of waste was generated annually per person on average (470 kg/person in 1995 and 505 kg/person in 2020). The country with the largest per capita production of MSW was Austria (834 kg per person), followed by Denmark (814 kg/person) and Luxembourg (790 kg/person). Romania, on the other hand, produced the least quantity of MSW per person (287 kg/person), followed by Poland (346 kg/person) and Hungary (403 kg/person). The variations are a reflection of varying consumption patterns and levels of economic prosperity, but they also rely on how MSW is gathered and managed. There are regional variations in the amount of waste from administration, trade and commerce that is gathered and managed alongside home waste. Since 2015, the amount of MSW produced each year in the EU has increased.

In the EU, the total quantity of waste recovered through recycling, backfilling or incineration with energy recovery increased by 29.4% from 870 million tonnes in 2004 to 1,164 million tonnes in 2020. Consequently, the share of such recovery methods in overall waste treatment rose from 45.9% to 59.1% during the same period. The amount of waste disposed of decreased by 21.3%, from 1,027 million tonnes in 2004 to 806 million tonnes in 2020, resulting in a decrease in the share of disposal from 54.1% to 40.9% in total waste treatment. In 2020, over half (59.1%) of the total waste in the EU underwent recovery operations, with recycling accounting for 39.9%, backfilling for 12.7% and energy recovery for 6.5%. The remaining 40.9% was either landfilled (32.2%), incinerated without energy recovery (0.5%) or disposed of through other means (8.2%). Notably, significant variations were observed amongst EU Member States in their utilisation of these treatment methods. The EU treated a total of 74.3 million tonnes of hazardous waste in 2020, with more than two-third of it treated in Germany, Bulgaria, France and Sweden. In the same year, 46.7% of the hazardous waste treated in the EU was recovered, with 38.5% through recycling or backfilling (equivalent to 64 kg per inhabitant) and 8.3% through energy recovery (14 kg per inhabitant). The remaining 53.3% was incinerated without energy recovery (5.8% or 9.7 kg per inhabitant), landfilled or subjected to land treatment (22.1% or 36.9 kg per inhabitant), or disposed of through other means (25.3% or 42.3 kg per inhabitant) [38].

Recent trends in municipal waste treatment in EU

Table 2 presents the comparative analysis of MSW treatment in the EU for the years 1995 and 2020. The data is categorised by treatment methods, including in kg per capita and million tonnes [38]. Figure 3 depicts the total amount of waste produced in the EU and the quantity of waste per type of treatment, which includes, landfill, incineration, material recycling, composting and others [38]. Despite the fact that the EU is producing more waste, less municipal waste is being landfilled overall. From 121 million tonnes (286 kg per person) in 1995 to 52 million tonnes (115 kg per person) in 2020, there was a 69 million tonnes or 58% decline in the amount of MSW that was landfilled in the EU during the reference period. This represents 4.0% decline on an annual average. Landfilling has decreased from 2005 to 2020 by an average of 3.4% per year. Therefore, the rate of landfilling in the EU decreased from 61% in 1995 to 23% in 2020. In EU, Germany recycled most municipal waste with 66% approximated recycling rate in 2020. Only eight EU countries have recycling rates that are higher than 50%, whilst others, including Malta, Romania and Cyprus, have rates that are less than 20% (Fig. 4, [38]). This highlights the wide disparities in the EU’s municipal waste recycling rates.

This decrease can be partially due to the enforcement of European legislation on packaging and packaging waste (Directive 62/1994). Member States were required to recover at least 50% of all packaging used in the market by the year 2001. The volume of packaging waste separately collected increased significantly due to the revised objective recovery of 60% to be attained by the 31st of December 2008. Packaging waste approximately 65% must be recycled by 31 December 2025. Moreover, the landfill-related provisions of Directive 31/1999 required Member States to reduce the proportion of municipal waste that is biodegradable waste going to landfills from 75% to 50% by July 2006 to 16 July 2009 and to 35% to 10% by 16 July 2016 until 2023. This reduction was calculated based on the total volume of biodegradable waste generated in 1995. The Directive has caused countries to implement various measures, including pre-treatment and incineration like biological and mechanical treatment and composting to prevent disposing of the organic portion of municipal waste in landfills.

Thus, at an average rate of 4.3% per year, the amount of recycled waste increased from 37 million tonnes (87 kg per person) in 1995 to 107 million tonnes (241 kg per person) in 2020. Overall, the percentage of municipal waste that was recycled increased from 19% to 48%. The ambitious Circular Economy Package, which the European Commission endorsed, contains updated waste-related measures with a higher standardised goal for the packaging and municipal waste recycling and lower restrictions for municipal waste landfilling.

In the reference period, waste incineration has also steadily increased, though not as much as composting and recycling. In the EU, municipal waste incineration since 1995 has increased by 105% or 31 million tonnes and consisting of 61 million tonnes in 2020. Thus, the amount of incinerated municipal waste per capita increased from 70 to 137 kg. Waste sorting and mechanical–biological treatment (MBT) are not explicitly covered. An additional final treatment is necessary for these pre-treatments. Substantially, the amounts provided for MBT or sorting should be reported based on the following final treatment processes. Nevertheless, the distribution of these amounts amongst the categories of four treatment processes (composting, recycling, incineration and landfilling) varies greatly, and some countries only report on the first (pre-) treatment stage.

Energy recovery and existing waste-to-energy plants in EU

The WtE plants are specifically designed for mixed MSW incineration, but these facilities also have the capacity to incinerated other wastes including, refuse derived fuel (RDF) wood waste, paper waste, etc. The amount of non-MSW incinerated in MSW-dedicated WtE plants cannot be fully estimated from the data on the plants that are currently available. This analyses results indicate that there were 504 WtE plants in Europe in 2020 (excluding plants for incineration hazardous waste). In 2020, 61 million tonnes (137 kg per capita) of total incineration capacity was estimated. Detail information on the number of plants, waste treated and their capacity are shown in Table 3. France has the most WtE (124) plants, even though Germany has 100 plants with a higher capacity for waste incineration. Whilst the annual capacity of incineration of waste in Europe is around 170,000 tonnes, in some countries (like, France, Switzerland, Denmark and Norway) smaller plants are more common (80,000–120,000 tonnes/year), whilst in countries (like, Austria, Spain, Hungary, Portugal and Netherlands), a very large plants are common (above 400,000 tonnes/year).

The primary energy production in Europe in 2020 was distributed across a variety of energy sources, with renewable energy sources accounting for the largest percentage (40.8%) of total primary energy output, followed by nuclear heat (30.5%), solid fossil fuels (14.6%), natural gas (7.2%), oil and petroleum derivatives (3.7%) and non-renewable waste (2.4%).

Even though from a relatively low base, the supply of primary energy from waste is increasing. The total energy produced from waste in 2019 was 41.2 MTOE (million tonnes of oil equivalent), with nearly half of that total was accounted by MSW. This includes non-renewable waste, MSW renewable and non-renewable waste and industrial waste. This statistic represents around 2.5% of the EU’s overall energy supply. According to the International Energy Agency (IEA), in EU from renewable MSW, the majority of energy recovery is used to generate electricity (22.7 MWh in 2018) in electricity-only facilities or either in combined heat and power (CHP). Data on electricity production at waste facilities reveal notable differences across EU state members. Germany (7.1 MWh) has the largest generation from waste in 2018, followed by the United Kingdom, France, Italy and the Netherlands having generation 4.4 MWh, 2.5 MWh, 2.4 MWh and 2.2 MWh respectively (Fig. 5, [38]). In 2021, Germany had the greatest installed capacity of municipal waste energy plants in Europe followed by UK, Sweden, France, Italy, Netherlands and Austria (Fig. 6, [38]).

Greenhouse gas (GHG) emissions from WtE plants

The incineration of one metric tonne of residual waste in a conventional WtE facility results in the generation of approximately one metric tonne of total CO2 emissions at the stack. However, it is important to differentiate CO2 emissions from WtE into two categories based on their sources:

-

1.

Fossil CO2: This type of CO2 primarily originates from the combustion of fossil-based waste materials, such as residual plastics.

-

2.

Biogenic CO2: This category encompasses CO2 emissions derived from the biogenic fraction of various waste streams, including residual paper and cardboard, wood, leather, food and contaminated green residues that cannot be recycled.

Despite increasing separate collection efforts for biowaste from households across Europe and numerous initiatives aimed at achieving higher recycling rates, significant quantities of biodegradable matter still persist in residual waste streams. Whilst separately collected biowaste is primarily treated in dedicated facilities like composting or anaerobic digestion plants, the residues resulting from these processes can be effectively treated in WtE facilities.

As per the guidelines provided by the Intergovernmental Panel on Climate Change (IPCC) [39], biogenic CO2 is considered carbon neutral and should not be accounted for separately. Therefore, in line with conventional practices in Life Cycle Assessment modelling [40,41,42,43], the climate burden associated with biogenic CO2 is considered to be zero.

The proportion of fossil and biogenic CO2 emissions depends on the composition of residual waste. On average, at the EU level, WtE plants monitor approximately 60% of biogenic CO2 emissions (represented by the green bar in Fig. 7), whilst the remaining 40% is fossil CO2 emissions (grey bar in Fig. 7). These figures have been documented by WtE plant operators across Europe (including Sweden, Denmark, Germany, etc.) and are corroborated by a recent study conducted by the French Environment Agency (ADEME) [44].

In the future, the percentage of biogenic content in residual waste could potentially increase due to improved source separation of plastics and the growing presence of bio-based products in the market (e.g. paper for packaging, bioplastics, etc.). These factors could result in a higher concentration of biogenic CO2 in the flue gas. This aspect should be considered when making future estimations, as it may naturally reduce the carbon impact of the European WtE sector. Currently, with the 60% biogenic CO2 and 40% fossil CO2 split, the average emission factor for WtE stands at 400 kg CO2 eq per metric tonne of waste treated [45].

According to the European Environmental Agency’s annual GHG inventories [46], historically, the total fossil CO2 emissions from WtE plants account for 1% of all GHG sources in Europe. The cumulative effect of direct emissions (positive = burden) and avoided emissions (negative = savings) results in an overall negative balance of −620 kg CO2 eq per metric tonne of waste treated. This signifies that WtE contributes to an average savings of 620 kg CO2 eq. per metric tonne of waste treated. Waste-to-energy strategies exhibit significant economic benefits, offering optimal GHG mitigation potential and energy generation capabilities. Furthermore, advanced WtE technologies represent an emerging field in renewable energy production, presenting valuable opportunities for reducing greenhouse gas emissions. The integration of WtE with carbon capture and storage (CCS) techniques could enable waste to become a net zero or even net-negative emissions energy source [47]. For instance, in Europe alone, the integration of CCS with WtE facilities has the potential to capture approximately 60–70 million metric tonnes of carbon dioxide annually [45].

Advanced techniques for thermal conversion

Pyrolysis and gasification are promising technologies for the treatment of solid waste. Gasification is a process that converts solid waste into a gas mixture composed mainly of hydrogen, carbon monoxide and methane. The gas can be used as a fuel for electricity generation or as a chemical feedstock. Pyrolysis, on the other hand, is a thermal decomposition process that breaks down solid waste into smaller molecules in the absence of oxygen, producing a liquid or gas product that can be used as fuel or chemical feedstock [48, 49]. Both gasification and pyrolysis offer several advantages over traditional waste management methods, such as incineration and landfilling. They can reduce the volume of waste by up to 90% and produce energy and valuable by-products. Furthermore, they have lower emissions of pollutants, such as particulate matter and greenhouse gases, compared to incineration. However, their widespread adoption is still hindered by technological and economic challenges, such as high capital and operational costs and the lack of proper infrastructure for waste collection and sorting. Nonetheless, with further research and development, gasification and pyrolysis could become viable and sustainable solutions for the treatment of solid waste, contributing to a more circular and resource-efficient economy [50, 51].

Pyrolysis

Pyrolysis is a thermal process that involves the decomposition of organic material in the absence of oxygen. During pyrolysis, the organic material is heated to high temperatures of around 400–800 °C, resulting in the formation of gas, liquid and solid products. The solid product, known as char or biochar, is a carbon-rich material that can be used as a soil amendment or as a source of fuel. The liquid product, known as pyrolysis oil or bio-oil, is a complex mixture of organic compounds that can be further processed into transportation fuels or chemicals. The gas product, known as pyrolysis gas or syngas, is composed of hydrogen, carbon monoxide, methane and other trace gases, and can be used as a fuel. Pyrolysis is considered a promising technology for the treatment of a variety of waste streams, including MSW, biomass and plastics. It offers several advantages over traditional waste treatment technologies, such as incineration, including lower emissions of greenhouse gases and other pollutants, as well as the potential for energy recovery [52].

Pyrolysis of MSW has gained significant attention in Europe as a promising solution for the effective management of waste. In 2020, it is estimated that there were approximately 50–100 pyrolysis plants operating in Europe. It should be acknowledged, however, that the precise number of pyrolysis plants during that period might deviate from this estimate due to factors, such as new establishments, closures and potential changes in industry developments. Pyrolysis offers a potential solution to the problem of reducing greenhouse gas emissions from waste disposal, as the process generates significantly less emissions compared to traditional incineration. According to the European Environment Agency (EEA), the total capacity of pyrolysis plants for MSW treatment in 2018 in the EU was approximately 330,000 tonnes per year. In Germany, several large-scale pyrolysis plants have been established in recent years, with a total capacity of approximately 150,000 tonnes per year as of 2020. Other countries in Europe with significant pyrolysis capacity include the Netherlands, Denmark and Sweden [53]. Table 4 shows the existing MSW pyrolysis plants in some European countries with their capacity and energy output [54, 55].

Gasification

Gasification usually includes the fractional oxidation by air, steam and/or O2 of the products to produce a gas mixture consisting primarily of CO, CH4, CO2, H2O and N2, which may also be supplied as a chemical feedstock and more realistic energy carrier than heat [56, 57]. And it can also be:

-

Used in gas turbines or engines for combustion,

-

Transformed into liquid fuel, or

-

Reforming into hydrogen-rich gas.

In the gasifier, by many sequential steps, the feedstock is converted. First, the feedstock, with a subsequent regulated volume of oxygen or air (and steam for certain gasifiers), is homogenate into fine particulates and then injected into the gasifier. Feedstock passes through multiple temperature regions where a series of reactions takes place before extracting the formed syngas from the chamber. Usually, the temperatures vary from 1100 to 1800 degrees Fahrenheit in a gasifier [58]. Solid precipitate and residue is extracted from the reaction chamber’s rear. There are many primary variations in conventional gasification systems, each with benefits for unique feedstock or product applications. The fundamental design of each form of system is constructed around the feedstock injection reaction chamber, but each has a varied heating mechanism, air inlet and ejection position for syngas, as shown in Fig. 8. Figure 9 shows the schematic diagram of gasification process [59].

Over the past few years, there has been significant progress in the WtE commercialization projects that utilise gasification technology. These initiatives are in various stages of development, ranging from early development to pilot-scale testing, and some have received approval for commercialization in multiple EU countries [60]. Table 5 presents a compilation of waste gasification plants operating at a commercial scale across the Europe [61,62,63].

Overall comparison of pyrolysis and gasification technology

Pyrolysis and gasification are both advance thermal conversion processes, used to convert biomass or other organic materials into useful products such as fuel or chemicals. In terms of efficiency, gasification is generally considered more efficient than pyrolysis because it can produce a higher percentage of gas and less char. Gasification also tends to produce cleaner gases than pyrolysis, which contain more impurities. However, pyrolysis is more versatile than gasification in terms of the types of feedstocks that can be used. Pyrolysis can handle a wider range of materials, including high-moisture feedstocks, and can produce a wider range of products, including bio-oil, which can be used as a direct substitute for fossil fuels [64, 65].

Ultimately, the choice between gasification and pyrolysis depends on the specific needs and goals, as well as factors, such as the availability and cost of feedstocks, the desired products and the efficiency requirements. Table 6 presents a comparison of these techniques [66, 67].

Conclusion

Due to population growth and industrialization, the production of solid waste increases day by day. Globally, the use of energy, water and mainly the waste production, is becoming an ever more important issue. The increasing volume of waste produced, coupled with a high rate of disposal in landfills and a low rate of waste reduction, necessitates the implementation of effective waste management practices. On the basis of statistical and geospatial analysis techniques, the current study evaluated the condition of waste resource energy recovery and the possibility for further production of solid waste as a renewable energy source in Europe. Over the last few years, waste reforms and legislative measures have directed major changes in waste management: a substantial rise in waste reusing and recycling, a decline in the rate of landfilling and an increase in energy recovery.

A study of prevailing WtE plants found that in 2020 in Europe, there were 504 plants, with 61 million tonnes of total incineration capacity was estimated. The findings show that in most European countries, the utilisation of MSW as an energy resource is under-exploited. In addition, through chemical processing (pyrolysis, gasification), solid waste can also be recycled into useful products (liquids and gases). The use of pyrolysis and gasification technology for MSW treatment has gained attention due to its potential for reducing waste volume and producing valuable products. However, the high capital and operational costs, complex nature of the process and potential environmental impacts are some of the challenges associated with these technologies. To ensure sustainable MSW management, a combination of different waste management approaches and technologies, including pyrolysis and gasification, should be considered to maximise waste reduction, recovery of valuable resources and minimise environmental impacts.

The analysis also showed that 225.7 million metric tonnes of municipal waste was generated in EU, with Germany recycled most municipal waste with 66% approximated recycling rate. 58% decline is observed in the amount of MSW that was landfilled, which represents 4.0% decline on an annual average. The findings also showed that only eight EU countries have recycling rates that are higher than 50%, whilst others, including Malta, Romania and Cyprus, have rates less than 20%. The MSW utilisation for energy production is increasingly considered as a viable approach to promote the transition towards a circular economy. However, for this approach to be successful, waste management strategies prioritising prevention, reuse and recycling must be in place. In addition, a proper balance between recycling and waste incineration needs to be established, whilst caution must be exercised in managing the potential risk of waste diversion towards incineration rather than recovery and recycling.

References

Van JCF, Tham PE, Lim HR, Khoo KS, Chang JS, Show PL (2022) Integration of internet-of-things as sustainable smart farming technology for the rearing of black soldier fly to mitigate food waste. J Taiwan Inst Chem Eng. https://doi.org/10.1016/j.jtice.2022.104235

Stoeva K, Alriksson S (2017) Influence of recycling programmes on waste separation behaviour. Waste Manage 68:732–741. https://doi.org/10.1016/j.wasman.2017.06.005

Wan C, Shen GQ, Choi S (2017) A review on political factors influencing public support for urban environmental policy. Environ Sci Policy 75:70–80. https://doi.org/10.1016/j.envsci.2017.05.005

Wan C, Shen GQ, Choi S (2018) Differential public support for waste management policy: the case of Hong Kong. J Clean Prod 175:477–488. https://doi.org/10.1016/j.jclepro.2017.12.060

Pietzsch N, Ribeiro JLD, de Medeiros JF (2017) Benefits, challenges and critical factors of success for zero waste: a systematic literature review. Waste Manage 67:324–353. https://doi.org/10.1016/j.wasman.2017.05.004

Monte MC, Fuente E, Blanco A, Negro C (2009) Waste management from pulp and paper production in the European Union. Waste Manage 29(1):293–308. https://doi.org/10.1016/j.wasman.2008.02.002

Mariyam S, Shahbaz M, Al-Ansari T, Mackey HR, McKay G (2022) A critical review on co-gasification and co-pyrolysis for gas production. Renew Sustain Energy Rev 161:112349. https://doi.org/10.1016/j.rser.2022.112349

Matheson T (2022) Disposal is not free: fiscal instruments to internalize the environmental costs of solid waste. Int Tax Public Finance 29(4):1047–1073. https://doi.org/10.1007/s10797-022-09741-1

Ma Y, Preveniou A, Kladis A, Pettersen JB (2022) Circular economy and life cycle assessment of alumina production: simulation-based comparison of Pedersen and Bayer processes. J Clean Prod 366:132807. https://doi.org/10.1016/j.jclepro.2022.132807

Hazarika J, Khwairakpam M (2022) Valorization of industrial solid waste through novel biological treatment methods—integrating different composting techniques. Advanced organic waste management sustainable practices and approaches. Elsevier, Amsterdam. https://doi.org/10.1016/B978-0-323-85792-5.00012-5

Hansen W, Christopher M, Verbuecheln M (2002) EU waste policy and challenges for regional and local authorities. Ecol. Inst. Int. Eur. Environ. Policy, Berlin, Germany, p 4

Sileryte R, Wandl A, van Timmeren A (2022) The responsibility of waste production: comparison of European waste statistics regulation and Dutch National Waste Registry. Waste Manage 151:171–180. https://doi.org/10.1016/j.wasman.2022.07.022

Szaniawski J (2015) Alexandra. In: Szaniawski J (ed) The cinema of Alexander Sokurov. Columbia University Press, New York, pp 233–249

Arias O, Pulgar JA, Soto M (2022) Application of organic wastes to soils and legislative intricacies in a circular economy context. Clean Technol Environ Policy 24:1871–1888. https://doi.org/10.1007/s10098-022-02293-2

Zhamiyeva R, Sultanbekova G, Balgimbekova G, Mussin K, Abzalbekova M, Kozhanov M (2022) Problems of the effectiveness of the implementation of international agreements in the field of waste management: the study of the experience of Kazakhstan in the context of the applicability of European legal practices. Int Environ Agreements Polit Law Econ 22(1):177–199. https://doi.org/10.1007/s10784-021-09549-0

Ramm K (2022) Considerations related to the application of the EU water reuse regulation to the production of snow from reclaimed water. Circ Econ Sustain 2(2):569–587. https://doi.org/10.1007/s43615-021-00075-4

Duquennoi C, Martinez J (2022) European Union’s policymaking on sustainable waste management and circularity in agroecosystems: The potential for innovative interactions between science and decision-making. Front Sustain Food Syst 6:327. https://doi.org/10.3389/fsufs.2022.937802

Friant MC, Vermeulen WJ, Salomone R (2021) Analysing European Union circular economy policies: Words versus actions. Sustain Prod Consum 27:337–353. https://doi.org/10.1016/j.spc.2020.11.001

Kurniawan TA, Maiurova A, Kustikova M, Bykovskaia E, Othman MHD, Goh HH (2022) Accelerating sustainability transition in St. Petersburg (Russia) through digitalization-based circular economy in waste recycling industry: a strategy to promote carbon neutrality in era of Industry 4.0. J Clean Prod 363:132452. https://doi.org/10.1016/j.jclepro.2022.132452

Ashfaq A, Iqbal Z, Ahmad K, Arslan M, Iftikhar M, Elghareeb EM (2022) Hazard of selenium metal contamination in vegetables grown in municipal solid waste amended soil: assessment of the potential sources and systemic health effects. Agric Water Manage 271:107768. https://doi.org/10.1016/j.agwat.2022.107768

Giorgi S, Lavagna M, Wang K, Osmani M, Liu G, Campioli A (2022) Drivers and barriers towards circular economy in the building sector: stakeholder interviews and analysis of five European countries policies and practices. J Clean Prod 336:130395. https://doi.org/10.1016/j.jclepro.2022.130395

Chioatto E, Sospiro P (2022) Transition from waste management to circular economy: the European Union roadmap. Environ Dev Sustain 25:249–276. https://doi.org/10.1007/s10668-021-02050-3

Bottausci S, Midence R, Serrano-Bernardo F, Bonoli A (2022) Organic waste management and circular bioeconomy: a literature review comparison between Latin America and the European Union. Sustainability 14(3):1661. https://doi.org/10.3390/su14031661

Colelli FP, Croci E, Pontoni FB, Zanini SF (2022) Assessment of the effectiveness and efficiency of packaging waste EPR schemes in Europe. Waste Manage 148:61–70. https://doi.org/10.1016/j.wasman.2022.05.019

Alam P et al (2022) Energy generation and revenue potential from municipal solid waste using system dynamic approach. Chemosphere 299:134351. https://doi.org/10.1016/j.chemosphere.2022.134351

Huang B et al (2022) Recent progress on the thermal treatment and resource utilization technologies of municipal waste incineration fly ash: a review. Process Saf Environ Prot 159:547–565. https://doi.org/10.1016/j.psep.2022.01.018

Piebalgs MOA (2022) Energy security meets the circular economy: a stronger case for sustainable biomethane production in the EU. Robert Schuman Centre

Milanović T, Savić G, Martić M, Milanović M, Petrović N (2022) Development of the waste management composite index using DEA method as circular economy indicator: the case of European Union countries. Polish J Environ Stud 31(1):771–784. https://doi.org/10.15244/pjoes/139896

Minelgaitė A, Liobikienė G (2019) Waste problem in European Union and its influence on waste management behaviours. Sci Total Environ 667:86–93. https://doi.org/10.1016/j.scitotenv.2019.02.313

Somlai C, Bullock C, Gallagher J (2023) Plastic packaging waste in Europe: addressing methodological challenges in recording and reporting. Waste Manag Res 41(6):1134–1143. https://doi.org/10.1177/0734242X221142192

Tauš P, Šimková Z, Cehlár M, Krajňáková I, Drozda J (2023) Fulfillment of EU goals in the field of waste management through energy recovery from waste. Energies 16(4):1913. https://doi.org/10.3390/en16041913

Psomopoulos CS, Kiskira K, Kalkanis K, Leligou HC, Themelis NJ (2022) The role of energy recovery from wastes in the decarbonization efforts of the EU power sector. IET Renew Power Gener 16(1):48–64. https://doi.org/10.1049/rpg2.12315

Altieri VG, De Sanctis M, Sgherza D, Pentassuglia S, Barca E, Di Iaconi C (2021) Treating and reusing wastewater generated by the washing operations in the non-hazardous plastic solid waste recycling process: advanced method vs. conventional method. J Environ Manage 284:112011. https://doi.org/10.1016/j.jenvman.2021.112011

Iordache M et al (2021) Temporal evolution of greenhouse gas emissions in European Union (Eu-28): a perspective on Romania. Smart Energy Sustain Environ 24(2):43–58. https://doi.org/10.46390/j.smensuen.24221.438

Fischer C (2011) The development and achievements of EU waste policy. J Mater Cycles Waste Manage 13(1):2–9. https://doi.org/10.1007/s10163-010-0311-z

van der Linden A, Reichel A (2020) Bio-waste in Europe: turning challenges into opportunities, no. 04. [Online]. Available https://www.eea.europa.eu/publications/bio-waste-in-europe. Accessed 4 Mar 2023

Du Y, Ju T, Meng Y, Lan T, Han S, Jiang J (2021) A review on municipal solid waste pyrolysis of different composition for gas production. Fuel Process Technol 224:107026. https://doi.org/10.1016/j.fuproc.2021.107026

“Eurostat: Environmental Data Centre on waste—European Environment Agency.” https://www.eea.europa.eu/themes/waste/links/eurostat-environmental-data-centre-on-waste. Accessed 25 July 2022

“IPCC—task force on national greenhouse gas inventories,” May 30, 2023

Amin M et al (2022) Hydrogen production through renewable and non-renewable energy processes and their impact on climate change. Int J Hydrogen Energy 47(77):33112–33134. https://doi.org/10.1016/j.ijhydene.2022.07.172

Amin M, Shah HH (2022) Effect of absorption time for the preparation of activated carbon from wasted tree leaves of Quercus alba and investigating life cycle. C J Carbon Res 8:57

Amin M, Chung E (2022) Effect of different activation agents for activated carbon preparation through characterization and life cycle assessment. Int J Environ Sci Technol 20:7645–7656. https://doi.org/10.1007/s13762-022-04472-6

Amin M et al (2022) Conversion of waste biomass into activated carbon and evaluation of environmental consequences using life cycle assessment. Appl Sci 12:5741

Vigier E, Curt C, Curt T, Arnaud A, Dubois J (2019) Joint analysis of environmental and risk policies: methodology and application to the French case. Environ Sci Policy 101:63–71. https://doi.org/10.1016/j.envsci.2019.07.017

CEWEP (2022) Waste-to-energy climate roadmap the path to carbon negative, pp 1–20

UNFCCC (2022) Canada. 2022 National Inventory Report (NIR). Natl. Invent. Reports, May 2022. [Online]. Available https://unfccc.int/documents/461919

Yamada K, Ii R, Yamamoto M, Ueda H, Sakai S (2023) Japan’s greenhouse gas reduction scenarios toward net zero by 2050 in the material cycles and waste management sector. J Mater Cycles Waste Manage. https://doi.org/10.1007/s10163-023-01650-7

Porshnov D (2022) Evolution of pyrolysis and gasification as waste to energy tools for low carbon economy. Wiley Interdiscip Rev Energy Environ 11(1):1–37. https://doi.org/10.1002/wene.421

Kavathia K, Prajapati P (2020) A review on biomass-fired CHP system using fruit and vegetable waste with regenerative organic Rankine cycle (RORC). Mater Today Proc 43:572–578. https://doi.org/10.1016/j.matpr.2020.12.052

Ngo PL, Udugama IA, Gernaey KV, Young BR, Baroutian S (2021) Mechanisms, status, and challenges of thermal hydrolysis and advanced thermal hydrolysis processes in sewage sludge treatment. Chemosphere 281:130890. https://doi.org/10.1016/j.chemosphere.2021.130890

Puricelli S, Cardellini G, Casadei S, Faedo D, van den Oever AEM, Grosso M (2021) A review on biofuels for light-duty vehicles in Europe. Renew Sustain Energy Rev 137(2019):110398. https://doi.org/10.1016/j.rser.2020.110398

Li C et al (2022) Pyrolysis of waste surgical masks into liquid fuel and its life-cycle assessment. Bioresour Technol 346(2021):126582. https://doi.org/10.1016/j.biortech.2021.126582

Ławińska O, Korombel A, Zajemska M (2022) Pyrolysis-based municipal solid waste management in Poland—SWOT analysis. Energies 15(2):510. https://doi.org/10.3390/en15020510

Sipra AT, Gao N, Sarwar H (2018) Municipal solid waste (MSW) pyrolysis for bio-fuel production: a review of effects of MSW components and catalysts. Fuel Process Technol 175:131–147. https://doi.org/10.1016/j.fuproc.2018.02.012

Hasan MM, Rasul MG, Khan MMK, Ashwath N, Jahirul MI (2021) Energy recovery from municipal solid waste using pyrolysis technology: a review on current status and developments. Renew Sustain Energy Rev 145:111073. https://doi.org/10.1016/j.rser.2021.111073

Chanthakett A, Arif MT, Khan MMK, Oo AMT (2021) Performance assessment of gasification reactors for sustainable management of municipal solid waste. J Environ Manage 291:112661. https://doi.org/10.1016/j.jenvman.2021.112661

Shah HH et al (2023) A review on gasi fi cation and pyrolysis of waste plastics. Front Chem 10:1–38. https://doi.org/10.3389/fchem.2022.960894

Wei J et al (2021) A review on reactivity characteristics and synergy behavior of biomass and coal co-gasification. Int J Hydrogen Energy 46(33):17116–17132. https://doi.org/10.1016/j.ijhydene.2021.02.162

Diao R, Lu H, Yang Y, Bai J, Zhu X (2022) Strategic valorization of bio-oil distillation sludge via gasification: a comparative study for reactivities, kinetics, prediction and ash deposition. Chem Eng J 433:134334. https://doi.org/10.1016/j.cej.2021.134334

Sajid M, Raheem A, Ullah N, Asim M, Ur Rehman MS, Ali N (2022) Gasification of municipal solid waste: progress, challenges, and prospects. Renew Sustain Energy Rev 168:112815. https://doi.org/10.1016/j.rser.2022.112815

Leckner B (2022) Hundred years of fluidization for the conversion of solid fuels. Powder Technol 411:117935. https://doi.org/10.1016/j.powtec.2022.117935

Santos SM, Assis AC, Gomes L, Nobre C, Brito P (2022) Waste gasification technologies: a brief overview. Waste 1(1):140–165. https://doi.org/10.3390/waste1010011

IEA Bioenergy: Task 33, “Status report on thermal gasification of biomass and waste 2021,” IEA Bioenergy, February 2022

Im-orb K, Wiyaratn W, Arpornwichanop A (2018) Technical and economic assessment of the pyrolysis and gasification integrated process for biomass conversion. Energy 153:592–603. https://doi.org/10.1016/j.energy.2018.04.049

Raheem A, He Q, Ding L, Dastyar W, Yu G (2022) Evaluating performance of pyrolysis and gasification processes of agriculture residues-derived hydrochar: effect of hydrothermal carbonization. J. Clean. Prod. 338:130578. https://doi.org/10.1016/j.jclepro.2022.130578

Velghe I, Carleer R, Yperman J, Schreurs S (2011) Study of the pyrolysis of municipal solid waste for the production of valuable products. J Anal Appl Pyrolysis 92(2):366–375. https://doi.org/10.1016/j.jaap.2011.07.011

Malinauskaite J et al (2017) Municipal solid waste management and waste-to-energy in the context of a circular economy and energy recycling in Europe. Energy 141:2013–2044. https://doi.org/10.1016/j.energy.2017.11.128

Acknowledgements

The authors would like to thank the Department of Engineering and the laboratory of Chemical Process Engineering, University of Sannio, Piazza Roma 21, Benevento, 82100, Italy.

Author information

Authors and Affiliations

Contributions

All authors (HHS, MA and FP) participated in all stages of this work, from conception to this review and final submission. We highlight some important stages: conceptualization, methodological development, data and results analysis, writing, drafting and original article, review and final edition.

Corresponding author

Ethics declarations

Conflict of interest

Authors have declared that no competing interests exist.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shah, H.H., Amin, M. & Pepe, F. Maximizing resource efficiency: opportunities for energy recovery from municipal solid waste in Europe. J Mater Cycles Waste Manag 25, 2766–2782 (2023). https://doi.org/10.1007/s10163-023-01733-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-023-01733-5