Abstract

Asia currently faces a serious crisis involving plastic wastes. Efforts to curb plastic waste in the region are mostly hampered by inadequate recycling infrastructure, unsustainable disposal practice, low level of recycling awareness and persistent shipping of large amounts of waste from developed countries to the region. The ban on plastic waste import by China in 2017 worsened the situation by causing unsustainable shipping of waste from high plastic waste-generating countries such as Japan to alternate destinations in Southeast and East Asia. The Japanese government is frantically looking for options to manage plastic waste piling up on the domestic front. Malaysia became one of the leading alternative destinations for plastic waste after the ban by China. This work is aimed at conducting a comparative analysis of plastic recycling policies and legislations between Malaysia and Japan to yield synergistic solutions between the two countries to combat the current predicament. The comparison will signify two typical development patterns in developed countries and developing countries and will be able elucidate future directions for other countries with similar policy and legislative transitions in the region. A set of nine criteria was employed to critically evaluate the policies and legislations of both countries. Barriers faced by both countries in plastic recycling are outlined and recommendations are proposed to overcome those barriers on the domestic front. Two strategies proposed to be jointly developed by both countries are enhancement of extended producer responsibility (EPR) through a regional policy platform and collaboration in establishing joint Ecotowns.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Plastic materials are widely used in the manufacturing of household appliances, automobiles, food containers and packaging and construction materials, amongst others. Over 78 wt% of the global plastic waste production corresponds to thermoplastics and the remaining to thermosets (Panda et al. 2010). Thermoplastics are composed of polyolefins such as polyethylene (PE); which can be divided into high density polyethylene or HDPE and low density polyethylene or LDPE, polystyrene (PS), polypropylene (PP), polyethylene terephthalate (PET) and polyvinyl chloride (PVC) and are all recyclable. On the other hand, thermosets mainly include epoxy resins and polyurethanes and are typically not as easily recycleable as thermoplastics due to stronger covalent bonds which are difficult to break. Globally, mass production of plastic products and poor disposal systems have led to annual increases in plastic waste entering the environment. Plastic waste has been observed to adversely impact the ecosystem by changing species distribution, entangling organisms, and causing biological harm and damage through ingestion. Plastic dumped in landfills can also emit harmful chemicals that seep into groundwater (Welden 2020). Currently, the largest contributor of plastic waste in the world is China, followed by countries in Southeast Asia. Together, Indonesia, the Philippines, Vietnam, Thailand and Malaysia generate 8.9 million tonnes of plastic waste annually. At the per-capita level, Japan ranks second globally (Gong and Trajano 2019). Furthermore, China’s decision to halt all waste plastic imports to curb domestic pollution in 2017 has caused huge impacts on the shipping routes of plastic wastes in the world, particularly in Asia. The ban has resulted in a spike in exports to other countries in Asia such as Malaysia, Thailand, Vietnam and Taiwan. Although the bans restricts import of plastic scrap, it allows the import of processed products, recycled products for instance. Such a loophole has led to switching of recycling routes for transport to China through Southeast and East Asian countries, after plastic waste shipped from high plastic waste-generating countries such as Japan has been processed in these countries (Yoshinori and Shiko 2018). Before the ban by China, Japan exported approximately 1.36 million tonnes of plastic waste in 2017, around a sixth of the annual amount generated, to China and Southeast Asia. In 2018, due to the ban, this amount reduced drastically to 0.91 million tonnes, prompting the Japanese government to search frantically for domestic processing sites as well as alternative destinations willing to accept its waste in regions such as Southeast Asia. Without mitigating measures, Japan’s predicament is expected to worsen. There are three types of recycling processes namely: material, chemical and thermal. Material recycling or mechanical recycling involve processes where the plastic is reprocessed into new plastic. Chemical recycling or feedstock recycling involves processes whereby the plastic waste is broken down into its constituents, which are then recombined to make new plastic products. Thermal recycling or energy recovery involves plastic being burned in incinerators to produce energy. In 2018, Japan managed to recycle up to 84% of total plastic collected, one of the highest in the world (PWMI 2019). In 2017, about 23% of plastic waste generated in Japan was processed through material recycling, 57% through thermal recycling, followed by 4% through chemical recycling (Yoshinori and Shiko 2018). Table 1 highlights the types of plastic recycling methods currently used around the world.

In recent years, Malaysia became the leading alternative destination for plastic scrap after China banned imports of such waste. There was a drastic surge in the shipping of plastic waste to Malaysia from developed countries upon China’s announcement of the ban, with the USA contributing approximately 218,000 tonnes in 2018, followed by Japan (119,000 tonnes) and the UK (112,000 tonnes) for the same year (Wong and Farha 2019). While a bulk of the plastic waste comes from domestic sources, the increase in the inflows of plastic waste from other countries, exacerbated by the ban in China, has raised attention on larger issues encircling Malaysia’s plastic waste dilemma. Dozens of recycling factories popped up, many operating without license, and residents in the surrounding areas often complained of pollution issues (Ananthalakshmi and Chow 2018; Chen et al. 2021; Tan 2019). Most of the plastics that are unsuitable for recycling end up in landfill, significantly polluting natural soil and water sources. This work is aimed at conducting a comparative analysis of plastic recycling policies and legislations between Malaysia and Japan. Both countries suffered under different circumstances after the China’s ban on plastic import: Japan was left to deal with the sheer amount of waste left to be treated domestically and Malaysia became an alternate destination for plastic waste for many developed nations including Japan. Malaysia and neighbouring countries in Southeast Asia are still at the learning phase in establishing an innovative plastic recycling regime. Experience from advanced countries in the region such as Japan who has so far dealt with large volumes of plastic waste can be incorporated into the learning process. As such, the time frame for policy development can be shortened. Although the development paces, recycling infrastructure, and recycling rate of plastics vary between the two countries, the policy and legislation enactment are worth comparing. The comparison will signify two typical development patterns in developed countries and developing countries and will be able to elucidate future directions for other countries with a similar policy and legislative transition in the region (Kanger et al. 2020). Hence, this study aims to make the following contributions to the existing literature: (i) to provide a comparative analysis of policy and legislative regimes for Malaysia and Japan where systematic gaps in latest policy and legislative regimes of both countries that are currently missing in literature is expounded. (ii) To identify the barriers that hinder change in plastic waste recycling regime to solve existing problems and critical gaps through transformative recommendations to counter these barriers, both on the domestic front in Malaysia and Japan, respectively, as well as through cooperation between the two countries. A set of nine criteria was employed to critically evaluate the policies and legislations of both countries. Barriers faced by both countries in plastic recycling are outlined and recommendations are proposed to overcome those barriers.

Methodology

This section discusses the motivation behind comparing plastic recycling policies and legislations in Malaysia and Japan and identifies which aspects needs to be compared. Comparative analysis of public policy can be divided into studies of policy differences and studies of institutional differences where the former focuses on policy differences to highlight issues while the latter attempts to explain how policies are made. Hill (2005) stressed the importance of policy learning over time and between nations, where newly industrialised economies can observe the strengths and limitations of policies adopted previously by their predecessors and learn from them selectively (Hill 2005). Various works have analysed waste management and related policies in Malaysia and Japan, respectively. Despite the considerable amount of work in the literature, none have analysed plastic recycling policies in Malaysia in the context of comparing with another country with more advanced policy regimes such as Japan. Previously, the impact and implications of the solid waste bill in Malaysia had been assessed and the policies implemented in Malaysia, Singapore, Japan and Phillipines were compared in terms of education campaigns implemented, 3R (Reduce, Reuse and Recycle) issues addressed, rate of recycling, practice of waste separation, extended producer responsibility (EPR), source of funding, outsourcing of operations, deterrence options, enforcement, plight of scavengers and effectiveness of waste management policy (Manaf et al. 2009; Moh and Abd Manaf 2014, 2017; Periathamby et al. 2009). Most of the information reported has since been outdated. The analysis of regulatory framework on plastic recycling has also been conducted in Northern Europe, a region which leads in recycling policy regimes and assesses the regulatory framework of Denmark, Norway, Sweden and Finland in terms of residual waste taxes, targets and bans, recycling and recovery targets, materials taxes, grants, approach to collections, waste management charges and EPR (Papineschi et al. 2019). Some of the criteria, while being at the forefront of sustainable plastic recycling such as residual taxes and material taxes, are not practical to be implemented in the developing region such as Southeast Asia where more pressing basic infrastructure and policy needs are much needed. As such, the comparative criteria used in this work is constructed based on previous studies of policy differences by incorporating the criteria assessed with latest data and taking the most relevant aspects for evaluation in the context of the Asian region, such as collections approach, recycling rate, composition and target, categorisation and labelling of waste, waste management charges, enforcement efficiency, practice of 3R, EPR, issues regarding scavengers, and public reception (Hill 2005; Manaf et al. 2009; Moh and Abd Manaf 2014, 2017; Papineschi et al. 2019; Periathamby et al. 2009; PWMI 2019; Usui et al. 2015). The following research questions are formulated as a result of the assimilation:

-

Q1.

How are plastic recycling wastes currently collected?

-

Q2.

What are the recycling rates, composition and targets?

-

Q3.

Is categorisation and labelling for plastic wastes practised?

-

Q4.

What are the waste management charges and how are they implemented?

-

Q5.

Is the enforcement efficient?

-

Q6.

How is the 3R concept practiced?

-

Q7.

How are Extended Producer Responsibility (EPR) practices incorporated into the current legislation?

-

Q8.

Are issues regarding scavengers adequately addressed?

-

Q9.

How are policies and legislations received by the public?

The methodology utilised in this study commences with the definition of search criteria through selective keywords (e.g. Plastic recycling Japan, plastic recycling Malaysia, waste legislation Japan, waste legislation Malaysia, etc.), followed by formulation of research questions mentioned above. The appropriate database for the search was then selected. Google Scholar and Science Direct were chosen as the database for the gathering of data. Data gathering was conducted through search of articles related to plastic recycling in Malaysia and Japan spanning from year 1999 to 2020. The literature review was conducted based on the search results involving published reports and scientific articles as well as evaluation of available statistics and information on plastic waste recycling legislations in both countries. Using the research questions formulated, comparative analysis of the legislations on plastic recycling of Japan and Malaysia was carried out and answers to the research questions are tabulated in the discussion and compared for both countries. A critical discussion is conducted focused on barriers faced by both countries in plastic recycling and recommendations to overcome those barriers. Figure 1 presents the flowchart summarising the methodology used in this work.

Malaysia

Waste management policy and legislation

Domestically, Malaysians generated 38,142 tonnes of waste daily in 2018, where approximately 20% are plastic waste or 2.78 million tonnes/year of plastic waste (Wong and Farha 2019). About 95% of total waste material gathered in Malaysia is discarded at open dumping or landfills and the rest is either reprocessed or dumped illegally though no details are available for these claims (Moh and Abd Manaf 2017). Overall waste composition in Malaysia is constituted by municipal solid waste (64%), industrial waste (25%), commercial waste (8%) and 3% consists of construction waste in 2009. About 70 to 80% of total waste in landfills come from household waste (Aja and Al-Kayiem 2014; Choon et al. 2017; Moh and Abd Manaf 2014). Waste plastics typically amassed are PET, PP and HDPE although detailed breakdown of the composition is yet to be made available. In Malaysia, current policies and legislations enforced are related to solid waste management and does not address plastic wastes specifically as a target. Early legislations (pre-1990s) were aimed at curbing pollution does not sufficiently address the management and handling of solid waste involving waste facilities and landfills. The Environmental Quality Act (EQA) 1974 is the earliest Act formulated to prevent, abate and control pollution, which subsequently enhances environment quality. The Local Government Act 1976 was enforced to specify crucial legislative and technical requirements for the local municipality, waste generator, waste recycler and disposal sites operator in managing industrial wastes (Mohamed 2009). Other acts that may touch on management of solid wastes are the Street, Drainage and Building Act 1974 and Town and Country Planning Act although they do not target waste management of solids elaborately. The Action Plan for a Beautiful and Clean Malaysia (ABC Plan) was introduced in 1987 to curb the solid waste generation in the country and led to the first and second recycling plans in the country. In 1991, a development vision also known as Vision 2020 was introduced to set the country on track to become a developed country by year 2020. In 1992, the Rio Declaration was signed by Malaysia to demonstrate its commitment to sustainable development goals. As part of Vision 2020, the National Strategic Plan (NSP) for management of waste was introduced. The plan was aimed at incorporating needs of all stakeholders involved into the economic development in enhancing national waste management. The plan was charted in 2002 and introduced in 2005. In 2006, the Japanese government cooperated with the Malaysian government to carry out an assessment of waste reduction in Malaysia. The Fundamental Law for Establishing a Sound Material-Cycle Society (FLMS), enacted in 2000 in Japan, was used as the basic plan for Waste Minimization Master Plan (WM-MP) using the 3Rs concept of reducing, reusing and recycling waste. Through the WM-MP, the Solid Waste and Public Cleansing Management (SWPCM) Act 2007 was charted and was aimed at ensuring effective household waste management through waste separation and recycling. Later, a comprehensive plan was implemented by Solid Waste and Public Cleansing Management Cooperation (SWCorp) Strategic Plan 2014–2020. The plan was aimed at integrating the practice of cleanliness in society, such as revision of school syllabus and standard operating procedures for solid waste management. Next, the Comprehensive Action Plan of Solid Waste Management 2015–2020 was formulated, and was targeted at improving public awareness, strengthening cooperation between the government and the industry as well as building of recycling infrastructure (Moh and Abd Manaf 2017). In 2018, Ministry of Energy, Science, Technology, Environment and Climate Change or MESTECC (renamed to Ministry of Science, Technology and Innovation or MOSTI in 2020), introduced Malaysia’s Roadmap Towards Zero Single-Use Plastics 2018–2030. The policy mainly centres on introducing biodegradable alternatives to plastic and reducing single-use plastic such as grocery bags and straws (Wong and Farha 2019). Figure 2 shows the chronology of policies and legislations related to plastic recycling in Malaysia.

Stakeholder relationships

The key stakeholders in managing solid waste in Malaysia are the Ministry of Environment and Water, Ministry of Housing and Local Governments, Department of Local Government, and the local governments (Mohamed 2009). MOSTI also has certain powers relegated to it, especially in terms of introducing policy guidelines to ensure environmental sustainability of plastic wastes. The non-governmental stakeholders can be divided into the following categories: Waste scavengers are typically individuals who make a living through waste collection and recycling. They may conduct waste picking from the street, landfill, dumpsites or households. Itinerant waste buyers constitute of individuals who move around to purchase waste that they can sell later (Zen et al. 2014) (Watanabe et al. 2018). There are also stationary buyers who run small businesses to purchase waste brought to them by other stakeholders such as waste scavengers. Micro-enterprises are small companies charging for services to cover areas in existing collection system where the municipality cannot provide. Small-scale recycling factories are small businesses that buy recyclable waste. Large-scale recycling factories are industrial establishments that buy suitable waste material in bulk (Mohamad and Keng 2013). Community-based organisations (CBOs) are informal organisations constitute of members of the local community to address local social needs. Non-governmental organisations (NGOs) typically conduct collection activities based on social concerns for waste scavengers or concerns for the poor environment where targeted groups live. The private waste concessionaire is contracted by the local authorities to carry out waste management activities. They primarily collect recyclable waste from households, commercial lots and the industry and dispose them in landfills. In certain municipalities, plastic wastes are sorted by waste concessionaires and transported to recycling factories though these quantities are very low. Recycling factories send the plastic wastes to plastic producers and manufacturers where the material is processed into plastic products. In some cases, recycling facilities may also process the waste into marketable products (Budhiarta et al. 2012; Bupe Getrude Mwanza et al. 2019; Bupe Getrude Mwanza et al. 2018; Wahab et al. 2007; Zen and Siwar 2015). Figure 3 illustrates the flow of plastic wastes amongst these aforementioned stakeholders.

Japan

Waste management policy and legislation

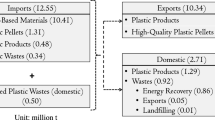

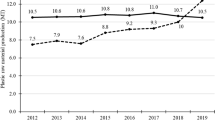

In 2018, Japan generated 8.08 million tonnes/year of plastic waste. For the same year, a total of 4.19 million tonnes/year of industrial waste was generated where 86.2% was recycled, 9.3% disposed at landfills, and 4.5% incinerated without power generation or heat utilisation (PWMI 2019). A total of 3.89 million tonnes/year of domestic waste was generated where 81.8% was recycled, 12.1% incinerated without power generation or heat utilisation, and 6.1% went to the landfill in 2018 (PWMI 2019). The practice of waste disposal by municipalities and regional governments in Japan started with the introduction of the Dirt Removal Law in year 1900. Night soil and household waste generated in urban area has been greatly enhanced since adoption of the law. The year 1954 saw the introduction of the Public Cleansing Law to improve hygiene in society. In 1970, the Waste Disposal and Public Cleansing Law followed suit. Both laws constitute the basic framework of Japan’s current legislation on waste management. In 1991, the Promotion of Resource Recycling and Reuse Law and a new Waste Disposal and Public Cleansing Law were introduced to regulate waste disposal and recycling. The former is aimed at promoting recycling at the various levels including manufacturing, distribution, and consumption, reduced waste production, efficient use of resources, and environmental conservation. In 1991, elements of waste discharge control and promotion of recycling were integrated into the new Waste Disposal and Public Cleansing Law. The Law for the Promotion of the Sorted Collection and Recycling of Containers and Packaging which was partially enforced in 1997 and fully enforced in 2000 obliges businesses related to manufacturing and utilisation of containers and packages to shoulder the financial burden of recycling through payment of fees to a public interest incorporated foundation, the Japan Containers and Packaging Recycling Association (JCPRA) (Liu and Rong 2013). The Fundamental Law for Establishing a Sound Material-Cycle Society (FLMS) which was enacted in 2000, emphasises EPR involving manufacturers to shoulder a fair amount of responsibility over the production of products all the way to the after-consumption phase. The law also ensures the sharing of responsibilities amongst other stakeholders, such as the national government, the municipal governments, manufacturers, as well as consumers. Under this framework, a series of recycling laws targeted at specific products were passed (Table 2).

In 2000, Japan introduced the Green Purchasing Law whereby both the national and municipal governments as well as related organisations are required to take charge in the procurement environmentally friendly products. The Act on Promotion of Recycling of Small Waste Electrical and Electronic Equipment which was enforced in 2010 authorized business operators to recycle small waste electronics equipments. In 2018, the “4th Fundamental Plan for Establishing a Sound Material-Cycle Society” was approved by the authorities, with periodic assessments to be conducted once every five year period. The plan incorporates concepts of “Regional Circular and Ecological Sphere,” “Proper Waste Management and Environmental Restoration,” “International Resource Circulation” and “Disaster Waste Management Systems”, amongst others. In 2019, Japan introduced the “Resource Circulating Strategy for Plastics” policy to promote circulation of plastic materials, prevent marine litter of plastic, and promote the use of bioplastic to substitute conventional plastic material. The policy targets a reduction of 25% in generation of single-use plastic waste by year 2030 and aims to have a total of 60% of plastics from containers and packaging to be recyclable by 2030; as well as 100% effective utilisation of used plastics by 2035. The Marine Plastic Litter Implementation Action Plan was also developed in 2019 to curb rampant disposal and plastic waste flow to the sea, enhance innovation in development of substitute materials, and boost international collaboration with developing countries (Akenji et al. 2020). Figure 4 shows the chronology of policies and legislations related to plastic recycling in Japan.

Stakeholder relationships

In Japan, the recycling process is built on collaboration between the Japan Containers and Packaging Recycling Association (JCPRA) and consumers, municipalities, businesses as well as recycling companies. The JCPRA is an organisation set-up by the government based on the Container and Packaging Recycling Act aimed at increasing recycling. The organisation takes over the recycling operations on behalf of the specific businesses related to plastic containers and wrappers in retail, manufacturing and shipping. The said businesses are required to pay recycling fees to the organisation. Consumers are obliged to adhere to waste sorting procedures set by the municipal governments when disposing waste (Liu and Rong 2013). The municipalities then collect waste and store the waste. The municipalities are also in charge of collecting waste from small businesses, which are currently exempted from recycling obligations. Recycling companies are then contracted by the JCPRA and they collect the waste containers and wrappers from the designated storage and subsequently recycle the waste. Recycling companies that pass registration examinations designated by the JCPRA qualify to bid for public tenders for waste recycling annually. Bidding is carried out throughout the country and the winner obtains a one-year contract (Liu and Rong 2013). Figure 5 shows the flow of plastic wastes amongst stakeholders in Japan.

Comparative analysis between plastic waste recycling policies and legislations of Japan and Malaysia

Plastic recycling rate in Malaysia is a fraction of that in Japan (11.4% for Malaysia in 2017 vs 84% in Japan for 2018). Generation of plastic waste per capita was 88.3 kg per capita in 2018 for Malaysia and 70.8 kg per capita in 2016 for Japan (PWMI 2019; Wong and Farha 2019). It is worth mentioning though that a large percentage of the plastic recycling rate in Japan incorporates incineration or thermal recycling of up to 57% of plastic waste recycled (Yoshinori and Shiko 2018). Many countries do not deem burning to qualify as recycling due to the large amounts of CO2 generated. As such, plastic waste processing in Japan incorporates a relatively high environmental load especially when it comes to incineration. Waste plastics typically collected in Malaysia are PET, PP and HDPE and detailed breakdown of the figures are limited while the types of plastic waste collected in Japan span a wider range with detailed figures available. The type of plastics recycled in Malaysia is largely driven by the price in the informal recycling market. Table 3 summarises the comparison between plastic recycling policies and legislation in Malaysia and Japan.

In Japan, recycling activities are coordinated by the JCPRA where the system is very much centralised. In Malaysia, while a variety of collection channels exists, the mechanism is less well-defined. Both Malaysia and Japan have EPR incorporated into their waste laws. The extent of this incorporation appears to be much more extensive for Japan and EPR is specified over a wide berth of waste laws and incorporated into the operation of EcoTowns around the country. In terms of implementation, Malaysia appears to fall short compared to Japan where EPR is mostly limited to mentions in the SWPCM Act. A schism exists between theory and practice due to general policy provisions without specific enforcement mechanisms. Two types of pay-as-you-throw (PAYT) systems exist in Japan (simple unit-pricing programs and two-tiered pricing programs) while Malaysia does not have a standardised PAYT system implemented nationwide. Through the SWPCM Act in Malaysia, illegal waste collecting activities have been regulated to curb health and safety issues on landfills and dumpsites associated with waste scavengers though their contribution to plastic waste recycling so far (albeit illegally conducted) has also been restricted. Their Japanese counterparts do not pose as much of an issue in terms of health and safety issues associated with illegal waste collection and hence, the law also does not specifically target these groups for their illegal or improper practices. Both countries have incorporated the 3R concept into policy making and legislation sufficiently. Awareness on the benefits of recycling amongst Malaysians are still low while the Japanese have inculcated the practice to the point of making it a family practice. Overall, the measurement of effectiveness of policy and legislative regimes on plastic waste recycling in Malaysia is hampered by limited data while Japan’s legislative regimes have been deemed relatively successful based on figures available before and after implementation. Import of plastic waste into the country is largely unregulated and currently no law exists in Malaysia to curb this predicament. On the Japanese side however, there has been a lack of transparency with regard to the information of plastic waste exported. Prior to the Amendment of the Annexes of the Basel Convention in 2021, detailed data on plastic waste shipped out of the country was largely not regulated (PWMI 2019; Yoshinori and Shiko 2018). The amendment establishes new restrictions on cross-border movement of plastic waste and Prior Informed Consent (PIC) will be needed when exporting plastic wastes subject to control by the Convention (Ministry of Environment Japan 2021). More time will be needed in order to assess the effectiveness of the amendment. In addition, both countries face a dire need to ramp capacities of existing landfills taking into account the impending amount of waste expected in the foreseeable future (Manaf et al. 2009; PWMI 2019; Usui et al. 2015).

Discussion

Malaysia

In Malaysia, a number of barriers persist with respect to sustainable plastic recycling such as management and logistics issues (B1), lack of data pertaining to plastic recycling (B2), lack of focus in implementation of plastic recycling law (B3) and lack of legislation targeted at illegal plastic import (B4). Several major shortcomings in waste management are lack of skilled workers, inconsistent collection schedules, insufficient equipment used for waste collection, insufficient legal provisions and resource limitations (Hassan et al. 2001; Kam et al. 2016; Murad and Siwar 2007; Yusoff et al. 2018). Current data on the detailed composition and source of waste from the municipalities is still lacking. Data provided by municipalities is usually not standardised and not consistent. In addition, the SWPCM Act 2007 cannot be effectively put into force due to the absence of supporting legislations (Ahsan et al. 2013; Pariatamby 2014). Consequently, policy could only be executed in an ad hoc manner by the government. In spite of the solid waste policy implemented, solid waste management services are yet to be standardized. Implementation of policy SWPCM vary from state to state. Proposed plan are also too focused on the removal of solid waste rather than effective use of waste as resources. Despite the large amounts of plastic waste imported illegally into the country after China’s plastic ban in 2017, regulations or policies that specifically target the plastic waste reaching the country’s shores illegally are yet to be enforced systematically.

Recommendations made to counter these issues are the introduction of a central agency for plastic recycling (R1), introduction of indicators and measurements for plastic recycling (R2), introduction of industry-specific legislations (R3), implementation of an efficient PAYT system (R4) and enforcement of targeted stringent laws on illegal plastic waste imports (R5). The introduction of a central agency to handle recycling amongst all major stakeholders may serve urgently to improve the administration and handling of wastes in Malaysia. The establishment of such an agency would also be able to tackle existing management and logistics issues pertaining to plastic waste. The agency is proposed to be positioned at the centre of the recycling coordination, much like the JCPRA in Japan (detailed explanation in Sect. Lessons from Japan and future perspectives). In addition, Malaysia would serve well to monitor the efficiency of its solid waste law by introducing indicators and measurements, such as the percent of waste recycled by type, particularly plastic waste and monitoring them in order assess policy performance done over time. The availability of these indicators and measurements would allow progressive improvements based on a set of baseline figures. In the medium to long run, industry-specific legislations can be introduced to boost plastic recycling, such as legislations enforced in Japan regarding material coming from construction, home appliances, end-of-life vehicles and food resources. Supporting legislations such as these will compliment the implementation and enforcement of the SWPCM Act 2007 by providing industry-specific details of procedures, regulations as well as stakeholder responsibilities. The advent of a well-structured PAYT in Malaysia is expected to yield similar benefits as seen in Japan. The simple-unit structure is preferred due to its simplicity and lower administrative load in comparison to the two-tiered structure although the two-tiered system has been shown to be more effective in Japan (Sakai et al. 2008). Our recommendation is that authorities may start implementing both systems separately in select municipalities before assessing their efficiency in increasing recycling rates over an extended amount of test period. Once incremental improvements can be seen, the suitable system that yields the best trade-off between recycling rate and administration load may be selected. The import of plastic scrap should be stringently controlled by the government through progressive stages starting with the imposition a levy on plastic waste imports to deter illegal importers and review of current procedures and legislations to enforce a set of laws targeted at regulating illegal plastic waste import.

Japan

Barriers currently faced in plastic recycling in Japan include the rise of plastic waste (B5), lack of incentive for recycling companies (B6), high environmental load of waste processing (B7), opposition to construction of waste treatment facility (B8) and lack of relevant information and data on plastic waste exports (B9). In Japan, two decades after the enforcement of the Containers and Packaging Recycling Law, the amount of recycled waste plastic and used PET bottle is still less than 0.54 million tonnes and rate of recycled plastic has plateaued (Kamo 2011 ; Nishijima et al. 2012). Another major issue lies in the legislation’s lack of incentives for companies to recycle containers and packaging used in the industry (Nakatani et al. 2010). Recycling plants in Japan still find it difficult to be profitable because pellets recycled using discarded PET bottles cost more than virgin materials. The government would do well to revise the existing commission system for recycling companies to overcome such hurdle. Also, the Containers and Packaging Recycling Law is currently targeted primarily at household waste. To effectively increase recycling rates, the law should include small businesses which are currently exempted. There is also a high environmental impact such as the emission of dioxin-related substances, carbon dioxide and sulphides associated during the waste processing (Jung et al. 2004). Dioxin-related substances are highly toxic and can cause birth defects and developmental abnormalities. Approximately 90% of dioxin-containing substances emitted into the air come from the incineration of wastes, which happens to be practiced widely in Japan (Zheng et al. 2017). Furthermore, the construction of waste processing facility is frequently opposed by adjacent residents in the neighbourhood. Cases of boycott have been on the rise in recent years (Zheng et al. 2017). There is also a lack of relevant information and data on the processing routes for plastic waste that is exported. Not much is known currently on the quality of plastic waste leaving Japan’s shores to countries in Southeast Asia such as Malaysia, Thailand and Vietnam posing much threat to sustainable waste recycling routes in the region.

Countering measures are proposed to lower the barriers mentioned such as the use of substitute material (R6), making full use of chemical recycling to complement mechanical recycling (R7), elaborate research on plastic recycling technologies (R8), compensation mechanism for stakeholders (R9), improving access to detailed figures on recycling and processing routes of plastic waste (R10) and computation of forecast data on plastic waste (R11). In 2020, the Japanese government, banned the free distribution of plastic bags (mostly made from PE), though bags made using marine biodegradable plastics with a lower environmental footprint are exempted from the ban. In this case, PE as a raw material can be progressively substituted using marine biodegradable plastics. Feedstock recycling processes that is currently employed, such as coke oven and gasification, are inherently less selective in terms of the quality of plastic waste feed compared to mechanical recycling (Okuwaki 2004). In this context, suitable material for feedstock recycling such as packaging waste discharged from households containing high percentages of PS can be recycled using coke ovens. This can ease the load of mechanical processes currently working near their maximum operating capacity. In addition, the stakeholders who are affected should be compensated, and those who benefit in the current scheme should bear the financial cost. For instance, the residents who live near the waste disposal sites face the potential consequences of pollution and should be compensated based on proper evaluation. In the long run, detailed figures on the recycling and processing routes for all types of plastic waste is key to formulate response plans and policy instruments. The data can be employed to ramp up national processing capacity for low-grade plastic scrap as well as decrease exports of low grade plastics to countries in Southeast Asia. Computation and evaluation of forecast data on the volume of plastic waste generation and processing would prove useful to encourage investment from the government to increase infrastructural processing capacity. The data can also be used to improve the quality of plastic waste circulating domestically and internationally.

Synergy between both countries

Both Malaysia and Japan face issues such as limitation in landfill capacity (B10) and indiscriminate waste disposal by the public (B11). In Malaysia, almost all wastes produced are currently discarded in the municipal landfills. There is an urgent need for improvement in the design of the landfill, site location and capacity of the disposal sites. Japan also faces a shortage of landfill capacity where currently 1,651 landfills can be found to provide a capacity of 103 million m3 or 21.8 remaining years for landfill. Exactly 297 municipalities do not possess landfills in their jurisdictions, and approximately 17% of municipalities send domestic waste to private-operated landfills (PWMI 2019) (Usui et al. 2015). Two strategies could be jointly developed by both countries to mitigate many of the issues faced by both countries: enhancing EPR (R12) and collaboration in establishing joint Ecotowns (R13). Japan is very much ahead of Southeast Asia in terms of implementation of EPR. Capacity development training and the establishment of joint institutions between Japan and the region are much needed and would prove to be beneficial (Putri et al. 2018; Thanh et al. 2011; Wichai-utcha and Chavalparit 2019). Regional policy platforms on waste management can be appropriate channels for enhanced implementation of EPR in Asia Pacific. A regional policy platform between Japan and Southeast Asia could be crucial in solving some of the problems. The platform will also allow regional agreements on EPR-based policies to deal more efficiently with products and end-of-life items that are shipped across borders. Such regional policy instrument can compliment the existing Basel Convention, enabling countries to achieve sustainable cross-border movement of plastic waste. Further cooperation can also be carried out by both countries in terms of the joint construction of EcoTowns (R13). From Japan’s experience, a minimum distance and support by the municipality, is required to facilitate the EcoTown’s success (Ohnishi et al. 2016)(Meng and Yoshida 2012). In Japan, the industry has so far designed high-value-added solutions and established a credit system to minimise greenhouse gas emissions. For instance, Kitakyushu EcoTown conducted a feasibility study of the recycling of wire harness through the brilliant use of a carbon credit system (Ohnishi et al. 2016). These experiences and capacities can prove valuable to be transferred to Malaysia and neighbouring countries where joint Ecotowns may be set up. EcoTowns in the region is expected to see developments in elaborate data-sharing platforms, intelligent sensors for material balance, algorithms to predict demand and standardisation of recycling product criteria in the foreseeable future. Also, there is a need for policymakers in the Asia Pacific region to develop an effective approach to mount a stable cross-border plastic waste recycling route while reducing the environmental impacts. Countries such as Japan and Malaysia would do well to develop common recycling rules in the region such as the introduction of a standardized certification system for environmentally compliant enterprises, practice of periodic checks, and ensuring data transparency in order to prevent environmental problems caused by plastic waste trade. Figure 6 maps the barriers of respective countries to the resolving strategies proposed. The recommendations highlighted coincide with global efforts to combat the mounting plastic waste issue where strategies are currently implemented in the analysis of EPR-based policies, development of regional approach to quality standards, joint creation of Ecotowns, provision of technical support to nations and regions, and use of standardised recycling metrics (Hartley et al. 2020; Papineschi et al. 2019; US Environmental Protection Agency 2019).

Lessons from Japan and future perspectives

Malaysia may do well to establish a central agency to oversee recycling under the purvey of the government, much like the JCPRA in Japan. The agency would fit well into the existing stakeholder relationships and plastic flow model and may be positioned under the Ministry of Environment and Water. Producers and manufacturers pay recycling fees to the agency and the agency put up competitive tenders for recycling companies to bid on. In return, the agency may pay commission fees to the recycling companies. Several challenges persists to establish such a central agency in the Malaysian setting. The first of these challenges would be the disruptions caused to the current contract between local governments and private waste concessionaires. Under the current contracts, waste concessionaires are to collect waste and dispose of them. Only in certain municipalities, plastic wastes are sorted and sent to recycling factories, in limited amounts (Chen et al. 2021). Introducing the efforts to collect and sort recyclable waste would involve renegotiation and charting of new contracts, incurring elevated costs to local governments, something that many local establishments prefer to avoid. Support for local governments may be provided in terms of funding from the federal government. A more centralised contract with standardised terms between the proposed agency, local governments and waste concessionaires may be needed. This way, the cost of waste collection and disposal paid by the municipality to the concessionaire may be covered partially or fully by the recycling fees paid by the producer and manufacturer to the proposed agency. Another challenge involves waste scavengers, stationary and itinerant buyers as well as micro-enterprises in the current recycling ecosystem. These smaller players stand a risk to be sidelined and lose their livelihoods if the agency places their focus solely on contracts between producers, manufacturers, recycling factories and waste concessionaires. Support for these stakeholders should be provided in the forms of training, provision of medical and health services, provision of Personal Protection Equipment (PPE), and introduction of financial incentives, should a central agency be set up (Asim et al. 2012). Figure 7 shows the proposed model for recycling coordination based on the establishment of a central agency in Malaysia.

Initiatives from the industry would serve well to aid the government in overcoming the barriers to implementation. For instance, in January 2021, industry leaders in the Fast Moving Consumer Goods (FMCG) in Malaysia have teamed up to form the Malaysian Recycling Alliance (MAREA), a not-for-profit, industry driven EPR platform (“Strategic Industry Alliance Created to Improve Collection and Recycling of Packaging Waste in Malaysia,” 2021). The establishment of such a platform, driven by the industry, serves as a catalyst to the dormant plastic recycling scene where the rate of waste collection for recycling can be boosted by providing a direct channel from the consumer to the recycling facilities. In Japan, the influence of industry in plastic recycling can also be observed where industry groups, consisting of large beverage companies are working to make new PET drink bottles completely from old ones, dubbed the “bottle to bottle” movement (Reiko 2019). The authors are in the opinion that future efforts in plastic recycling, depends to a large extent on support of governmental efforts from the industry and joint collaboration between the two. Three areas of collaboration are proposed for the government and the industry in Malaysia: improving collection and recycling rates, boosting awareness on better recycling methods, and introduction of incentives schemes for consumers. In the long run, a series of long term strategies should be directed at the following in Japan and Malaysia: strengthening recycling infrastructure, enhancing secondary materials market, and transitioning to circular economy. The increasing cost of recycling coupled with low market price for recyclable material is leading to higher generation of waste and decreased recycling rates. New investments in infrastructure are crucial to meet these mounting recycling needs. Due to high recycling costs, products made from recycled materials face stiff competition from those made from virgin products from a pricing perspective. Policies encouraging recycled markets need to be implemented while incentives should be devised to encourage manufacturers to use post-consumer content in their products. Ultimately, both economies should transition to circular economy approach where stakeholder engagement can be initiated to adopt circular design standards and norms across industries, development of circular trading platforms to boost reuse and recycling markets, and development of a global material flow accounting database. Such a database should cover the type, amount and condition of waste generated across borders to aid policy analysis and research.

Conclusion

A comparative analysis of policy regimes was carried out for Malaysia and Japan where gaps in latest policies and legislations of both countries are expounded. Barriers that hinder change in plastic waste recycling regime are identified and key recommendations are proposed to counter these barriers, on the domestic front in Malaysia and Japan, respectively. Malaysia and neighbouring countries in Southeast Asia are still at the learning phase in establishing an innovative plastic recycling regime. Experience from advanced countries in the region such as Japan who is dealing with large volumes of plastic waste effectively can be incorporated into the learning process. As such, the time frame for policy development can be shortened. Some of the intricate issues currently faced by Japan is not yet deemed as critical in the current phase of development in Malaysia such as rise of PET waste and the pressing need for detailed information on plastic waste exports. Malaysia and neighbouring countries can consider these issues faced by Japan and learn valuable lessons on what works and address them proactively in the future. Opportunities for cooperation and synergy exist between the countries especially in the setting up of regional policy platforms focused on enhancing EPR and the establishment of joint EcoTowns in the region. In the long run, both countries would do well to consider strengthening the recycling infrastructure, enhancing secondary materials market and transitioning to circular economy.

Availability of data and material

Data sharing not applicable to this article as no datasets were generated or analysed during the current study.

References

Ahsan A, Ismail N, Rahman MM, Imteaz M, Rahman A, Mohammad N, Salleh MAM (2013) Municipal solid waste recycling in Malaysia: Present scenario and future prospects. Fresenius Environ Bull 22(12):3654–3664

Aja OC, Al-Kayiem HH (2014) Review of municipal solid waste management options in Malaysia, with an emphasis on sustainable waste-to-energy options. J Mater Cycles Waste Manage 16(4):693–710. https://doi.org/10.1007/s10163-013-0220-z

Akenji L, Bengtsson M, Hotta Y, Kato M, Hengesbaugh M (2020) Policy responses to plastic pollution in Asia. Plastic Waste Recycl. https://doi.org/10.1016/b978-0-12-817880-5.00021-9

Ananthalakshmi A, and Chow E (2018) Swamped with plastic waste: Malaysia struggles as global scrap piles up. Reuters. Retrieved from https://www.reuters.com/article/us-malaysia-waste-idUSKCN1MZ0P4

Asim M, Batool SA, Chaudhry MN (2012) Scavengers and their role in the recycling of waste in Southwestern Lahore. Resour Conserv Recycl 58:152–162. https://doi.org/10.1016/j.resconrec.2011.10.013

Budhiarta I, Siwar C, Basri H (2012) Advanced science information technology current status of municipal solid waste generation in Malaysia. Int J Adv Sci Eng Inf Technol 2(2):16–21

Bünemann A, and Brinkmann J (2019) Legal Framework Study of Extended Producer Responsibility. Retrieved from www.cyclos.de

Chen HL, Nath TK, Chong S, Foo V, Gibbins C, Lechner AM (2021) The plastic waste problem in Malaysia: management, recycling and disposal of local and global plastic waste. SN Appl Sci 3(4):1–15. https://doi.org/10.1007/s42452-021-04234-y

Choon SW, Tan SH, Chong LL (2017) The perception of households about solid waste management issues in Malaysia. Environ Dev Sustain 19(5):1685–1700. https://doi.org/10.1007/s10668-016-9821-8

Gong L, and Trajano JS (2019) Tackling East Asia’S new environmental challenge: marine plastic pollution. Jstor, (June). Retrieved from https://about.jstor.org/terms

Hartley K, van Santen R, Kirchherr J (2020) Policies for transitioning towards a circular economy: expectations from the European Union (EU). Resour, Conserv Recycl 155:104634. https://doi.org/10.1016/j.resconrec.2019.104634

Hassan MN, Chong TL, Rhman M, Salleh MN, Zakaria Z, and Awang M (2001) Solid waste management in Southeast Asian countries with special attention to Malaysia. Proceedings Sardinia 2001, Eighth International Waste Management and Landfill Symposium, (October 2001), 1–10

Hill M (2005) The public policy process. In Pearson Education Limited (4th edition). https://doi.org/10.1145/2967878.2967894

Jereme IA, Alam MM, Siwar C (2015) Waste recycling in Malaysia: transition from developing to developed country. Indian J Edu Inf Manage 4(1):1–14

Jung CH, Matsuto T, Tanaka N, Okada T (2004) Metal distribution in incineration residues of municipal solid waste (MSW) in Japan. Waste Manage 24(4):381–391. https://doi.org/10.1016/S0956-053X(03)00137-5

Kam HW, Baharum MR, Chua SJL (2016) A review of commercial waste recycling policy in Malaysia. Int J Environ Sustain Develop 15(4):404–422. https://doi.org/10.1504/IJESD.2016.079482

Kamo T (2011) Overview of the waste plastic recycling system in Japan and future tasks. 15–18

Kanger L, Sovacool BK, Noorkõiv M (2020) Six policy intervention points for sustainability transitions: A conceptual framework and a systematic literature review. Res Policy 49(7):104072. https://doi.org/10.1016/j.respol.2020.104072

Kong SC, Wong TL, Yang M, Chow CF, Tse KH (2017) Emerging practices in scholarship of learning and teaching in a digital era. Emerg Pract Sch Learn Teach Digital Era. https://doi.org/10.1007/978-981-10-3344-5

Kuo YL, Perrings C (2010) Wasting time? Recycling incentives in Urban Taiwan and Japan. Environ Resour Econ 47(3):423–437. https://doi.org/10.1007/s10640-010-9386-1

Liu G, and Rong J (2013) Research on the Eco-towns in Japan based on recycling perspective and the apocalypse to China. Proceedings of 2013 IEEE International Conference on Service Operations and Logistics, and Informatics, SOLI 2013, (12):205–210 https://doi.org/10.1109/SOLI.2013.6611410

Manaf LA, Samah MAA, Zukki NIM (2009) Municipal solid waste management in Malaysia: practices and challenges. Waste Manage 29(11):2902–2906. https://doi.org/10.1016/j.wasman.2008.07.015

Meng X, Yoshida T (2012) The impact analysis of waste plastic trade between China and Japan—from policy view. Design Innov Value towards Sustain Soc. https://doi.org/10.1007/978-94-007-3010-6_46

Ministry of Environment Japan (2021) Basel convention: Japan’s activities for the basel convention. Retrieved June 10, 2021, from http://www.env.go.jp/en/recycle/basel_conv/

Moh YC, Abd Manaf L (2014) Overview of household solid waste recycling policy status and challenges in Malaysia. Resour Conserv Recycl 82:50–61. https://doi.org/10.1016/j.resconrec.2013.11.004

Moh YC, Abd Manaf L (2017) Solid waste management transformation and future challenges of source separation and recycling practice in Malaysia. Resour Conserv Recycl 116(2017):1–14. https://doi.org/10.1016/j.resconrec.2016.09.012

Mohamad Z, and Keng J (2013) Opportunities and challenges in sustainable waste management transition in Malaysia: A multi-level socio-technical perspective. Globelics Seminar on Low Carbon Development, 1–14. Retrieved from http://www.globelics.org/wp-content/uploads/2013/03/Zeeda-and-Keng-2013-Malaysia.pdf

Mohamed AF (2009) Recycling system in Malaysia: case studies on industrial waste. 3R Policies for Southeast and East Asia, (March), 53–72

Murad W, Siwar C (2007) Waste management and recycling practices of the urban poor: a case study in Kuala Lumpur city Malaysia. Waste Manage Res 25(1):3–13. https://doi.org/10.1177/0734242X07070766

Mwanza BG, Mbohwa C, Telukdarie A (2018) Strategies for the recovery and recycling of plastic solid waste (PSW): a focus on plastic manufacturing companies. Procedia Manuf 21(2017):686–693. https://doi.org/10.1016/j.promfg.2018.02.172

Mwanza BG, Mbohwa C, Telukdarie A, Medoh C (2019) Value addition to plastic solid wastes: informal waste collectors’ perspective. Procedia Manuf 33:391–397. https://doi.org/10.1016/j.promfg.2019.04.048

Nakatani J, Fujii M, Moriguchi Y, Hirao M (2010) Life-cycle assessment of domestic and transboundary recycling of post-consumer PET bottles. Int J Life Cycle Assess 15(6):590–597. https://doi.org/10.1007/s11367-010-0189-y

Nakatani J, Maruyama T, Moriguchi Y (2020) Revealing the intersectoral material flow of plastic containers and packaging in Japan. Proc Natl Acad Sci USA 117(33):19844–19853. https://doi.org/10.1073/pnas.2001379117

Nishijima A, Nakatani J, Yamamoto K, Nakajima F (2012) Life cycle assessment of integrated recycling schemes for plastic containers and packaging with consideration of resin composition. J Mater Cycles Waste Manage 14(1):52–64. https://doi.org/10.1007/s10163-011-0032-y

Ohnishi S, Fujii M, Fujita T, Matsumoto T, Dong L, Akiyama H, Dong H (2016) Comparative analysis of recycling industry development in Japan following the Eco-Town program for eco-industrial development. J Clean Prod 114:95–102. https://doi.org/10.1016/j.jclepro.2015.04.088

Okuwaki A (2004) Feedstock recycling of plastics in Japan. Polymer Degradation and Stability, 85(3 SPEC. ISS.) 981–988 https://doi.org/10.1016/j.polymdegradstab.2004.01.023

Panda AK, Singh RK, Mishra DK (2010) Thermolysis of waste plastics to liquid fuel A suitable method for plastic waste management and manufacture of value added products-A world prospective. Renew Sustain Energy Rev 14(1):233–248. https://doi.org/10.1016/j.rser.2009.07.005

Papineschi J, Hogg D, Chowdhury T, Durrant C, and Thomson A (2019) Analysis of Nordic regulatory framework and its effect on waste prevention and recycling. https://doi.org/10.6027/TN2019-522

Pariatamby A (2014) MSW management in Malaysia-changes for sustainability. In Pariatamby A and Tanaka M (Eds.), Municipal Solid Waste Management in Asia and the Pacific Islands (pp 195–232) https://doi.org/10.1007/978-981-4451-73-4_11

Periathamby A, Hamid FS, Khidzir K (2009) Evolution of solid waste management in Malaysia: Impacts and implications of the solid waste bill, 2007. J Mater Cycles Waste Manage 11(2):96–103. https://doi.org/10.1007/s10163-008-0231-3

Putri AR, Fujimori T, Takaoka M (2018) Plastic waste management in Jakarta, Indonesia: evaluation of material flow and recycling scheme. J Mater Cycles Waste Manage 20(4):2140–2149. https://doi.org/10.1007/s10163-018-0753-2

PWMI (2019) An Introduction to plastic recycling. Plastic Waste Management Institute, 1–33

Reiko M (2019) Refuse to resource: suntory’s bottle-to-bottle initiative to reshape plastic recycling. Nippon.Com. Retrieved from https://www.nippon.com/en/japan-topics/c06302/refuse-to-resource-suntory’s-bottle-to-bottle-initiative-to-reshape-plastic-recycling.html

Sakai S, Ikematsu T, Hirai Y, Yoshida H (2008) Unit-charging programs for municipal solid waste in Japan. Waste Manage 28(12):2815–2825. https://doi.org/10.1016/j.wasman.2008.07.010

SIRIM-QAS International (2020) Retrieved November 25, 2020, from https://www.sirim-qas.com.my/

Strategic Industry Alliance Created to Improve Collection and Recycling of Packaging Waste in Malaysia. (2021). Malaysian Recycling Alliance (MAREA). Retrieved from https://www.marea.com.my/strategic-industry-alliance-created-to-improve-collection-and-recycling-of-packaging-waste-in-malaysia/

Tan Y (2019) Plastic pollution: One town smothered by 17,000 tonnes of rubbish. BBC. Retrieved from https://www.bbc.com/news/world-asia-46518747

Tanaka M (1999) Recent trends in recycling activities and waste management in Japan. J Mater Cycles Waste Manage. https://doi.org/10.1007/s10163-999-0006-5

Thanh NP, Matsui Y, Fujiwara T (2011) Assessment of plastic waste generation and its potential recycling of household solid waste in Can Tho City Vietnam. Environ Monitor Assess 175(1–4):23–35. https://doi.org/10.1007/s10661-010-1490-8

US Environmental Protection Agency (2019) Status report: framework for advancing the U.S. recycling System. (November) 0–10

Usui T, Kakamu K, Chikasada M (2015) To introduce recycling or not: A panel data analysis in Japan. Resour Conserv Recycl 101:84–95. https://doi.org/10.1016/j.resconrec.2015.05.006

Wahab DA, Abidin A, Azhari CH (2007) Recycling trends in the plastics manufacturing and recycling companies in Malaysia. J Appl Sci 7:1030–1035. https://doi.org/10.3923/jas.2007.1030.1035

Watanabe K, Sasaki S, Tiew KG, Irwan D (2018) Comparison of recycling activities at landfills in Indonesia and Malaysia. Worldwide Waste: J Interdiscip Stud 1(1):1–6. https://doi.org/10.5334/wwwj.8

Welden NA (2020) The environmental impacts of plastic pollution. Plastic Waste Recycl. https://doi.org/10.1016/b978-0-12-817880-5.00008-6

Wichai-utcha N, Chavalparit O (2019) 3Rs policy and plastic waste management in Thailand. J Mater Cycles Waste Manage 21(1):10–22. https://doi.org/10.1007/s10163-018-0781-y

Wong EK, and Farha JA (2019) Plastic : an undegradable problem. In Khazanah Research Institute

Yagai Y (n.d.) Recycling scheme of a WEEE in Japan. Office of Sound Material-Cycle Society and Office of Recycling Promotion, Waste Management and Recycling Department, 2015. Ministry of the Environment Japan

Yoshinori M, and Shiko H (2018) Proposals to strengthen Japan’s domestic measures and regional cooperation on stable and environmentally sound plastic scrap recycling: response to China’s ban on imports of plastic scrap. Institute for Global Environmental Strategies

Yusoff MS, Kamaruddin MA, Aziz HA, Adlan MN, Zaman NQ, Mahmood NZ (2018) Municipal solid waste composition, characterization and recyclables potential: A case study evaluation in Malaysia. J Solid Waste Technol Manage 44(4):330–343. https://doi.org/10.5276/JSWTM.2018.330

Zen IS, Siwar C (2015) An analysis of household acceptance of curbside recycling scheme in Kuala Lumpur, Malaysia. Habitat Int 47:248–255. https://doi.org/10.1016/j.habitatint.2015.01.014

Zen IS, Noor ZZ, Yusuf RO (2014) The profiles of household solid waste recyclers and non-recyclers in Kuala Lumpur, Malaysia. Habitat Int 42:83–89. https://doi.org/10.1016/j.habitatint.2013.10.010

Zheng P, Zhang K, Zhang S, Wang R, Wang H (2017) The door-to-door recycling scheme of household solid wastes in urban areas: a case study from Nagoya, Japan. J Clean Prod 163:S366–S373. https://doi.org/10.1016/j.jclepro.2016.03.106

Acknowledgements

This work was supported by The Sumitomo Foundation [grant number 198493] granted to Universiti Tunku Abdul Rahman, with Seng How Kuan as the principal investigator.

Funding

This work was supported by The Sumitomo Foundation [grant number 198493] granted to Universiti Tunku Abdul Rahman, with Seng How Kuan as the principal investigator.

Author information

Authors and Affiliations

Contributions

All authors contributed to the idea of the article. Literature search, data collection and analysis were performed by Seng How Kuan. The first draft of the manuscript was written by Seng How Kuan and all authors critically revised the work. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflicts or interest to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kuan, S.H., Low, F.S. & Chieng, S. Towards regional cooperation on sustainable plastic recycling: comparative analysis of plastic waste recycling policies and legislations in Japan and Malaysia. Clean Techn Environ Policy 24, 761–777 (2022). https://doi.org/10.1007/s10098-021-02263-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-021-02263-0