Abstract

The United States Bureau of Reclamation (USBR) formula was derived from a table presenting values of hydraulic conductivity as a function of grain size, K = f(d20). The original table was empirically designed as a sequence of variation of different permeability coefficients of deposits and was intended for the design of earth dams, for the purpose of assessing leakage where percolation tests are not available. The USBR formula has since been used for predicting the hydraulic conductivity of water-bearing uniform sand deposits but systematically derives values of hydraulic conductivity several times lower than realistic values for materials. In this article, the optimal analytical formulation of the series of original data for K = f(d20) from Justin et al. (1945) is presented. Additionally, through calibration using results of hydrogeological research in Croatia, Germany, China and Nigeria, a formula (named USCRO) for predicting the permeability of sediments over a wide range of uniformity and d20 grain size was derived. The validity of this function for expressing permeability and the utilization of relative nondimensional coefficients is examined through a graphical correlation of the permeability of uniform and especially well-graded materials. Samples of poorly graded sand (63) and well-graded sandy gravel (131) were included in the calibration procedure. Data for mechanical analyses were taken from published articles. The numerical correlation of the USCRO formula for uniform sand samples resulted in a Pearson correlation coefficient of R2 = 0.902; for the well-graded sandy gravel, R2 = 0.838. Justin JD, Hinds J, Creager WP (1945) Engineering for Dams (Vol III), John Wiley & Sons.

Résumé

La formule du Bureau des Réhabilitations des Etats-Unis d’Amérique (USBR) a été déduite d’un tableau des valeurs de conductivité hydraulique en tant que fonction de la granulométrie, K = f(d20). Le tableau original a été conçu empiriquement comme une séquence de variation des différents coefficients de conductivité hydraulique des dépôts et était destiné à la conception de barrages de terre, dans le but d’évaluer les fuites lorsque des tests de percolation ne sont pas disponibles. La formule de l’USBR a été depuis utilisé pour déterminer la conductivité hydraulique de dépôts de sable uniforme saturé en eau, mais les valeurs de conductivité hydraulique déduites sont systématiquement inférieures de plusieurs ordres aux valeurs réalistes pour de tels matériaux. Dans cet article, la formule analytique optimale des séries des données d’origine pour K = f(d20) Justin et al. (1945) est présentée. De plus, à partir de l’étalonnage utilisant des résultats de recherche hydrogéologique en Croatie, Allemagne, Chine et Nigeria, une formule (nommée USCRO) pour la prévision de la conductivité hydraulique des sédiments pour une large gamme d’uniformité et de granulométrie d20, a été dérivée. La validité de cette fonction pour l’expression de la conductivité hydraulique et l’utilisation de coefficients relatifs adimensionnels sont examinés à l’aide d’une représentation graphique de la corrélation de la conductivité hydraulique de matériaux uniformes et spécialement bien classés. Des échantillons de sable mal classé (63) et de gravier sablonneux bien classé (131) ont été intégrés dans la procédure d’étalonnage. Des données relatives aux analyses mécaniques ont été tirées d’articles publiés. La corrélation numérique de la formule USCRO pour des échantillons de sable uniforme a donné lieu à un coefficient de corrélation de Pearson de R2 = 0.902; pour le gravier sablonneux bien classé, de R2 = 0.838. Justin JD, Hinds J, Creager WP (1945) Engineering for Dams (Vol III) (Ingénierie des barrages (Vol III)), John Wiley & Sons.

Resumen

La fórmula del United States Bureau of Reclamation (USBR) se derivó de una tabla que presenta valores de conductividad hidráulica en función del tamaño de grano, K = f(d20). La tabla original fue diseñada empíricamente como una secuencia de variación de diferentes coeficientes de permeabilidad de los depósitos y fue diseñada para el diseño de presas de tierra, con el propósito de evaluar las filtraciones cuando no se dispone de pruebas de percolación. La fórmula USBR se ha utilizado desde entonces para predecir la conductividad hidráulica de depósitos de arenas uniformes que contienen agua, pero sistemáticamente deriva valores de conductividad hidráulica varias veces más bajos que los valores reales de los materiales. En este artículo se presenta la formulación analítica óptima de la serie de datos originales para K = f(d20) Justin et al. (1945). Adicionalmente, a través de la calibración usando los resultados de la investigación hidrogeológica en Croacia, Alemania, China y Nigeria, se obtuvo una fórmula (llamada USCRO) para predecir la permeabilidad de los sedimentos sobre un amplio rango de uniformidad y tamaño de grano d20. La validez de esta función para expresar la permeabilidad y la utilización de coeficientes relativos no dimensionales se examina a través de una correlación gráfica de la permeabilidad de materiales uniformes y especialmente bien clasificados. En el procedimiento de calibración se incluyeron muestras de arena mal clasificada (63) y grava arenosa bien clasificada (131). Los datos para los análisis mecánicos se tomaron de los artículos publicados. La correlación numérica de la fórmula de USCRO para muestras de arenas uniformes resultó en un coeficiente de correlación de Pearson de R2 = 0.902; para la grava arenosa bien gradada, R2 = 0.838. Justin JD, Hinds J, Creager WP (1945) Engineering for Dams (Ingeniería de Presas) (Vol III), John Wiley & Sons.

摘要

美国垦务局(USBR)公式是根据渗透系数值与颗粒大小函数关系(K = f(d20))的表推导得出的。最初的表格是依照沉积物不同渗透系数的变化序列, 结合经验设计。该表格多被用于设计土坝, 以便在没有进行渗透试验的情况下评估坝体渗漏情况。自此, USBR公式经常被用来估算均匀含水砂土沉积物的渗透系数, 但据表推导出的渗透系数通常比实际值低几倍。本文给出了来自于Justin等(1945)的K = f(d20)公式最初数据序列的最优解析公式。此外还使用了克罗地亚、德国、中国和尼日利亚等国水文地质研究成果校正经验表, 推导出了新公式(USCRO), 该公式可在更大范围的均匀度以及d20粒径预测沉积物的渗透率。在均匀且级配良好的材料中, 渗透率的相关性结果图证实了该函数所计算出的渗透率和相对无因次系数的有效性。级配较差的砂(63)和级配较好的砂砾(131)的样品作为校准样品。机理分析的数据来源于已经发表的论文。通过USCRO公式对均匀砂样的数值相关性分析, 得到了皮尔逊相关系数R2 = 0.902; 对于级配良好的砂砾石R2 = 0.838。Justin JD, Hinds J, Creager WP (1945) Engineering for Dams (Vol III) (大坝工程 (第III卷)), John Wiley & Sons.

Resumo

A fórmula do Bureau of Reclamation dos Estados Unidos (USBR) foi derivada de uma tabela que apresenta valores de condutividade hidráulica em função do tamanho do grão, K = f(d20). A tabela original foi projetada empiricamente como uma sequência de variações de diferentes coeficientes de permeabilidade dos depósitos e foi projetada para o projeto de barragens de terra, com o objetivo de avaliar vazamentos onde os testes de percolação não estão disponíveis. Desde então, a fórmula USBR tem sido usada para prever a condutividade hidráulica de depósitos de areia uniformes que suportam água, mas sistematicamente deriva valores de condutividade hidráulica várias vezes inferiores aos valores realistas dos materiais. Neste artigo, a solução analítica ótima da série de dados originais para K = f(d20) de Justin et al. (1945) é apresentada. Além disso, através da calibração usando resultados de pesquisas hidrogeológicas na Croácia, Alemanha, China e Nigéria, uma fórmula (denominada USCRO) para prever a permeabilidade de sedimentos em uma ampla faixa de uniformidade e do tamanho do grão (d20) foi derivada. A validade desta função para expressar permeabilidade e a utilização de coeficientes não dimensionais relativos é examinada através de uma correlação gráfica da permeabilidade de materiais uniformes e especialmente bem graduados. Amostras de areia com baixa classificação (63) e cascalho com classificação boa (131) foram incluídas no procedimento de calibração. Os dados para análises mecânicas foram retirados de artigos publicados. A correlação numérica da fórmula USCRO para amostras uniformes de areia resultou em um coeficiente de correlação de Pearson de R2 = 0.902; para areia bem graduada e de R2 = 0.838 para cascalho de classificação boa. Justin JD, Hinds J, Creager WP (1945) Engineering for Dams (Vol III) (Engenharia para barragens (Vol III)), John Wiley & Sons.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The determination of hydraulic conductivity and/or permeability using data from grain size analysis is frequently used in hydrogeological research. Such an indirect determination of permeability of non-cohesive materials is quick, practical and economical, but its reliability is questionable, especially when determining the properties of natural materials from aquifers and aquitards for hydrogeological purposes. The most commonly used formulae for the calculation of permeability are described by Hazen (1892), Slichter (1902), USBR (Justin et al. 1945), Beyer (1966) and Kozeny-Carman (Carman 1939).

The United States Bureau of Reclamation (USBR) method for determining hydraulic conductivity (K) using grain size analysis stands out from the other methods. In that regard, the emphasis is on the formulation of the function K = f(d20), where K is calculated using the effective grain size “d20” with an exponent of 2.3; however, the specialty of the USBR method is an empirical procedure that uses a gauge data table that contains K values for samples with relative effective grain size (d20) ranging from 0.005 to 2.0 mm. Justin et al. (1945) presented the table “Approximate permeability coefficients k of various soils from clay to fine sand” and explained that it is based on several hundred percolation tests at Zanesville and Quabbin (northeastern USA), Fort Peck (northwestern USA), and Kingsley (central USA) earth dams (Fig. 1).

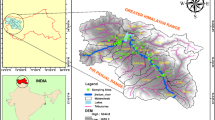

Sample origins. Red points are locations of original samples (Justin et al. 1945) in the USA, i.e. 1st calibration data; yellow points are locations of samples from Croatia (Urumovic 2013; Urumović and Urumović Sr 2016), Nigeria (Ishaku et al. 2011) and China (Odong 2008), i.e. 2nd calibration data; the green point is the location of samples from Germany (Vienken 2010; Vienken and Dietrich 2011) for correlation and verification data

Practical application of the USBR method is conducted in two ways. In the nomographic procedure, a log-log diagram is used, where the curve of a series of hydraulic conductivity values for relative grain size d20 from the table of Justin et al. (1945) are plotted (Talbot 2008). McCook (1991) increased the grain size range in the diagram from 0.0025 to 3.5 mm. This method was utilized at both the USBR and United States Department of Agriculture (USDA). The second form of the USBR method is a simple analytical relationship between hydraulic conductivity and d20 grain size. The analytical form is more commonly used in work published in both scientific and professional literature. Both forms make use of results from the same table, but with a different range of validity because the analytical form is usually recommended only for the prediction of hydraulic conductivity of uniform medium-grained sand.

The analytical form (known as the USBR formula) is commonly used in hydrogeological research. In recent papers (Cheng and Chen 2007; Odong 2008; Ishaku et al. 2011; Vienken and Dietrich 2011; Rosas et al. 2015; Devlin 2015; Cabalar and Akbulut 2016a, b; Biswal et al. 2018), results from the USBR formula were compared with results from different methods for the calculation of hydraulic conductivity from grain size data. The formulation of the USBR method can be found in Vuković and Soro (1992) and Kasenow (1997, 2010). The hydraulic conductivity values calculated using the USBR formula were regularly underestimated compared to the results of other verified methods.

This article analyzes the potential for the modification of the USBR formula so that it is suitable for a wider range of d20 grain sizes and wider range of graduation. The basic concept of the model K = f(d20) was calibrated using original data (Justin et al. 1945, p. 649) through the criteria of minimal error. The data collected and processed from two PhD dissertations were used for the modification of the USBR formula into a form suitable for the realistic prediction of the permeability of unconsolidated and noncohesive deposits in hydrogeological investigations. The processed data are the result of analyses of sand and sandy gravel samples from test fields in northern Croatia (Urumovic 2013) and samples of various materials from the Bitterfield test site in Germany (Vienken 2010; Fig. 1). In both cases, these data are the result of mechanical analyses of numerous samples from exploratory boreholes. Published data from China (Odong 2008) and Nigeria (Ishaku et al. 2011; Fig. 1) were used for the verification of the results of calculating hydraulic conductivity of uniform sands. The values for a total of 63 samples of uniform sands and 126 samples of well graded sandy gravels were correlated. In order to avoid the effect of fluid viscosity (which is dependent on aquifer temperature) on hydraulic conductivity K (m/s), the correlations between the permeability k (cm2) of samples were analyzed. All the symbols used in this text are described in an abbreviation table (Table 1).

The research workflow was as follows:

USBR formula development

Calibration with original data

Calibration with data from Croatia pilot fields and published data from China and Nigeria

Correlation and verification with data from Germany (Fig. 1)

Basic gauge data and formation of the USBR formula

The limitation of the USBR formula for the prediction of hydraulic conductivity (Vuković and Soro 1992; Kasenow 1997, 2010) for samples of medium sands with uniformity coefficients of U = d60/d10 < 5 is not based on the original presentation. Justin et al. (1945) presented the original hydraulic conductivity data of various soils based on d20 grain size—see Table 2 of Justin et al. (1945). Approximate permeability coefficients of various soils were based on 20% size, and the table is part of a brief section of text (see pp. 645–650 of Justin et al. 1945) that discusses the concept of the permeability coefficient and its dependence on soil and water properties.

Analyzed materials and pattern of gauge data

In Table 2 of Justin et al. (1945), permeability coefficient data for materials identified as coarse clay up to fine gravel are presented; yet, the emphasis was on materials from fine silt up to coarse sand (Fig. 2). Only one example of the relationship between hydraulic conductivity and relative grain size d20 is listed for each of the other materials in Justin et al. (1945): clay, fine silt and fine gravel.

Logarithmic graph presenting the relationship between hydraulic conductivity Kj (cm/s) and grain size d20 (mm) from Justin et al. (1945), and Kj and the hydraulic conductivity values calculated by the USBR formula K = 0.36 d202.3 (cm/s)

The graphical presentation of the relationship ln(K) = f[ln(d20)] (Fig. 2) shows a continuous, almost straight line with a minor deflection in the area of fine-grained materials. The commonly used formula K = 0.36d2.3 (cm/s) is good at approximating the listed values of hydraulic conductivity for samples with d20 > 0.1 mm. Despite that, in hydrogeological research, this formula results in significantly lower hydraulic conductivity values than the tested values obtained by analyses of long-term pumping test data or laboratory analysis results.

Material gradation and representativity of original data

In the original text of Justin et al. (1945) a gradation of materials was not represented through the parameters. A variable gradation was presumed because analyzed samples were of natural gradation, namely samples consisted of characteristic materials in river valleys where earth dams were constructed. In the relevant chapter, mechanical analysis curves for six samples are presented. Four curves present the results of the analyses of fine sand and sandy loess with the uniformity coefficient U = d60/d10 = 5–10, one curve presents the results of the mechanical analysis of well-graded sand with U = 12, and one curve presents the results of the mechanical analysis of silt with a small portion of clay with U = 75. Uniform material with U < 5 (as alleged in later work by Vuković and Soro (1991, 1992) and Kasenow (1997, 2010)) was never mentioned in the original text, while the “rough approximation of average conditions on the field” was emphasized twice (pp. 648–649 of Justin et al. 1945).

Special attention was paid to the impact of porosity on hydraulic conductivity, according to Slichter (1902): “… the flow varies as the square of size of the soil grain, this element in the formula has a most important effect …. The variation in porosity is quite as important as the variation in temperature…”. Additionally, the impact of dry bulk density on the “permeability rate” for the six previously mentioned samples (presented by mechanical analysis curves) was presented graphically (Fig. 24 of Justin et al. 1945), indicating compacted materials.

The purpose of the original data K = f(d20)

Documented facts are: (1) Table 2 in Justin et al. (1945) includes all noncohesive granular materials from fine silt up to fine gravel, (2) the results of the sieve analyses of various grading and grain size samples were used to form the table, and (3) the listed values of hydraulic conductivity K were empirically determined based on results of the field testing of relevant materials at the locations of earth dams. Therefore, published data were based on results from numerous field research studies and were empirically determined from the relationships between K and d20. Also, analyzed materials were of a wide range of grain sizes and grading; however, these studies did not include a discussion on the theoretical relationship between the function of permeability and the granulometric composition of samples.

Analytical expression of K = f(d20) for original data

In scientific literature (Vuković and Soro 1992; Kasenow 1997, 2010; Cheng and Chen 2007; Odong 2008; Vienken and Dietrich 2011; Devlin 2015), the USBR formula for K (cm/s) is of the form:

Following the series of original data (Fig. 2, Kj) from the table of K = f(d20) (Justin et al. 1945), the formula of Eq. (1) was derived following the general form:

For the case of grain size d20 = 1.0 mm; K = 0.36 cm/s. In that case, d20b = 1.0, and C = K(d20 = 1) = 0.36.

Simulation of hydraulic conductivity for data from Justin et al.’s table using the USBR formula (Eq. 1) results in slightly overestimating values of hydraulic conductivity (Fig. 3). When including d202.35, the results are slightly underestimating, and using exponent 2.32 results in values of minimal discrepancy from data in Justin et al.’s table. Accordingly, the USBR formula can be written as:

Equation (3) results in minimal discrepancy from the relation presented in Justin et al.’s table; however, this correction does not solve the problems of application of the USBR formula for hydrogeological investigations. The conducted calibration did not result in solving two crucial issues of the USBR formula. The first issue refers to the dimensional misbalance of the equation, and can be interpreted with the fact that grain size strongly affects two parameters which are crucial for the value of hydraulic conductivity. The basic impact of grain size is expressed through the square value of the d20 grain size, (d202). The secondary factor is the nondimensional effect of grain size, d200.32 representing the effect of bulk density and flow tortuosity (Fig. 3).

The dimensional misbalance of d202.32 in the relation was resolved by extracting d202 (which represents the direct impact of grain size on permeability) and d200.32—which represents the nondimensional variable of the effect of the porosity function, as originally referred to by Justin et al. (1945) and which is quoted in Slichter (1902). Including this relationship in the basic form of the hydraulic conductivity function (Sullivan and Hartel 1942; Bear 1988, Vuković and Soro 1992) and extracting the impact of water fluidity ρg/μ, the hydraulic conductivity (K, cm/s) can be expressed as:

and the permeability of a solid (cm2) can be expressed as:

where C [L−1 T−1] represents the constant from Eq. (3) which results from the correlation between d20 and K, g represents the conventional standard value of gravitational acceleration, ρ/μ represents the ratio of density to the viscosity of water at T = 10 °C, Cs = 4.80E-6 represents a dimensionless constant of the impact of the solid’s parameters on sample permeability, and d200.32 represents a variable dimensionless parameter of the porosity function effect. When using homogenous dimensions in Eq. (4), the nondimensional constant is CSU = 4.8E × 10−4.

The correlation between the gauge data from the table in Justin et al. (1945) and the USBR formula did not result in a significant alteration of the formula. The coefficient C = 0.36 (cm−1 s−1) was defined through the hydraulic conductivity of the sample with d20 = 1.0 mm. The difference in the effects of grain size between d200.30 and d200.32 on the predicted K of uniform sands is practically negligible (Fig. 4).; however, it is important to note that d200.32 increases the predicted K value for grains larger than 1 mm, and decreases the predicted K value for finer grains (Fig. 4). The effect of this formula modification does not significantly change the underestimation of the results of the K that is calculated using the USBR formula. The results were compared to the results of the most efficient methods for the calculation of K from the granulometric composition of samples.

Calibration of analytical relations of K = f(d20) using hydrogeological research data from test fields

In hydrogeological research, hydraulic conductivity is often determined from deposit samples acquired from cores taken from exploration boreholes. Circumstances related to drilling technology and resulting core sampling, along with circumstances affecting testing conditions, depend on grain size and the grading of the sample. The table from Justin et al. (1945) contains gauge data from “average conditions in the field”. Here, calibrations are performed for two specific cases: uniform sands and well-graded sandy gravels. In all calibration procedures, the parameter of solid permeability (intrinsic permeability) k (cm2) was used, which avoids the problem of the temperature impact on water viscosity and the relative effect on hydraulic conductivity K (cm/s).

Uniform sand deposits

The calibration of data for K(d20) using the results of pumping tests in uniform sandy deposits was conducted using data from two test-field aquifers (Urumović 2013): one relatively shallow (aquifer BM) and one deep (aquifer DM; Fig. 5). In both cases, tested aquifers consisted of uniform medium-grained sands. The mean hydraulic conductivity of both test fields was identified by pumping tests and was, for this purpose, converted into tested permeability kt (Fig. 5). The predicted permeability at various depths was calculated from grain-size-analysis data for samples from high-quality exploratory borehole cores drilled in the vicinity of tested wells. Individual and mean values of hydraulic conductivity that were calculated using the USBR formula were approximately three times lower than the results from other methods.

Results of predicted permeability k (cm2) calculated using different methods—Hazen, USBR, USCRO and Kozeny-Carman (KC)—for individual samples of uniform sand and the average permeability kt of aquifers identified from pumping test data on the test fields BM (Beli Manastir) and DM (Donji Miholjac) in Croatia

For the purpose of graphical correlation, the results of the calculation of K (cm/s) and k (cm2) using Hazen method and the Kozeny-Carman formula were used:

- 1.

Hazen’s method (most frequently used for comparison with the USBR method):

-

2.

Kozeny-Carman (KC) formula, which is valid within the limits of Darcy’s law when properly used—including effective porosity ne in the formula and use of the geometrical mean dg (mm) of all the grains in the sample or d40 grain size (mm) (as an approximate value to dg) as the referential grain size (Urumović and Urumović Sr 2016):

In the analytical formulation of k for calibration data from Justin’s table (Justin et al. 1945, p. 649; Eq. 5) the nondimensional coefficient CSU was varied until the mean value of the permeability kUSCRO was almost equal to the hydraulically tested permeability kt when CSU = 1.56E-5. The formula with the nondimensional coefficient CSU = 1.56E-5 and exponent b = 2.32 was named USCRO (Fig. 5), since it is based on calibration sample sets from the USA and Croatia:

The mean k values of researched aquifers (aquifer BM and aquifer DM) that were predicted using the USCRO, Hazen, KCdg and KCd40 methods differ by less than 5% from the values of hydraulically tested permeability derived from pumping test analysis. However, the permeability of individual samples was substantially underestimated using the USBR formula (Fig. 5).

The correlation of the kUSCRO formula with tested hydraulic conductivity kt, as presented in Fig. 5, is deficient due to a small range of d20 grain size (0.18–0.23 mm, U = 1.5–2.3). This problem was avoided by including data from 22 analyses (0.075 mm < d20 < 0.508 mm, U = 2.47–5.0) of uniform sand from a large data set from Germany (Vienken 2010), published data from China (Odong 2008) for four samples (0.19 mm < d20 < 0.47 mm, U = 1.5–5.3), and data from 15 samples taken in Nigeria (Ishaku et al. 2011; 0.17 mm < d20 < 0.60 mm, U = 1.8–6.7). The inclusion of these data substantially increased the number of samples and grain size range. In Odong (2008) and Ishaku et al. (2011), only data for d10, d20, d40 and d60 were listed, so the relation KKCdg ≈ KKCd40 published in the paper by Urumović and Urumović Sr (2016) was adopted here. This relation—kKCdg ≈ kKCd40, (Fig. 5)—was also confirmed by calculations undertaken as part of this study. The results of the KC method were selected as the gauge permeability (kg = kKC). For calculations of permeability kg = kKC of samples from Croatia and Germany, the geometric mean grain size (kg = kKCdg) was used, and for samples from Nigeria and China, the d40 grain size was used (kg = kKCd40) as shown in Fig. 5. These two grain sizes are very similar (dg ≈ d40) for uniform grain-size materials, which allows the formation of a consistent group of all the used data. The result is a continuous series of permeability values that is calculated using the listed formulae for a relatively wide range of gauge permeabilities (Fig. 6).

The consistent results for the correlation of kUSCRO and kKC(dg) (kKC(d40) respectively) using calibration data from various sources have been verified numerically, through Pearson’s correlation coefficient R2 = 0.902. This correlation confirmed the validity of the nondimensional coefficient CSU = 0.0000156 and the USCRO formula for the calculation of permeability of uniform sand:

with d20 in mm.

In engineering practice, it is extremely difficult to acquire undisturbed samples of uniform sand from deep boreholes, especially in conditions of relatively high groundwater levels. In the case of uniform sands, the variation in grain size is relatively small, so the order of magnitude of permeability can be reasonably predicted. The exception to this is when using formula with a systematic error such as the USBR formula. Such an example is presented in Fig. 7 for the cases of test fields with sandy aquifers in northeastern Croatia. All the data presented were a result of analyses of samples from six test fields in eastern Croatia. The aquifers (40–120 m depth) consisted of poorly graded sand of diverse grain size. Test fields are mutually distanced several tens of kilometers apart. The exploitation well and exploratory boreholes were constructed on each test field, using the same technology, approximately 40 years ago. Hydraulic conductivity was determined from pumping test analyses and grain-size-distribution data. The original report showed significantly more realistic results when using Hazen than USBR method. For the purposes of this research, the KC and USCRO methods were applied, resulting in an interesting illustration (Fig. 7) for cases of analyses of rinsed borehole core samples of uniform sands. The values of permeability predicted using the Hazen, KC and USCRO formulae scatter randomly around the tested values, and exhibit a similar trend. In contrast, the USBR formula separates from the system formed by the other formulae, and shows the effect of systematic error.

The graphical correlation of the tested hydraulic conductivity of aquifers Kt for six test fields and the mean values of K predicted from the grain-size distribution charts of sand samples. Uniform sand samples were taken from rinsed borehole cores from six test fields in southeastern Slavonia, Croatia

Well-graded gravelly deposits

The relationships between permeability and d20 grain size, which are well calibrated for uniform and poorly graded sands, are not as applicable for well-graded gravel deposits because material grading complicates the schematization of water flow. Two facts motivated further modification of the relation between k and d20 for well-graded deposits. First, well-graded deposits were also listed in a table from Justin et al. (1945). The second motivation was the fact that the determined relations between K and d20, along with relationship of their squares, also included variable d200.32 that varies with grain size and therefore simulates the effect of porosity. In the primary phase of this research, data from the study of a large gravelly aquifer in Đurđevac, Republic of Croatia (Đurđevac test site; Urumović 2013) were used. The correlation of the mean permeability of samples, predicted using the USCRO and KC formulas, with mean aquifer permeability kt determined through pumping test analysis resulted in consistent results and a high correlation between the USCRO results and the mean tested permeability. The verification of the identified nondimensional coefficient CSW for well-graded noncohesive materials was achieved through applying the USCRO formula on 140 mechanical analysis data points from the Bitterfeld test site, Germany (Vienken 2010). The results of these analyses were primarily observed as a random group of mechanical analyses of diverse, mostly gravelly materials. In a later stage, samples were grouped according to the value of the uniformity coefficient, which confirms compliance with relative groups of similar grading in the final stage of analysis.

Gravelly aquifer test site

Mechanical analyses of samples from gravelly aquifer on the Đurđevac test field were previously used for studying the applicability and range of the validity of the KC model (Urumović and Urumović Sr 2016) for predicting hydraulic conductivity. In that research, a very high correlation coefficient (R2 = 0.998) between the tested and mean hydraulic conductivity that was predicted using the KC formula when applying referential geometrical mean grain size and effective porosity was determined. In this research, the applicability of the USCRO method for the same data (mechanical analyses of 6–8 samples of well-graded gravel from five scattered exploration boreholes 60–70 m deep; a total of 34 samples) was studied. Samples of gravel were evenly distributed from between 20 and 70 m depth. Samples with d20 < 0.05 mm and uniformity coefficient U = d60/d10 > 150 contained very large pebbles and were excluded from the analysis. Subsequently, three to six samples per borehole remained, which was a total of 22 samples, e.g., 74% of all of the available samples. Two boreholes with the highest number of samples are presented in Fig. 8. Mechanical analysis data for these 22 samples were used to determine the nondimensional coefficient CSW for well graded gravelly deposits.

Predicted permeability k calculated using the KC, USBR and USCRO equations for samples from the gravelly aquifer at Đurđevac test site. a borehole S1 [small discrepancy between predicted and tested permeability k(cm2)]; b borehole S5 [large discrepancy between predicted and tested permeability k(cm2)]

The graphical correlation of tested permeability kt (cm2) and the permeability predicted using the USBR, USCRO, KCdg and KCd40 methods was conducted for each of the five boreholes. The dissipation of the results of individual methods around the mean tested aquifer permeability is presented graphically in Fig. 8a,b, showing significantly less deviation of permeability values calculated using USCRO formula from the hydraulically tested value than the one calculated using USBR formula. The determined value of the coefficient CSW = 4.3E-05 was used in USCRO formula.

The numerical relations between the value of predicted permeability kUSCRO and (1) the mean tested permeability kt (determined by pumping tests analyses) and (2) the calculated value from the KC formula kKC for all of the selected samples, were used for the determination of the coefficient CSW. Averaging of ratios was conducted in two phases: in the first phase locally for individual boreholes, and in the second phase regionally for the entire test field. The geometric and arithmetic mean values of analyzed ratios for the entire wellfield are presented in Fig. 9 for a range from CSW = 1.56E-5 (suitable for uniform sands, Eq. 8) to CSW = 7.0E-5. In three cases, (geom)kUSCRO/kKC(dg), kUSCRO/kt and (ar)kUSCRO/kKC(d40), the ratios are close to 1.0 for CSW = 4.3E-5.

The relation of permeability kUSCRO/kKC(dg) is presented in homogenous dimensions for the range of CSW = 1.56E-5 (identical to CSU) to CSW = 7.0E-5 (Fig. 9). The straight line of the geometric mean of the ratios for all of the samples’ x-axis intercepts the unit relation for CSW = 4.30E-5. This value of geometric mean is almost identical to three out of the five compared relations that were analyzed in the case of samples from Đurđevac test field (Fig. 9). This confirms the correct selection of CSW for this type of deposit.

Verification: random group of analyses of sand and gravel samples

A large number of mechanical analysis results for samples of noncohesive materials with a wide range of d20 grain size and uniformity were taken from Vienken (2010). In this study, mechanical analysis results for 140 samples were processed. Analyzed samples were collected from borehole cores up to 12 m depth. From this data set, analyses of samples with unreliably determined d20 grain size were excluded. Such samples are frequent in the case of extreme gradation with U > 150. In total, 129 samples remained. The grain sizes d20 of samples were 0.0015 < d20 < 1.41 mm, and the uniformity coefficient was 2.47 < U < 91.4 (Fig. 10).

Samples were observed as a random group of samples, which is convenient for the validity check of the USCRO formula for permeability calculations. Gauge permeability was calculated using the KC formula with the geometric mean grain size of the sample kKC(dg) and relative effective porosity (Urumović and Urumović Sr 2016). The ratio values between predicted permeability values kUSCRO, kUSBR and kHAZEN relative to kKC are very diverse. As shown in Fig. 11, the ratios of predicted permeability kUSCRO/kKC are aggregated close to the value of one. The relative samples for the ratio values kUSBR/kKC are within the range from 0.021 to 0.39, and kHAZEN/kKC(dg) in the range from 0.003 to 1.2; however, on average, both cases are scattered close to 0.1.

The correlation of the predicted permeability values of kUSCRO and kKC of all of the samples from this group of results were interesting but yielded rather low values of Pearson’s correlation coefficient R2 = 0.608. Uniform sands (U < 5) from this group of samples were included in a group of uniform materials (samples included in Figs. 6 and 7), which is appropriate for the relative group with a high correlation coefficient. The remaining 106 samples form a group of well graded (5 < U < 91.4, Fig. 11), gravelly and sandy materials that are suitable for the USCRO nondimensional coefficient CSW = 4.3E-05. The correlation of kUSCRO and kKC for this group resulted in a relatively high Pearson correlation coefficient R2 = 0.838 (Fig. 11).

Discussion

Regarding the application of the USBR formula on uniform (U < 5) medium-grained sands, the limitation as quoted by numerous authors is not found in the original data from Justin et al. (1945). It is also very important to emphasize that Justin’s Table 2 for K = f(d20) of the relationships of various materials was designed for the assessment of leakage through earth dams. This explains the results of many authors—the application of the USBR formula results in substantially underestimated values of hydraulic conductivity for the purpose of hydrogeological research. The USBR formula, which is recommended by the US Bureau of Reclamation, agrees with the original data (Justin et al. 1945) relatively well. A slight improvement can be achieved by the modification of exponent b from d202.30 to d202.32.

This research resulted in distinguishing two characteristic cases of grading—the first is for uniform sands, for which the USBR formula was originally intended, and the second case is for well-graded samples of gravel and sand. Both cases were primarily calibrated using data from test fields. In the later phase of analysis, the relations were verified using data from other locations and formations. It is important to emphasize that the data from various authors were used for these analyses and that the correlation resulted in practically identical results. The correlativity was not dependent on data source nor d20 grain size but was dependent on the grading of grains in the sample. Through calibration, the USCRO formula for the calculation of permeability k(cm2) was identified as:

for uniform sands (U < 5) with the Pearson’s correlation coefficient R2 = 0.902 and

for well-graded sandy gravels (5 < U < 92) with the Pearson’s correlation coefficient R2 = 0.838.

The hydraulic conductivity K(cm/s) for uniform sands (U < 5) at 10 °C and d in mm is:

and for well graded (5 < U < 92) sandy gravels:

Dimensional misbalance between the numerical formulation of the USBR method (Eq. 1) and Justin’s empirical model of variations of permeability in the function of d20 grain size was a consequence of an effect of two functions. Primal f(d20)2 is dimensionally balanced with a permeability. Superimposed secondary dimensionless function d200.32 represents the variation of the porosity function depending of d20 grain size. Such presentation of the USCRO method was confirmed by the good correlation with the KC method (Figs. 5 and 10).

Following the previously mentioned characteristics, the USCRO formula can be included in the group of verified methods of various formulations of permeability in the form k = f(d). Such methods are usually in the function of mean grain size, giving them the advantage when determining permeability of small samples of well-graded materials. When using the USCRO method, one fact should be emphasized: credibility of d20 grain size in the samples of gravel from the borehole core is disrupted by rinsing the core and is also increased due to the reduction of borehole diameter at greater depths. Despite that, when using high quality drilling and coring, and taking samples from longer intervals, these unfavorable conditions can be reduced, and using the USCRO formula enables quite solid predictions of permeability. Such an example is given in Fig. 7 for two 60–70-m deep boreholes from test site Đurđevac.

Conclusions

Finally, two characteristics of data of K = f(d20) from the table in Justin et al. (1945) should be pointed out. First, these data were conceptualized empirically, based on numerous data from the field testing of various compacted materials of earth dams. Second, the sequence of ratios between k and d20 is compatible to the sequence of referential ratios in field hydrogeological investigations, despite the significant underestimation of kUSBR in comparison to the tested values of kt. This deficiency was efficiently corrected by the new calculation method. The new method was named USCRO and can be applied for uniform sands and well-graded gravels using different nondimensional coefficients. In the dimensionally homogenous USCRO formula, the coefficient CSU = 1.56 × 10−3 should be used for the calculation of permeability of uniform deposits (U < 5), and the coefficient CSW = 4.3 × 10−3 should be used for well-graded deposits (5 < U < 92). This formulation of the USCRO method is illustrated graphically (Fig. 7) and was confirmed numerically through Pearson’s correlation coefficient RSU2 = 0.902 for a group of 60 samples of uniform sands, and RSW2 = 0.838 for a group of 106 samples of well-graded sandy gravels (Fig. 11).

Additionally, the procedure of excluding several samples of sandy gravel from analyses should be pointed out as illustrating the credibility risk of fine sieve “effective grain size” (d10, d20) from borehole core samples. As described in the preceding, well-sorted samples of sandy gravel or gravel should be sampled in voluminous samples. Also, permeability should be calculated using two (or preferably more than two) methods of calculation, including ones based on using the geometric mean grain size of the whole sample.

References

Bear J (1988) Dynamics of fluids in porous media. Elsevier, Philadelphia, PA, p 134

Beyer W (1966) Hydrogeologische Untersuchungen bei der Ablagerung von Wasserschadstoffen [Hydrogeological investigations on the deposition of water pollutants]. Zeitschrift Angewandte Geol 12(11):599–606

Biswal S, Jha MK, Sharma SP (2018) Hydrogeologic and hydraulic characterization of aquifer and nonaquifer layers in a lateritic terrain (West Bengal, India). Hydrogeol J 26(6):1947–1973. https://doi.org/10.1007/s10040-018-1722-5

Cabalar AF, Akbulut N (2016a) Evaluation of actual and estimated hydraulic conductivity of sands with different gradation and shape. SpringerPlus. 5:820. https://doi.org/10.1186/s40064-016-2472-2

Cabalar AF, Akbulut N (2016b) Effects of the particle shape and size of sands on the hydraulic conductivity. Acta Geotech Slov 2(4):83–93

Carman PC (1939) Permeability of saturated sand, soil and clay. J Agric Sc 29:263–273

Cheng C, Chen X (2007) Evaluation of methods for determination of hydraulic properties on an aquifer-aquitard system hydrologically connected to river. Hydrogeol J 15:669–678

Devlin JF (2015) HydrogeoSieveXL: an excel-based tool to estimate hydraulic conductivity from grain-size analysis. Hydrogeol J 23:837–844

Hazen A (1892) Some physical properties of sands and gravels, with special reference to their use in filtration. Massachusetts State Board of Health, Boston, MA

Ishaku JM, Gadzama EW, Kaigama U (2011) Evaluation of empirical formulae for the determination of hydraulic conductivity based on grain-size analysis. J Geol Min Res V 3(4):105–113

Justin JD, Hinds J, Creager WP (1945) Earth, rock-fill, steel and timber dams. In: Creager WP, Justin JD, Hinds J (eds) Engineering for dams, vol III. Wiley, New York, pp 619–650

Kasenow M (1997) Applied ground-water hydrology and well hydraulics. Water Resources Pub., Littleton, CO, 552 pp

Kasenow M (2010) Determination of hydraulic conductivity from grain size analysis. Water Resources Pub., Littleton, CO, 83 pp

McCook D (1991) Measurement and estimation of permeability of soils for animal waste storage facility design. Technical note 717, US Dept. of Agriculture, Soil Conservation Service, Washington, DC

Odong J (2008) Evaluation of empirical formulae for determination of hydraulic conductivity based on grain-size analysis. J Am Sci 4(1)

Rosas J, Jadoon KZ, Missimer TM (2015) New empirical relationship between grain size distribution and hydraulic conductivity for ephemeral streambed sediments. Environ Earth Sci 73:1303. https://doi.org/10.1007/s12665-014-3484-2

Slichter CS (1902) The motions of underground waters. US Geol Surv Water Suppl Irrig Pap 67:13–106

Sullivan RR, Hartel KI (1942) The permeability method for determining specific surface of fibers and powders. In: Advances in coloid science, vol 1. Interscience, New York, pp 38–80

Talbot WR (2008) Feasibility study for water supply system, Santee Sioux nation, Santee, Nebraska and village of Niobrara, Nebraska. US Bureau of Reclamation, Washington, DC

Urumovic K (2013) Parameter quantification of clastic sediments hydrogeological properties based on test fields in northern Croatia. PhD Thesis, University of Zagreb, Zagreb, Croatia, 164 pp. https://www.bib.irb.hr/655913

Urumović K, Urumović K Sr (2016) The referential grain size and effective porosity in Kozeny-Carman model. Hydrol Earth Syst Sci 20:1669–1680

Vienken T (2010) Critical evaluation of vertical high resolution methods for determining hydraulic conductivity. PhD Thesis, Eberhard Karls Universität, Tübingen, Germany

Vienken T, Dietrich P (2011) Field evaluation of methods for determining hydraulic conductivity from grain size data. J Hydrol 400:58–71

Vuković M, Soro A (1992) Determination of hydraulic conductivity of porous media from grain size composition. Water Resources Pub., Littleton, CO

Acknowledgements

The authors would like to thank Mr. Thomas Vienken, Ph.D., for his perseverance and help in collecting large amounts of laboratory data used in this study as well as for his suggestions and early review of the manuscript. We would also like to thank Prof. Zoran Nakić, Ph.D. for encouragement for this research.

Funding

This study was supported by the Ministry of Science, Education and Sports of the Republic of Croatia (Basic Hydrogeological Map of the Republic of Croatia 1:100.000 - basic scientific project of Croatian Geological Survey) and was carried out within the studies of analyses for the purpose of the project ISSAH (Impact of specific surface area on hydrogeological properties of loess deposits and loess-derived soils in eastern Croatia) UIP-2017-05-9345, funded by the Croatian Science Foundation.

Author information

Authors and Affiliations

Corresponding author

Additional information

Kosta Urumović Sr Retired

Rights and permissions

About this article

Cite this article

Urumović, K., Borović, S., Urumović, K. et al. Validity range and reliability of the United States Bureau of Reclamation (USBR) method in hydrogeological investigations. Hydrogeol J 28, 625–636 (2020). https://doi.org/10.1007/s10040-019-02080-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10040-019-02080-2