Abstract

Yttrium-stabilized tetragonal zirconia polycrystalline (Y-TZP) ceramic is widely used as an all-ceramic core material because of its enhanced mechanical and aesthetic properties. The bond strength of Y-TZP restorations affects long-term success; hence, surface treatment is required on ceramic boundaries. This study evaluated the effect of different laser beam angles on Y-TZP–resin cement shear bond strength (SBS). Forty plates of Y-TZP ceramics were randomly assigned to four groups (n = 10). A femtosecond amplifier laser pulse was applied on Y-TZP surface with different incidence angles (90°, 75°, 60°, 45°). The resin cement was adhered onto the zirconia surfaces. The SBS of each sample was measured using universal testing machine at crosshead speed of 1 mm/min. The SBS was analyzed through one-way analysis of variance (ANOVA)/Tukey tests. The results showed that the degree of laser beam angle affects the SBS of resin cement to Y-TZP. The laser beam was applied to a surface with a 45° angle which resulted in significantly higher SBS (18.2 ± 1.43 MPa) than other groups (at 90° angulation (10.79 ± 1.8 MPa), at 75° (13.48 ± 1.2 MPa) and at 60° (15.85 ± 0.81 MPa); p < 0.001). This study shows that decreasing of the angle between the ceramic surface and the laser beam increased the SBS between the resin cement and the ceramic material, as well as the orifice.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

All-ceramic dental restorations, alternatives to metal-ceramic restorations, offer better aesthetics, strength, and toughness [1]. Yttrium-stabilized tetragonal zirconia polycrystalline (Y-TZP) is used widely as an all-ceramic core material, due to their enhanced mechanical and aesthetic properties [2]. Although zirconia ceramics is widely used in dentistry, nonetheless, no consensus has been reached regarding the optimum bonding protocol for ceramic surfaces and tooth structures [3]. Conventional cements provide adequate adhesion for zirconium restorations, however, resin cements have been shown to have a higher bonding strength, due to their wettability and composition [4]. However, the bond strength of restoration to tooth and other materials affects long-term success of the Y-TZP restoration and that may achieve potential surface treatments of ceramic boundaries [5, 6]. Over the last decade, numerous studies have aimed to develop new preparation methods that increase the bond strength between resin cement and the ceramic surface; these include airborne-particle abrasion (APA), tribochemical silica coatings, hydrofluoric (HF)-acid etching, and neodymium-doped yttrium aluminum garnet (Nd:YAG) laser irradiation [7–9].

Laser surface treatments are becoming increasingly popular [7–9]. Li et al. [10] demonstrated improved bond strength of resin cement to ceramic surfaces, prepared via Nd:YAG laser surface irradiation, in comparison with HF-acid etching. Akın et al. [11] used Nd:YAG and erbium-doped yttrium aluminum garnet (Er:YAG) lasers, resulting in increased bond strength between the resin cement and Y-TZP surface. Yassaei et al. [12] showed that the etching of porcelain surfaces with Er:YAG irradiation increased the bond strength. A study carried out by Paranhos et al. [13] examined the effect of Nd:YAG and CO2 laser irradiation on zirconia ceramics; the CO2 laser produced microcracks in the sample surface. Stübinger et al. [14] examined the effect of Er:YAG, CO2, and diode laser irradiation on the surface of zirconia ceramics; Er:YAG and CO2 irradiation produced microcracks, pits, and melted areas on the zirconia surface.

The use of ultrashort (femtosecond) laser pulses has been shown to facilitate micromachining of many materials, including zirconia ceramics, with minimal damage and improved precision [15]. Femtosecond (FS) laser micromachining increases the surface roughness of zirconium with precision and a low thermal load, reducing the presence of residual elements. Additionally, the resulting surface retains its characteristics permanently and does not exhibit phase transformation [16]. FS laser systems produce circular shape laser beam. When the laser beam contacts to surface of object, an ablation occurs as a circular shape. The angle which occurred between laser beam and surface of object changes by laser beam angulation or surface angulation. In this case, the shape of ablation which occurred on the surface changes to elliptical shape instead of circular shape. Haris and Stocker [17] stated that if the plane is titled with respect to a circular cross section, the resulting top of the cylindrical segment has an elliptical cap, and surface area of this elliptical cap is given in Fig. 1.

When the theta (θ) degree increased, surface area of elliptical could be increased. Sano et al. [18] stated that there is a positive relationship between bond strength and surface area.

However, few studies have examined the effect of the laser irradiation angle on the bond strength between Y-TZP ceramics and resin cement. The purpose of this study was to evaluate the effect of the irradiating laser beam angle (LBA) on Y-TZP–resin cement shear bond strength (SBS). The hypothesis tested was that different LBAs would influence the SBS between Y-TZP and resin cement.

Materials and methods

Forty square-shaped (10 × 10 × 2 mm) Y-TZP (Zirconzahn, Zirconzahn USA Inc., USA) samples were produced with a copy-milling machine (Yenamak, Ezcam, Istanbul, Turkey) and then sintered according to manufacturer’s instructions. The samples were embedded in 20-mm height and 25-mm diameter PVC ring using autopolymerizing acrylic resin block.

Y-TZP surface was ground finished with 240–400–600–800 grit silicon carbide abrasive papers for 1 min using a 600-rpm grinding machine (Minitech 233; Presi, Grenoble, France) under cooling, running water. Surfaces were cleaned by acetone and dried in air stream. All samples were divided into four groups (n = 10). The surface treatment procedure in the study was as follows:

-

Group A:

Laser beam was applied to surface with a 90° angle that was defined as the control group

-

Group B:

Laser beam was applied to surface with a 75° angle

-

Group C:

Laser beam was applied to surface with a 60° angle

-

Group D:

Laser beam was applied to surface with a 45° angle

A FS amplifier laser pulse (Quantronix Integra-C-3.5, NY, USA) was applied on Y-TZP surface with different degrees of angle (Fig. 2). FS laser parameters were as follows: Laser was delivering pulse with 750 mW per pulse at wavelength of 810 nm, and with 90 fs, and 2 kHz repetition rate. Laser beam was delivered to surface by laser marker (Q-Mark, Quantronix, NY, USA) system that have a 11-cm back focal length (which is, distance between cover glass of the f-theta lens of marking system to the paraxial focal point), and it can scan work plane for 30 mm/s scanning speed. After the surface treatments were finished, all samples were ultrasonically cleaned in 96 % isopropyl alcohol for 380 s and dried. An extra sample from each group was selected for examining scanning electron microscope (SEM) (Zeiss Evo LS10, Carl Zeiss Microscopy GmbH, Jena, Germany). Cylindrical Teflon molds with hole with an inner diameter of 4 mm and a height of 3 mm were fabricated. PVC ring was seated in the center of hole, and resin cement (RelyXTM U100 self-adhesive resin cement, 3MTM ESPETM, USA) was applied in the hole and polymerized by LED curing light (Elipar, 3M ESPE) for 20 s. Light intensity was 800 mW/cm2. Teflon molds were gently removed, and all samples were kept in a desiccator at room temperature for 24 h prior to SBS testing.

The SBS test of Y-TZP–resin cement was performed with a universal testing machine (Shimadzu AGS-X, Shimadzu Corporations, Tokyo, Japan) at a crosshead speed of 1 mm/min until bonding failure occurred. After the SBS test was completed, one sample from each group was assessed with SEM for cross-section image (Fig. 3).

Statistical analysis

The ultimate stress (MPa) of the Y-TZP–resin cement was calculated as follows: [19]

The SBS values were analyzed with statistical software (SPSS PC, Vers. 11 5; SPSS, Chicago, IL). One-way analysis of variance (ANOVA) was used to analyze the data for significant differences. Tukey honestly significant difference (HSD) test was used to perform multiple comparisons among at a significance level set at p < 0.05.

Results

Shear bond strength evaluation

The average debonding forces, their standard deviations, and the distributions of bond strength in all surface treatment groups are detailed in Table 1. ANOVA and multiple comparison tests indicated significant differences among the surface treatment groups (p < 0.001). Tukey’s HSD post hoc test indicated that the bond strength of group A (10.79 ± 1.8 MPa) was significantly lower than those of the other groups (p < 0.001), followed by group B (13.48 ± 1.2 MPa), group C (15.85 ± 0.81 MPa), and group D (18.2 ± 1.43 MPa).

In simulations using the SolidWorks software, when the cutting angle was reduced, the contact surface area between two objects increased (e.g., for a contact angle of 90°, the surface area was 3848 μm2; for 75°, 3982 μm2; 60°, 4442 μm2; and 45°, 5447 μm2) (Fig. 4). Drawings obtained using the SolidWorks software indicated a positive correlation between SBS values and the size of the orifice (p < 0.001). With respect to the mode of failure, most of the specimens failed due to a lack of adhesion between the Y-TZP body and the resin cement.

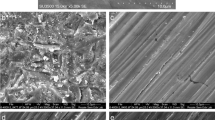

Scanning electron microscope evaluation

SEM images (×500 magnification) of a Y-TZP surface treated by FS laser pulses, as a function of the incident angle of irradiation (90°, 75°, 60°, and 45°), are shown in Fig. 3. The group corresponding to an incident irradiation angle of 45° exhibited the largest value for the orifice. Additionally, the SEM image of the 90° laser-treated surfaces indicated a relatively small orifice, compared with images for other irradiation angles.

Discussion

This study evaluated the effect of FS laser irradiation angle on the SBS of Y-TZP ceramics to resin cement. Significant differences were observed among the irradiation angles used. Thus, the hypothesis tested that use of different laser beam angles would influence the Y-TZP–resin cement SBS was accepted.

The roughness of the ceramic surface is an important factor for adhesion. Various roughness-enhancing techniques, such as APA, tribochemical silica coating, HF-acid etching, and laser etching have been reported [9, 20–22]. Although the APA method is commonly used to roughen the ceramic surface, it often results in the formation of microcracks in the ceramic material [23]. Üşümez et al. [8] reported that HF-acid etching of the zirconia surface did not significantly enhance the SBS of resin cement to the ceramic, similar to the results reported for APA. However, irradiation of the ceramic surface using different types of laser (e.g., Nd:YAG and CO2 laser irradiation) improved the SBS of resin to zirconium ceramic [13, 22]. Nevertheless, some studies have indicated that Nd:YAG treatment of the ceramic surface induced microcrack formation and phase transformation [8, 22]. In the literature, although several surface roughness techniques have been evaluated, researchers have yet to reach consensus on the optimal approach for ceramic surface roughening.

Ultrashort-pulsed lasers have become increasingly popular in medicine and dentistry. Compared with long-pulsed lasers, use of ultrashort-pulsed lasers for surface treatment is more convenient, due to their precision and the absence of thermal side effects. Fiedler et al. [24] reported that alumina-toughened zirconia ceramics could be micromachined without thermal side effects or microcracks. Delgado-Ruiz et al. [16] observed that microstructuring of zirconia implant surfaces using a FS laser provided the necessary surface roughness and contaminant removal without phase transformation. Few studies have investigated the effect of FS laser irradiation on Y-TZP–resin cement bonding strength, and none evaluated the effect of irradiation angle on SBS.

To substantiate this hypothesis, the study was divided into two main parts which are theoretical and physical. Theoretically, when the cylinder was cutting in different angles, cutting surface has different surface area values depending on angle (Figs. 1 and 4). As degree of angle between object surface and cutting plane is grown up, the contact surface area in between two objects will be increased. There is a positive correlation between adhesion and contact surface area. O’Brien [19] stated surface area gained directly increases bond strength. The laser beam configured as a parallel-shaped light which simulated a cylinder. It can arrive to the surface with different orientations: the first way, treated object is moving while laser beam is fixed. The second way is opposite of the first way. In this situation, effects of the laser can be changed in surface. In a study of nimonic materials, Kamalu et al. [25] observed that a larger laser-drilling angle produced a larger diameter aperture than did a normal laser angle. In the present study, when the cross section of the ablated holes was examined in SEM images (Fig. 3), the diameter of the hole increased gradually as the LBA decreased from 90° to 45°. Additionally, as the LBA value decreased from 90° to 45°, the ablation depth decreased. Çehreli et al. [26] determined that the dentin tubule orientation might affect the bond strength of restorative material to primary dentin. In the current study, as the LBA value decreased from 90° to 45°, the SBS value increased. This study has claimed that there was correlation between the theoretical and physical test data. These findings were confirmed by calculating Pearson’s correlation coefficient. However, further study is required to determine the relationship between the ablation depths, the size of the orifice, and SBS.

Conclusions

An experimental study was conducted to evaluate the effects of different laser beam angles produced by FS laser on SBS between Y-TZP and resin cement. The following conclusions were drawn:

-

When the angle between surface and laser beam increases, the orifice of the hole in the surface decreases.

-

As the angle between surface and laser beam decreases, the ablation depth decreases.

-

As the angle between surface and laser beam decreases, the SBS value of the resin cement to zirconia material increases.

References

Luthy H, Loeffel O, Hammerle CH (2006) Effect of thermocycling on bond strength of luting cements to zirconia ceramic. Dent Mater 22:195–200

Luthardt RG, Sandkuhl O, Reitz B (1999) Zirconia-TZP and alumina—advanced technologies for the manufacturing of single crowns. Eur J Prosthodont Restor Dent 7:113–119

Dias de Souza GM, Thompson VP, Braga RR (2011) Effect of metal primers on microtensile bond strength between zirconia and resin cements. J Prosthet Dent 105:296–303

Menani LR, Farhat IA, Tiossi R, Ribeiro RF, Guastaldi AC (2014) Effect of surface treatment on the bond strength between yttria partially stabilized zirconia ceramics and resin cement. J Prosthet Dent 112:357–364

Burke FJ, Fleming GJ, Nathanson D, Marquis PM (2002) Are adhesive technologies needed to support ceramics? An assessment of the current evidence. J Adhes Dent 4:7–22

Özcan M, Vallittu PK (2003) Effect of surface conditioning methods on the bond strength of luting cement to ceramics. Dent Mater 19:725–731

Erdem A, Akar G, Erdem A, Köse T (2014) Effects of different surface treatments on bond strength between resin cements and zirconia ceramics. Oper Dent 39:E118–E127

Üşümez A, Hamdemirci N, Köroğlu BY, Şimşek İ, Parlar Ö, Sarı T (2013) Bond strength of resin cement to zirconia ceramic with different surface treatments. Lasers Med Sci 28:259–266

Borges GA, Sophr AM, de Goes MF, Sobrinho LC, Chan DC (2003) Effect of etching and airborne particle abrasion on the microstructure of different dental ceramics. J Prosthet Dent 89:479–488

Li R, Ren Y, Han J (2000) Effects of pulsed Nd:YAG laser irradiation on shear bond strength of composite resin bonded to porcelain. Hua Xi Kou Qiang Yi Xue Za Zhi 18:377–379

Akın H, Özkurt Z, Kırmali Ö, Kazazoğlu E, Özdemir AK (2011) Shear bond strength of resin cement to zirconia ceramic after aluminum oxide sandblasting and various laser treatments. Photomed Laser Surg 29:797–802

Yassaei S, Moradi F, Aghili H, Kamran MH (2013) Shear bond strength of orthodontic brackets bonded to porcelain following etching with Er:YAG laser versus hydrofluoric acid. Orthodontics (Chic) 14:82–87

Paranhos MP, Burnett LH Jr, Magne P (2011) Effect Of Nd:YAG laser and CO2 laser treatment on the resin bond strength to zirconia ceramic. Quintessence Int 42:79–89

Stübinger S, Homann F, Etter C, Miskiewicz M, Wieland M, Sader R (2008) Effect of Er:YAG, CO(2) and diode laser irradiation on surface properties of zirconia endosseous dental implants. Lasers Surg Med 40:223–228

Rizvi NH (2003) Femtosecond laser micromachining: current status and applications. Riken Rev 50:107–112

Delgado-Ruiz RA, Calvo-Guirado JL, Moreno P, Guardia J, Gomez-Moreno G, Mate-Sanchez JE, Ramirez-Fernandez P, Chiva F (2011) Femtosecond laser microstructuring of zirconia dental implants. J Biomed Mater Res B Appl Biomater 96:91–100

Harris J, Stöcker H (1998) Handbook of mathematics and computational science. Springer, New York

Sano H, Shono T, Sonoda H, Takatsu T, Ciucchi B, Carvalho R, Pashley DH (1994) Relationship between surface area for adhesion and tensile bond strength—evaluation of a micro-tensile bond test. Dent Mater 10:236–240

O’Brien WJ (2002) Dental materials and their selection, 3rd edn. Quintessence Pub. Co., Chicago

Atsü SS, Kılıçarslan MA, Küçükeşmen HC, Aka PS (2006) Effect of zirconium-oxide ceramic surface treatments on the bond strength to adhesive resin. J Prosthet Dent 95:430–436

Sriamporn T, Thamrongananskul N, Busabok C, Poolthong S, Uo M, Tagami J (2014) Dental zirconia can be etched by hydrofluoric acid. Dent Mater J 33:79–85

Akyıl MŞ, Uzun İH, Bayındır F (2010) Bond strength of resin cement to yttrium-stabilized tetragonal zirconia ceramic treated with air abrasion, silica coating, and laser irradiation. Photomed Laser Surg 28:801–808

Kosmac T, Oblak C, Jevnikar P, Funduk N, Marion L (2000) Strength and reliability of surface treated Y-TZP dental ceramics. J Biomed Mater Res 53:304–313

Fiedler S, Irsig R, Gieseke M, Vehse M, Senz V, Oniszczuk AW, Tiggesbäumker J, Schuster C, Svanidze AV, Rothe N, Kaierle S, Hustedt M, Haferkamp H, Sternberg K, Schmitz KP, Seitz H, Lochbrunner S, Meiwes-Broer KH (2012) Material processing with femtosecond laser pulses for medical applications. Biomed Tech 57:603–605

Kamalu J, Byrd P, Pitman A (2002) Variable angle laser drilling of thermal barrier coated nimonic. J Mater Process Technol 122:355–362

Çehreli ZC, Akça T (2003) Effect of dentinal tubule orientation on the microtensile bond strength to primary dentin. J Dent Child (Chic) 70:139–144

Acknowledgments

The authors gratefully acknowledge Dr. Elif S. Tobi for the precise cutting of samples and Lec. Nezahat Dilekci for the figure design.

Conflict of interest

The authors declare that they have no competing interests.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Akpinar, Y.Z., Kepceoglu, A., Yavuz, T. et al. Effect of femtosecond laser beam angle on bond strength of zirconia-resin cement. Lasers Med Sci 30, 2123–2128 (2015). https://doi.org/10.1007/s10103-015-1762-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10103-015-1762-1