Abstract

The stability of rock slopes is an important area of interest in civil and mining engineering. This study investigated rockfall occurring around the Gökgöl tunnel along the Zonguldak-Ankara roadway. Extensive field studies, including determination of geological description of the rock mass, scan-line surveys on discontinuities, identification of slope profiles, measurement of actual fallen block dimensions, and sampling procedures, were carried out. The study area and its surroundings are part of a Lower Carboniferous limestone formation. The assessments based on field studies indicated that two joint sets and a bedding plane were the main types of discontinuity. Two slope profiles were then created by considering the most frequently encountered rock fall events. The present study aimed to investigate the rockfall potential in this area by means of numerical analyses. For this purpose, RocFall software based on the lumped-mass method was utilized. Based on these analyses, traffic safety is threatened by potential rockfall. In Case I, a 30 % portion of the falling blocks reached the side of the main road, while about 70 % of them remained on the slope. However, falling blocks reached the end of the road in Case II. The study area requires some protection measures, such as the construction of retaining barriers and steel mesh to hold small size rock blocks. As a result, barrier heights to hold falling blocks were calculated as 0.5 m and 4 m for Case I and Case II, respectively. Barrier heights sufficient to hold falling rocks were determined using numerical analysis. In Case II, from such analyses, the energy required for a protection barrier for 1000 kg was found to be 200 kJ.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Rockfall is a widespread phenomenon in rock cuts for highways and railways in mountainous areas (Whalley 1984; Selby 1993; Erismann and Abele 2001). Rockfall is a relatively small landslide, including the removal of individual and irregular rocks from a steep face (Selby 1982). Rockfall occurs when a single rock, boulder or a small group of independently moving rocks, becomes extracted from a submitted face or slope and moves downwards by means of some combination of sliding, rolling, bouncing or free fall under the effect of gravity. Essentially, rockfall is a phenomenon influenced mainly by processes that are active near the surface, generally resulting in very rapid movement (Ritchie 1963; Bjerrum and Jørstad 1968).

The factors causing and affecting rockfall can be divided into three categories: structural, environmental and man-made (Fig. 1). Rockfall behaviour is influenced chiefly by slope geometry, rock geometry and material properties (Ritchie 1963; Ashfield 2001). First of all, structural factors involve rock properties, as well as slope and rock geometry. Secondly, environmental factors involve physical and chemical weathering, freeze–thaw, water effects, earthquake, and tree roots (Chen et al. 1994; Wasowski and Gaudio 2000; Ashfield 2001; Marzorati et al. 2002; Dorren 2003). Environmental factors generally act as triggering forces but may also influence the structure and cause instability. Man-made factors constitute the third category, and involve vibration due to blasting and operating of construction plant and machinery, the process of excavation itself, and passing traffic, all of which can effectively trigger rockfall (Ashfield 2001).

Causes of, and factors affecting, rockfall (modified from Ashfield 2001)

The size of rock involved in a rockfall can range from gravel to huge blocks with masses of hundreds of tonnes (Spang 1987), and there is no generally accepted size of rock in a rockfall (Ashfield 2001). Therefore, characterization of contributing factors to rockfall initiation becomes important and should be elaborately investigated (Binal and Ercanoğlu 2010). Empirical/experimental techniques or modelling can be used for rockfall analysis (Giani 1992; Evans and Hungr 1993; Okura et al. 2000; Pierson et al. 2001; Ulusay et al. 2006). Two-dimensional (2D) computer modelling for rockfall analysis can be used to predict block trajectory, travel distance, velocity, bounce height and kinetic energy of the blocks (Schweigl et al. 2003). Various rockfall-related parameters, such as fall-out distance, bounce height, kinetic energy, and rock velocity along each section were simulated using RocFall 4.0 software (Rocscience 2012).

During the last decade, rockfalls occurring on the steep slopes located between the Gökgöl tunnel portal and the Gökgöl Cave entrance have caused serious damage to traffic passage and delayed traffic on the road (Fig. 2). Especially in recent years, many rockfall problems have been encountered along the Gökgöl tunnel road. To evaluate rockfall risk in the study area, an investigation was conducted in three stages comprising in situ rock mass characterisation, laboratory geomechanical tests, and analyses. The site was described by detailed discontinuity measurements to determine possible detached rock blocks dimensions. Block trajectory, run-out distance, bounce height, kinetic energy and velocity of the blocks were analyzed using 2D rockfall analyses, including two different slope profiles. Finally, additional analyses including barriers for protection against rockfall were performed, and the capacity of proposed precautions is discussed.

Methods

Geology of the study area

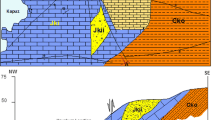

The study area is located between the Gökgöl Tunnel portal and Gökgöl Cave entrance near to the Zonguldak-Ankara roadway (Fig. 3). The study area and its surroundings are part of a Lower Carboniferous limestone formation near the contact of the Alacaağzı formation, which forms Zonguldak Carboniferous and Lower Carboniferous (Visean) aged Yılanlı formation. The Alacaağzı formation consists of interbedded claystone, siltstone and sandstone, and it is impermeable. The lithostratigraphic properties of the Visean limestone are favourable for karst processes and cave development (Fig. 4). This marly and chalky limestone base has an increasing proportion of dolomite towards the top, which is dominated by CaCO3 (Nazik et al. 1995). The cave known as Gökgöl has a total length of 3350 m with a 875 m section open to the public. Some stability problems encountered in the cave have been studied in detail by Geniş and Çolak (2015).

Geological map around the study area (modified from Özler et al. 1992)

In situ rock mass characterization

Discontinuity orientation measurements were taken around study area, in order to determine the strike and dip of the bedding planes and joint sets. For this purpose, a total of 213 measurements was taken on bedding planes and joint set to locate the surface perpendicular to bedding, and random measurements were taken on the road cut. Contour and rose diagrams showing the lower hemisphere using the steore-net projection technique were prepared in order to determine the discontinuity orientation based on geological data. Joints and bedding were the main discontinuity types observed in rock mass. The strike of layers has an east–west direction and a dip to the North. Beds dip at about 52°, while dips of the joints range between 41° and 76°. The contour diagrams of the discontinuities obtained from the limestone suggest two dominant joint sets (dip/dip direction): 76/104 and 41/212 and bedding plane (52/359) (Fig. 5).

a Contour diagram and b rose diagram of measurements taken from discontinuity planes (modified from Geniş and Çolak 2015)

To determine block sizes of the discontinuities, the volumetric joint count (J v) was calculated, as specified in ISRM (2007). For this purpose, line surveys were conducted for every single joint set and bedding plane as given in Table 1. The J v is a relative expression of block size and expresses the total number of discontinuities observed in a rock mass per unit volume. The discontinuities in the study area were defined as small blocks based on J v (i.e. J v = 11.5 joint/m3) (ISRM 2007).

The joints are closely spaced, ranging from 20 cm to 60 cm, persistent, and their surfaces are slightly rough or rough. The apertures of discontinuities are 5 mm in width filled by calcite and soft infill material. The filling condition of apertures is unaltered and slightly altered. Regarding water conditions, no water or seepage was observed on the joints. It was found that average block size was 0.21 m3; however, there were some blocks of up to 1 m3. The variations of the discontinuity spacing showed in Fig. 6.

Geomechanical properties of limestone and discontinuities

Strength and deformation tests were performed according to methods suggested by International Society for Rock Mechanics (ISRM 2007) in BEÜ Mining Engineering Department, on rock samples collected from the road cut (Table 2) (Çolak 2012).

In order to determine the cohesion and internal friction angle of intact rock, tri-axial compression tests suggested by ISRM (2007) were performed. Cohesion and internal friction angle of intact rock were determined as 19.8 MPa and 38°, respectively, by applying lateral pressure values changing between 10 and 40 MPa on 14 limestone samples (Çolak 2012).

The roughness of the discontinuity planes was measured through a pin-type profiler to determine the joint roughness coefficient (JRC). According to these measurements, the roughness of the discontinuity surfaces varies between 2 mm and 3 mm. These measurements were compared with those measured by the roughness profiles suggested by ISRM (2007). The JRC value was determined as between 4 and 8.

A tilting test was conducted at the Rock Mechanics Laboratory of Tokai University, Japan, (Aydan 2011) to determine the basic friction angle between limestone blocks. Tilting amount and movement of blocks were measured using sensitive laser meters (Fig. 7). Friction angles of the bedding plane were determined as minimum 38° and maximum 50°. Average basic friction angle was identified as 44° and used as an input parameter in numerical analysis.

Rockfall analysis

In recent years, rockfall parameters, i.e. block orientation, fall out distances, velocity, bounce heights and kinetic energy, have been analyzed using 2D and 3D computer software. Within this concept, numerous studies have been presented by various researchers (Ashfield 2001; Schweigl et al. 2003; Crosta and Agliardi 2004; Ulusay et al. 2006; Yılmaz et al. 2008; Binal and Ercanoğlu 2010; Saroglou et al. 2012; Keskin 2013). In this study, to evaluate potential rockfall incidents, two different slope profiles (Cases I and II) close to the Gökgöl Tunnel portals were analyzed in 2D by using RocFall (version 4.0) (Fig. 8). This software performs statistical analyses of rockfalls based on the lumped-mass method, considering the mass of a boulder to be a simple point moving through the air along a trajectory with x and y coordinates (Akın et al. 2014).

Slope profiles were created regarding the locations of the hanging blocks and slope angles. Rock blocks, which have a potential for falling or bouncing onto the road from the slope surface, are restricted with joints and bedding plane. In this study, weights of possible blocks have been calculated depending on the block sizes and the average density of limestone. Thus, block weights of 10 kg, 100 kg and 1000 kg were used for rockfall analyses. Initial velocities of these blocks were taken to be 0 m/s in both the vertical and horizontal direction because of the slope geometry and block orientation.

The coefficient of restitution is one of the most important parameters in rockfall analysis, and is commonly found in the literature for various strata conditions. Also, this parameter can be determined from real rockfall tests in the field (Schweigl et al. 2003; Ulusay et al. 2006). The coefficiency of restitution is defined with normal (R n) and tangential (R t) components. Restitution parameters are not constant, and depend on particle velocities, geometry and rock mass, etc. (Goldsmith 1952; Peng 2000). In this study, the coefficient of restitution parameters with normal and tangential direction was determined from back analysis in RocFall (v.4.0) software of Rocscience (2012). Six already fallen blocks of different sizes were identified in the study area. The number of falling rock blocks, whose volume is more than 0.5 m3, varies between three and ten in a year. Some samples of fallen blocks are shown in Fig. 9.

Different Rt values and corresponding Rn values related to the fallen blocks are shown in Fig. 10. The normal and tangential coefficients of restitution of the limestone blocks were assigned as 0.230 ± 0.101 and 0.669 ± 0.099, respectively, by taking the average values of these curves. In rockfall analysis, throwing block numbers were received as 1000, similar to previous studies (Ulusay et al. 2006; Topal et al. 2007; Binal and Ercanoğlu 2010). Selected input parameters for the analyses are given in Table 3.

Results and discussion

Rockfall trajectories of two different slope profiles and three different weight conditions of each case are given in Fig. 11. The output of analysis for each different case is given Table 4. Also, detailed analyses of each output (location of rock end points, bounce heights, total kinetic energy and velocity envelopes) are shown in Figs. 12 and 13.

Analysis results for each case are shown in Table 4. According to the result of the analysis, existing traffic on the main road might be affected by falling blocks. In Case I, 30 % of falling blocks reached the side of the main road, while about 70 % of them remained on the slope. However, the falling blocks reached the end of the road in Case II. This is because the Case II slope gradient is higher than that of Case I.

The bounce height of the blocks depends on the surface topography, slope face angle, block shape and initial velocity given for the simulation (Youssef et al. 2015). Bounce heights of fallen blocks were determined separately for each slope profile. In this study, values for the maximum bounce heights for Cases I and II were found 3.5 m and 9.7 m, respectively.

The number of rocks for Case I is greater than one because of the fact that the slope geometry has different dip conditions. That is why the kinetic energies of falling blocks along the profile peaked several times. These energies and velocities decrease after each impact along the slope. Minimum and maximum kinetic energy values proportional to the mass and velocity of the blocks were determined as 0.02 kJ and 97 kJ, respectively. On the other hand, the observed values regarding kinetic energy and velocity for Case II are higher than those of Case I because the slope geometry is steep and hanging blocks are free to fall down the slope surface. For Case II, kinetic energy values were determined as being between 0.03 kJ and 219 kJ.

Kinetic energy is the most important parameter defining the intensity of any rockfall problem. Rockfall degrees of falling blocks are classified into three categories—high, medium and low—with respect to their kinetic energy magnitude. In this scope, values were classified as follows: values greater than 300 kJ are “high” degree, values between 30 kJ and 300 kJ are “medium” degree, and values smaller than 30 kJ are “low” degree. According to the rockfall classification of Perret et al. (2004), rockfall kinematic values tested numerically can be determined as “low” and “medium” degree for this study. In the case of “low” and “medium” degree of rockfall kinematics, roads can be damaged and interrupted for short periods of time. Even small stones can be very dangerous in terms of the effects of rockfall on roads; a vehicle may either be hit directly by a falling stone or it can crash into a block lying on the road (Perret et al. 2004).

To prevent or minimize the movement of the rock blocks, several techniques (rock bolts, barriers, shotcrete, mesh, tunnels, trimming etc.) have been used. In this study, barrier options were considered in rock fall analysis to protect from rockfall events. Rockfall analysis for each case was computed with a barrier protection and these calculations were based on non-elastic barriers for the worst conditions and also protection barriers placed near the road. The barrier height for Case I was taken as 0.5 m, and was 4 m for Case II. The analysis carried out resulted in the finding that barrier heights considered for each case are enough to prevent the falling blocks from reaching the road. Rockfall trajectories of the cases with barrier protection are shown in Fig. 14.

Conclusions

This study investigated the rockfall problems experienced frequently on slopes along the main Zonguldak–Ankara road. The study area is restricted to between the Gökgöl tunnel and Gökgöl cave. First of all, the dimensions of fallen rock blocks and falling profiles in the field were observed and recorded over 4 years. In the study area, rockfall events increased during the period of seasonal rainfall. As a result of discontinuity measurements on the slope surface, rock mass average block sizes vary between 0.21 m3 and 1 m3. The results of field and laboratory studies and numerical analysis of investigation sites are as follows:

The slope profiles of the surfaces in the region where rockfall event frequently occurs were determined. Thus, in the studied area, two slope profiles were drawn and the profiles with rockfall problems were identified as Case I and Case II. Discontinuities on the slope surface were measured, and then the size of the rock blocks with the potential to fall was determined. Block weights along the surveyed slope surface were designated as 10 kg, 100 kg and 1000 kg based on block sizes.

The study area and rockfall conditions were modelled with Rockfall v4.0 and analyzed. As a result of these analyses, the maximum velocities of the limestone blocks were found to be between 0.36 m/s and 20.05 m/s. In addition, the bounce heights were determined to be between 0.01 m and 10.03 m, and the horizontal location to rock end point was determined as 5.78–28.71 m. The result of the analysis reveals the danger to the safety of existing main road traffic.

The investigated slope is located near Gökgöl Cave, which is open for public visitation in Zonguldak. Reducing the slope gradient in the investigated area may be implemented but the negative influence on cave stability needs to be taken into consideration. Therefore, it seems impossible to change the road slope geometry. In this paper, barrier options were considered for the prevention of rockfall hazard.

Rockfall analyses were repeated for the protection barrier height calculations based on non-elastic barriers located at the edge of the road. Barrier heights to hold falling blocks were calculated as 0.5 and 4 m for Case I and Case II, respectively. According to our results, the barrier height for Case II is higher than that needed for Case I because of the high slope gradient and hanging blocks on the rock surface. As the worst of the two conditions of studied slope profiles, the capacity energy of barriers for Case II were calculated as 200 kJ for 1000 kg of falling blocks. In addition, covering the slope surface with steel mesh, which muffles the kinetic energy of the falling rock blocks should be considered.

References

Akın M, Topal T, Akın MA (2014) The rockfall potential of the southwestern part of Kastamonu Castle (Turkey) based on 2-D and 3-D analyses. In: Sassa K et al (eds) Landslide Science for a Safer Geoenvironment, vol 3. Springer, Basel, pp 123–127

Ashfield JR (2001) The computer simulation and prediction of rock fall. PhD Thesis, Durham University. http://etheses.dur.ac.uk/4383/

Aydan Ö (2011) Personal communication. (Formerly with Tokai University, Shizuoka, Japan; Presently the University of Ryukyus, Nishihara, Japan) Ocean Research Institute

Binal A, Ercanoğlu M (2010) Assessment of rockfall potential in the Kula (Manisa, Turkey) Geopark Region. Environ Earth Sci 61:1361–1373

Bjerrum L, Jørstad F (1968) Stability of rock slopes in Norway. Norwegian Geotechnical Institute 79:1–11

Chen H, Chen RH, Huang TH (1994) An application of an analytical model to a slope subject to rockfalls. Bull Assoc Eng Geol 31(4):447–458

Çolak B (2012) Assessment of the Gökgöl cave stability with analytical and numerical analysis methods. Bülent Ecevit University, Graduate School of Natural and Applied Sciences, M.Sc. Thesis, Zonguldak, Turkey, p 185

Crosta GB, Agliardi F (2004) Agliardi. Parametric evaluation of 3D dispersion of rockfall trajectories. Nat Haz Earth Sys Sci 4(4):583–598

Dorren LKA (2003) A review of rockfall mechanics and modelling approaches. Prog Phys Geogr 27(1):69–87

Erismann TH, Abele G (2001) Dynamics of rockslides and rockfalls. Springer, New York

Evans SG, Hungr O (1993) The assessment of rockfall hazard at the base of talus slopes. Can Geotech J 30:620–636

Geniş M, Çolak B (2015) Stability assessment of the Gökgöl karstic cave (Zonguldak, Turkey) by analytical and numerical methods. Rock Mech Rock Eng 48(6):2383–2403

Giani GP (1992) Rock slope stability analysis. Taylor & Francis, Balkema

Goldsmith W (1952) The coefficient of restitution. Bull Mech Div Am Soc Eng Educ 2:10–13

ISRM (2007) The complete ISRM suggested methods for rock characterization, testing and monitoring: 1974–2006. In: Ulusay R, Hudson JA (eds.), Suggested Methods Prepared by the ISRM Commission on Testing Methods, Compilation Arranged by the ISRM Turkish National Group. Kozan Ofset, Ankara, p 628

Keskin İ (2013) Evaluation of rock falls in an urban area: the case of Boǧaziçi (Erzincan/Turkey). Environ Earth Sci 70:1619–1628

Marzorati S, Luzi L, Amicis MD (2002) Rock falls Induced by earthquakes: a statistical approach. Soil Dyn Earthq Eng 22(7):565–577

Nazik L, Mengi H, Özel E, Bircan A, Beydeş S (1995) Natural caves around Zonguldak (in Turkish). Mineral Research and Exploration General Directorate of Turkey (MTA), Report No:9764, Ankara

Okura Y, Kitahara H, Sammori T, Kawanami A (2000) The effects of rockfall volume on runout distance. Eng Geol 58:109–124

Özler I, Tongal O, Canca N, Kır N, Yaver Y, Bakan Z (1992) Geology and coal occurance of Zonguldak district between Değirmenağzı and Göbü (in Turkish). Mineral Research and Exploration General Directorate of Turkey (MTA), Report No:9599, 1, Ankara

Peng B (2000) Rockfall trajectory analysis—parameter determination and application. MSc Thesis, University of Canterbury, p 199

Perret S, Dolf F, Kienholz H (2004) Rockfalls into forests: analysis and simulation of rockfall trajectories—considerations with respect to mountainous forests in Switzerland. Landslides 1:123–130

Pierson LA, Gullixson CF, Chassie RG (2001) Rockfall Catchment Area Design Guide. Final report for Oregon Department of Transportation—Research Group & FHWA, SPR-3(032), p 77

Ritchie AM (1963) Evaluation of rock fall and its control. In: Highway Research Record 17, HRB, National Research Council, Washington, DC, pp 13–28

Rocscience (2012) ROCFALL-computer program for risk analysis of falling rocks on steep slopes. Version 4.0 Toronto, Canada, https://www.rocscience.com

Saroglou H, Marinos V, Marinos P, Tsiambaos G (2012) Rockfall hazard and risk assessment: an example from a high promontory at the historical site of Monemvasia, Greece. Nat Haz Earth System Sci 12(6):1823–1836

Schweigl J, Ferretti C, Nössing L (2003) Geotechnical characterization and rockfall simulation of a slope: a practical case study from South Tyrol (Italy). Eng Geol 67:281–296

Selby MJ (1982) Controls on the stability and inclinations of hillslopes formed on hard rock. Earth Surf Proc Land 7:449–467

Selby MJ (1993) Hillslope materials and processes, 2nd edn. Oxford University Press, New York

Spang RM (1987) Protection against rockfall—Stepchild in the design of rock slopes, 6th International Congress on Rock Mechanics, International Society for Rock Mechanics, pp 551–557

Topal T, Akin M, Ozden Utku A (2007) Assessment of rockfall hazard around Afyon Castle, Turkey. Environ Geol 53(1):191–200

Ulusay R, Gokceoglu C, Topal T, Sonmez H, Tuncay E, Erguler ZA, Kasmer O (2006) Assessment of environmental and engineering geological problems for the possible re-use of an abandoned rock-hewn settlement in Urgüp (Cappadocia), Turkey. Environ Geol 50:473–494

Wasowski J, Gaudio VD (2000) Evaluating seismically induced mass movement hazard in Caramanico Terme (Italy). Eng Geol 58(3):291–311

Whalley WB (1984) Rockfalls. In: Brunsden D, Prior DD (eds) Slope instability, chapter 7. Wiley, New York, pp 217–256

Yılmaz I, Yıldırım M, Keskin İ (2008) A method for mapping the spatial distribution of Rockfall computer program analyses resuts using ArcGIS software. Bull Eng Geol Environ 67:547–554

Youssef AM, Pradhan B, Al-Kathery M, Bathrellos GD, Skilodimou HD (2015) Assessment of rockfall hazard at Al-Noor Mountain, Makkah city (Saudi Arabia) using spatio-temporal remote sensing data and field investigation. J Afr Earth Sci 101:309–321

Acknowledgments

The authors wish to express their deep gratitude to Prof. Ömer Aydan (University of the Ryukyus, Japan) for laboratory studies, and to the editor and two anonymous reviewers for their constructive comments to improve the manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Geniş, M., Sakız, U. & Çolak Aydıner, B. A stability assessment of the rockfall problem around the Gökgöl Tunnel (Zonguldak, Turkey). Bull Eng Geol Environ 76, 1237–1248 (2017). https://doi.org/10.1007/s10064-016-0907-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-016-0907-1