Abstract

The difference in decomposition behavior of lignin from Japanese cedar (Cryptomeria japonica) as softwood and Japanese beech (Fagus crenata) as hardwood treated by hot-compressed water was investigated. The obtained residual lignin was then evaluated by the alkaline nitrobenzene oxidation analysis, the relative proportion of ether type linkages had decreased for both species as the hot-compressed water treatment was prolonged. Furthermore, the microscopic observation of the residual lignin indicated that lignin in tracheid cell walls was removed to a greater extent than that in middle lamella in Japanese cedar. Similarly in Japanese beech, lignin in fiber cell walls was removed more extensively, with middle lamella lignin remaining after two-step treatment. Such observation was supported by a result obtained from the methoxyl content analysis per C9 unit of the residual lignin. Based on these lines of evidence, lignin in middle lamella must be rich in condensed type, and these differences between softwood and hardwood can be attributed to the intrinsic characteristics of the original lignin and its topochemistry in woods.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Introduction

Woody biomass has gained attention as an alternative resource to fossil fuel due to its abundance and noncompetition with foodstuff. In order to utilize the woody biomass as biofuels and chemicals, various chemical and physical degradation methods have been examined. Among them, hydrothermal treatments such as steam explosion, subcritical and supercritical water, and hot-compressed water treatments are expected as a promising technology due to its catalyst-free and environmentally benign characteristics. As a feature of hydrothermal treatment, an increase in temperature of water at a high pressure results in a decrease in its dielectric constant and an increase in its ionic product [1, 2].

Compared with supercritical water, hot-compressed water is milder in its condition for hydrothermal reaction; thus, it has gained considerable attention as a promising decomposition medium for lignocellulosics [2]. Among hot-compressed water treatment systems, semi-flow type can prevent obtained products from excessive decomposition due to the appropriate residence time [3, 4]. Phaiboonsilpa et al. [5] and Lu et al. [6] treated Japanese cedar (Cryptomeria japonica) and Japanese beech (Fagus crenata) with semi-flow hot-compressed water (1st stage: 230 °C/10 MPa/15 min, 2nd stage: 270 °C/10 MPa/15 min), and the hemicelluloses and cellulose were decomposed in the 1st and 2nd stages, respectively. Lignin has been decomposed and eluted in hot-compressed water at both stages [7, 8].

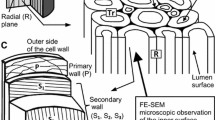

These polymer components such as cellulose, hemicelluloses and lignin are not uniformly distributed within wood cells, and their concentrations are different from one morphological region to another. Therefore, it would be quite essential to understand the topochemistry of wood to discuss the decomposition behavior of its chemical constituents.

Therefore, the delignification behaviors by pulping such as kraft [9, 10], sulphite [11–14], soda methods [9] have been studied. In addition, some researchers studied the topochemistry of wood with hydrothermal treatment as pretreatment media [15–17]. However, delignification behavior of wood by hydrothermal treatment has not been discussed yet. Thus, the aim of this study is to elucidate the topochemical differences in delignification between softwoods and hardwoods as treated by hot-compressed water.

Materials and methods

Hot-compressed water treatment

Extractive-free wood flour of Japanese cedar (Cryptomeria japonica) and Japanese beech (Fagus crenata) were prepared according to the previous reports [5, 6]. All chemicals used in this study were of reagent grade without purification.

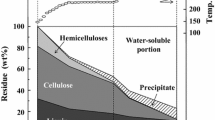

Hot-compressed water treatment was conducted with two-step (1st stage: 230 °C/10 MPa/15 min and 2nd stage: 270 °C/10 MPa/15 min) as shown in Fig. 1. Each step of the treatment includes time up for 10 and 5 min for the 1st and 2nd stages, respectively, followed by time at for 15 min. The pressure was increased up to 10 MPa by pressure pump, and controlled with a back-pressure regulator. A half gram of oven-dried extractive-free wood flour was placed in the reaction vessel, for which the two-step semi-flow hot-compressed water treatment was carried out as described in previous papers [5, 6].

Analytical methods

The lignin content of insoluble residue was examined as the combined yields of Klason lignin and acid-soluble lignin [18]. For acid-soluble portion, the amounts of various monosaccharides were determined by high-performance anion-exchange chromatography. Its cellulose and hemicellulose contents were then estimated based on the amounts of monosaccharides [5].

In order to evaluate chemical characteristics of residual lignin, alkaline nitrobenzene oxidation was conducted and the total yields of vanillin and syringaldehyde were analyzed with gas chromatography [19].

The obtained insoluble residues of the 1st and 2nd stage treatments were gradually dehydrated with ethanol–water mixtures with increasing ethanol concentration up to 99.5 %. After the ethanol was replaced by propylene oxide, the residues were embedded in epoxy resin. Ultrathin sections of 0.5 μm for ultraviolet (UV) microscopy and 80 nm for transmission electron microscopy (TEM) were prepared from embedded samples with a diamond knife mounted on ultramicrotome (Leica Reichert Supernova Microtome: Leica Reichert). For UV microscopy, the obtained sections were placed on quartz slides, mounted with glycerin, and then covered with quartz cover glass. They were, then, examined under MSP-800 (Carl Zeiss) at a wavelength of 280 nm with a wavelength width of ±10 nm. For TEM observation, lignin was selectively stained with 1 % aqueous solution of KMnO4 and the stained sections, mounted on copper grids, were observed by JEM-1400 (JEOL) at an acceleration voltage of 100 keV.

Methoxyl content of residual lignin was analyzed according to general method [20]. After insoluble residues were treated with 57 % of hydroiodic acid, the yield of obtained methyl iodide was determined with gas chromatography to study the average methoxyl content of the residual lignin.

Results and discussion

The hot-compressed water treatment was conducted under constant pressure (10 MPa) with two-step treatment consisting of the 1st stage (230 °C/10 MPa) and 2nd stage (270 °C/10 MPa) as shown in Fig. 1. The 1st stage consists of 10 min time up towards the maximum temperature 230 °C for 15 min, while the 2nd stage consists of 5 min time up towards the maximum temperature 270 °C for 15 min.

Table 1 shows the yield of the obtained insoluble residues from Japanese cedar and Japanese beech treated by hot-compressed water as mentioned above. The insoluble residues at the end of the time up and time at for both stages were collected and examined. For both species, more than half of the initial wood was decomposed and removed with hot-compressed water at the end of the 1st stage, and at the end of the 2nd stage, 13 % of Japanese cedar and 7 % of Japanese beech remained as insoluble residue.

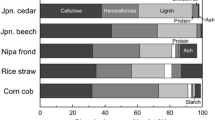

The chemical composition of the insoluble residues is also shown in Table 1. It seems apparent that the insoluble residues consist of lignin together with cellulose and hemicelluloses without any chars. For both species, hemicelluloses were decomposed completely, while cellulose was partly remained as insoluble residues after two-step treatment. On the other hand, the lignin concentration increased as the hot-compressed water treatment was prolonged, for both species. Consequently, insoluble residues at the end of the 2nd stage were mostly composed of lignin to be 0.87 g/g in Japanese cedar and 0.77 g/g in Japanese beech, indicating that lignin has much higher resistance to hot-compressed water than other cell wall components.

The delignification of insoluble residue is also shown in Table 1. It is apparent that the delignification progressed as the hot-compressed water treatment was prolonged, while around one-third of lignin in Japanese cedar and one-fourth of lignin in Japanese beech still remained as insoluble residues. Thus, lignin of Japanese cedar has higher resistance to hot-compressed water than that of Japanese beech.

Linkage between the phenylpropane units is one of the significant factors in the decomposition behavior of lignin. Lignin has two types of linkages which are ether type linkages such as β-O-4, and condensed type linkages such as 5–5′. Ehara et al. [21] treated dimeric model compounds of β-O-4 and 5–5′ types with the subcritical water (330 °C/50 MPa/10 s), and ether linkages were readily cleaved, while condensed type linkages had resistance to subcritical water.

Based on this information, alkaline nitrobenzene oxidation analysis was conducted for the insoluble residues in order to compare the relative proportion of ether linkages of the residual lignin. The obtained yields of the products from insoluble residue of Japanese cedar and Japanese beech are shown in Fig. 2. Vanillin derived from guaiacyl (G) lignin and syringaldehyde from syringyl (S) lignin were mainly obtained as decomposed products. Just comparison, the yields of obtained products from the untreated wood are also shown. For both species, the yields of products decreased as hot-compressed water treatment was prolonged. The obtained products would mainly be derived from ether type linkages of lignin. Considering the previous experiment of lignin model compounds, this result would indicate that the relative proportion of ether linkages in the residual lignin was decreased by hot-compressed water treatment. Consequently, lignin in the final residues would be rich in condensed type lignin and/or unknown structures produced in the hot-compressed water treatment. This result would be owing to the fact that hot-compressed water cleaves only ether linkages of lignin but not condensed type linkages, as observed in a study on the lignin model compounds [21].

In order to observe the distribution of lignin in the insoluble residues, UV microscopic observations were performed as shown in Fig. 3. Among the main cell wall components, only lignin can absorb UV light due to its aromatic structure. Thus, the darker area in UV micrographs shows the higher concentration of lignin. The destruction of a part of the cell wall would be caused by the physical burden during the preparation of wood flour. In case of Japanese cedar, the tracheid cell wall structure has been maintained until the end of the 1st stage. However, at the end of the 2nd stage, tracheid cell walls were extensively compressed and their structure altered greatly. A similar tendency has been observed in Japanese beech. The structure of fiber and vessel cell walls has been maintained until the end of 1st stage, whereas at the end of the 2nd stage, most of the cell walls disappeared, with only middle lamella portions remaining. The dotted square portion was enlarged to show the remaining middle lamella portion consisting mainly of the lignin.

Such an observation can be made more clearly in the high magnified TEM images as shown in Figs. 4 and 5, in which the middle lamella at cell corner region remained as insoluble residue with some residual lignin fraction from the cell walls, all of which are stained with KMnO4 specific for lignin. However, in case of Japanese cedar (Fig. 4), lignin in tracheid cell walls partly remained. From these lines of evidence, lignin in tracheid cell wall of Japanese cedar had higher resistance to hot-compressed water than fiber cell wall of Japanese beech.

Lignin is composed of up to three different phenylpropane (C9) units, which are guaiacyl (G), syringyl (S) and p-hydroxyphenyl (H) lignins with, respectively, one, two and no methoxyl groups per aromatic ring. The distribution of these phenylpropane units is different from one morphological region to another. For example, in case of softwood tracheid, Whiting and Goring elucidated that lignin in the cell wall is mainly composed of G lignin, whereas that in middle lamella, especially at cell corner, is composed of H and G lignins according to the methoxyl content analysis [22]. On the other hand, hardwood lignin is composed of G and S lignins, distributed differently from one morphological region to another. Saka and Goring examined the distribution of lignin in white birch (Betula papyrifera) with UV-EDXA analysis and elucidated that G:S ratio of lignin in fiber S2 layer, which occupied most of the cell wall, is 12:88, while G:S ratio of the cell corner middle lamella is 88:12 [23]. Thus, lignin in middle lamella has lower methoxyl content per C9 unit than that in cell wall for both softwood tracheid and hardwood fiber.

The methoxyl content of residual lignin was, therefore, analyzed and shown in Fig. 6 as lignin-derived wt%. In order to make the discussion understandable clearly, the methoxyl content per phenylpropane unit is also shown in Fig. 6. Sarkanen and Hergert [24] indicated that normal hardwood lignins are composed of G and S lignins in varying ratio with the methoxyl content per phenylpropane units in a range of 1.2–1.5. Japanese beech used in this study was 0.21 % (≒1.35/C9 unit) in its content as in Fig. 6. On the other hand, normal softwood lignins are mainly composed of G lignin with a trace amount of H lignin, as observed to be 0.16 % (≒0.96/C9 unit) for Japanese cedar. If both lignins in cell wall and middle lamella were uniformly removed at the same rate, the average methoxyl content per C9 unit should be the same during hot-compressed water treatment. However, the methoxyl content per C9 unit was decreasing for both species as the delignification was progressed. According to the analysis of the lignin-derived products in water-soluble portion, the methoxyl residue was not removed from aromatic ring by hot-compressed water treatment [8]. Thus, this result in Fig. 6 indicates that the relative proportion of middle lamella lignin has increased, compared with cell wall lignin, as observed in Fig. 3 through Fig. 5 for insoluble residues.

The phenylpropane units with lower methoxyl content have higher possibility to form condensed type linkages at 3 or 5 position of aromatic ring. Based on these lines of evidence, lignin in middle lamella must be rich in condensed types, thus remaining after two-step treatment. Similarly, lignin in tracheid cell wall of Japanese cedar would have higher condensed types than lignin in fiber cell wall of Japanese beech. Thus, lignin in Japanese cedar had higher resistance to hot-compressed water than that in Japanese beech as shown in Table 1 and Fig. 4.

A part of lignin in the insoluble residue might be intermolecularly condensed during hot-compressed water treatment. If the condensed type linkages in insoluble residue are the result of condensation during the treatment, condensation would be occurred not only in the middle lamella but also in the cell wall. However, as described already, the delignification behavior was different from each other. Thus, the distribution of the remaining lignin must be reflected from that in the original condensed type lignin itself. Moreover, the semi-flow type of the hot-compressed water treatment may minimize its possibility due to prompt removal of the delignified products.

Concluding remarks

The difference in delignification from Japanese cedar and Japanese beech as treated by hot-compressed water was investigated from a topochemical viewpoint. Due to the preferential cleavage of ether linkages of lignin, lignin in cell walls of the tracheid and fiber was preferentially decomposed and removed in hot-compressed water. Consequently, lignin in middle lamella remained as insoluble residue after treatment. Although some alternation of the lignin through condensation might result during hot-compressed water treatment and obscure the data, overall the results obtained would suggest that middle lamella lignin is rich in condensed type. For cell wall lignin, on the other hand, Japanese cedar tracheids would have relatively higher condensed type lignin than Japanese beech fibers. These results, thus, indicate that the decomposition behaviors of softwood and hardwood differ due to their intrinsic characteristics of lignin. Such information must elucidate the importance of topochemistry in the decomposition behaviors of lignin.

References

Rogalinski T, Ingram T, Brunner G (2008) Hydrolysis of lignocellulosics biomass in water under elevated temperatures and pressures. J Supercrit Fluids 47:54–63

Ando H, Sakaki T, Kokusho T, Shibata M, Uemura Y, Hatate Y (2000) Decomposition behavior of plant biomass in hot-compressed water. Ind Eng Chem Res 39:3688–3693

Mosier N, Wyman C, Dale B, Elander R, Lee YY, Holtzapple M, Ladisch M (2005) Features of promising technologies for pretreatment of lignocellulosic biomass. Bioresour Technol 96:673–686

Sakaki T, Shibata M, Sumi T, Yasuda S (2002) Saccharification of cellulose using a hot-compressed water-flow reactor. Ind Eng Chem Res 41:661–665

Phaiboonsilpa N, Yamauchi K, Lu X, Saka S (2010) Two-step hydrolysis of Japanese cedar as treated by semi-flow hot-compressed water. J Wood Sci 56:331–338

Lu X, Yamauchi K, Phaiboonsilpa N, Saka S (2009) Two-step hydrolysis of Japanese beech as treated by semi-flow hot-compressed water. J Wood Sci 55:367–375

Yamauchi K, Phaiboonsilpa N, Kawamoto H, Saka S (2013) Characterization of lignin-derived products from Japanese beech as treated by two-step semi-flow hot-compressed water. J Wood Sci 59:149–154

Takada M, Saka S (2015) Characterization of lignin-derived products from Japanese cedar as treated by semi-flow hot-compressed water. J Wood Sci 61:299–307

Saka S, Thomas RJ, Gratzl JS, Abson D (1982) Topochemistry of delignification in Douglas-fir wood with soda, soda-anthraquinone and kraft pulping as determined by SEM-EDXA. Wood Sci Technol 16:139–153

Aguayo MG, Ferraz A, Elissetche JP, Masarin F, Mendonҫa RT (2014) Lignin chemistry and topochemistry during kraft delignification of Eucalyptus globulus genotypes with contrasting pulpwood characteristics. Holzforschung 68:623–629

Whiting P, Goring DAI (1981) The topochemistry of delignification shown by pulping middle lamella and secondary wall tissue from black spruce wood. J Wood Chem Technol 1:111–122

Mondonca R, Ferraz A, Kordsachia O, Koch G (2004) Cellular UV-microspectrophotometric investigations on pine wood (Pinus taeda and Pinus elliottii) delignification during biopulping with Ceriporiopsis subvermisprora (Pilát) Gilbn. & Ryv. and alkaline sulfite/anthraquinone treatment. Wood Sci Technol 38:567–575

Koch G, Rose B, Patt R, Kordsachia O (2003) Topochemical investigations on delignification of Picea abies L. Karst. during alkaline sulfite (ASA) and bisulfite pulping by scanning UV microspectrophotometry. Holzforschung 57:611–618

Rohbein M, Pereira M, Koch G, Kordsachia O (2010) Topochemical investigations into the delignification of Eucalyptus globulus chips during semi-chemical sulfite pulping. Wood Sci Technol 44:435–449

Mou H, Heikkila E, Fardim P (2014) Topochemistry of environmentally friendly pretreatments to enhance enzymatic hydrolysis of sugar cane bagasse to fermentable sugar. J Agric Food Chem 62:3619–3625

Biziks V, Andersons B, Beļkova Ļ, Kapača E, Militz H (2013) Changes in the microstructure of birch wood after hydrothermal treatment. Wood Sci Technol 47:717–735

Milagres AMF, Carvalho W, Ferraz A (2010) Topochemistry, porosity and chemical composition affecting enzymatic hydrolysis of lignocellulosic materials. In: Buchentidge MS, Goldman GH (eds) Routes to cellulosic ethanol. Springer, New York, pp 53–72

Dence CW (1992) The determination of lignin. In: Lin SY, Dence CW (eds) Methods in lignin chemistry. Springer, Berlin, pp 33–39

Chen CL (1992) Nitrobenzene and cupric oxide oxidations. In: Lin SY, Dence CW (eds) Methods in lignin chemistry. Springer, Berlin, pp 33–39

Baker SM (1996) Rapid methoxyl analysis of lignins using gas chromatography. Holzforschung 50:573–574

Ehara K, Saka S, Kawamoto H (2002) Characterization of the lignin-derived products from wood as treated in supercritical water. J Wood Sci 48:320–325

Whiting P, Goring DAI (1982) Chemical characterization of tissue fractions from the middle lamella and secondary wall of black spruce tracheids. Wood Sci Technol 16:261–267

Saka S, Goring DAI (1988) The distribution of lignin in white birch wood as determined by bromination with TEM-EDXA. Holzforschung 42:149–153

Sarkanen KV, Hergert HL (1971) Classification and distribution. In: Sarkanen KV, Ludwig CH (eds) Lignins. Occurrence, formation, structure and reactions. Wiley, New York, pp 43–94

Acknowledgments

This work has been done as part of the JST (ALCA) project “Ethanol Production with Acetic Acid Fermentation from Lignocellulosics” The authors gratefully acknowledge all the support.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Takada, M., Saka, S. Comparative study on topochemistry of delignification from Japanese cedar and Japanese beech by hydrothermal treatment. J Wood Sci 61, 602–607 (2015). https://doi.org/10.1007/s10086-015-1501-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10086-015-1501-z