Abstract

Sustainability and the circular economy have become indispensable attributes of the supply chains of any industry or field of action in the effort to prevent damage to the environment and its negative economic and social impacts. Currently, most supply chains have focused on maximizing economic returns, neglecting the environmental and social impacts generated from the acquisition/processing of raw materials until the supply of products in the market and the post-consumer stage. An emerging alternative for achieving these attributes is the sustainable closed-loop supply chain (SCLSC). This paper offers a critical review of the literature on SCLSCs, their formulation as mathematical problems and the associated optimization models. No literature reviews were found with the focus, structure, and scope proposed in the present article, given that most publications associated with SCLSCs have a focus on the managerial perspective, including different topics, such as green supply chains, sustainable linear supply chains, reverse logistics management, collaborative practices, qualitative reviews of the effects of sustainability and circular economy. This review aims to identify gaps in the existing studies and the consequent opportunities for advancing the frontier of knowledge in future research on SCLSC optimization. We find that although studies for various specific industries that propose SCLSC optimization models have been published, they focus mainly on the economic and environmental dimensions of sustainability and with varying degrees of success, generally neglecting the social dimension. Furthermore, not all the technical cycles of the circular economy are dealt with in the literature in sufficient depth or detail, and, overall, the proposed models do not consider frameworks of reference in terms of economic, environmental, and social sustainability.

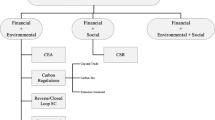

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

At present, the linear structure managed in the vast majority of supply chains has been focused exclusively on maximizing economic returns, neglecting the possible environmental and social impacts generated from acquiring and processing raw materials until the supply of products in the market, also considering the post-consumer stage. Common problems observed in the management of many supply chains in different industries are, for example, a selection of raw material suppliers without minimum environmental and social sustainability criteria or manufacture and distribution processes of products that are aggressive with the environment and harmful to society.

In particular, the delivery of products on the market whose design, material and functionality do not allow these products to be treated again through any circular strategy, namely remanufacturing, repair, reuse, recycling, which means that the useful life of such products cannot be extended; in many cases, littering is the final destination, bringing pollution to the environment as well as social problems associated, such as damage to people’s health; visual pollution; scarcity of future resources for the satisfaction of human needs. In addition, the processes executed for obtaining the products can also have negative environmental or social impacts, depending on the internal treatments utilized, the resources consumed, and the type of technology implemented. The arguments presented above have led to a reformulation of the design of most supply chains in the different industries, considering not only an economic perspective but also the social and environmental components of a sustainable vision of the future.

Thus, a growing interest in the progress of efforts to achieve economic, environmental, and social sustainability has prompted many important and prestigious organizations and institutions worldwide to promote targets for sustainable development. At the United Nations, for instance, the General Assembly on 25 September 2015 adopted resolution A/RES/70/1 proposing 17 goals for the year 2030 (United Nations 2015) that provide guidelines and key indicators for each one. Among the goals listed were ending poverty and hunger, promoting health and well-being, ensuring quality education, achieving gender equality, guaranteeing access to clean energy, promoting decent employment and economic growth, reducing inequalities, building sustainable cities and communities, and ensuring sustainable patterns of consumption and production. According to Golpîra and Javanmardan (2022), the agenda of the United Nations 2030 has contributed to raising worldwide interest in modeling and studying the loops that arise in circular supply chain networks and the way to close such loops in a sustainable way.

Another example is the Global Reporting Initiative (2022), an international organization that has drawn up a broad and highly adaptable structure of standards for reporting on the sustainability of public and private entities’ economic, environmental, and social impacts. The standards are ultimately aimed at facilitating responsible investing and formulating sustainable development policies. In the specific area of environmental sustainability, non-governmental organizations such as Greenpeace are working to protect the environment and promote behavioral changes that minimize the risk of negative effects on nature.

In light of the foregoing, one of the central challenges faced by the supply chains of every industry is to find the best way of responding intelligently to demands for increased awareness of sustainability emanating from governments, laws, policies, regulatory agencies, customers, and consumers, private and public institutions and other influential stakeholders. Indeed, the pressures exerted on manufacturers by consumers and governments for a greater environmental consciousness are getting stronger by the day (Chen and Ulya 2019).

Thus, although the demand for quality products and services at reasonable prices also continues to grow, so does the requirement that their characteristics and production processes have no negative effects on the fundamentals of sustainability, especially in its environmental and social dimensions. If ways are not found to integrate sustainability into supply chains, the long-term availability of resources will not be guaranteed, and the environment will sustain heavy damage, with serious social consequences.

Increasing awareness of sustainability issues has already prompted structural changes in many supply chains to reflect the limits on resources and the environmental and social problems occasioned by their use, with a view to ensuring that economies can continue to perform at high levels. This has led to the emergence of sustainable supply chains (SSCs), one of whose alternative forms is the sustainable closed-loop supply chain (SCLSC).

The structure of SCLSCs is a combination of SSCs and closed-loop supply chains (CLSCs). It involves traditional processes of forward and reverse logistics typical of the circular economy (remanufacture, recycle, reuse, repair, and renovate) that testify to its origins in CLSCs, but it is framed within a perspective of total sustainability, that is, sustainable economically, environmentally and socially. Helping to promote that perspective is that environment-conscious consumers consider remanufactured products significantly more attractive than those not (Abbey et al. 2015).

For SCLSCs to generate sustainable value added, there must be continuous monitoring of sustainability and circular economy indicators, with targets established by local, regional, and global authorities. To ensure the best possible supply chain performance, while meeting the agreed-upon sustainability objectives, it is essential that such targets be based on optimality criteria. In this sense, optimization models as tools for balancing performance with sustainability have a central role to play.

To address strategic, tactical, and operational problems in the context of any supply chain, proper mathematical formulations, optimization models, and solution algorithms are crucial for the success of the entire chain. SCLSCs are not the exception, as they require rigorous analysis and objective decision-making based on the objectives set by managers in the different stages of the chain following the established organizational mission and vision.

The present article offers a critical overview of the specialized literature in SCLSC. The novelty of our review is in the accent we have given to the revision and classification of papers, where among many aspects that could be chosen, we selected to classify the papers according to the SCLSC’s formulations as mathematical problems and the associated optimization models, with an eye to identifying gaps in the existing studies on SCLSC optimization and the consequent opportunities for advancing the frontier of knowledge in future research on SCLSC optimization.

Sect. “Previous related review articles” presents a description of the related previous reviews of the literature related to sustainability and closed-loop supply chains, while Sect. “Review methodology” briefly presents the methodology conducted to conceive and organize the present review study. Then, Sect. “Research framework”, which is the main body of this paper, describes SSCs and CLSCs and then reviews in depth the characteristics of the various SCLSC optimization models that have been proposed thus far, highlighting the differences in focus with respect to the present classification. Based on the analyses performed in Sect. “Research framework”, Sect. “Limitations and opportunities for future studies” identifies and describes a series of related research gaps and opportunities. Finally, Sect. “Conclusions” presents our conclusions.

Previous related review articles

Revising the specialized literature, we found some recently published review articles related to sustainability and closed-loop supply chains. However, the emphases of those reviews differ from ours: the present paper proposes a classification, structure, and analysis of the documents guided by aspects associated with SSC, CLSC, and SCLSC optimization models. We identified a few relevant articles reviewing sustainability and closed-loop supply chain aspects but from different standpoints.

Sahamie et al. (2013) conducted a review addressing the administration of closed-loop supply chains, identifying the need for transdisciplinary collaboration by developing a framework that highlights the benefits of collaboration between research areas in closed-loop supply chain management; they show that most of the research focuses on recycling.

Brandenburg et al. (2014) systematically review the literature on quantitative models focused on the management of sustainable supply chains, a topic that is broader than the one revised in the present study. These authors focus their analysis on four research questions regarding which dimensions of SCM are considered in formal models for sustainable SCM, which sustainability aspects are reflected in forward SCs, which models and tools are currently employed in SSCM research, and which directions should be considered in the future. They identify as fertile areas of future development the integration of social issues into modeling, expanding the research in scope including other industries and the need for more stochastic modeling. They also highlight the need for more validation and integration of the research into business and practice.

Govindan et al. (2015) carried out a systematic and descriptive review of the state-of-the-art of articles dealing with reverse logistics and closed-loop supply chains from 2007 to 2013; this is a similar topic to that of this article but treated in a broader context. The authors focus their analysis on publications regarding mainly CLSC, reserve, sustainable, and green supply chains. They try to fill a gap by comprehensively reviewing supply chains in an integrated way for both reverse and closed-loop logistics. They identify several research opportunities regarding the interrelation of RL and CLSC. They conclude that the integration of different levels of decision-making, including uncertainty, defining new decision variables, and paying attention to multi-objective approaches, are future opportunities for development.

Recently, Chiaraluce et al. (2021) performed a bibliographic review, using the VOSviewer software, on the circular economy model in the agri-food sector, with particular relevance in the reuse and recovery of waste and by-products. Another bibliometric review deals with the management of sustainable supply chains under the circular economy, analyzing the attributes of a well-documented knowledge base and describing some theoretical trends, mostly based on co-citation inferences (Theeraworawit et al. 2022).

Alkhuzaim et al. (2021) review the assessment of the characteristics of the circular economy, emergy analysis, and sustainable supply chain management. Emergy analysis is a useful technique introduced in thermodynamics and general systems theory that can be used in sustainability and circular development on various levels, primarily as an environmental accounting tool identifying the cumulative energy consumed when producing a service or product. This study highlights the identification of the sustainability dimensions (economic, social, and environmental) that are analyzed in the papers, but from a managerial perspective and without getting into the details of its components.

Furthermore, Sudusinghe & Seuring (2022) explore different collaborative practices in the supply chain, circular economy strategies (e.g., reduce, reuse, recycle), sustainability performance (environmental, economic, social), and their underlying interrelationships, arguing that relational, collaborative practices, such as sharing responsibility for product recalls, incentives, and penalties, improve the circularity of supply chains by enabling the product return process.

Kiss et al. (2019) developed a qualitative review of the literature on short supply chains and their effects on sustainability and circular economy aspects, such as carbon dioxide emissions, energy consumption, environmentally friendly production, product quality, consumer health, and income. This work does not enter into the details of the mathematical models that optimize the aforementioned aspects. Likewise, Meherishi et al. (2019) develop a descriptive review based on the distribution of methods used in the management of supply chains with sustainable packaging, describing the publications by journal type and year, general map of thematic content clusters of the literature, classification by main themes and dimensions of sustainability (environmental, social, economic), among others.

Additionally, Walker et al. (2021) propose an integrated framework of approaches to assess the sustainability of circular economy practices in circular networks between companies. Although they make a certain description of quantitative approaches to decision support, their scope is directed towards sustainable evaluation of networks between companies, involving approaches of circular management, industrial ecology, Industrial symbiosis, eco-industrial parks, and others; notice that the aspects and the scope of Walker et al. review is broader than what we propose in the present work.

Finally, De Lima et al. (2022) explore and descriptively analyze the proper management of uncertainty from a strategic mitigation perspective, the characterization of circular economy practices, and sustainability outcomes in circular supply chains. Once again, this review does not focus on characterizing the optimization models applied in sustainable closed-loop chains.

None of these reviews cover the details of the optimization models associated with SCLSCs as a core aspect for their classification, which is a major feature of the present paper, valuable not only for researchers but also for practitioners involved in any stage of the supply chain design. In what follows, we set out the general characteristics of SSCs and CLSCs and then analyze the SCLSCs in detail, with particular emphasis on optimization models, taking into consideration some aspects of sustainability and circular economy discussed in previous reviews of the related literature. A key contribution of our methodology is the focus and detail given to the methodological aspects, the components of the sustainability dimensions modeled as objectives, the different circular economy strategies used, and the different decision levels, among other relevant aspects regarding the optimization modeling focus given to our proposal of state-of-the-art revision.

Based on the review, we identify gaps in the literature, and opportunities for future studies are established from the mathematical features associated with the different optimization models and solution algorithms.

Review methodology

As previously mentioned, this article provides a critical review of SCLSCs from the framework of optimization models to subsequently identify gaps and opportunities for future studies that could make valuable contributions in the treatment and optimization of this type of chains. It is essential to mention that the intention of this article is neither to present an exhaustive systematic review of the literature nor a bibliometric one. According to the classification proposed in Grant & Booth (2009), the present document can be classified under the literature review category. Our review is mainly oriented towards characterizing the main attributes embedded in the different SCLSCs optimization models in the most interesting articles to find possible gaps and opportunities for further studies.

Thus, for this review, we compiled a sample of the most relevant articles according to the scope of this work, which is subscribed to the selection of papers from the Web of Science database with a publication date until December 2022 using the following search string in either the abstract or the title: sustainable OR sustainability AND closed-loop supply chain AND optimization. Other related topics, such as reverse logistics, green supply chains, sustainable linear supply chains, green closed-loop supply chains, or closed-loop chains, are not included in this review; we focus our classification and descriptions on those articles with a solid optimization framework in the context of sustainable closed-loop supply chains (SCLSCs).

Research framework

Sustainable supply chains

Competition in every industry is driving demand for high-quality, reasonably priced products and services that are also environmentally friendly and meet commitments to create social value. Underlying this phenomenon are pressures originating among consumers, public and private entities, governments, and other sectors of society for greater awareness of sustainability and the adoption of sustainable practices. According to Kumar et al. (2020), in recent years, there has been increasing emphasis on environmental, economic, and social issues from a sustainable development perspective, leading in turn to the emergence of sustainable supply chains in which human behavior factors play a central role.

A consequence of the foregoing is that SSCs have become indispensable in the development of sustainable cities (Nagurney 2015), given that they enable a series of innovations and policies based on sustainability indicators. Businesses and societies as a whole that promote sustainable development are considered to be healthy economies (Oniszczuk-Jastrzabek et al. 2020).

Narimissa et al. (2020) posit that SSCs are characterized by three dimensions of sustainability: economic (e.g., costs, profits, profitability, added market value), social (e.g., health, labor climate, work opportunities, social well-being, country development, customer satisfaction) and environmental (environmental impacts, recycling, pollution, and environmental risks). Various other works in the literature also conceive of sustainability under this threefold classification (for example, Allaoui et al. 2019).

The success of an SSC depends on the extent to which its vision, mission, and organizational processes are based on sustainability principles. Bratt et al. (2021) underline the importance of an SSC for the organizational learning of external stakeholders such as suppliers, an operational definition of social and ecological sustainability, and procedural support for co-creating strategic plans for change. SSC strategies should take into account customers, stakeholders, and specific product requirements (Medina-Serrano et al. 2019).

SSC power structures also play a central role given that, as has been shown (Li et al. 2017), in decentralized supply chains, the dominant player, whether manufacturer or retailer, always benefits economically. Factors such as effective communication and direct interaction between chain links, suppliers, and retailers are of equal importance in improving sustainability processes (Berning & Venter 2015).

According to Sajjad et al. (2015), the adoption of SSC practices is motivated by the ethical values of upper management and stakeholder risk management but strongly hindered by suppliers’ lack of awareness, negative perceptions, and inadequate government support. Supply chains must have a thorough understanding of their sustainability strategy in order to adapt circular economy initiatives in such a way that they can be effectively and efficiently managed (Sehnem et al. 2019).

A number of other elements are key to the success of SSCs. Under the current information society paradigm, social media may be useful in managing sustainability, given the incidence of formal institutions and personal connections in the execution of environmental and social practices in the supply chain (Lu et al. 2018). Measuring the carbon footprint of SSCs’ products and services is also fundamental in managing their environmental impact (He et al. 2019). Information sharing enhances profits through reductions in buyers’ unit prices and the establishment of environmental and social cost parameters (Khan et al. 2016). Sustainable supply chain practices are decisive in generating positive impacts on financial performance (Mann and Kaur 2020). Finally, the social dimension of SSC sustainability can be strengthened by judicious management of strategic networks designed to facilitate knowledge flow and gain advantages for the enterprise.

Closed-loop supply chains

It is widely recognized that remanufacturing must be incorporated into supply chains for reasons ranging from the scarcity of resources and damage to the environment to increasingly strict environmental laws and policies. One form of sustainable supply chain in particular that can control environmental impacts and ensure economic performance is the closed loop supply chain (CLSC), which incorporates both forward and backward flows of products, materials, and parts (Schenkel et al. 2015b). CLSCs thus integrate the practices of the circular economy into their structure and operation (Russo et al. 2019).

The foregoing implies that a CLSC has as many forward flows, that is, processes ranging from raw material extraction to finished product distribution to end customers, as it does backward flows, the latter including especially the reacquisition of used products or parts from end users in which reverse logistics play a crucial part. The processes involved in these return flows include testing, sorting, and determining which reprocessing alternatives (remanufacturing, remarketing, reuse, repair, recycling) are the most appropriate (Lassinovskaia et al. 2017).

This return flow element in CLSCs adds considerable complexity to supply chain management (Cannella et al. 2016). The incorporation of the technical cycles in the circular economy, such as remanufacturing and other similar processes, has been fundamental in environmental protection (Wang et al. 2017) and is becoming ever more so under the pressure of local laws and international regulation (Dou and Cao 2020).

Shekarian et al. (2021) suggest that consumers’ willingness to choose remanufactured products has a greater influence on prices and profits than their perception of the environmental component. Xu et al. (2017), however, maintain that CLSCs are a response to consumers’ green awareness, which is a contributing factor in the adoption of environmental protection legislation. Policies and laws on environmental control promote the creation by businesses of circular chains that make use of second-hand materials and ensure scrap materials are not dumped into the environment (Wang et al. 2019). This requires that CLSCs be designed for almost all industries (Özkır and Başlıgil 2013).

Xie et al. (2017) and Zhang et al. (2020) highlight the environmental responsibilities of supply chains, and in this sense, CLSCs are in line with green awareness, incorporating processes such as remanufacturing and recycling that have positive environmental impacts while lowering costs and increasing profits. Such chains create value by generating opportunities, reducing risks, and emphasizing strategic success factors such as product design and customer service (Schenkel et al. 2015a). The various benefits of CLSCs explain their presence in every type of industry (Choi et al. 2013).

However, a condition for CLSCs’ success is that their designs are efficient, a significant challenge given the level of uncertainty in the quality, quantity, and timing of product returns (Zu-Jun et al. 2016). Both demand and returns are correlated stochastic variables, so the exchange of information between manufacturers and remanufacturers plays an important role in the generation of benefits for the manufacturer and the productive system in general (Hosoda et al. 2015).

Also essential is that CLSC planning and operating take into account the uncertainty in customer demand and carbon policies (Tao et al. 2020). Other factors not to be ignored are the design, planning, control, and operation of CLSCs aimed at maximizing the generation of value over the entire product lifecycle, especially in the case of product returns and the related technical cycles, such as remanufacturing, recycling, and reusing (Yang et al. 2021).

Product returns have the potential to create value by reducing impacts on the environment, providing customer value, and generating economic resources for the productive system (Krikke et al. 2013). For a CLSC to realize this potential, a number of requirements must be met: (i) a configuration that optimally balances key factors such as prices, product return rates, and profits (Jalali et al. 2020); (ii) coordination of activities both forward and backward (Choi et al. 2013); (iii) the definition of power structures, roles and leadership levels between supply chain links (Quan et al. 2021); (iv) optimization of product return flows (Zheng et al. 2021); (v) optimization of investment in design and advertising (Li et al. 2020); and (vi) flexible policies to avoid excess capacity in processes such as collection and remanufacturing (Georgiadis and Athanasiou 2013).

Other aspects to consider in boosting the value added of circular chains are determining the financial risk involved in design and planning with a view to optimizing net present value and minimizing the associated risks (Cardoso et al. 2016); the optimal product return rate as a function of costs, lead times and demand variability (Ponte et al. 2020); manufacturing and remanufacturing capacity constraints in accordance with demand and returns uncertainty (Dominguez et al. 2019); policies for the optimal design of a reward-penalty mechanism that stimulate better waste collection rates (Wang et al. 2015); and infrastructure, technology and personnel qualifications (Ghisolfi et al. 2017).

Note further that processes such as remanufacturing and product returns must be regulated not only by policies but also by benchmarks (Xintong et al. 2021). The variability in costs associated with circular processes when estimating optimal production rates that minimize total costs should also be kept in mind (Hosoda et al. 2021).

There can be no doubt, then, that CLSCs are capable of creating economic, environmental, and customer value (Schenkel et al. 2015b). Governments and business leaders should, therefore, adopt CLSC models and practices, particularly in order to achieve sustainable economic and environmental impacts (Russo et al. 2019). Nevertheless, economic feasibility is an essential input to the process of defining sustainable policies in the environmental context, for example (Bhattacharjee and Cruz 2015). Also needed to ensure sustainable supply chains is the development and incorporation of a holistic vision, together with the adoption of policies and mechanisms for promoting value creation that avoid vicious feedback loops (Schenkel et al. 2019).

Sustainable closed-loop supply chains and their optimization models

According to Lu et al. (2018), one of the emerging practices in SSCs is the circular economy, which requires a high level of integration. In such cases, they are known as closed-loop supply chains (CLSCs), already reviewed in the previous subsection. Whereas the management of CLSCs generally focuses on optimizing economic and environmental factors, SCLSCs are concerned not only with the circular economy but also with economic, environmental and social sustainability based on its circular structure.

Thus, an SCLSC is a CLSC that also incorporates all the characteristics of an SSC. The idea is to protect the environment through such strategies as recycling and minimizing carbon emissions while lowering manufacturing costs and incrementing profit margins, thus reflecting both the environmental and economic dimensions of sustainability (Zou et al. 2018).

Thanks to their circular structure, SCLSCs reduce waste by circling back discarded products into the supply chain through processes such as repairing, reselling, or dismantling them for parts (Nasr et al. 2021). Managing SCLSCs involves underlying social goals related to labor practices, work opportunities, social well-being, social development, and customer satisfaction without neglecting economic and environmental demands.

Whereas in a CLSC, the management of economic, environmental, and social performance is complex (Khorshidvand et al. 2021a), an SCLSC balances the three optimally via its circular and sustainable structure. On this aspect, there are opportunities for further research in the development of optimization models for sustainable circular supply chains. The models proposed in the publications included in this survey display a series of key characteristics whose presence, absence, or description, as the case may be, are summarized in Table 1 through 5. The attributes covered in the tables are the following: multiproduct, multiperiod, methodology employed, treatment of uncertainty, industry or sector, decision level (strategic, tactical, operational), product pricing, resilience, sustainable supplier selection criteria, transport model, circular economy technical cycle, and sustainability dimensions. The notation used in the tables is explained in the Appendix. The attributes identified in Table 1 are multiproduct, multiperiod, methodology employed, treatment of uncertainty, and industry or sector.

Methodology and industry of application

As is shown in Table 1, published studies have presented SCLSC optimization models for various industries or applications. These include automobile manufacturing and assembly, water tank supply chains, dairy products, photovoltaic systems, perishable agricultural products, plastics production and recycling, clothing manufacturing and distribution, LED light bulbs, pet toy supply chains, LED and LCD television sets, steel, mining, tire manufacturing, pulp and paper, nuts, pharmaceutical supply chains, and COVID-19 medical equipment and masks. Clearly, SCLSC modeling can be applied to a variety of different industry contexts, providing decision-making tools that aid in improving sustainability indicator results (see Table 4). The publications are concentrated on the years starting in 2012 because the number of works on the optimization aspect has steadily grown since that year.

However, the review of this literature reveals that few studies consider multiple periods or products. Furthermore, although some models are deterministic (e.g., Devika et al. 2014; Govindan et al. 2016; Hajiaghaei-Keshteli and Fathollahi-Fard 2019), the management of the uncertainty is conducted through sensitivity analysis or scenario analysis; in other papers, the uncertainty is addressed through a range of techniques, such as fuzzy optimization (Soleimani et al. 2017), stochastic programming (Mohammadi et al. 2020), robust-stochastic programming (Shahparvari et al. 2021), or stochastic possibilistic programming (Zhalechian et al. 2016). The above aspect is relevant, given that supply chains are subject to numerous uncertain variables and parameters, such as prices, costs, demand, supply, and the quantities, qualities, and timing of product returns.

As for methodological approaches, the optimization models in the studies surveyed all generally employ mixed integer linear, mixed integer nonlinear or stochastic programming, multi-objective mixed integer programming, multi-objective mixed integer nonlinear programming, some of which are supported by multi-objective solution techniques such as weighted goal programming, weighted Tchebycheff method, or ε-constraint with its extensions.

At this point, it is clear that sustainability is a multidimensional concept (economic, social, and environmental). In fact, the literature covers SCLSC optimization models that involve these three dimensions of sustainability under a multi-objective approach. Examples are Pourmehdi et al. (2020) optimize total profits, CO2 emissions and water consumption, and social sustainability with employment opportunities and work days lost due to random accidents; Nasr et al. (2021) optimize total costs, environmental impacts caused by facility opening and transportation and employment opportunities; and Govindan et al. (2016) optimize total profits, CO2 emissions and responsibilities towards stakeholders at regional level among others. However, other studies that model a single objective are also reviewed here, in which the limited scope of their analyses comes from the following possible situations: (1) studies that are limited to economic performance objectives without considering environmental and social impacts, minimize total costs (Salehi-Amiri et al. 2021) or maximize total benefits (Al-Refaie et al. 2021); (2) economic and environmental sustainability is managed as a single global objective expressed in terms of costs, for example Jiao et al. (2018) minimize total costs in which the environmental dimension is related to costs associated with CO2 emissions and greenhouse gas emission burdens.

The components of the objective functions are studied in Sect. “Modeled objectives”. Finally, to address large problems, many studies resort to heuristics (Shahparvari et al. 2021), Lagrange relaxation (Vali-Siar and Roghanian 2022), and meta-heuristics (Babaeinesami et al. 2021), among others.

Decision levels and other aspects

Table 2 identifies publications as regards the inclusion of decision-level attributes and those relating to pricing, resilience, transport modes, and sustainable supplier selection criteria.

The majority of the articles surveyed consider strategic decisions in the modeling, particularly facility location and capacity in the design of SCLSCs. For example, Behzadianfar et al. (2022) consider potential plants, distribution centers, and collectors, Abdallah et al. (2012) analyze potential remanufacturing centers, and Tehrani and Gupta (2021) consider decisions to open facilities with a specific capacity. In some models, strategic decisions associated with the technologies used in the facilities are identified, e.g., the type of recycling technology (Sahebjamnia et al. 2018) or the type of manufacturing technology (Mirzagoltabar et al. 2021). With regard to tactical decisions, there are many works with a focus on features such as output level, resource allocation, storage, prices, or supplier selection. Only some, however, propose models that simultaneously treat all three levels (strategic, tactical, and operational). Also, few works treat only the operational level by fixing all the higher levels associated.

Many of the models do not consider different transport modes. In addition, the studies rarely address pricing decisions. Exceptions are Khorshidvand et al. (2021a, b), where pricing and advertising decisions are included. Resilience is also dealt with in just a handful of articles. For example, Das (2020) includes supply-side flexibility and capacity to contribute to economic sustainability; Mehrjerdi and Shafiee (2021) consider resilience measures in terms of multiple sourcing, contracting with standby suppliers/facilities, and information sharing; and Babaeinesami et al. (2021) evaluate improving system resilience by increasing routing options (operational) and additional capacity to storage warehouses (strategic).

As for supplier selection criteria, a minor proportion of the articles directly or indirectly includes sustainability principles in the form of attributes such as transport costs, raw materials prices, environmental impacts associated with raw materials production and transport, and supply capacity. Nasr et al. (2021), for example, utilize the fuzzy best–worst method to choose the most suitable suppliers in terms of economic, environmental, social, and circular factors. Esmaeilian et al. (2021) consider raw materials prices, supply capacity, transport cost, the unemployment rate, economic value, and the impact of supplier choice on regional development and job creation. Mehrjerdi and Shafiee (2021) take into account supplier disruptive capacity as a criterion for supplier selection, while other authors consider other criteria like transportation costs of raw materials (Mirzagoltabar et al. 2021), purchase price of raw materials (Pourjavad and Mayorga 2019), supply capacity and environmental impact of transportation from suppliers (Moheb-Alizadeh et al. 2021).

Finally, no studies were found proposing optimization models that jointly address pricing mechanisms, resilience, sustainable supplier selection criteria, and diverse transport modes.

Circular economy technical cycles

The elements of circular economy contemplated in the models surveyed are presented in Table 3.

Among the various dimensions of the circular economy, the most typical is the recycling technical cycle, with remanufacturing a rather distant second. In fact, recycling proves to be a circular strategy that can be applied to a wide variety of industries, including Glass, Tire, Lighting, Food, Plastic, Automobile, Mining, Paper, Pharmaceuticals, Electrical or electronic products, among others, as seen in several studies. However, much less commonly found in models are the repair, recovery, refurbishing, or reuse technical cycles for a number of possible reasons:

-

They are outsourced.

-

They are not part of the business’s economic focus.

-

The incorporation of the circular economy concept into supply chain management is not fully understood.

-

There are no incentives or government policies that facilitate their adoption.

-

A reduced number of circular economy technical cycles can be applied to the product depending on the types of materials in its composition; for example, food waste can be recycled but not remanufactured or repaired.

No models were found that integrate other aspects of the circular economy, such as redesign and reduction. Redesign refers, for example, to modeling the maximization of products’ useful life and the minimization of pollution and waste during after-sales use of products not treatable by any circular economy strategy. Reduction, on the other hand, refers to the setting of direct targets for minimizing the consumption of natural resources and virgin raw materials, and other requirements for carrying out processes associated with operating SCLSCs.

Modeled objectives

Virtually all of the studies surveyed address the traditional economic dimension of sustainability, which is essential for the adequate performance of a SCLSC (see Table 4). The majority of them define the minimization of total cost and the maximization of total profit as specific objectives. However, very few consider other possibilities such as return on investment, product sales in secondary markets (for product reuse), savings due to circular economy practices, lost sales, pricing, investment in advertising, or sustainable supplier value based on environmental, social and circular as well as economic criteria. Nor does the literature consider the optimization of key performance indicators for economic sustainability, such as market value added (MVA) or economic value added (EVA); only a single article considers net present value (NPV).

As regards the environmental dimension of sustainability, most of the studies do give sufficient attention to optimization indicators. The ones most commonly considered are CO2 emissions or their equivalent and environmental impacts associated with manufacturing, remanufacturing, transport, distribution, and the operation/opening of facilities. Less frequently included are the impacts of factors such as fuel and water consumption in manufacturing activities, generation of industrial wastewater, importation of products, asbestos emissions, energy consumption, and greenhouse gases other than CO2.

Equal prominence is given by the literature to the social dimension of sustainability, with work opportunities and lost work days being particularly frequent. Other social indicators found on the occasion include energy deprivation, road development in remote areas, customer order response capacity, customer risk, potentially harmful products for consumers, regional or local economic value, and regional unemployment rates.

Limitations and opportunities for future studies

In this section, we review, from a sustainability and circular economy standpoint, the state of the art in SCLSC optimization models, their various limitations, and the consequent opportunities for future research.

-

In the case of economic sustainability, the literature generally presents models whose objective is the optimization of traditional indicators such as total costs, revenues, and profits; savings due to circular economy practices; and in a very few cases, other indicators such as return on investment, advertising investment, and price optimization.

-

Regarding environmental sustainability, the models’ objective functions are frequently confined mainly to optimizing impacts associated with CO2 emissions, transport, and consumption of resources such as energy, fuel, and water. Less commonly optimized are environmental effects related to inventory storage, the opening of facilities, operations at various links in the supply chain (e.g., production, distribution, warehouses, retailers, collection centers, remanufacturing, and recycling), circular economy practices, and the ecologization of products.

-

Social sustainability is not always addressed in the models’ objective functions, and when it is, the aspects included are, in most cases, limited to maximizing fixed and variable work opportunities arising from the opening of installations and minimizing such factors as lost work days due to workplace accidents, injuries, and work-related illnesses. Few studies consider other social attributes such as customer order response capacity, product shortages at demand points, products sold but not yet delivered, regional development and economic value, unemployment rates, the effect of waste on society, worker satisfaction, extended producer responsibility, health indices, products potentially harmful to consumers, and other consumer risks.

In light of the foregoing, there is a need for industry-specific models and general case studies that treat more thoroughly the various aspects of sustainability objectives, especially those in the environmental and social dimensions. This would include, but not be limited to, those already mentioned here, based on recognized concepts in circular economy and sustainability. In addition, the most relevant case studies are based on recognized frameworks, such as The Sustainable Development Goals (SDGs) adopted by the United Nations, which recognize that social sustainability must be balanced, economically and environmentally, the Global Reporting Initiative (GRI), which is an organization whose purpose is to promote the preparation of economic, social and environmental sustainability reports in all types of organizations, or the OECD Inventory of Circular Economy Indicators (2021), which provides input, process and output indicators to monitor and assess the progress of circular economy strategies, to improve the performance in the context of circular economy in organizations.

Also needed are analyses that integrate the circular economy technical cycles applicable to each industry and models for those that have yet to be addressed in the literature, such as the industrial product redesign. In particular, regarding this last concept, Stahel (2019) mentions that more and more industrial designers are widely using Eco-design principles for waste prevention and energy efficiency. A possible way to achieve such principles would be to model the optimal configuration in the design of the products so that they can be modularized according to ecological constraints (Smith and Yen 2010). Thus, if the design stage of the products considered those principles either to close the cycle or to facilitate the application of circular economy strategies, the waste that ends up in landfills or anywhere (littering) could be reduced.

In addition to more thorough treatments and the extension of models to other industries, there are various aspects of the methodological and modeling approaches that are worthy of further exploration, some of a general nature and others more specific, whose application will depend on the particularities of each industry case study. In our view, the main challenges for future research are as follows:

-

Management of uncertainty. This involves two challenges. One is to attain a full understanding of the effects of uncertainty on key parameters such as demand, supply, prices, costs, capacity, distance, inventory scarcity, unstable supplier shipments, product returns rate, returned product quality, and the useful life of products. The other challenge is to apply rigorous optimization approaches (e.g., robust, stochastic, fuzzy, possibilistic) in dynamic contexts where many processes are new, and there is little in the way of field data for making precise parameter estimates.

-

Multi-objective analyses. This challenge is also twofold: understanding the commitments implied by the different objectives and actors in the decision-making processes but also the choice of methodology or multi-criteria algorithm that will generate solutions satisfying the needs of the problem in question.

-

The extension of complex supply chains. The main challenges in this area are the modeling of a complex system with various actors and the development of advanced optimization methods for solving the consequentially large-scale problems.

-

The incorporation of the time component. Many strategic studies do not consider this element, yet it is important in such tasks as modeling transformation processes and designing supply chain expansion projects.

-

Modeling the transport of products, raw materials, and other physical flows. Among other aspects in this area are cross-docking decisions, vehicle routing, transhipments, incorporation of efficient vehicle fuel consumption parameters, analysis of road network traffic states and availability of alternative vehicles, evaluating the potential for the use of non-conventional transport modes such as drones and other emerging technologies, consideration of transshipment as a complement to the transport problem, the possibilities for transferring inventories from one facility to another, and the quantification of the impacts associated with importing products or raw materials with different prices and qualities.

-

Product ordering. Challenges here include designing a multi-channel structure for a supply chain that makes products available across multiple media and analyzing the relationships between product prices sold through regular and discount channels. For example, products offered online and offline may be sold at different prices and with different delivery times and conditions and may involve time window restrictions due to issues such as product expiration dates or meeting customer service commitments.

-

Additional economic and financial factors are essential for circular sustainable supply chain investment and implementation. Examples are green investment, budgeting, sources of finance, key economic and financial performance indicators, predefinition of shares in total supply chain profits to be distributed among partners and participating organizations based on the power structure, modeling sources of risk (financial, customer, the deterioration/disruption of a supply chain link), cost structure, lost sales, economies, and diseconomies of scale, and different cost assumptions for each category of raw material inputs in each industry.

Another interesting challenge in this context is the selection of the optimal sustainable circular income model for the chain, according to the particularities of each case. Henzen and Weenk (2022) mention the existence of several alternatives, among which we can mention: (1) subscription model or rental of products or services; (2) a model that includes additional revenue associated with reverse logistics, for example, evaluating the possibility of establishing repair, reconditioning, or remanufacturing facilities instead of outsourcing or deciding not to do so; (3) generation of income based on long-lasting products whose prices are high but with lifetime guarantees; (4) income model based on the collection of product waste at the end of their useful life to be transformed into new forms of value, for example, into secondary raw materials for the generation of other attractive products for environmentally friendly consumers; (5) similar to the previous model, industrial symbiosis focuses on converting waste from one process into input for another internal or external process, which allows for reducing costs or generating income from possible new business lines or local collaborations).

-

Government policies and incentives. This would involve developing analyses of performance under different global and regional policies, regulations, and government incentives associated with the circular economy and sustainable development for different industries and operating locations. For example, to analyze the impacts related to the regulations establishing Extended Producer Responsibility (EPR), which are gaining much strength today. The EPR defines guidelines subject to penalties for producers to get rid of the waste generated post-consumer properly; moreover, it defines the regulations associated with single-use products, provides guidelines for encouraging the use of materials that are easy to recycle or recover, and establishes restrictions on CO2 emissions, among other statements. Also, it would be important to understand the effect of the establishment of mechanisms such as discounts, incentives, and other strategies for the return of products used in the supply chain after defined time limits.

-

Operational decisions. Challenges in this area are addressing supply chain efficiency through data analysis or other novel alternatives, incorporating additional operating decision variables, and adopting inventory control policies, for example, using other methods such as data envelopment analysis (DEA) and multi-criteria decision-making (MCDM) to maximize the efficiency in some links along the supply chain.

-

Supply chain power structure. Analyzing centralized and decentralized structures is relevant to quantifying their relevance to the impacts on sustainability (economic, social, and environmental) and circular economy strategies.

-

Aspects of the digital age, technologies, and architectures of the chain’s facilities. This includes a wide variety of elements such as digital and flexible manufacturing systems for multiple product source flows, the use of blockchains, and Industry 4.0 elements like artificial intelligence, robots, nanotechnology, quantum computing, autonomous vehicles, biotechnology, and the internet of things. Regarding this last concept, Henzen and Weenk (2022) argue that this enables the unification of digital and manufacturing technologies, creating products that can notify any problem and specify when they need to be repaired or even schedule their own maintenance; this issue involves essential information for an adequate application of circular strategies such as reuse and repair.

The architectural design of the facilities and elements through the supply chain is an aspect that also plays a leading role in sustainability. Lau (2021) calls on industry members to mitigate the environmental damage generated by the architecture of the facilities, highlighting that in order to achieve the United Nations SDGs, sustainable architectural designs for supply chains must be considered.

Thus, the consideration of the best operating technology as well as the most appropriate architectural design according to criteria of economic, social, and environmental sustainability (e.g., green architecture, eco-architecture, sustainable architecture) in the modeling decisions represents another challenge not profoundly explored in the reviewed literature.

Conclusions

Sustainable supply chains (SSCs) are emerging as the result of a growing sustainability awareness expressed by a range of actors encompassing consumers, producers, public and private organizations, and governments, and are driven by factors, such as competition, legislation, and ever-stronger local and global policies. The underlying issue is the need to simultaneously manage a series of economic, environmental, and social issues more sustainably in response to the limits on natural resources and the directly or indirectly negative effects of traditional, non-sustainable supply chains on the environment in which they interact.

One particular form of SSCs is the sustainable closed-loop supply chain, which takes an integral approach to sustainability in that it involves both the forward and reverse processes of the circular economy, enabling it to generate added socioeconomic value while remaining environment-friendly. It thus constitutes an alternative that is capable of a systematic response to the challenge of balancing the many variables involved in the three dimensions of sustainability: economic, environmental, and social.

No literature reviews were found with the focus, structure, and scope proposed in the present article. Although there are some publications associated with SCLSCs, they have a different focus, often from a managerial perspective or related, but in which different topics are studied (for example, green supply chains, sustainable linear supply chains, reverse logistics management, collaborative practices, qualitative reviews of the effects of sustainability and circular economy).

The conclusion drawn from this review of the state of the art in sustainable closed-loop supply chain optimization models is that the existing literature has not yet fully addressed sustainability in all three dimensions. In particular, social sustainability is very vague, in most cases limited to maximizing job opportunities and reducing workplace accidents, while environmental sustainability is mostly focused on reducing carbon dioxide emissions. The same is true of the technical cycles making up the circular economy; then, there is a great opportunity to delve into little or unexplored circular technical cycles, such as the sustainable design of industrial products, and integrate circular strategies according to the type of industry. Furthermore, the published studies are not generally based on world-level standard principles and guidelines for the optimization of the objectives associated with sustainability. This, in turn, means that there exist many opportunities for undertaking new lines of research that could produce new developments contributing to the advancement of the knowledge frontier in this area.

Finally, we note that sustainable closed-loop supply chains have a fundamental role to play, both in the design of sustainable cities and societies, due to their potential for strengthening the bases of sustainability while simultaneously creating added value and through their interactions within the network of other similar supply chains helping to sustain the production of goods and services over the long term that are useful for humanity without damaging the environment, exhausting natural resources or producing major negative impacts on economic and social values.

Data availability

No datasets were generated or analyzed during the current study.

References

Abbey JD, Meloy MG, Guide VDR, Atalay S (2015) Remanufactured products in closed-loop supply chains for consumer goods. Prod Oper Manag 24(3):488–503. https://doi.org/10.1111/poms.12238

Abdallah T, Diabat A, Simchi-Levi D (2012) Sustainable supply chain design: a closed-loop formulation and sensitivity analysis. Prod Plann Control 23(2–3):120–133. https://doi.org/10.1080/09537287.2011.591622

Alinezhad M, Mahdavi I, Hematian M, Tirkolaee EB (2021) A fuzzy multi-objective optimization model for sustainable closed-loop supply chain network design in food industries. Environ Develop Sustain 0123456789:1–28. https://doi.org/10.1007/s10668-021-01809-y

Alkhuzaim L, Zhu Q, Sarkis J (2021) Evaluating emergy analysis at the nexus of circular economy and sustainable supply chain management. Sustain Prod Consumpt 25:413–424. https://doi.org/10.1016/j.spc.2020.11.022

Allaoui H, Guo Y, Sarkis J (2019) Decision support for collaboration planning in sustainable supply chains. J Clean Prod 229:761–774. https://doi.org/10.1016/j.jclepro.2019.04.367

Al-Refaie A, Jarrar Y, Lepkova N (2021) Sustainable design of a multi-echelon closed loop supply chain under uncertainty for durable products. Sustainability (Switzerland) 13(19):11126. https://doi.org/10.3390/su131911126

Babaeinesami A, Tohidi H, Seyedaliakbar SM (2021) Designing a data-driven leagile sustainable closed-loop supply chain network. Int J Manag Sci Eng Manag 16(1):14–26. https://doi.org/10.1080/17509653.2020.1811794

Baghizadeh K, Pahl J, Hu G (2021) Closed-loop supply chain design with sustainability aspects and network resilience under uncertainty: modelling and application. Math Probl Eng 2021:1–23. https://doi.org/10.1155/2021/9951220

Başlıgil Ö (2013) Multi-objective optimization of closed-loop supply chains in uncertain environment. J Cleaner Prod 41:114–125. https://doi.org/10.1016/j.jclepro.2012.10.013

Behzadianfar M, Eydi A, Shahrokhi M (2022) A sustainable closed loop supply chain design problem in intuitionistic fuzzy environment for dairy products. Soft Comput 26(3):1417–1435. https://doi.org/10.1007/s00500-021-06409-6

Berning A, Venter C (2015) Sustainable supply chain engagement in a retail environment. Sustainability (Switzerland) 7(5):6246–6263. https://doi.org/10.3390/su7056246

Bhattacharjee S, Cruz J (2015) Economic sustainability of closed loop supply chains: a holistic model for decision and policy analysis. Decis Support Syst 77:67–86. https://doi.org/10.1016/j.dss.2015.05.011

Brandenburg M, Govindan K, Sarkis J, Seuring S (2014) Quantitative models for sustainable supply chain management: developments and directions. Eur J Oper Res 233:299–312

Bratt C, Sroufe R, Broman G (2021) Implementing strategic sustainable supply chain management. Sustainability (Switzerland) 13(15):8132. https://doi.org/10.3390/su13158132

Cannella S, Bruccoleri M, Framinan JM (2016) Closed-loop supply chains: what reverse logistics factors influence performance? Int J Prod Econ 175:35–49. https://doi.org/10.1016/j.ijpe.2016.01.012

Cardoso SR, Barbosa-Póvoa AP, Relvas S (2016) Integrating financial risk measures into the design and planning of closed-loop supply chains. Comput Chem Eng 85:105–123. https://doi.org/10.1016/j.compchemeng.2015.10.012

Chen CK, Ulya MA (2019) Analyses of the reward-penalty mechanism in green closed-loop supply chains with product remanufacturing. Int J Prod Econom 210:211–223. https://doi.org/10.1016/j.ijpe.2019.01.006

Chiaraluce G, Bentivoglio D, Finco A (2021) Circular economy for a sustainable agri-food supply chain: a review for current trends and future pathways. Sustainability (Switzerland) 13(16):9294. https://doi.org/10.3390/su13169294

Choi TM, Li Y, Xu L (2013) Channel leadership, performance and coordination in closed loop supply chains. Int J Prod Econ 146(1):371–380. https://doi.org/10.1016/j.ijpe.2013.08.002

Das K (2020) Planning environmental and economic sustainability in closed-loop supply chains. Operat Supply Chain Manag 13(1):64–81. https://doi.org/10.31387/OSCM0400253

De Lima FA, Seuring S, Sauer PC (2022) A systematic literature review exploring uncertainty management and sustainability outcomes in circular supply chains. Int J Prod Res 60(19):6013–6046. https://doi.org/10.1080/00207543.2021.1976859

Devika K, Jafarian A, Nourbakhsh V (2014) Designing a sustainable closed-loop supply chain network based on triple bottom line approach: a comparison of metaheuristics hybridization techniques. Eur J Oper Res 235:594–615

Dominguez R, Ponte B, Cannella S, Framinan JM (2019) On the dynamics of closed-loop supply chains with capacity constraints. Comput Ind Eng 128:91–103. https://doi.org/10.1016/j.cie.2018.12.003

Dou G, Cao K (2020) A joint analysis of environmental and economic performances of closed-loop supply chains under carbon tax regulation. Comput Ind Eng 146:53. https://doi.org/10.1016/j.cie.2020.106624

Emamian Y, Kamalabadi IN, Eydi A (2021) Developing and solving an integrated model for production routing in sustainable closed-loop supply chain. J Cleaner Prod 302:126997. https://doi.org/10.1016/j.jclepro.2021.126997

Esmaeilian S, Mohamadi D, Esmaelian M, Ebrahimpour M (2021) A multi-objective model for sustainable closed-loop supply chain of perishable products under two carbon emission regulations. J Model Manag. https://doi.org/10.1108/JM2-11-2020-0299

Fathollahi-Fard AM, Ahmadi A, Al-e-Hashem SMJM (2020) Sustainable closed-loop supply chain network for an integrated water supply and wastewater collection system under uncertainty. J Environ Manag 275:111277. https://doi.org/10.1016/j.jenvman.2020.111277

Fazli-Khalaf M, Naderi B, Mohammadi M, Pishvaee MS (2021) The design of a resilient and sustainable maximal covering closed-loop supply chain network under hybrid uncertainties: a case study in tire industry. Environ Dev Sustain 23(7):9949–9973. https://doi.org/10.1007/s10668-020-01041-0

Georgiadis P, Athanasiou E (2013) Flexible long-term capacity planning in closed-loop supply chains with remanufacturing. Eur J Oper Res 225(1):44–58. https://doi.org/10.1016/j.ejor.2012.09.021

Ghisolfi V, Diniz Chaves G, de Ribeiro Siman LR, Xavier LH (2017) System dynamics applied to closed loop supply chains of desktops and laptops in Brazil: a perspective for social inclusion of waste pickers. Waste Manag 60:14–31. https://doi.org/10.1016/j.wasman.2016.12.018

Gholamian N, Mahdavi I, Mahdavi-Amiri N, Tavakkoli-Moghaddam R (2021) Hybridization of an interactive fuzzy methodology with a lexicographic min-max approach for optimizing a multi-period multi-product multi-echelon sustainable closed-loop supply chain network. Comput Ind Eng 158:107282. https://doi.org/10.1016/j.cie.2021.107282

Gholizadeh H, Jahani H, Abareshi A, Goh M (2021) Sustainable closed-loop supply chain for dairy industry with robust and heuristic optimization. Comput Ind Eng 157:107324. https://doi.org/10.1016/j.cie.2021.107324

Global Reporting Initiative (2022). Consolidated Set of the GRI Standards. GRI STANDARDS. https://www.globalreporting.org/how-to-use-the-gri-standards/gri-standards-english-language/

Golpîra H, Javanmardan A (2022) Robust optimization of sustainable closed-loop supply chain considering carbon emission schemes. Sustain Prod Consumpt 30:640–656. https://doi.org/10.1016/j.spc.2021.12.028

Govindan K, Soleimani H, Kannan D (2015) Reverse logistics and closed-loop supply chain: a comprehensive review to explore the future. Eur J Oper Res 240:603–626

Govindan K, Jha PC, Garg K (2016) Product recovery optimization in closed-loop supply chain to improve sustainability in manufacturing. Int J Prod Res 54(5):1463–1486. https://doi.org/10.1080/00207543.2015.1083625

Grant MJ, Booth A (2009) A typology of reviews: an analysis of 14 review types and associated methodologies. Health Information Lib J 26(2):91–108. https://doi.org/10.1111/j.1471-1842.2009.00848.x

Guo Y, Shi Q, Guo C (2022a) A fuzzy robust programming model for sustainable closed-loop supply chain network design with efficiency-oriented multi-objective optimization. Processes 10:1963. https://doi.org/10.3390/pr10101963

Guo Y, Shi Q, Guo C, Li J, You Z, Wang Y (2022) Designing a sustainable-remanufacturing closed-loop supply chain under hybrid uncertainty: cross-efficiency sorting multi-objective optimization. Comput Ind Eng 172:108639. https://doi.org/10.1016/j.cie.2022.108639

Hajiaghaei-Keshteli M, Fathollahi-Fard AM (2019) Sustainable closed-loop supply chain network design with discount supposition. Neural Comput Appl 31:5343–4377. https://doi.org/10.1007/s00521-018-3369-5

He B, Liu Y, Zeng L, Wang S, Zhang D, Yu Q (2019) Product carbon footprint across sustainable supply chain. J Clean Prod 241:118320. https://doi.org/10.1016/j.jclepro.2019.118320

Henzen R, Weenk E (2022) Mastering the circular economy. Marge Books, A practical approach to the circular business model transformation

Hosoda T, Disney SM, Gavirneni S (2015) The impact of information sharing, random yield, correlation, and lead times in closed loop supply chains. Eur J Oper Res 246(3):827–836. https://doi.org/10.1016/j.ejor.2015.05.036

Hosoda T, Disney SM, Zhou L (2021) The yield rate paradox in closed-loop supply chains. Int J Prod Econom 239:108187. https://doi.org/10.1016/j.ijpe.2021.108187

Irawan CA, Abdulrahman MD, Salhi S, Martino L (2022) An efficient matheuristic algorithm for bi-objective sustainable closed-loop supply chain networks. IMA J Manag Math 33:603–636. https://doi.org/10.1093/imaman/dpac003

Jabarzadeh Y, Reyhani YH, Kumar V, Ghaffarinasab N (2020) A multi-objective mixed-integer linear model for sustainable fruit closed-loop supply chain network. Manag Environ Qual Int J 31(5):1351–1373. https://doi.org/10.1108/MEQ-12-2019-0276

Jafari HR, Kazemi A (2020) Sustainable closed-loop supply chain design for the car battery industry with taking into consideration the correlated criteria for supplier selection and uncertainty conditions. Revista Gestão & Tecnologia 20:3–29. https://doi.org/10.20397/2177-6652/2020.v20i0.1749

Jalali H, Ansaripoor AH, De Giovanni P (2020) Closed-loop supply chains with complementary products. Int J Prod Econom 229:107757. https://doi.org/10.1016/j.ijpe.2020.107757

Jiao Z, Ran L, Zhang Y, Li Z, Zhang W (2018) Data-driven approaches to integrated closed-loop sustainable supply chain design under multi-uncertainties. J Clean Prod 185:105–127. https://doi.org/10.1016/j.jclepro.2018.02.255

Kalantari S, Kazemipoor H, Movahedi Sobhani F, Molana MH (2022) Designing sustainable closed-loop supply chain network with considering spot-to-point inflation and carbon emission policies: a case study. Comput Ind Eng 174:108748. https://doi.org/10.1016/j.cie.2022.108748

Khan M, Hussain M, Saber HM (2016) Information sharing in a sustainable supply chain. Int J Prod Econ 181:208–214. https://doi.org/10.1016/j.ijpe.2016.04.010

Khan AS, Khalid QS, Naeem K, Ahmad R, Khan R, Saleem W, Pruncu CI (2021) Application of exact and multi-heuristic approaches to a sustainable closed loop supply chain network design. Sustainability (switzerland) 13(5):1–25. https://doi.org/10.3390/su13052433

Khorshidvand B, Soleimani H, Sibdari S, Seyyed MM (2021) Developing a two-stage model for a sustainable closed-loop supply chain with pricing and advertising decisions. J Cleaner Prod 309:127165. https://doi.org/10.1016/j.jclepro.2021.127165

Khorshidvand B, Soleimani H, Sibdari S, Seyyed MM (2021b) A hybrid modeling approach for green and sustainable closed-loop supply chain considering price, advertisement and uncertain demands. Comput Ind Eng 157:107326

Kiss K, Ruszkai C, Takács-György K (2019) Examination of short supply chains based on circular economy and sustainability aspects. Resources 4:1–21. https://doi.org/10.3390/resources8040161

Krikke H, Hofenk D, Wang Y (2013) Revealing an invisible giant: a comprehensive survey into return practices within original (closed-loop) supply chains. Resour Conserv Recycl 73:239–250. https://doi.org/10.1016/j.resconrec.2013.02.009

Kumar A, Moktadir MA, Khan SAR, Garza-Reyes JA, Tyagi M, Kazançoğlu Y (2020) Behavioral factors on the adoption of sustainable supply chain practices. Resour Conserv Recycl 158:104818. https://doi.org/10.1016/j.resconrec.2020.104818

Lassinovskaia G, Limbourg S, Riane F (2017) The inventory-routing problem of returnable transport items with time windows and simultaneous pickup and delivery in closed-loop supply chains. Int J Prod Econ 183:570–582. https://doi.org/10.1016/j.ijpe.2016.06.024

Lau SSY (2021) Design and technological applications in sustainable architecture: the perspective of China, Japan, Singapore and Thailand. Springer, Singapore, p 10

Li Z, Xu Y, Deng F, Liang X (2017) Impacts of power structure on sustainable supply chain management. Sustainability (Switzerland) 10(1):55. https://doi.org/10.3390/su10010055

Li Q, Sun H, Zhang H, Li W, Ouyang M (2020) Design investment and advertising decisions in direct-sales closed-loop supply chains. J Cleaner Prod 250:119552. https://doi.org/10.1016/j.jclepro.2019.119552

Lotfi R, Mehrjerdi YZ, Pishvaee MS, Sadeghieh A, Weber GW (2021) A robust optimization model for sustainable and resilient closed-loop supply chain network design considering conditional value at risk. Numer Algebra Control Optimiz 11(2):221–253. https://doi.org/10.3934/naco.2020023

Lu HE, Potter A, Sanchez Rodrigues V, Walker H (2018) Exploring sustainable supply chain management: a social network perspective. Supply Chain Manag Int J 23(4):257–277. https://doi.org/10.1108/SCM-11-2016-0408

Mann BJS, Kaur H (2020) Sustainable supply chain activities and financial performance: an indian experience. Vision 24(1):60–69. https://doi.org/10.1177/0972262919863189

Medina-Serrano R, Gonzalez R, Gasco J, Llopis J (2019) Collaborative and sustainable supply chain practices: a case study. J Enterpris Commun People Places Global Economy 14(1):3–21. https://doi.org/10.1108/jec-09-2019-0085

Meherishi L, Narayana SA, Ranjani KS (2019) Sustainable packaging for supply chain management in the circular economy: a review. J Cleaner Prod 237:117582. https://doi.org/10.1016/j.jclepro.2019.07.057

Mehrjerdi YZ, Shafiee M (2021) A resilient and sustainable closed-loop supply chain using multiple sourcing and information sharing strategies. J Cleaner Prod 289:125141. https://doi.org/10.1016/j.jclepro.2020.125141

Mirmohammadi SH, Sahraeian R (2018) A novel sustainable closed-loop supply chain network design by considering routing and quality of products. Int J Eng Trans B 31(11):1918–1928. https://doi.org/10.5829/ije.2018.31.11b.16

Mirzaei MG, Goodarzian F, Maddah S, Abraham A, Gabralla LA (2022) Investigating a dual-channel network in a sustainable closed-loop supply chain considering energy sources and consumption tax. Sensors 22(9):3547. https://doi.org/10.3390/s22093547

Mirzagoltabar H, Shirazi B, Mahdavi I, ArshadiKhamseh A (2021) Sustainable dual-channel closed-loop supply chain network with new products for the lighting industry. Comput Ind Eng 162:107781. https://doi.org/10.1016/j.cie.2021.107781

Mishra M, Hota SK, Ghosh SK, Sarkar B (2020) Controlling waste and carbon emission for a sustainable closed-loop supply chain management under a cap-and-trade strategy. Mathematics 8(4):466. https://doi.org/10.3390/math8040466

Mogale DG, De A, Ghadge A, Aktas E (2022) Multi-objective modelling of sustainable closed-loop supply chain network with price-sensitive demand and consumer’s incentives. Comput Ind Eng 168:108105. https://doi.org/10.1016/j.cie.2022.108105

Mohammadi AS, Alemtabriz A, Pishvaee MS, Zandieh M (2020) A multi-stage stochastic programming model for sustainable closed-loop supply chain network design with financial decisions: a case study of plastic production and recycling supply chain. Sci Iranica 27(1):377–395. https://doi.org/10.24200/SCI.2019.21531

Moheb-Alizadeh H, Handfield R, Warsing D (2021) Efficient and sustainable closed-loop supply chain network design: a two-stage stochastic formulation with a hybrid solution methodology. J Cleaner Prod 308:127323. https://doi.org/10.1016/j.jclepro.2021.127323

Momenitabar M, Dehdari Ebrahimi Z, Arani M, Mattson J, Ghasemi P (2022) Designing a sustainable closed-loop supply chain network considering lateral resupply and backup suppliers using fuzzy inference system. Environ Develop Sustain. https://doi.org/10.1007/s10668-022-02332-4

Mondal A, Roy SK (2021) Multi-objective sustainable opened- and closed-loop supply chain under mixed uncertainty during COVID-19 pandemic situation. Comput Ind Eng 159:107453. https://doi.org/10.1016/j.cie.2021.107453

Nagurney A (2015) Design of sustainable supply chains for sustainable cities. Environ Plann B Plann Des 42(1):40–57. https://doi.org/10.1068/b39039

Narimissa O, Kangarani-Farahani A, Molla-Alizadeh-Zavardehi S (2020) Evaluation of sustainable supply chain management performance: indicators. Sustain Dev 28(1):118–131. https://doi.org/10.1002/sd.1976

Nasr AK, Tavana M, Alavi B, Mina H (2021) A novel fuzzy multi-objective circular supplier selection and order allocation model for sustainable closed-loop supply chains. J Cleaner Prod 287:124994. https://doi.org/10.1016/j.jclepro.2020.124994

Nayeri S, Paydar MM, Asadi-Gangraj E, Emami S (2020) Multi-objective fuzzy robust optimization approach to sustainable closed-loop supply chain network design. Comput Ind Eng 148:106716. https://doi.org/10.1016/j.cie.2020.106716

Nili M, Seyedhosseini SM, Jabalameli MS, Dehghani E (2021) A multi-objective optimization model to sustainable closed-loop solar photovoltaic supply chain network design: a case study in Iran. Renew Sustain Energy Rev 150:111428. https://doi.org/10.1016/j.rser.2021.111428

Nobari A, Kheirkhah A (2018) Integrated and dynamic design of sustainable closed-loop supply chain network considering pricing. Sci Iran 25(1):410–430. https://doi.org/10.24200/sci.2017.4411

OECD (2021). The OECD inventory of circular economy indicators. 2021, 1–57. Retrieved from https://www.oecd.org/cfe/cities/InventoryCircularEconomyIndicators.pdf

Oniszczuk-Jastrzabek A, Czermański E, Cirella GT (2020) Sustainable supply chain of enterprises: value analysis. Sustainability (switzerland) 12(1):1–15. https://doi.org/10.3390/SU12010419

Pant K, Yadav VS, Singh AR (2021) Design of multi-tier multi-time horizon closed-loop supply chain network with sustainability under uncertain environment for Indian paper industry. Int J Sustain Eng 14(2):107–122. https://doi.org/10.1080/19397038.2020.1774817

Ponte B, Framinan JM, Cannella S, Dominguez R (2020) Quantifying the bullwhip effect in closed-loop supply chains: the interplay of information transparencies, return rates, and lead times. Int J Prod Econom 230:107798. https://doi.org/10.1016/j.ijpe.2020.107798

Pourjavad E, Mayorga RV (2018) Optimization of a sustainable closed loop supply chain network design under uncertainty using multi-objective evolutionary algorithms. Adv Prod Eng Manag 13(2):216–228. https://doi.org/10.14743/apem2018.2.286

Pourjavad E, Mayorga RV (2019) Multi-objective fuzzy programming of closed-loop supply chain considering sustainable measures. Int J Fuzzy Syst 21(2):655–673

Pourmehdi M, Paydar MM, Asadi-Gangraj E (2020) Scenario-based design of a steel sustainable closed-loop supply chain network considering production technology. J Cleaner Prod 277:123298. https://doi.org/10.1016/j.jclepro.2020.123298

Quan Y, Hong J, Song J, Leng M (2021) Game-theoretic analysis of trade-in services in closed-loop supply chains. Transp Res Part E 152:102428

Rafigh P, Akbari AA, Bidhandi HM, Kashan AH (2021) Sustainable closed-loop supply chain network under uncertainty: a response to the COVID-19 pandemic. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-021-16077-6

Rajak S, Vimal KEK, Arumugam S, Parthiban J, Sivaraman SK, Kandasamy J, Duque AA (2021) Multi-objective mixed-integer linear optimization model for sustainable closed-loop supply chain network: a case study on remanufacturing steering column. Environ Develop Sustain 24:0123456789. https://doi.org/10.1007/s10668-021-01713-5

Rezaei S, Kheirkhah A (2018) A comprehensive approach in designing a sustainable closed-loop supply chain network using cross-docking operations. Comput Math Organ Theory 24(1):51–98

Russo I, Confente I, Scarpi D, Hazen BT (2019) From trash to treasure: the impact of consumer perception of bio-waste products in closed-loop supply chains. J Clean Prod 218:966–974. https://doi.org/10.1016/j.jclepro.2019.02.044

Sahamie R, Stindt D, Nuss C (2013) Transdisciplinary research in sustainable operations - an application to closed-loop supply chains. Bus Strateg Environ 22(4):245–268. https://doi.org/10.1002/bse.1771

Sahebjamnia N, Fathollahi-Fard AM, Hajiaghaei-Keshteli M (2018) Sustainable tire closed-loop supply chain network design: hybrid metaheuristic algorithms for large-scale networks. J Clean Prod 196:273–296