Abstract

A robust and rapid HPLC method for β-carotene and β-apo-8′-carotenal analyses in various processed foods was developed. The analysis method was validated for low-fat, moderate-fat, and high-fat food matrices. The two carotenoids were identified by LC–MS/MS. The detection limits for β-carotene and β-apo-8′-carotenal in the three food matrices were 0.08–0.27 µg/g and 0.09–0.18 µg/g, respectively. The inter- and intra-day accuracy and precision were in accordance with the Codex guidelines. The validated method was applied to 57 processed food samples, possibly containing β-carotene and β-apo-8′-carotenal, obtained in Korea. The detected β-carotene and β-apo-8′-carotenal levels in the samples ranged from not detected (ND) to 6.92 µg/g and ND to 1.63 µg/g, respectively. Chocolate and cheese samples had the highest β-carotene and β-apo-8′-carotenal levels, respectively. Notably, several samples with no labeled carotenoid additives contained β-carotene. Moreover, the developed analytical method was compatible with various processed food matrices.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Color is the food quality attribute that is closely associated with food acceptability. Food colorants are widely used in food processing and are often added to (1) enhance the color of foods, (2) add color to uncolored foods, and (3) mitigate color loss during food processing. Various food colors are used as additives, including natural food colors derived from living organisms (e.g., carmine obtained from cochineal extract), synthetic food colors found in nature [e.g., β-carotene (E 160a) and β-apo-8′-carotenal (E 160e)], synthetic food colors not found in nature (e.g., azo-dyes), and inorganic colors (e.g., titanium dioxide) (Mortensen, 2006).

Synthetic food colorants have been widely used in processed foods because of their vivid color, high stability, and low cost. However, they may cause allergic reactions (Sigurdson et al., 2017). Therefore, recently, consumer demand for natural colorants or synthetic food colors that are also found in nature has been increasing (Shahid et al., 2013). Natural colorants include carotenoids, betalains, anthocyanins, and chlorophylls (Luzardo-Ocampo et al., 2021).

In nature, carotenoids are found in various food materials, including spinach, broccoli, carrots, zucchini, mango, watermelon, tomato, papaya, crustaceans, and egg yolks as well as in the skin and flesh of certain fishes. Among the carotenoids in food sources, β-carotene, α-carotene, lutein, zeaxanthin, lycopene, and β-cryptoxanthin are the most commonly found ones (de Freitas Santos et al., 2021). Carotenoids are precursors of vitamin A, which is an essential vitamin that is not synthesized in the body, and therefore, people must acquire it through dietary intake. Carotenoids also act as oxygen and peroxyl radical scavengers in the body, protecting against photooxidation (Van Rooyen et al., 2008). The dietary intake of carotenoids reduces the risk of several chronic diseases, including cardiovascular disease and cancer (Bohn et al., 2021). Carotenoids are converted to apocarotenoids (e.g., β-apo-8′-carotenal) through oxidative cleavage, forming other colorants (e.g., bixin) and volatile compounds (e.g., β-ionone) (Rodriguez-Concepcion et al., 2018).

The β-carotene and β-apo-8′-carotenal have been widely used as colorants in various processed foods, such as soft drinks, snacks, bread, cheese, margarine, and butter. β-Carotene is an intense dark red to brownish-red colored pigment that is chemically unstable when exposed to light and heat (EFSA, 2012a); however, it is stable over a wide pH range and can be added to most processed foods (Bell et al., 2016; Liu et al., 2018). β-Apo-8′-carotenal is a dark orange colorant that can be formed through the oxidative degradation of β-carotene (EFSA, 2012b). It has a high color intensity and can be produced in various colors, in addition to orange, depending on the extraction solvents used (Song and Cho, 1997).

In 2011, the acceptable daily intake (ADI) of the two carotenoids was set at 5 mg/kg of body weight; however, the ADI of β-carotene was later withdrawn and that of β-apo-8′-carotenal was reset to 0.3 mg/kg of body weight by the Joint FAO/WHO Expert Committee on Food Additives (JECFA, 2019a; JECFA, 2019b). According to Codex (FAO, 2019), β-carotene can be added at concentrations between 200 and 1000 mg/kg in various processed foods and at 20,000 mg/kg in nuts. β-Carotene is permitted by various regulatory bodies, such as Health Canada, the European Union (EU), and the USA. β-Apo-8′-carotenal can be used at up to 100 mg/kg in the EU; 6.80 mg/kg (15 mg/lb) in solid, semi-solid, and liquid food in the USA; and 35 mg/kg in Canada (EU, 2008; FDA, 2021; HC, 2021). Although standards and specifications have been set for each country, additives that are currently considered safe may have side effects in the future. Therefore, as a preemptive response, to develop a robust and fast analysis method is important.

According to the Korea Food Additives Code, the two carotenoids can be used in good manufacturing practice (GMP), although they are not allowed in certain foods such as red pepper powder (MFDS, 2021b; MFDS, 2021d). In Korea, any food additive that is added to processed foods must be labeled. In this context, although they can be used in GMP, there are no studies on these food additives in processed foods available in Korea.

According to JECFA and the Korea Food Additives Code, a spectrophotometric method was proposed for the determination of the two carotenoids (JECFA, 2016; MFDS, 2021a; MFDS, 2021c). However, when compared to high-performance liquid chromatography (HPLC) methods, the spectrophotometric measurement of carotenoids has the disadvantage of possible overestimation and accuracy variation depending on the individual matrix (Biehler et al., 2010). The simultaneous HPLC analysis of β-carotene and β-apo-8′-carotenal has been reported previously; however, β-apo-8′-carotenal was used as an internal standard (I.S.) instead of as a target compound (Kaiser et al., 2007; Santos et al., 2012). Importantly, few studies have investigated the two carotenoids content of processed foods. Most carotenoid analysis studies have identified naturally occurring carotenoids (mostly β-carotene) in fruits and vegetables (Anunciação et al., 2019; Barba et al., 2006; Wall et al., 2001). Carotenoids are typically extracted using strong organic solvents because of their hydrophobicity (Irakli et al., 2011; Scotter et al., 2003; Zhang et al., 2019); however, strong organic solvents can also extract interfering compounds, such as lipids, along with the carotenoids from high-fat-content processed foods. Therefore, further purification processes may be required for the analysis of the two carotenoids in processed food extracts.

To address these issues, a method for extracting β-carotene and β-apo-8′-carotenal from various food matrices (including most processed food matrices commonly containing β-carotene and β-apo-8′-carotenal as food colorants) and a HPLC method for the simultaneous determination of the two carotenoids was developed and optimized. The analysis method was validated, and the analytes were identified by UHPLC-(ESI)-QqQ MS. The validated method was applied to 57 processed food samples from common brands, either labeled as containing β-carotene and/or β-apo-8′-carotenal additives or suspected of containing naturally occurring carotenoids.

Materials and methods

Chemicals and reagents

Authentic standards of trans-β-carotene (≥ 95%), trans-β-apo-8′-carotenal (≥ 96%), and retinyl acetate (≥ 99.9%) were purchased from Sigma-Aldrich (St. Louis, MO, USA). Calcium carbonate, ethyl acetate, acetone, ethanol (EtOH), butylated hydroxytoluene (BHT), n-hexane, diethyl ether, potassium hydroxide, ascorbic acid, HPLC-grade methanol (MeOH), and triethylamine (TEA) were purchased from Sigma-Aldrich. Petroleum ether (40/60) and HPLC-grade methyl tert-butyl ether (MTBE) were obtained from Fisher Scientific (Waltham, MA, USA).

Sample collection

A total of 57 processed food samples (4 beverage, 15 bread, 7 snack, 18 cheese, 3 chocolate, 8 butter, and 2 margarine samples) from high-selling brands were purchased from local markets in Anseong and Seoul, Korea, from June 2020 to October 2020. Processed food samples were classified into seven groups (i.e., beverage, bread, snack, cheese, chocolate, butter, and margarine). Among the chosen food products, 30 and 7 samples were labeled as containing β-carotene and β-apo-8′-carotenal additives, respectively. As per the label, the remaining samples did not contain β-carotene or β-apo-8′-carotenal and were therefore considered “negative” samples.

Optimization of sample preparation method

As representatives of the processed food types containing β-carotene and/or β-apo-8'-carotenal as food colorants, food samples were divided into three groups, namely, low-fat liquid, moderate-fat solid, and high-fat solid matrices. To optimize the analytical method, sparkling water, string cheese, and lard, which were free from the two carotenoids, were used as blank matrices for low-fat liquid, moderate-fat solid, and high-fat solid foodstuffs, respectively. Retinyl acetate was used as an I.S. Spike recovery tests were conducted by adding known amounts of β-carotene and β-apo-8'-carotenal standards to each matrix (at final concentrations of 10 µg/mL extract). After the optimization of the extraction methods, the beverage samples were prepared according to the low-fat liquid matrix preparation method; the moderate-fat solid sample extraction method was applied to bread, snack, cheese, and chocolate samples; the high-fat solid matrix extraction method was applied to the butter and margarine samples.

Optimization of extraction method for low-fat liquid samples

The two carotenoids were extracted from the low-fat liquid matrix according to the method of Scotter et al. (2003) with modifications. The detailed method was as follows.

A 5.0 g sample of low-fat liquid food was weighed into a 50 mL polyethylene (PE) conical tube, and calcium carbonate (0.2 g) was added. A 25 mL aliquot of solvent containing ethyl acetate, acetone, and EtOH at a ratio of 2:1:1 (v/v/v), 30 mg/L BHT, and 90 µg I.S. was added to the tube. Subsequently, the mixture was either homogenized using a homogenizer (T18 digital ULTRA TURRAX, IKA, Staufen, Germany) for 10 min, sonicated (ultrasonic bath, CPX3800H-E, Branson, CT, USA) for 15 min, or vortexed for 1 min. A 5 mL aliquot of the supernatant of the extract was transferred into a flask, and 5 mL each of EtOH and n-hexane was added. After vigorously shaking the contents of the flask, the hexane layer was collected, and the solvent was evaporated to near dryness using a EYELA N-1300 rotary vacuum evaporator (EYELA, Tokyo, Japan). Thereafter, 1 mL of EtOH was added and filtered (0.2 µm, nylon, Whatman, Maidstone, England), and the filtrate was analyzed using HPLC.

Optimization of extraction method for moderate-fat solid samples

The two carotenoids were extracted from the moderate-fat solid matrix according to the modified method of Scotter et al. (2003). They suggested using a homogenizer for 10 min for a moderate-fat solid matrix (e.g., cheese), if needed; however, in this study, when a homogenizer (T18 digital ULTRA TURRAX, IKA) was applied to string cheese samples, the cheese aggregated onto the dispersion tool of the homogenizer. Therefore, we replaced the homogenization step with sonication using either a bath sonicator (CPX3800H-E, Branson) or a probe type VCX-130 Ultrasonic Processor sonicator (Sonics, Newtown, CT, USA). In addition, the solvent used to redissolve the extract after concentration was changed from MeOH only to MTBE and MeOH. The optimized method is described as follows.

A 2.5 g portion of the sample was weighed into a fluorinated ethylene propylene (FEP) tube. Thereafter, 10 mL of solvent, comprising diethyl ether:petroleum ether (40/60) (2:1, v/v), and 37.5 µg of I.S. were added to each tube. The mixture was sonicated using either a bath sonicator (CPX3800H-E, Branson) for 10 min or a probe sonicator (VCX-130 Ultrasonic Processor, Sonics) for 10 s. The mixture was centrifuged at 1763×g for 5 min and the supernatant was collected and concentrated using a nitrogen concentrator (MG-2200, EYELA, Tokyo, Japan). Scotter et al. (2003) used MeOH to re-dissolve the concentrate; however, the two carotenoids were not fully dissolved using methanol alone, and yellow-colored compounds were found to remain on the surface of the concentration tube. Therefore, in this study, 2 mL of MTBE was added to re-dissolve the concentrate and the volume was adjusted to 5 mL using MeOH. The extract was filtered (0.2 µm, nylon, Whatman) and analyzed using HPLC.

Optimization of extraction method for high-fat solid samples

The two carotenoids were extracted from a high-fat solid matrix according to a method modified from that of Zhang et al. (2019). A high-fat matrix usually requires saponification, and the saponification step of the method was modified. The recovery of analytes using the saponification method (75 °C for 40 min with sonication) was compared with the recoveries using the methods proposed by Irakli et al. (80 °C for 15 min) and AOAC (56 °C for 20 min) (Irakli et al., 2011; AOAC, 1997). The most effective saponification temperature and time were found to be 56 °C and 20 min, respectively. The optimized method is described as follows.

A 0.2 g portion of sample was accurately weighed into a 15 mL PE conical tube. Next, 2 mL of EtOH, 0.1 g of ascorbic acid, and 37.5 µg of I.S. were added to the tube. For saponification, 100 µL of KOH solution (80% w/v in water) was added and the mixture was heated to 56 °C using a water bath and mixed thoroughly every 5 min for 20 min. After cooling to room temperature, centrifugation was performed at 1763 × g for 5 min. Subsequently, the supernatant was transferred to a new tube and the saponification step was repeated twice. The combined supernatant was mixed with 3.5 mL of a water:n-hexane mixture (1:1) and shaken vigorously. The hexane layer was then collected. The pellet was re-extracted until the solution was colorless. The collected hexane layer was concentrated using a nitrogen concentrator (MG-2200, EYELA), and the concentrate was re-dissolved in a mixture of 1 mL of 1:1 MTBE: MeOH, filtered (0.2 µm, nylon, Whatman), and transferred into an HPLC vial.

Method validation

For method validation, sparkling water, string cheese and lard were used as blank matrices for the low-fat liquid, moderate-fat solid, and high-fat solid groups, respectively. The methods were validated according to the U.S. food and drug administration (FDA) guidelines (FDA, 2020). Signal-to-noise ratios of 3 and 10 were used for estimating the detection limit and quantitation limit, respectively. The instrument detection limit (IDL) and instrument quantitation limit (IQL), which were obtained after spiking the solvent (i.e., MeOH:MTBE (v:v, 50:50)) with β-carotene and β-apo-8'-carotenal, were calculated by comparing the measured signals from known low concentrations of analyte with those of the blank (solvent). The method detection limit (MDL) and method quantitation limit (MQL) were calculated using a spike recovery test for sparkling water, string cheese, and lard at low concentrations. To evaluate intra-day (n = 5) accuracy and precision, known amounts of β-carotene and β-apo-8'-carotenal were added to the three matrices at final concentrations of 2.5–20 µg/mL. For inter-day (n = 15, 3 days) accuracy and precision, known amounts of β-carotene and β-apo-8'-carotenal were added to the three matrices at final concentrations of 5, 10, and 20 µg/mL. Accuracy and precision were validated at three different laboratories for cross-lab validation.

HPLC method for quantification of the two carotenoids

The β-carotene and β-apo-8'-carotenal content were determined using an 1260 Infinity II HPLC system (Agilent Technologies, Santa Clara, CA, USA) with a diode array detector (DAD, G7115A, Agilent Technologies), using a method of Santos et al. (2012). C18 and C30 HPLC columns are usually used for carotenoid separation (Koh et al., 2008; Scotter et al., 2003; Cardoso et al., 2011; Santos et al., 2012; Kim et al., 2021). We selected a C30 column [YMC C30 carotenoid analytical column (4.6 × 250 mm, 5 µm, YMC Co., LTD., Kyoto, Japan)] because sharper peaks and lower limits of detection were obtained compared to those obtained with a C18 column at a signal-to-noise (S/N) of 3. Retinyl acetate was used as an I.S. in this study, and it was monitored at 325 nm.

The composition of solvent B was changed, and a sharper gradient was applied to shorten the running time of the method described by Santos et al. (2012). A layer separation occurred in the HPLC mobile phase with solvent B (MTBE:MeOH:water (90%:6%:4%) containing 0.1% triethylamine (TEA)). Solvent B was mixed via vigorous stirring and/or shaking; however, layer separation occurred again during the HPLC analysis possibly because MTBE and water are immiscible owing to the difference in polarity. Thus, the optimized HPLC mobile phases were 90% MeOH:10% water containing 0.1% TEA (mobile phase A) and 90% MTBE:10% MeOH containing 0.1% TEA (mobile phase B). The analysis time of the method proposed by Santos et al (2012) was 56 min; however, by applying a sharper gradient, the running time was reduced to 26 min. The gradient was as follows: 0–20 min, 6.5–100% (B); 20–23 min, 100% (B); 23–26 min, 100–6.5% (B). Additionally, a 20 min post analysis time was added in order to have robust chromatographic conditions.

The optimized extraction processes and HPLC method were applied to the food samples. To calculate the β-carotene and β-apo-8'-carotenal content, the area ratio of the β-carotene or β-apo-8'-carotenal peak to the I.S. peak was used in the calibration curves. All samples were extracted and analyzed in triplicate. Samples containing β-carotene and β-apo-8'-carotenal levels above the method detection limit (MDL) but below the method quantitation limit (MQL) were included when calculating the detection rate (% of detected samples).

For method validation, sparkling water, string cheese and lard were used as blank matrices for the low-fat liquid, moderate-fat solid, and high-fat solid groups, respectively. The methods were validated for limit of detection, limit of quantitation, linearity, accuracy and precision, according to the U.S. food and drug administration (FDA) guidelines (FDA, 2020).

Identification of β-carotene and β-apo-8'-carotenal using UHPLC-(ESI)-QqQ

To confirm the correct identification of the analytes, positive samples were prepared using the relevant optimized extraction method. Extracts of β-carotene and β-apo-8′-carotenal were obtained from food samples labeled as containing the respective additives and having the largest peak areas of the two compounds. Thereafter, 100 µL of the extract was injected into the HPLC, and the eluent fractions of β-carotene and β-apo-8'-carotenal were collected, corresponding to their retention time.

The identification of the two carotenoids was performed using an 1290 Infinity II UHPLC system coupled with an 6470 triple quadrupole (QqQ) mass spectrometer (Agilent Technologies). Separation was performed on a Zorbax Eclipse Plus C18 column (2.1 × 50 mm, 1.8 µm, Agilent) according to the method of Zhang et al. (2019). Briefly, the mobile phase consisted of 0.02% formic acid in MeOH:ACN (95:5, v/v) and was eluted in isocratic mode for 15 min. The flow rate was 0.2 mL/min. The injection volume was 3 µL, and the column oven temperature was maintained at 35 °C. MS1 scan mode was used, and product ion scans were performed. The MS was operated with electrospray ionization (ESI) in the positive mode. A capillary voltage of 3.5 kV, gas temperature of 300 °C, nebulization of 45 psi, and fragment voltage of 135 V were used. The collision energies of β-carotene and β-apo-8'-carotenal were 23 and 14 eV, respectively. Identification was confirmed by comparing the retention time and MS1 and MS2 data for the analytes extracted from the samples with the fragmentation patterns of the authentic standards.

Statistical analysis

Statistical analyses were conducted using the IBM SPSS Statistics software V23 (v.23.0, SPSS, Inc., Chicago, IL, USA). Significant differences in the β-carotene and β-apo-8'-carotenal recovery% among extraction methods and their contents among processed foods were determined using the t-test or analysis of variance (ANOVA), followed by the Duncan’s test at p < 0.05.

Results and discussion

Optimized analysis method of β-carotene and β-apo-8'-carotenal in processed foods

β-Carotene and β-apo-8′-carotenal are often used as coloring agents in beverages, cheese, butter, margarine, and snacks. For some matrices (e.g., cheese matrix), application of the published method was not successful or resulted in low recovery and/or repeatability (relative standard deviation %, RSD) (Scotter et al., 2003). The previously published extraction method for the simultaneous analysis of β-carotene and β-apo-8′-carotenal was modified to improve the recovery and repeatability, using three model matrices (sparkling water for low-fat liquid, string cheese for moderate-fat solid, and lard for high-fat solid samples) for the determination of β-carotene and β-apo-8′-carotenal contents in a range of processed foods possibly containing β-carotene and/or β-apo-8′-carotenal.

The spike-recovery test results comparing the published and proposed methods for the three matrices are presented in Table 1. When Scotter et al.’s (2003) method of homogenization was applied to the sparkling water matrix, the recovery of β-carotene (60.8%) did not meet the Codex guidelines (i.e., recovery of 70–110% and RSD of 10%) at 10 μg/mL (Codex, 2001). However, the recovery of β-carotene met the guideline when vortexing (80.4%) or sonication (75.9%) was applied at 10 μg/mL; the RSD (%) for β-carotene recovery obtained using the sonication method was 12.9%, which was not within the acceptable range. Therefore, the vortexing method was selected. The recovery and RSD for β-apo-8′-carotenal using the vortexing method met the Codex guidelines.

While using the method proposed by Scotter et al. (2003), string cheese was aggregated onto the dispersion tool of the homogenizer. Sonication methods using a bath sonicator and a probe sonicator were then proposed. Table 1 presents the results. When a bath sonicator was used, the RSD of β-carotene did not meet the Codex guidelines. When a probe sonicator was used, recovery and RSD values for both carotenoids met the Codex guidelines. Additionally, the treatment time using the probe sonicator (10 s per sample) was much shorter than that using the bath sonicator (10 min per sample). The redissolving solvent was changed from MeOH to MTBE/MeOH to improve the solubility of the extracted compounds.

The extraction method for the high-fat (lard) matrix was modified from that of Zhang et al. (2019). Saponification is commonly used to release any carotenoids that have been esterified to fatty acids and to remove interferences in a high-fat matrix (Petry and Mercadante, 2016). However, this may degrade carotenoids owing to the application of high temperatures over long periods of time (Granado et al., 2001). Herein, lower temperatures and/or shorter saponification times compared with those used in previously published methods were used (Irakli et al., 2011; AOAC, 1997). The use of the method proposed by Zhang et al. resulted in low repeatability (RSD (%) of 10.2%), which did not meet the Codex guidelines (Table 1). This may have been caused by the sonication step used in this method. The recovery of β-apo-8′-carotenal at a concentration of 10 μg/mL increased from 75.1 to 93.7% when the temperature was lowered from 75 to 56 °C. The optimal saponification conditions were selected as 56 °C and 20 min. In addition, we modified the solvent used to redissolve the extracted carotenoids.

A C30 column was selected for HPLC analysis. The mobile phase solvent was changed, and a faster gradient was applied, which reduced the run time from 56 to 26 min. An I.S. calibration curve, instead of an external standard calibration curve, was used to determine β-carotene and β-apo-8'-carotenal levels.

Method validation for β-carotene and β-apo-8'-carotenal analyses

Method validation was performed by spiking a known amount of authentic standards into the three matrices (i.e. sparkling water, string cheese, and lard), and the results are presented in Tables 2, 3 and 4. In the three matrix-based calibration curves, the determination coefficient (r2) showed acceptable linearity over a range of 2.5–20 µg/mL in three matrices (Table 2). The IDL of β-carotene and β-apo-8'-carotenal was 0.08 µg/mL and 0.09 µg/mL, respectively. The IQL of β-carotene and β-apo-8'-carotenal was 0.25 µg/mL and 0.28 µg/mL, respectively. The IDL of β-carotene was similar to a previously reported value (0.08 µg/mL) (Mitrowska et al., 2012). The MDL and MQL of β-carotene and β-apo-8'-carotenal were calculated as 0.08–0.27 µg/g and 0.26–0.91 µg/g, respectively. The accuracy and precision of β-carotene and β-apo-8'-carotenal analyses are listed in Tables 3 and 4. Accuracy and precision are expressed as the recovery and RSD, respectively. The intra-day accuracy (n = 5) ranged from 94.0 to 109.4%, inter-day accuracy (n = 15, 3 days) ranged from 93.5 to 108.0%, intra-day precision ranged from 0.1 to 9.5%, and inter-day precision ranged from 1.1 to 8.7%. The calculated values for both the recovery and RSD were within the acceptable Codex guidelines (recovery of 70–110% and RSD < 10%) (Codex, 2001). Cross-validation studies for the three matrices were conducted at three universities. The results are summarized in Table S1. Across the three matrices, the recovery and RSD were 86.4–102.0% and 2.1–9.4%, respectively. These results met the Codex guidelines (recovery of 70–110% and RSD < 16%) (Codex, 2001).

Applying the β-carotene and β-apo-8'-carotenal analysis method to food samples

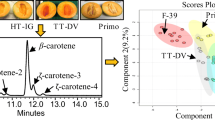

The validated method was applied to determine the β-carotene and β-apo-8'-carotenal content of various processed food samples. Representative HPLC chromatograms of the extracts of the β-carotene-labeled and β-apo-8'-carotenal-labeled samples are shown in Fig. S1. β-Carotene and the β-apo-8'-carotenal peaks were observed in the chocolate samples labeled as containing these carotenoids.

The identification of β-carotene and β-apo-8'-carotenal in the positive samples (i.e., the samples labeled as containing β-carotene or β-apo-8'-carotenal additives) was confirmed using UHPLC-QqQ MS in the positive ESI mode. The fragmentation patterns and retention times of the positive samples were compared with those of authentic standards. The mass spectra of the representative positive samples are shown in Fig. 1. The precursor ions of β-carotene and β-apo-8'-carotenal were observed at m/z 536 [M]+ and 417 [M + H]+, respectively. The MS/MS spectrum demonstrated characteristic fragment ions at m/z 444, 119, and 177, corresponding to β-carotene fragmentation (Ren and Zhang, 2008; Rivera et al., 2011; Vallverdú‐Queralt et al., 2012). The MS/MS spectrum of β-apo-8'-carotenal peak featured characteristic ions of m/z 325, 133, and 119 (Britton et al., 2004; Van Breemen et al., 2012). The fragments of β-carotene and β-apo-8'-carotenal peaks were observed at m/z 444 and m/z 325, respectively, corresponding to the loss of C7H8 (m/z 92) (Van Breemen et al., 2012). The observed m/z for β-carotene and β-apo-8'-carotenal precursor and their fragment ions matched with their predicted m/z, calculated based on chemical formula.

The range and mean of the two carotenoid content are presented in Fig. 2 and Table 5, respectively. The β-carotene contents in positive (those labeled as containing carotenoid additives) and negative samples (those not labeled as containing carotenoid additives, such as bread, cheese, butter, and margarine) are presented in Fig. 2A and B. The β-apo-8'-carotenal content is presented in Fig. 2C. Of the samples labeled as containing β-carotene additive, 90% were positive for the β-carotene content, whereas among the β-apo-8'-carotenal labeled samples, 43% were positive for β-apo-8'-carotenal. The fact that β-carotene and β-apo-8'-carotenal were not detected in the remaining positive samples can be explained by the likely auto-oxidation, thermal degradation, and photodegradation of carotenoids during processing, storage, and distribution (Boon et al., 2010). Some of the negative samples contained up to 0.67 µg/g of β-carotene; however, β-apo-8'-carotenal was not detected in any of the negative samples.

Boxplot of the β-carotene and β-apo-8′-carotenal content of processed food samples. (A) β-carotene content in β-carotene-labeled samples, (B) β-apo-8′-carotenal content in β-apo-8′-carotenal-labeled samples, and (C) β-carotene content in negative samples. β-Apo-8′-carotenal was not detected in negative samples

In Korea, when any food additive including β-carotene or β-apo-8'-carotenal is added, it must be labeled in samples. The β-carotene levels in samples labeled as containing β-carotene additives ranged from ‘not detectable’ (ND) to 6.92 µg/g. As there are no other published data on the β-carotene contents of food products labeled as containing β-carotene additives, we could not compare our results for the labeled products. However, previous studies conducted in the UK and USA showed that β-carotene levels in processed food generally ranged from ND to 13.8 µg/g, which are in agreement with our data (Scotter et al., 2003; USDA, 2015). Among the β-carotene-labeled processed foods, the chocolate (snack) group showed the highest mean β-carotene content, ranging from 0.79 to 6.92 µg/g. β-Carotene was detected in chocolate-containing snacks and cookies (ND to 1.5 µg/g) in the products of the USA markets, according to the United States Department of Agriculture database (USDA, 2015). The β-carotene contents of β-carotene-labeled snack and bread samples ranged from ND to 4.96 µg/g and ND to 3.27 µg/g, respectively. In the USDA database, most plain snacks and bread did not contain β-carotene; however, some vegetable-based snack and bread samples had a high β-carotene content (e.g., pumpkin bread: 15.9 µg/g) (USDA, 2015). In the study by Scotter et al. (2003), snack and bread samples sold in the UK contained β-carotene ranging from ND to 0.1 µg/g and 0.4 to 3.9 µg/g, respectively, while beverages (soft drinks) and cheeses sold in the UK contained β-carotene ranging from 1.0 to 1.4 µg/g and 0.3 to 14.5 µg/g, respectively (Scotter et al., 2003). The USDA database indicates that soft drinks do not contain β-carotene, while some cheese and margarine samples contain up to 4.0 µg/g and 6.1 µg/g β-carotene, respectively (USDA, 2015). In the study by Scotter et al. (2003), butter samples had a β-carotene content of 1.3–2.5 µg/g.

Some negative samples of cheese, butter, and margarine contained up to 2.05 µg/g of β-carotene. Cheese and butter are made from milk, and β-carotene may be naturally derived from the lipid fraction of the milk (Rombaut et al., 2006; Alothman et al., 2019). Margarine is made from vegetable oil, which may naturally contain β-carotene (Rader et al., 1997). As milk, butter, and margarine are often used for bread-making, the β-carotene detected in the negative bread samples may have been derived from the ingredients used for baking.

Among the seven samples labeled as containing β-apo-8'-carotenal, β-apo-8'-carotenal was detected shredded cheese (1.31 µg/g) and in two samples of cheddar cheese (0.35 and 1.63 µg/g). No negative samples were found to contain β-apo-8'-carotenal. The cheese group showed both a higher detection rate (60%) and the highest β-apo-8'-carotenal content mean value (1.10 µg/g) of detected samples. Similar to β-carotene, no study has been published on β-apo-8'-carotenal levels in β-apo-8'-carotenal-labeled processed foods. A study from UK reported that β-apo-8'-carotenal was not detected in cakes and cheeses (Scotter et al., 2003); however, we assume that they analyzed negative samples. Significantly, high levels of β-apo-8'-carotenal were found in a blood orange and nectarine juice drink (6.1 µg/g) in another UK-based study, where the authors attributed the high β-apo-8'-carotenal level to the degradation of β-carotene added as a food colorant (Xu et al., 2019).

In many regulatory jurisdictions, β-carotene can be added to processed foods without restriction; however, Codex has restricted its use to 200–1000 µg/g (FAO, 2019; FDA, 2021; Health Canada, 2021; MFDS, 2021a, 2021b, 2021c, 2021d). The addition of β-apo-8'-carotenal is permitted up to 100 µg/g in the EU, 6.80 µg/g in the USA, and 35 µg/g in Canada (EU, 2008; FDA, 2021; Health Canada, 2021). Notably, none of the samples analyzed in this study had β-carotene contents over 200 µg/g nor β-apo-8'-carotenal levels above 6.80 µg/g.

An extraction and analysis method was developed for the determination of β-carotene and β-apo-8'-carotenal levels in various processed food matrices. Additionally, the HPLC method was optimized by comparing different columns and mobile phases. The new method overcomes existing limitations of the conventional methods, shortens the extraction and analysis time, and improves the accuracy and precision. The optimized method was validated according to the FDA guidelines (FDA, 2020). The validated method was successfully applied to 57 processed food samples, which were either labeled as containing β-carotene and/or β-apo-8′-carotenal as food colorants or suspected to have their presence naturally. The β-carotene content was highest in β-carotene-labeled chocolate snacks, and the β-apo-8'-carotenal content was highest in the correspondingly labeled cheeses. Some negative samples (i.e., those not labeled as containing carotenoid additives), such as butter, also contained β-carotene; however, no negative sample contained β-apo-8'-carotenal.

The validated method could be applied to determine β-carotene and β-apo-8'-carotenal levels in food samples that are either prohibited from using carotenoids or suspected to exceed the regulated amounts, depending on the regulatory bodies.

References

Alothman M, Hogan SA, Hennessy D, Dillon P, Kilcawley KN, O’Donovan M, Tobin J, Fenelon MA, O’Callaghan TF. The “grass-fed” milk story: understanding the impact of pasture feeding on the composition and quality of bovine milk. Foods. 8: 350 (2019)

Anunciação PC, Giuffrida D, Murador DC, de Paula Filho GX, Dugo G, Pinheiro-Sant’Ana HM. Identification and quantification of the native carotenoid composition in fruits from the Brazilian Amazon by HPLC–DAD–APCI/MS. Journal of Food Composition and Analysis. 83 (2019)

AOAC. Vitamin A in margarine. Spectrophotometric method. p. Association of Official Analytical Chemists; p. 3.

Barba AIO, Hurtado MC, Mata MCS, Ruiz VF, Tejada MLSd. Application of a UV–vis detection-HPLC method for a rapid determination of lycopene and β-carotene in vegetables. Food Chemistry. 95: 328–336 (2006)

Bell T, Alamzad R, Graf BA. Effect of pH on the chemical stability of carotenoids in juice. Proc Nutr Soc. 75(OCE3)(OCE3: Summer Meeting): E94 (2016)

Biehler E, Mayer F, Hoffmann L, Krause E, Bohn T. Comparison of 3 spectrophotometric methods for carotenoid determination in frequently consumed fruits and vegetables. Journal of Food Science. 75: C55–C61 (2010)

Bohn T, Bonet ML, Borel P, Keijer J, Landrier JF, Milisav I, Ribot J, Riso P, Winklhofer-Roob B, Sharoni Y, Corte-Real J. Mechanistic aspects of carotenoid health benefits–where are we now? Nutrition Research Reviews. 34: 276–302 (2021)

Boon CS, McClements DJ, Weiss J, Decker EA. Factors influencing the chemical stability of carotenoids in foods. Critical Reviews in Food Science and Nutrition. 50: 515–532 (2010)

Britton G, Liaaen-Jensen S, Pfander H. Carotenoids [Handbook]. 1st ed. Switzerland: Springer (2004)

Cardoso PC, Tomazini APB, Stringheta PC, Ribeiro SMR, Pinheiro-Sant’Ana HM. Vitamin C and carotenoids in organic and conventional fruits grown in Brazil. Food Chemistry. 126: 411–416 (2011)

Codex. Codex alimentarius. Harmonized IUPAC guidelines for the use of recovery information in analytical Measurement. CAC/GL 37-2001 (2001)

Codex. Codex alimentarius. Guideline on measurement uncertainty. CAC/GL 54-2004

de Freitas Santos PD, Rubio FTV, da Silva MP, Pinho LS, Favaro-Trindade CS. Microencapsulation of carotenoid-rich materials: A review. Food Research International. 147 (2021)

EFSA. Scientific opinion on the re‐evaluation of mixed carotenes (E 160a (i)) and beta‐carotene (E 160a (ii)) as a food additive. EFSA J. European Food Safety Authority:10: 2593 (2012a)

EFSA. Scientific opinion on the re‐evaluation of β‐apo‐8'‐carotenal (E 160e) as a food additive. EFSA J. European Food Safety Authority:10: 2499 (2012b)

EU. Regulation (EC) No 1333/2008 of the European parliament and of the council of on food additives. European Union (2008)

FAO. Food and Agriculture Organization. General standard for food additives codex stan 192–1995 (2019)

FDA. Food and drug administration office of regulatory affairs ORA laboratory manual volume II. Methods, method verification and validation. ORA-LAB.5.4.5 (2020)

Food and Drug Administration. Color additive status list. Food and Drug Administration (U.S.). Available from: https://www.fda.gov/industry/color-additive-inventories/color-additive-status-list. Accessed Dec. 29, 2021 (2021)

Granado F, Olmedilla B, Gil-Martinez E, Blanco I. A fast, reliable and low-cost saponification protocol for analysis of carotenoids in vegetables. Journal of Food Composition and Analysis. 14: 479–489 (2001)

HC. List of permitted colouring agents (lists of permitted food additives). https://www.canada.ca/en/health-canada/services/food-nutrition/food-safety/food-additives/lists-permitted/3-colouring-agents.html. Health Canada. Accessed Dec. 29, 2021 (2021)

Irakli MN, Samanidou VF, Papadoyannis IN. Development and validation of an HPLC method for the simultaneous determination of tocopherols, tocotrienols and carotenoids in cereals after solid-phase extraction. Journal of Separation Science. 34: 1375–1382 (2011)

JECFA. Joint FAO/WHO expert committee on food additives. Compendium of food additive specifications. pp. 117–119 (2016)

Joint FAO/WHO Expert Committee on Food Additives. Evaluations of the joint FAO/WHO expert committee on food additives (JECFA)-beta-apo-8'-carotenal. Joint FAO/WHO expert committee on food additives. Available from: https://apps.who.int/food-additives-contaminants-jecfa-database/chemical.aspx?chemID=941. Accessed Sept. 21, 2022 (2019a)

Joint FAO/WHO Expert Committee on Food Additives. Evaluations of the joint FAO/WHO expert committee on food additives (JECFA)-beta-carotene (synthetic). Joint FAO/WHO expert committee on food additives. Available from: https://apps.who.int/food-additives-contaminants-jecfa-database/chemical.aspx?chemID=1514. Accessed Sept. 21, 2022 (2019b)

Kaiser P, Surmann P, Vallentin G, Fuhrmann H. A small-scale method for quantitation of carotenoids in bacteria and yeasts. Journal of Microbiological Method. 70: 142–149 (2007)

Kim E-H, Lee KM, Lee S-Y, Kil M, Kwon O-H, Lee S-G, Lee S-K, Ryu T-H, Oh S-W. Infuence of genetic and environmental factors on the contents of carotenoids and phenolic acids in red pepper fruits (Capsicum annuum L.). Applied Biological Chemistry. 64: 1-11 (2021)

Koh E, Wimalasiri KM, Renaud EN, Mitchell AE. A comparison of flavonoids, carotenoids and vitamin C in commercial organic and conventional marinara pasta sauce. Journal of the Science of Food and Agriculture. 88: 344–354 (2008)

Liu W, Wang J, McClements DJ, Zou L. Encapsulation of β-carotene-loaded oil droplets in caseinate/alginate microparticles: Enhancement of carotenoid stability and bioaccessibility. Journal of Functional Foods. 40: 527–535 (2018)

Luzardo-Ocampo I, Ramírez-Jiménez AK, Yañez J, Mojica L, Luna-Vital DA. Technological applications of natural colorants in food systems: A review. Foods. 10: 634 (2021)

Ministry of Food and Drug Safety. Food additves code - β-apo-8′-carotenal. Available from: https://www.foodsafetykorea.go.kr/foodcode/04_03.jsp?idx=289. Accessed Sept. 21, 2022 (2021a)

Ministry of Food and Drug Safety.Food additves code - β-apo-8′-carotenal. Available from: https://www.foodsafetykorea.go.kr/foodcode/04_03.jsp?idx=8200285 Accessed Sept. 21, 2022 (2021b)

Ministry of Food and Drug Safety.Food additives code - β-carotene. Available from: https://www.foodsafetykorea.go.kr/foodcode/04_03.jsp?idx=450 Accessed Sept. 21, 2022 (2021c)

Ministry of Food and Drug Safety.Food additves code - β-carotene. Available from: https://www.foodsafetykorea.go.kr/foodcode/04_03.jsp?idx=8200447 Accessed Sept. 21, 2022 (2021d)

Mitrowska K, Vincent U, von Holst C. Separation and quantification of 15 carotenoids by reversed phase high performance liquid chromatography coupled to diode array detection with isosbestic wavelength approach. Journal of Chromatography A. 1233: 44–53 (2012)

Mortensen A. Carotenoids and other pigments as natural colorants. Pure and Applied Chemistry. 78: 1477–1491 (2006)

Petry FC, Mercadante AZ. Composition by LC-MS/MS of new carotenoid esters in mango and citrus. Journal of Agricultural and Food Chemistry. 64: 8207–8224 (2016)

Rader JI, Weaver CM, Patrascu L, Ali LH, Angyal G. α-Tocopherol, total vitamin A and total fat in margarines and margarine-like products. Food Chemistry. 58: 373–379 (1997)

Ren D, Zhang S. Separation and identification of the yellow carotenoids in Potamogeton crispus L. Food Chemistry. 106: 410–414 (2008)

Rivera S, Vilaró F, Canela R. Determination of carotenoids by liquid chromatography/mass spectrometry: Effect of several dopants. Analytical and Bioanalytical Chemistry. 400: 1339–1346 (2011)

Rodriguez-Concepcion M, Avalos J, Bonet ML, Boronat A, Gomez-Gomez L, Hornero-Mendez D, Limon MC, Meléndez-Martínez AJ, Olmedilla-Alonso B, Palou A, et al. A global perspective on carotenoids: Metabolism, biotechnology, and benefits for nutrition and health. Progress in Lipid Research. 70: 62–93 (2018)

Rombaut R, Camp JV, Dewettinck K. Phospho- and sphingolipid distribution during processing of milk, butter and whey. International Journal of Food Science and Technology. 41: 435–443 (2006)

Santos J, Mendiola JA, Oliveira MBPP, Ibáñez E, Herrero M. Sequential determination of fat- and water-soluble vitamins in green leafy vegetables during storage. Journal of Chromatography A. 1261: 179–188 (2012)

Scotter MJ, Castle L, Croucher JM, Olivier L. Method development and analysis of retail foods and beverages for carotenoid food colouring materials E160a(ii) and E160e. Food Additives and Contaminants. 20: 115–126 (2003)

Shahid M, Shahid-ul-Islam F, Mohammad F. Recent advancements in natural dye applications: A review. Journal of Cleaner Production. 53: 310–331 (2013)

Sigurdson GT, Tang P, Giusti MM. Natural colorants: Food colorants from natural sources. Annu Rev Food Sci Technol. 8: 261–280 (2017)

Song J, Cho W. Processed food and food coloring. 10: 62–80 (1997)

USDA. The United States Department of Agriculture. USDA national nutrient database for standard reference release 28 (2015)

Vallverdú‐Queralt A, Martínez‐Huélamo M, Arranz‐Martinez S, Miralles E, Lamuela‐Raventós RM. Differences in the carotenoid content of ketchups and gazpachos through HPLC/ESI (Li+)‐MS/MS correlated with their antioxidant capacity. Journal of the Science of Food and Agriculture. 92: 2043–2049 (2012)

Van Breemen RB, Dong L, Pajkovic ND. Atmospheric pressure chemical ionization tandem mass spectrometry of carotenoids. International Journal of Mass Spectrometry. 312: 163–172 (2012)

Van Rooyen J, Esterhuyse AJ, Engelbrecht AM, Du Toit EF. Health benefits of a natural carotenoid rich oil: A proposed mechanism of protection against ischaemia/reperfusion injury. Asia Pacific Journal of Clinical Nutrition. 17(1). Suppl 1: 316–319 (2008)

Wall MM, Waddell CA, Bosland PW. Variation in β-carotene and total carotenoid content in fruits of capsicum. Hortscience. 36: 746–749 (2001)

Xu M, Chen T, Butt CM. Identification of beta‐carotene degradation compounds and their structural elucidation by high‐resolution accurate mass spectrometry. J of Food Science. 84: 3535–3545 (2019)

Zhang L, Wang S, Yang R, Mao J, Jiang J, Wang X, Zhang W, Zhang Q, Li P. Simultaneous determination of tocopherols, carotenoids and phytosterols in edible vegetable oil by ultrasound-assisted saponification, LLE and LC-MS/MS. Food Chemistry. 289: 313–319 (2019)

Acknowledgements

This study was supported by grants from the Ministry of Food and Drug Safety in 2020 [Grant Numbers 18162MFDS009) and by a 2019 Chung-Ang University Graduate Research Scholarship. We thank the BT research facility center, Chung-Ang University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jang, W., Lee, C., Suh, HJ. et al. β-Carotene and β-apo-8′-carotenal contents in processed foods in Korea. Food Sci Biotechnol 32, 1501–1513 (2023). https://doi.org/10.1007/s10068-023-01285-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10068-023-01285-2