Abstract

Biocementation is a biochemical reaction that occurs in soil structures in which insoluble calcium carbonate forms in the soil pores and ultimately improves the soil stiffness and strength. The present study investigates this process by injecting and mixing Bacillus pasteurii into clay soils from the Meighan Desert of Iran, which contain specific salt and mineralogical compounds. Unconfined compressive strength tests were performed to evaluate the strength of the soils after being treated to a range of bacteria injection and mixing conditions. The plastic properties, pH, and electrical conductivity of the samples were measured to examine the soil changes after treatment. To address the specific regional and standard culture medium characteristics, two new culture media were prepared and tested according to the salt composition in the regional soil. Wind tunnel and flexural strength tests were also conducted to examine the sample changes after bacterial treatment. Scanning electron microscopy and X-ray diffraction analyses were applied to evaluate the microstructural changes in the samples. The method of mixing clay with bacteria was found to increase the clay sample strength by 78.5% after 28 days compared with the untreated sample. This environmentally friendly method can be used to increase soil strength and reduce wind erosion in geotechnical engineering projects.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Geotechnics research has developed new methods to improve soil properties by combining a variety of procedures, including chemical and biological processes. Traditional soil improvement techniques include compaction, stabilization, the mixture of soil with cement, deep mixing, chemical injection, or freezing within the ground. However, these approaches have certain disadvantages such as limited stabilization area, high cost, need for heavy equipment, or environmental pollution owing to the extraction of raw materials from mines, land degradation, and increased destructive gases produced during their preparation processes (Briaud 2013; Widjajakusuma and Winata 2017). These disadvantages have been addressed during the transition period toward the use of green technology and reduction of greenhouse gases worldwide. The construction industry and geotechnics should therefore also move in this direction and integrate new, green, and environmentally friendly technologies. New and environmentally friendly methods have thus been proposed, including biogrouting and biocementation.

Carbonate deposition results from the activity of microbially induced calcium carbonate precipitation (MICP). Biocementation refers to the natural biochemical reaction that occurs in soil structures, which produces insoluble calcium carbonate (i.e., calcium carbonate deposits) as a biological product (Chu et al. 2012). MICP drives the activities of microorganisms in the pores or on the surfaces of soil particles, and generates larger aggregates in the soil by creating bonds among particles and improving the soil hardness and strength. MICP can be applied in the soil stabilization and strengthening process in geotechnical engineering (DeJong et al. 2006; Whiffin et al. 2007; Meyer et al. 2011; Mahawish et al. 2019; Naveed et al. 2020; Fattahi et al. 2020; Ivanov and Stabnikov 2016). The most common biocementation processes are carried out using gram-positive ureolytic bacteria, which involve Sporosarcina pasteurii and Bacillus owing to their high urease activity and thus strong ability to rapidly produce large amounts of carbonate (Bang et al. 2011; A’la et al. 2020). The hydrolysis process of urea to ammonium and carbonate using these bacteria increases the electrical conductivity (EC) and pH of the environment, which can be considered indicators of bacterial function in the environment and the formation of calcite deposits (Kim et al. 2014; He et al. 2020).

Numerous studies have applied bacterial injection methods in sandy soils via the MICP process to study the effects of nutrients, repeated injections of bacterial cells and nutrients, and injection uniformity in the soil (Ng et al. 2012; Iamchaturapatr and Piriyakul 2014; Bang et al. 2011; Gomez et al. 2015; Tian et al. 2018; Mujah et al. 2017). The soil shear strength has been shown to increase the bacterial sediment performance in sandy soils. The behavior of soil samples has also been shown to change from strain hardening to strain softening. The tendency for general shear failure therefore changes to local shear failure (Montoya and Dejong 2015). Modified specimens have a higher flexibility than specimens stabilized using other methods (Wani and Mir 2020).

Unconfined compressive strength (UCS) tests are commonly performed in geotechnical engineering to evaluate the increase of soil strength owing to biocementation (Whiffin et al. 2007; Van Paassen et al. 2009; Harkes et al. 2010; Al Qabany et al. 2012; Cheng et al. 2013; Nafisi and Montoya 2018; Mahawish et al. 2019). Uniaxial compressive strength tests are conducted in this study to investigate the effect of bacteria and cementation on the resistance changes of clay from the Meighan region of Iran, which includes a group of saline and alkaline soils. Different processing times were investigated to assess the effect of curing duration on the strength of the modified samples (Baghbanan and Razani 2016). The UCS values of the bacterial-modified soils obtained under different conditions range from 150 to 34,000 kPa. The relationship between the amount of calcite deposition and UCS values is also established (Wani and Mir 2020).

Various methods of bacteria injection and mixing with soil are investigated (Stocks-Fischer et al. 1999; van Paassen et al. 2010; A’la et al. 2020; Harkes et al. 2010; Ng et al. 2012; Shahrokhi-Shahraki et al. 2015). The results of Cheng et al. (2019) showed that the use of equal molar quantities of urea and CaCl2 can prevent biological obstruction and reduce ammonia gas production by 90%, which is considered an environmental issue. Hence, equal molar quantities of the cementation solution compounds were used.

The samples were prepared from clay collected from the Meighan Desert region in Iran. The samples were subjected to the microbial modification process following a variety of injection and mixing methods. The implementation of the MICP method can be a difficult task for modifying fine-grained soils (e.g., clay soils) and several aspects of this process remain obscure. The modification of clay soils is considered an engineering challenge because in addition to the pore size of clay soils, other parameters such as scale and mineral type in the soil can also affect the stabilization process and uniformity of the calcite sediment distribution using the injection method (Müller and Défago 2006; Chen et al. 2009).

Other issues that affect the stabilization process of this soil type include the presence of various salts in the region, especially sulfate salts. Previous studies demonstrated a reducing effect of salts on the uniaxial compressive strength of soils owing to excessive swelling under the influence of cement and lime (Dingwen et al. 2013; Firoozi et al. 2017). Recent studies showed that sulfate-containing soils over-swell when treated with lime or cement.

This study is dedicated on the special aspects of the microbial modification process based on the environmental importance of the region. This study also includes unique plants in the saline areas and their regional importance as a habitat for migratory cranes. Injection and biological mixing techniques have not been previously reported on this soil, and different culture media are compared. One sample group was subjected to the mixing process, and another group was injected using different methods. The uniaxial compressive strength, failure strain, and elastic moduli of the samples were measured and compared after 14- and 28-day processing periods.

The plastic and chemical properties of the soil were analyzed using a scanning electron microscope (SEM) and X-ray diffraction (XRD) to study the bacteria’s function on the soil. In addition to the mentioned experiments, modified and unmodified soil samples were also exposed to wind tunnels, and the effect of bacteria on the soil resistance to wind erosion was investigated, which is a common problem in the study area.

Material and methods

Materials

Soil

Meighan Desert clay was used in this study. The Meighan Desert is one of Iran’s wetlands located in Markazi Province, which includes desert, arid, and semi-arid regions, and is 8 km northeast of Arak (Fig. 1). This region contains one of the main sodium sulfate mines in Iran, and the soil contains significant amounts of sulfate salts.

Arak is the industrial capital of Iran and is located 280 km from Tehran, Iran’s capital. The climate in this region is hot and dry Mediterranean with a maximum temperature of 44 °C and minimum temperature of − 33 °C. The southern parts of this region are composed of clay sediments. The particle size distribution curve for the soil is shown in Fig. 2 (ASTM D 422 2007, ASTM D7928-17 2016). The physical and chemical characteristics of this soil are presented in Table 1 according to the American Society for Testing and Materials (ASTM). Soil-saturated paste (Richards et al. 1954) and an EC meter were used to measure the EC. A 1:1 soil: water ratio and electric pH meter were used to determine the soil pH.

The amount of exchangeable sodium is high in saline and alkaline soils. In this soil type, the EC is > 4 mmohs and their exchangeable sodium percentage is higher than 15%. The pH value of these soils is above 8.5. The results in Table 1 indicate that the soil is classified as a group of saline and alkaline soils. The amount of soluble salts in the soil is low, whereas the amount of sodium is high. An excessive amount of exchangeable sodium can lead to aggregate disintegration. The physical properties of these soils are therefore not suitable for engineering purposes. Cement and lime are not appropriate options for soil remediation considering the limitation of the plastic index and presence of sulfate. In contrast, the high concentration of mineral salts and pH greater than 8.5 are appropriate conditions for producing biocement via urease in alkalophilic bacteria (Mortensen et al. 2011). This soil can therefore be considered a good candidate for biocementation treatment.

Microorganisms

The microorganism used in this study was Bacillus pasteurii (BP), which was reclassified as Sporosarcina pasteurii (PTCC NO: 1645, DSM33, ATCC11859) and prepared at the collection center of industrial microorganisms in Iran. Sporosarcina pasteurii is a highly active, native alkalophilic bacterium with a high production level of urease used in laboratory studies to precipitate calcite. This bacterium belongs to a group of rod-shaped and obligate aerobes or facultative anaerobes and non-pathogenic gram-positive Bacillus bacteria, which are naturally found in soils. BP can produce endospores to help this bacterium survive under harsh environmental conditions, which is a desirable property owing to the region’s specific conditions. Previous studies have shown that diet-grade yeast extract can be used to grow bacteria in MICP applications at a reduced cost (Omoregie et al. 2019). The bacterial surface acts as the deposition nucleus, and carbonate deposition creates cement bridges among the soil particles by adhering to the bacteria and attaching bacteria to the soil particles (Ghosh et al. 2019). After preparing the lyophilized ampoules and obtaining the standard nutrient agar culture medium (Table 2), bacterial culture steps were performed following the instructions in DSMZ (2019).

Two new culture media of NaCl and CaSO4 were prepared to investigate the effect of the culture medium on the bacterial yield and soil strength owing to the specific compounds and salts in the soil of the study area. A standard culture medium was also used for comparison.

Cementation solution

Bacillus pasteurii bacteria use urease as an energy source under favorable environmental conditions. This causes a hydrolysis reaction of urease and produces ammonia and carbon dioxide. Free calcium cations are typically supplied by the calcium chloride solution, which is attached to the bacteria owing to the negative charge of bacterial cells. Carbonate ions react with calcium ions and precipitate as calcium carbonate (CaCO3) crystals, which binds the soil grains together. To accelerate the bacterial activity for the calcite precipitation and MICP process, the cementation solution was prepared to contain urea as a nutrient and calcium chloride (CaCl2) as a calcium source. Calcium chloride is suitable for stabilizing silty and clay soils; if this material is used alone, its stabilizing properties are eliminated by washing and removing it from the pore water. Urea is consumed by bacteria as a nutrient and does not remain free in the environment. The cementation solution contains an equimolar (1:1) combination of urea and CaCl2, including 111 g of water-free CaCl2 and 60 g of urease dissolved in 1 L of distilled water (Knorr 2014). Different types of wastes or residuals (e.g., mining and agricultural residuals, organic materials from municipal solid waste) can be used as nutrients to reduce the cost of large-scale biogeotechnical projects (Pacheco-Torgal et al. 2015).

Sample preparation

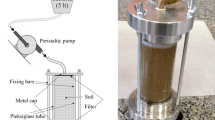

The soil used in this study was prepared from the regional surface soil collected at a depth of 0–30 cm. The samples were prepared in two cylindrical PVC molds with an inner diameter of 3.5 cm (ASTM D2166 2016). To effectively remove the samples from the mold, a very thin layer of transparent plastic was wrapped around the sample, which was in contact with inner wall surface of mold, and a foam layer and filter paper were placed at the end of each mold. Three clamps were used to hold the two halves of the mold together. To prepare the samples with a maximum dry density, dry soil (oven-dried) and water were well mixed and poured in layers in a mold and compacted to achieve a final sample height of 7 cm. After filling the mold, the sample was covered with a filter layer. The bacteria percentage in all specimens was 100%, and a bacterial cell solution volume of 1.5 Vv (1.5 × volume of soil voids) was injected into each specimen under a pressure head (Shahrokhi-Shahraki et al. 2015). After sealing the molds with washers and grease, the injection operation was performed. Some typical samples are shown in Fig. 3.

The samples were prepared for different cases as follows (Table 3).

-

1.

Sample C: Water was mixed with soil and placed in a mold with the maximum dry unit weight (Ɣd(max)).

-

2.

Sample CB: Soil was mixed with bacterial solution and placed in a mold with Ɣd(max).

-

3.

Sample CBC: Soil, bacteria, and cementation solution were mixed and placed in a mold with Ɣd(max).

-

4.

Sample Co: Dry soil was placed in a mold without compaction (i.e., only under its weight). In this case, the sample dry density = 60% Ɣd(max).

Uniform calcite precipitation throughout the total sample mass is an important and influential factor in the method of bacterial fixation via injection. Different injection methods including MICP and mixing methods were investigated. The performance of the injected clay soil samples differs substantially from that of sandy and silty soils. Different bacterial injection methods in granular soils were examined on the prototype samples. The final selected methods are listed in Table 3. As an example, the injection method involving a mixture of cementation solution and bacteria and the simultaneous injection of cementation solution and bacteria on prototypes was examined.

With regard to the soil fineness and immediate reaction of the bacteria with the cementation solution, this solution formed a white coating in the filter layer, which prevented the infiltration of the solution into the soil. This method was therefore excluded in the final experiments. In the samples in which the cementation solution was injected over several stages (every 6 h), the absorption process progressed very slowly from the second 6 h onward. The complete absorption of the last cycle of the cementation solution to the sample required approximately 1 week, including necessary arrangements to prevent water evaporation. A bacterial cell solution volume of 1.5 Vv was injected into each specimen under the pressure head using an outflow rate of 15 mL/min from the specimen base controlled by a peristaltic pump. The purpose of the pressure head was to achieve a more uniform distribution over the entire specimen length. After this volume of bacterial cell solution was introduced into each specimen, the flow was stopped. At the end of the retention period, the peristaltic pump was disconnected from the hydraulic line and the bacterial cell solution was allowed to drain. The cementation solution of volume Vv flowed into the sample under the influence of its own weight. Cementation solutions with slightly lower densities than the bacterial cell solutions were allowed to permeate downward through specimens at an outflow rate of 5 mL/min from each specimen’s base controlled by a peristaltic pump. After the cementation solution had entered each specimen, the flow was stopped to allow the bacteria to react with the cementation solution. Two series of each sample were prepared to check the repeatability of the experiments and check with the test standard. Two periods of 14 and 28 days were tested to investigate the effect of curing duration on the sample compressive strength. Owing to the rapid withdrawal of bacteria and cementation solution in the soil sample with a density of 60% Ɣd(max), the injection procedure was continuously repeated until the sample output solution reached 0. The resistance parameters and properties were also investigated. After reviewing the injection and mixing results, the specimen with the maximum compressive strength was selected, and flexural specimens were prepared and tested.

Mortar bending molds with dimensions of 16 × 4 × 4 cm were used to prepare the flexural specimens using the maximum specific dry weight and optimum humidity. Two specimens were prepared from the modified and unmodified specimens. After 28 days, the specimens were subjected to flexural strength testing in a 5-ton tensile test machine (STM-50, SANTAM Model Company). At least two replicates were prepared for testing if the variation between the tested replicates was less than 10%, indicating uniformity (Mandal et al. 2018). The mean number obtained from the two samples was recorded as the flexural strength of the sample.

Results and discussion

Unconfined compression tests

After the injection and curing period (14 and 28 days), the samples were subjected to unconfined compression tests following standard ASTM D2166 at a loading speed of 1 mm/min. Considering the effect of the injection and bacterial infiltration depth, some sample heights were reduced and the ratio of the height to the standard diameter (2–2.5) was not provided. In these samples, the compressive strength values were modified as follows (Thuro et al. 2001):

where UCS* is the modified unconfined compression strength, UCS represents the unconfined compression strength derived from the device, and H and D are the sample length and diameter, respectively. The strength improvement factor (SIF) is presented as follows to evaluate the strength improvement of the treated samples (Salimi and Ghorbani 2020):

Strength Improvement Factor (SIF) =

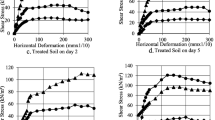

Figure 4 and Table 4 show the UCS and SIF results for the samples cured for 14 and 28 days.

The results in Table 4 show that in the major cases of bacteria and cement injection into soil, the optimal height of the bacterial penetration and cementation effect was considered to be 6 cm. The uniaxial test standard had a height of 6 cm and diameter of 3 cm, which can be applied to investigate the injection process in soil clay samples.

The cementation solution acts as a nutrient for bacteria and enhances the bacterial growth and activity. In sample CB-T1-S, which was immediately injected after preparing the cementation solution bacterial soil sample, the SIF decreased by 0.56 (a factor of 2.72), which may be owing to the low viscosity of the cementation solution and bacterial leaching. Soluble salts in the soil also affect the soil resistance and consequently reduce the soil resistance. In sample CB-T4-S, the SIF decreased by 0.47 (a factor of 1.88), which may again be based on the leaching of bacteria and solutes in the soil by the cementation solution injection. The cementation solution relative to the bacterial solution was easily removed from the structure and passed and collected in the output container. However, the SIF of sample CB-T4-S was higher than that of sample CB-T1-S, which can be attributed to the 6-h delay of the cementation solution injection. Because some bacteria attached to the soil particles during this time, which were not removed from the sample during the washing process, the resulting resistance compensated for the resistance reduction process caused by the leaching of salts in the soil.

The SIF changes of the 28-day bacterial soil mixture samples were similar to those of the 14-day samples and follow the same procedure. Figure 4 shows the SIF results of the samples where the soil was prepared in molds and then injected with bacteria and cementation solution. In all of the 14-day samples, the SIF amount decreased compared with the control sample, and only increased in sample C-T3-S by 0.3. In this sample, only bacteria were injected, whereas cement was not injected. As a result, salt and bacteria leaching did not occur and the low bacterial activity increased the SIF. In sample C-T1-S, only the cementation solution was injected into the sample. Figure 4 shows that the cementation solution injection did not influence the increase of sample strength and also reduced the SIF amount owing to the washing of solutes (e.g., salts, such as sodium and calcium chloride). In the samples injected with bacteria and cementation solution, the SIF values only differed by 0.09. A decrease of the SIF amount compared with the control sample was also evident owing to bacterial and solute leaching during cement injection, which became more apparent by multiple cement injections (SIF = 0.3). The SIF values of the 28-day samples from this group decreased compared with the 28-day control sample. In these samples, the SIF amount in the three cases without bacteria injection and with bacteria and cementation solution injection was the same and equal to 0.53. This indicates that the absence of bacteria in these methods was related to bacteria washing from the soil after injection of the cementation solution.

On the 28th day of processing of sample C-T3-S, the SIF amount was lower than all of the samples and control sample by a factor of 2.3, unlike the 14-day sample. The reason for this reduced resistance can be attributed to the reduction and termination of cementation, which is attributed to the lack of nutrients for the bacteria in the environment. Figure 4c compares the strengths of the different samples on the 14th and 28th days of processing. The 28-day resistance of most samples increased compared with the 14-day resistance, except for samples CBC and C-T3-S where the 28-day resistance decreased compared with the 14-day resistance. The reason for this reduced resistance in sample C-T3-S can be attributed to the lack of cementation solution as a nutrient, the growth and activity of bacteria, the ceased cement production process from day 14 onward, and the bacteria feeding from salts and substances in the soil. This is attributed as a nutrient that gradually reduces the soil resistance compared with the control and 14-day samples. Stress–strain diagrams, microstructural studies, and XRD analysis were used to investigate the cause of the 23% decrease in resistance in the 28-day CBC sample compared with the 14-day sample.

The 14-day compressive strength of the soil without bacterial modification or the control sample (C) was 77.5 kN/m2, which belongs in the group of medium-strength soils (Das 2007a, b). In the 14-day samples, the highest strength is associated with the samples in which the soil, bacteria, and cementation solution (CBC) are mixed. In sample CBC, the strength increased 20-fold compared with the control sample. This sample is classified within the group of hard soils with compressive strength values greater than 400 kN/m2 (Das 2007a, b). This increased resistance owing to the biocementation process is a result of bacterial activity. The cementation process and cement bridges are uniform in terms of the distribution of bacteria and cement in the sample and complete retention of bacteria and cement in the sample volume. During this period, curing the soil sample in which only bacteria were injected (C-T3-S) showed a 23% increase in strength compared with the control sample. The CB-T4-S samples, which belong in the next strength rank, have a strength of 47% less than the control sample (C). The sample with combined soil and bacterial injection and immediate injection of cement (CB-T1-S) has a strength of 56% less than the control sample. The two culture media of NaCl and CaSO4 showed a 67% strength reduction compared with the control sample and 25% compared with the samples in the standard culture medium under the same conditions. The soil sample (C0-T2-S) did not gain any strength on the 14th day of curing.

The 28-day control sample had a compressive strength of 143 kN/m2. The strength of sample CBC on day 28 of curing was 1187 kN/m2 (Table 4), which is 8.3 times higher than the control sample and is within the UCS range of hard clay soils (Das 2013). A curing period of 28 days is therefore suggested (Baghbanan and Razani 2016). The soil samples that combined with the cement-free bacteria (CB-S) showed a 69% increase in strength after 28 days compared with the 14-day sample. This indicates the availability of growth conditions and bacterial nutrients in the desert soil even without the presence of cementation solution. The 28-day sample in the CaSO4 culture medium showed a 70% strength increase compared with the 14-day sample, and a 26% increase compared with the sample under the same conditions in the standard culture medium. This can be a result of the availability of suitable nutrients in this culture medium for bacteria and its effect on the soil composition in the medium. In contrast, the NaCl culture medium showed a 22% strength reduction compared with the standard culture medium. In the 28-day samples in the three different culture media under the same injection conditions, the sample with CaSO4 culture medium showed the highest strength and failure strain. The NaCl culture medium is therefore not suitable for the mentioned bacteria in the soil owing to the culture medium’s strength and use in this area, and the presence of Bacillus pasteurii is not appropriate. Sample C0-T2-S had the minimum strength after 28 days and the bacterial modification of this soil during the 28-day curing period enhanced the strength from 0 to 20 kN/m2. In this sample, the bacterial and cementation solution was removed from the space among the soil particles owing to the low sample density and large amount of space among the soil particles, and cement bridges did not form among the soil particles, whereas the removal of bacterial and cementation solution was clearly visible during injection. A slight increase in resistance is observed in these samples after 28 days owing to the activity and low growth of the bacteria adhering to the soil particles and formation and increasing amount of cementitious material compared with the 14-day samples. The 28-day increase in sample strength indicates the continuation of bacterial function after 14 days, in which the bacteria continued to function as long as a suitable medium and nutrients were available. Figure 5 shows the stress–strain curves of the 14- and 28-day samples, which present the changes in soil behavior after bacterial modification. Compared with the curves in Fig. 5, the behavior of the 14-day samples was close to the strain hardening state. However, upon increasing the curing duration to 28 days, the sample behavior changed to softening behavior.

Attractive forces exist between clay particles and between clay particles and bacteria owing to the positive and negative charges. This completely differs from the behavior of sand samples. The forces acting on the specimens should overcome these interatomic forces. In the modified 28-day samples, more energy is required prior to failure to overcome the bonds between particles owing to the formation of cement bridges among particles, and the creation of biological shells alters the sample behavior to ductile behavior. The strain–stress diagram of sample CBC can be used to interpret the reduced strength of the 28-day sample compared with the 14-day sample. In the 14-day sample, the behavior is close to elastic and the sample behaves in a completely brittle manner. In the 28-day sample, the sample behavior has changed to ductile owing to the creation of cement bridges and biological crust. The elastic modulus significantly increased compared with the 14-day sample. The energy absorbed by the soil structure is therefore higher in the 28-day sample, but this energy is used to overcome the forces between the particles and cement bridges. These behavioral changes are observed in the stress–strain diagram.

Comparison with previous studies

Table 5 compares the UCS results obtained from clay fixation in the present study with previously reported results. The results of the soil resistance in the bacterial and cement mixing samples in the present study are found to be 2.4 times higher than those reported for clay with low plasticity (Kulanthaivel et al. 2020).

Elastic modulus and failure strain

The elastic modulus is an important parameter to analyze the soil structure behavior and failure mechanism for computational models of soil stiffness. The cementation phenomenon in soil causes a significant increase in the soil elastic modulus. Figure 6 shows the elastic modulus (Et) of the samples after 14 and 28 days of curing.

The highest elastic modulus is related to the sample composed of clay, bacteria, and CBC. In this sample, the 28-day elastic modulus increased by 68% compared with the 14-day sample, reaching 861 kg/cm2. After mixing with bacteria and cement, the elastic modulus of clay ranged from that of dense sand, which may explain the different behavior of this sample compared with the unmodified sample (Das 2001). This increase can have a positive effect on reducing the rate of elastic settlement and soil behavior. The reason for the increased elastic modulus of the 28-day CBC sample compared with the 14-day samples can be observed in Fig. 5j, despite the decrease in compressive strength. In the 14-day sample, the sample behavior followed a linear trend. Hence, in the 28-day sample, the behavior changed to that of an over-consolidated clay. The strain-softening behavior changed and elastic modulus increased, thus indicating that the soil-bacteria interaction and soil behavior changed over time. Its elastic modulus increased, which indicates an increase in the cementation process and density in the 28-day sample compared with the 14-day sample. The elastic moduli of the CBC samples increased by a factor of 4.5 compared with the 14-day control sample and a factor of 6.5 compared with the 28-day sample. In the other samples, the elastic modulus was lower than that of the control sample. The soil elastic modulus is therefore not constant and decreases with increasing shear strain (Budhu 2010). A comparison of the CBC sample results in Figs. 5 and 6 shows a reduced compressive strength owing to the increased elastic modulus in the 28-day samples. Figure 7 shows the failure pattern of sample CBC at curing days of 14 and 28 and the two samples’ different behavior. In the 28-day sample, considerably fewer cracks and more ductile behavior are observed compared with the 14-day sample owing to the cementation process along the sample and its completion by 28 days.

In the method of mixing soil, bacteria, and cementation solution using all of the injection methods, the soil elastic modulus increased after 28 days compared with the 14-day samples. Even in soil sample C0-T2-S, the elastic modulus increased from 0 to 5 kN/m2 (range of very soft clay), which indicates the occurrence of cementation in the soil structure. In the bacterially modified soil samples, those with the same unconfined compression strength had different elastic moduli, which indicates the effect of the injection method on the sample stiffness. The unconfined compression strength was lower for soil samples without bacterial modification. However, the elastic moduli of the samples increased, which indicates an increase in the soil stiffness owing to the bacteria addition. A comparison of the results presented herein and those reported by Jesmani et al. (2008) on clay of the Meighan region shows an increase of 71.8% and 66% in the elastic modulus and UCS of the bacteria-modified samples (CBC), respectively, compared with 9% in the lime-modified samples. Failure strain can be considered the endpoint of the material behavior test (Jesmani et al. 2008). The UCS amount in the clay soils was reported to be less than 350 kN/m2 owing to cement modification (Das 2007a, b). The highest failure strain in the 14-day samples was found in the bacterial-modified sample in the CaSO4 medium (Fig. 8).

The strength of soil sample C0-T2-S increased after 28 days, and its failure strain increased by 7.2%, which demonstrates the positive effect of bacterial modification. The lowest failure strain in the 28-day samples was found in the soil sample without bacterial modification, which showed brittle behavior (Fig. 5). Considering the changes in the failure strain, it can be concluded that the failure strain decreased with increasing curing duration, except for the two mentioned samples. Figure 9 shows the failure of the samples and cracks generated in the 28-day samples. The sample failure is indicated by the bulging form.

The general cracking pattern in the samples reflects longitudinal cracks. In sample C-T1-S, in which bacteria were not injected into the sample and only cementation solution was injected, a state of crushing is observed in the middle section of the sample. Considerable crushing was observed at the top of the control soil sample (C), in addition to the fact that the intact sample was removed from the mold at a lower height-to-diameter ratio. The results in Fig. 8 show that the soil samples mixed with bacteria but without cementation solution underwent less failure at the failure strains than the other samples. The diagrams in Fig. 5 show that after failure and disintegration, these samples exhibited strain hardening behavior. Because sample CBC showed the highest compressive strength, it is considered an example to improve the region’s clay soil, and further experiments were continued using this sample.

Flexural strength tests

After placing the specimens in the flexural strength test machine and applying a single-point force, the ultimate force was recorded, and the flexural strength or rupture modulus (MPa) was calculated using the material strength relationships (Popov 1999). Because sample CBC is regarded as the sample with the best strength result, bending samples were also prepared and examined in the same manner. Table 6 shows that the flexural strength decreases in the bacterially modified specimens, and the crack patterns are shown in Fig. 10. The results indicate that the flexural strength decreases with increasing percentage of bacteria.

The addition of bacteria to regional clay is therefore shown to reduce the flexural strength of the investigated specimens. In stabilization projects where flexural strength is a priority, further investigation is required using materials such as fibers with bacteria in clay soils (Zhao et al. 2020). The reason for the decreased flexural strength can be related to the cementation effect on the soil structure and the creation of a rock-like state in the soil, which increases the sample compressive strength but reduces the tensile strength. This reduced flexural strength can be attributed to the creation of a new mineralogical structure and composition, and the formation of a rock-like state in the modified soil with bacteria with increasing UCS and elastic modulus. This indicates that a new and different material was formed, which reflects a completely different flexural behavior. The mechanical behavior of biocemented soil was not fully investigated, and further study is required, especially in situ tests, to better understand the behavior of MICP-stabilized soils.

Physical and chemical tests

To assess the importance of the plastic limit and electrochemical environment (e.g., pH, presence of salts, cations) on the properties, behavior, and structure of clay soils, liquid and plastic limit (ASTM D4318 2010), pH, and EC tests were conducted on the samples treated with bacteria in a standard culture medium. The results are presented in Table 7.

By stabilizing clay soils with lime, the plastic properties and plasticity index of soil are observed to decrease with increasing lime consumption percentage (Al-Mukhtar et al. 2012), which affects the soil mass ductility. In contrast, treating soil with bacteria was not found to affect the soil plastic properties, and the soil’s plastic range did not change. After bacterial modification, the soil pH decreased and the electrical conductivity increased. This is in contrast with the bacterial remediation process of sandy soils, which is associated with an increase of pH (Kim et al. 2014). One of the disadvantages of MICP is the increased pH (Pacheco-Torgal and Labrincha 2013). Owing to the salts and minerals in the regional clay and bacteria activity in the soil, this process leads to a decrease in pH, which is a positive step in this field. After modifying the soil with bacteria, the strongly alkaline conditions changed to alkaline conditions. The soil alkalinity was reduced by decreasing the amount of exchangeable sodium after bacterial modification.

The bacteria-modified samples showed an increase in EC, which confirms the urease hydrolysis process (He et al. 2020). Table 7 shows the clay samples of the area before and after bacterial modification, and that the oxidation and reduction potential (Eh) of samples was negative. This indicates that oxidation occurred in the modified soil: a process by which an object (oxidant) receives electrons and the oxidation number of an element increases. This reflects bacterial activity and electron uptake in the bacterial biological process in the soil. This parameter can be used as an indicator to evaluate the bacterial activity and occurrence of cementation in the soil environment.

XRD, EDS, and SEM analysis

The untreated and bacterial-treated soil samples after 28 days of curing were prepared and subjected to XRD and SEM analysis to study the calcium carbonate precipitation, changes of the soil mineralogical structure, and soil microstructure in the presence of bacteria. The soil samples were prepared as a powder for XRD testing (EN 13,925–1:2003 (E)) and randomly scanned using a Siemens D5000 X-ray diffractometer operating at 40 kV and 30 mA, using a step size 0.02° and counting time of 1 s. Samples of untreated and bacterial-treated soil (clay, bacterial, and cementation mixture) were prepared for SEM analysis, coated, and microscopic images were taken at different magnifications using a VEGA\\ series SEM with a tungsten heated filament.

A comparison of Fig. 11a, b highlights that changes in the clay structure are visible in the presence of bacteria, and a biological crust formed on the clay plates. The presence of bacteria in the soil structure caused calcite precipitation, which filled the empty spaces between the soil particles and created cement bridges. Flocculated clay flakes were found in the structure of the soil without bacterial treatment (Fig. 11a), which formed a complete solid and integrated the soil structure after modification (Fig. 11b), which may be a mechanism by which the compressive strength of the clay samples is increased in the presence of bacteria.

The XRD samples were prepared and analyzed to investigate the effect of bacterial presence on the soil mineralogical structure and the effect of the culture medium on the bacterial yield in the soil. The XRD results (Fig. 12) show the presence of calcite in treated and untreated specimens. Some changes occurred in the calcite peaks before and after bacterial treatment in the standard culture medium. The mineralogical analysis of the soil samples without bacteria, with bacteria in conventional culture medium, and with bacteria in a culture medium of NaCl and CaSO4 is presented in Table 8.

The results indicate the presence of a few different minerals between the soils with and without bacterial modification. In 28-day samples, upon the developing soil reaction process and bacteria, cristobalite (Moh’s hardness = 6.5) was removed from the soil environment and illite (Moh’s hardness = 1–2) formed in the soil structure. This mineral conversion and change in hardness owing to the processes caused by the presence of bacteria and nutrients in the soil environment can be an explanation for the reduced strength of the 28-day CBC sample compared with 14-day sample because these changes were completed in the 28-day sample. In the CaSO4 medium, thenardite, cristobalite, muscovite, and clinochlore were removed, and feldspar and calcite minerals formed. In the NaCl culture medium, in addition to the removed cases in the CaSO4 culture medium, calcite did not occur in pure form, and only feldspar was observed. These results demonstrate the effects of bacteria and its activity in the soil using different culture media. A notable result in Table 8 is the change of minerals in the clay structure in the presence of bacteria and different bacterial behaviors in the different culture media. The absence of calcite in the NaCl culture medium confirms the low compressive strength of these samples and inadequacy of this culture medium for bacterial growth in the Meighan soil.

Energy-dispersive X-ray spectroscopy analysis was performed before and after modification, as shown in Fig. 13. The results show a reduced amount of sodium and sulfur and an increased amount of calcium after bacteria treatment. The decreased sodium levels indicate the bacterial use of salts, and the increased calcium levels indicate calcite deposition in the soil structure.

Comparison of treated and untreated specimens in a wind tunnel

The maximum resistance was obtained in the samples that involved soil mixed with bacteria. This group was therefore considered for wind tunnel testing. This section compared bacterial-treated and untreated specimens to evaluate microbial treatment effects on specimen erosion, as shown in Table 9.

The bacterial treatment was found to strongly reduce the surface erosion of the clay specimens by 98%, from 354 to 1 kg/m2h. Figure 14 shows the treated clay specimens cured for 28 days before and after exposure to the wind tunnel. No significant changes occurred in the specimen surfaces after wind tunnel exposure, whereas a positive effect was observed for the microbial treatment to prevent wind erosion.

The UCS tests and wind tunnel results demonstrate the relationship between clay UCS and wind erosion. By increasing the clay resistance in the area using bacteria to the extent of hard clay resistance, the crust resistance of this method has also significantly increased against erosion. In the absence of wind tunnels in the laboratory, a UCS test can be used to evaluate the increase of shell resistance to wind erosion in the presence of bacteria.

Conclusion

This study investigated the formation and effects of calcium carbonate precipitation owing to bacterial activity on clay from the Meighan Desert region after treatment with Bacillus pasteurii using various mixing and injection methods. The increased soil strength, wind erosion resistance, and specimen failure owing to biocementation were investigated by a series of unconfined compression strength tests and wind tunnel tests. Additional experiments and microstructural studies were performed to investigate the effect of bacterial treatment on the samples. The results are summarized as follows.

-

The unconfined compression strength (UCS) of clay in the study area increased by 78.5% after 28 days of mixing with bacteria and cementation solution compared with the soil without bacterial treatment (control sample). The mixed sample of soil and bacteria without cementation solution also showed a 44% increase in strength after 28 days compared with the control sample, which indicates appropriate conditions for soil growth in the region and the availability of nutrients for growth and cementation of bacteria in the soil even without cement. The saline and sulfate conditions of this soil are therefore suitable for the applied bacteria.

-

Sporosarcina pasteurii is a suitable choice for the bacterial remediation of saline soil in the Meighan region. The experimental results show that this type of bacteria can use substances in the soil for growth and survival.

-

The UCS tests results indicate that the injection method is unable to uniformly distribute the bacteria and salts within the clay mass. The injection method is therefore not suitable for modifying clay soils, especially salt-bearing soils such as sodium chloride and calcium chloride.

-

The UCS and wind tunnel test results show that the method of mixing bacteria, soil, and cementation solution can be a suitable option to improve the resistance properties of salty clay soils.

-

The use of bacteria to stabilize saline and alkaline clay soils without suitable stabilization conditions using conventional stabilizers (e.g., lime, cement) is a good option that produces higher UCS values and elastic moduli of these stabilizers in the soil.

-

The stress–strain curves of samples treated to different injection and mixing scenarios demonstrate the effect of bacteria on the changing soil behavior owing to the ductility and failure of the soil samples, which causes a softening behavior in the soil. The complex ductility in bacterial-modified soils therefore increases upon rupture loads. Owing to the reduced flexural strength of the stabilized specimens, this stabilization method is not suitable for the investigated soil in projects such as road paving.

-

The test results and changes in the strength and elastic modulus of salt clay samples with 14 and 28 days of curing time indicate that a 28-day curing duration is recommended for samples modified with bacteria.

-

The pH of the bacterial-treated soil decreased, which differs from sandy soils and non-alkaline clays where the enhanced pH poses an environmental problem. After modifying the soil with bacteria, the strongly alkaline conditions of the soil changed to alkaline conditions. The treated samples show an increased electrical conductivity, which confirms the hydrolysis process of urease and increasing cations in the soil environment.

-

The bacterial stabilization of clay did not cause a significant change in the soil plastic liquid limit, in contrast to the soil behavior in the presence of stabilizers (e.g., lime), which reduce the plastic limits of clay.

-

The flexural strength of the clay samples decreased during the bacteria modification process. Further studies are required for bacterial stabilization projects where the flexural and tensile strengths are important, such as the use of fibers in the soil and bacteria in clay.

-

Using bacteria to stabilize clay soils is a good option in the absence of suitable conditions for stabilization using conventional stabilizers (e.g., lime, cement, oil mulch). This method is shown to have reduced the surface erosion of the clay specimens by 98%, from 354 to 1 kg/m2h.

-

The UCS test and wind tunnel results indicate a relationship between the UCS of clay and soil crust resistance (biocrust) to wind erosion. In the absence of wind tunnels in the laboratory, a UCS test can thus be used to evaluate the increase of shell resistance to wind erosion in the presence of bacteria.

-

A comparison of samples under the same conditions in different culture media and investigation of the XRD analysis indicate the effects of culture medium on the bacterial behavior, structure, and minerals of the clay soils, and soil mechanical properties. The SEM images clearly demonstrate the formation of a biocrust in the soil structure.

In light of the transition toward green technology and the reduction of greenhouse gases worldwide, the construction and geotechnical industry should also move in this direction to embrace new, green, and friendly environmental technologies, including biogeotechnology. The results of the present study demonstrate that the method of mixing soil, bacteria, and cementation solution can be a good option for stabilizing clays that contain sulfate salts. This method significantly increases the uniaxial strength, fracture strain, and elastic modulus of the soil compared with cement and lime, and is also an environmentally friendly approach. The results indicate that the surface mixing of soil and bacteria can increase the soil resistance and create a resistant surface crust (biocrust), which can be used as an environmentally friendly method to control dust owing to wind erosion in the Meighan Desert without harming the environment and living organisms.

References

A’la H, Rahayu W, Lisdiyanti P (2020) Effect of increasing urease enzim concentration on shear strength properties sand clay biocementation IOP. Conf Ser Earth Environ Sci 426. https://doi.org/10.1088/1755-1315/426/1/012029

Al-Mukhtar M, Khattab S, Alcover J-F (2012) Microstructure and geotechnical properties of lime-treated expansive clayey soil. Eng Geol 139–140:17–27. https://doi.org/10.1016/j.enggeo.2012.04.004

Al Qabany A, Soga K, Asce M et al (2012) Factors Affecting Efficiency of Microbially Induced Calcite Precipitation. https://doi.org/10.1061/(ASCE)GT.1943-5606.0000666

ASTM D422 - 63 (2007) Standard test method for particle-size analysis of soils . https://www.astm.org/Standards/D422

ASTM D2166M–16 AD/ (2016) Standard test method for unconfined compressive strength of cohesive soil

ASTM D4318 (2010) Standard test methods for liquid limit, plastic limit, and plasticity index of soils. https://www.astm.org/Standards/D4318.

ASTM D7928 - 17 (2016) Standard test method for particle-size distribution (Gradation) of fine-grained soils using the sedimentation (Hydrometer) Analysis. In: ASTM Int. www.astm.org

Baghbanan A, Razani M (2016) Possibility of using biogrout for stabilization of sand dunes in desert areas with approach in conservation of archaeological remains. Artic J Res Archaeom. https://doi.org/10.29252/jra.2.1.17

Bang S, Min SH, Bang SS (2011) Application of microbiologically induced soil stabilization technique for dust suppression. Int J Geo-Engineering 3:27–37

Briaud J (2013) Geotechnical engineering: unsaturated and saturated soils

BS EN 13925–1 (2003) Non-destructive testing. X-ray diffraction from polycrystalline and amorphous materials. General principles. British European Standard, London, United Kingdom.

Budhu M (2010) Soil Mechanics and Foundations, 3rd edn

Chen XC, Hu SP, Shen CF et al (2009) Interaction of Pseudomonas putida CZ1 with clays and ability of the composite to immobilize copper and zinc from solution. Bioresour Technol 100:330–337. https://doi.org/10.1016/j.biortech.2008.04.051

Cheng L, Cord-Ruwisch R, Shahin MA (2013) Cementation of sand soil by microbially induced calcite precipitation at various degrees of saturation. Can Geotech J 50:81–90. https://doi.org/10.1139/cgj-2012-0023

Cheng L, Shahin MA, Chu J (2019) Soil bio-cementation using a new one-phase low-pH injection method. Acta Geotech 14:615–626. https://doi.org/10.1007/s11440-018-0738-2

Chu J, Stabnikov V, Ivanov V (2012) Microbially induced calcium carbonate precipitation on surface or in the bulk of soil. Geomicrobiol J 29:544–549. https://doi.org/10.1080/01490451.2011.592929

Das (2013) Principles of geotechnical engineering, Seventh Ed. Cengage Learning

Das BM (2007a) Principles of foundation engineering, SI Seventh Edition, 7th edn. Cengage Learning

Das BM (2007b) Fundamentals of geotechnical engineering, 3rd edn. CL-Engineering, Spain

Das BM (2001) Principles of geotechnical engineering, 5th edn. CL Engineering

DeJong JT, Fritzges MB, Nüsslein K (2006) Microbially induced cementation to control sand response to undrained shear. J Geotech Geoenvironmental Eng 132:1381–1392. https://doi.org/10.1061/(ASCE)1090-0241(2006)132:11(1381)

Dingwen Z, Libin F, Songyu L, Yongfeng D (2013) Experimental investigation of unconfined compression strength and stiffness of cement treated salt-rich clay. Mar Georesources Geotechnol 31:360–374. https://doi.org/10.1080/1064119X.2012.690826

DSMZ (2019) German collection of microorganisms and cell cultures GmbH. In: Labrys portucalensis

Fattahi SM, Soroush A, Huang N (2020) Biocementation control of sand against wind erosion. J Geotech Geoenvironmental Eng 146. https://doi.org/10.1061/(ASCE)GT.1943-5606.0002268

Firoozi AA, Guney Olgun C, Firoozi AA, Baghini MS (2017) Fundamentals of soil stabilization. Int J Geo-Engineering 8:1–16. https://doi.org/10.1186/s40703-017-0064-9

Ghosh T, BhaduriID S, Montemagno C, KumarID A (2019) Sporosarcina Pasteurii Can Form Nanoscale Calcium Carbonate Crystals on Cell Surface. https://doi.org/10.1371/journal.pone.0210339

Gomez MG, Martinez BC, DeJong JT et al (2015) Field-scale bio-cementation tests to improve sands. Proc Inst Civ Eng - Gr Improv 168:206–216. https://doi.org/10.1680/grim.13.00052

Harkes MP, van Paassen LA, Booster JL et al (2010) Fixation and distribution of bacterial activity in sand to induce carbonate precipitation for ground reinforcement. Ecol Eng 36:112–117. https://doi.org/10.1016/j.ecoleng.2009.01.004

He J, Gao Y, Gu Z et al (2020) Characterization of crude bacterial urease for CaCO 3 precipitation and cementation of silty sand. J Mater Civ Eng 32. https://doi.org/10.1061/(ASCE)MT.1943-5533.0003100

Iamchaturapatr J, Piriyakul K (2014) Effect of urease dosages in biocementation process for improving strength of sandy soil. In: Adv. Mater. Res. https://www.scientific.net/AMR.931-932.698. Accessed 3 Jul 2020

Ivanov V, Stabnikov V (2016) Construction biotechnology: biogeochemistry, microbiology and biotechnology of construction materials and processes

Kim D, Park K, Kim D (2014) Effects of ground conditions on microbial cementation in soils. Materials (basel) 7:143–156. https://doi.org/10.3390/ma7010143

Knorr B (2014) Enzyme-induced carbonate precipitation for the mitigation of fugitive dust. Arizona State University.

Kulanthaivel P, Soundara B, Das A (2020) Performance study on stabilization of fine grained clay soils using calcium source producing microbes. KSCE J Civ Eng 24:2631–2642. https://doi.org/10.1007/s12205-020-2028-4

Mandal T, Edil TB, Tinjum JM (2018) Study on flexural strength, modulus, and fatigue cracking of cementitiously stabilised materials. Road Mater Pavement Des 19:1546–1562. https://doi.org/10.1080/14680629.2017.1325772

Mahawish A, Bouazza A, Gates WP (2019) Strengthening crushed coarse aggregates using bio-grouting. Geomech Geoengin 14:59–70. https://doi.org/10.1080/17486025.2018.1521999

Memarian H, Jesmani M, Jamshidi M (2008) Investigation of geotechnic characteristics of soils on Mighan kavir with aim of soil amendment and stabilization. Scientific Quarterly Journal of Iranian Association of Engineering Geology (JIRAEG) 1(1):23-34

Meyer FD, Bang S, Min S et al (2011) Microbiologically-induced soil stabilization: application of sporosarcina pasteurii for fugitive dust control. Geotech Spec Publ 4002–4011. https://doi.org/10.1061/41165(397)409

Montoya BM, DeJong JT (2015) Stress-strain behavior of sands cemented by microbially induced calcite precipitation. J Geotech Geoenvironmental Eng 141:04015019. https://doi.org/10.1061/(ASCE)GT.1943-5606.0001302

Mortensen BM, Haber MJ, Dejong JT et al (2011) Effects of environmental factors on microbial induced calcium carbonate precipitation. J Appl Microbiol 111:338–349. https://doi.org/10.1111/j.1365-2672.2011.05065.x

Mujah D, Shahin MA, Cheng L (2017) State-of-the-art review of biocementation by microbially induced calcite precipitation (MICP) for soil stabilization. Geomicrobiol J 34:524–537

Müller B, Défago G (2006) Interaction between the bacterium Pseudomonas fluorescens and vermiculite: effects on chemical, mineralogical, and mechanical properties of vermiculite. J Geophys Res Biogeosciences 111:n/a-n/a. https://doi.org/10.1029/2005JG000054

Nafisi A, Montoya BM (2018) A new framework for identifying cementation level of MICP-treated sands. In: Geotechnical Special Publication. Am Soc Civil Eng (ASCE), pp 37–47

Naveed M, Duan J, Uddin S et al (2020) Application of microbially induced calcium carbonate precipitation with urea hydrolysis to improve the mechanical properties of soil. Ecol Eng 153:105885

Ng W, Lee M, Technol SH-WASE (2012) An overview of the factors affecting microbial-induced calcite precipitation and its potential application in soil improvement

Omoregie AI, Ngu LH, Ong DEL, Nissom PM (2019) Low-cost cultivation of Sporosarcina pasteurii strain in food-grade yeast extract medium for microbially induced carbonate precipitation (MICP) application. Biocatal Agric Biotechnol 17:247–255. https://doi.org/10.1016/j.bcab.2018.11.030

Pacheco-Torgal F, Labrincha JA (2013) Biotech cementitious materials: some aspects of an innovative approach for concrete with enhanced durability. Constr Build Mater 40:1136–1141. https://doi.org/10.1016/j.conbuildmat.2012.09.080

Pacheco-Torgal F, Labrincha JA, Diamanti MV et al (2015) Biotechnologies and biomimetics for civil engineering. Biotechnol Biomimetics Civ Eng 1–437. https://doi.org/10.1007/978-3-319-09287-4

Popov EP (1999) Engineering mechanics of solids, 2nd edn. Pearson

Richards LA, Allison LE, Bernstein L et al (1954) Diagnosis and improvement of United States salinity laboratory staff

Salimi M, Ghorbani A (2020) Mechanical and compressibility characteristics of a soft clay stabilized by slag-based mixtures and geopolymers. Appl Clay Sci 184. https://doi.org/10.1016/j.clay.2019.105390

Shahrokhi-Shahraki R, Zomorodian SMA, Niazi A, Okelly BC (2015) Improving sand with microbial-induced carbonate precipitation. Proc Inst Civ Eng Gr Improv 168:217–230. https://doi.org/10.1680/grim.14.00001

Stocks-Fischer S, Galinat JK, Bang SS (1999) Microbiological precipitation of CaCO3. Soil Biol Biochem 31:1563–1571. https://doi.org/10.1016/S0038-0717(99)00082-6

Thuro K, Plinninger RJ, Zäh S, Schütz S (2001) Scale effects in rock strength properties. Part 1: Unconfined compressive test and Brazilian test

Tian K, Wu Y, Zhang H et al (2018) Increasing wind erosion resistance of aeolian sandy soil by microbially induced calcium carbonate precipitation. L Degrad Dev 29:4271–4281. https://doi.org/10.1002/ldr.3176

van Paassen LA, Daza CM, Staal M et al (2010) Potential soil reinforcement by biological denitrification. Ecol Eng 36:168–175. https://doi.org/10.1016/j.ecoleng.2009.03.026

Van Paassen LA, Harkes MP, Van Zwieten GA et al (2009) Scale up of BioGrout: a biological ground reinforcement method. Proc 17th Int Conf Soil Mech Geotech Eng Acad Pract Geotech Eng 3:2328–2333. https://doi.org/10.3233/978-1-60750-031-5-2328

Wani KMNS, Mir BA (2020) Microbial geo-technology in ground improvement techniques: a comprehensive review. Innov Infrastruct Solut 5. https://doi.org/10.1007/s41062-020-00335-6

Whiffin VS, van Paassen LA, Harkes MP (2007) Microbial carbonate precipitation as a soil improvement technique. Geomicrobiol J 24:417–423. https://doi.org/10.1080/01490450701436505

Widjajakusuma J, Winata H (2017) Influence of rice husk ash and clay in stabilization of silty soils using cement. MATEC Web Conf 138. https://doi.org/10.1051/matecconf/201713804004

Zhao Y, Xiao Z, Fan C et al (2020) Comparative mechanical behaviors of four fiber-reinforced sand cemented by microbially induced carbonate precipitation. Bull Eng Geol Environ 79:3075–3086. https://doi.org/10.1007/s10064-020-01756-4

Acknowledgements

We thank Esther Posner, PhD, from Edanz (www.edanz.com/ac) for editing a draft of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Rights and permissions

About this article

Cite this article

Shafiei, H., Lajevardi, S.H., Ghareh, S. et al. Evaluating the application of carbonate precipitation driven by bacterial activity for stabilizing saline and alkaline clays. Bull Eng Geol Environ 81, 141 (2022). https://doi.org/10.1007/s10064-022-02634-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10064-022-02634-x