Abstract

The indiscriminate use of petroleum-based polymers and plastics for single-use food packaging has led to serious environmental problems due the non-biodegradable characteristics. Thus, much attention has been focused on the research of new biobased and biodegradable materials. Yeast and fungal biomass are low-cost and abundant sources of biopolymers with highly promising properties for the development of biodegradable materials. This study aimed to select a preparation method to develop new biodegradable films using the whole biomass of Paecilomyces variotii subjected to successive physical treatments including ultrasonic homogenization (US) and heat treatment. Sterilization process had an important impact on the final filmogenic dispersion and mechanical properties of the films. Longer US treatments produced a reduction in the particle size and the application of an intermediate UT treatment contributed favorably to the breaking of agglomerates allowing the second US treatment to be more effective, achieving an ordered network with a more uniform distribution. Samples that were not filtrated after the sterilization process presented mechanical properties similar to plasticized materials. On the other hand, the filtration process after sterilization eliminated soluble and hydratable compounds, which produced a reduction in the hydration of the films.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Food packaging is mainly used to protect food from the environment and to provide consumers with information about ingredients and nutritional values. Materials traditionally used for food packaging include glass, metal, paper and cardboard, and plastics. The use of plastics over glass and metals has continued to increase due to their good material properties and low cost (Tang et al. 2012; Coma et al. 2019). For this reason, in recent years, much attention has been focused on research to replace petroleum-based commodity plastics, cost-effectively, with biodegradable materials offering competitive mechanical properties (Vieira et al. 2011). Biopolymers, such as polysaccharides and proteins, have been considered the most promising materials for this purpose (Campos et al. 2011; Vieira et al. 2011; Janjarasskul and Krochta 2010; Pan et al. 2014). Biodegradable films and coatings made from these materials may be used to cover food surfaces. They can serve as barriers to control the transfer of moisture, oxygen, carbon dioxide, lipids, and flavour components, thus preserving the quality of food and extending its shelf life (Bourtoom 2008). Among other remarkable properties, they can be used as carriers of functional agents, as antimicrobials or antioxidant compounds, and to improve appearance and handling (Siracusa et al. 2008).

Film characteristics are dependent on the structure and chemical properties of the biopolymers that make up the film. Polysaccharides and proteins interact strongly with water; therefore, films made of these biopolymers are hydrophilic films. These films also include those obtained from the whole cell biomass of microorganisms such as yeast, which contain both polysaccharides and proteins (Delgado et al. 2016; 2018a; 2018b). Polysaccharides and proteins are generally used for their ability to establish polymer interactions and create a continuous network responsible for the functional properties of biodegradable films (Giancone et al. 2009; Kuorwel et al. 2011).

Yeast and fungal biomass are low-cost and abundant sources of biopolymers with highly promising properties for the development of biodegradable materials (Cottet et al. 2020). Their properties make them a remarkably interesting system for the development of biodegradable films with potential applications in food packaging. Also, they could be obtained as a residue from some industrial processes such as the brewing industry (Kadimaliev et al. 2015; Peltzer et al. 2018) or other biotechnological processes (Guimarães et al. 2006) where the biomass (cells or mycelia) is discarded after obtaining the final product. Several research works have investigated the use of yeasts and their constituents as film-forming materials (Novak et al. 2012; Delgado et al. 2016; 2018a; 2018b), but in contrast, there is not much specific literature on the use of filamentous fungi as film-forming agents.

Filamentous fungi biomass is mainly used for human consumption, and fungal enzymes and bioactive compounds production in the medical and food industry (Choque et al. 2015; Meyer et al. 2016; López de León et al. 2019). New investigations have demonstrated that the use of mycelial structure is promising for new application areas, such as, the fabrication of structures that contain a vegetal fibre filler, glued by fungal mycelium (Santhosh et al. 2018; Sun et al. 2019; Cottet et al. 2020). Additionally, the development of sustainable products by using fungi biomass was described for the textile, packaging, and automotive industries (Cerimi et al. 2019). Recent studies by our research group have shown that it is possible to obtain films from mycelia of Penicillium nalgiovense, Mucor hiemalis, and Aspergillus niger by casting of filmogenic dispersions (Sanchez-Díaz et al. 2023). This study showed that the properties of the films, such as colour and mechanical properties, strongly depend on the fungal strain they are made of. Many authors have reported that the formation of films based on isolated and purified β-glucan from brewer’s yeast and plant β-glucan from oats is possible (Thammakiti et al. 2004; Novak et al. 2012; Razzaq et al. 2016). Both, filamentous fungi, and yeasts are important sources of β-glucans. Kyanko et al. (2013) investigated and characterized the total dietary fibre, β-glucan, protein, and RNA content of 37 non-toxic filamentous fungal strains isolated from various sources. Paecilomyces variotii presented the highest content of β-glucan (23.8 ± 2.4% w/w) and total dietary fibre (51.7 ± 5.5% w/w) among all filamentous fungi studied. These results suggested the potential use of this fungus as a film-forming agent.

The genus Paecilomyces was split from Penicillium by Bainier in 1907 based on their differences in phialide shape and conidial colour. Paecilomyces species are important as soil fungi and insect pathogens. Only two species are commonly isolated from foods: Paecilomyces variotii and Paecilomyces lilacinus (Pitt and Hocking 2009). P. variotii has not been reported as a mycotoxin producer and is used in the food industry as a producer of enzymes (Pitt and Hocking 2009). Like other hyaline fungi species, P. variotii is classified as a medium-risk BSL2 group by the Centres for Disease Control and Prevention (CDC), and the National Institutes of Health (NIH) (Meechan and Potts 2020). This classification includes pathogens that can cause disease in humans and animals, but do not pose a serious threat to the health of laboratory personnel, the human population, domestic animals, or the environment (Kojima et al. 2020) so that production could be scaled up with appropriate safety measures without major complications.

Traditionally, the most common approach to developing new biodegradable materials has been to purify biopolymers of interest from their original biomass by physical or chemical modification to improve their ability to form films. In this work, the whole biomass of Paecilomyces variotii is used, thus this novel approach contributes to a more efficient process with less waste.

Films derived from biopolymers are usually fragile and brittle, so they require the addition of plasticizers to improve their functional properties and meet industry requirements (Vieira et al. 2011; Farahnaky et al. 2013). Therefore, it is important to study the effect of plasticizers in polymer matrices. Glycerol is the most used plasticizer in biopolymer-based films due to its suitable properties of miscibility and low cost (Delgado et al. 2018b).

The aim of this study was to select a preparation method to develop a new biodegradable film using the whole biomass of Paecilomyces variotii subjected to successive physical treatments including ultrasonic homogenization and heat treatment. Functional characterization of the material was carried out, examining the thermal, mechanical, hydration, and water vapour barrier properties of the resulting films.

Materials & methods

Materials

Paecilomyces variotii was obtained from the fungal culture collection of the Food Mycology Laboratory of National University of Quilmes. The strain was reactivated by growing it for 5 days at 25 °C in potato dextrose agar medium (PDA, Britania, Argentina). The reagents and salts used in this work were of analytical grade.

Production of fungal biomass

The conidia production was carried out in Malt Extract Agar (MEA) plates with incubation of 5 days at 37 °C. The conidia formed were collected and a suspension in sterile distilled water was performed to inoculate 250 ml of Yeast Extract Sucrose (YES) broth at a concentration of 105 conidia/ml. The cultures were incubated in a SONTEC OS22 orbital shaker (Sontec Científica, Buenos Aires, Argentina) at 37ºC, with shaking at 135 rpm, for 5 days. The formed biomass was collected by vacuum filtration using Whatman Nº1 filter paper, to eliminate the growth medium Then, two washes were performed with sterile distilled water, and dry weight was determined in triplicate in an oven at 105 °C for 2 h, which value resulted in 10 ± 1% of solids. The filtered biomass was stored at -18 °C.

Preparation of fungal dispersions and film development

For the preparation of fungal dispersion, two methodologies were performed. In the first one, a 3% dry weight/volume dispersion was prepared using the filtered biomass and coded as “Treatment 1” (T1). Then, the second one was performed using 100 g of filtered biomass in distilled water, these dispersions were coded as “Treatment 2” (T2). T2 was assayed for the sterilization of wet biomass with a non-specific relation of dry biomass to water. For both methodologies, a standard sterilization heat treatment (121 °C, 15 min) was performed. The T1 dispersion was transferred to a plastic vessel for further treatment by ultrasound (US) and high-speed homogenization (UT). For the dispersion T2, after the heat treatment, the biomass was filtered again, and the dry weight was determined for the preparation of a 3% dry weight/volume (%wt) dispersion, then it was transferred to a plastic vessel for further treatment by UT and US (Sanchez-Díaz et al. 2023). The cell disruption procedure was developed by different conditions, using a VCX-750 ultrasonic processor (Sonics and Materials, Inc., Newtown, CT U.S.A), at a power of 100%. The working temperature was controlled with a thermocouple placed inside the vessel. A limit of 40 °C was established, since above this temperature the collapse of the bubbles that occur during cavitation is weaker, reducing the effect of sonication (Zhang et al. 2013). The high-speed homogenization was carried out using an Ultraturrax IKA T25 device (IKA® Works, Inc. Wilmington, USA) at 12000 rpm for 1 min. Then, the different conditions for cell rupture were:

-

US 15 min (1US15')

-

US 30 min (1US30')

-

US 15 min + UT + US 15 min (2US15')

Then, 25% wt (concerning dry matter of fungal biomass) of glycerol (Gly) was added to the treated dispersions as a plasticizer, based on the dry weight of the biomass present in the dispersion. The dispersions were homogenized by magnetic stirring for 20 min at room temperature. A control dispersion without plasticizer was also prepared and subjected to the same magnetic stirring treatment.

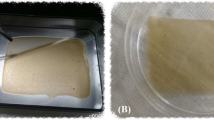

The films were prepared by placing 20 g of dispersion in 90 mm diameter plastic Petri dishes and finally obtained in an oven at 35 °C for 24 h.

Characterization of filmogenic dispersion

To evaluate the degree of cell rupture in the dispersion a qualitative evaluation of the degree of fragmentation of the cellular structures due to the US treatments was performed by using a light microscope ECLIPSE E200 (Nikon, Japan). The samples were stained with lactophenol cotton blue and observed at 40 × magnification. In addition, the particle size distribution (PSD) was determined by using a Mastersizer 2000E light scattering kit (Malvern Instruments, Worcestershire, UK) in the range of 0.1 to 1000 μm was used. The added volume of the dispersions was 2 ml in 600 ml of water, with stirring at 2000 rpm (Hydro Pump 2000MU Unit, Malvern Instruments, Worcestershire, UK) at room temperature. Experiments were performed in triplicates. The results obtained of PSD in µm were recorded based on volume and number fraction percentages. From volume fraction (%) the mean De Brouckere mean diameter (D4,3) was determined (Eq. 1). This parameter is defined as the average particle size in volume distribution. The particle size distribution span (span) was also determined (Eq. 2), defined as the measure of the width of the distribution.

Where ni is the number of particles with a size di (µm)

Where dv0,1, dv0.5 and dv0.9 are the percentile values. These are statistical parameters that can be read directly from the cumulative particle size distribution and are given by the instrument. They indicate the size below which 10%, 50%, or 90% of all particles are found.

The optical parameters applied for PSD were the relative refractive index of the dispersed particle of 1.52 and the adsorption coefficient of 0.1.

Characterization of developed films

Mechanical test

The uniaxial tensile tests were carried out by a universal mechanical test machine Megatest® TC-500 series II (Micrometric SRL, Buenos Aires, Argentina) at 24 °C, equipped with a 30 N cell load and experiments were performed at 5 mm min−1. The tests were carried out on rectangular specimens of 50 mm × 10 mm, the initial grip separation was 25 mm, and 10 replicates were made per formulation and the mean values were reported with their respective standard deviations. The parameters studied were tensile strength (TS, MPa), Young’s modulus (YM, MPa), and elongation at break (ɛ%). Before testing, samples were conditioned at 53% relative humidity (rh). Thicknesses of films were measured with a digital micrometer (Insize Co. Ltd., Japan) at 10 random positions on the film.

Thermogravimetric analysis (TGA)

The mass loss as a function of temperature was registered by TGA in a Q-500 equipment (TA Instruments, Delaware, USA) in the temperature range of 30 to 550 °C. Between 6 to 10 mg of sample were weighted and analyzed at 10 °C/min under a nitrogen atmosphere, with a flow of 40 ml/min (purge gas) and 60 ml/min (reactive gas). Initial degradation temperature (T0) was determined at 15% of mass loss, while temperatures at the maximum degradation rate (Tmax) for each degradation stage were determined from peaks of derivative curves. All samples were analyzed in duplicate.

Hydration and water vapour transport

Water sorption isotherms

The hydration properties of films were analyzed through the water sorption isotherms and were determined gravimetrically at 22 °C according to the standard procedure previously described (Ramírez Tapias et al. 2020). Dried samples of films of a superficial area of 58 cm2 and thicknesses of 0.10 ± 0.01 mm were placed in 4 L desiccators and equilibrated at different water activities aw (aw = % r.h./100). For this, saturated solutions of LiCl, MgCl2, NaBr, NaCl, and BaCl2 were used to generate conditions of aw of 0.11, 0.33, 0.57, 0.75, and 0.90, respectively. Dried atmospheres were obtained using silica gel. Samples were periodically weighed using an analytical balance (± 10−4 g) and the evolution to equilibrium at each moisture condition was checked until constant weight. The hydration or water content h, given in units of g of water per g of dry matter (d.m.), was obtained by taking the difference between the mass of the hydrated film and that of the dried film and was evaluated as a function of aw. Experiments were performed in triplicates. Isotherms were fitted using the Guggenheim-Anderson-De Boer (GAB) model (Guggenheim 1966) through Eq. 3:

where N is the monolayer water content (g of water per g of d.m.) related to primary binding sites of water molecules, c is a parameter linked to the sorption heat monolayer that represents the force of the water-binding to primary binding sites, and k is related to sorption heat multilayer that represents the capability of water to bind to the multilayer (Salvay et al. 2003). For each sample, a water sorption isotherm was obtained, and the water content h corresponding to each aw was determined as the mean of three experimental measurements, along with their respective errors. The values of the parameters N, c, and k, as well as their associated errors, were derived by fitting the experimental data points to the GAB model using OriginPro 8.

Experimental water vapor permeability measurements

Water vapour transport was assayed by measuring water vapor permeability following the standard ASTM-E96 (2016) with some modifications (Delgado et al. 2018a). For this, films were sealed on the top of cups containing a saturated salt solution of BaCl2 that provides the highest r.h. of 90%. Test cups were placed in desiccators maintained at a constant temperature of 22 °C and containing a saturated solution of NaOH that provides the lowest r.h. of 10%. Therefore, water vapor flux was determined from the weight loss of the cup. A fan was used to maintain uniform conditions inside the desiccators over the films (Mc Hugh et al. 1993). Weight loss measurements were taken by weighing the test cup using an analytical balance (± 10−3 g). Weight loss m versus time t was plotted and when the steady-state (straight line) was reached 36 h further were registered. The experimental water vapor permeability Pwexp was calculated according to Eq. 4 (Delgado et al. 2022):

where Pwexp is given in units of g s−1 m−1 Pa−1, A is the effective area of exposed film (2.2 × 10–3 m2), (Δm/Δt) is the slope of a linear regression of weight loss versus time, L is the film thickness (0.10 ± 0.01 mm), and Δpw = (pw1-pw2) is the differential water vapor partial pressure across the film, pw1 and pw2 are the partial pressures (Pa) of water vapor at the film surface inside and outside the cup, respectively. pw1 was corrected by the mean air gap distance (5 × 10–3 m in the present study) between the saturated solution level in the cup and the film position (Gennadios et al. 1994). Experiments were performed in triplicate.

Statistical analysis

An analysis of variance (ANOVA) was carried out and it was verified if there were significant differences in the variables measured for each sample in mechanical tests of the films, through a Tukey multiple comparison analysis using PSPP 0.8.5 (Free Software Foundation, Boston, USA), with a confidence level of a p < 0.05.

Results & discussion

Characterization of filmogenic dispersion

Figure 1 shows the images of dispersions T1 and T2 submitted to different US treatments. Figures 1a and 1d show dispersions T1 and T2 submitted to 1US15´. In both cases, it was possible to observe the presence of longer hyphae than the other treatments. Regarding 30-min ultrasound treatments, those dispersions submitted to 2US15’ (Fig. 1c and 1f for T1 and T2, respectively) presented the most severe rupture, since is possible to see shorter hyphae. Therefore, the ultraturrax treatment after the first US treatments led to a greater breakage of the fungal cells. This corresponds to what was reported for Aspergillus niger and Penicillium nalgiovense biomass dispersions (3% wt, on a dry basis) treated with 2US15' (Sanchez-Díaz et al. 2023).

Regarding the optical microscopy images, the severity of the US treatments to break cellular structures of Paecylomyces variotii, focusing on the rupture grade for both T1 and T2, could be ordered as follows: 2US15’ > 1US30’ > 1US15’.

Dispersions and the effect of US treatments were also characterized through the particle size distribution (PSD) of dispersion T1 and T2. Figure 2 shows the PSD of the tested samples. Figure 2a and b showed %volume and %number of T1 dispersions, respectively. The particle size distributions (% volume) of T1 dispersions 1US15' and 1US30' were similar, with populations centred on 5, 100, and 700 µm. This variety of peaks is probably related to the fact that these dispersions were not filtered after heating treatment with the autoclave, and therefore there was a greater amount of particles of different sizes. Bzducha-Wrobel et al. (2014) studied the effect of sterilization as a method of cell disruption in yeasts and they found that those compounds released during the heating treatment, were part of the cell wall of microorganisms and they were solubilized at high temperatures (Bzducha-Wróbel et al. 2014). Dispersion T1-2US15´ presented a bimodal PSD, with maxima at 0.7 and 5 µm. In this case, the order of the treatments applied to the dispersion played an important role, since the first 15 min of US treatment, may produce cells fracture or breakage but also might break possible aggregates of particles produced during autoclaving, which with high-speed homogenization with ultraturrax (UT) they were broken or leave them more exposed, and through the second US treatment of 15 min, smaller particles were generated. Figure 2b shows the PSD in % number of the T1 dispersions. Samples 1US15' and 1US30' showed similar populations of less than 10 µm with a maximum at 2.5 µm. In the case of sample 2US15', a different result was obtained compared to samples 1US15' and 1US30' (in agreement with what was seen in the size distributions in % volume), where two populations with maxima at 0.7 µm and 2.8 μm were observed.

Dispersions T2 showed different profiles in particle distribution with respect T1. Figure 2c demonstrated that %volume distribution presented a bimodal profile for all US treatments (1US15’, 1US30’ y 2US15’), with two populations well defined, a minor population centred at 0.7 µm and a major one centred at 6 µm. No differences were found between US treatments in smaller populations. However, differences were observed in the amplitude of the larger population, where 1US15´ dispersions presented a span value that doubled approximately the span value of 1US30 and 2US15 (Table 1). This result indicates that the 2US15' dispersion was the one with the most homogeneous particle size distribution (% volume). Sanchez-Díaz et al. (2023) also reported more homogeneous particle distributions for Aspergillus niger and Penicillium nalgiovense biomass dispersions (3% wt, on a dry basis) treated with 2US15', but in these cases monomodal distributions were achieved by this treatment. The PSD of the T2 dispersions in % number (Fig. 2d) also presented two populations, where the largest number of particles had a maximum of around 0.7 µm and the smallest around 3 µm. It is interesting to note that in these distributions no peaks in sizes greater than 10 µm were observed, indicating that the fraction of the total number of particles (% number) in that area is very small. No differences were observed in the distributions for the three treatments in sample T2.

Table 1 shows the parameters obtained from the PSD in %volume. In both dispersions T1 and T2, the span value and D4.3 values indicated that in those longer US treatments, there was a reduction in the particle size. The values obtained for T2 1US15’ are comparable with those reported for Aspergillus niger and Penicillium nalgiovense biomass dispersions (3% wt, on a dry basis) treated with 2US15' (Sanchez-Díaz et al. 2023). Comparing those US treatments with the same time of US (1US30´and 2US15´), the intermediate homogenization at high speed contributed positively to the breaking of agglomerates, generating a more uniform distribution, being the span value lower for these dispersions. These corresponds to what was observed for Mucor hiemalis and Aspergillus niger dispersions treated by 15-min ultrasound with and without an intermediate UT homogenization (Sanchez-Díaz et al. 2023).

Characterization of films based on Paecilomyces variotii biomass

Mechanical test

To evaluate the effect of the US treatments on the obtained films from dispersions T1 and T2 tensile tests were carried out and Table 2 shows the results of plasticized and non-plasticized samples. The films obtained from T2 dispersions without plasticizer showed a typical pattern of a brittle material, since the maximum tensile strength values (TS) and Young’s modulus values (YM) of these samples were very high and the elongation at break (ɛ%) values was low (Maliet al. 2005). It was observed that there were no significant differences between the ɛ% values for the three rupture treatments studied, but there were differences in the TS values. The highest values were obtained in those films formed with 30 min of US, either with or without the intermediate ultraturrax treatment. While for the YM values, significant differences were observed between 1US15' and 2US15'. The T1 films 1US15' and 1US30' without glycerol also showed a typical pattern of a brittle material, although in these cases it is highlighted that the YM values were lower compared to those of the T2 films. In particular, for T1-2US15' sample without the addition of plasticizer, it was interesting to note that the mechanical parameters were very similar to those of the plasticized samples, with low values of YM and TS and the value of ɛ% was increased, in comparison to the films 1US15' and 1US30'. These may be due to the presence of low molecular weight compounds formed during heating treatment that remained in the media since these samples were not filtered after the sterilization process. Comparing mechanical properties with petroleum based films, such as LDPE films, this material is characterized by the tensile strength (TS) no lower than 10 MPa, similar to those fungal films without glycerol, however the LDPE films use to present elongation at break is no less than 200% (Szlachetka et al. 2021).

The mechanical properties of the fungal films obtained in this work could be compared with those reported by other authors in the literature (Ciannamea et al. 2014; Jost and Stramm 2015; Sanchez-Díaz et al. 2023). The values of the parameters TS, YM, and ɛ% depend on the biopolymer that conforms the film matrix. Generally, films based on polysaccharides are more rigid compared to those based on proteins, which are more extensible than the former (Osés et al. 2009; Farahnaky et al. 2013). Then, the mechanical properties of films based on mixtures of polysaccharides and proteins depend on the ratio of these biomolecules in the dispersions. Pranoto et al. found that the strength and flexibility of films composed of a mixture of gelatine and gellan gum, could be modified by varying the proportion of each biopolymer, and related the best mechanical properties with an optimal level of interaction between biomolecules (Pranoto et al. 2007). In films formed from fungal biomass composed of polysaccharides and proteins, only glycerol was added as an extra component, so the interaction between biomolecules might be modified through the US treatments, and in this study, the optimal level of interaction was found in the sample T2 2US15´ with 25% Gly. The values of the parameters TS, YM, and ɛ% obtained in the sample T2 2US15´ with 25% Gly were comparable with those reported for Aspergillus niger and Penicillium nalgiovense films obtained from 2US15´ treated dispersions with 25% Gly (Sanchez-Díaz et al. 2023). Nevertheless, no significant differences were found in TS, YM, and ɛ% among the different cell rupture treatments except for P. nalgiovense films. On the other hand, films obtained from dispersions T1 2US15' without glycerol were less rigid and more extensible than those reported by other authors. This result was interesting since those films presented characteristics of a plasticized material. This phenomenon was probably related to the content of solubilized compounds during the sterilization process already described in the particle size determinations.

Thermogravimetric analysis (TGA)

Figure 3 shows the Mass loss (%) versus temperature thermograms of the films T1 and T2, while Fig. 4 shows the derivative curve of weight versus temperature (DTGA, %/°C). Thermograms showed that all the studied films presented a degradation profile with several stages as expected for biobased films (Delgado et al. 2018b; Peltzer et al. 2018; Sanchez-Díaz et al. 2023). The first stage is from 30 to 100 °C (information not shown in the figures), corresponding to the loss of moisture and possible low molecular weight compounds present in the formulations (Zohuriaan and Shokrolahi 2004; Hoque et al. 2011). The second stage was extended from 100 to 240ºC, where the loss of the plasticizer and initial decomposition of proteins and other compounds were mostly observed (Delgado et al. 2018b). Regarding this zone, Fig. 4b and d shows the thermograms of the plasticized samples where a pronounced peak appeared in the degradation zone of glycerol (Peltzer et al. 2018). Ramos et al. studied the thermal degradation of films based on whey proteins with glycerol and concluded that in the degradation zone of the plasticizer, other compounds were lost such as structurally bound water, volatilization of compounds associated with glycerol, and incipient protein degradation (Ramos et al. 2013). However, in the plasticized samples T2 2US15', only a shoulder was observed in this area, corresponding to the degradation of the plasticizer, while in the other two samples 1US15' and 1US30' a notable peak was observed. Figure 4a, which showed the thermogram of sample T1 without plasticizer, presented a shoulder in this second zone of degradation, indicating that small compounds from the fungal matrix were present and were degraded at these temperatures. Finally, the stage that extends between 240 to 550 °C corresponds to the pyrolysis of β-glucan and other carbohydrates and massive protein degradation (Stawski et al. 2008; Kagimura et al. 2015; Delgado et al. 2018b; Sanchez-Díaz et al. 2023).

The parameters determined by TGA were the initial degradation temperature considered when the films registered a weight loss of 15% (T0), the temperature of the maximum degradation rate of the material in each stage (Tmax), corresponding to the peak temperature in the DTGA curves. All these parameters are shown in Table 3.

From the table, it could be seen that the sample T2 2US15′ 25%G showed the highest thermal resistance compared. This could be explained by the UT treatment carried out after the first US treatment, which breaks agglomerates that allowed the second US treatment to be more effective, achieving a more ordered network more resistant to thermal degradation. This corresponds to the reported for A. niger and M. hiemalis films obtained with an intermediate UT treatment with 15 min of US (Sanchez-Díaz et al. 2023). Table 3 also shows that the addition of plasticizer produced a decrease in the T0, both in the T1 and T2 films. The presence of the plasticizer reduces the interaction between the polymer chains of the film matrix, exposing them to degradation and thus reducing their thermal resistance (Peltzer et al. 2018). All films presented the greatest percentage of weight loss at 260 °C. Without glycerol, T2 samples presented higher thermal stability than T1, maybe due to the presence of small molecules that remained in T1 samples after sterilization that in samples T2 were eliminated with the filtration process.

Hydration and water vapor transport

Biopolymer-based films are hydrophilic matrices that exhibit strong interactions with water. Therefore, understanding hydration properties is essential for predicting optimal storage conditions, shelf life, and their behavior under varying humidity conditions. Water sorption isotherms provide valuable insights into the interaction between water and the film matrix, as well as the structuring of water within the material (Lago et al. 2023). Water sorption isotherms of Paecilomyces variotii biomass biomass-based films are shown in Fig. 5. Experimental points were fitted with the GAB model (Eq. 3) and fitted parameters are displayed in Table 4. Table 4 also shows the measured values of Pwexp.

It could be observed from Fig. 5a that the shape of isotherms of all unplasticized T1 films showed a slight increase in the hydration water content at low values of aw, and a sharp increase for aw > 0.6. This shape of isotherms suggested the existence of a small amount of water directly bound to the polymeric matrix, forming the hydration monolayer. Then, most of the hydration water was forming multilayers and was indirectly bound to the polymeric matrix. In contrast, the isotherms of unplasticized T2 films displayed a larger increase at low values of aw, and a soft increase for aw > 0.6, as compared with T1 films.

The convexity or concavity of isotherms in the region at aw < 0.6 is linked to the value of parameter c of Eq. 3 (Salvay et al. 2003; Ramírez Tapias et al. 2021), which is related to the force of the water-binding to the monolayer. As could be observed in Fig. 5a and Table 4, the values of parameter c for T2 films are larger compared to T1 films, and the isotherms of T2 films at aw < 0.6 becomes more concave. Parameter N related to the number of primary binding sites of hydration did not present drastic differences between unplasticized films T1 and T2. However, parameter k related to the capability of water to be bounded to the multilayer was higher in the T1 films, resulting in higher hydration for aw > 0.6 and consequently in greater values of h90%r.h. (see Table 4). In this way, in unplasticized T1 films, most of the hydration water was forming multilayers and was indirectly bound to the polymeric matrix. Therefore, as compared with unplasticized T2 films, the hydration water in T1 films is more susceptible to being moved by the diffusion mechanism (Delgado et al. 2022). This is reflected in the higher Pwexp values obtained for the unplasticized sample T1, as compared to T2 (see Table 4). This difference could be due to the presence of low molecular weight compounds in the T1 films, which would promote the separation of the polymeric chains in the film matrix, increasing the free volume to be occupied by mobile water (Guggenheim 1966; Coma et al. 2019).

On the other hand, it could be observed that the ultrasonic homogenisation treatment affected the hydration and the water vapour permeability of the unplasticized films T1 and T2 in a different way. In particular, regarding values of h90%rh and Pwexp in Table 4, the difference produced by the treatments was more noticeable in the T1 films, where the unplasticized samples T1 1US30’ and T1 2US15’ presented higher values of h90%rh and Pwexp as compared to T1 1US15. This could be due to the increased aggregate breakdown and size reduction of the polymer chains produced by a longer ultrasound application time, which increases hydration and water mobility. Concerning the effect of glycerol, it could be observed in Fig. 5 and Table 4 that the addition of the plasticizer in all samples increases the global hydration and Pwexp values. It was observed in thermogravimetric studies (Sect. 3.2.2) that glycerol incorporated into the film matrix decreased the attractive forces between polymer chains, favouring thermal degradation. Consequently, the addition of glycerol increases free volume and segmental motions, producing a global increase in hydration water content and allowing greater mobility to water molecules that increase Pwexp (Coma et al. 2019). Furthermore, in a similar way to what was observed for the unplasticized films, T1 samples with 25% glycerol showed higher values of h90%rh and Pwexp as compared with T2 films with the plasticizer.

Conclusion

This research contributes to reinforcing the novel idea that it is feasible to obtain materials from whole biomass of filamentous fungi by casting from filmogenic dispersions. This approach provides an innovative alternative source of biopolymers that do not require further purification and is not limited by crop failure or climate conditions. In this work it was feasible to obtain films from all treated dispersions of P. variotti regardless of the rupture condition applied.The three combined conditions of ultrasound (US) and ultraturrax (UT) were effective for cell rupture, verified by optical microscopy of dispersions and PSD. Longer US treatments produced a reduction in the particle size and the application of the intermediate UT treatment contributed favorably to the breaking of agglomerates allowing the second US treatment to be more effective, achieving an ordered network with a more uniform distribution. This arrangement gave a greater thermal resistance to the fungal biomass films. It was possible to determine that the filtration process after sterilization when obtaining the filmogenic dispersions, eliminated soluble and hydratable compounds, which produced a reduction in the hydration properties of the films produced with T2 dispersions. Through the characterization of mechanical tests, it is highlighted that in the T1 2US15′ 0%G films, the values obtained were very similar to those of the plasticized samples, with low values of YM and TS.

Data availability

Data are available on request.

References

ASTM-E96 (2016) Standard test methods for water vapor transmission of materials. West Conshohocken, ASTM Int. https://doi.org/10.1520/E0096_E0096M-16

Bourtoom T (2008) Review article edible films and coatings: characteristics and properties. Int Food Res J 15:237–248

Bzducha-Wróbel A, Blazejak S, Kawarska A, Stasiak-Rózanska L, Gientka I, Majewska E (2014) Evaluation of the efficiency of different disruption methods on yeast cell wall preparation for β-glucan isolation. Molecules 19:20941–20961. https://doi.org/10.3390/molecules191220941

Campos CA, Gerschenson LN, Flores SK (2011) Development of edible films and coatings with antimicrobial activity. Food Bioprocess Technol 4(6):849–875. https://doi.org/10.1007/s11947-010-0434-1

Cerimi K, Akkaya KC, Pohl C, Schmidt B, Neubauer P (2019) Fungi as source for new bio-based materials: a patent review. Fungal Biol Biotechnol 6:17. https://doi.org/10.1186/s40694-019-0080-y

Choque E, El Rayess Y, Raynal J, Mathieu F (2015) Fungal naphtho-γ-pyrones secondary metabolites of industrial interest. Appl Microbiol Biotechnol 99:1081–1096. https://doi.org/10.1007/s00253-014-6295-1

Ciannamea EM, Stefani PM, Ruseckaite RA (2014) Physical and mechanical properties of compression molded and solution casting soybean protein concentrate based films. Food Hydrocolloids 38:193–204. https://doi.org/10.1016/j.foodhyd.2013.12.013

Coma ME, Peltzer MA, Delgado JF, Salvay AG (2019) Water kéfir grains as an innovative source of films: Study of plasticizer content on film properties. Eur Polymer J 120. https://doi.org/10.1016/j.eurpolymj.2019.109234

Cottet C, Ramirez-Tapias YA, Delgado JF, de la Osa O, Salvay AG, Peltzer MA (2020) Biobased materials from microbial biomass and its derivatives. Materials 13(6):1263. https://doi.org/10.3390/ma13061263

Delgado JF, Sceni P, Peltzer MA, Salvay AG, de la Osa O, Wagner JR (2016) Development of innovative biodegradable films based on biomass of Saccharomyces cerevisiae. Innov Food Sci Emerg Technol 36:83–91. https://doi.org/10.1016/j.ifset.2016.06.002

Delgado JF, Peltzer MA, Wagner JR, Salvay AG (2018a) Hydration and water vapour transport properties in yeast biomass based films: a study of plasticizer content and thickness effects. Eur Polym J 99:9–17. https://doi.org/10.1016/j.eurpolymj.2017.11.051

Delgado JF, Peltzer MA, Salvay AG, de la Osa O, Wagner JR (2018b) Characterization of thermal, mechanical and hydration properties of novel films based on Saccharomyces cerevisiae biomass. Innov Food Sci Emerg Technol 48:240–247. https://doi.org/10.1016/j.ifset.2018.06.017

Delgado JF, Peltzer MA, Salvay AG (2022) Water vapour transport in biopolymeric materials: effects of thickness and water vapour pressure gradient on yeast biomass-based films. J Polym Environ 30:2976–2989. https://doi.org/10.1007/s10924-022-02412-6

Farahnaky A, Saberi B, Majzoobi M (2013) Effect of glycerol on physical and mechanical properties of wheat starch edible films. J Texture Stud 44:176–186. https://doi.org/10.1111/jtxs.12007

Gennadios A, Weller CL, Gooding CH (1994) Measurement errors in water vapor permeability of highly permeable, hydrophilic edible films. J Food Eng 21:395–409. https://doi.org/10.1016/0260-8774(94)90062-0

Giancone T, Torrieri E, Masi P, Michon C (2009) Protein–polysaccharide interactions: phase behaviour of pectin–soy flour mixture. Food Hydrocoll 23(5):1263–1269. https://doi.org/10.1016/j.foodhyd.2008.09.001

Guggenheim EA (1966) 1st. ed. Oxford: Claredon Press. ISBN 10:0198553315. https Applications of statistical mechanics. https://doi.org/10.1002/ange.19670791621

Guimarães HHS, Peixoto-Nogueira SC, Michelin M, Rizzatti ACS, Sandrim VC, Zanoelo FF, Polizeli MDL (2006) Screening of filamentous fungi for production of enzymes of biotechnological interest. Braz J Microbiol 37:474–480. https://doi.org/10.1590/s1517-83822006000400014

Hoque S, Benjakul S, Prodpran T (2011) Effects of partial hydrolysis and plasticizer content on the properties of film from cuttlefish (Sepia pharaonis) skin gelatin. Food Hydrocolloids 25:82–90. https://doi.org/10.1016/j.foodhyd.2010.05.008

Janjarasskul T, Krochta JM (2010) Edible packaging materials. Annu Rev Food Sci Technol 1:415–448. https://doi.org/10.1146/annurev.food.080708.100836

Jost V, Stramm C (2015) Influence of plasticizers on the mechanical and barrier properties of cast biopolymer films. J Appl Polym Sci 133(2). https://doi.org/10.1002/app.42513

Kadimaliev D, Kezina E, Telyatnik V, Revin V, Parchaykina O, Syusin I (2015) Residual Brewer’s yeast biomass and bacterial cellulose as an alternative to toxic phenol-formaldehyde binders in production of pressed materials from waste wood. BioResources 10:1644–1656. https://doi.org/10.15376/biores.10.1.1644-1656

Kagimura FY, da Cunha MAA, Barbosa A, Dekker RFH, Malfatti CRM (2015) Biological activities of derivatized d-glucans: a review. Int J Biol Macromol 72:588–598. https://doi.org/10.1016/j.ijbiomac.2014.09.008

Kojima K, Heisz M, Booth C, McKinney M, Summermatter K, Blacksell S (2020) Laboratory biosafety manual fourth edition and associated monographs, 4th edn. Geneva

Kuorwel KK, Cran MJ, Sonneveld K, Miltz J, Bigger SW (2011) Antimicrobial activity of biodegradable polysaccharide and protein based films containing active agents. J Food Sci 76(3):R90–R102. https://doi.org/10.1111/j.1750-3841.2011.02102.x

Kyanko V, Canel RS, Ludemann V, Pose G, Wagner JR (2013) β-glucan content and hydration properties of filamentous fungi. Appl Biochem Microbiol 49(1):41–45. https://doi.org/10.1134/s0003683813010080

Lago A, Delgado JF, Rezzani GD, Cottet C, Ramírez Tapias YA, Peltzer MA, Salvay AG (2023) Multi-component biodegradable materials based on water kefir grains and yeast biomasses: effect of the mixing ratio on the properties of the films. Polymers 15:2594. https://doi.org/10.3390/polym15122594

López de León L, Caceres I, Bornot J, Choque E, Raynal J, Taillandier P et al (2019) Influence of culture conditions on production of NGPs by Aspergillus tubingensis. J Microbiol Biotechnol 29:1412–1423. https://doi.org/10.4014/jmb.1905.05015

Mali S, Sakanaka LS, Yamashita F, Grossmann MVE (2005) Water sorption and mechanical properties of cassava starch films and their relation to plasticizing effect. Carbohyd Polym 60(3):283–289. https://doi.org/10.1016/j.carbpol.2005.01.003

Mc Hugh TH, Avena-Bustillos R, Krochta JM (1993) Hydrophilic edible films: modified procedure for water vapor permeability and explanation of thickness effects. J Food Sci 58:899–903. https://doi.org/10.1111/j.1365-2621.1993.tb09387.x

Meechan PJ, Potts J (2020) Biosafety in microbiological and biomedical laboratories. 6th ed. US Department of Health and Human Services, Washington, D.C., USA. No. (CDC) 300859

Meyer V, Andersen MR, Brakhage AA, Braus GH, Caddick MX, Cairns C et al (2016) Current challenges of research on filamentous fungi in relation to human welfare and a sustainable bio-economy: a white paper. Fungal Biol Biotechnol 3:6. https://doi.org/10.1186/s40694-016-0024-8

Novak M, Synytsya A, Gedeon O, Slepicka P, Procházka V, Synytsya A et al (2012) Yeast β(1–3), (1–6)-D-glucan films: preparation and characterization of some structural and physical properties. Carbohyd Polym 87:2496–2504. https://doi.org/10.1016/j.carbpol.2011.11.031

Osés J, Fabregat-Vázquez M, Pedroza-Islas R, Tomás SA, Cruz-Orea A, Maté JI (2009) Development and characterization of composite edible films based on whey protein isolate and mesquite gum. J Food Eng 92(1):56–62. https://doi.org/10.1016/j.jfoodeng.2008.10.02

Pan H, Jiang B, Chen J, Jin Z (2014) Blend-modification of soy protein/lauric acid edible films using polysaccharides. Food Chem 151:1–6. https://doi.org/10.1016/j.foodchem.2013.11.075

Peltzer MA, Salvay AG, Delgado JF, de la Osa O, Wagner JR (2018) Use of residual yeast cell wall for new biobased materials production: effect of plasticization on film properties. Food Bioproc Tech 11:1995–2007. https://doi.org/10.1007/s11947-018-2156-8

Pitt JI, Hocking AD (2009) Fungi and food spoilage. 3rd. ed. Springer Dordrecht Heidelberg London New York. https://doi.org/10.1007/978-0-387-92207-2

Pranoto Y, Lee CM, Park HJ (2007) Characterizations of fish gelatin films added with gellan and κ-carrageenan. LWT-Food Sci Technol 40(5):766–774. https://doi.org/10.1016/j.lwt.2006.04.005

Ramírez Tapias YA, Peltzer MA, Delgado JF, Salvay AG (2020) Kombucha tea by-product as source of novel materials: formulation and characterization of films. Food Bioproc Tech 13:1166–1180. https://doi.org/10.1007/s11947-020-02471-4

Ramírez Tapias YA, Di Monte MV, Peltzer MA, Salvay AG (2021) Bacterial cellulose films production by Kombucha symbiotic community cultured on different herbal infusions. Food Chem 372:131346. https://doi.org/10.1016/j.foodchem.2021.131346

Ramos ÓL, Reinas I, Silva SI, Fernandes JC, Cerqueira MA, Pereira RN et al (2013) Effect of whey protein purity and glycerol content upon physical properties of edible films manufactured therefrom. Food Hydrocoll 30(1):110–122. https://doi.org/10.1016/j.foodhyd.2012.05.001

Razzaq HAA, Pezzuto M, Santagata G, Silvestre C, Cimmino S, Larsen N et al (2016) Barley β-glucan-protein based bioplastic film with enhanced physicochemical properties for packaging. Food Hydrocol 58:276–283. https://doi.org/10.1016/j.foodhyd.2016.03.003

Salvay AG, Colombo MF, Grigera JR (2003) Hydration effects on the structural properties and haem-haem interactions in haemoglobin. Phys Chem Chem Phys 5:192–197. https://doi.org/10.1039/B209560B

Sanchez-Díaz MR, Lazarte MS, Moavro A, Peltzer MA, Ludemann V (2023) Naturally multicomponent materials obtained from filamentous fungi: impact of different cell rupture treatment on film properties. J Polym Environ 31:2347–2363. https://doi.org/10.1007/s10924-023-02766-5

Santhosh BS, Bhavana DR, Rakesh MG (2018) Mycelium composites: an emerging green building material. Int Res J Eng Technol 5:3066–3068

Siracusa V, Rocculi P, Romani S, Dalla Rosa M (2008) Biodegradable polymers for food packaging: a review. Trends Food Sci Technol 19:634–643. https://doi.org/10.1016/j.tifs.2008.07.003

Stawski D, Rabiej S, Herczyńska L, Draczyński Z (2008) Thermogravimetric analysis of chitins of different origin. J Therm Anal Calorim 93(2):489–494. https://doi.org/10.1007/s10973-007-8691-6

Sun W, Tajvidi M, Hunt CG, McIntyre G, Gardner DJ (2019) Fully bio-based hybrid composites made of wood, fungal mycelium and cellulose nanofibrils. Sci Rep 9:3766. https://doi.org/10.1038/s41598-019-40442-8

Szlachetka O, Witkowska-Dobrev J, Baryła A, Dohojda M (2021) Low-density polyethylene (LDPE) building films–Tensile properties and surface morphology. J Build Eng 44:103386. https://doi.org/10.1016/j.jobe.2021.103386

Tang XZ, Kumar P, Alavi S, Sandeep KP (2012) Recent advances in biopolymers and biopolymer-based nanocomposites for food packaging materials. Crit Rev Food Sci Nutr 52(5):426–442. https://doi.org/10.1080/10408398.2010.500508

Thammakiti S, Suphantharika M, Phaesuwan T, Verduyn C (2004) Preparation of spent brewer’s yeast β-glucans for potential applications in the food industry. Int J Food Sci Technol 39:21–29. https://doi.org/10.1111/j.1365-2621.2004.00742.x

Vieira MGA, da Silva MA, dos Santos LO, Beppu MM (2011) Natural-based plasticizers and biopolymer films: a review. Eur Polymer J 47(3):254–263. https://doi.org/10.1016/j.eurpolymj.2010.12.011

Zhang L, Ye X, Xue SJ, Zhang X, Liu D et al (2013) Effect of high-intensity ultrasound on the physicochemical properties and nanostructure of citrus pectin. J Sci Food Agric 93:2028–2036. https://doi.org/10.1002/jsfa.6011

Zohuriaan M, Shokrolahi F (2004) Thermal studies on natural and modified gums. Polym Testing 23(5):575–579. https://doi.org/10.1016/j.polymertesting.2003.11.001

Funding

The authors of this article acknowledge the financial support from National University of Quilmes (UNQ, Argentina) through R&D program (Expediente 1300/19).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study’s conception and design. Material preparation, data collection and analysis were performed by Ezequiel A. Martinez, Macarena R. Sanchez-Díaz, Andres G. Salvay, Vanesa Ludemann, and Mercedes A. Peltzer. The funds were managed by Vanesa Ludemann. The manuscript was written and approved by all authors.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Martinez, E.A., Salvay, A.G., Sanchez-Díaz, M.R. et al. Functional characterization of biodegradable films obtained from whole Paecilomyces variotii biomass. Int Microbiol (2024). https://doi.org/10.1007/s10123-024-00501-1

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10123-024-00501-1