Abstract

Blasting in high in situ stress fields is different from blasting at the earth’s surface because of the dynamic unloading effect in the former. In order to study the coupling of dynamic loading and dynamic unloading in the blasting process, the explicit finite element method and explicit-implicit finite element method are employed respectively to investigate the influence of high stress on blasting effects. The results show that the stress and strain change rules of the two methods are clearly different. The stress and strain change rates calculated by the explicit-implicit algorithm simulation are greater than the results simulated by the explicit finite algorithm. The radius of the blasting cavity calculated by the explicit-implicit finite element method is 0.015 m larger than that of the explicit finite element method. Based on the results of the explicit finite element method, a theoretical model is also established, which helps to clarify the effects of high in situ stress unloading when blasting in a high in situ stress field. The model shows that the maximum tensile radial displacement caused by high in situ stress dynamic unloading at the edge of the blasting cavity is 0.12 mm, and the dynamic unloading radial tensile effect can lead to rock failure. This research illustrates that high stress has a considerable influence on the blasting process and on rock-breaking effects. According to the findings, certain blasting engineering design suggestions are made.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

With development in Western China and the strategy of promoting the Belt and Road Initiative, many deep tunnel engineering and mining projects are being built under high in situ stress. In the deep excavation process, underground engineering works are in high in situ stress fields. These conditions lie at the foundation of improving excavation efficiency in order to control the deformation of rock masses and to prevent engineering disasters such as rock bursts (He et al. 2005; Fan et al. 2016).

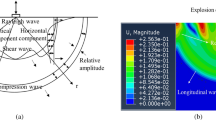

Blasting excavation is a widely adopted technique for breaking rock in many deep mines and tunnels. There are two types of dynamic unloading waves in a rock mass when blasting in a high in situ stress field: blasting unloading waves and high in situ stress unloading waves. Cook et al. (1966) pointed out that the sudden release of a load may lead to tensile stress in a medium. However, no similar evidence has been found to support such a mechanism of super relaxation in blasting engineering in the laboratory. Hagan (1979) pointed out that the strain energy stored in a rock medium around a hole can be released rapidly to form a circumferential crack called an “unloading crack.” Currently, the principal method used to investigate the effects of dynamic loading considers the dynamic unloading process as a function of load and time (i.e., stress path). Miklowitz (1960) first studied the dynamic unloading of a stretched elastic plate with a suddenly punched circular hole based on elastic mechanics and the Laplace transform technique. Carter and Booker (1990) extended the study to demonstrate that gradual excavation induces fewer dynamic effects. Later, there were many studies that analyzed the influence of various in situ stresses, the unloading rate (Li et al. 2014), and the stress path (Guo et al. 2012; Cai 2008; Cantieni and Anagnostou 2009) on dynamic effects (Lucier et al. 2009).

In order to study the effects of coupling between blast loading and dynamic unloading in high in situ stress fields (Karekal et al. 2011; Ning et al. 2011; Abdelmeguid et al. 2003), common methods for numerical simulation of the rock-blasting process include mesh-based methods (such as the finite difference method (FDM) and the finite element method (FEM)) and discrete particle methods (such as the discrete element method (DEM) and hybrid FEM–DEM methods). Lu et al. (2012) proposed an equivalent simulation method to study the transient characteristics of the release process[17]. Furthermore, Hu et al. (2015) provided a numerical simulator capable of reproducing the complete blasting response of a rock mass by incorporating large deformation, damage distribution, and blasting vibration within a single numerical model. Yan et al. (2015) studied the contributions of in situ stress transient redistribution to blasting excavation damage zones in deep tunnels using the dynamic finite element method. Tao et al. (2012) applied LS-DYNA to the unloading process of rocks under three-dimensional (3D) stresses. Tao et al. (2013a, b) also applied implicit and the explicit finite element methods to investigate the unloading process of rocks in a confined state.

In engineering, it is meaningful to identify the difference between blasting in high in situ stress and normal blasting; this can guide applications in real scenarios. However, in terms of research on the mechanism of blasting dynamic unloading, there are two problems to consider in the coupling of blasting loading and dynamic unloading: (1) it is difficult to confine the edge of a blasting cavity, which is a reflecting boundary for unloading stress waves; and (2) it is difficult to confine waves when high in situ stress begins to unload at the end of the blasting loading process. Furthermore, high in situ stress and blasting loads, respectively, are static and dynamic loads, so it is necessary to consider the coupling process between static loading and dynamic unloading. In this paper, the explicit finite element method of LS-DYNA was used to simulate the hard rock blasting process for a single blasting hole. Then, based on the simulation, the influence of the dynamic unloading of high in situ stress on rock fragmentation was studied using a theoretical solution. Finally, the explicit-implicit algorithm in ANSYS Multiphysics/LS-DYNA was used to simulate the coupling process between loading and unloading. The high in situ stress field was generated by the implicit algorithm while the dynamic loading and unloading process were calculated by the explicit algorithm. It is convenient to calculate the coupling of loading and unloading in the blasting process. Based on the results, the unloading mechanism in the blasting process was examined.

Analysis of the blasting process under high in situ stress

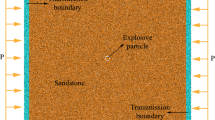

Suppose that a cylindrical blasting hole with a radius of ra is located in an initial geostress field with the vertical principal in situ stress of σv and horizontal principal in situ stress of σH. Rock masses are considered linearly elastic materials, and the calculation model is shown in Fig. 1.

After the initiation detonation of explosives, the rock mass near the explosives is extensively crushed. A blasting cavity with a radius of Ra is formed under the impact of strong shock waves. Meanwhile, there is a solid compression layer formed outside of the explosion cavity. When shock waves are transferred to the edge of the compression zone, the shock wave velocity is decreased to that of an elastic wave or a plastic wave with the wave velocity of Cw. With the spreading of compressive stress waves, radial cracks are formed in the rock mass by the radial stretching effect of stress waves. Then, radial cracks driven by blasting gas lead to the formation of cracked regions. The radius of the blasting cavity increases to R0, as shown in Fig. 2.

The temperature of the blasting gases reach 2000–3000 °C, and their pressure reaches from several tens of thousands of MPa to more than 100,000 MPa. Because of the propagation of cracks and blasting gas heat conduction, a sharp decrease in the pressure of blasting gases in the blasting cavity leads to the rapid release of the elastic energy stored in the rock (Hua and You 2001). An unloading wave with a velocity of C is reflected from the edge of the blasting cavity to the tensile rock. The radial stress is transformed from compressive stress to tensile stress. When the radial tensile stress exceeds the dynamic tensile strength of the rock, circumferential cracks are formed in the rock mass. In this process, because the pressure in the blasting cavity is converted into negative pressure, the in situ stress is also quickly released after a decrease of the pressure in the blasting cavity. At that moment, the radius of the blasting cavity increases to R and the radius of the crack zone increases to Rc, as seen in Fig. 3.

The high in situ unloading waves continue to impact the rock mass, leading to the formation of ring direction cracks and a new damage zone with a radius of Rd. The final cavity radius is R1, as shown in Fig. 4. The energy of the stress waves continues to decay so that only elastic deformation and vibration appear outside of the region of the cracks. Therefore, there are two types of loads that break rock, including blasting loads and dynamic unloading stress waves.

The blasting process and calculation flow chart are shown in Fig. 5. The figure shows that the theoretical solution must calculate the loading and blasting unloading process first. The study of the coupling between dynamic loading and unloading is the key to characterizing the blasting mechanism in deep subsurface detonation (Bastante et al. 2012; Hamdi et al. 2010).

High in situ stress unloading follows the end of the impact effect of the explosive shock waves. The curves of the blasting load and blasting cavity radius versus time are plotted in Fig. 6. When the pressure on the blasting cavity contour σmax decays to a level equal to the in situ stress of the surrounding rock mass, the release of the in situ stress begins. σmax is the initial pressure of detonation gas, q is the redistributed in situ stress of the surrounding rock mass, and ta, t1, and t0 are the rise time of the blasting load, the start time of the release of in situ stress, and the duration of the blasting load, respectively (Lu et al. 2012).

Simulation of the blasting process without high in situ stress

The radius of the blasting hole is 50 mm, which does not correspond to an in situ stress field. The blasting process in this case is a dynamic impact process. DYNA, which originated at the Lawrence Livermore National Laboratory, has been widely used in impact dynamics fields such as blasting engineering, astronautical engineering, vehicle engineering. The blasting process can be simulated using the explicit algorithm of ANSYS-DYNA when taking no account of in situ stress.

The size of the numerical model was 4 m × 4 m, as shown in Fig. 6. Approximately 4000 elements and 8000 nodes were used in the computation.

A kinematic hardening model was applied to the materials model, which is suited to modeling isotropic and kinematic hardening plasticity with the option of including rate effects (LSTC 2010). This is a very cost-effective model and is available for beam, shell, and solid elements. Its parameters are shown in Table 1.

The Jones-Wilkens-Lee (JWL) equation of state was used to model the pressure generated by the expansion of the detonation products of the chemical explosive. It has been widely used in engineering calculations and can be written as (LSTC 2010):

where A, R1, B, R2, and ω are material constants, P is the pressure, V is the relative volume of the detonation product, and E is the specific energy with an initial value of E0. Table 2 gives the JWL parameters for the explosive used. The algorithm of fluid-solid interaction was used to solve the blasting model.

The radial displacement of the nodes versus different detonation distances is plotted in Fig. 7. As shown in Fig. 7, the radial displacement decreased with increased detonation distances. At the edge of the blasting cavity, the peak displacement reached 0.0905 m. Tangential displacement of the nodes versus different detonation distances is plotted in Fig. 8. The tangential displacement is tension displacement. The maximum tangential displacement was −0.0065 m at the edge of the blasting cavity. At double and triple the distance of the blasting cavity, the maximum tangential displacements were, respectively, −0.0019 m and −0.0012 m. This indicated that the tangential displacement clearly decreased followed by an increase of the detonation distance. According to the results of these two graphs, the duration of blasting loading was about 1 s.

The fringe of effective stress at 1 ms is plotted in Fig. 9, where the radius of the blasting cavity without considering high in situ stress was 0.17 m. The maximum effective stress was 533.5 MPa. Fig. 10 shows that the maximum plane displace was 1.217 cm. The results also show that the strongest tangential tensile effect was at the edge of the blasting cavity. The weakening extent of the tensile effect enlarged with increasing distance from the blast center.

Theoretical model and solution

Because high in situ stresses are quickly unloaded near the free surface of a blasting cavity, it is necessary to determine the radius of the blasting cavity before using the theoretical model to obtain a solution. “Analysis of the blasting process under high in situ stress” section showed that radius of the blasting cavity is 0.34 m at the end of the blasting loading. Notably, the theoretical solution needs to replace the original material as an elastic material.

Suppose that the blasting hole is subjected to uniform in situ stress q (σv = σH = q = 20 MPa) which is typically the stress at a depth of 800 m. The differential equation for the equilibrium of a circular blast hole in polar coordinates based on the elastic dynamic theory can be written as follows:

This equation holds for plane strain problems in which u is the radial displacement and σr and σθ are the radial and tangential components of stress applied to the edge of the blasting cavity, respectively. ρ is the density of the rock mass and u is the radial displacement. Second-order partial differential equations require at least two initial conditions:

Various unloading paths differ in their boundary conditions, which can be described as follows:

where t0 is the unloading time. The physical equation given by the generalized Hooke’s law can be described as follows:

where λand μ are the Lamé parameter and the shear modulus of the rock mass, respectively. Substituting (6) and (7) into (2) gives the governing equation:

in which C is the propagation speed of the P-wave through the rock mass, which is defined as follows:

The Laplace transform and its inverse solution can serve as a mathematical tool for solving such problems. Subject to the initial condition in (2), the governing equation in (7) is transformed into the following (Carter and Booker 1990):

where \( \overline{u} \) is the transform of u and s is the transformation parameter, which can be described as follows:

In the case of (7), the general solution is given by:

where I1 and K1 are modified Bessel functions of the first and second kinds, respectively. Consider that the initial condition sets A equal to 0. Substituting (4) into (5) and (11) gives the constant B as:

Because obtaining a theoretical solution is difficult, the Talbot algorithm (Talbot 1979; Cohen 2007; Cao et al. 2016) was applied to the numerical inversion.

The maximum tensile radial stress σrt and the maximum tensile radial train urt are expressed as:

where σrq and urq are the static radial stress and the static radial displacement, respectively. Those can be calculated based on elastic mechanics theory.

Based on the results of the explicit finite element simulation regarding the radius of the blasting cavity without considering high in situ stress, the theoretical solution of a columnar cavity loaded with an instantaneous load in an elastic medium was calculated. A three-dimensional contour map of the variations in σr and σθ with t and r is shown in Fig. 11. According to Fig. 11, the maximum σr and σθ were achieved at approximately 1.0 ms. Their curves at R, 2R, and 3R are respectively shown in Figs. 12 and 13. Fig. 12 illustrates that the radial stress is tensile stress. Unloading velocity decreased successively with increasing distance from the edge of the blasting cavity. Based on Eq. (14), the maximum value of tensile radial stress reach to 0.142q. Fig. 13 shows that the tangential stress is converted to compressive stress.

As shown in Fig. 14, the maximum radial displacement was 0.714 mm. The curves of u at different detonation distances are plotted in Fig. 15. Based on (14), The maximum radial tensile displacement at the edge of the blasting cavity was 0.12 mm, indicating that the radial displacement caused by dynamic unloading was relatively small. However, it may also lead to the failure of some of the hard rock mass because of tensile effects. Through the theoretical solution, we can obtain the stress and strain variation during high in situ stress unloading. This provides a basis for understanding the evolution of the high in situ stress unloading response in blasting processes. However, the disadvantage of this approach is that it cannot fully consider coupling with the blasting process.

Numerical model implementation

When the theoretical solution is used to calculate the dynamic unloading, it is necessary to calculate the radius of the blasting cavity first. This means that the blasting process and dynamic unloading process are separate, so this approach cannot accurately describe the dynamic loading and unloading coupling process in high in situ stress fields. Rock mass blasting in high in situ stress fields is a static-dynamic coupled loading and unloading process which can be simulated using the explicit-implicit algorithm in ANSYS Multiphysics/LS-DYNA (Tao et al. 2012). The simulation steps are as follows:

-

Step 1.

The element type was defined. In this case, Solid 185 was used for the element type. Then the material model was defined and material parameters were set.

-

Step 2.

20 MPa pressure was applied on the boundary of the model, and then the static stress field model was solved.

-

Step 3.

The distribution of stress and strain surrounding the blasting hole in high in situ stress were obtained by implicit solution. The strain information was deleted and the stress calculation results were saved.

-

Step 4.

The element type was changed from implicit to explicit. Parts were created and a no-reflection boundary was applied at the edge of the model. The .rst file was loaded in order to create the dynamic relaxation file.

-

Step 5.

The K file was exported and material parameters were modified. The algorithm for fluid-solid interaction was used to solve the model. The parameters of the explosive were modified as shown in Table 1. Finally, the K file was solved by the implicit-explicit sequential LS-DYNA solver.

The fringe of effective stress at 1 ms is plotted in Fig. 16, which shows that the radius of the blasting cavity was 0.185 m. It increased by 0.015 m compared with the result in “Analysis of the blasting process under high in situ stress” section. The fringe of plastic displacement at 1 ms is plotted in Fig. 17, which shows that the maximum plastic displacement was 1.248 cm.

Figs. 18 and 19 also show that high in situ stress unloading and blasting load unloading are not two separate processes, but that they work together. Compared with the theoretical solution, the explicit-implicit algorithm does not need to re-establish the failure criterion in order to calculate the damage region during the loading and unloading process. Compared with the explicit finite element results, the change rules for stress and strain are different. The stress and strain change rates caused by dynamic unloading were clearly greater. It can be concluded that the blasting process in high in situ stress is different from ordinary blasting.

In hard rock blasting engineering, the radius of the cracked region is much larger when the radius of the blasting cavity is much larger because the dynamic unloading effect can improve the effect of the tension in breaking rock. This means that a higher level of explosives, larger blasting hole size, and larger compensation space are required in order to obtain a better cutting blasting effect than in ordinary blasting design. In order to reduce the disturbance of the surrounding rock, controlled blasting must use detonators with a larger segment number. The unloading of high in situ stress occurred after the blasting and unloading, but presplitting blasting can create high in situ stress ahead of the blasting loading in the main blasting zone. The specific engineering applications of this effect are worth further research.

Conclusion

In the present study, a theoretical analysis method and the explicit-implicit finite element method were used to simulate dynamic unloading in high in situ stress. The analytical solution showed that the maximum radial tensile displacement at the edge of the blasting cavity was 0.12 mm, which indicates that the radial tensile displacement caused by high in situ stress dynamic unloading is relatively small. The maximum value of tensile radial stress reach to 0.142q. However, it may nevertheless lead to the failure of some hard rock masses because of tensile effects. The radius of the blasting cavity calculated by the explicit-implicit finite element method increased 0.015 m more than the result calculated by the explicit finite element method. Compared with the explicit finite element results, the change rules of stress and strain were different. The stress and strain change rates in the explicit-implicit algorithm simulation were greater than the results simulated by the explicit finite algorithm. This illustrates that high in situ stress has a marked impact on the blasting process and rock-breaking effects. The results also demonstrated that high in situ stress unloading and blast loading are not two separate processes; instead, they work together such that dynamic unloading has a prominent effect. This study can contribute to the optimal selection of an appropriate blasting method.

References

Abdelmeguid M, Rowe RK, Lo KY (2003) Three-dimensional analysis of unlined tunnels in rock subjected to high horizontal stress. Can Geotech J 40(6):1208–1224

Bastante FG, Alejano L, González-Cao J (2012) Predicting the extent of blast-induced damage in rock masses. Int J Rock Mech Min 56(2):44–53

Cai M (2008) Influence of stress path on tunnel excavation response-numerical tool selection and modeling strategy. Tunn Undergr Space Technol 23(6):618–628

Cantieni L, Anagnostou G (2009) The effect of the stress path on squeezing behavior in tunneling[J]. Rock Mech Rock Eng 42(2):289–318

Cao W, Li X, Tao M, Zhou Z (2016) Vibrations induced by high initial stress release during underground excavations. Tunn Undergr Space Technol 53:78–95

Carter JP, Booker JR (1990) Sudden excavation of a long circular tunnel in elastic ground. Int J Rock Mech Min Sci Geomech Abstr 27(2):129–132

Cohen, AM (2007) Numerical methods for Laplace transform inversion. Springer

Cook MA, Cook UD, Clay RB (1966) Behavior of rock during blasting. 10:17–25

Fan Y, Lu W, Zhou Y (2016) Influence of tunneling methods on the strainburst characteristics during the excavation of deep rock masses. Eng Geol 201:85–95

Guo Y, Yang C, Mao H (2012) Mechanical properties of Jintan mine rock salt under complex stress paths. Int J Rock Mech Min Sci 56(12):54–61

Hagan TN (1979) Rock breakage by explosives. Acta Astronaut 6(3):329–340

Hamdi E, Romdhane NB, Lecléach JM (2010) A tensile damage model for rocks: application to blast induced damage assessment. Comput Geotech 38(5):133–141

He M, Xie H, Peng S, Jiang Y (2005) Study on rock mechanics in deep mining engineering. Chin J Rock Mech Eng 24(16):2083–2013 (in Chinese)

Hu Y, Lu W, Chen M, Yan P, Zhang Y (2015) Numerical simulation of the complete rock blasting response by SPH–DAM–FEM approach. Simul Model Pract Theory 56:55–68

Hua A, You M (2001) Rock failure due to energy release during unloading and application to underground rock burst control. Tunn Undergr Space Technol 16(3):241–246

Karekal S, Das R, Mosse L, Cleary PW (2011) Application of a mesh-free continuum method for simulation of rockcaving processes. Int J Rock Mech Min 48(2):703–711

Li X, Cao W, Zhou Z, Zou Y (2014) Influence of stress path on excavation unloading response. Tunn Undergr Space Technol 42(42):237–246

LSTC (2010) LS-DYNA keyword user’s manual, version 970. Livermore Software Technology Corporation, Livermore

Lu W, Yang J, Yan P, Chen M (2012) Dynamic response of rock mass induced by the transient release of in-situ stress. Int J Rock Mech Min Sci 53(9):129–141

Lucier AM, Zoback MD, Heesakkers V, Reches Z, Murphyd SK (2009) Constraining the far-field in situ stress state near a deep south African gold mine. Int J Rock Mech Min Sci 46(3):555–567

Miklowitz J (1960) Plane-stress unloading waves emanating from a suddenly punched hole in a stretched elastic plate. J Appl Mech 27(4):165

Ning Y, Yang J, Ma G, Chen P (2011) Modelling rock blasting considering explosion gas penetration using discontinuous deformation analysis. Rock Mech Rock Eng 44(1):483–490

Talbot A (1979) The accurate numerical inversion of Laplace transforms. IMA J Appl Math 23(1):97–120

Tao M, Li X, Wu C (2012) Characteristics of the unloading process of rocks under high initial stress. Comput Geotech 45(9):83–92

Tao M, Li X, Li D (2013a) Rock failure induced by dynamic unloading under 3D stress state. Theor Appl Fract Mech 65(3):47–54

Tao M, Li X, Wu C (2013b) 3D numerical model for dynamic loading-induced multiple fracture zones around underground cavity faces. Comput Geotech 54(10):33–45

Yan P, Lu W, Chen M, Hu Y, Zhuo C, Wu Z (2015) Contributions of in-situ stress transient redistribution to Blasting excavation damage zone of deep tunnels. Rock Mech Rock Eng 48(2):715–726

Acknowledgments

First of all, the authors give sincere acknowledgement to CAS Pioneer Hundred Talents Program for the completion of this research. The research presented in this paper was also jointly supported by the National Natural Science Foundation of China (Grant No. 41502334) and the 973 Program of China (Grant No. 51278397). The authors wish to acknowledge these financial contributions and convey their appreciation of these organizations for supporting this basic research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xiao, SY., Su, LJ., Jiang, YJ. et al. Numerical analysis of hard rock blasting unloading effects in high in situ stress fields. Bull Eng Geol Environ 78, 867–875 (2019). https://doi.org/10.1007/s10064-017-1067-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-017-1067-7