Abstract

The aim of this research is to investigate the effect of the additive metakaolin on the strength parameters of clayey sand soil. For this purpose, in addition to identification tests, a set of experiments including Atterberg limits and modified Proctor, uniaxial compressive strength, direct shear, permeability, and pH tests have been performed on some samples of the clayey sand soil under non-stabilized and stabilized conditions for different percentages of metakaolin. Furthermore, scanning electron microscopy (SEM) and X-ray diffraction (XRD) have been performed to investigate the microstructure of the non-stabilized and stabilized soil. The results showed that the maximum extent of increase in the strength occurred by metakaolin 25% and after 28 days of curing. Furthermore, elevation of the weight percentage of metakaolin in clayey sand soil causes to increase shear strength, diminish hydraulic conductivity, reduce the maximum specific dry weight of soil, and increase optimal water content, but it has a minor effect on pH value during the curing time. Investigation of the results obtained from XRD of the sample treated with metakaolin indicated the emergence of the cement compound called calcium silicate hydrate (CSH). Furthermore, the results of SEM imaging indicated that with the addition of metakaolin, the dispersed structure of soil changes into a flocculated structure, thereby enhances the soil strength.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Using additives for stabilization of soil has always been of interest to researchers. Meanwhile, the use of inexpensive and environmental-friendly additives such as natural pozzolans is important. Natural pozzolans refer to silica and alumina silicate compounds, which do not have intrinsic cement properties, but in the presence of water with calcium hydrate, they develop compounds with cement properties. By reviewing previous researches, it is observed that using pozzolan materials in synthesis of concrete is first environmentally friendly and then causes to save energy and costs and reduce permeability and elevation of the chemical strength of concrete (Ghrici and Kenai 2007). In recent years, application of pozzolan materials to improve soil strength parameters has also attracted a great deal of attention.

Jedari Salehzadeh (2001) investigated the effect of adding pozzolan on the physical and mechanical properties of divergent clay. They found that elevation of the pozzolan percentage alongside lengthening the curing time causes to diminish dispersivity, uniaxial compressive strength, maximum dry density of soil, and increase liquidity limit and optimal water content of soil. Ghabezloo (2001) examined the effect of adding pozzolan and “pozzolan and lime” on the physical and mechanical properties of a kind of marl soil; they found that pozzolan has no significant effect on improving the mechanical properties of marl due to its low free lime content. However, the effect of concurrent use of lime and pozzolan was considerable on the characteristics of the samples and caused to improve strength parameters of marl soil. Hossain and Mol (2011) performed Atterberg limits, standard proctor, uniaxial compression, tensile strength, elasticity modulus, and California bearing ratio (CBR) tests and studied the engineering properties of clays stabilized with pozzolan and industrial wastes. The results indicated that with concurrent addition of these materials, the strength and durability of the stabilized samples increased. Al-Swaidani et al. (2016) examined the effect of natural pozzolan on the geotechnical properties of clay soil stabilized with lime. In this study, the soil was stabilized with pozzolan 0 through 20% and lime 0 through 8%. The results obtained from this study showed that with the addition of natural pozzolan, CBR increased while the plasticity index of the soil stabilized with lime diminished. The results of this study showed that silicate and aluminate gel formed in the soil stabilized with lime and soil stabilized with “pozzolan and lime” have been the major causes of these changes.

Metakaolin is a natural pozzolan with high reactivity and usually contains 50–55% of SiO2. In reaction with Ca(OH)2 at ordinary temperatures, it produces calcium silicate hydrate (CSH). This material has also 40 through 45% of Al2O3, which reacts with Ca(OH)2 and produces aluminate phases. Metakaolin is obtained from calcination of kaolin soil at 550–900 °C. The first documented use of this material in concrete dates back to 1962 in Jupia Dam in Brazil. Using metakaolin in the concrete industry has a short lifetime of around 20 years. However, it has recently been accepted as an effective pozzolan material, such that it has been entered into the market since 1994. Various studies have been performed about the effects of substituting cement with metakaolin as a pozzolan and its effect on improving the mechanical properties and stability of concrete. The results of these studies show that addition of metakaolin to concrete causes to increase compressive strength and tensile and bend the strengths. Furthermore, this material enhances concrete strength against corrosion.

In spite of different studies on the effects of adding metakaolin to concrete, the use of this material for stabilizing soil and soil–cement has remained understudied (Wild et al. 1996; Qian and Li 2001; Courard et al. 2003; Batis et al. 2005).

Similar studies on the physical and mechanical properties of soilcrete and sandcrete materials modified with metakaolin have been conducted by Kolovos et al. (2013, 2016); Asteris and Kolovos (2017) and Asteris et al. (2019). Also in recent years, the application of soft computing techniques to predict the properties of the soilcrete and sandcrete materials’modified with metakaolin have been investigated (Asteris et al. 2017).

Investigation of the effect of metakaolin on hydraulic conductivity and mechanical behavior of marine clay modified with cement indicates that with the elevation of the metakaolin percentage from 3 to 5%, the hydraulic conductivity diminished by 10 through 100 times. The uniaxial compressive strength of soil containing cement 3% and metakaolin 5% is 2 through 3 times as large as that of the soil without metakaolin. Furthermore, the rate of elevation of soil strength containing metakaolin is higher in early days of curing compared to the soil without metakaolin. Indeed, metakaolin accelerates pozzolan reactions (Zhang et al. 2014; Deng et al. 2015).

Wu et al. (2016) examined the effect of “metakaolin and cement” on the strength and structure of MHS soil (containing sand 33%, silt 45.5%, and clay 20.5%, with liquidity limit, plasticity limit, and plasticity index of 55.5, 38.1, and 17%, respectively). They found that adding metakaolin to the soil stabilized with cement diminishes soil sensitivity to water, while significantly increasing the uniaxial compressive strength and tensile strength of soil. The optimal cement-to-kaolin ratio in this study has been evaluated as 2 through 3. Micro-structural investigations also suggested increased pozzolan reactions and production of new minerals including CSH and calcium aluminate hydrate (CAH).

Wianglor et al. (2017) investigated the effect of increasing the percentage of alkaline active metakaolin on compressive strength and structure of mortar particles treated at 23 and 60 °C. They found that elevation of metakaolin percentage and curing temperature was associated with increased compressive strength of samples, which is clearly observed in the structure of treated mortar particles including silicate and aluminate gel. Recently, investigations by Wang et al. (2018) on stabilizing sand cemented with metakaolin coal indicated that this type of additive causes to improve pores in the soil, increase hydration rate and improve soil strength.

In recent years, the use of metakaolin for synthesis of geopolymers has attracted attention. The results of synthesis of geopolymers with metakaolin and combining metakaolin with other materials such as zeolite, nanosilica, kaolin, cement materials, and others indicate that metakaolin causes to improve physical and chemical properties, diminish environmental contamination and generally improve performance of geopolymers. Accordingly,the use of geopolymers with the basis composed of materials such as metakaolin in synthesis of concrete, mortar, and soil modification has developed, which will result in increasing their strength and efficiency (Sudagar et al. 2018; Avent et al. 2018; El-Eswed et al. 2017).

Review of previous studies suggests using cement as one of the most important materials employed for stabilizing soil. In recent years, although the effect of combining metakaolin and cement for soil stabilization has been studied sparsely, metakaolin alone has not already been used for stabilizing and modifying the soil. Metakaolin can be a suitable substitute for cement as an effective natural and environmental friendly pozzolan and is able to enhance the strength and durability of the soil. Furthermore, metakaolin is produced at lower temperatures compared to clinker. Therefore, its usage can be more economical than cement.

Considering these points, the present study aims to investigate the effect of different percentages of metakaolin considering its unique properties on the results of tests including Atterberg limits and modified Proctor, uniaxial compressive strength, direct shear, permeability, and pH tests on clayey sand soil emphasizing the micro-structural characteristics of the soil.

Materials and methods

Materials

In this research, clayey sand soil with clay 20% and sand 80% of Firoozhooh (a type of typical sand in north of Iran) has been studied. The color of Firoozkooh 161 sand is white to yellow with a density of 2680 kg/m3 and angular coefficient of less than 1.3. The No. 200-sieve passage percentage of this sand is less than 1%. Chemical analysis of Firoozkooh sand is according to Table 1.

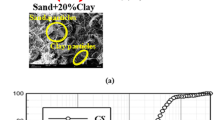

Figure 1 demonstrates the XRD diagram of clay and metakaolin. Analysis of the XRD of the clay used in this study (Fig. 1b) indicates that in the structure of clay soil, there are quartz (SiO2), calcite (CaCO3), albite ((Na, Ca)Al(Si,Al)3O8), and muscovite (KAl3Si3O10(OH)2) crystals.

The specific weight of the metakaolin used in this research is 2630 kg/m3 and its specific surface area is 16.3 m2/g. According to Fig. 1a, in the XRD pattern of metakaolin in many ranges, no graphical prominence is observed, suggesting amorphicity of the sample. Indeed, metakaolin is a mixture of crystals and amorphous materials. The crystals in metakaolin include illite ((K, H3O)(Al, Mg, Fe)2(Si Al)4O10[(OH)2, (H2O)]), quartz (SiO2), and anatase (TiO2). The chemical analysis of metakaolin is presented in Table 1 (Sudagar et al. 2018).

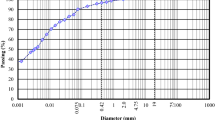

In this study, in order to identify the materials used in the research and characterize their physical and mechanical properties, identification tests including granulation, hydrometry, Atterberg limits, and density tests were performed on the soil. Based on their results, this type of clayey sand soil lacks plastic properties due to the low clay percentage. Based on the results obtained from the index tests, the optimal water content of this soil and its maximum dry unit weight were determined as 10.35% and 2040 kg/m3, respectively. Figure 2 shows grain size distributions of the clayey sand soil used in this study.

To prepare the testing samples, water was continously supplied to the premixed soil- metakaolin powders until the water content was equal to the optimum water content and mixed thoroughly with spatula for 10 min. These samples were sealed in plastic bags to avoid variation of the water content and later cured at 20 ± 2 °C for 7, 14, and 28 days.

Compaction test

The modified proctor compaction test (ASTM D1557-12; 2012), producing a compactive effort of 2700 kN-m/m3, was adopted to evaluate the compactability and determine the maximum dry unit weight and the optimum water content of clay sand soil stabilized with 0, 5, 15, and 25% metakaolin.

Unconfined compression test

Uniaxial compressive strength test was performed based on ASTM D2166-16 (2016) standard on stabilized and non-stabilized soil with metakaolin additive at percentages of 5, 10, 15, 20, and 25 and at curing times including immediately after mixing, as well as 7, 14, and 28 days after curing initiation. To reconstruct the uniaxial sample, a mold with a diameter and height of 3.8 and 7.6 cm, respectively was used. To prepare the samples, dry mixing method was employed Pakbaz and Farzi (2015). For this purpose, first metakaolin was mixed with soil in a dry form, to which water was gradually added, so that the samples would reach their optimal water content. The soil was poured in the uniaxial mold and compressed across three layers with almost the same thickness. Since the samples that were compressed with the same number of impacts in all layers, the level of fracture developed in uniaxial compressive strength tests occurred only in the top layer (due to the weak compression in the top layer). Thus, to overcome this problem, the soil compression operations for synthesizing uniaxial samples were considered per 30, 40, and 50 impacts for the first to third layers, respectively. In this test, the loading was applied at the constant rate of 0.1 mm/min and continued until reaching the final strength of the samples.

Direct shear test

The shear strength of soils is an important aspect in many foundation engineering problems such as the bearing capacity of shallow foundations and piles, the stability of the slopes of dams and embankments, and lateral earth pressure on retaining walls. In this research, direct shear test (10 × 10 × 2 cm) was conducted on samples prepared with the optimal water content and maximum dry unit weight. The non-stabilized and stabilized compressed soil samples were prepared through manual mixing of dry soil, metakaolin, and water. Then, the sample was transferred to the shear box. The test was performed for three saturated samples for 6 h with different overheads of 50, 100, and 150 kPa and at 1 mm/min. The direct shear test was performed on the samples stabilized with metakaolin additive at 5, 10, 15, 20, and 25% of the soil dry weight at the immediate time.

Permeability test

To investigate the effect of metakaolin on the soil hydraulic conductivity, clayey sand soil with metakaolin 5, 10, 15, 20, and 25% was prepared using dry mixing method. Then, the prepared mixture was poured from a specific height into the permeability mold with a height and diameter of 8.65 and 5 cm, respectively. In this research, concerning the considerable effect of fine-grained soils on hydraulic conductivity, falling head test was used to determine the permeability coefficient.

SEM and XRD tests

In the rest of the research, the morphology of the clayey sand soil without additives and stabilized with metakaolin 15% was examined through scanning electron microscopy (SEM) test and investigating the soil composition before and after stabilization using X-ray powder diffraction (XRD) test. For this purpose, the clayey sand soil samples were prepared without additive and those stabilized with metakaolin 15% at the optimal water content (obtained from the modified Proctor test), and then tested on day 28 of curing.

Results and discussion

The results of compaction test

Figure 3 displays the changes of the compaction curve against elevation of metakaolin percentage. According to the Fig. 3, the optimal water content and maximum dry unit weight of the soil without additive were 10.35% and 2040 kg/m3, respectively. Here, the optimal water content of the soil stabilized with metakaolin 25% was 14.1%, and its maximum dry unit weight was 1840 kg/m3. Previous studies have shown that stabilization of soil with cement, volcanic ash, fly ash, and rice husk ash causes increased soil demand for water to perform the hydration reaction and retain the extra water in the integrated soil-additive structure. Therefore, the optimal water content of the soil increases (Wu et al. 2016). In a similar process, adding metakaolin to soil also leads to increase soil optimal water content. According to Fig. 2, the maximum dry unit weight of the samples stabilized with metakaolin additive was less than that of the clayey sand soil without additives. The reason of these changes can be attributed to the lower volumetric mass of metakaolin and high activity of this material compared to clayey sand soil.

The results of uniaxial compression test

Figure 4 illustrates the changes in the uniaxial compression in relation to the changes in the percentage of metakaolin at different curing times. According to Fig. 3, with elevation of metakaolin percentage up to 25%, a considerable rise occurred in the strength of the clayey sand soil. In this regard, at the immediate curing time, the strength of the samples without additive grows from 0.184 to 0.78 MPa, representing 324% increase. The reason of this elevated strength at the immediate curing time can be attributed to alteration of the soil’s physical texture. Indeed, the finer metakaolin particles and the higher activity of this additive compared to soil, increase the uniaxial strength of the stabilized samples at the immediate curing time.

According to Fig. 4, over time, the strength of the samples stabilized with metakaolin grows significantly. For example, the strength of samples stabilized with metakaolin 25% at the immediate curing time is 0.78 MPa. This value grows by 1.49 times with curing time lengthening, reaching 1.163 MPa after 28 days of curing. The reason of this growth can be incidence of cation exchange reactions and flocculation occurring at initial times following stabilization. In these reactions, the monovalent cations present in the clay double layer are replaced with bivalent cations. These reactions cause variations in the plasticity index and increase in soil strength. In addition, the incidence of long-term pozzolan reactions between clayey sand soil and metakaolin as a natural pozzolan in the presence of water and free lime can lead to production of CSH and CAH, which in turn enhances the soil strength. In non-stabilized samples, the 7-day strength of the samples was 0.56 times as large as the 28-day strength. However, with the addition of metakaolin, the rate of growth of uniaxial strength of the samples rises, such that due to elevation of the rate of pozzolan reactions in the samples stabilized with metakaolin, the strength of samples stabilized with metakaolin 25% on the seventh day of the curing time was 0.75 times as large as that of the 28-day strength. In other words, a considerable portion of the strength elevation occurs in the early 7 days of the curing.

Figures 5 and 6 demonstrate the stress–strain curve of the uniaxial compressive strength test at immediate time and 28 days after the curing. Based on these figures, elevation of metakaolin percentage results in increased uniaxial strength and ductility of samples compared to the soil without additives. Furthermore, under these conditions, across all strains, most samples are able to tolerate more stress compared to the soil without additive. This is more tangible at 28th day of curing (Fig. 6).

According to Fig. 5, the samples stabilized with metakaolin 5 and 20% are less able to tolerate stress compared to the soil without additives at immediate curing time with the same strain. Over time (Fig. 6), the strength of the samples rises and the tolerance of stress of the samples across all strains exceeds that of the soil without additive.

In this study, the uniaxial strength of the samples stabilized with metakaolin was read up to 0.3 mm deformation after reaching the final strength. As observed in Figs. 5 and 6, after reaching the final strength, all samples are still able to suffer the exerted stress, and elevation of metakaolin percentage causes to increase final strength reduction rate of the samples. For example, the final strength of the sample stabilized with metakaolin 5% at the immediate time is 0.306 MPa. This value, at 0.3 mm deformation after reaching the final strength, decreases to 0.28 MPa (8.5% fall). However, in the samples stabilized with metakaolin 25%, the strength of the samples diminishes up to 21.8%.

The results of direct shear test

Figure 7 reveals the changes in the cohesion and internal friction angle of the soil stabilized with different percentages of metakaolin. According to the figure, the cohesion of the clayey sand soil without additive and its internal friction angle were measured as 0.025 MPa and 25.91°, respectively. Addition of metakaolin leads to the elevation of the soil cohesion. In this regard, addition of metakaolin 5, 10, 15, 20, and 25% to the soil led to 188, 216, 272, 284, and 256% increase in soil cohesion compared to the sample without additive.

Addition of metakaolin to the soil leads to alteration of the soil’s physical texture and increased fine grain content. This, in turn, causes to diminish internal friction angle. Thus, according to Fig. 7, addition of metakaolin across all percentages results in lowered internal friction angle. For example, addition metakaolin 25% to soil causes 60% decrease in the friction angle.

As an example, in Fig. 8, the stress–strain curve of the samples stabilized with metakaolin has been shown at normal stress of 50 kPa. According to the figure, it is clear that with increasing the percentage of metakaolin, at equal strains, the samples withstand more stress.

The results of direct shear test on the samples indicate that generally with the elevation of the weight percentage of metakaolin, the shear strength of the soil-metakaolin mixture also grows. Specifically, with the addition of metakaolin 5, 10, 15, 20, and 25% to the soil under the normal stress state of 50 kPa, the shear strength of the soil mixture rose from 0.45 MPa for the non-stabilized sample to 0.62, 0.68, 0.81, 0.9, and 0.99 MPa, respectively.

The results of permeability test

Literate review suggests that adding pozzolan to soil affects the hydraulic conductivity under the influence of two factors. The first factor is the free lime content in the soil, leading to cationic reactions and flocculation of the clay grains. The cationic reaction causes todiminish the thickness of the double layer and enhance the hydraulic conductivity. Also, flocculation of clay grains augments the water retention capacity and causes to diminish hydraulic conductivity. The second factor is the physical effect of pozzolan introduction into the environment. In other words, if pozzolan grains are larger than soil grains, hydraulic conductivity grows (Deng et al. 2015). In this test, due to the sparseness of the free lime present in metakaolin and performing the test at initial times after mixing, chemical reactions cannot have a major impact on reduction of hydraulic conductivity. Thus, the main influence of metakaolin on hydraulic conductivity arises from its physical effect. Figure 9 demonstrates the changes in soil permeability coefficient in terms of different percentages of metakaolin. According to this figure, with the elevation of metakaolin percentage, the permeability coefficient diminishes significantly, where with 25% growth of metakaolin in the clayey sand soil, the permeability coefficient undergoes 93% decline compared to the soil without additive. Generally, the finer metakaolin grains compared to soil and the high activity of metakaolin have led to diminish hydraulic conductivity.

The results of pH test

Figure 10 illustrates the results of pH of the clayey sand soil stabilized with metakaolin 0, 5, 10, 15, 20, and 25% at immediate curing time as well as 7, 14, and 28 days after the curing. The pH of the additive-free soil at the immediate time is 8.1, which drops to 7.5 with the addition of metakaolin 25%. These changes are due to the low pH of metakaolin. According to Fig. 10, in the course of curing time, the pH value was stabilized with metakaolin growth, reaching to 7.9 and 7.8 during 7 days for all metakaolin percentages. It can be stated that as long as bivalent calcium exists in the environment for replacement with monovalent sodium and the environment is still not saturated with the calcium ions resulting from the free lime ionization process, the pH of the environment has increased. Reduction of pH during 14-day curing can be explained by lime consumption for the pozzolan reaction, since positive ion exchange (cationic exchange) affects the hydroxide ion concentration. According to the results presented in Fig. 10, generally the pH variations of the stabilized samples are low. Indeed, the low free lime content in soil causes calcium ion not to be present in adequate amounts in the environment. Furthermore, due to the low pH of metakaolin, the environment’s pH is less than 8.1, and thus the silica and alumina degradation rate of soil and pozzolan is not fast; hence, the extent of pozzolan reactions has been low. The minor pH variations of the soil in response to stabilization with the additive represent high compatibility of stabilizers with the environment. The reason is that pH rise in response to adding typical materials such as cement and lime causes removal of minerals in soil and thus detrimental environmental effects. It is predicted that in case of using pozzolan with a high lime content (and in turn high pH), the obtained results will be very different. Indeed, due to the elevation of soil pH, the silica and alumina degradation rate grows, and with increase in calcium ion content in the environment, pozzolan reactions will grow.

The results of SEM

Figure 11 demonstrates the SEM image of the non-stabilized clayey sand soil across different magnifications. According to this figure, the dispersed structure of the clayey sand soil can be clearly observed.

Figure 12 displays the SEM images of clayey sand soil stabilized with metakaolin 15% during 28-day curing time. Comparing Figs. 11 and 12, it can be concluded that stabilization of clayey sand soil with metakaolin applying the curing time has completely transformed and improved soil structure. The changes developed in the soil structure can be attributed to incidence of physicochemical reactions. Indeed, as can be seen in Fig. 12, addition of metakaolin to the clayey sand soil applying the curing time has changed the soil structure into a flocculated structure, and thus soil pores have also grown. This can be due to incidence of cationic reactions and flocculation occurring at initial curing times. Furthermore, in the soil structure, the new CSH cement compound emerges, which is a result of incidence of pozzolan reactions between soil and metakaolin in the long run.

The planar and scalar grains shown in Fig. 12 are metakaolin grains. According to Fig. 12, addition of these grains to soil leads to pore filling, increasing soil cohesion, and generally altering soil physical texture.

XRD test results

In this study, X-ray diffraction (XRD) test has been done on non-stabilized samples and those stabilized with metakaolin 15% during the 28-day curing time (Fig. 13). Based on Fig. 13a, the non-stabilized soil contains calcium carbonate or free lime, which can react with the kaolin in the presence of humidity and develop compounds with cement properties.

Comparison of Fig. 13a and b shows that the addition of metakaolin has caused a significant change in X-ray diffraction of clayey sand soil. Here, the peak intensity 29.44, which is common to calcium carbonate and CSH, is weak in the non-stabilized soil, but in the soil stabilized with metakaolin, it has shown strong reflections in this distance. This represents formation of CSH crystals. In spite of formation of strong reflections for CSH crystal in the stabilized soil, the reflections developed for CAH crystals is trivial at the distance of 7.62.

CSH crystals which are formed in response to pozzolan reactions can fill soil pores, thereby reduce porosity and permeability of the sample. This crystal has cement properties and can significantly enhance soil strength and confirm the results of the tests performed in this study.

Conclusion

The aim of this study was to investigate the effect of the additive metakaolin on strength parameters of clayey sand soil. For this purpose, modified Proctor, uniaxial compressive strength, direct shear, permeability, and pH tests as well as SEM and XRD imaging were done on natural clayey sand soil samples and those stabilized with metakaolin at different percentages of the additive and different curing times. The main results are listed as follows:

-

1.

The results of uniaxial compressive tests suggested that with the elevation of metakaolin percentage and curing time, the uniaxial compressive strength and rate of decrease in strength following the failure are increased. The results also showed that rate of increase in strength of the samples stabilized with metakaolin was great on the early days of curing; indeed, metakaolin causes to accelerate the pozzolan reactions.

-

2.

Elevation of the weight percentage of metakaolin in clayey sand soil causes to increase shear strength, 93% decline in hydraulic conductivity, reduced maximum specific dry weight of the soil, and increased optimal humidity percentage. Nevertheless, it has only a minor effect on pH value during the curing time.

-

3.

SEM imaging results showed that the dispersed structure of soil changed with the addition of metakaolin and the passage of curing time of 28 days, and changed into an integrated structure, which in turn caused to enhance soil strength. According to XRD results, with the addition of metakaolin and conductance of pozzolan reactions, the inter-granular pores of the soil were filled, decreasing porosity and permeability of the sample. Furthermore, calcium silicate hydrate (CSH) could enhance soil strength considerably with its cement property.

References

Al-Swaidani A, Hammoud I, Meziab A (2016) Effect of adding natural pozzolana on geotechnical properties of lime-stabilized clayey soil. J Rock Mech Geotech Eng 8(5):714–725. https://doi.org/10.1016/j.jrmge.2016.04.002

Asteris PG, Kolovos KG (2017) Data on the physical and mechanical properties of soilcrete materials modified with metakaolin. Data Brief 13:487–497. https://doi.org/10.1016/j.dib.2017.06.014

Asteris PG, Kolovos KG, Athanasopoulou A, Plevris V, Konstantakatos G (2019) Investigation of the mechanical behaviour of metakaolin-based sandcrete mixtures. Eur J Environ Civ Eng 23(3):300–324. https://doi.org/10.1080/19648189.2016.1277373

Asteris PG, Roussis PC, Douvika MG (2017) Feed-forward neural network prediction of the mechanical properties of sandcrete materials. Sensors 17(6):1344. https://doi.org/10.3390/s17061344

ASTM D1557–12 (2012) Standard test methods for laboratory compaction characteristics of soil using modified effort (56,000 ft-lbf/ft3 (2,700 kN-m/m3)). ASTM International, West Conshohocken, PA

ASTM D2166–16 (2016) Standard test method for unconfined compressive strength of cohesive soil

Avent F, Li X, Scrivener K (2018) Determination of the amount of reacted metakaolin in calcined clay blends. Cem Concr Res 106:40–48. https://doi.org/10.1016/j.cemconres.2018.01.009

Batis G, Pantazopoulou P, Tsivilis S, Badogiannis E (2005) The effect of metakaolin on the corrosion behavior of cement mortars. Cem Concr Compos 27(1):125–130. https://doi.org/10.1016/j.cemconcomp.2004.02.041

Courard L, Darimont A, Schouterden M, Ferauche F, Willem X, Degeimbre R (2003) Durability of mortars modified with metakaolin. Cem Concr Res 33(9):1473–1479. https://doi.org/10.1016/S0008-8846(03)00090-5

Deng Y, Yue X, Liu S, Chen Y, Zhang D (2015) Hydraulic conductivity of cement-stabilized marine clay with metakaolin and its correlation with pore size distribution. Eng Geol 193:146–152. https://doi.org/10.1016/j.enggeo.2015.04.018

El-Eswed BI, Aldagag OM, Khalili FI (2017) Efficiency and mechanism of stabilization/solidification of Pb(II), Cd(II), Cu(II), Th(IV) and U(VI) in metakaolin based geopolymers. Appl Clay Sci 140:148–156. https://doi.org/10.1016/j.clay.2017.02.003

Ghabezloo S (2001) Improvement of mechanical properties of marl soil using pozzolan. Dissertation, Tarbiat Modarres University, Tehran, Iran, (In Persian)

Ghrici M, Kenai S (2007) Mechanical properties and durability of mortar and concrete containing natural pozzolana and limestone blended cements. Cem Concr Compos 29(7):542–549. https://doi.org/10.1016/j.cemconcomp.2007.04.009

Hossain KMA, Mol L (2011) Some engineering properties of stabilized clayey soils incorporating natural pozzolans and industrial wastes. Constr Build Mater 25(8):3495–3501. https://doi.org/10.1016/j.conbuildmat.2011.03.042

Jedari Salehzadeh (2001) Investigating the effect of pozzolan on the physical and mechanical properties of dispersive clay. Dissertation, Tarbiat Modarres University, Tehran, Iran, (In Persian)

Kolovos KG, Asteris PG, Cotsovos DM, Badogiannis E, Tsivilis S (2013) Mechanical properties of soilcrete mixtures modified with metakaolin. Constr Build Mater 47:1026–1036. https://doi.org/10.1016/j.conbuildmat.2013.06.008

Kolovos KG, Asteris PG, Tsivilis S (2016) Properties of sandcrete mixtures modified with metakaolin. Eur J Environ Civ Eng. https://doi.org/10.1080/19648189.2016.1246690

Pakbaz MS, Farzi M (2015) Comparison of the effect of mixing methods (dry vs. wet) on mechanical and hydraulic properties of treated soil with cement or lime. Appl Clay Sci 105–106:156–169. https://doi.org/10.1016/j.clay.2014.11.040

Qian X, Li Z (2001) The relationships between stress and strain for high-performance concrete with metakaolin. Cem Concr Res 31(11):1607–1611. https://doi.org/10.1016/S0008-8846(01)00612-3

Sudagar A et al (2018) A novel study on the influence of cork waste residue on metakaolin-zeolite based geopolymers. Appl Clay Sci 152:196–210. https://doi.org/10.1016/j.clay.2017.11.013

Wang L, Li X, Cheng Y, Bai X (2018) Effects of coal-metakaolin on the properties of cemented sandy soil and its mechanisms. Constr Build Mater 166:592–600. https://doi.org/10.1016/j.conbuildmat.2018.01.192

Wild S, Khatib JM, Jones A (1996) Relative strength, pozzolanic activity and cement hydration in superplasticised metakaolin concrete. Cem Concr Res 26(10):1537–1544. https://doi.org/10.1016/0008-8846(96)00148-2

Wianglor K, Sinthupinyo S, Piyaworapaiboon M, Chaipanich A (2017) Effect of alkali-activated metakaolin cement on compressive strength of mortars. Appl Clay Sci 141:272–279. https://doi.org/10.1016/j.clay.2017.01.025

Wu Z, Deng Y, Liu S, Liu Q, Chen Y, Zha F (2016) Strength and micro-structure evolution of compacted soils modified by admixtures of cement and metakaolin. Appl Clay Sci 127–128:51–44. https://doi.org/10.1016/j.clay.2016.03.040

Zhang T, Yue X, Deng Y, Zhang D, Liu S (2014) Mechanical behaviour and micro-structure of cement-stabilised marine clay with a metakaolin agent. Constr Build Mater 73:51–57. https://doi.org/10.1016/j.conbuildmat.2014.09.041

Acknowledgements

The authors wish to express their gratitude to Mr. Basir and all the staff of the Iran Khak Laboratory for providing laboratory equipment.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rajabi, A.M., Hamrahi, Z. An experimental study on the influence of metakaolin on mechanical properties of a clayey sand. Bull Eng Geol Environ 80, 7921–7932 (2021). https://doi.org/10.1007/s10064-021-02396-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-021-02396-y